Control method and system of side guide plate

A control method and technology of side guide plates, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as the inability to eliminate the influence of the final opening of side guide plates, and achieve improved centering effect and strip threading stability. The effect of ensuring rolling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The embodiment of the present invention solves the technical problem in the prior art that the influence of the gap on the final opening of the side guide plate cannot be eliminated by providing a control method and system for the side guide plate, and achieves the technical effect of ensuring the rolling precision of the strip steel.

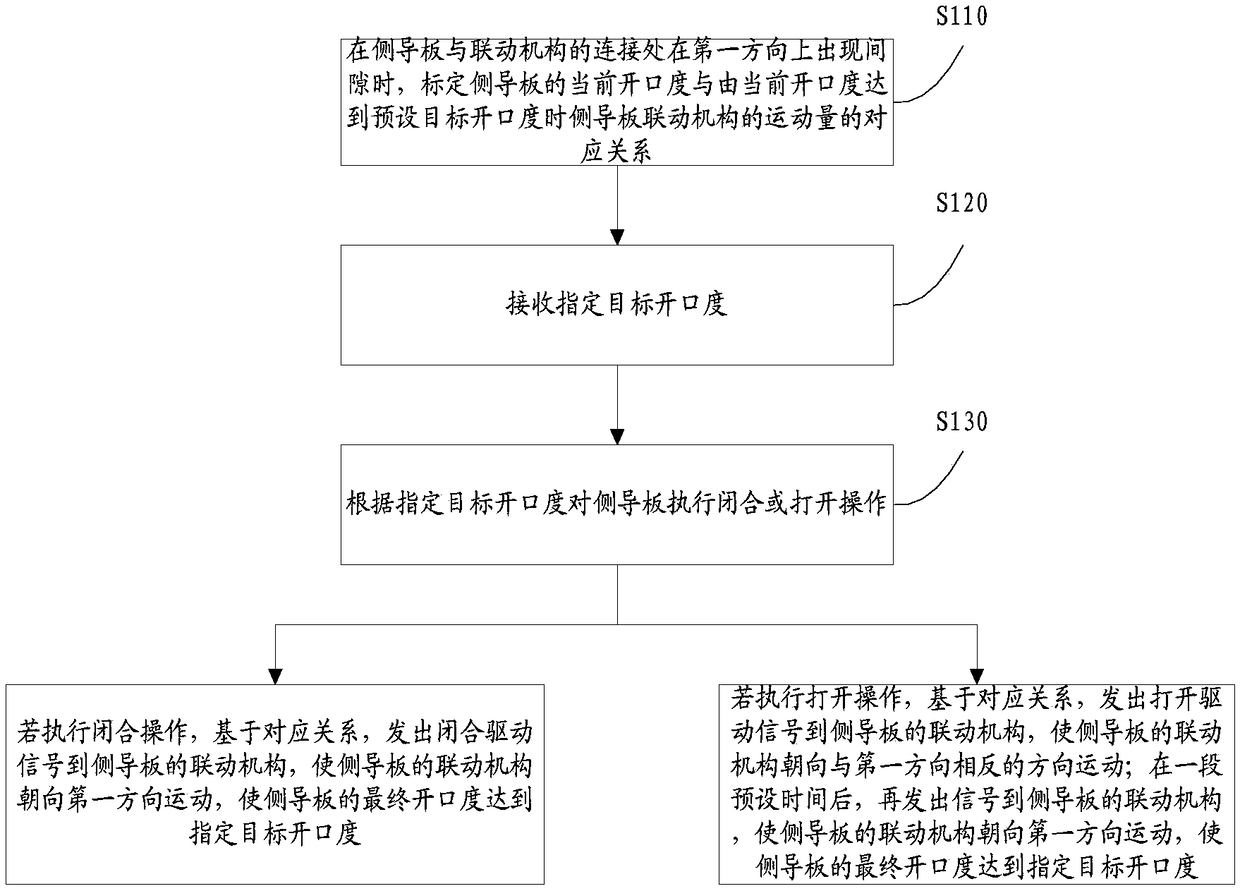

[0058] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

[0059] By controlling the action process of the side guide plate, when it is opened or closed, it will eventually move in the same direction (such as the first direction) to the target opening degree, so that the mechanical clearance is always concentrated on the same side, thereby eliminating The impact on the final opening of the side guide plate is minimized, the centering effect of the strip and the stability of strip threading are improved, and the rolling accuracy of the strip is en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com