Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Good reassuring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing rectangular-tooth spline sleeve using 42CrMoE high-quality alloy steel as material

InactiveCN102534374AImprove wear resistanceImprove bending abilityCouplings for rigid shaftsPhosphorylationThermal treatment

The invention discloses a method for processing a rectangular-tooth spline sleeve using 42CrMoE high-quality alloy steel as a material, belonging to the technical field of thermal treatment. The method comprises the steps of: free forging of a blank, normalizing treatment, rough turning, hardening and tempering thermal treatment, finish turning, spline drawing, drilling, burr gripping, carburization treatment, surface deposition treatment, phosphorylation treatment, electroplating, drying and detection. In the invention, due to the new material and new technology, the wear resistance of the produced rectangular-tooth spline sleeve is greatly enhanced, the phenomenon of crack of the rectangular-tooth spline sleeve is avoided, the surface is smooth, the friction is low, the heat dissipation is good, and the service life is prolonged, thus the processing technology is widely applied.

Owner:无锡市万邦机械制造厂

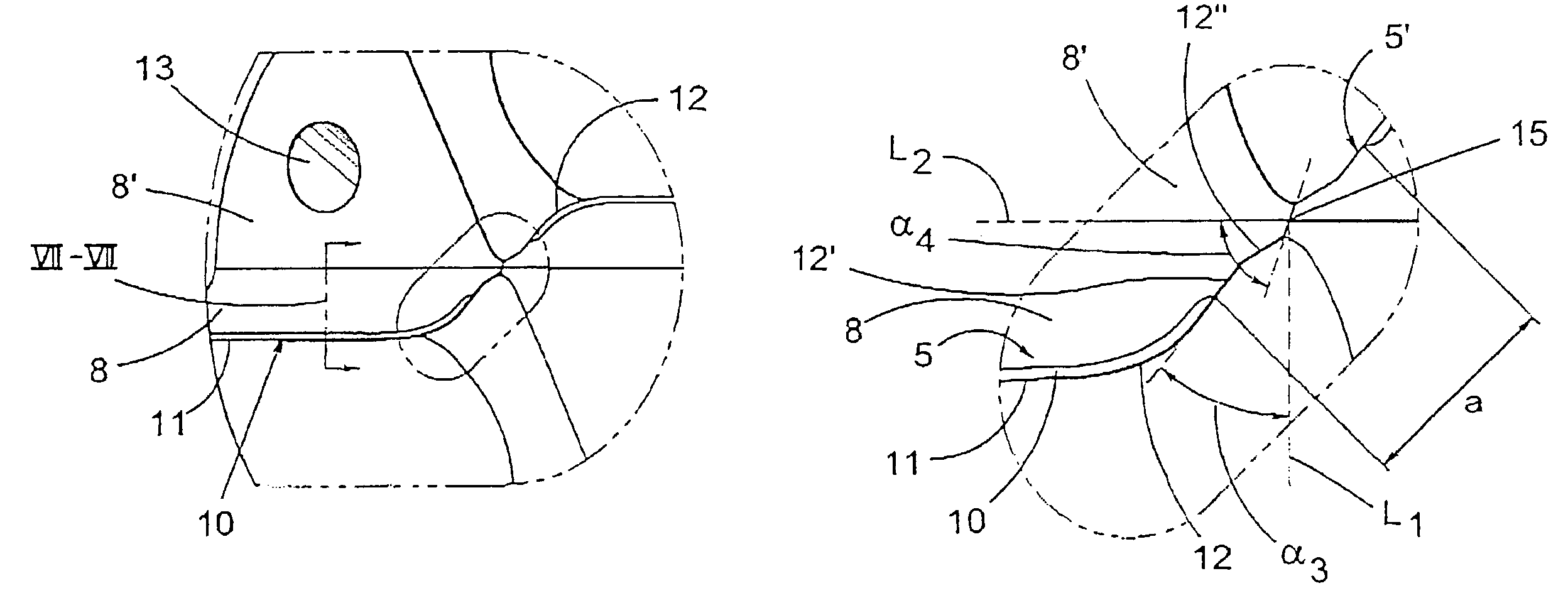

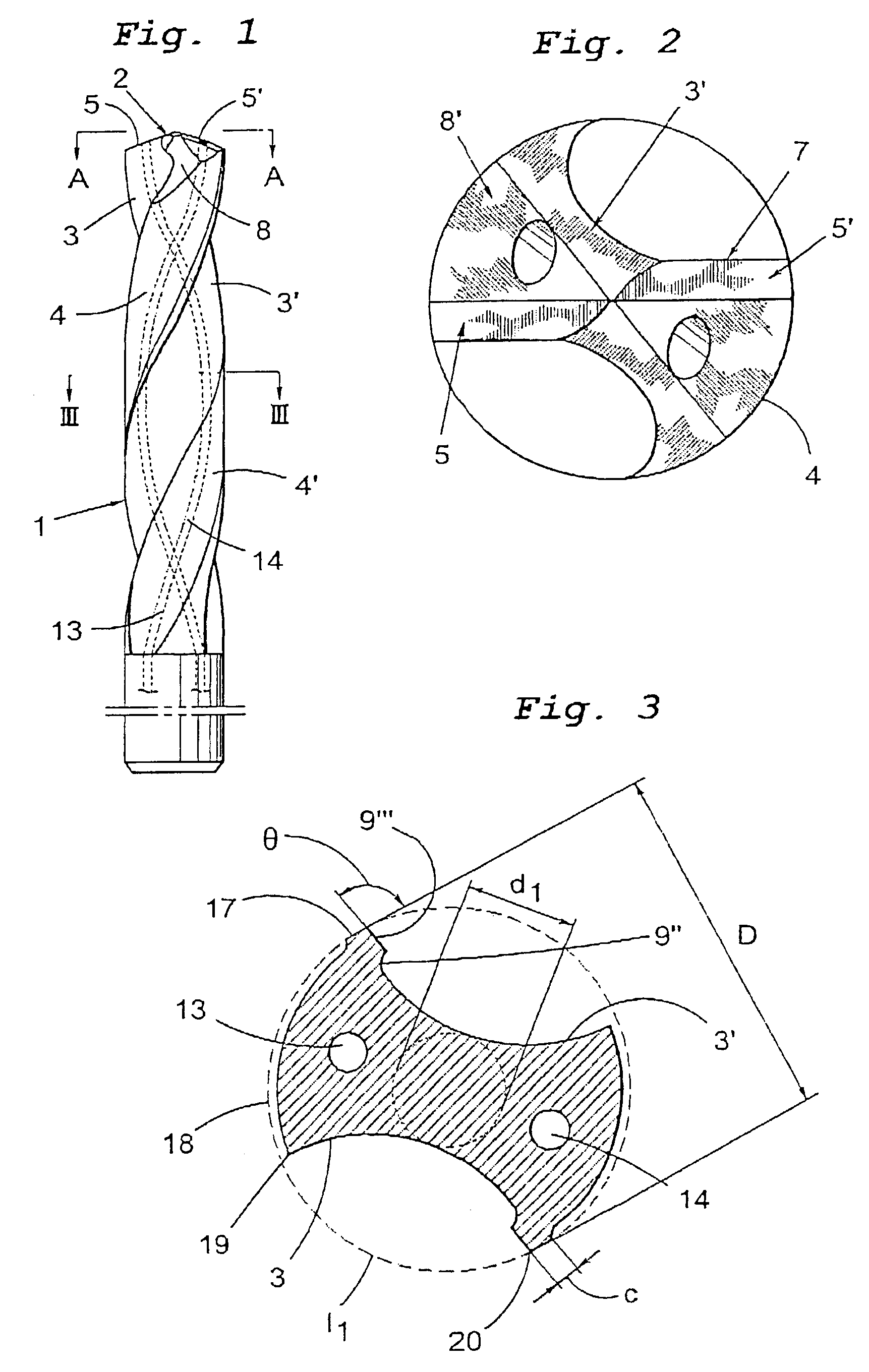

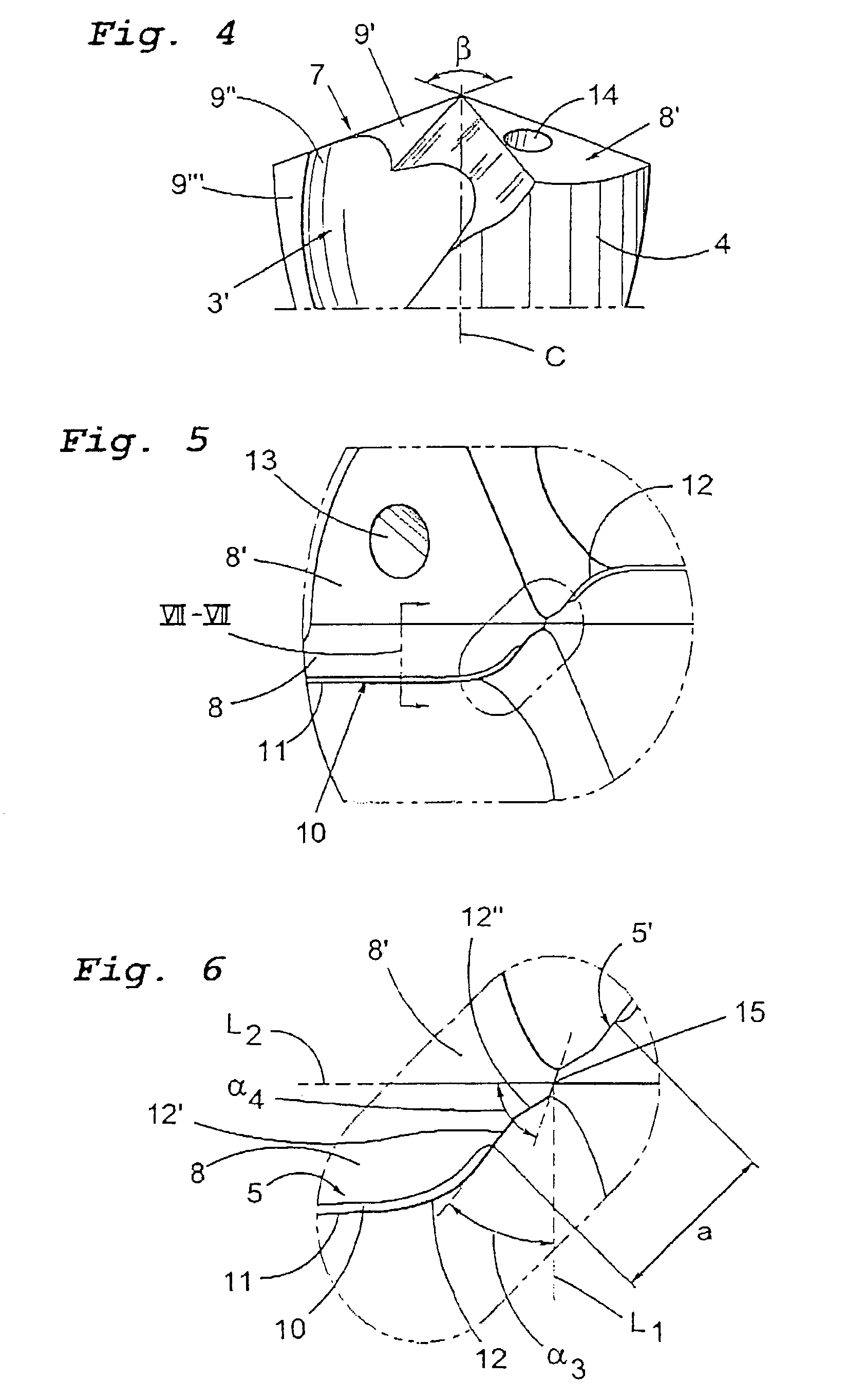

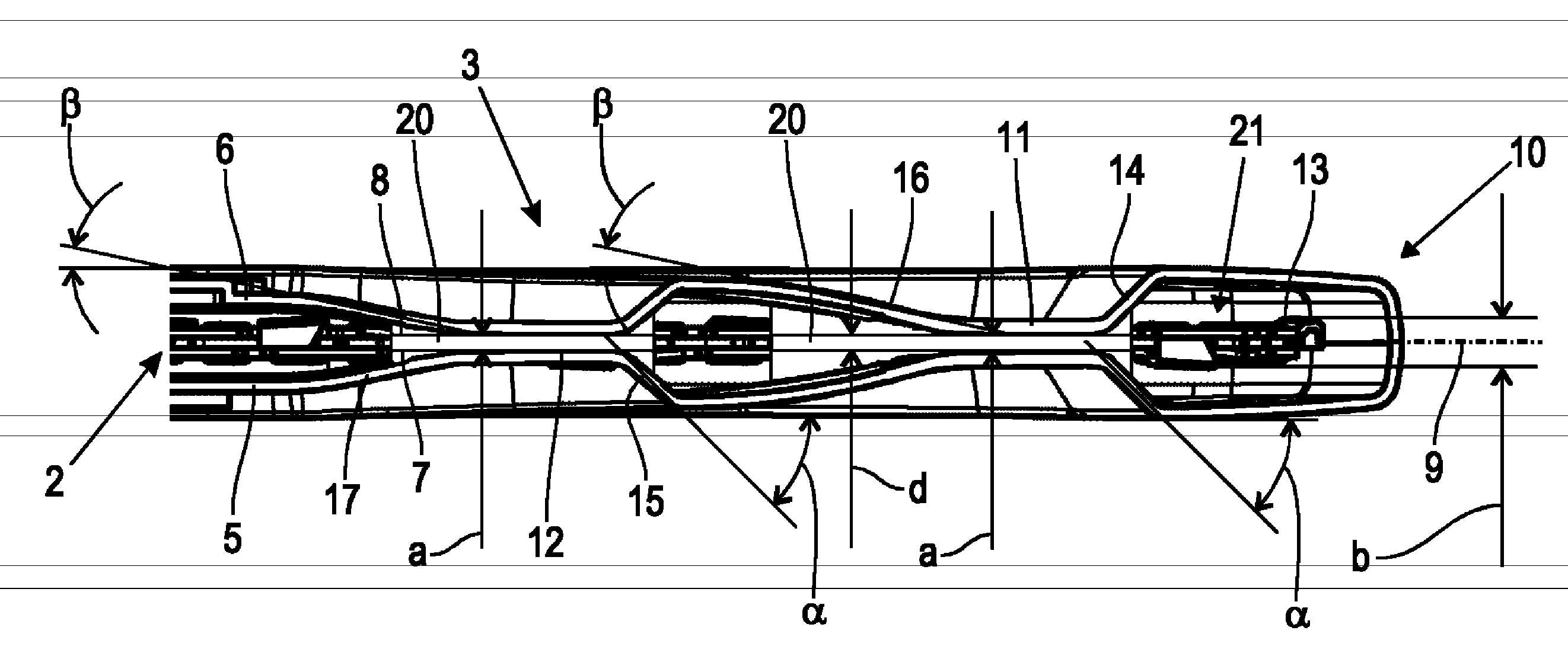

Drilling tool for holemaking in metallic workpieces

ActiveUS7241085B2Improve centering abilityGood centering abilityWood turning toolsTransportation and packagingFluteLevel line

A drill comprises a shaft with chip conveying flutes and a drill head at its forward end with at least two cutting inserts. Each cutting insert is provided with at least one cutting edge which is delimited between a chipbreaking surface and first relief surface and which includes an outer straight edge. In the proximity of the center axis of the shaft, a curved cutting edge section is provided, to which there is connected an adjacent enforcement bevel. The cutting edge is in direct proximity to a center axis, and is terminated by a chisel edge between the cutting inserts to serve as a centering core portion. The curved cutting edge section is inwardly followed by a primary straight portion without an adjacent enforcement bevel in a direction that is oriented at an angle of between approximately 40–50° in relation to a horizontal line that extends through the center axis of the drill.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

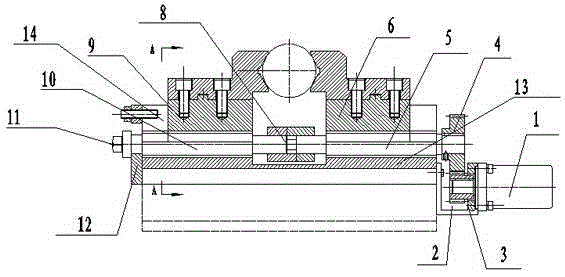

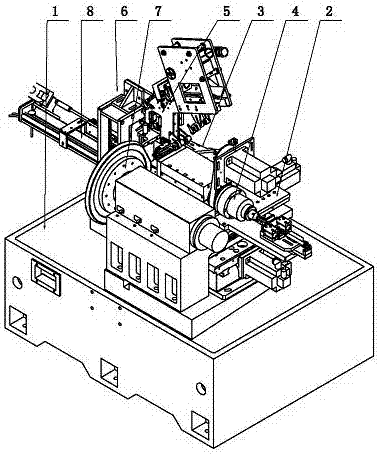

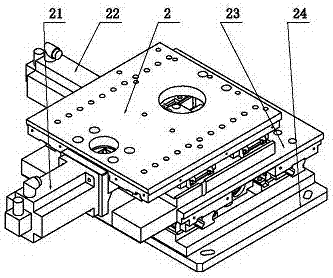

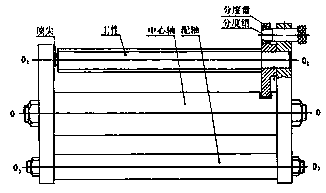

Rotary table for numerical control floor type boring miller

InactiveCN102773719AGuaranteed positioningGuaranteed positionLarge fixed membersNumerical controlGear wheel

The invention relates to a rotary table for a numerical control floor type boring miller. The rotary table comprises a rotary slide base, and a core shaft and a table top which are installed on the rotary slide base. The table top is installed on the rotary slide base through the core shaft; the rotary slide base is connected with a lead screw transmission mechanism used for driving the rotary slide base to move; a double-gear anti-backlash rotary mechanism is arranged between the rotary slide base and the table top, and is used for driving the table top to rotate; a rotary centering mechanism is arranged at the center of the table top, and comprises a two-line tapered roller bearing and a taper sleeve sheathed on the two-line tapered roller bearing; and the two-line tapered roller bearing is sheathed on the core shaft. The rotary table has the advantages that a backlash does not exist when the rotary slide base moves, so that the movement accuracy is high; and the backlash does not exist when the table top rotates, the rotary centering mechanism can guarantee the good centering performance of the rotary table when the load is large, the problem of rotary eccentricity is effectively solved, and the rotary table is positioned through a positioning air cylinder, so that the positioning performance of the table top is further guaranteed.

Owner:QINGDAO HUITENG MACHINERY EQUIP

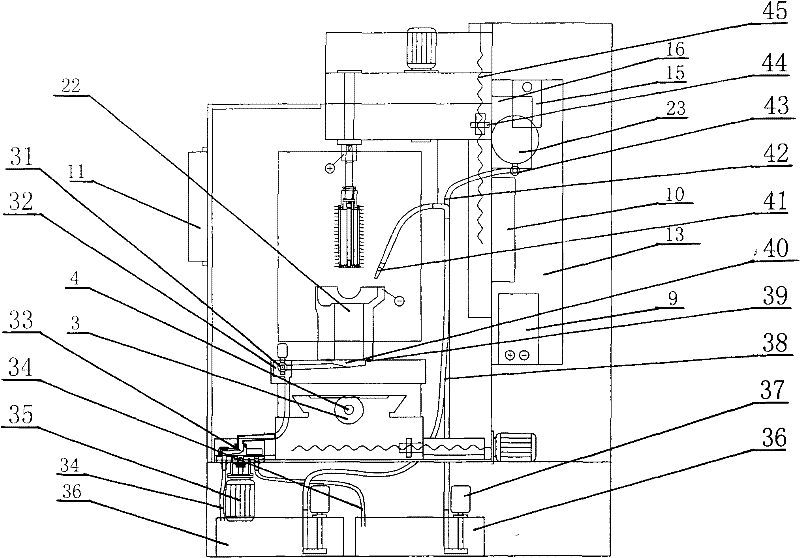

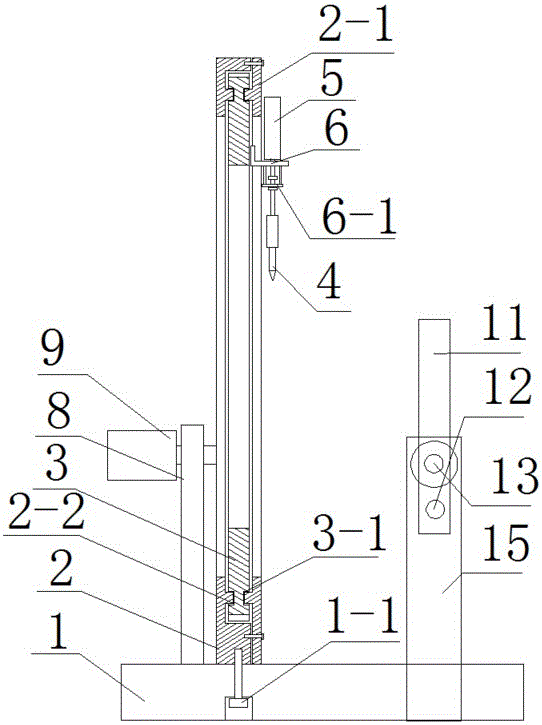

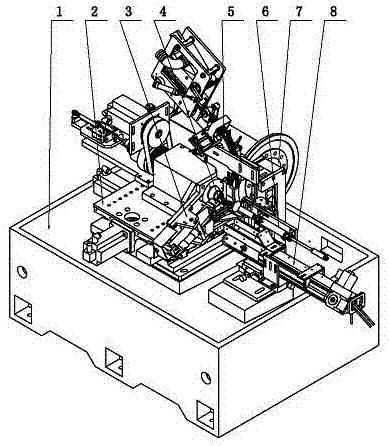

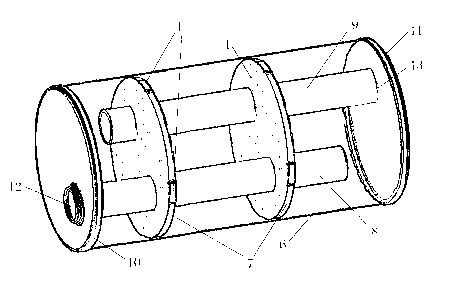

Engine cylinder body full-automatic vertical electro brush plating equipment

The invention discloses engine cylinder body full-automatic vertical electro brush plating equipment with X, Y and Z three-dimensional slide guides to perform accurate positioning, wherein the working procedure and the steps are controlled by a microcomputer procedure. The equipment comprises a 'plating solution providing and recovering system' which automatically injects according to the working procedure and storing in a classifying and recovering way with a solution dividing pan; a 'centered plating head' which is installed on a main spindle box on the Z slide guide, is provided with electrolysis material, and is connected with a sealed chamber; a nonmetal 'insulating platform' with the multifunction of insulating, self-weight multi-position sealing, plating solution collecting and positioning work piece bearing; a cylindrical 'temperature-increasing system' which is hung behind a shield cover for heating cleaning water before and after changing the solution; a 'temperature-reducing system' of a microcomputer and a program control electrical cabinet large-power brush plating electric source; an 'exhausting device' for volatilizing gas of the plating solution; and a 'vertical electro brush plating center' which performs one-off clamp multi-work position electro brush plating repair for worn and broken 'multi-pore workpieces' and can be continuously produced with large power and on a large scale.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Angle adjustable rapid laser cutting device of power construction elbow

InactiveCN106112273AEfficient cuttingQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingMechanical engineering

The invention discloses an angle adjustable rapid laser cutting device of a power construction elbow. The angle adjustable rapid laser cutting device comprises a base, a shell, a gear ring, a laser cutting head, a telescopic mechanism and a workpiece clamping mechanism, wherein the workpiece clamping mechanism is arranged on the base, axial through holes are formed in both side walls of the shell, the gear ring is movably connected with the shell by virtue of a sliding connecting mechanism, the telescopic mechanism is fixedly connected with the gear ring by virtue of a bracket, the laser cutting head is connected to the telescopic end of the telescopic mechanism, the gear ring is connected with a rotary driving mechanism by virtue of a driving gear engaged with the gear ring, and the rotary driving mechanism is fixedly connected with the base; the workpiece clamping mechanism comprises a support rod, a left electric telescopic mechanism and a right electric telescopic mechanism, the support rod is arranged on the base, the left electric telescopic mechanism and the right electric telescopic mechanism are arranged on the support rod, left clamping pieces and right clamping pieces are respectively arranged on both ends of the left electric telescopic mechanism and the right electric telescopic mechanism, and at least one clamping piece righting mechanism is arranged on the support rod. According to the device, a multi-connected elbow can be quickly cut, the quality is reliable, and a notch does not need to be trimmed.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Automatic centering and clamping device for pipes

InactiveCN105619100AReliable clampingThe clamping process is automatically centered and firmWork holdersPositioning apparatusMotor driveEngineering

An automatic centering and clamping device for pipes is provided with a base 13, wherein a right screw rod 5 and a left screw rod 10 are arranged in the base 13, and a right rotation slide base 6 is arranged in a T-shaped groove, located above the right screw rod 5, of the base 13; when a hydraulic oil motor 1 works, a pinion drives a gearwheel to do rotation motion, then the left screw rod 10 and the right screw rod 5 rotate synchronously, a left rotation slide base and the right rotation slide base are driven to move inwards or outwards simultaneously, and therefore a V-shaped clamping jaw 7 automatically clamps or releases the pipes. By arranging the clamping jaw to be of the V shape, the pipes can be automatically centered in the clamped process and can be clamped more firmly. The hydraulic oil motor drives the pinion and the gearwheel to rotate for driving the screw rods to rotate, and therefore the left rotation slide base and the right rotation slide base move outwards after moving inwards simultaneously for clamping or releasing the pipes. The automatic centering and clamping device is simple in structure, good in centering effect, large in clamping force and high in clamping efficiency.

Owner:扬州市油田金达实业有限公司

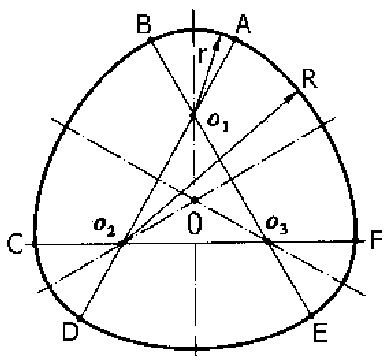

Drilling tool internal thread rotary detection device based on magnetic memory effect

ActiveCN103884457AAchieve damageEnable early detectionForce measurement by measuring magnetic property varationMaterial magnetic variablesMagnetic memoryEngineering

The invention discloses a drilling tool internal thread rotary detection device based on the magnetic memory effect. The drilling tool internal thread rotary detection device based on the magnetic memory effect comprises a centering structure assembly and a rotary detection assembly, wherein the centering structure assembly can enable the axis of the rotary detection assembly to be coincide with the axis of a threaded hole of a detected drilling tool joint, thereby enabling a magnetic memory sensor in the rotary detection assembly to keep a constant lift-off value in rotation measurement when abutting against the detected internal thread surface. Therefore, the drilling tool internal thread rotary detection device based on the magnetic memory effect has the characteristics of high detection precision, simple and convenient operation and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

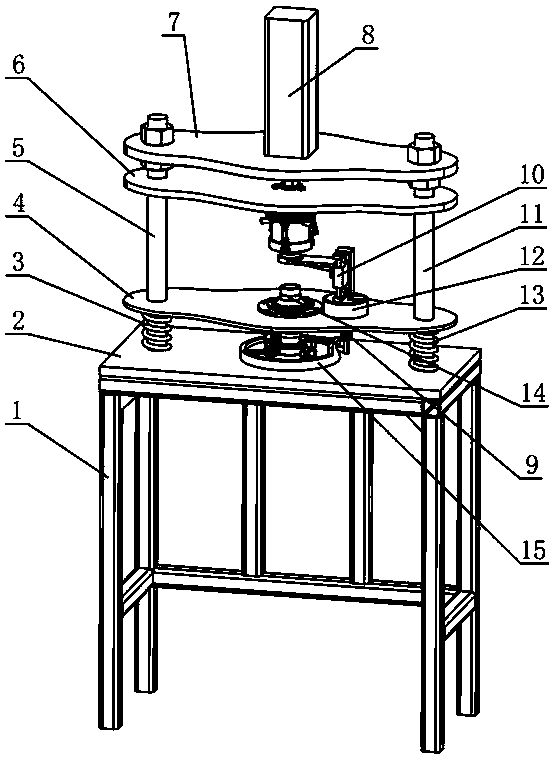

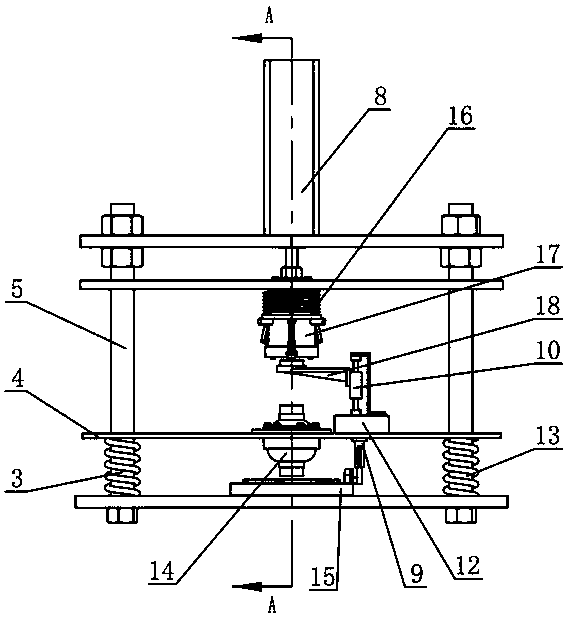

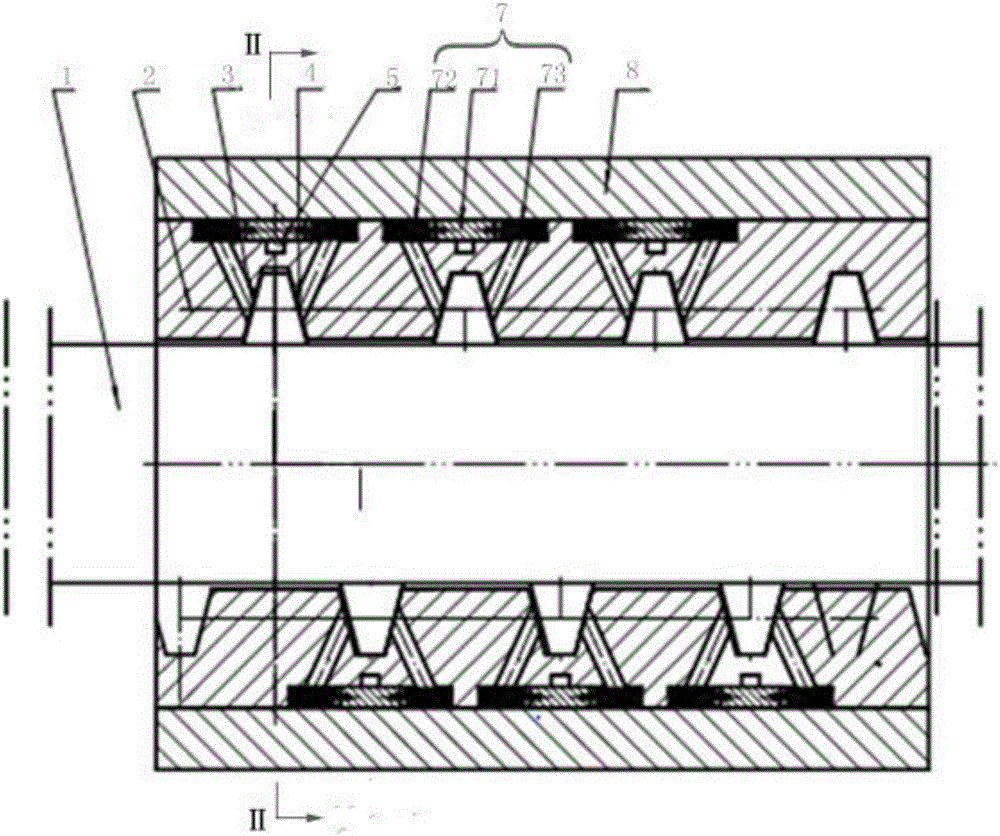

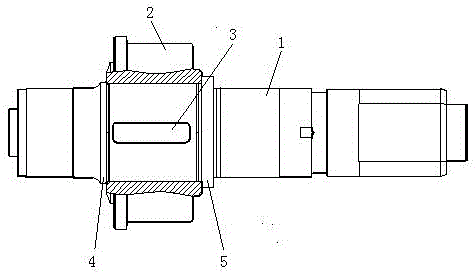

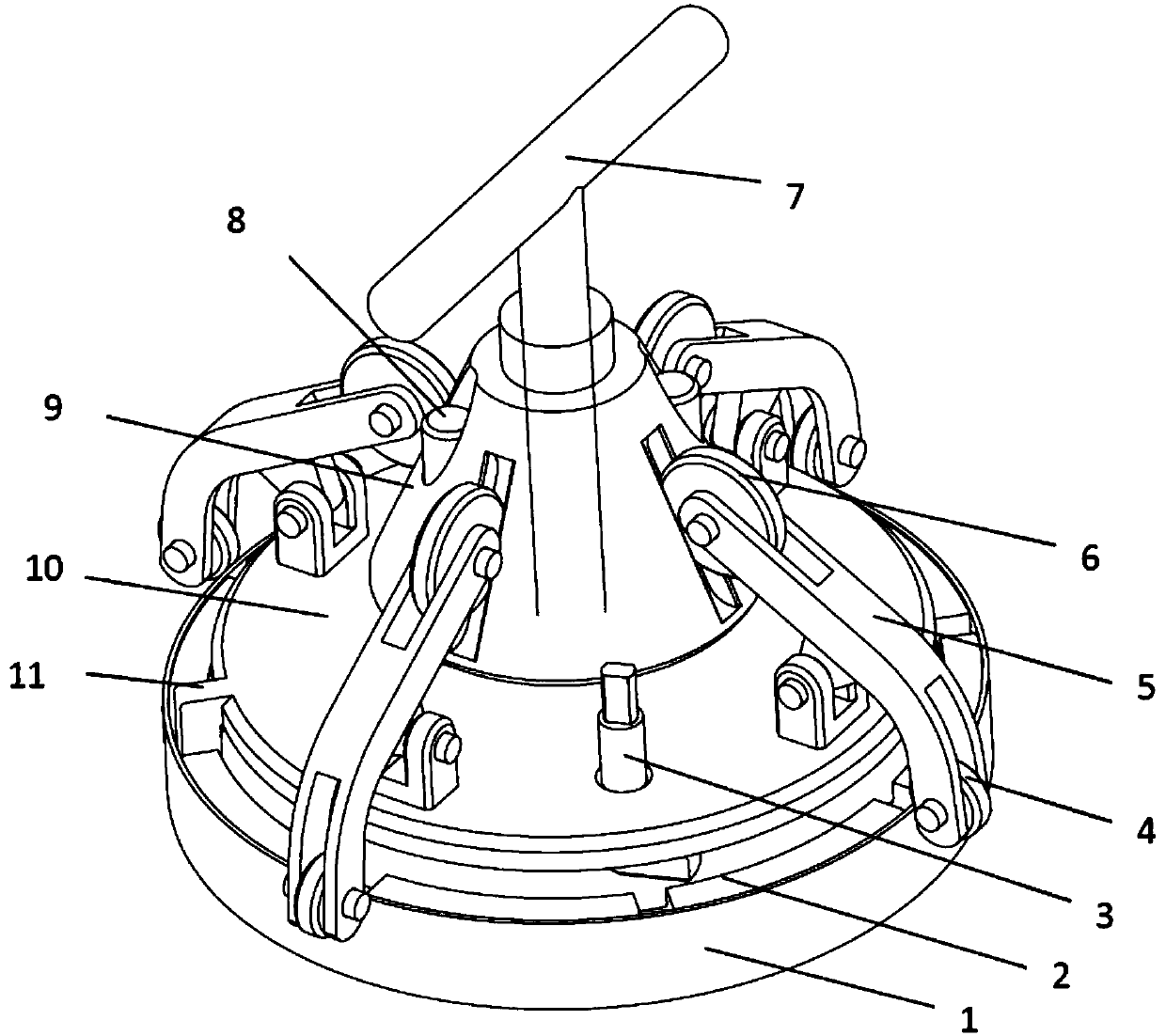

Differential bearing mounting device with bilateral bearing self-centering function and mounting method thereof

InactiveCN110153687AGood reassuring effectAvoid individual controlAssembly machinesMetal working apparatusEngineeringPiston rod

The invention discloses a differential bearing mounting device with a bilateral bearing self-centering function. The differential bearing mounting device comprises upper-side self-centering bearing clamping mechanisms, lower-side self-centering bearing clamping mechanisms and a bottom plate; the lower ends of a left upright column and a right upright column are fixed to the bottom plate; a differential carrier plate and a pressure plate are in sliding connection with the left upright column and the right upright column; the cylinder fixing plate is fixed to the left upright column and the right upright column; a lifting cylinder is fixed to the cylinder fixing plate; a mandrel and the pressure plate are fixed with a piston rod of the lifting cylinder; a bearing fixing seat is fixed to thepressure plate; the bearing fixing seat and the mandrel are provided with a cylindrical cavity for accommodating an upper-side bearing; the upper-side self-centering bearing clamping mechanisms are arranged on the bearing fixing seat; the lower-side self-centering bearing clamping mechanisms are arranged on the bottom plate; the differential carrier plate is provided with a structure for fixing adifferential and an upper-side bearing lifting mechanism; the left upright column is provided with a left compression spring between the differential carrier plate and the bottom plate; and the rightupright column is provided with a right compression spring between the differential carrier plate and the bottom plate. The self-centering fixing of the upper-side bearing and a lower-side bearing ofthe differential is realized, and the mounting of the bilateral bearings of the differential is simpler and more convenient.

Owner:ANYANG INST OF TECH

Hydrostatic nut pair with internal variable throttling function

InactiveCN105805255AGood throttling effectVariable flowGearingGear lubrication/coolingSpool valveElastic component

The invention discloses a hydrostatic nut pair with an internal variable throttling function and relates to the field of precision machinery automation equipment. The hydrostatic nut pair with the internal variable throttling function comprises a lead screw and a nut which are mutually matched, wherein a first oil cavity and a second oil cavity are formed in the two sides of each inner thread tooth surface of the nut, and the radial section projections of both the first oil cavity and the second oil cavity are fan trapezoids; through the corresponding first oil cavity and second oil cavity, a hydrostatic oil film of lubricating oil can be formed between the lead screw and each tooth side surface of the nut; a groove used for communicating with the corresponding first oil cavity and the corresponding second oil cavity is formed in each internal thread tooth of the outer circle of the nut; a movable throttling part is mounted in each groove, and comprises a slide valve, a first elastic component and a second elastic component; an oil supply groove communicating with each groove is formed in the outer circle of the nut; an external sleeve is mounted on the outer circle of the nut in a matched manner; and an oil supply hole communicating with the oil supply groove is formed in the external sleeve. By adoption of the hydrostatic nut pair provided by the invention, not only can an oil supply pipeline be simplified, but also the throttling performance can be improved.

Owner:SHANDONG UNIV

Clamping and laser cutting device of power engineering elbow

InactiveCN106141449AEfficient cuttingQuality improvementMetal working apparatusLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a laser cutting device for clamping elbows in electric power engineering, which comprises a base, a casing, a ring gear, a laser cutting head, a telescoping mechanism and a workpiece clamping mechanism, and axial through holes are arranged on the two side walls of the casing , the ring gear is movably connected to the housing through a sliding connection mechanism, the telescopic mechanism is fixedly connected to the ring gear through a bracket, the laser cutting head is connected to the telescopic end of the telescopic mechanism, and the ring gear is connected to the rotating drive mechanism through the driving gear meshed with it, The rotary driving mechanism is fixedly connected with the seat body. The device solves the problems of laser cutting such as irregular shape of the bent pipe and inclined incision, realizes high-quality and high-efficiency cutting of the bent pipe, has high cutting precision, and can greatly improve production efficiency.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

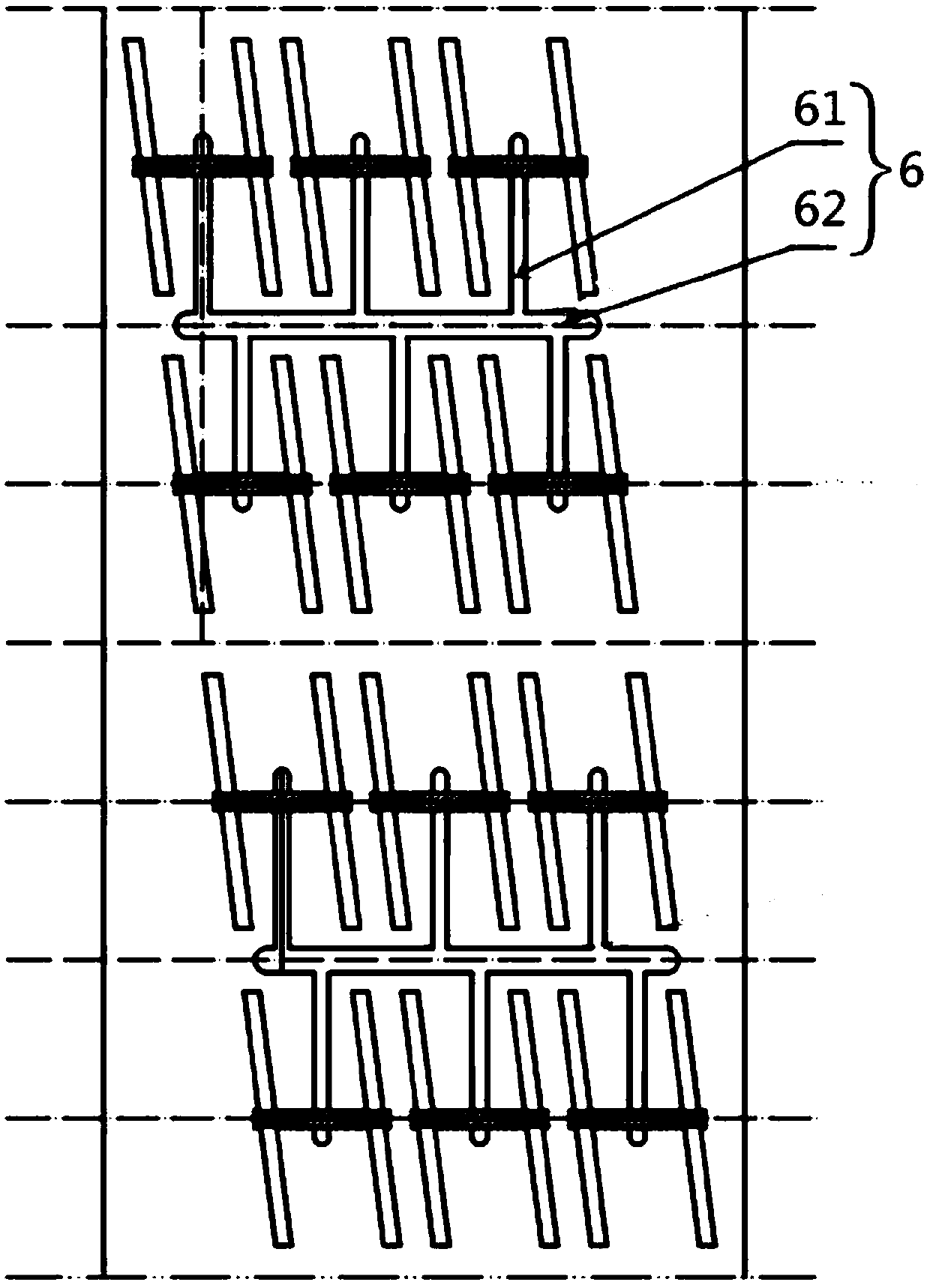

Built-in slide valve throttling static-pressure nut pair

InactiveCN105822739AGood throttling effectShorten the lengthGearingGear lubrication/coolingAutomationEngineering

The invention discloses a built-in slide valve throttling static-pressure nut pair, and relates to the field of precision mechanical automation equipment. The built-in slide valve throttling static-pressure nut pair comprises a lead screw and a nut which are matched with each other, wherein a first oil cavity and a second oil cavity are respectively formed in two sides of each inner thread surface of the nut; and by the first oil cavity and the second oil cavity, lubricating oil can form a static-pressure oil film between the lead screw and a thread side surface of the nut; a groove which communicates with the first oil cavity and the second oil cavity is formed in each inner thread on an excircle of the nut; a movable throttling component is mounted in each groove; oil supply grooves which communicate with the grooves are further formed in the excircle of the nut; a jacket is mounted on the excircle of the nut in a matched manner; and oil supply holes which communicate with the oil supply grooves are formed in the jacket. By the built-in slide valve throttling static-pressure nut pair, an oil supply pipeline can be simplified, and furthermore, the throttling performance can be improved.

Owner:SHANDONG UNIV

Tool for turning excircle of transmission shaft universal joint fork and method for positioning and centering universal joint fork

ActiveCN102211283ASimple structureEasy to useAuxillary equipmentPositioning apparatusUniversal jointDrive shaft

The invention discloses a tool for turning the excircle of a transmission shaft universal joint fork. The tool comprises a connecting flange and a tailstock center which are arranged on an external machine tool, wherein the connecting flange is connected with a V-shaped block; a V-shaped groove in press fit with the two lug parts of the universal joint fork is formed on the V-shaped block; one end of the tailstock center is provided with a centering part matched with an inner nest of the universal joint fork; and a press center matched with a central nest of the universal joint fork is convexly arranged in the center of the centering part. The centering part is matched with the inner nest, so that the inner nest with relatively high blank quality can be used as a centering standard to achieve a better centering effect; and the press center is matched with the central nest of the universal joint fork, so that the universal joint fork can be firmly pressed on the V-shaped block through the press center. The invention also discloses a method for positioning and centering the universal joint fork by using the tool for turning the excircle of the transmission shaft universal joint fork. The better centering effect can be achieved; meanwhile, press operation is simple and convenient, and work efficiency is improved.

Owner:XUCHANG YUANDONG DRIVE SHAFT

Once-forming valve grinding machine

PendingCN107471097ASports reliableAvoid displacementGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

The invention discloses a once-forming valve grinding machine. The once-forming valve grinding machine comprises a lathe as well as a workpiece main shaft and a grinding main shaft which are rotatably supported on the lathe and are parallel to each other, wherein the workpiece main shaft is rotatably supported on the lathe through a workpiece main shaft base and a feeding workbench; a spring chuck is arranged in an inner hole of the workpiece main shaft; the spring chuck is connected with a pulling tube drive device through a pulling tube; a positioning rod is spiced in a pulling tube; the rear end of the positioning rod is connected with a discharge air cylinder; a positioning air cylinder is further arranged on the workbench; the positioning air cylinder is in one-way driving connection with the positioning rod; a valve centering supporting mechanism is arranged on the workbench; a centering block on the valve centering supporting mechanism and the grinding wheel main shaft are oppositely arranged at the two sides of the workpiece main shaft; an automatic feeding device, an automatic loading device and a discharge conveying device are further arranged on the lathe. The once-forming valve grinding machine can be suitable for requirements of valve once-forming grinding processing, is high in degree of automation, and can guarantee positioning precision; and a processed valve has a determined position state in a conveying process.

Owner:东台市伟锋机械厂

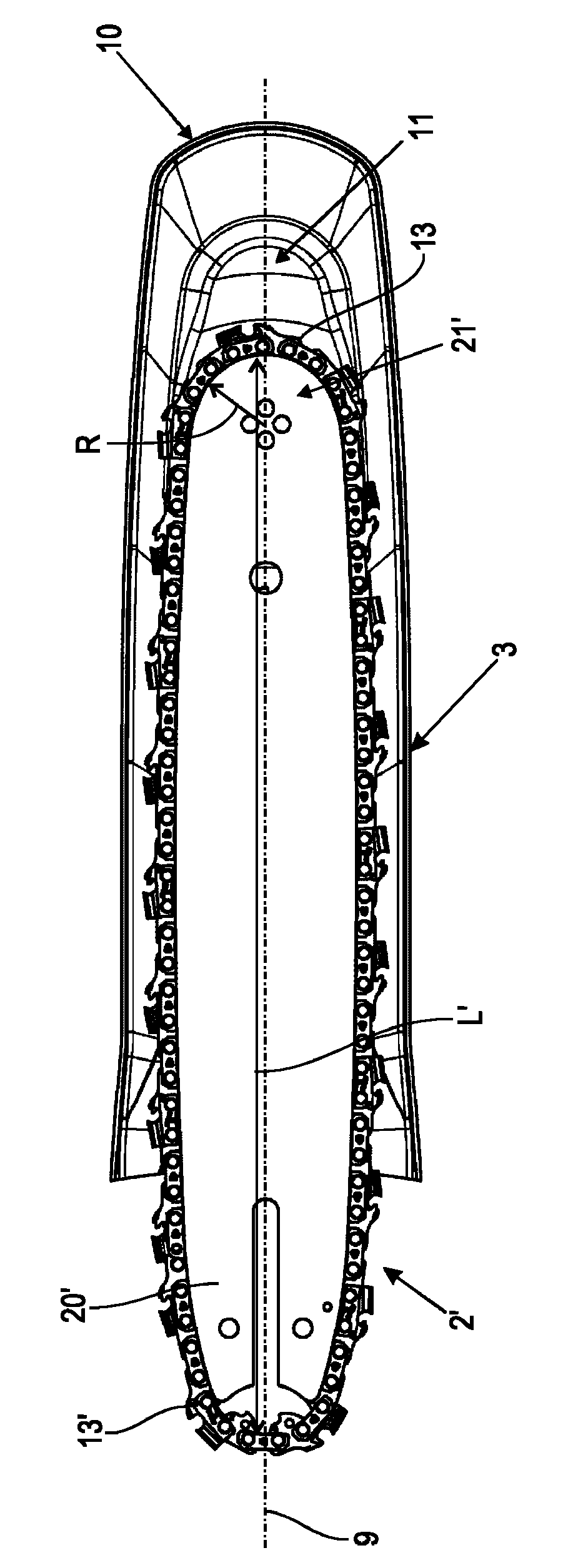

Chain guard and chainsaw system

ActiveCN103447616AReliable holdSymmetrical arrangementMetal sawing devicesMetal sawing accessoriesEngineeringChain saw

The application relates to a chain guard for a chainsaw with interchangeable cutting attachments of different lengths, said cutting attachments having cutting chains, wherein the chain guard comprises an insertion opening for inserting a cutting attachment, at least two side walls for covering lateral surfaces of the cutting attachment, a front end opposite the insertion opening, a first latching depression formed in at least one side wall, and a second latching depression formed in at least one side wall at a distance closer toward the insertion opening with respect to the first latching depression, wherein the first latching depression and the second latching depression each comprise an arcuate latching surface for latching in a form-fitting manner with a cutting chain of the cutting attachment, said latching being active in the direction of a longitudinal axis of the chain guard, and also to a chainsaw system having such a chain guard.

Owner:ANDREAS STIHL AG & CO KG

Key-connection combined vertical roll

InactiveCN106694559AOvercome the problem of high production costReduce manufacturing costRollsMetal rolling arrangementsMechanical engineeringBearing capacity

The invention discloses a key-connection combined vertical roll and belongs to the technical field of rolls. The key-connection combined vertical roll comprises a roll shaft and a roll sleeve. The roll sleeve is connected to the outer circumference of the middle of the roll shaft through a key in a matched mode. By adoption of the key-connection combined vertical roll, the problem that the difference between the diameter of a roll body and the diameter of a roll neck of the vertical roll is large, the overall casting gross-to-net ratio is large, and consequentially the production cost is high is solved, the production cost is greatly lowered, the centring performance is good, and the bearing capacity is high.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

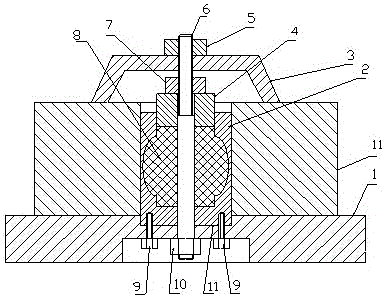

Centering clamping device

ActiveCN105014437AAchieve the purpose of reassuranceGood reassuring effectWork clamping meansPositioning apparatusEngineeringMachine tool

The invention discloses a centering clamping device and belongs to the technical field of machine tool clamps. The centering clamping device mainly comprises a centering shaft installed on a base. A large hole is formed in the middle of the centering shaft. An annular waist hole with a larger diameter is formed in the waist portion of the large hole, so that the centering shaft wall at the portion is thinner. By means of the method of pouring hydraulic media into the internal space of the centering shaft and using a piston for pressurizing the hydraulic media for expansion to enable the centering shaft wall of the annular waist hole to expand outwards, the workpiece centering purpose is achieved. The centering clamping device has the beneficial effects of being good in centering effect and high in precision.

Owner:宿迁天成锋精机股份有限公司

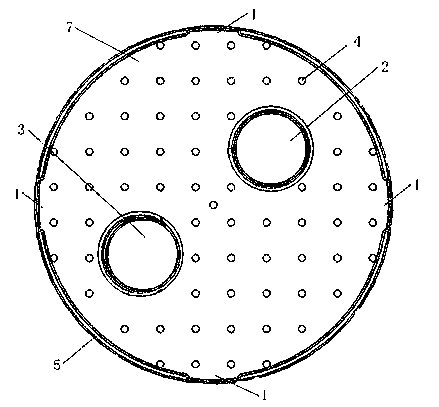

Silencer clapboard and silencer

InactiveCN103195549ASolve the problem of howlingNo reduction in noise reductionExhaust apparatusSilencing apparatusInterference fitEngineering

The invention provides a silencer clapboard and a silencer. At least three lug bosses are arranged on the outer edge of the clapboard, and the clapboard is provided with an air inlet pipe hole, an air outlet pipe hole and air venting holes and is connected trough the in an interference fit and contact between the lug bosses and the shell. The silencer comprises the shell and the clapboard, wherein the at least three lug bosses are arranged on the outer edge of the silence clapboard, the lug bosses are in interference fit and contact with the inner wall of the shell, and a gap is formed between a part, except for the lug bosses, on the outer edge of the clapboard and the shell. According to the silencer clapboard and the silencer, the gap is reserved between the part, except for the lug bosses, on the outer edge of the clapboard and the shell, the harsh whistler generated when air passes through the small gap between the clapboard and the shell is avoided, the excellent sound proofing property is ensured, so that the manufacturing yield is high, and the product quality is stable; and the silencer clapboard is suitable for various silencers with clapboards.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

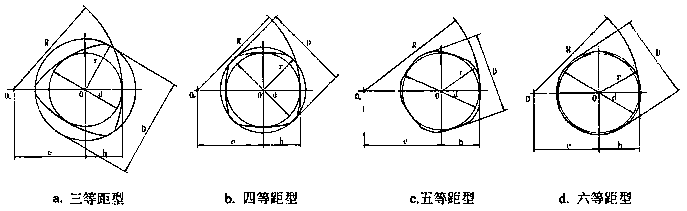

Equidistant arc surface and machining device

The invention discloses an equidistant arc surface and a machining device. The center Oe of the equidistant arc surface R is designed to be outside an equidistant arc profile inscribed circle, namely,R is larger than d; centers O of small arcs r1 in the equidistant arc surface are designed to be on a center O of an equidistant large arc surface, namely, the plurality of small arcs are concentriccircles, and the radius r2 of a small arc in a hub hole is larger than the radius r1 of a small arc on an equidistant arc surface axis (r2 > r1). The equidistant arc surface with the high precision (h5-h6) and the high degree of finish (Ra0.8-0.4 micron) can be quickly produced through grinding by the machining device.

Owner:赵国英

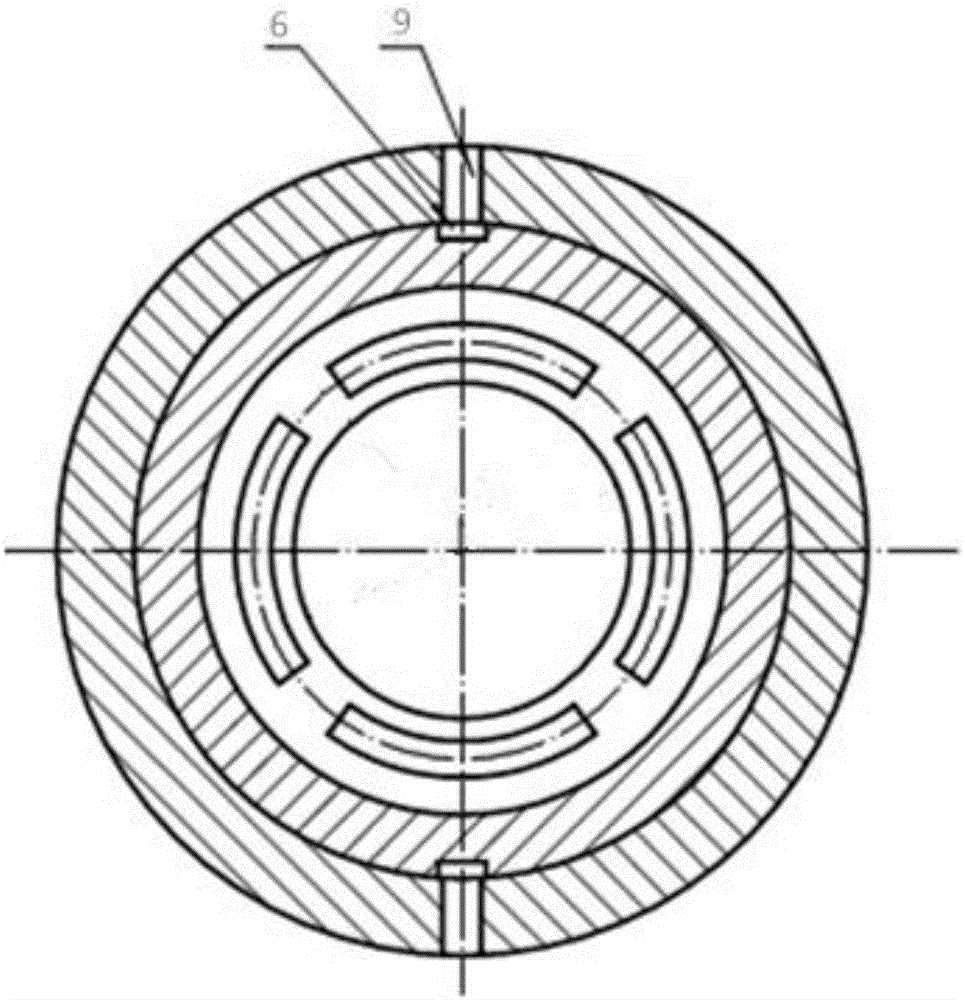

Single-rotation-direction four-oil-wedge inner hole heavy-load sliding bearing

PendingCN107906127AMeasure directly and convenientlyUniform stiffnessShaftsBearing componentsSlider bearingEngineering

The invention provides a single-rotation-direction four-oil-wedge inner hole heavy-load sliding bearing. A bearing body is divided into an upper bearing body and a lower bearing body. The upper bearing body and the lower bearing body are connected through screws and cylinder pins. Four pads are installed in the bearing body. Four oil inlet holes phiD are designed in the bearing body and penetratethrough the inner circle and the outer circle of the bearing body. The four oil inlet holes are distributed among the pads. An inner hole of the sliding bearing and a shaft form four wedge-shaped oilwedges. During start, the four pads form four uniform oil wedges, and the shaft can be stably started. Finally, hydrodynamic pressure is generated in each oil wedge, and the oil film rigidities in allthe directions are uniform. In this way, the four-oil-wedge sliding bearing of the structure has the performance characteristics of being high in rotation precision, good in centering performance, high in oil whipping resistance, high in rigidity and high in damping. Meanwhile, since the pad inner holes can be installed on the bearing body to form the four oil wedges after being fine machined, the phenomenon that since the inner hole of an integrated four-oil-wedge sliding bearing can be only formed through milling, the axial taper defect, the circumferential cutter grain defect and other defects of the inner hole are caused is avoided; and besides, when the pads are independently machined, the advantages of direct measurement, convenience and the like are achieved.

Owner:CSIC NO 12 RES INST

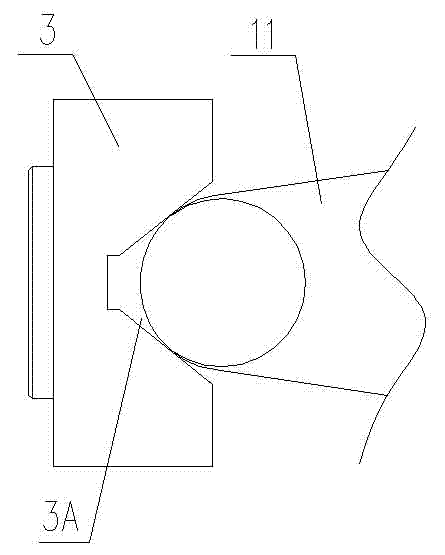

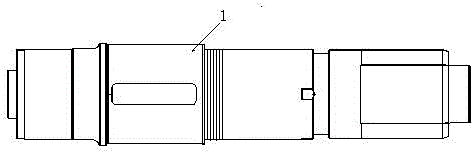

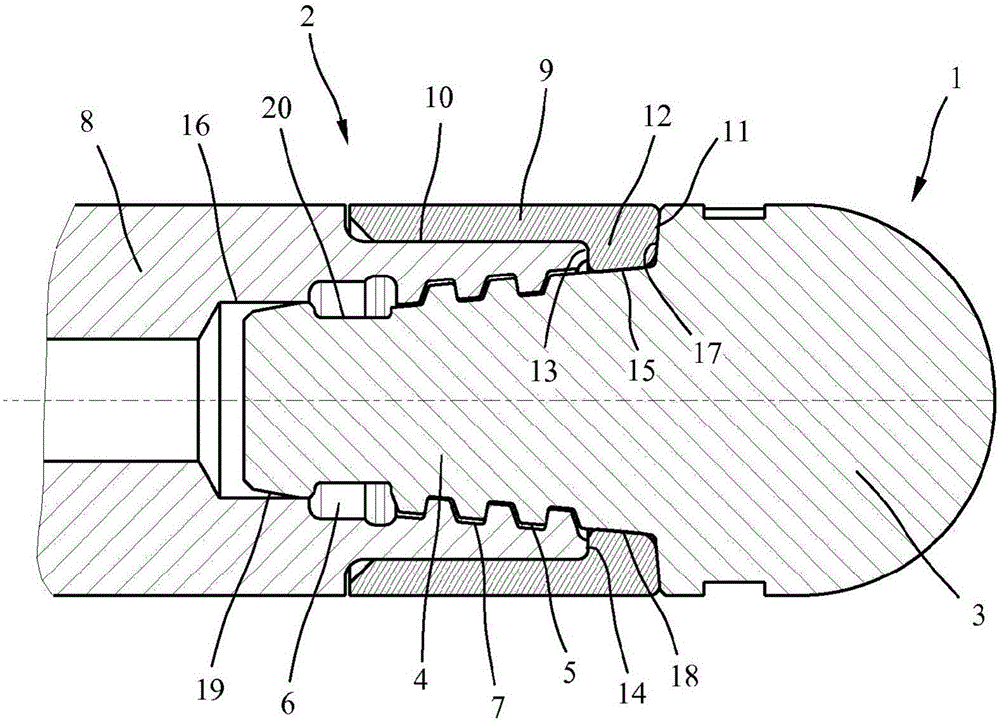

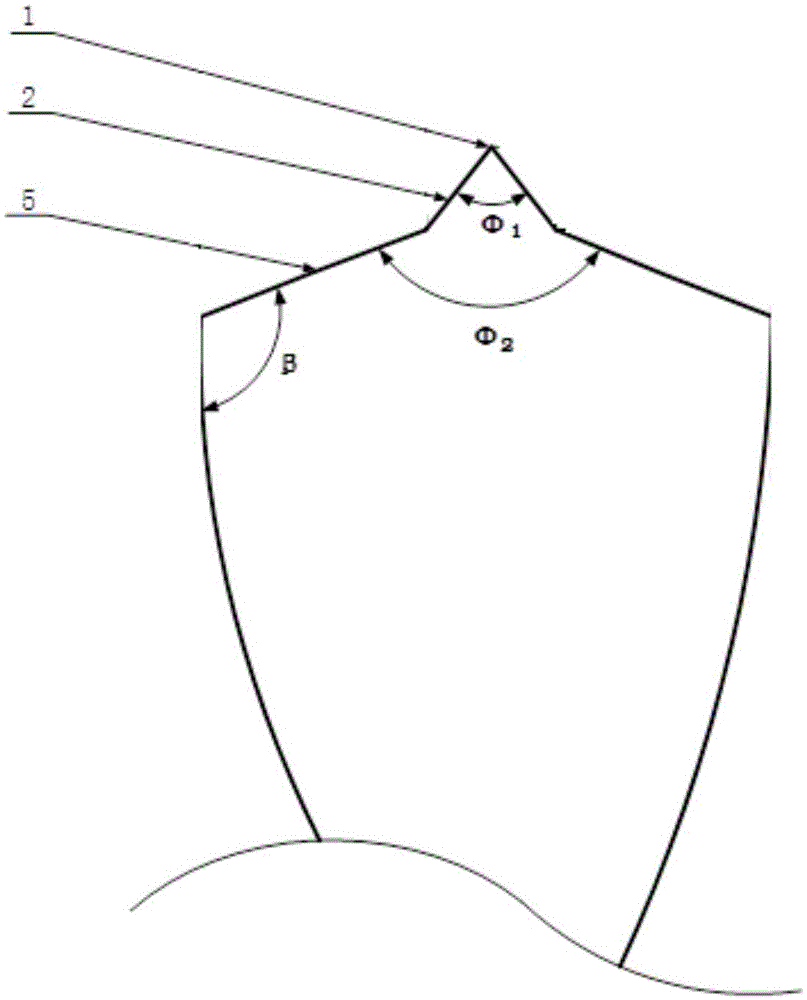

Screwdriving tool and tool holder for such a screwdriving tool

ActiveCN104093513ALarge bearing surfaceGood reassuring effectSleeve/socket jointsTool workpiece connectionEngineeringTool holder

The invention relates to a screwdriving tool (1) and to a tool holder (2) for such a screwdriving tool. the screwdriving tool (1) contains a tool head (3) and a tool shank (4) having an outer thread (5) and a supporting region arranged between the tool head (3) and the outer thread (5). according to the invention, the supporting region is formed by two conical bearing faces (6, 8) having different cone angles.

Owner:FRANZ HAIMER MASCHINENBAU KG

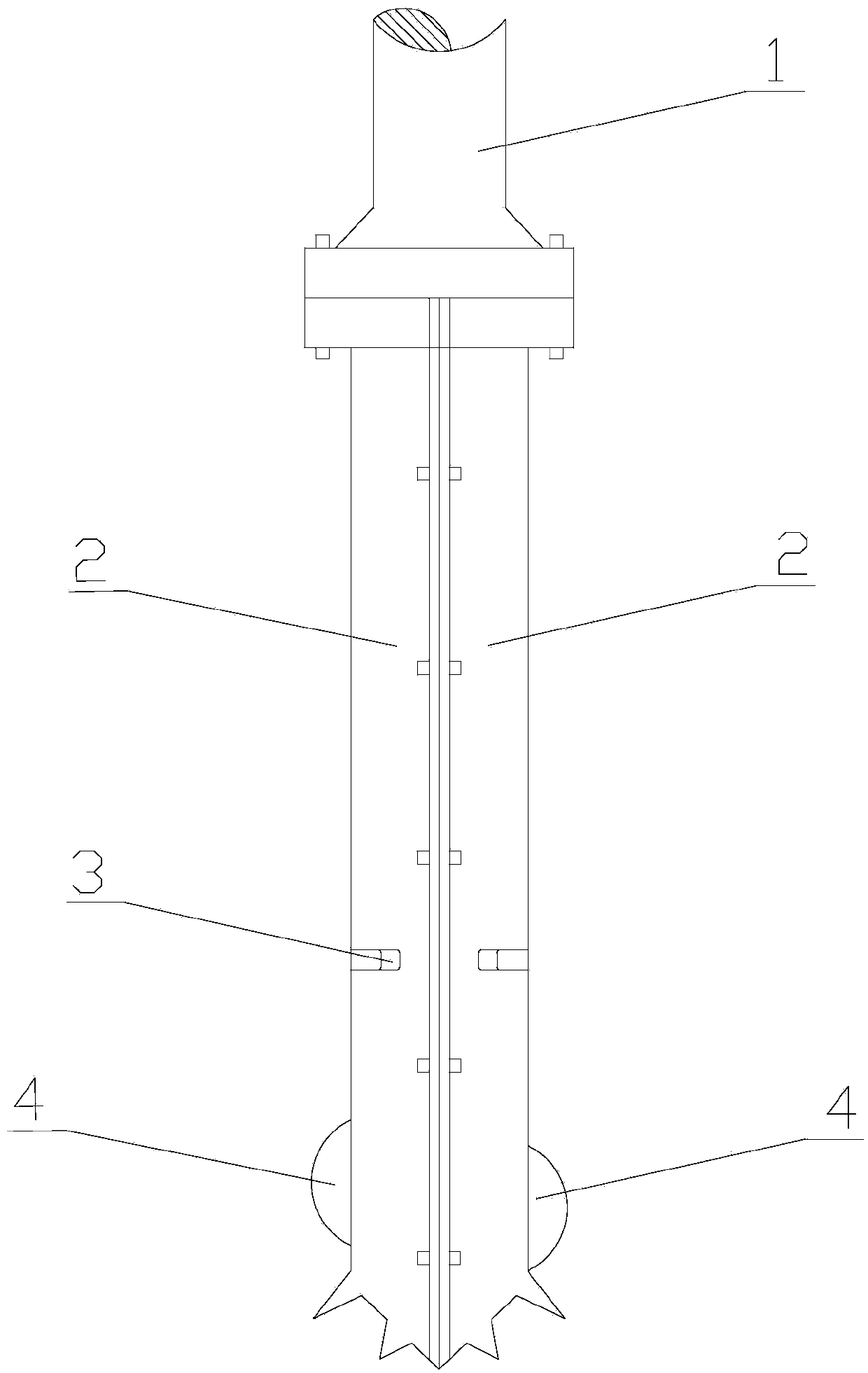

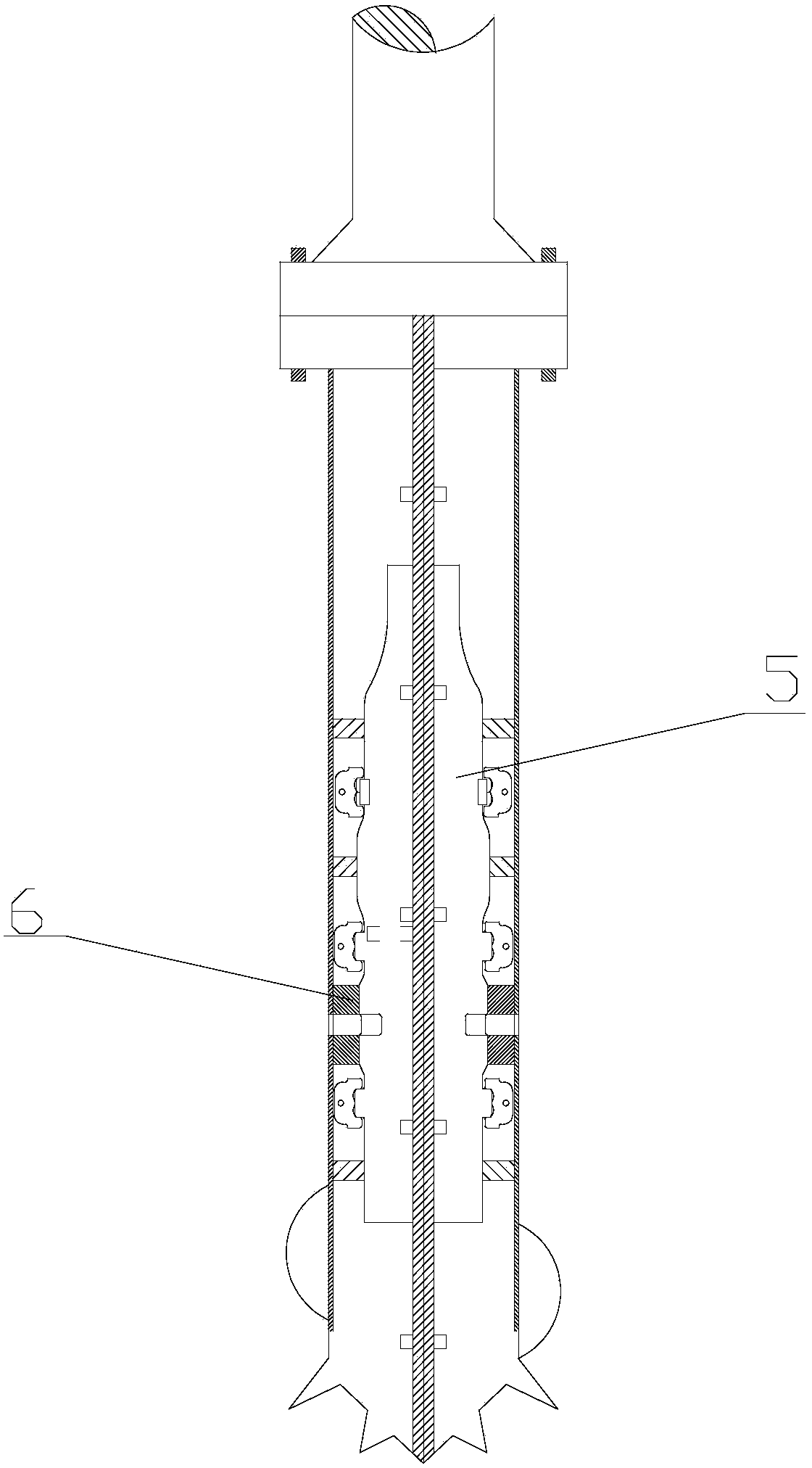

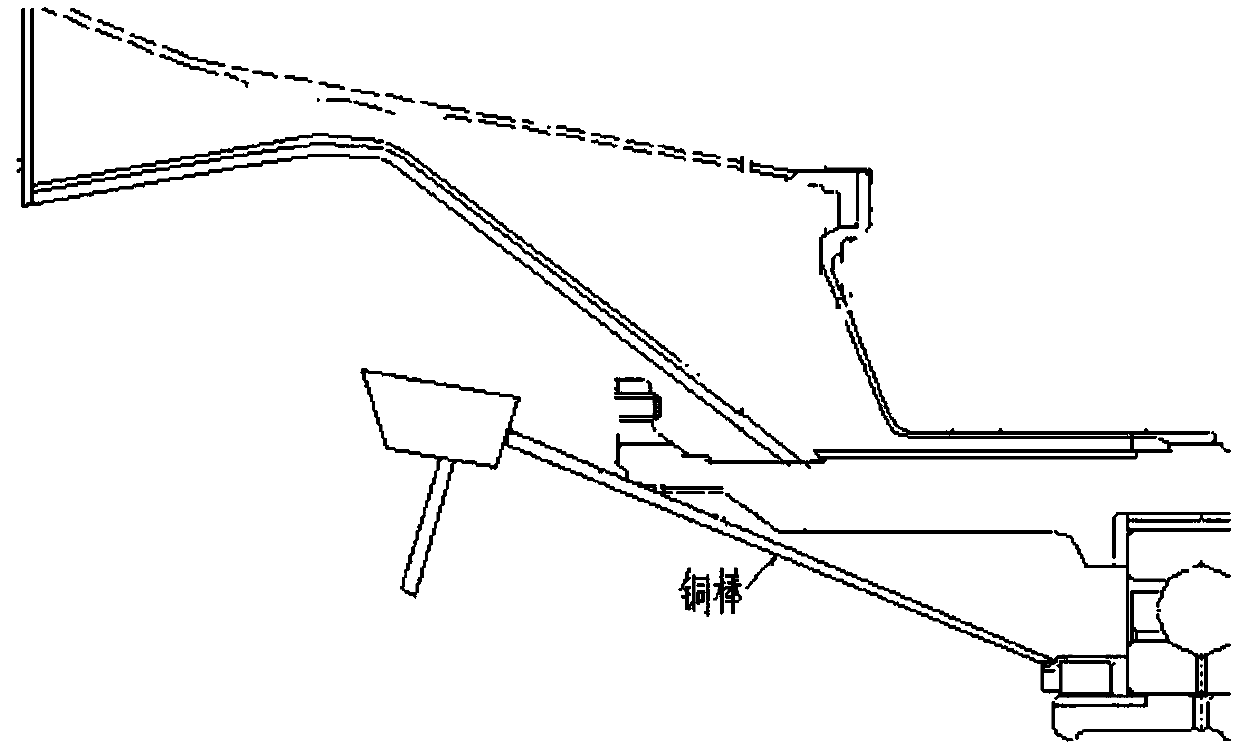

Geophysical exploring device and method for transitional zone areas between bog and shallow beach sea

ActiveCN103995291AGood reassuring effectFix flutterSeismology for water-covered areasEngineeringFlange

A geophysical exploring device method for the transitional zone areas between bog and shallow beach sea belongs to the technical field of geophysical exploration. An air gun is arranged in a drill bit composed of two drill bit piece bodies, filling blocks are welded into the two drill bit piece bodies, a drill stem connecting flange is arranged at the bottom of a drill stem, the drill stem connecting flange is of an integrated structure, drill bit connecting flanges are arranged at the upper portions of the drill bit piece bodies, the drill bit connecting flanges are of two semi-annular structures, the drill stem connecting flange is sleeved by an anti-loosen screw to be connected with the drill bit connecting flanges, and accordingly the drill stem and the drill bit piece bodies are combined to form a main body structure of a detachable type air gun drill bit. Two symmetrical spiral pieces are welded to the bottoms of the drill bit piece bodies respectively to form a dual-spiral drill bit structure. The diameter of the drill bit composed of the two combined spiral piece is 500mm. The drill bit piece bodies are of hollow structures, composed of two semi-tubular structures respectively and sleeved by screws to be fixed. The air gun is arranged in the hollow structures. By means of the dual-spiral drill bit structure, stimulating operation of the air gun can be finished synchronously.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

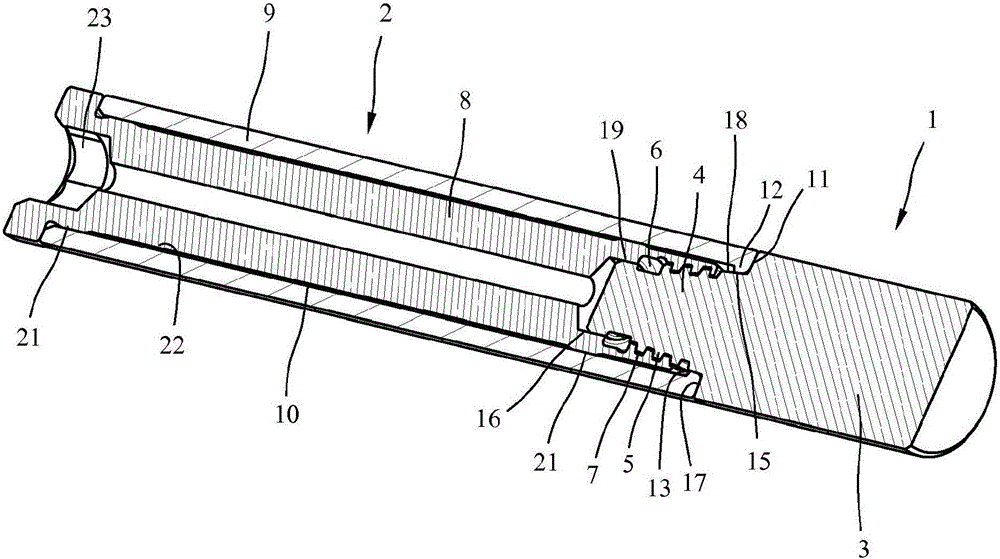

Tool holder for a tool with a tool shaft provided with an outer thread

ActiveCN104955596ATo achieve reinforcementEasy to replaceSleeve/socket jointsTool workpiece connectionEngineeringScrew thread

The invention relates to a tool holder (2) for a screw-in tool (1), comprising a receiving body, which comprises a receiving opening (6) with an inner thread (7) and a support region with at least one guide surface (11) for receiving the screw-in tool (1) in the tool holder (2) accurately in position. The receiving body according to the invention comprises a receiving part (8) and a guide part (9), which is fixed on the receiving part (8) and on which the support region with the at least one guide surface (11) is provided.

Owner:FRANZ HAIMER MASCHINENBAU KG

Roller type synchronous locking device

The invention provides a roller type synchronous locking device aiming to achieve the purposes of efficiently completing a locking task, achieving that a locking cup reliably locks a nut and improvingthe work efficiency and reliability of engine assembly. The roller type synchronous locking device comprises connection rod assemblies and an actuating assembly. Each connection rod assembly comprises a connection rod body, a roller and a compression cam, wherein the roller and the compression cam are rotationally fixed to the two ends of the connection rod body and the compression cam is in contact with the portion to be locked of the locking cup. The actuating assembly comprises a fixed portion ad a moving portion. The fixed portion is fixed to the shaft end, and each connection rod is hinged to the fixed portion. The surface of the movable portion is in contact with each other roller. During synchronous locking, the movable portion moves in the axial direction relative to the fixed portion, so that the rollers are promoted to drive one ends of the connection rod bodies to move, and then the compression cams synchronously lock the to-be-locked portion of a lock cup into a clamping groove structure of a shaft end nut.

Owner:AECC SICHUAN GAS TURBINE RES INST

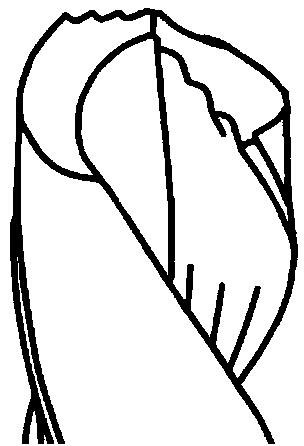

Twist drill with grooved front tool faces and bent blades

ActiveCN103737073AImprove drilling performanceEasy to save energyTwist drillsPolygonal lineEngineering

The invention discloses a twist drill. The twist drill is characterized in that main blades of the twist drill are bent blades, in other words, a plurality of spiral grooves are formed in spiral surfaces of front tool faces of the main blades, projection of each spiral groove on an end plane of the twist drill is a curve or a fold line which is used as a generating line, and the spiral grooves spirally move around a drill spindle from the generating lines. The invention further discloses application of the twist drill to drilling machining. The twist drill and the application have the advantages that the twist drill is excellent in comprehensive drilling performance, holes can be drilled and machined within a short time, the twist drill is low in drilling power consumption and high in tool durability, and a tool sharpening method is simple and convenient and is easy to implement.

Owner:HUAZHONG UNIV OF SCI & TECH

Brake disc especially for rail vehicles

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

Coal seam gas drilling rig power head tap device

A coal seam gas drilling rig power head tap device comprises a water joint and a power head floating core shaft; a positioning nut sleeves a water inlet end of the power head floating core shaft; the positioning nut is in threaded connection with the power head floating core shaft. The coal seam gas drilling rig power head tap device is characterized in that a sealing connection mechanism is arranged between the positioning nut and the water joint; the sealing connection mechanism comprises a centering supporting sleeve which is fixedly connected with the positioning nut; a core pipe which is fixedly connected with the water joint is arranged inside the centering supporting sleeve; an inner chamber of the core pipe is communicated with an inner chamber of the power head floating core shaft and the water joint to form a water inlet channel; a centering mechanism is arranged between the outer wall of a water inlet end of the core pipe and the inner wall of the centering supporting sleeve; a sealing device is arranged between the outer wall of a water outlet end of the core pipe and the inner wall of the centering supporting sleeve. According to the coal seam gas drilling rig power head tap device, the structure is compact, the work is stable, sealing parts are convenient to replace, the integral installation and detachment is simple, the requirements of the actual use of the existing coal seam gas drilling rig are met, and the guarantee is provided for the improvement and innovation of the traditional core drill.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

Built-in slide valve throttling static pressure nut pair

InactiveCN105822739BGood throttling effectShorten the lengthGearingGear lubrication/coolingSpool valveOil can

The invention discloses a built-in slide valve throttling static-pressure nut pair, and relates to the field of precision mechanical automation equipment. The built-in slide valve throttling static-pressure nut pair comprises a lead screw and a nut which are matched with each other, wherein a first oil cavity and a second oil cavity are respectively formed in two sides of each inner thread surface of the nut; and by the first oil cavity and the second oil cavity, lubricating oil can form a static-pressure oil film between the lead screw and a thread side surface of the nut; a groove which communicates with the first oil cavity and the second oil cavity is formed in each inner thread on an excircle of the nut; a movable throttling component is mounted in each groove; oil supply grooves which communicate with the grooves are further formed in the excircle of the nut; a jacket is mounted on the excircle of the nut in a matched manner; and oil supply holes which communicate with the oil supply grooves are formed in the jacket. By the built-in slide valve throttling static-pressure nut pair, an oil supply pipeline can be simplified, and furthermore, the throttling performance can be improved.

Owner:SHANDONG UNIV

Twist drill for machining holes of laminated welded steel

ActiveCN110842259ANo change in sharpnessGood reassuring effectTransportation and packagingTwist drillsChiselStructural engineering

The invention discloses a twist drill for machining holes of laminated welded steel. The twist drill for machining holes of the laminated welded steel includes a cutting part and a shank part. The cutting part includes a drill tip and a secondary cutting part, and the drill tip is provided with two main cutting edges and a chisel edge connecting the two main cutting edges. The secondary cutting part is provided with two chip discharging grooves and two first cutting edge belts, and the first cutting edge belts and the chip discharging grooves intersect to form a secondary cutting edge. The main cutting edges are provided with negative chamfers, and the negative chamfers do not pass the intersections of the main cutting edges and the chisel edge. The length of the chisel edge is L5, whereinthe L5 is larger than or equal to 0.017D and less than or equal to 0.03D, and D is the diameter of the cutting part. According to the twist drill for hole machining of the laminated welded steel, thelength of the chisel edge is only one third of that of a conventional chisel edge, the length of the chisel edge of the drill tip is small, the centering capacity during drilling of the laminated welded steel is increased, the twist drill for hole machining of the laminated welded steel is suitable for drilling machining of steel with varying hardness among different materials, the problem of drilling deviation in the drilling process is reduced, the negative chamfers are arranged on the main cutting edge, no negative chamfer is arranged on the entire chisel edge, and the sharpness of the chisel edge is not changed while the strength of the main cutting edge is increased, so that the centering performance of the chisel edge is better.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

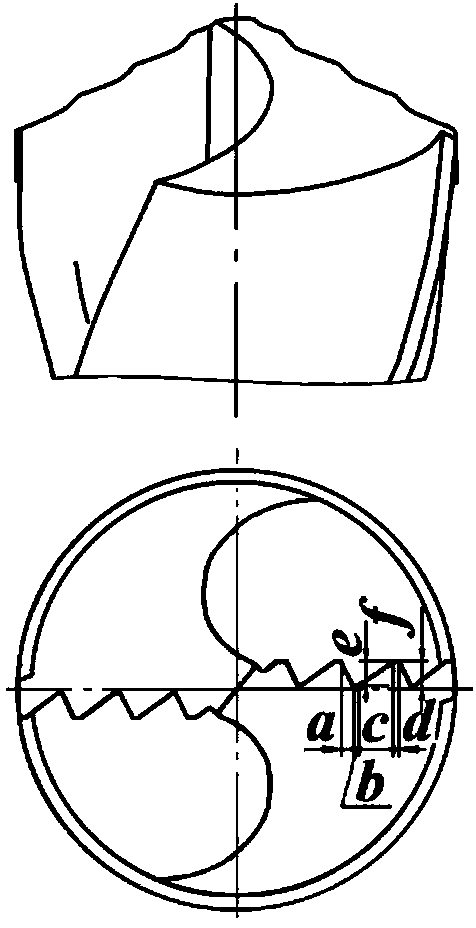

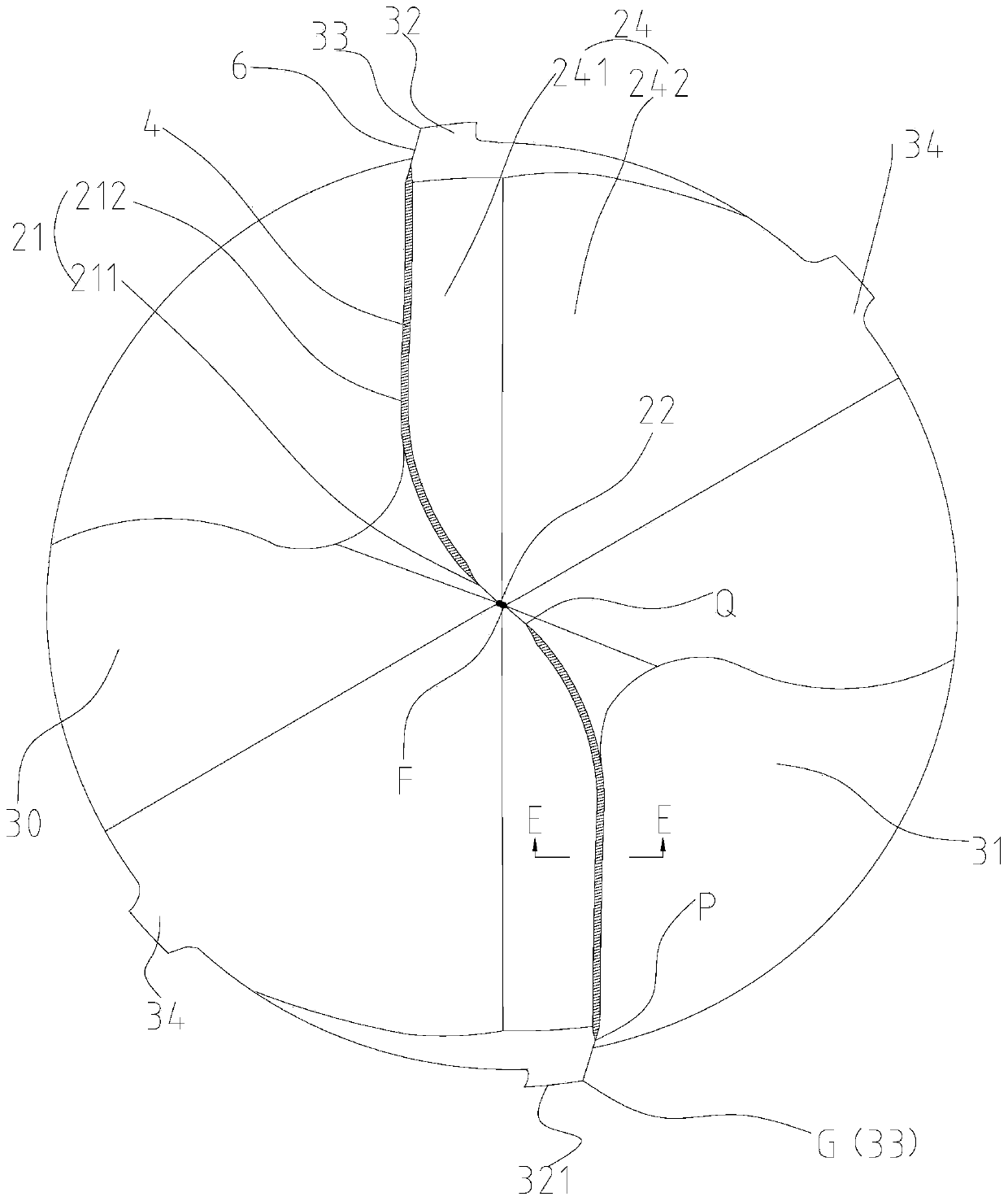

General-purpose multiple-cutting edge drill

InactiveUS9545676B2Good centering effectReduce resistanceWood turning toolsTransportation and packagingGeneral purposeChisel

A general-purpose multiple-cutting edge drill includes: a drill point (1); a drill body (2); margins (3) located on an outer wall of the drill body (2); two lips, wherein, if viewed from an axial direction, from out to inside, each of the two lips successively includes an outer cutting edge (11), an arc cutting edge (12) and an inner cutting edge (13); a chisel edge (14); outer peaks (15) formed by intersection of the outer cutting edges (11) and the arc cutting edges (12); a center peak (16) formed by intersection of two inner flank surfaces and two split surfaces. Moreover, an included angle between the inner cutting edges (13) ranges from 108° to 128°, an included angle between the outer cutting edge (11) ranges from 130° to 140°, and an included angle between the inner cutting edge (13) and outer cutting edge (11) ranges from 28° to 40°.

Owner:NINGBO HUAREN TOLLS +1

Self-centering micro drill bit without chisel edge

ActiveCN105033328AImproved centering effectAvoid skewTransportation and packagingTrepanning drillsDrill holeMicro drilling

The invention relates to the technical field of the machining, in particular to a micro-drilling tool. According to the technical scheme of a self-centering micro drill bit without a chisel edge, the self-centering micro drill bit without the chisel edge comprises a drill bit body, a first-level drill point and a second-level drill point; the first-level drill point starts from the drill bit body; the second-level drill point starts from the top of the first-level drill point; a drill core point is the apex of the second-level drill point and formed by grinding inner edge rake faces on the two sides of the second-level drill point; the drill core point is not provided with the chisel edge. According to the self-centering micro drill bit without the chisel edge, due to the fact that the original chisel edge structure of a common twist drill is omitted from the second-level drill point, so that on the one hand, the centering effect of the micro drill bit is improved, the deflection of the drill points is effectively avoided when drilling is carried out, and hole site precision and hole type precision of drilled holes are increased; on the other hand, cutting resistance is effectively reduced in the drilling process, stressed conditions of the micro drill bit are improved, abrasion and breakage of the micro drill bit are reduced, and the service life of the micro drill bit is prolonged.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com