Molding and preparation method of carbon fiber transmission shaft for Formula Student racing car

A technology for Formula Student and transmission shafts, which is applied in the field of forming and preparation of carbon fiber transmission shafts for Formula Student racing cars. It can solve the problems of unstable quality, corrosion resistance, and unstable connection between the carbon fiber shaft body and the metal connection end, and achieve The effect of small moment of inertia, improved transmission performance and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

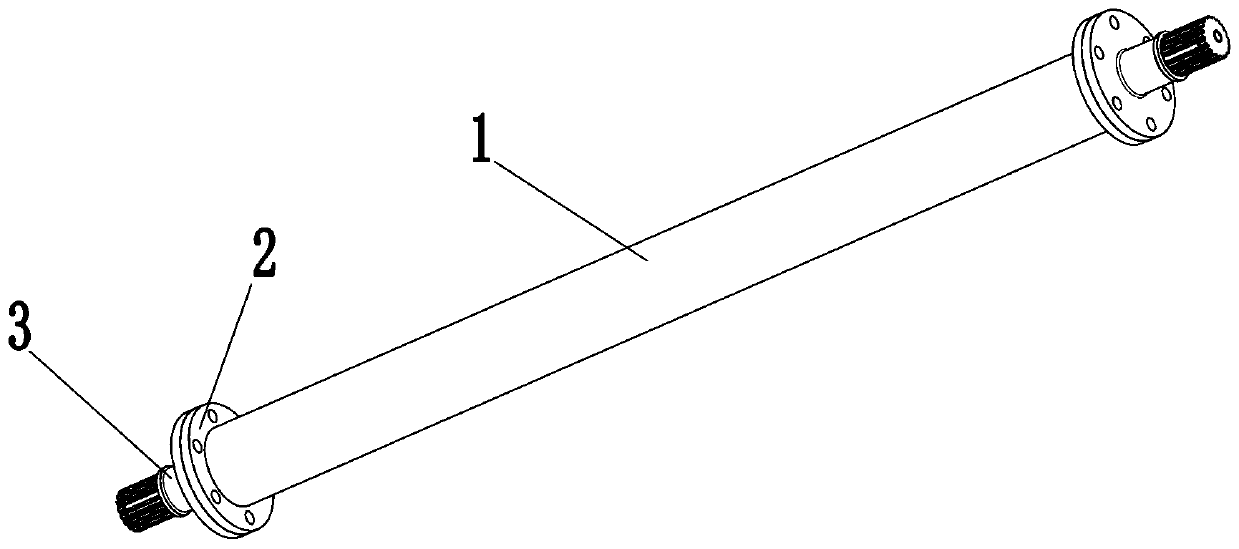

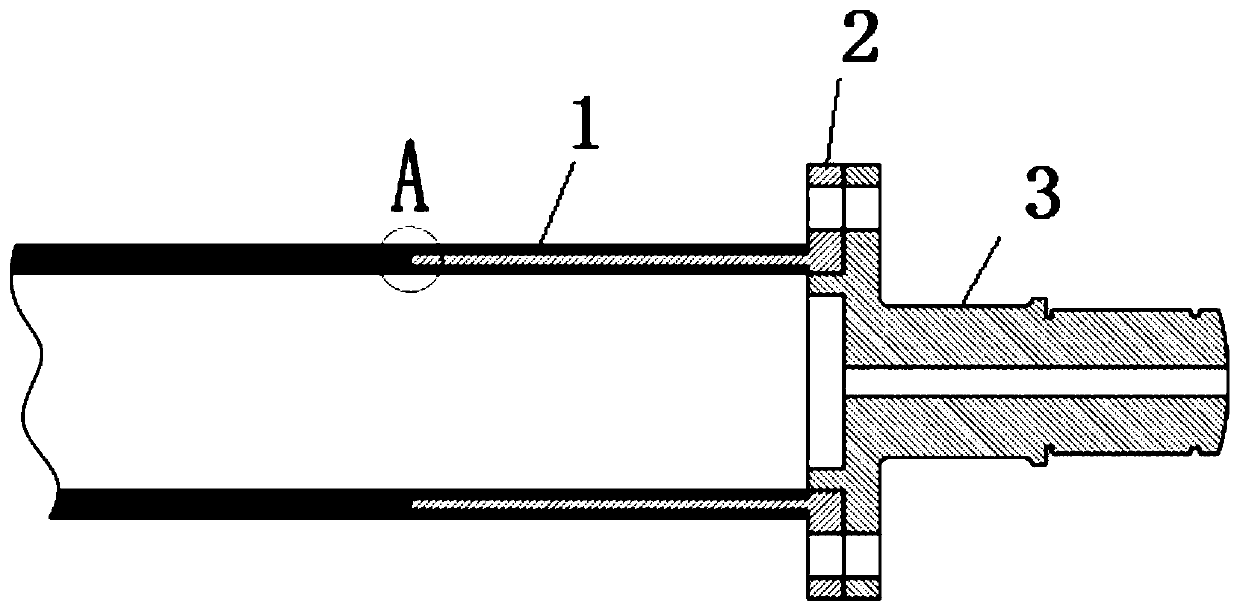

[0046] Below in conjunction with embodiment and attached Figure 1-12 The present invention is described in detail.

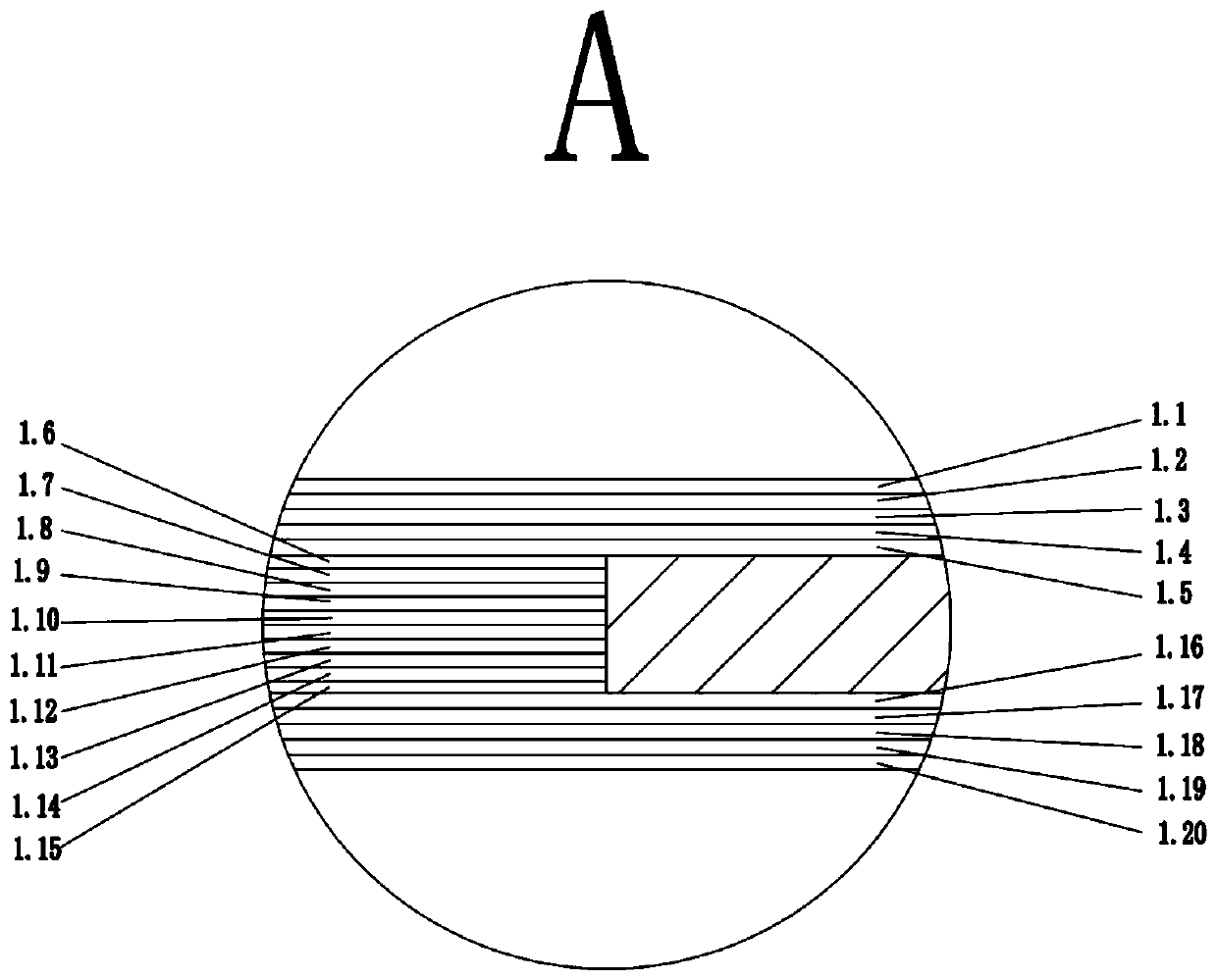

[0047] figure 1 The shown carbon fiber transmission shaft for a Formula Student racing car includes a carbon fiber transmission shaft body 1 , a metal connection end 2 and a spline end 3 . The shaft body 1 of the carbon fiber transmission shaft is hollow, and it is mainly divided into three stages of lamination. Figure 4 The metal connection end 2 shown is in the shape of a sleeve of a rotary body. The metal connection end 2 is divided into two parts, one part is the flange end 2.1, and the other part is the glue connection end 2.2. 6 holes 2.5 of M6 have a hole 2.6 with a diameter of 30mm in the central part. Figure 8 The spline end 3 shown is divided into two parts, one part is the spline 3.3 designed according to the three-ball pin, and the other side is the flange 3.1 matched with the metal connection end, and there are 6 M6 evenly distributed on the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com