Disassembling method of cold-end unit body

A unit body, cold end technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of rotor stuck, rotor and stator axial friction, etc., to improve reliability and ensure the progress of scientific research and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

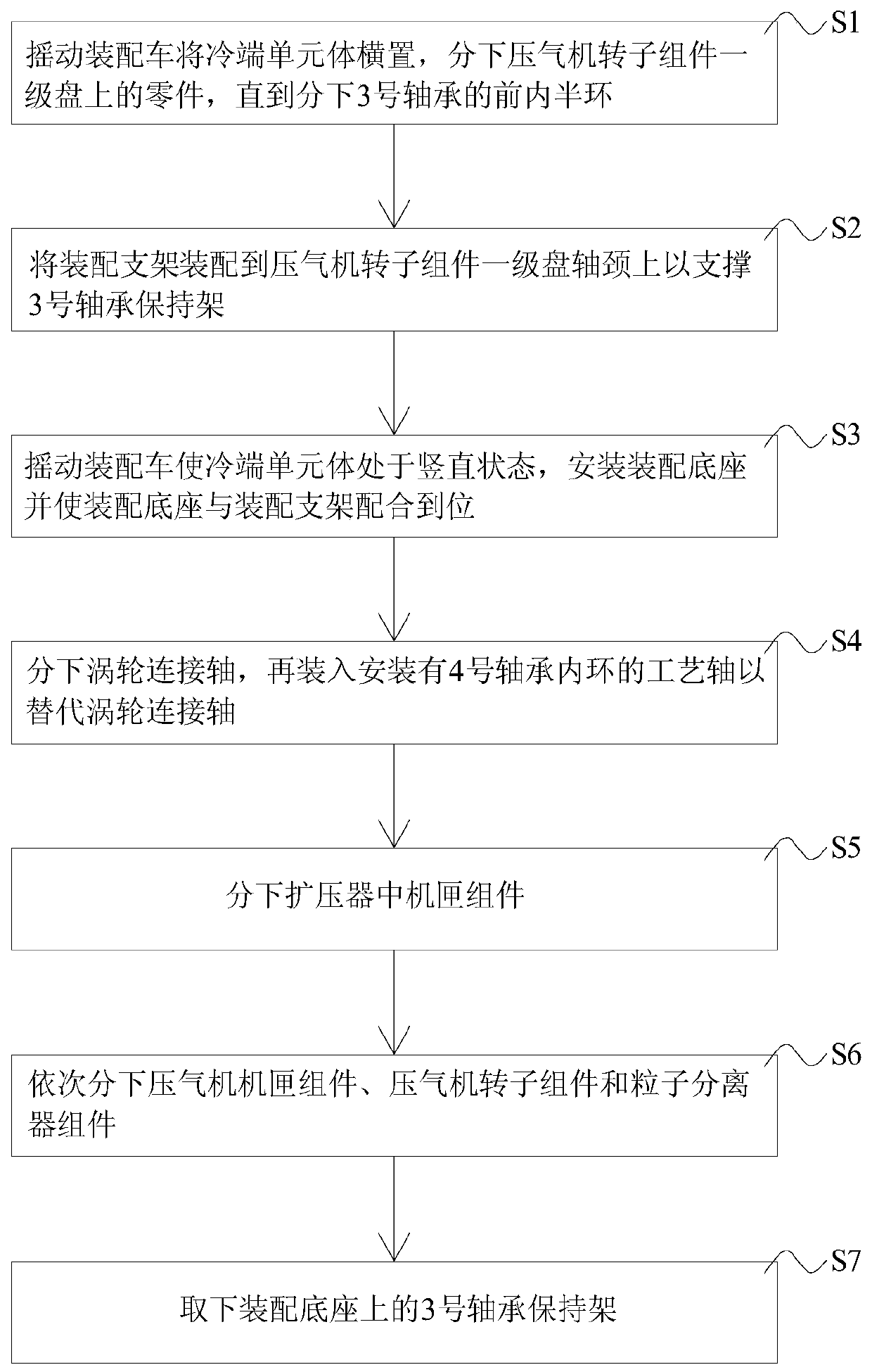

[0035] When the engine is disassembled, the engine needs to be placed on the assembly vehicle. After the engine is disassembled, the power turbine unit, the accessory drive unit, and the hot end unit are decomposed to obtain the cold end unit. The compressor rotor assembly in the cold end unit includes The 1st to 5th stage axial flow integral blade disc, centrifugal impeller, central tie rod, turbine connecting shaft, long bolts, No. 3 bearing and No. 4 bearing and other parts, among which, No. 3 bearing is a double inner half-ring angular contact ball bearing, and its Both the front and rear inner half rings are assembled on the front journal of the first-stage blade disc of the compressor, and their supporting points are located in the lubricating oil chamber of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com