Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Fix flutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

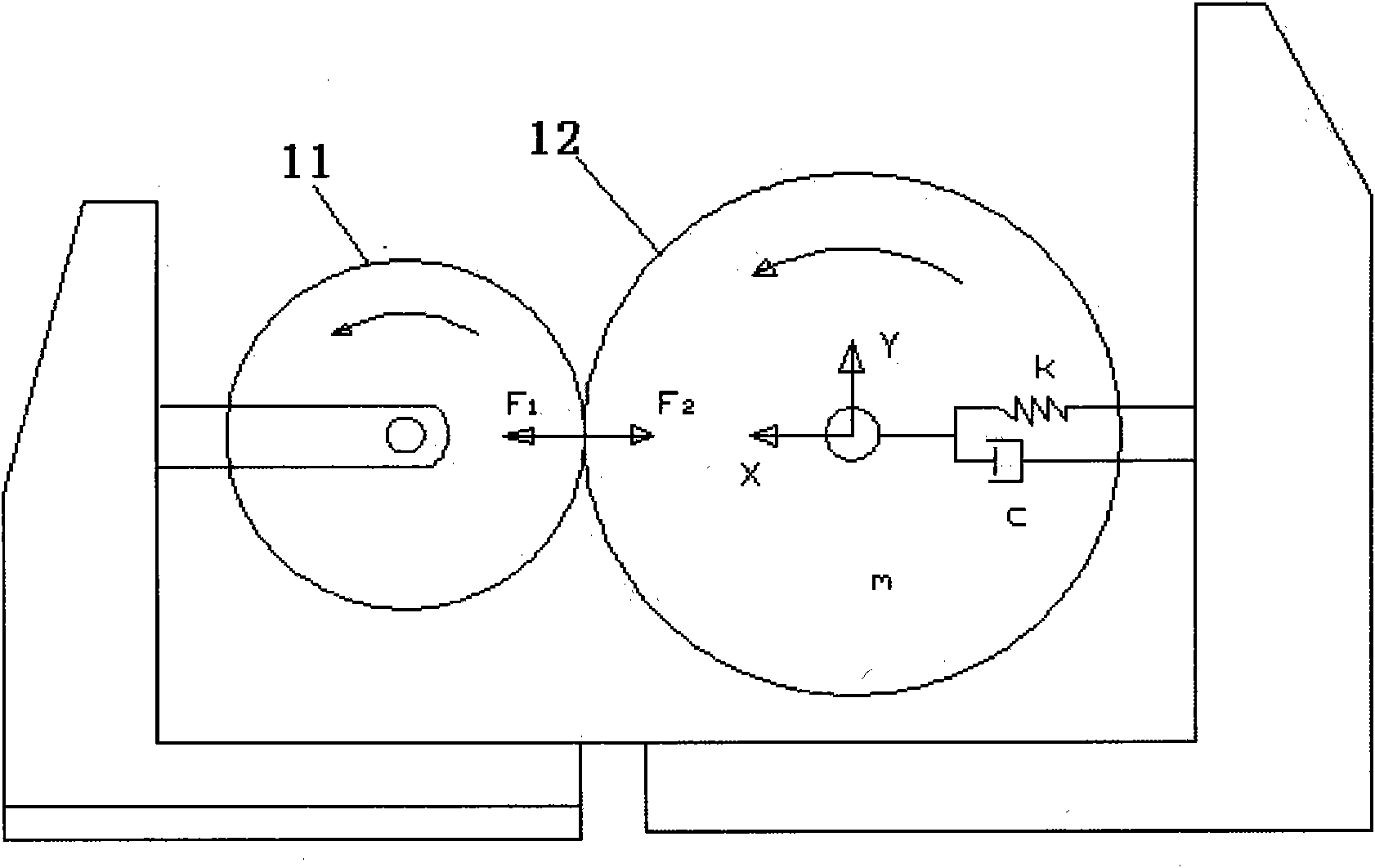

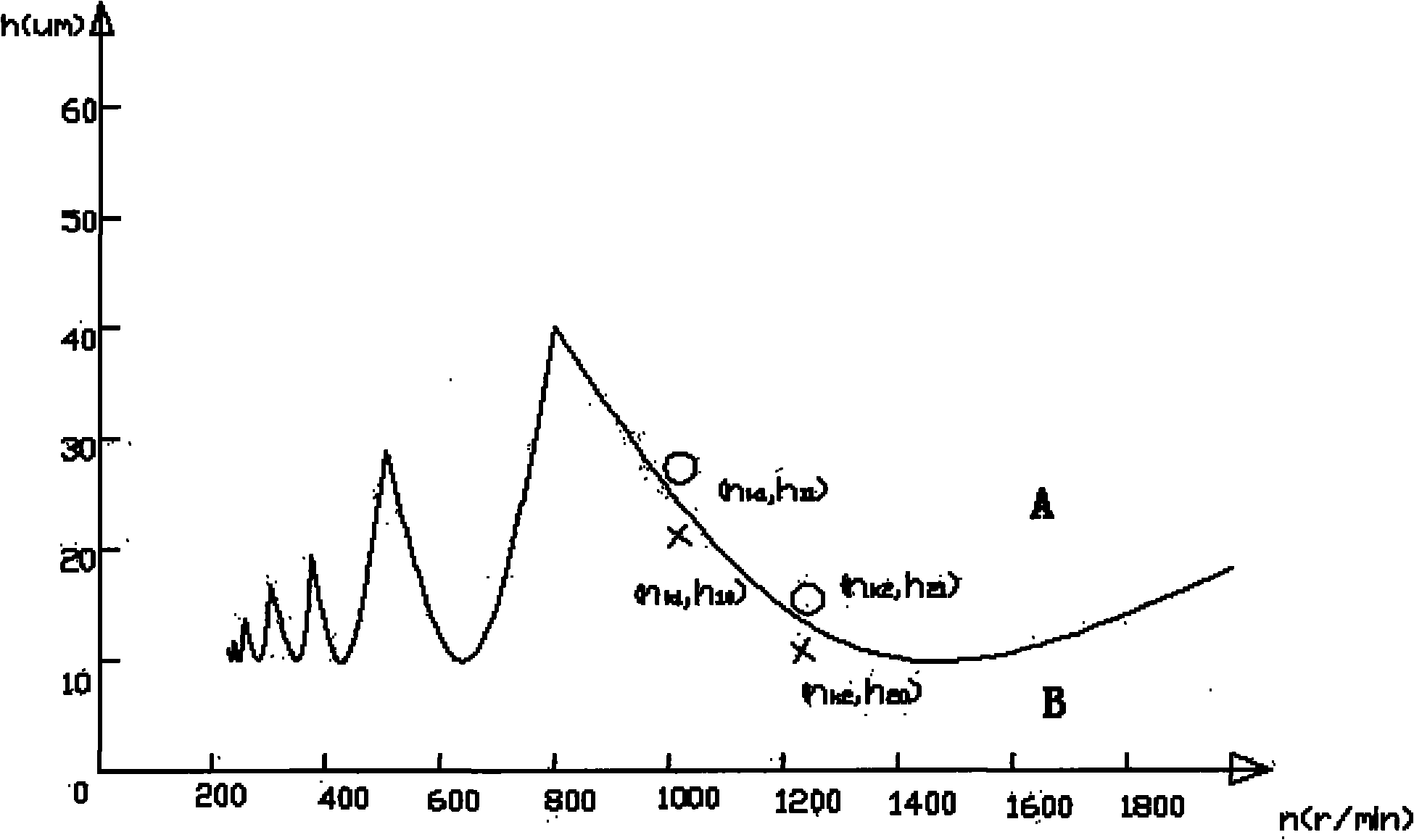

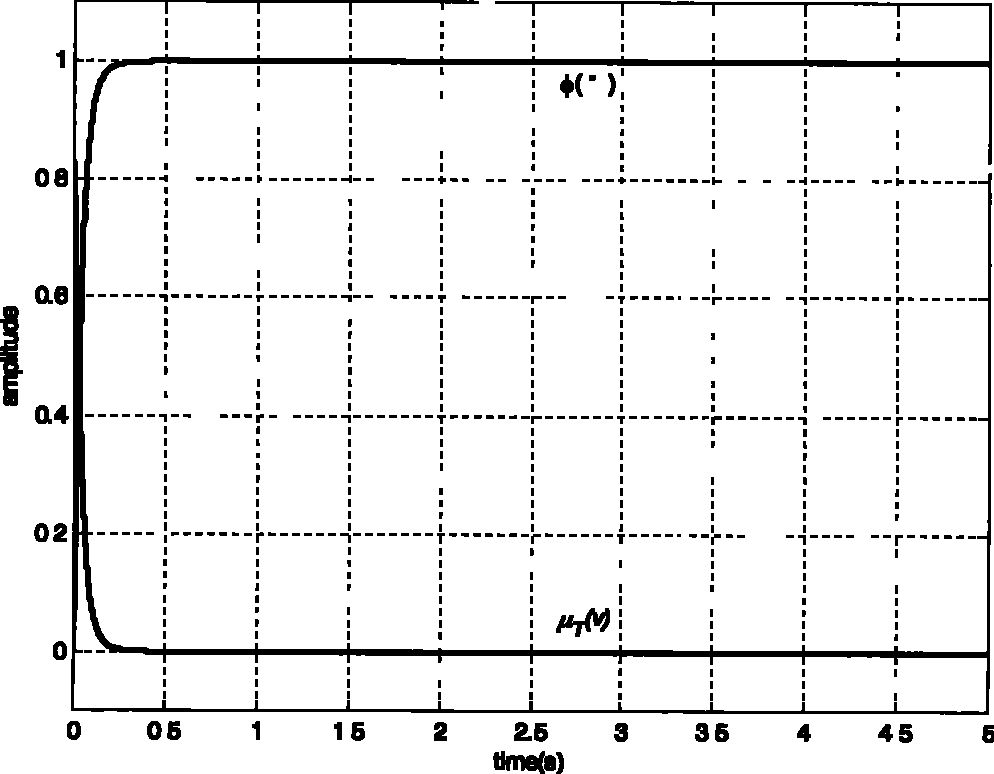

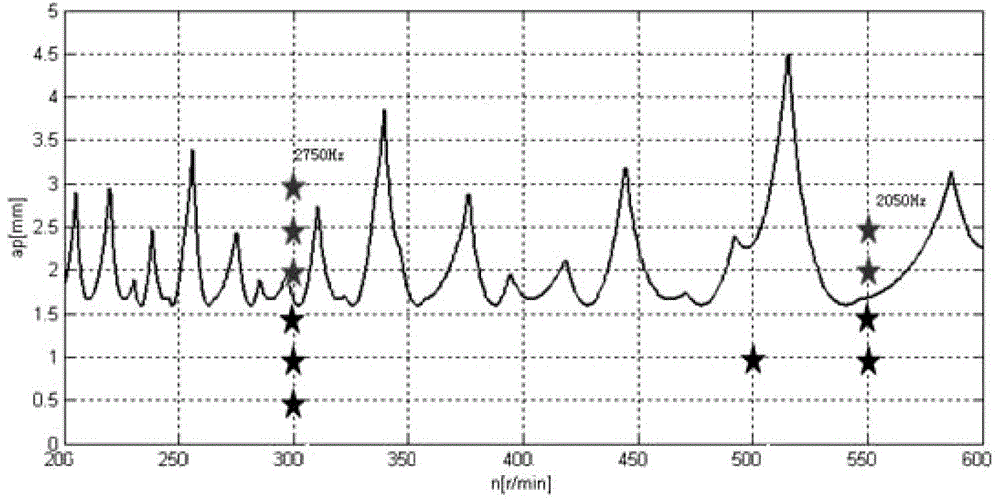

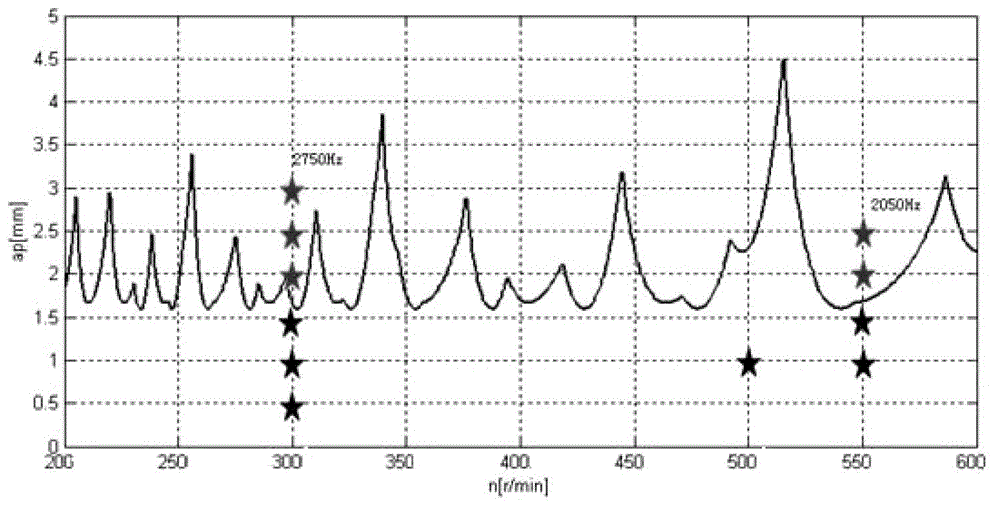

Ball screw grinding chatter stability limit graph determining method

InactiveCN101934487AImprove quality and efficiencyImprove grinding efficiencyGrinding machinesStability criterionCybernetics

The invention relates to a ball screw grinding chatter stability limit graph determining method, comprising the steps: 1) establishing a dynamics model of a grinding process via an experimental method; 2) according to the stability criterion of cybernetics, determining a grinding chatter stability limit graph; and 3) according to the grinding chatter stability limit graph, determining the parameters of the grinding technique for ensuring the grinding stability. The invention mainly aims at solving the chatter inhibition problem of a numerical control thread grinder in the grinding process of a ball screw, adopts the experimental design method to accurately identify the parameters of the grinding dynamics model, determines the grinding chatter stability limit graph according to the parameters, and provides the parameters of the grinding technique to ensure the grinding stability, thereby effectively solving the chatter inhibition problem in grinding process. The curve can be used to determine the parameters of the grinding technique, namely the abrasion wheel main shaft speed n and the grinding depth h to avoid flutter, thus the invention can improve the grinding quality and efficiency of the ball screw.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

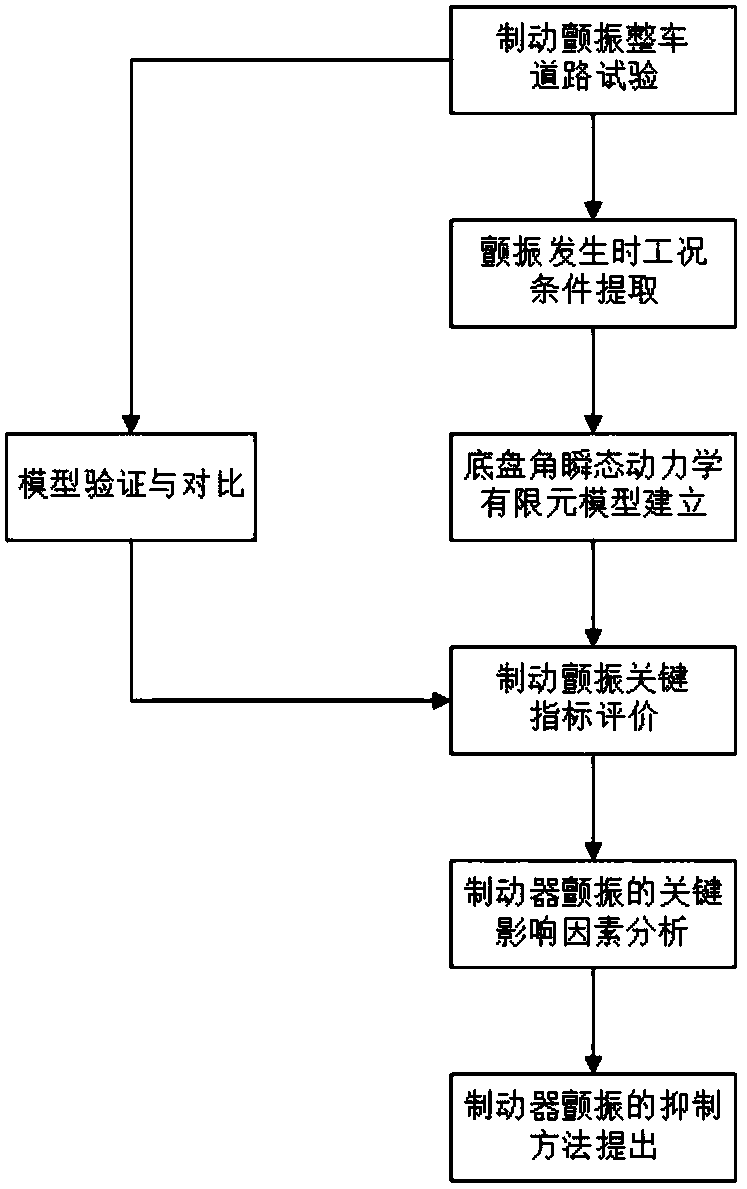

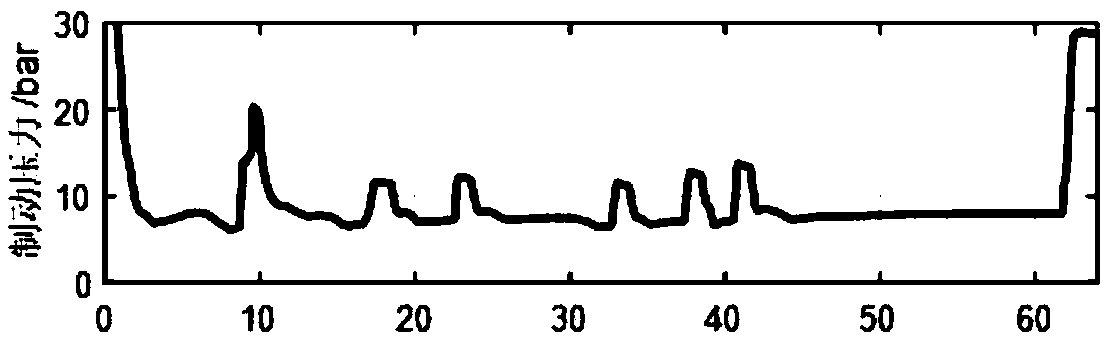

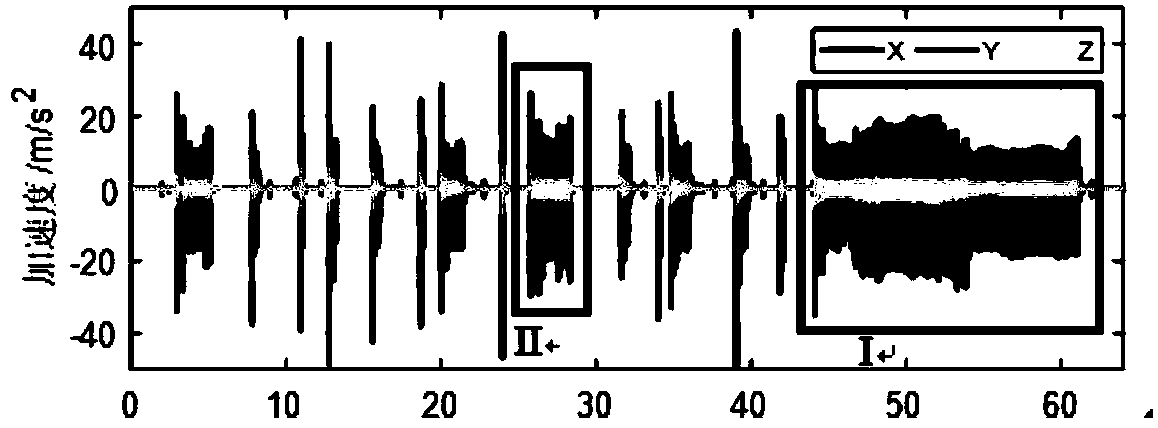

Braking flutter inhibition method based on chassis angle assembly transient dynamics

InactiveCN107908871AFix flutterChoose accurate and reasonableGeometric CADSustainable transportationElement modelSimulation

The invention relates to a braking flutter inhibition method based on chassis angle assembly transient dynamics. The method comprises the following steps that: performing a braking flutter finished automobile road experiment; obtaining experiment data, according to the obtained data, obtaining a working condition parameter and a flutter evaluation index when flutter happens; establishing a finiteelement model of the chassis angle assembly transient dynamics, setting an input parameter according to the working condition parameter when the flutter happens, and verifying the model; according tothe finite element model, obtaining stick slip motion characteristics when the flutter happens, and determining a relationship among a system structure parameter input by the model, frictional characteristics and stick slip motion; and inputting the parameters into the model, and according to a model output result, selecting the input parameter which exhibits a highest influence amplitude value onthe flutter evaluation index output by the model, and obtaining a method for inhibiting the flutter of a vibrator. Compared with the prior art, the method has the advantages that a flutter problem ina braking process is effectively solved from a principle, automobile improvement cost is low, feasibility is high and the like.

Owner:TONGJI UNIV

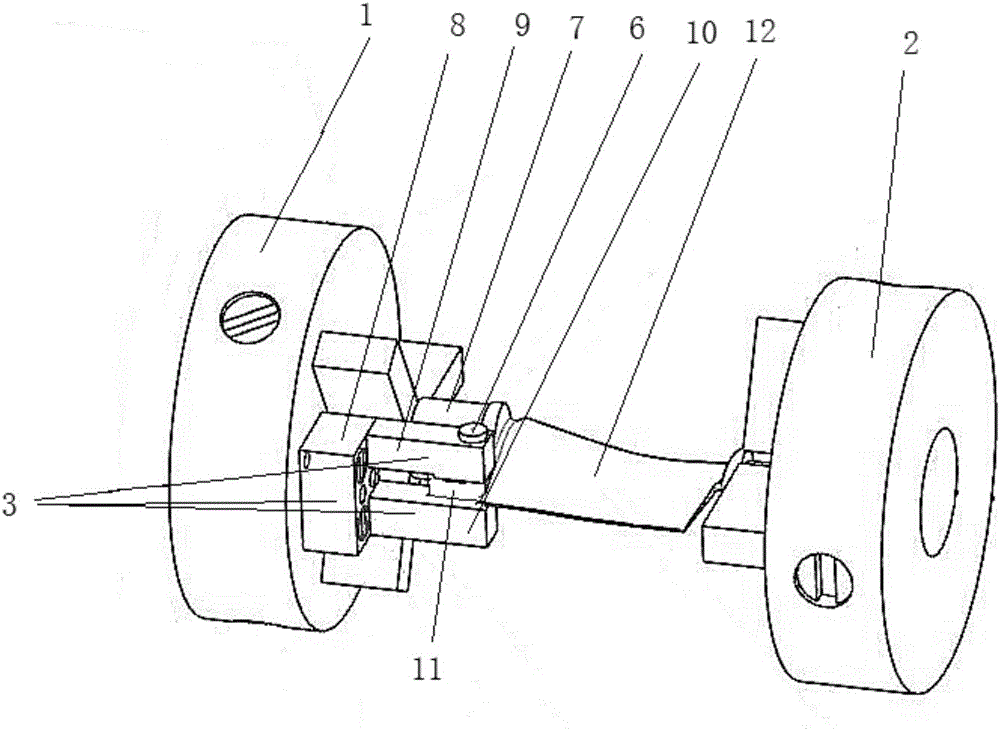

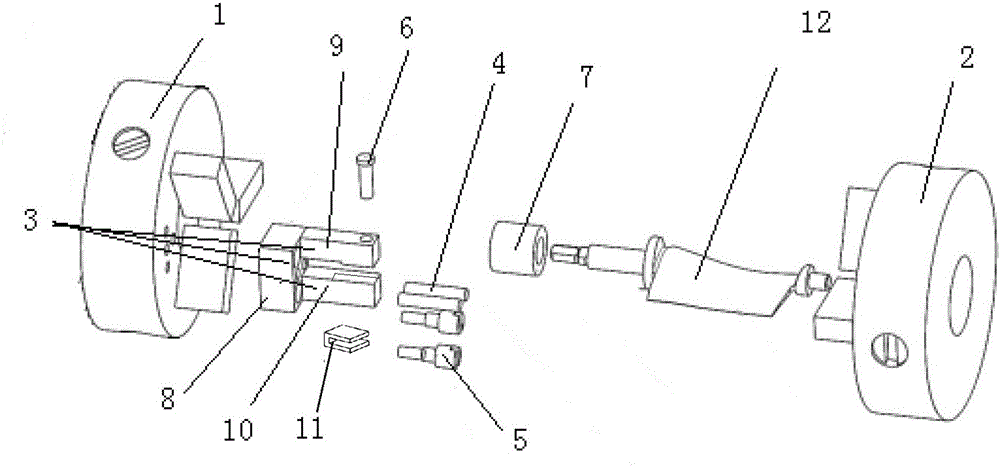

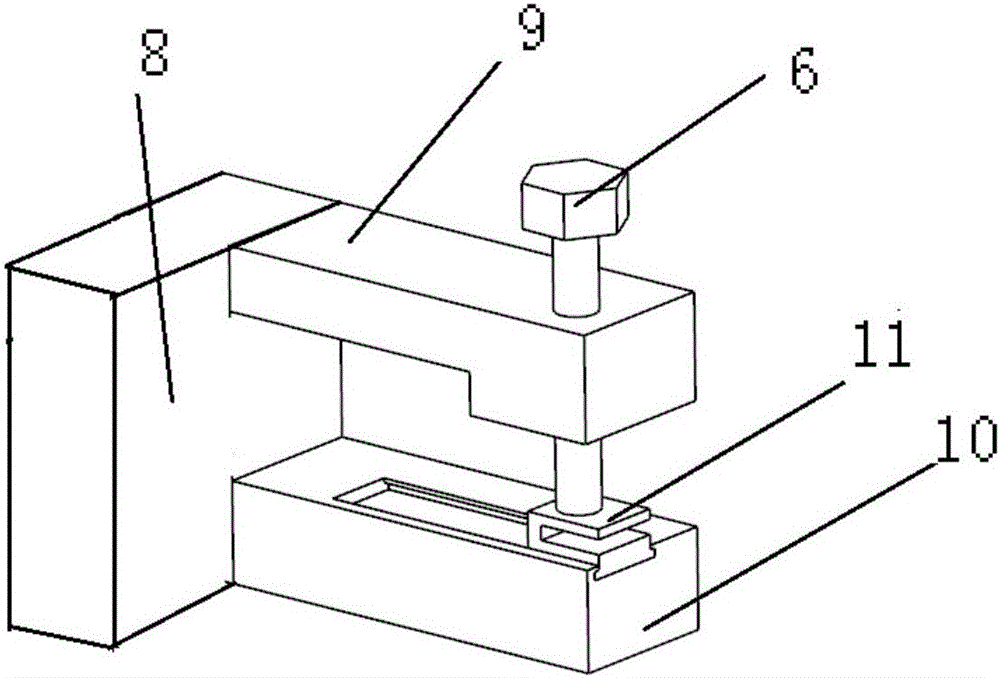

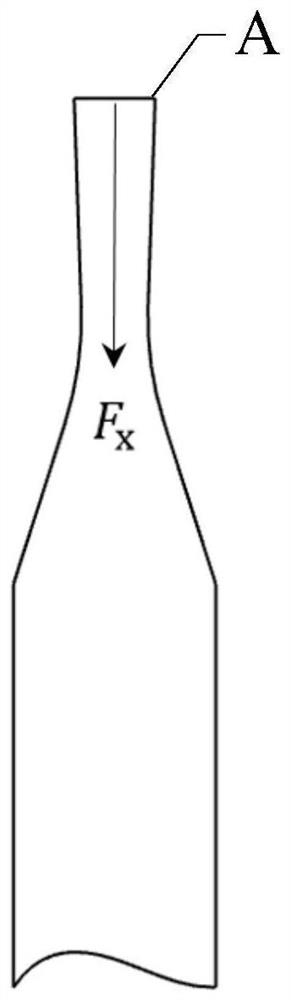

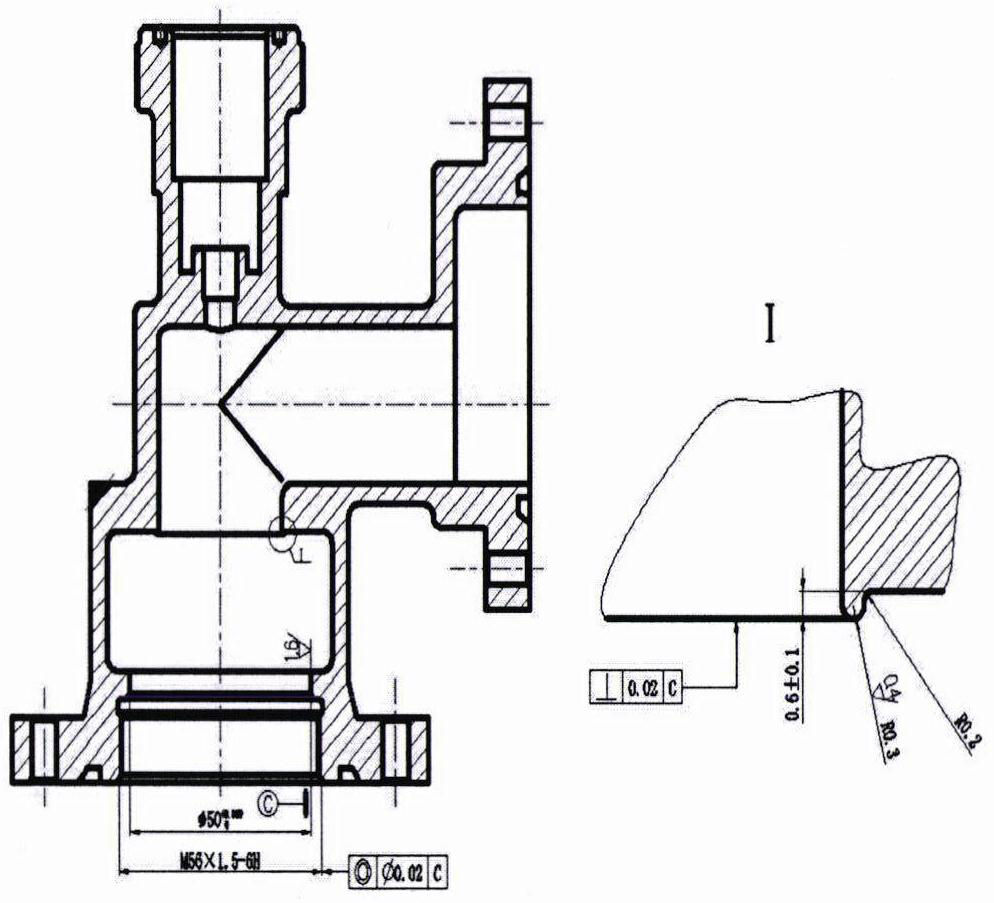

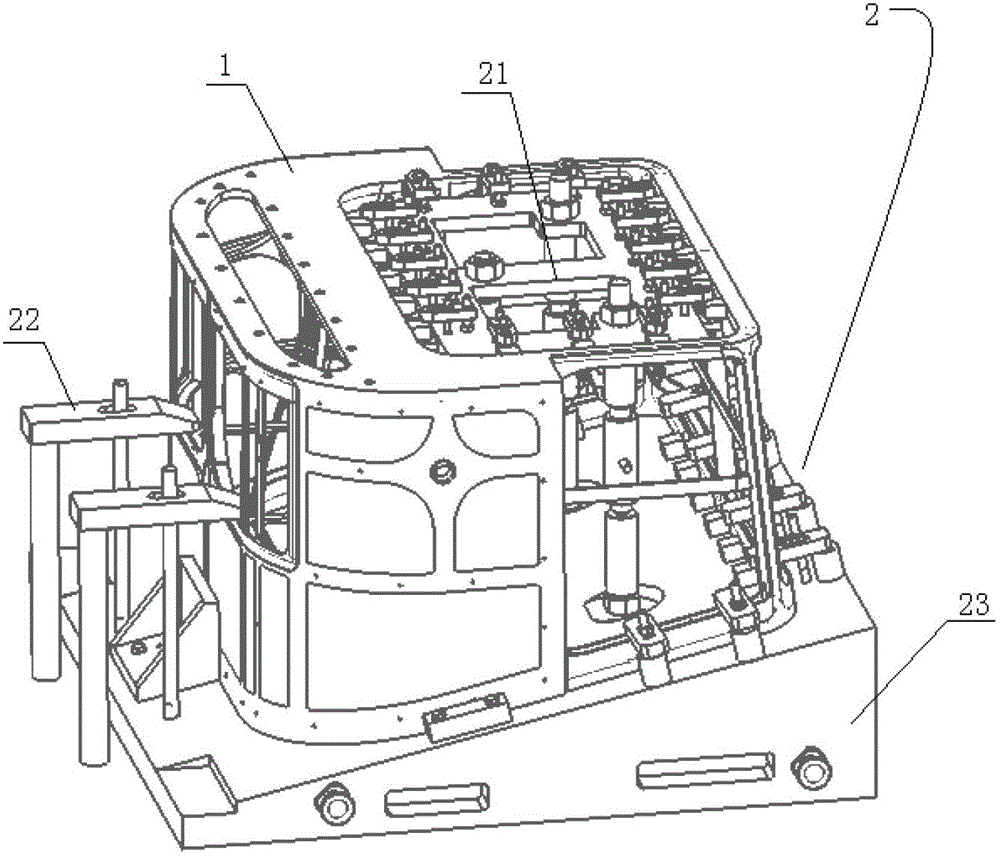

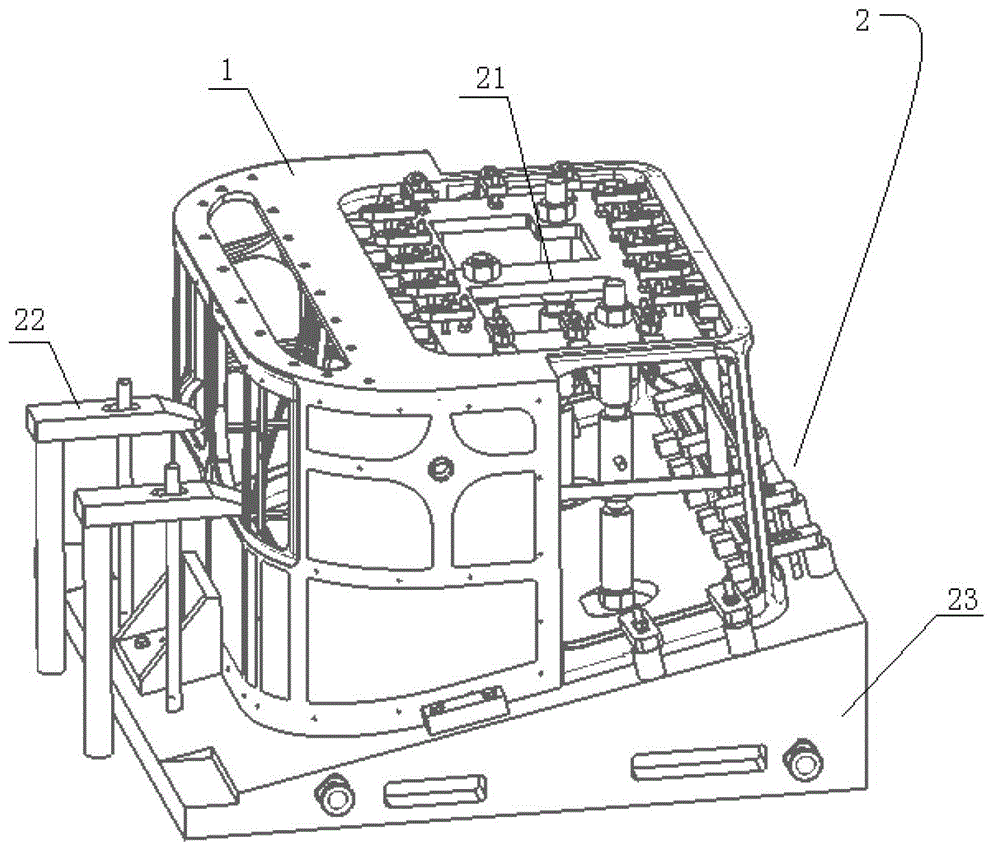

Special positioning fixture for blade numerical control precision machining

InactiveCN105817918AGuaranteed coaxialGuaranteed machining accuracyPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a special positioning fixture for blade numerical control precision machining. The special positioning fixture comprises a chuck a and a chuck b, the chuck b is connected with a tailstock of a machine tool, the chuck a is connected with a main shaft head of the machine tool, a fixture body and a baffle ring are connected to the end face of the chuck a, and the fixture body is located between two clamping jaws of the chuck a and comprises a fixing block; and an L-shaped connecting rod a and a connecting rod b are vertically connected to the fixing block, a fastening screw is arranged on the connecting rod a, the connecting rod b is provided with a sliding block sliding along the connecting rod b, and the sliding block is located between the connecting rod a and the connecting rod b. When the special positioning fixture for blade numerical control precision machining is used, it is guaranteed that the blade and the main shaft of the machine tool are coaxial; the two ends of the blade are fastened to solve the problems of chattering caused by dynamic cutting force in the cutting process and deformation caused in the machining process. The special positioning fixture is simple and compact in structure, high in positioning accuracy, rapid and convenient to operate and demount, and capable of effectively guaranteeing the machining accuracy of the front face and the back face of the blade.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

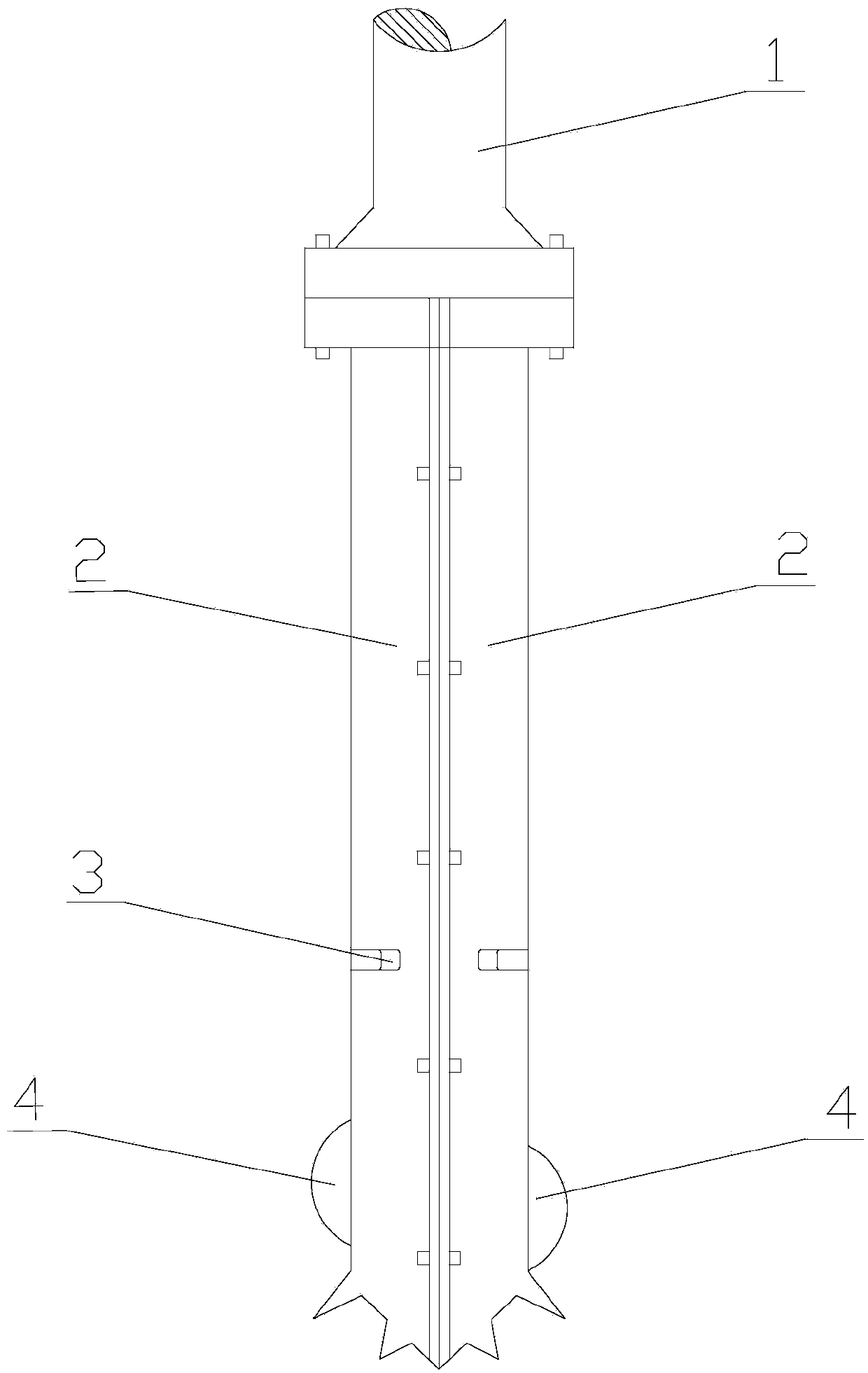

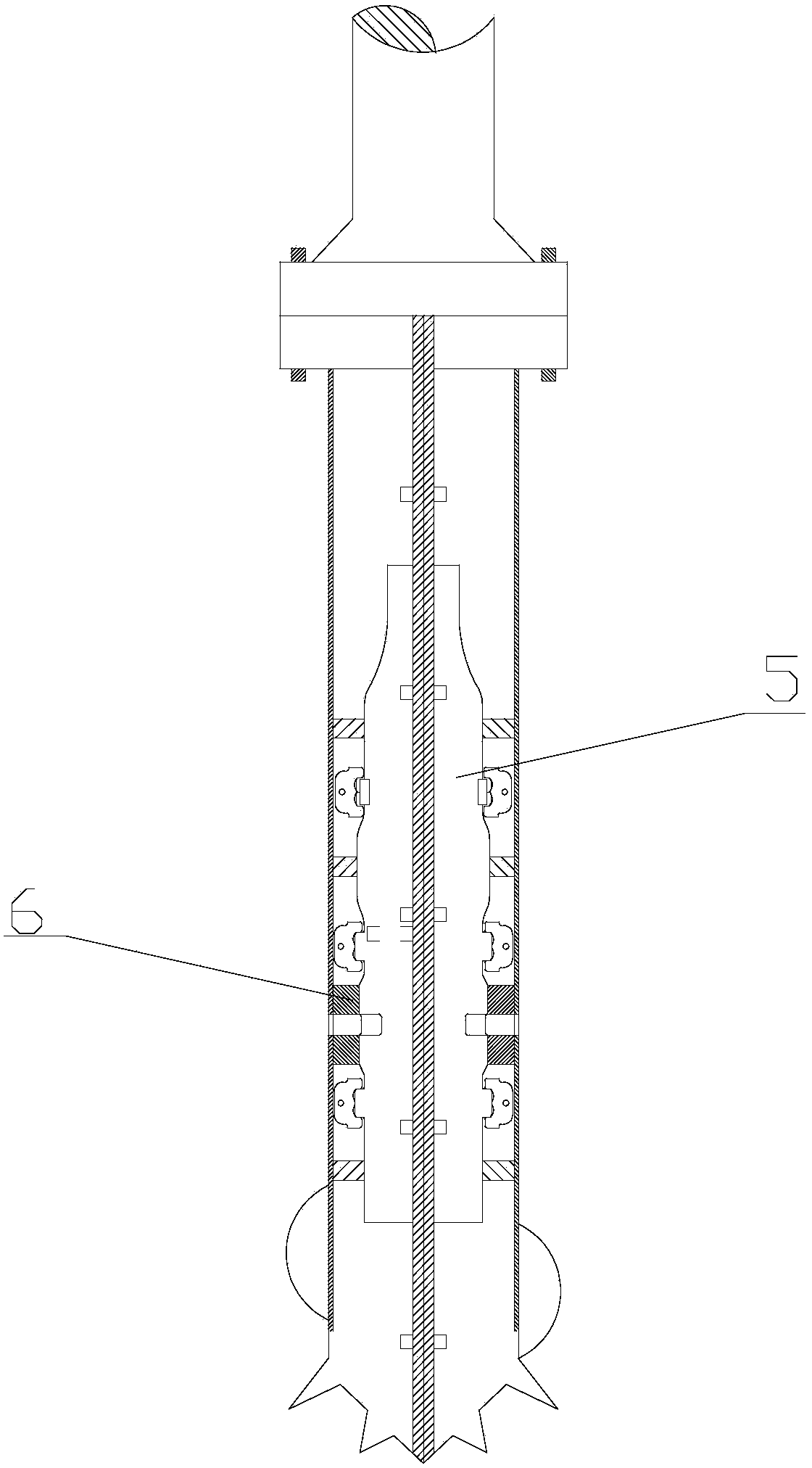

Geophysical exploring device and method for transitional zone areas between bog and shallow beach sea

ActiveCN103995291AGood reassuring effectFix flutterSeismology for water-covered areasEngineeringFlange

A geophysical exploring device method for the transitional zone areas between bog and shallow beach sea belongs to the technical field of geophysical exploration. An air gun is arranged in a drill bit composed of two drill bit piece bodies, filling blocks are welded into the two drill bit piece bodies, a drill stem connecting flange is arranged at the bottom of a drill stem, the drill stem connecting flange is of an integrated structure, drill bit connecting flanges are arranged at the upper portions of the drill bit piece bodies, the drill bit connecting flanges are of two semi-annular structures, the drill stem connecting flange is sleeved by an anti-loosen screw to be connected with the drill bit connecting flanges, and accordingly the drill stem and the drill bit piece bodies are combined to form a main body structure of a detachable type air gun drill bit. Two symmetrical spiral pieces are welded to the bottoms of the drill bit piece bodies respectively to form a dual-spiral drill bit structure. The diameter of the drill bit composed of the two combined spiral piece is 500mm. The drill bit piece bodies are of hollow structures, composed of two semi-tubular structures respectively and sleeved by screws to be fixed. The air gun is arranged in the hollow structures. By means of the dual-spiral drill bit structure, stimulating operation of the air gun can be finished synchronously.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

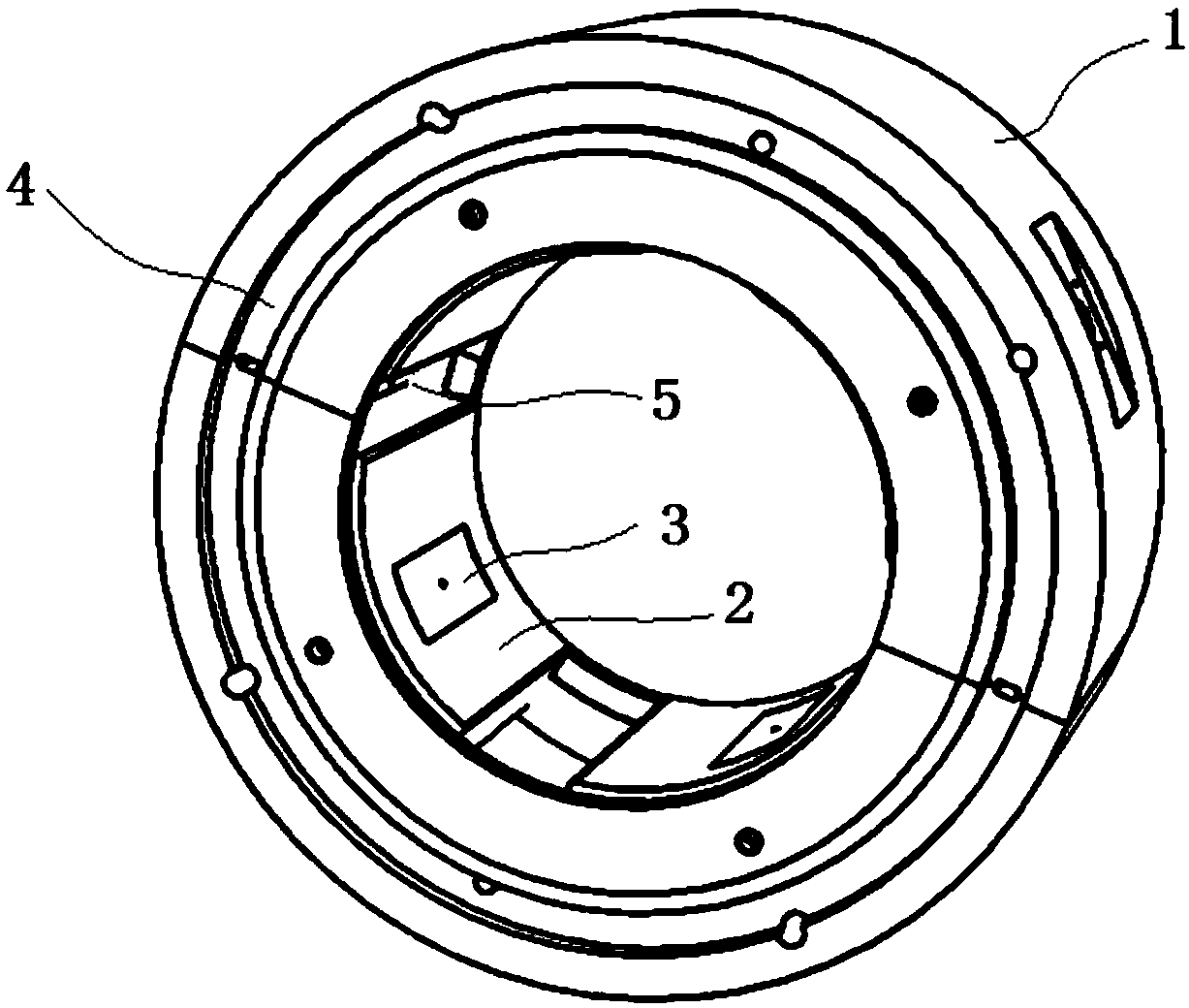

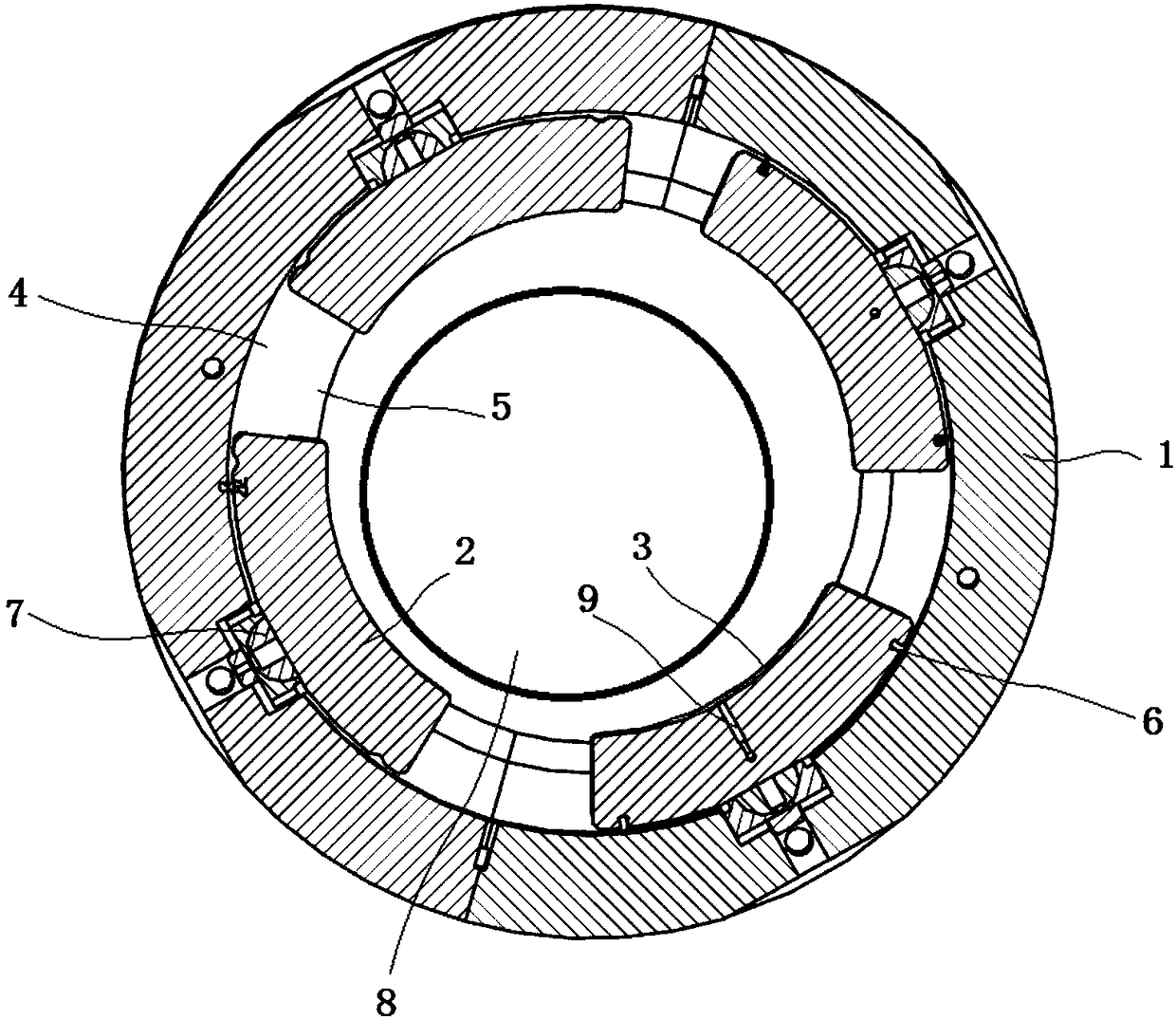

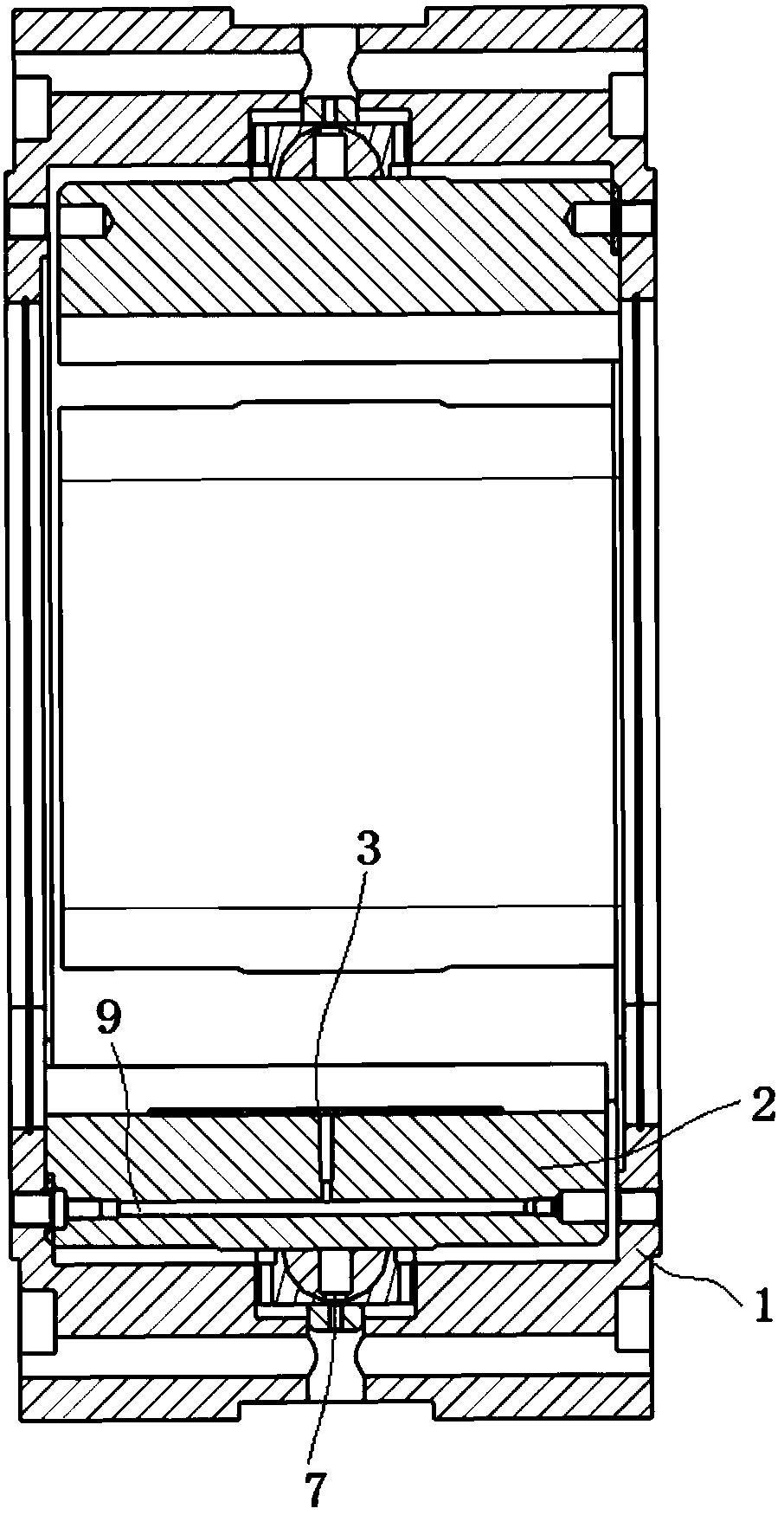

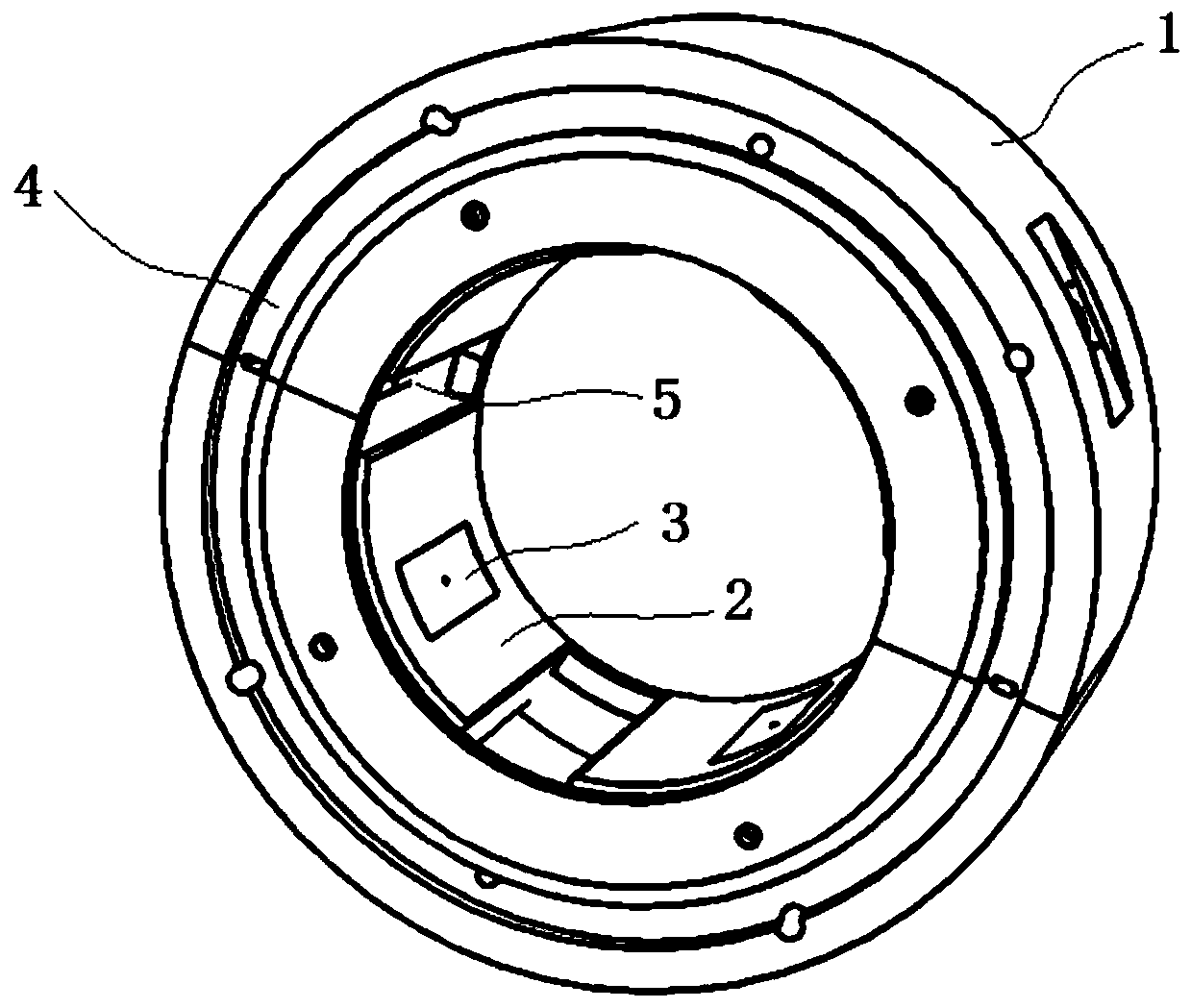

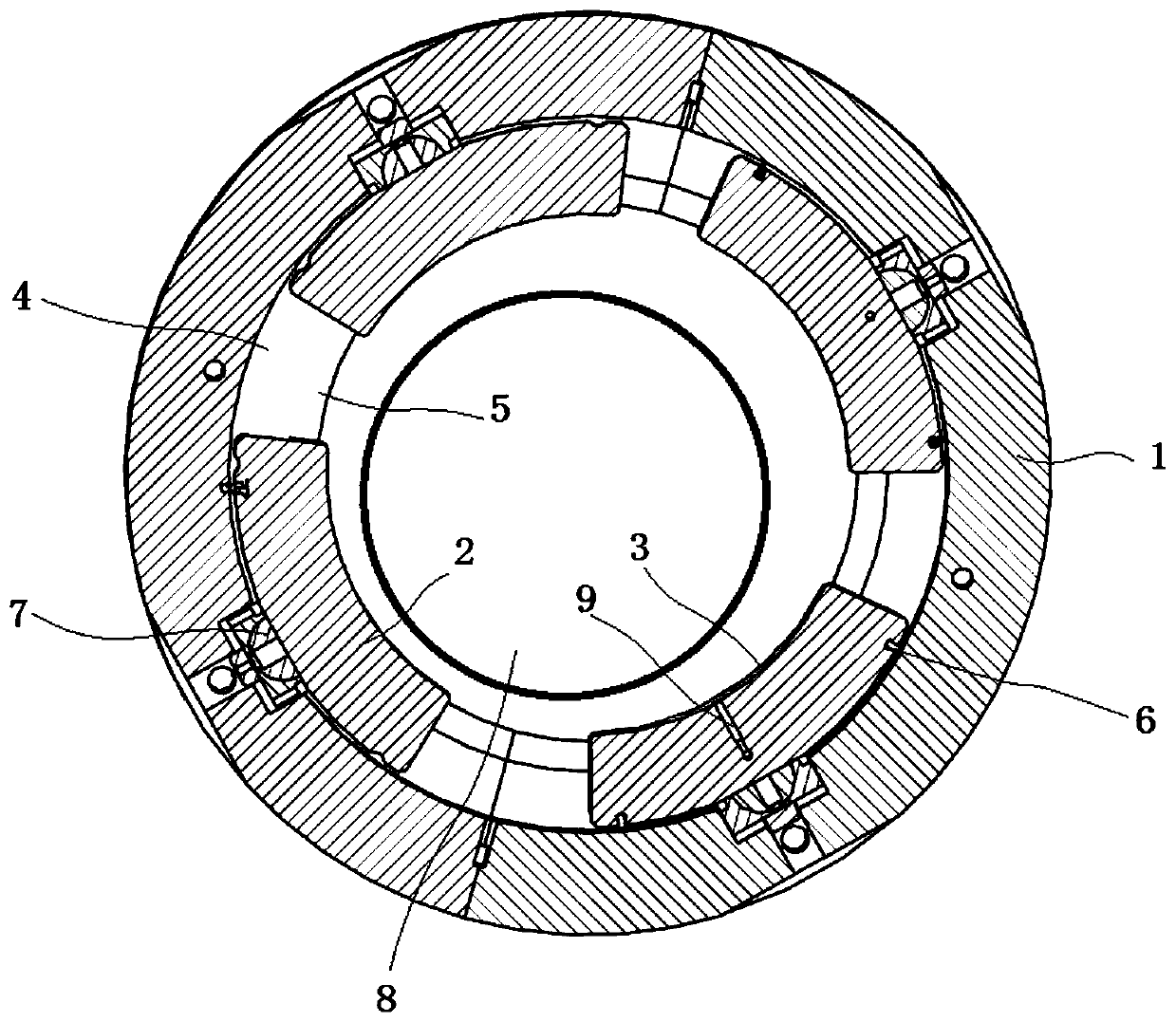

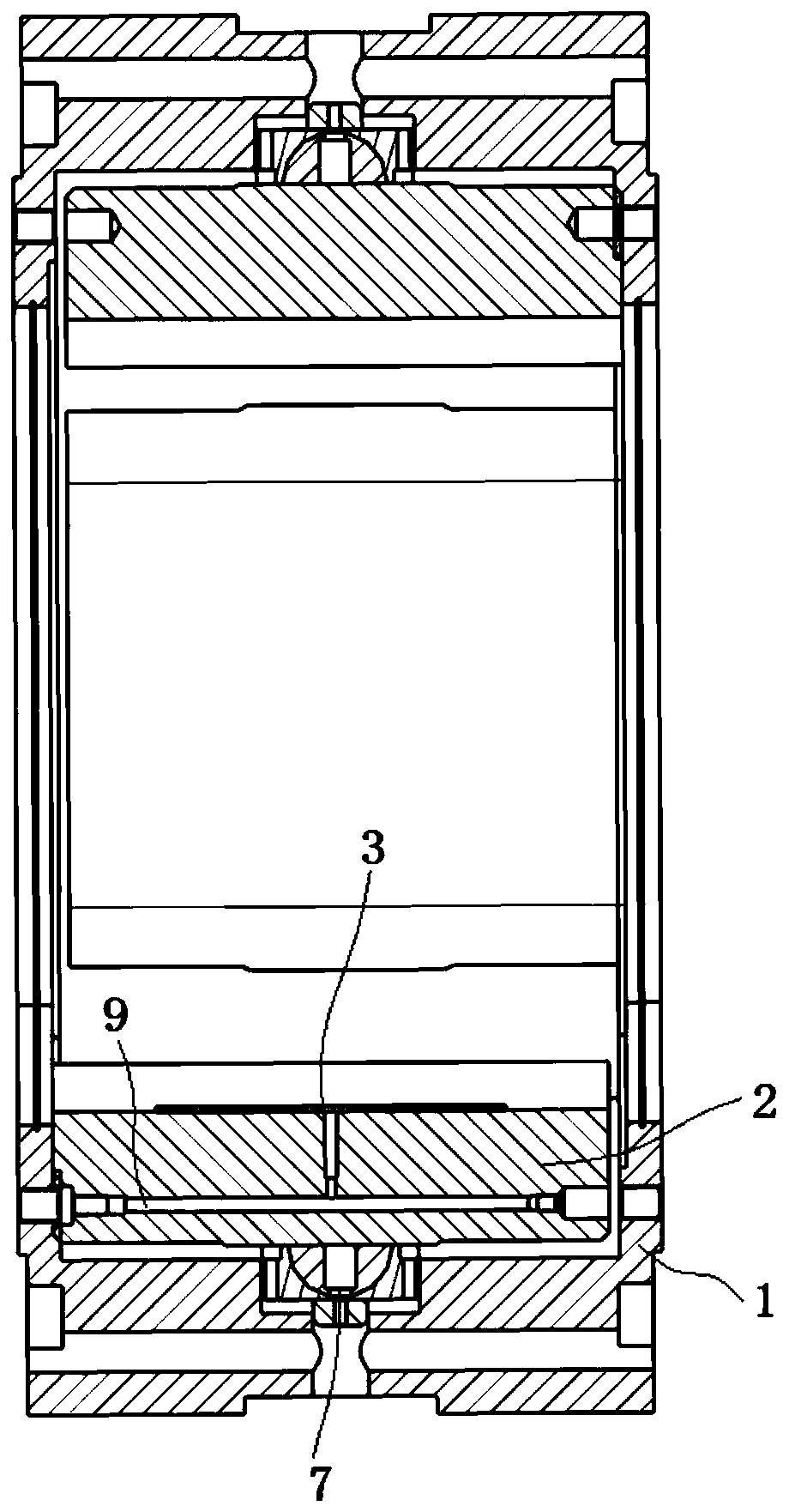

Bearing structure lubricated with supercritical CO2

ActiveCN108223557ASolve the problem of low carrying capacityFix flutterShaftsBearing componentsEngineeringMechanical engineering

The invention discloses a bearing structure lubricated with supercritical CO2, which includes a bush sleeve and tiltable bush pieces which are arranged in an inner ring of the bush sleeve; a controllable opening-type supporting static pressure mechanism, with the supercritical CO2 as a medium, is installed in each tiltable bush piece at the lower side of the bearing; a damping structure for preventing vibration of the bush piece is arranged on each bush piece. The structure can improve bearing capacity of the bearing under lubrication by the supercritical CO2, and excellently solves the problem of rotor supporting of a supercritical CO2 dynamic cycle power generation device.

Owner:DONGFANG TURBINE CO LTD

Numerical control card-less rotary cutter

InactiveCN101628438AAchieve compactionAchieve top tightVeneer manufactureNumerical controlDrive wheel

The invention discloses a numerical control card-less rotary cutter, which comprises a base, a front tool post, a rear tool post, a moving motor, compression rollers, a compression roller speed control system and a compression roller rotating motor, wherein two ends of the base are provided with upright brackets which are provided with round timber clamping mechanisms; the base is provided with a tool post slideway, and two ends of the front and the rear tool posts are arranged on the tool post slideway through slide blocks which are sleeved on a sliding leading screw; two compression rollers are arranged on the front tool post in parallel, one compression roller is arranged on the rear tool post, and the three compression rollers are arranged in a triangular shape; the base is provided with a rotary motor which is matched with the round timber clamping mechanisms through a triangular belt, a driven wheel and a big gear wheel, and the driven wheel is matched with a cutting feed speed reducer, a rear transmission gear box, a rear driving shaft and the sliding leading screw; the compression roller rotating motor is matched with the front tool post compression roller; and the motors are connected with a master control system of a computer control cabinet through conducting wires, and an integrated circuit chip is arranged in the computer control cabinet. The numerical control card-less rotary cutter solves the technical problems of rotary cutting bending and fluttering of thin round timbers and operation semi-automation in the prior art.

Owner:朱景振

Thin-wall cavity part machining rigid supporting method

ActiveCN110712047AKeep it steadyFix flutterPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a thin-wall cavity part machining rigid supporting method. The thin-wall cavity part machining rigid supporting method comprises the following steps: (1) flexible basal body layers A and basal body layers B are mounted in each molding cavity and at the two ends of thin-wall cavity parts; (2) curing agents are coated on the basal body layers A and the basal body layers B toform curing layers A and curing layers B; and (3) multiple supporting tool pieces A and at least two supporting tool pieces B are correspondingly mounted on the curing layers A and the curing layers B, so that the curing layers A and the curing layers B are naturally dried under natural conditions. Under the effects of the multiple supporting tool pieces A and the two supporting tool pieces B, thethin-wall cavity parts are rigidly supported, so that the vibration phenomenon is solved, and the dimensional tolerance and the form and location tolerance of the machined thin-wall cavity parts meetthe requirements.

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

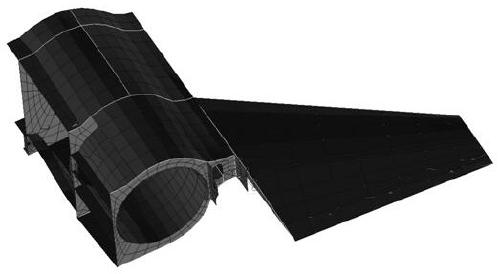

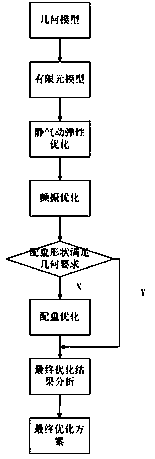

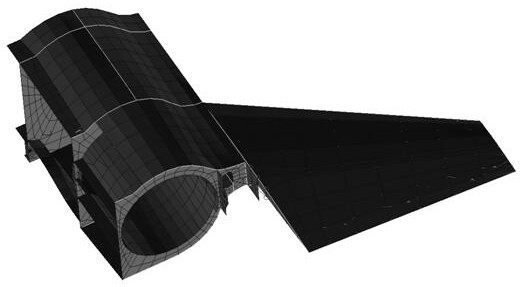

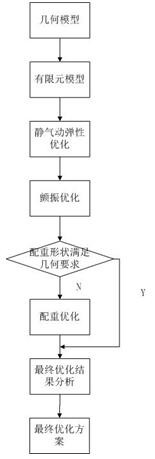

Method for optimizing static aeroelasticity and flutter of all-moving horizontal tail

ActiveCN111125829AImprove matchSatisfy the static aeroelasticity problemGeometric CADDesign optimisation/simulationElement modelAeroelasticity

The invention discloses a method for optimizing static aeroelasticity and flutter of an all-moving horizontal tail. Firstly, a finite element model is established, then static aeroelasticity, flutterand balance weight are optimized one by one, the matching degree is high, the minimum-weight full-motion horizontal tail which meets the requirements for static aeroelasticity and flutter and does notaffect the appearance of the horizontal tail is obtained, constraint conditions are met, and the problems of static aeroelasticity and flutter of an airplane are effectively solved.

Owner:JIANGXI HONGDU AVIATION IND GRP

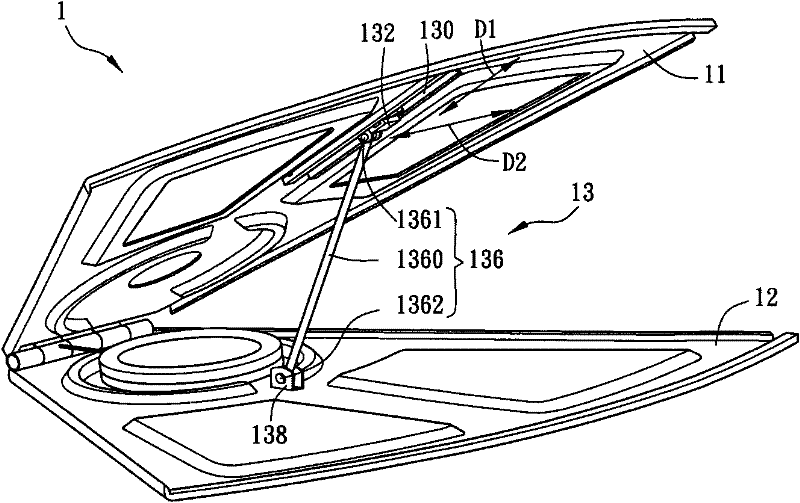

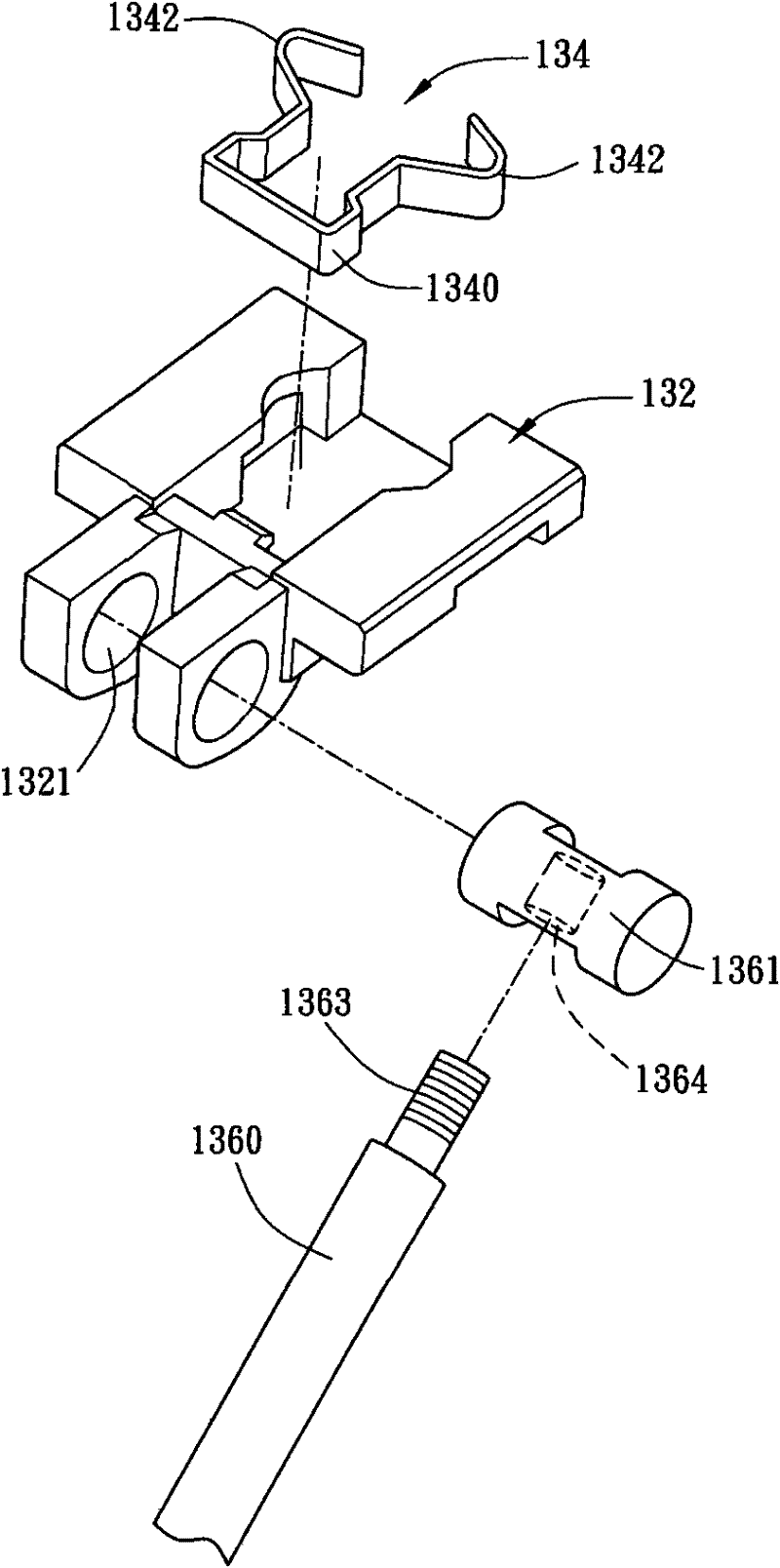

Supporting module, and electronic device applying same

InactiveCN102413647ASimple structureEasy to operateMicrophonesTransducer detailsComputer moduleMechanical engineering

Owner:PROTEK SHANGHAI +1

Novel dual-blade-groove cutting tool

The invention discloses a novel dual-blade-groove cutting tool. The cutting tool comprises a tool bar and two profiling cutting blades; the two profiling cutting blades are installed on a same workingsurface of the end part of the tool bar; a main blade bit of a working end of one of the profiling cutting blades is skew to the left by an angle alpha, and a main blade bit of a working end of the other profiling cutting blade is skew to the right by an angle alpha; and the two profiling cutting blades are symmetrically distributed, and alpha is an acute angle. Compared with a standard groove cutting tool, the contacting area between the cutting tool and a cutting workpiece is reduced in the feeding process along the radial direction, so the radial cutting force is reduced; groove processingis conducted by back-and-forth and layer-by-layer feeding of the cutting tool along the axial direction, so the cutting force generated by processing is mainly axial and the radial cutting force is greatly reduced; and the problem of vibration in the process of processing is solved, the processing precision is improved, and processing efficiency is conveniently improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

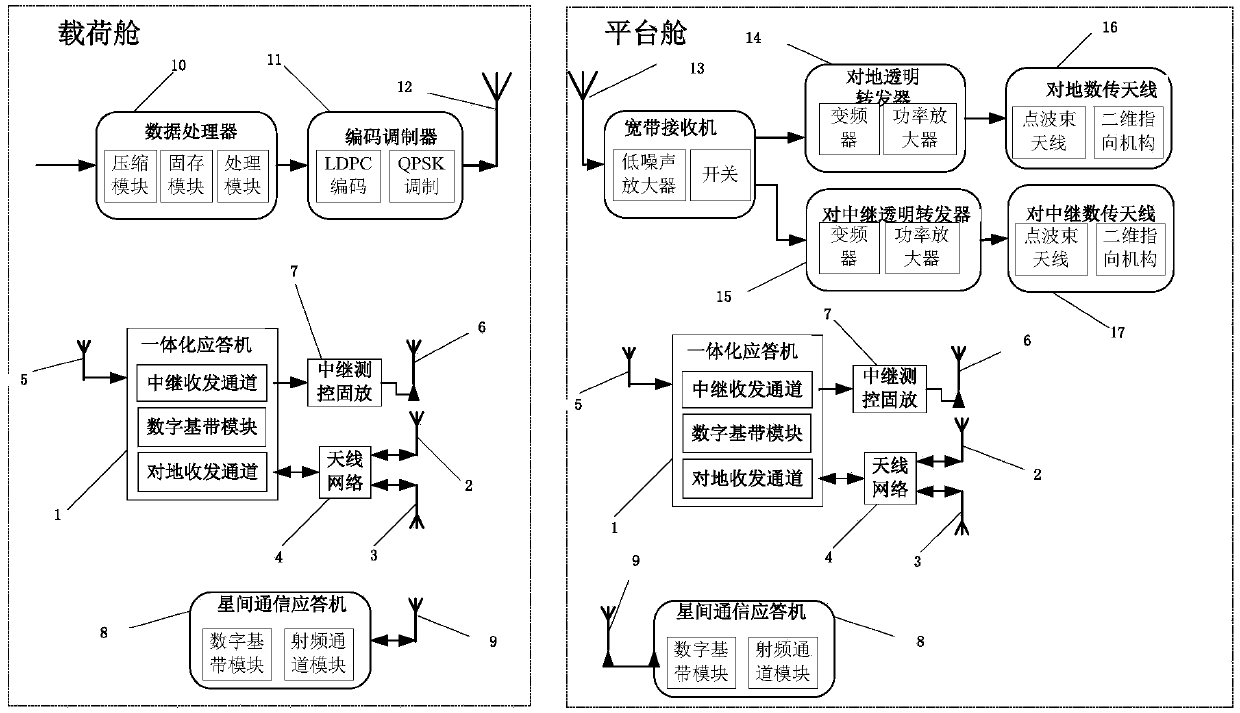

Double supersatellite inter-cabin data transmission system and its operation method

The invention provides a data transmission system between noncontact double super satellite cabins and an operation method thereof. The integrated responder of a measurement and control subsystem supports measurement and control to the ground and measurement and control to the relay through different frequencies, and a load cabin and a platform cabin adopt the working mode of different pseudo-codes. The data integrated processor of a data transmission subsystem receives the high speed data of camera load, and the data are wirelessly transmitted to the platform cabin in real time to perform data transmission or the data are stored and arranged back to the platform cabin from a storage device and then data transmission is performed according to the situation of whether the satellite is within the border or the visual arc segment of the relay satellite. The inter-satellite communication responder adopts the modulation mode of an inter-satellite non-coherent direct sequence spread spectrum communication system and works in the S-band and the duplex mode, and the inter-satellite communication responder between the two cabins adopts the mode of different bands and different codes. The load cabin and the platform cabin communicate in a noncontact manner so that the problems of interference and fluttering caused by vibration of large flexible structures and moving parts can be solved, and the inter-satellite communication efficiency and the communication efficiency to the ground and the relay can be enhanced.

Owner:SHANGHAI SATELLITE ENG INST

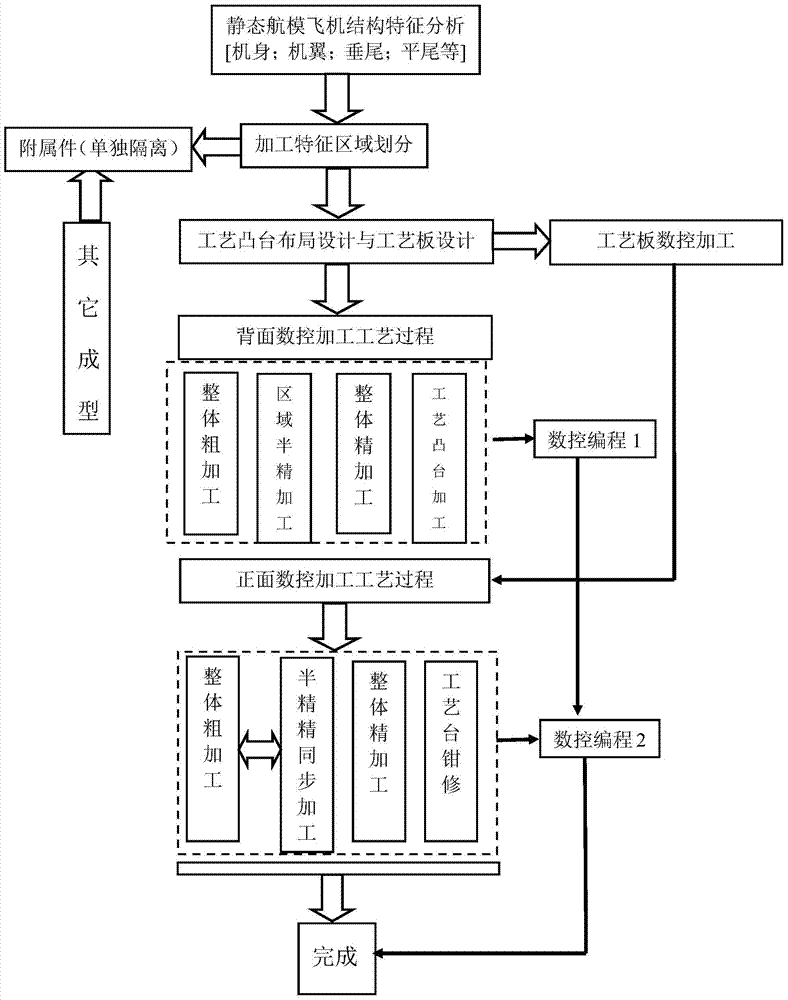

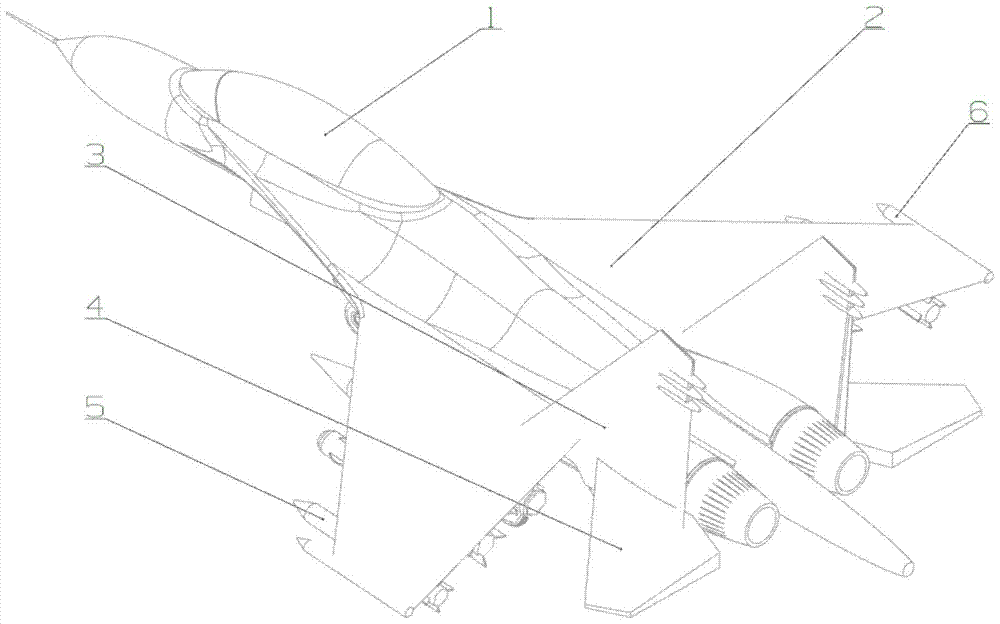

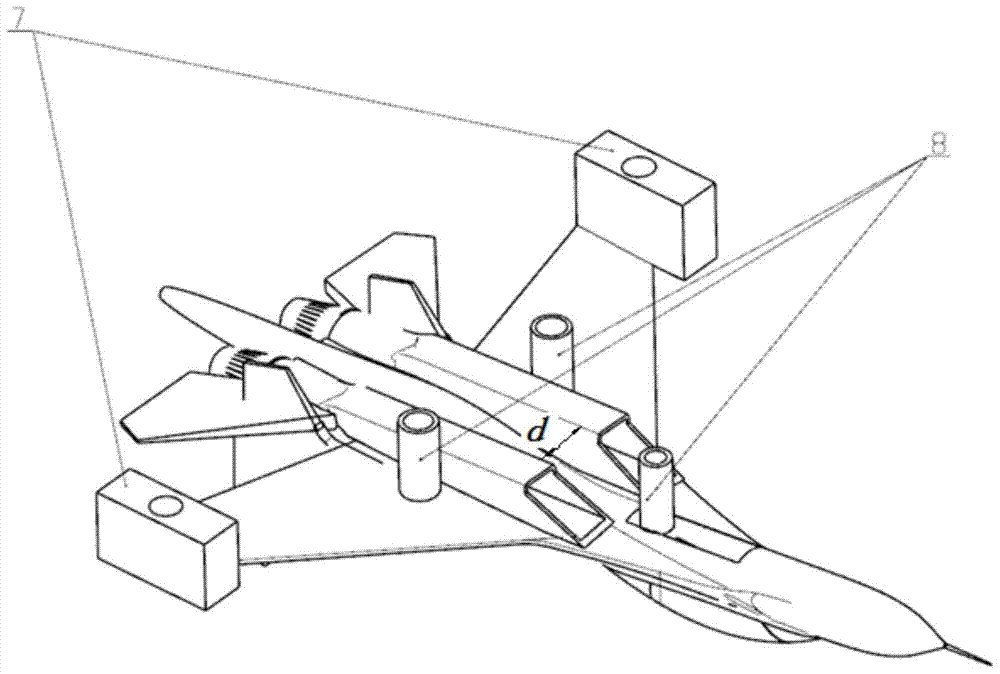

A kind of numerical control processing method of aircraft model

The invention discloses a numerical control machining method of an airplane model. The method specifically comprises the following steps that firstly, the airplane model is partitioned according to structural characteristics; secondly, back faces of the airplane model are independently machined according to partitions in the first step, and process bosses are machined on the back faces of the airplane model; thirdly, the front faces of the airplane model are independently machined according to the partitions in the first step; and fourthly, the process bosses on the back faces of the airplane model are cut away, or the machined process bosses on the back faces of the airplane model are machined into airspeed heads, surface treatment is carried out by waxing polishing paste or applying a grinding agent, and the machining of the airplane model is finished. According to a method for vibration restraining of numerical control machining of an airplane, the problem that complex airplane curved surfaces and airplane thin-wall pieces vibrate during numerical control machining is solved, the consistency of the profile machining quality and the exterior surface size is guaranteed, and meanwhile production efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Brake shoe outer circle machining clamp

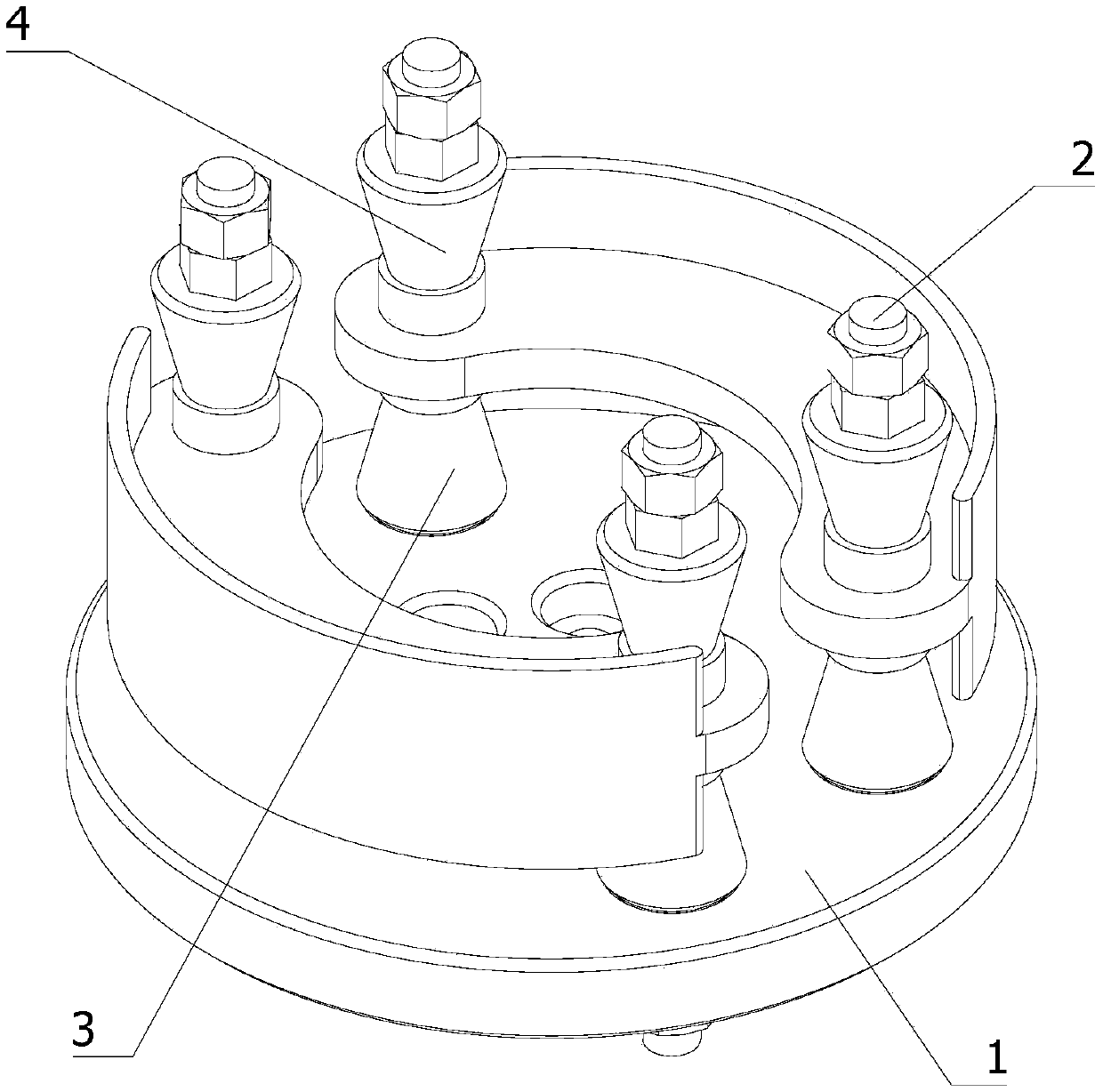

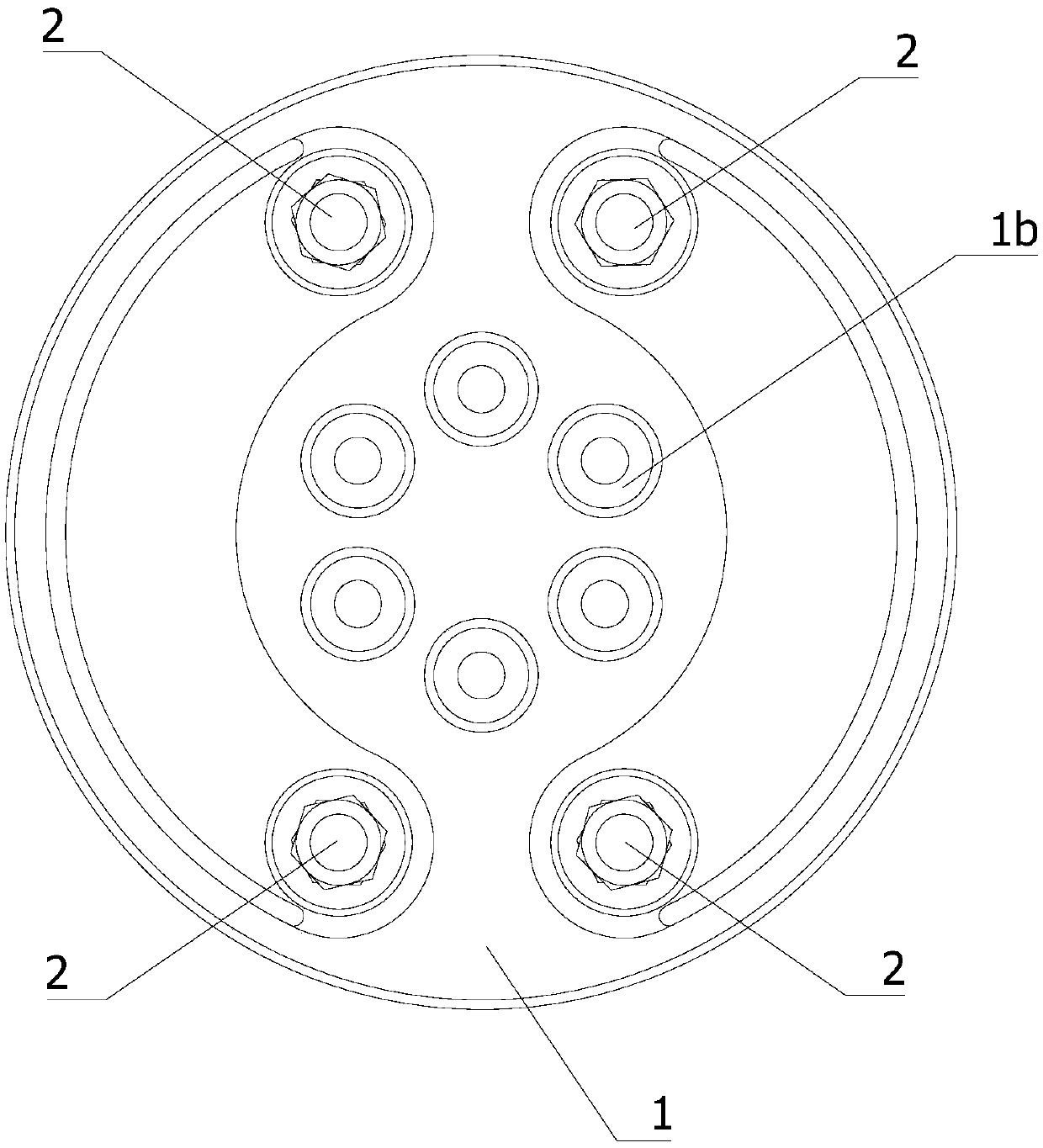

InactiveCN109648367ASolve the problem of reduced machining accuracyFix flutterPositioning apparatusMetal-working holdersCircular discBrake shoe

The invention relates to the technical field of automobile part machining clamps, in particular to a brake shoe outer circle machining clamp. The brake shoe outer circle machining clamp comprises a rotary machining table, positioning mandrels, a lower fixed circular truncated cone and an upper fixed circular truncated cone, wherein the rotary machining table is in a disc shape, and two sides of the rotary machining table are respectively provided with two first mounting holes which vertically penetrate through the disc surface of the rotary machining table, the positioning mandrels are fixedlyarranged in the first mounting holes, the lower fixed circular truncated cone and the upper fixed circular truncated cone are arranged on the positioning mandrels in a sleeved mode, the fine end of the lower fixed circular truncated cone is arranged upwards, and the thin end of the upper fixed circular truncated cone is arranged downwards, the clamp can fix and machine two brake shoes at the sametime, and the end faces of the brake shoes are not in contact with the clamp, so that the problem that the machining precision of the outer circle surface is reduced due to the fact that the end faceof the brake shoe is uneven is solved, and the positioning hole of the brake shoe is clamped between the upper fixed circular truncated cone and the lower fixed circular truncated cone, so that the problem that the brake shoe is vibrated during machining due to the fact that the positioning hole of the brake shoe is in clearance fit with the positioning mandrel is solved.

Owner:丽水市信裕机械制造有限公司

Novel marine self-floating type wind-wave power generating device

InactiveCN110410262AImprove stabilityAct as a constraintWind motor supports/mountsHydro energy generationWind waveAxial force

The invention relates to a novel marine self-floating type wind-wave power generating device. The novel marine self-floating type wind-wave power generating device is composed of four self-floating type multi-energy collecting wheels fixed by an anchored rectangular rod frame and used for driving power generators separately. The novel marine self-floating type wind-wave power generating device ischaracterized in that six arc-shaped blades are arranged on a hub of each self-floating type multi-energy collecting wheel, the above-water portions of the blades receive wind energy, and the underwater portions of the blades receive wave energy; and the hollow hubs are used for achieving self-floating, ratchets are arranged on the inner rings of the hollow hubs, ratchet wheels on speed-up machines force the wave energy and the wind energy to selectively rotate in the same direction to push the hollow hubs to rotate the ratchet wheels only in the same direction. The sector blades can be used for receiving the wind energy or the wave energy, the wind energy or the wave energy is absorbed by arc-shaped concave surfaces of the blades, the wind energy or the wind energy is converted into mechanical axial force to push the hollow hubs to rotate, the ratchets cooperating with the ratchet wheels are arranged on the inner rings of the hollow hubs, the ratchet wheels force the wave energy or the wind energy to selectively rotate in the same direction to push the hollow hubs to rotate only in the same direction, thus, the speed-up machines are driven to rotate, and the power generators coaxial with the speed-up machines rotate at a high speed to start to generate power.

Owner:ANHUI UNIV OF SCI & TECH

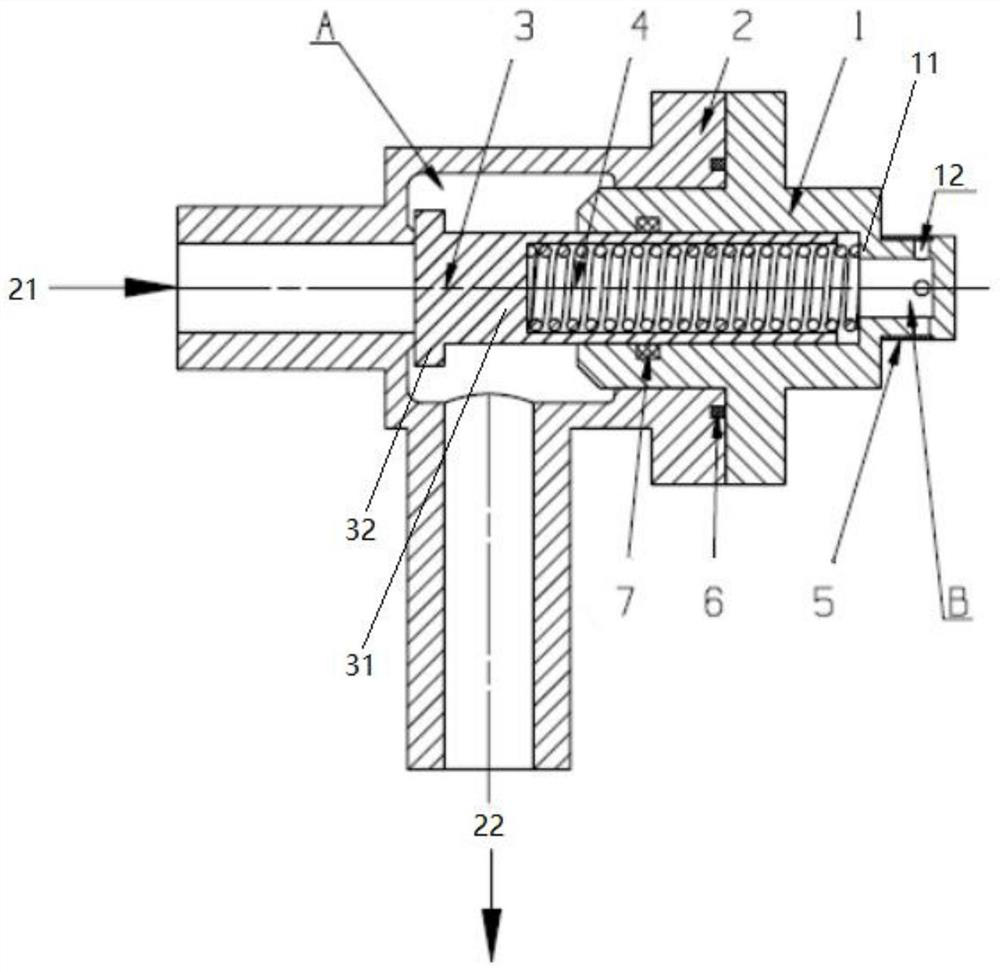

One-way valve, rocket engine supercharging system and rocket engine

PendingCN114060574AAchieving reverse sealingSolve the problem that the seal is easily brokenCheck valvesRocket engine plantsClassical mechanicsVALVE PORT

The invention discloses a one-way valve, a rocket engine supercharging system and a rocket engine. The one-way valve comprises a guide cylinder, a valve body and a valve element. The guide cylinder is provided with an open end, a closed end and a first boss which transits from the closed end to the open end; the valve body is connected with the outer wall of the guide cylinder to form a main cavity, and is provided with an inlet channel and an outlet channel communicated with the main cavity; the axial cross section of the valve element is in a T shape, the small-diameter end of the valve element is a connecting end, the large-diameter end of the valve element is a force application end, the connecting end is movably arranged on a first boss in the guide cylinder through an elastic piece, and the force application end is used for sealing the inlet channel under the action of the elastic piece. A discharge cavity is formed between the closed end and the elastic piece, and a leakage opening is formed in the portion, forming the discharge cavity, of the guide cylinder and used for discharging media leaked from the main cavity to the discharge cavity. In the state that the force application end seals the inlet channel, the contact areas of the two surfaces in the thickness direction of the force application end and the main cavity are the same, so that the valve is prevented from being opened when the valve is reversely communicated with a high-pressure medium.

Owner:BEIJING LANDSPACETECH CO LTD

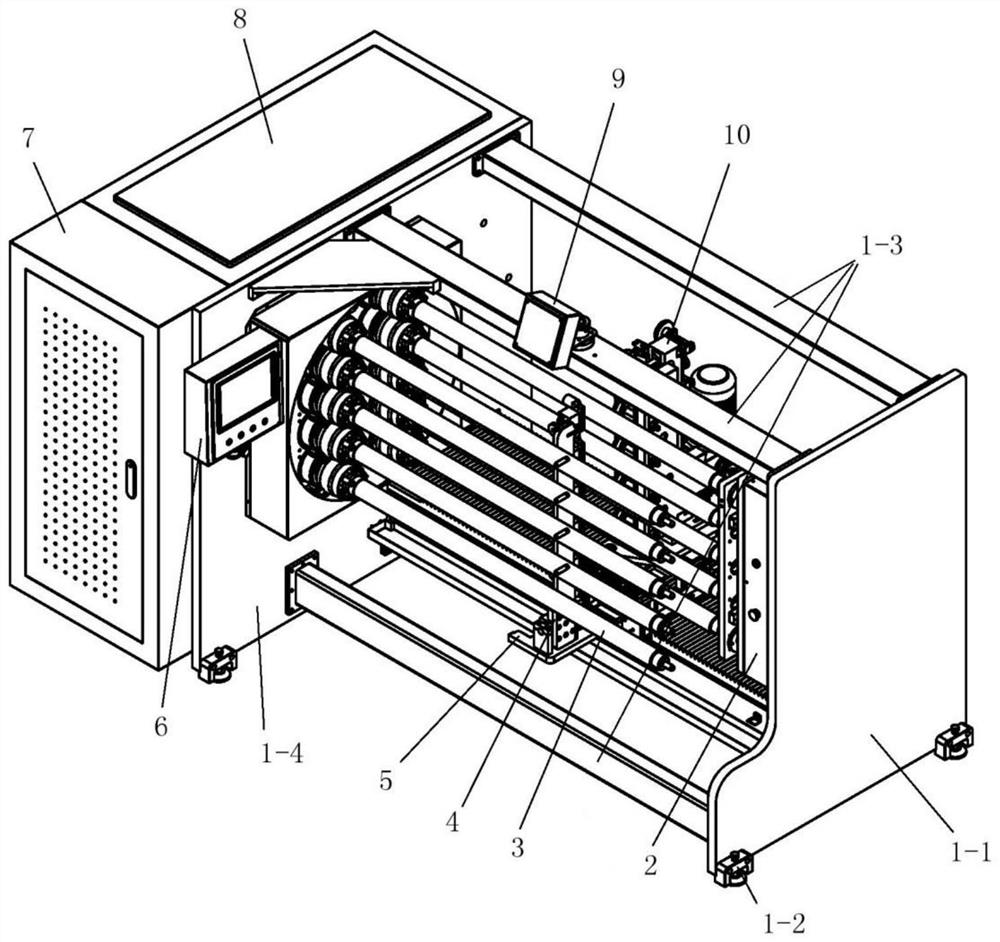

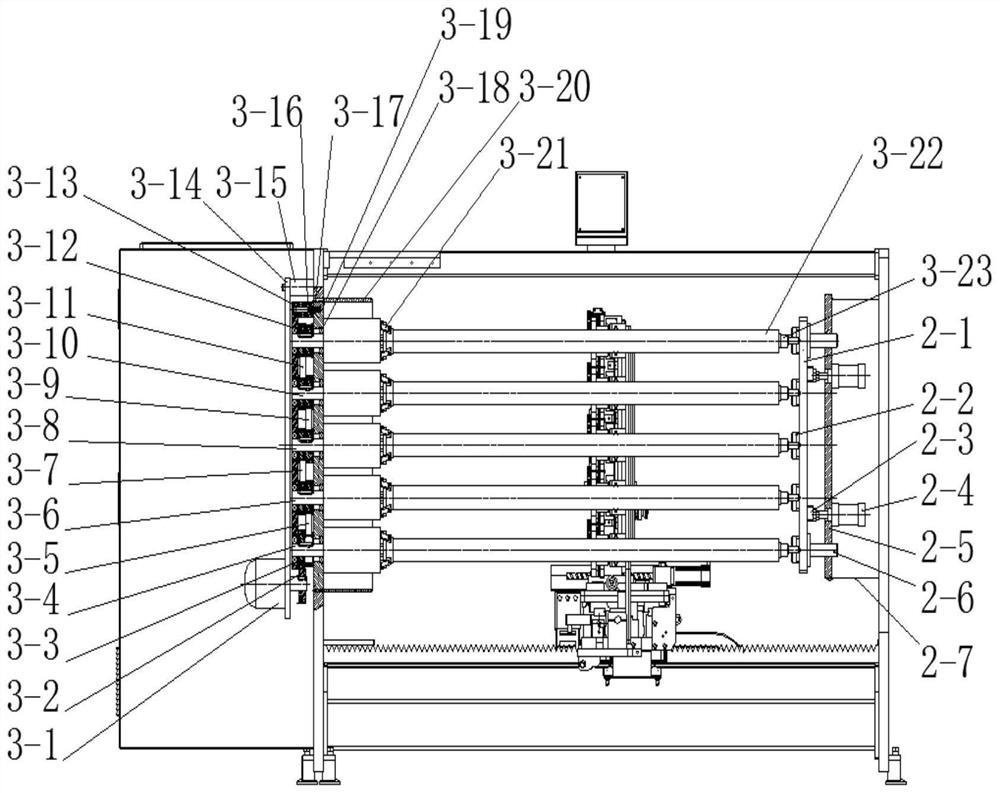

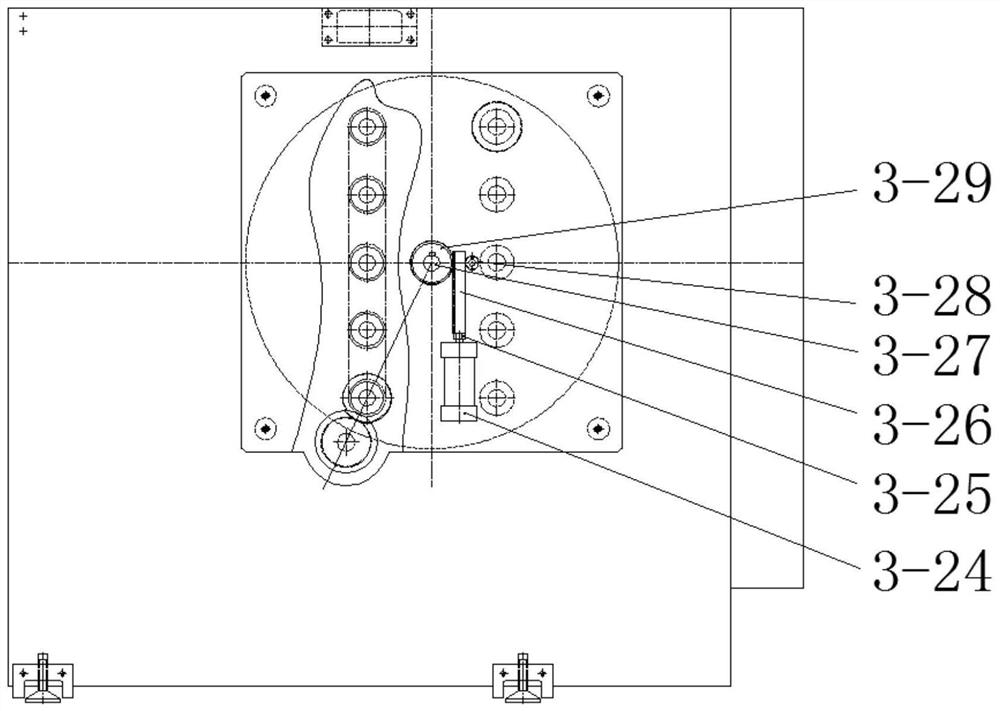

Semi-automatic five-shaft dividing and cutting machine

InactiveCN111873019AReduce processing timeIncrease productivityMetal working apparatusRotational axisSemi automatic

The invention discloses a semi-automatic five-shaft dividing and cutting machine which comprises a machine frame, a shaft supporting component, a rotating shaft component, a supporting wheel component, a cutting and moving platform, a control panel, an electrical box, a driving box, a displayer and a cutting component. Five cutting shafts are symmetrically installed on a shaft bottom plate and a shaft installation rear plate through radial bearings respectively, and two sets of shafts are installed on the shaft bottom plate. One set of shafts are used for cutting, the other set of shafts are used for feeding and discharging, can rotate around a T-shaped shaft and are interchanged in position, shaft supports are arranged during cutting of the cutting shafts, supporting wheels are arranged on one side of a workpiece and used for offsetting cutting radial force, five shafts carry out cutting at the same time, the production efficiency is nearly five times that of a single shaft, the overall machining time is shortened due to coincidence of feeding and discharging auxiliary time and cutting basic time, the production efficiency is improved, due to the application of the shaft supportsand the support wheels, the problems of flutter, cutter back-off and the like in the cutting process are effectively solved, the cutting quality is improved, and the defects are overcome.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

High-speed elevator tensioning device

PendingCN113233283AFix flutterIncrease swingElevatorsVibration suppression adjustmentsElectric machineryControl theory

The invention discloses a high-speed elevator tensioning device. According to the high-speed elevator tensioning device, the problem that a tensioning device vibrates in the vertical direction under the emergency braking working condition of an existing elevator is solved through a damping assembly. When the elevator is braked emergently, upward pulling and throwing force is generated on the tensioning device, a damping rod is driven to move through the pulling and throwing force, a buffer plate A, a buffer plate B and a buffer plate C move, a spring A, springs B, a spring C, a spring D and springs E deform, and impact energy generated during emergency braking is converted into kinetic energy and elastic potential energy. The problem that the tensioning device is clamped due to the fact that the swing amplitude of an existing steel wire rope in the horizontal direction is too large is solved through the adjusting assembly. An adjusting motor drives a driving rod to rotate, a driving ring moves in the central axis direction of the driving rod, an adjusting base moves in an adjusting frame while moving along with the driving ring, the adjusting rod is driven to move, and therefore the distance between an adjusting wheel and a steel wire rope is changed.

Owner:丹阳市华富机械有限公司

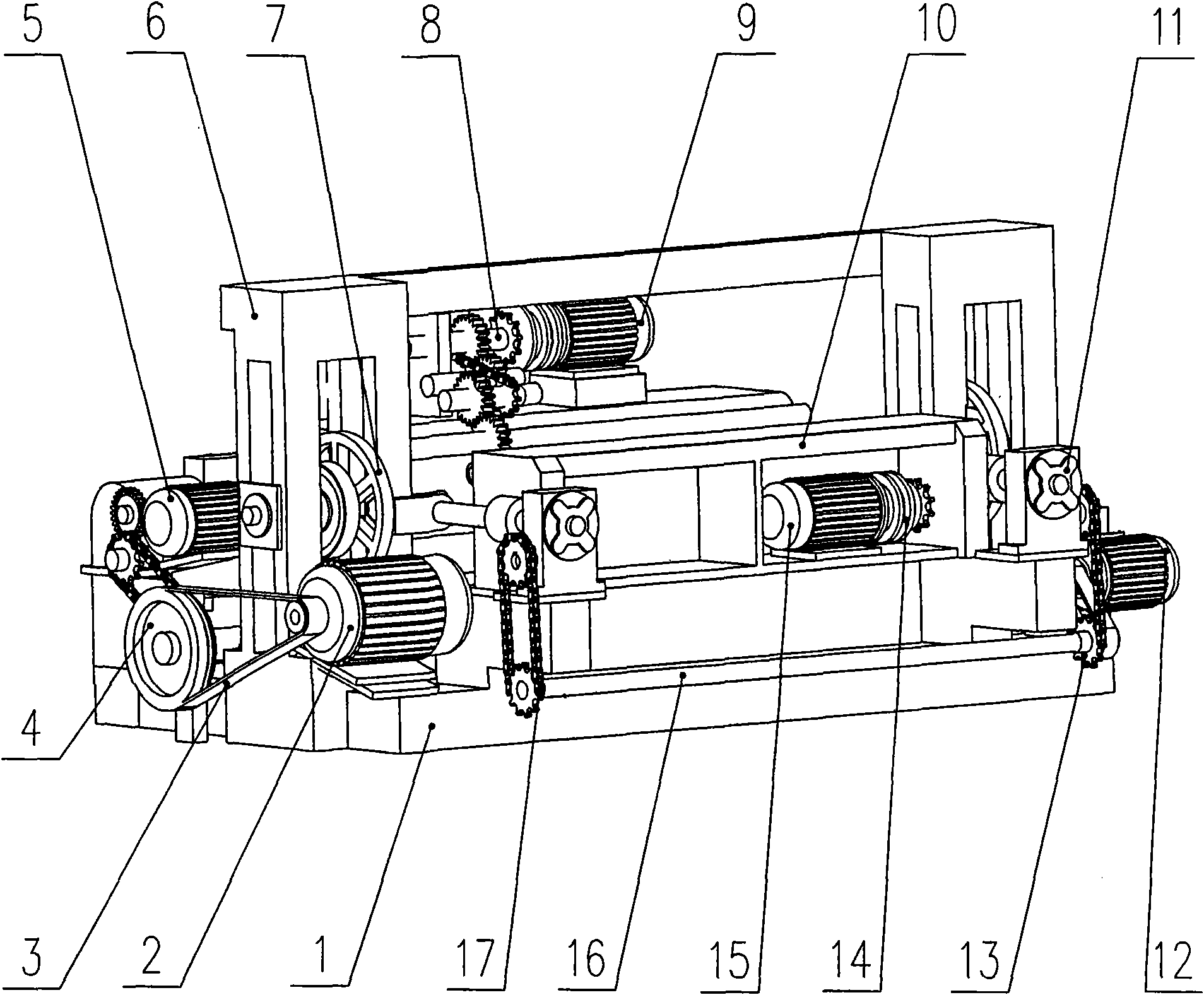

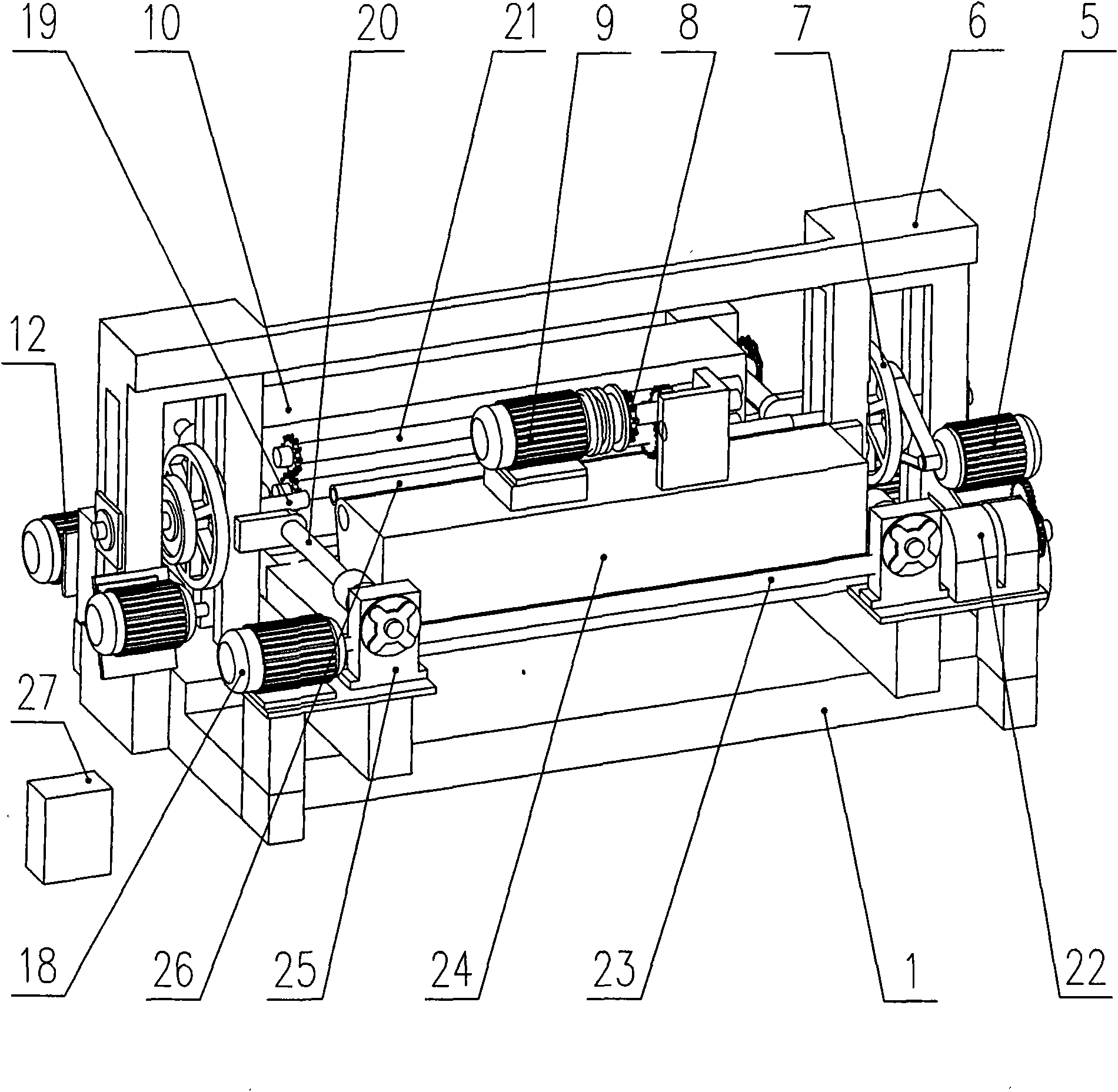

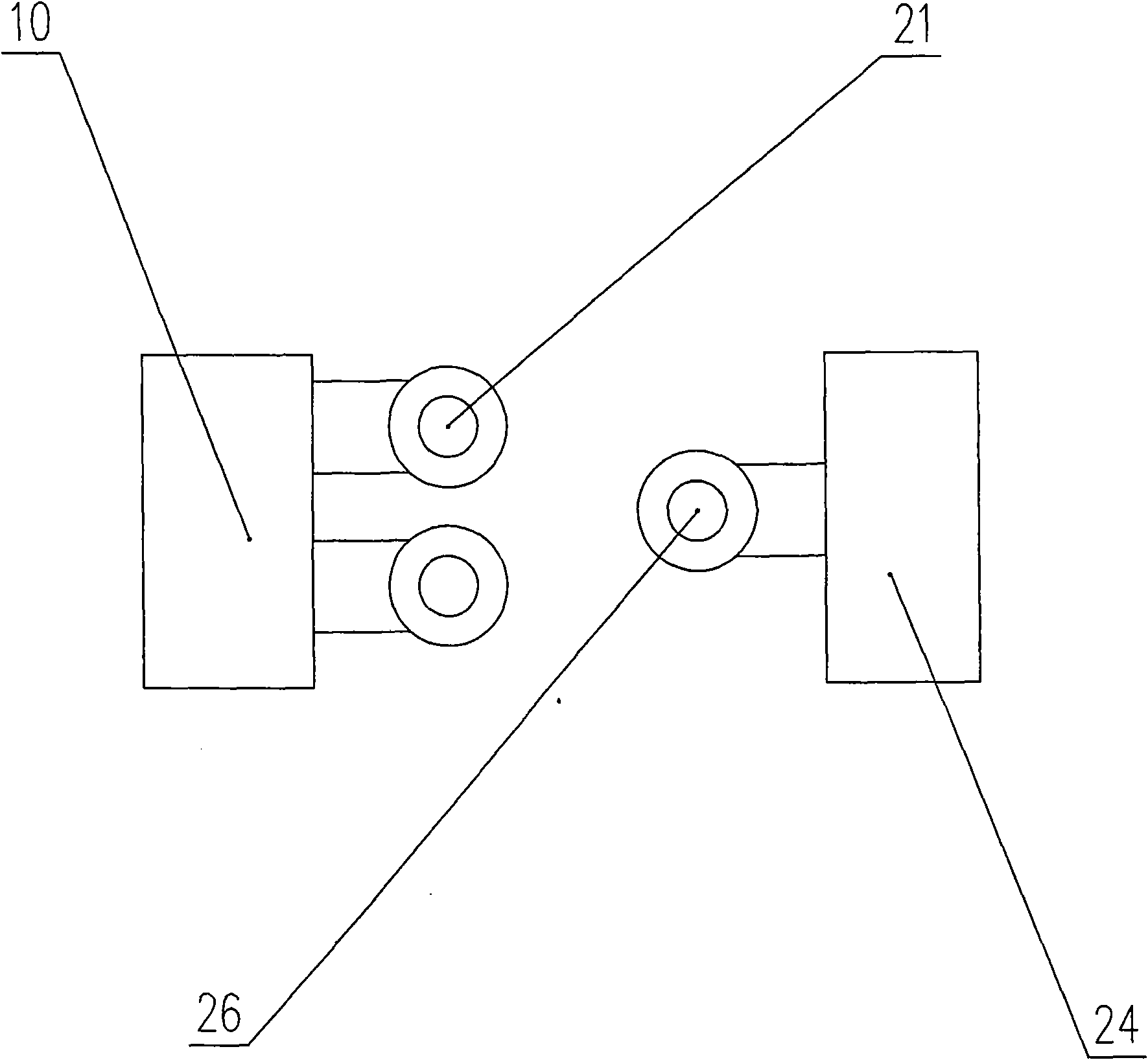

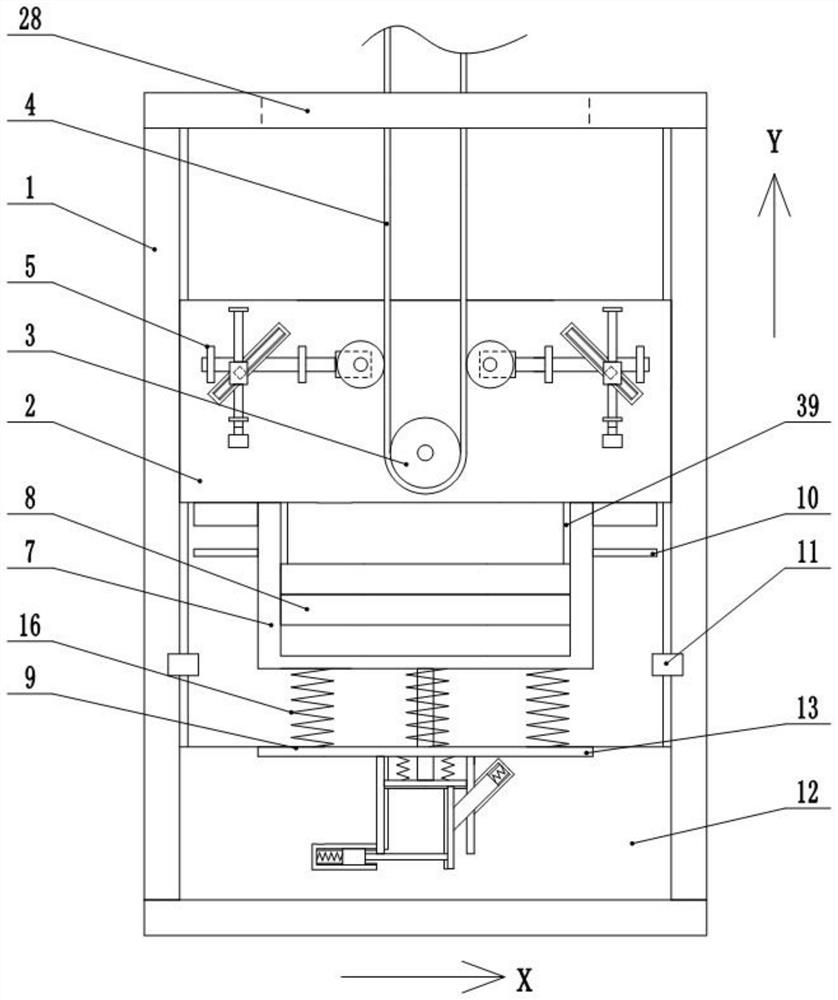

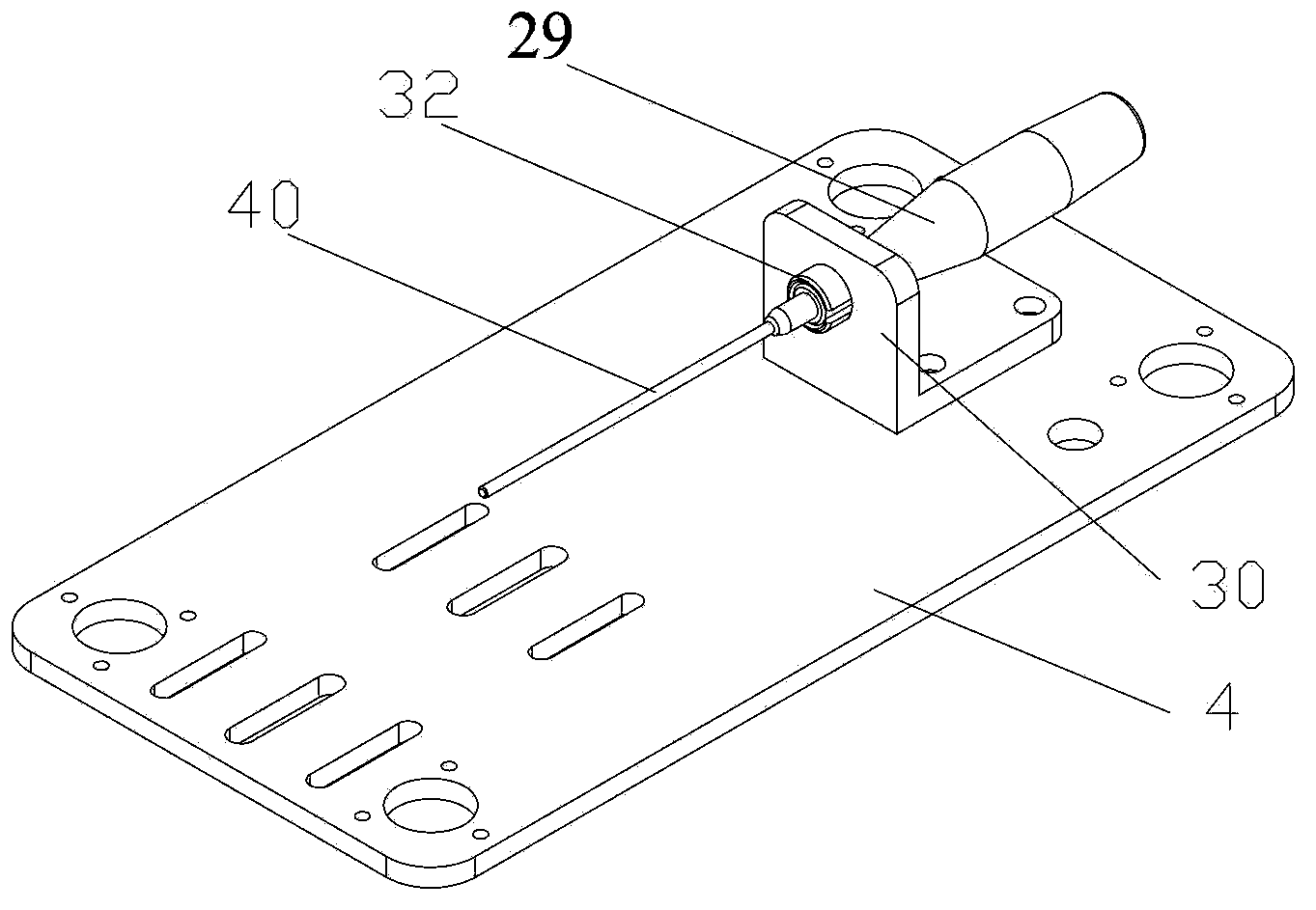

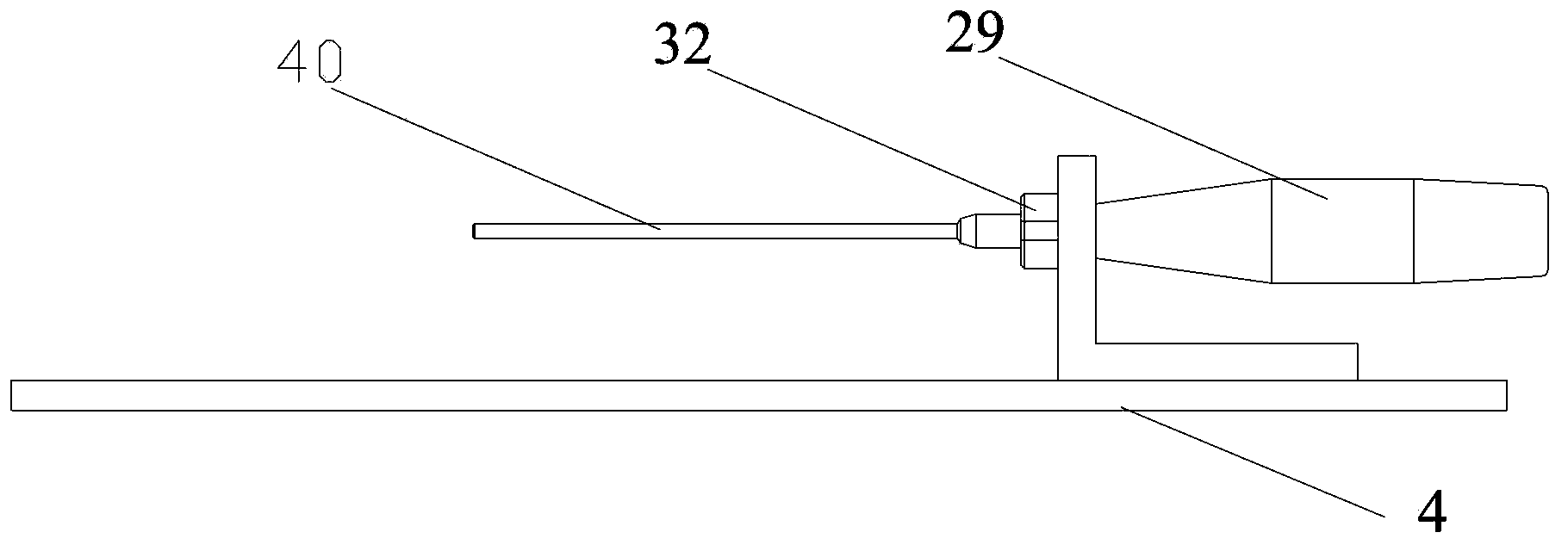

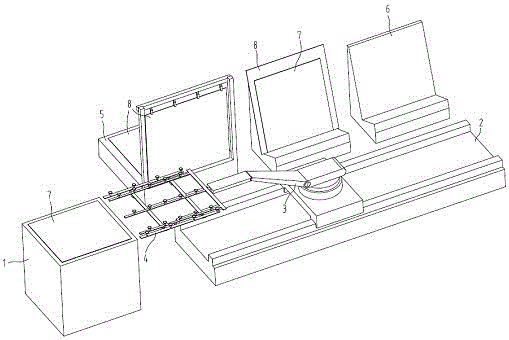

Artificial blood vessel forming machine

InactiveCN103655000AEnsure consistencyGuaranteed repeatabilityBlood vesselsMarine engineeringBlood vessel

The invention discloses an artificial blood vessel forming machine which comprises a collecting rod 40. One end of the collecting rod 40 is driven to rotate by a motor. The other end of the collecting rod 40 is provided with a supporting unit in a floating-connecting mode. According to the artificial blood vessel forming machine, a front end support is used for well solving the problem of collecting rod vibration, and the problem that finished product rate is low is well solved. In addition, an insulation structure of a motor and the collecting rod is improved, motor damage is avoided, and the quality of an artificial blood vessel is further improved. Qualified artificial blood vessels can be manufactured through the artificial blood vessel forming machine, operation is easy, the specifications of the artificial blood vessels can be changed freely, and pass percent can reach more than 95%.

Owner:DALIAN SHENGLONG MACHINERY

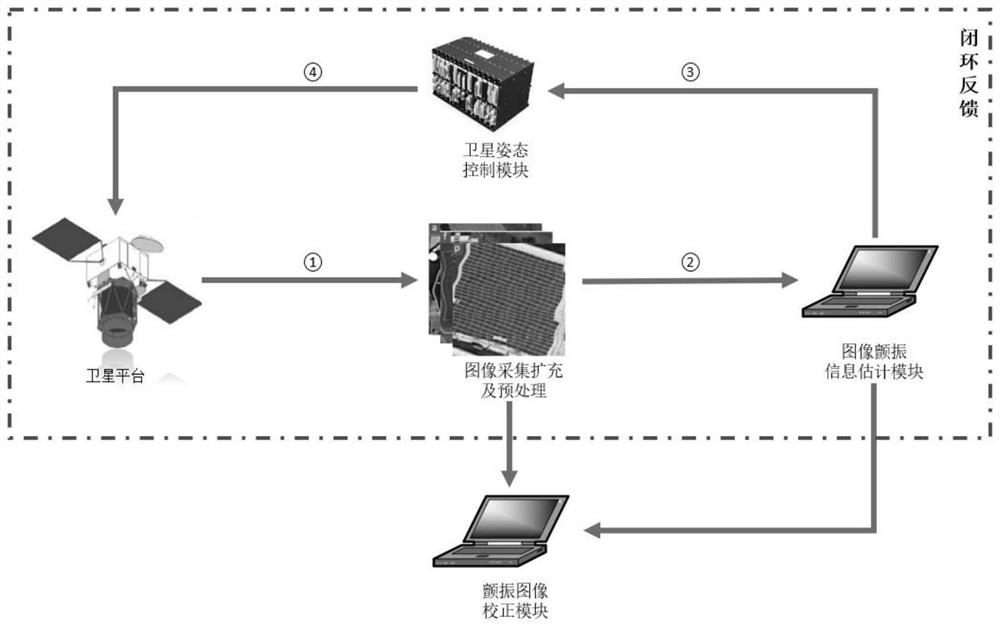

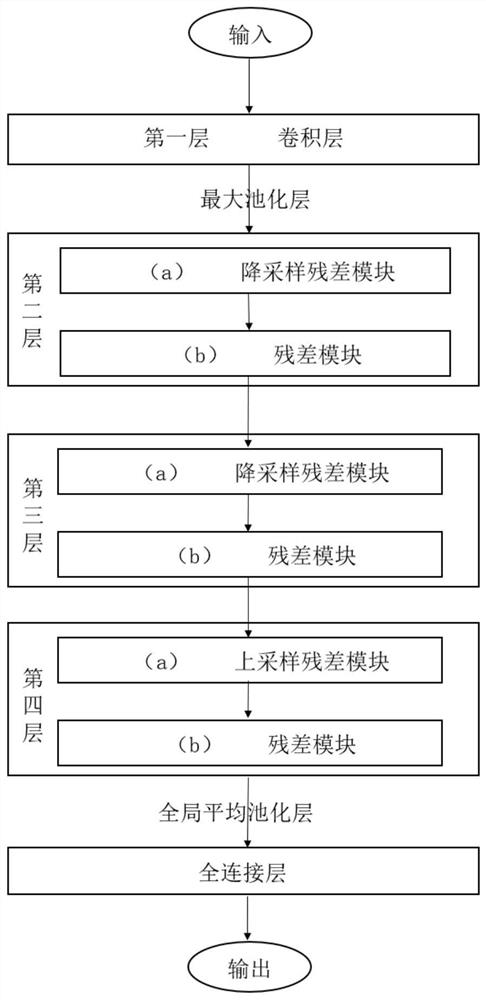

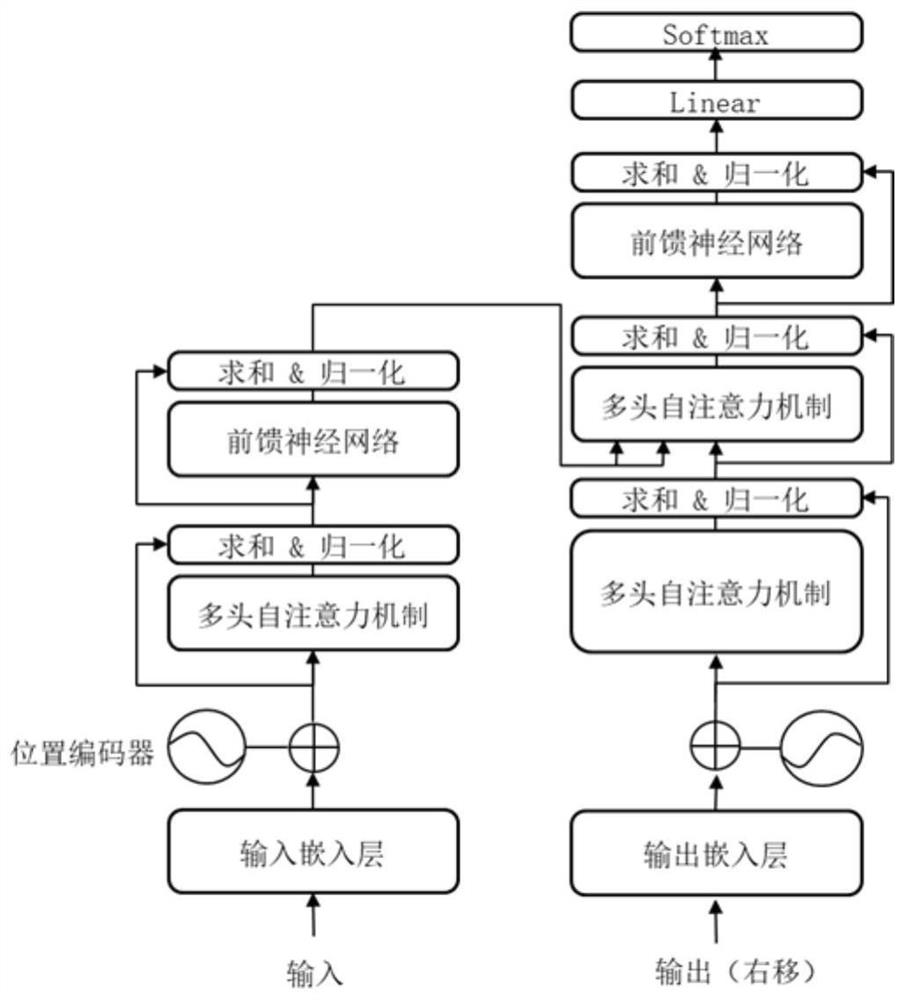

Remote sensing satellite platform control and image correction method based on flutter information

PendingCN114545959AFix flutterSolve the problem of clear imagingImage enhancementImage analysisData setImage correction

The invention discloses a remote sensing satellite platform control and image correction method based on flutter information. The method comprises the steps of simulating satellite motion and constructing a flutter image data set, expanding data volume through data enhancement, preprocessing flutter image data, extracting image flutter information by using a ResNet algorithm, feeding back the flutter information to a satellite attitude control system for control, and guiding a Transformer model to perform image correction by using the flutter information. In order to solve the technical problem that space tasks such as high-resolution reconnaissance cannot be clearly imaged due to limitation of high-frequency low-amplitude micro-vibration of a spacecraft, satellite flutter information is solved by using a flutter image, and a satellite platform is controlled and image correction network learning is guided by using the flutter information. Therefore, a satellite flutter estimation, attitude control feedback and image correction closed-loop system is built. The invention provides a satellite flutter information estimation and attitude control information feedback based on a ResNet algorithm and a flutter image correction intelligent method based on a Transform model, and the spatial information intelligent processing capability of China is effectively improved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

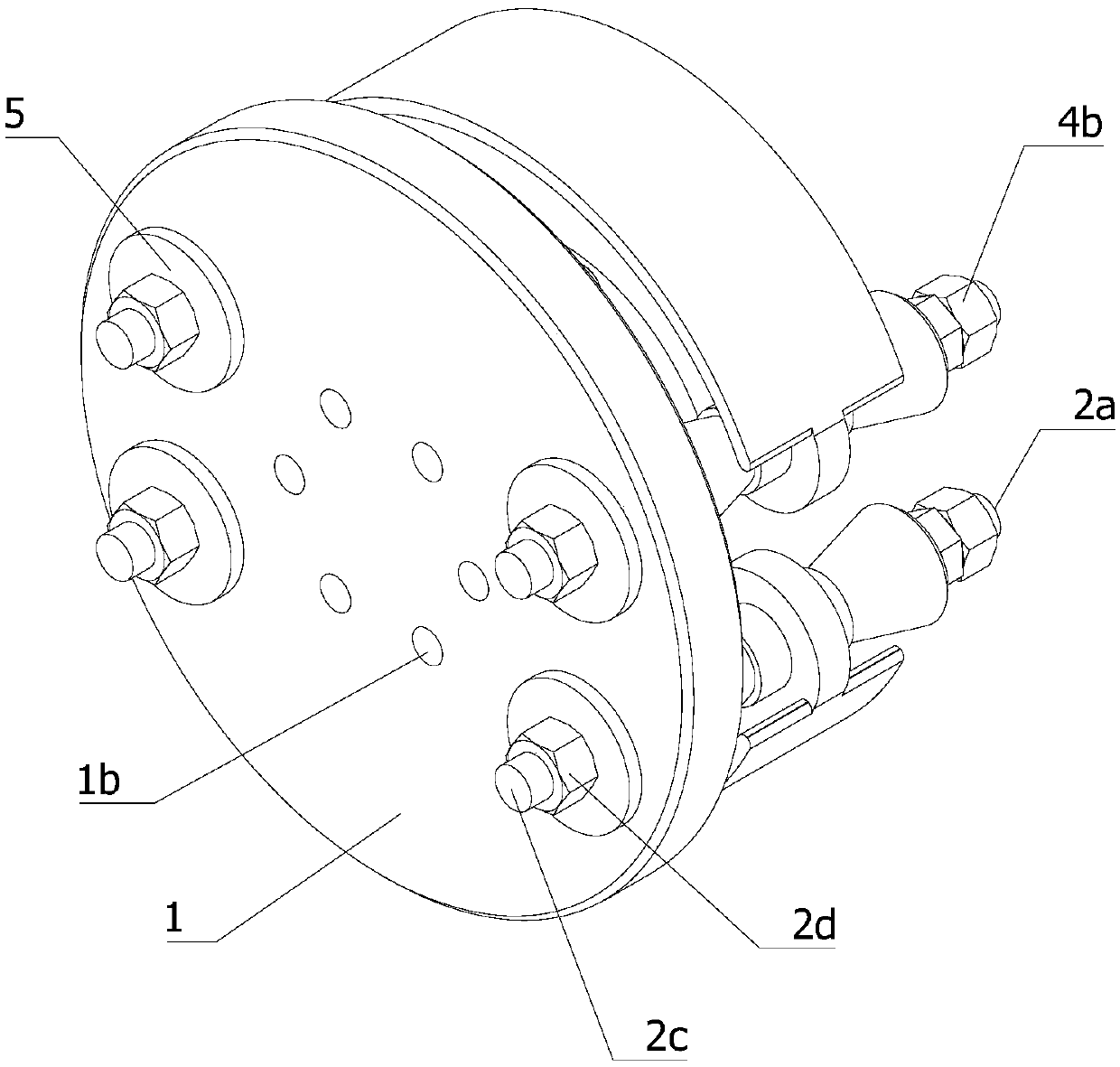

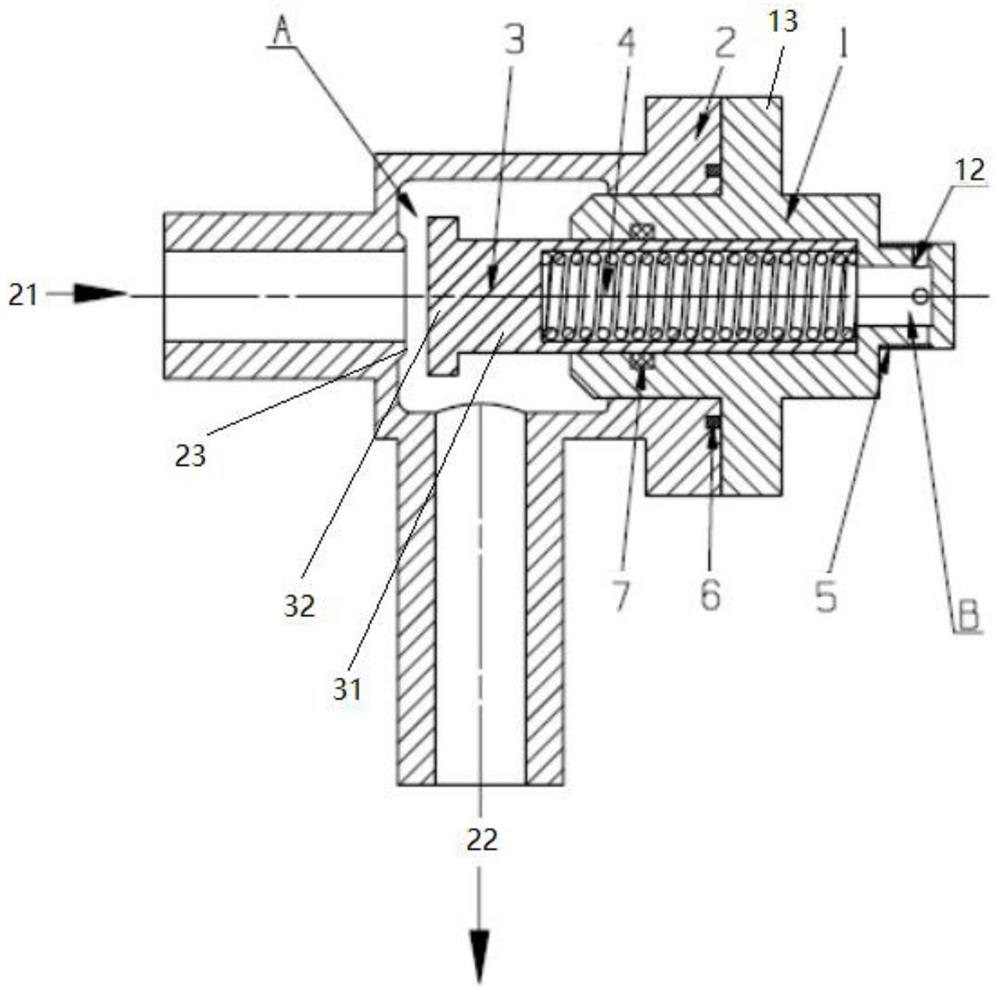

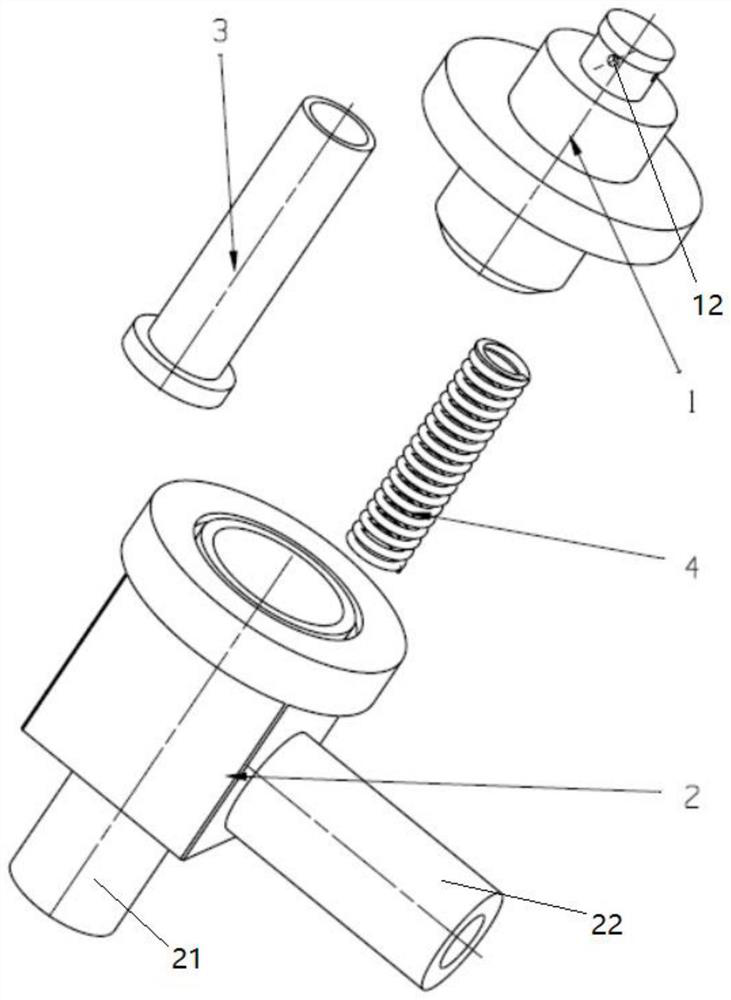

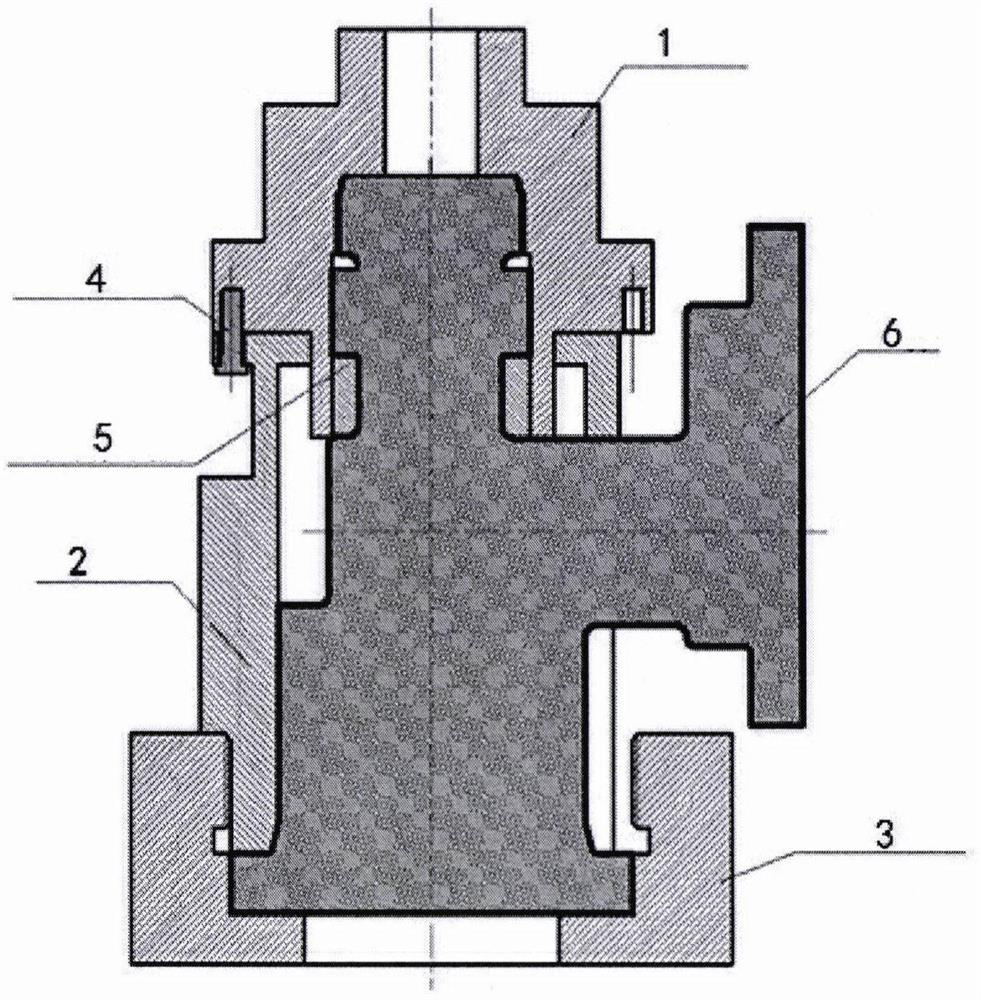

Anti-flutter fixture for processing weakly rigid parts

ActiveCN112405055BFix flutterQuality assurancePositioning apparatusMaintainance and safety accessoriesVibration ProblemScrew thread

The invention discloses an anti-flutter fixture for processing weakly rigid parts. The vibration problem is guaranteed, the surface quality and shape and position tolerance of the thread and valve seat are guaranteed, and the qualified rate reaches 95%, which enhances the sealing performance of the whole valve and greatly reduces the disassembly, repair and reinstallation caused by the unqualified valve sealing performance. The waste of manpower and resources caused by this process shortens the production cycle of the product.

Owner:CAPITAL AEROSPACE MACHINERY

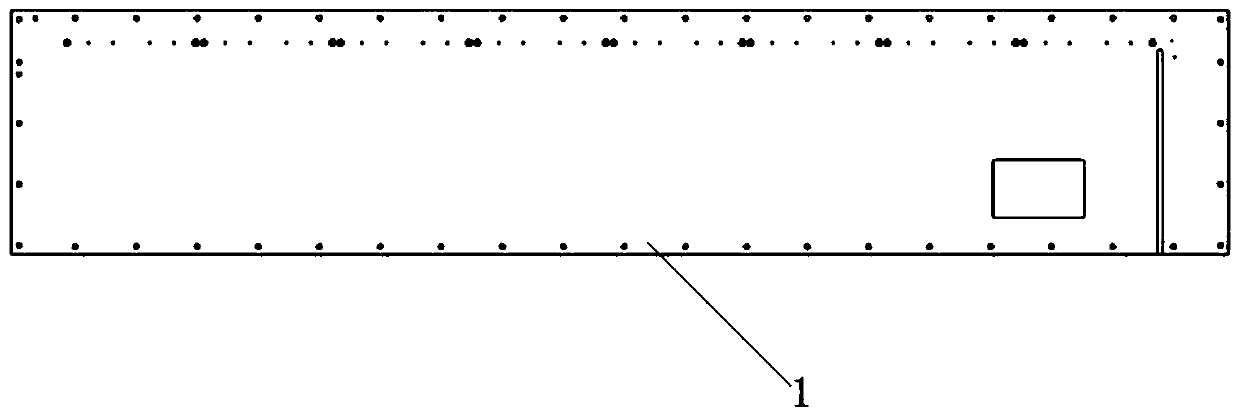

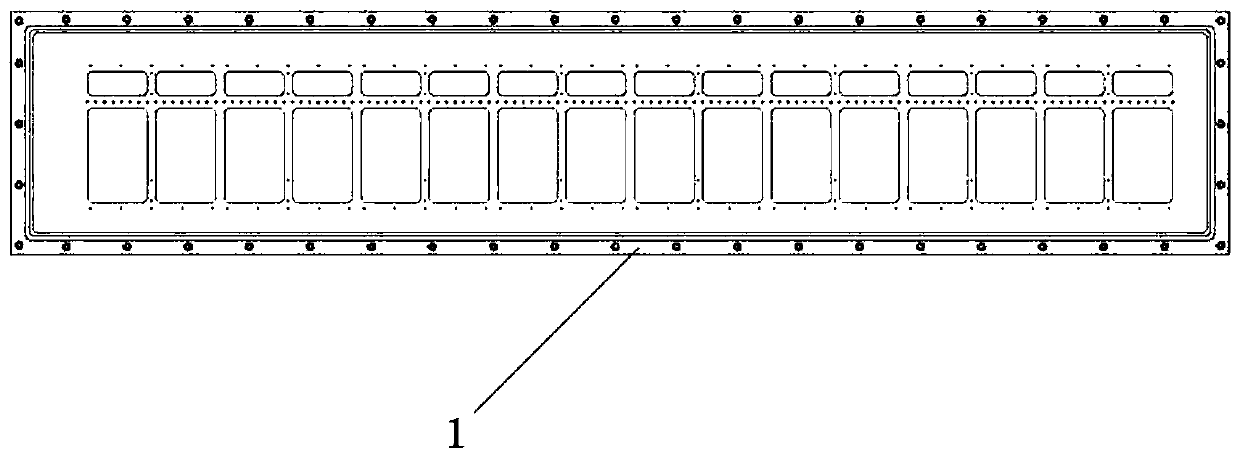

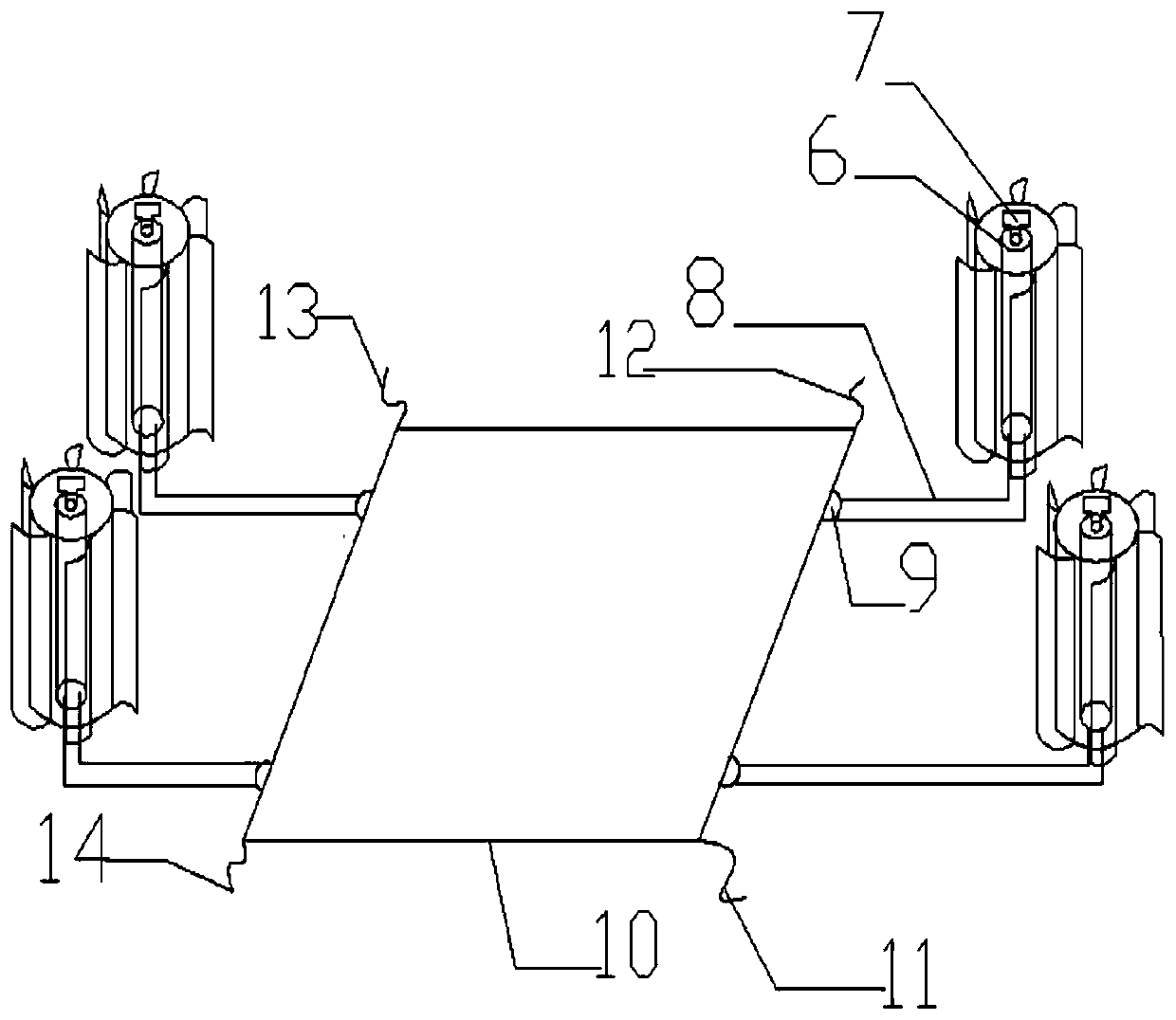

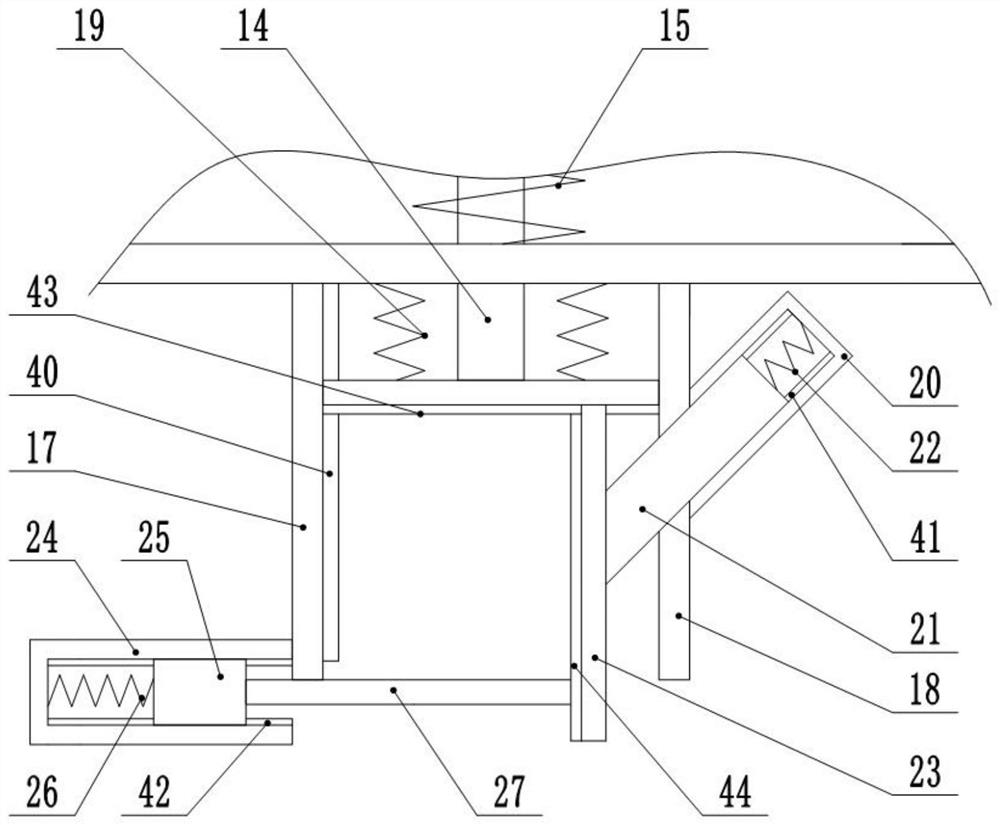

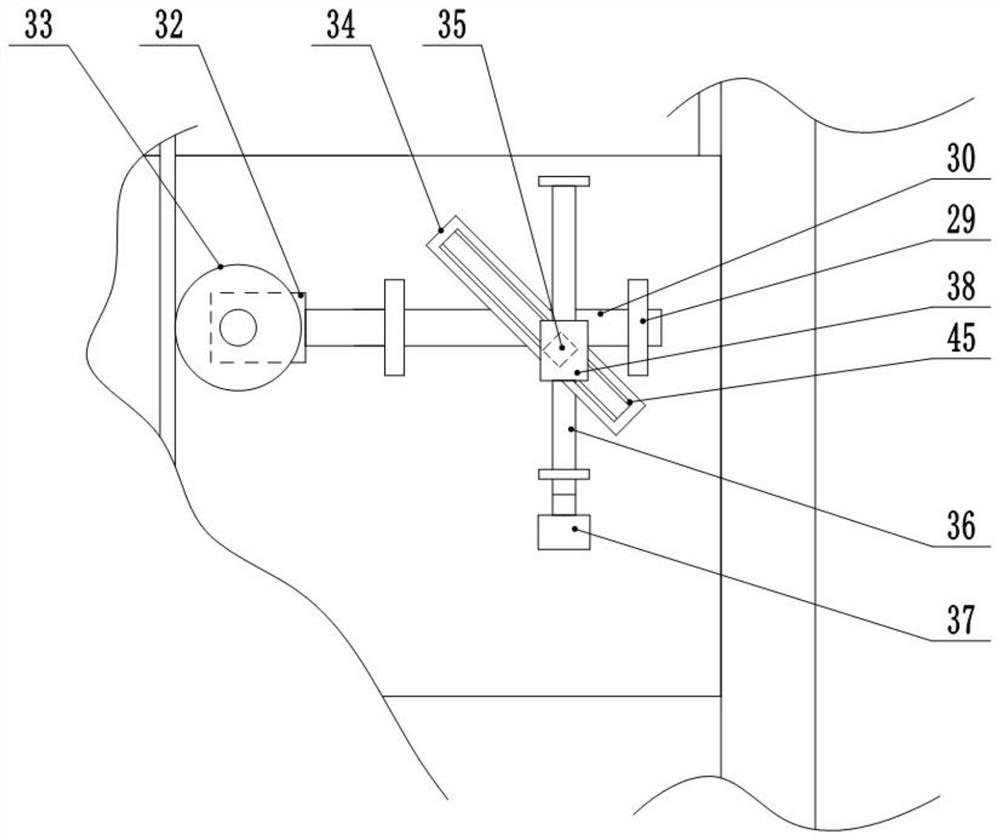

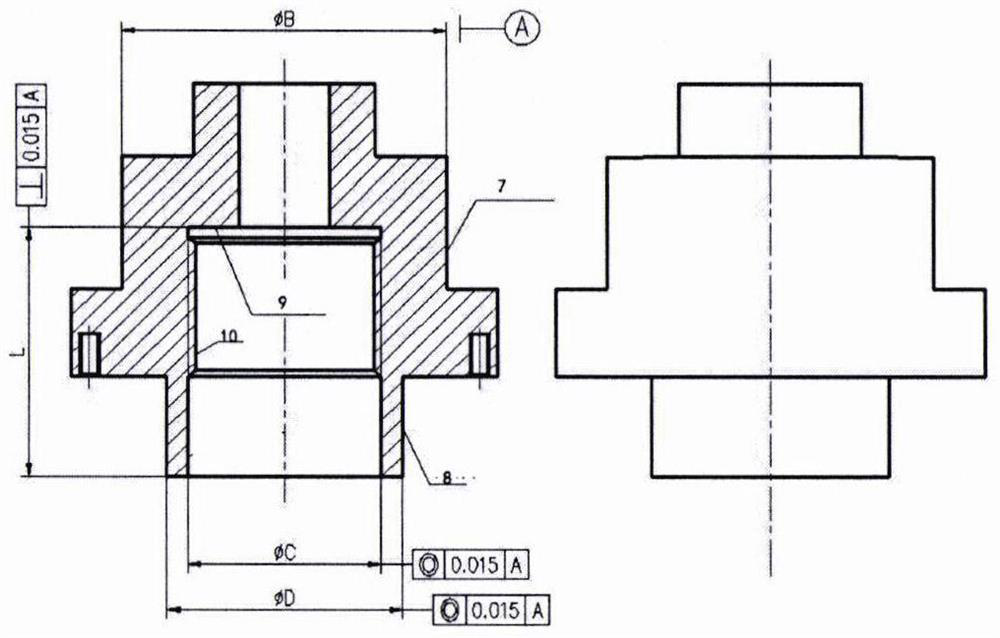

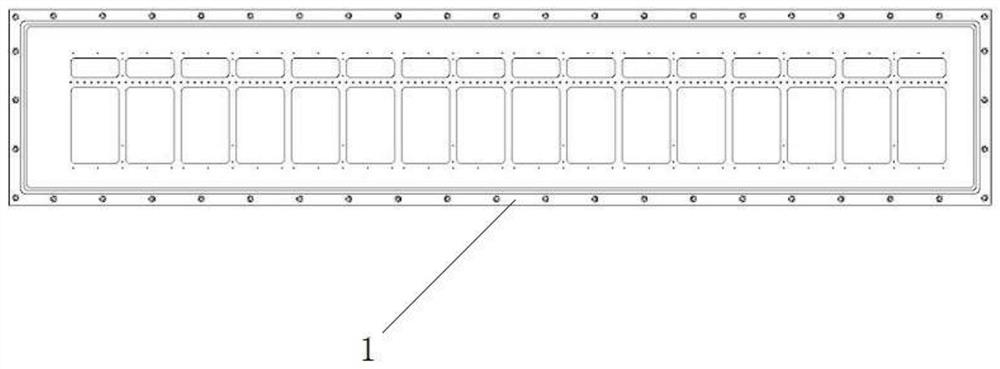

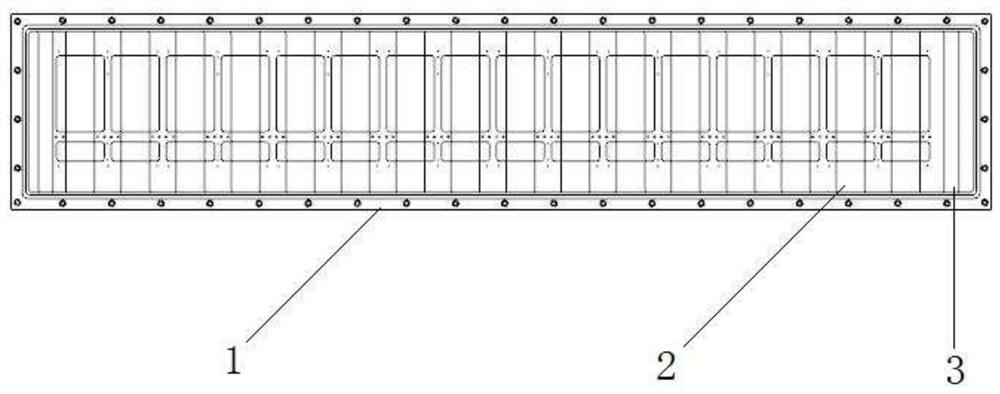

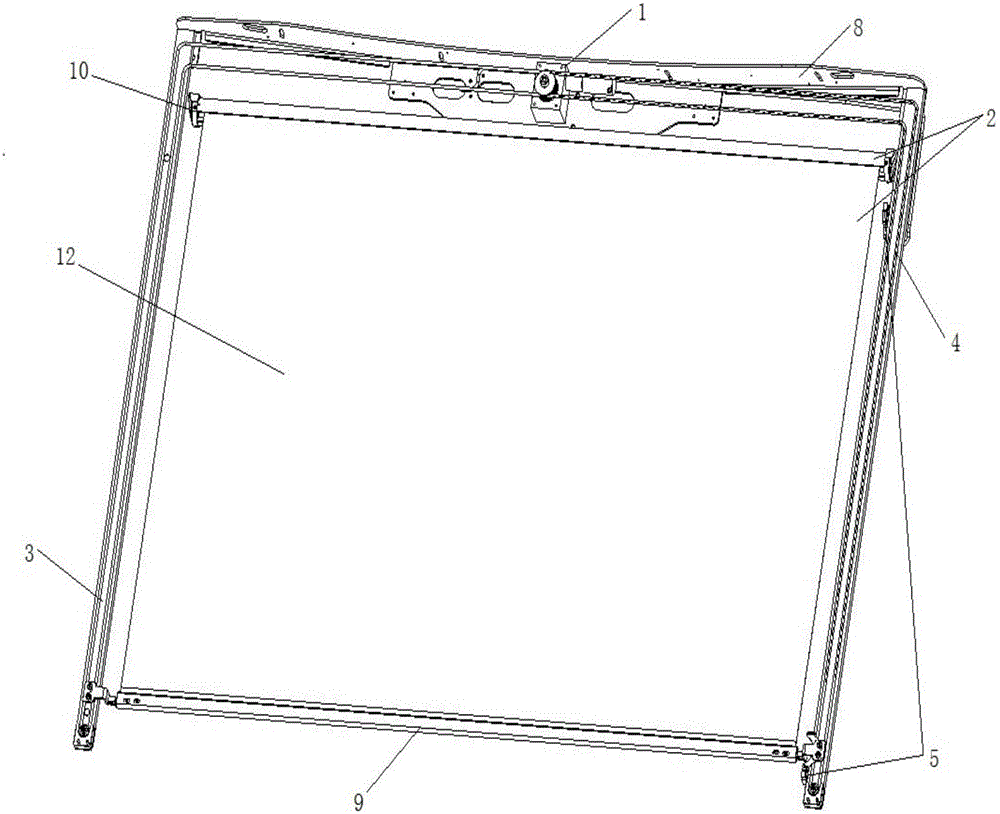

A packaging equipment suitable for high-generation liquid crystal glass substrates

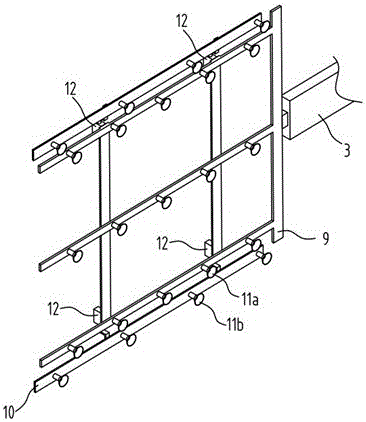

ActiveCN104648715BFix flutterReduce production line costsShock-sensitive articlesProduction lineEngineering

Packaging equipment applicable to advanced-line liquid crystal glass base plate relates to the packaging field of a glass base plate, particularly relates to packaging equipment of a liquid crystal glass base plate and is used for a glass base plate production line. The packaging equipment comprises a glass base plate loading platform (1), a robot slide platform (2), a robot (3), a robot arm (4) for connecting the robot, a paper feeding mechanism (5) and an A-shaped frame (6), and is characterized in that the robot arm (4) comprises a glass base plate suction disc bracket (9) and a paper taking suction disc bracket (10); two brackets are provided with a glass base plate taking suction plate (11a) and a paper taking suction disc (11b) respectively; the paper feeding mechanism (5) comprises a paper feeding platform (13), a bracket (14) with a guide rail, a pneumatic claw movable transverse beam (15), a pneumatic claw mounting bracket (16) and a pneumatic claw (17); the A-shaped frame is fixed on the ground by a positioning device. With the adoption of the packaging equipment, the production efficiency can be improved and the production line cost is reduced.

Owner:北京远大信达科技有限公司

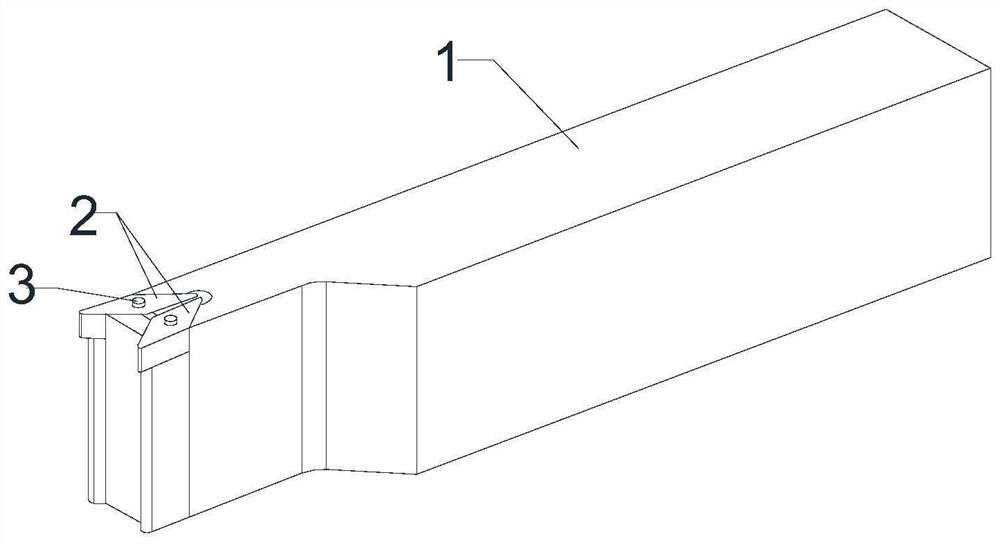

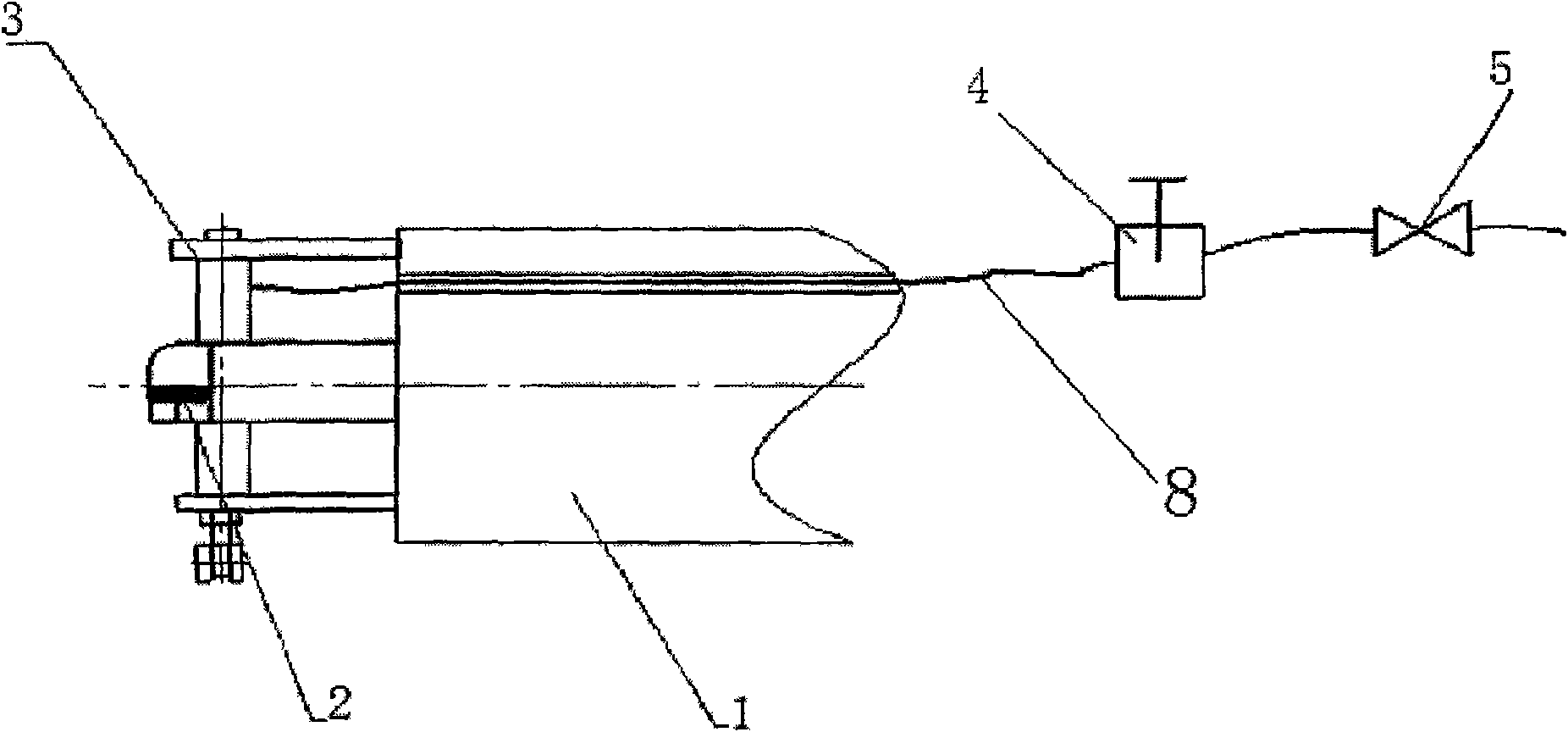

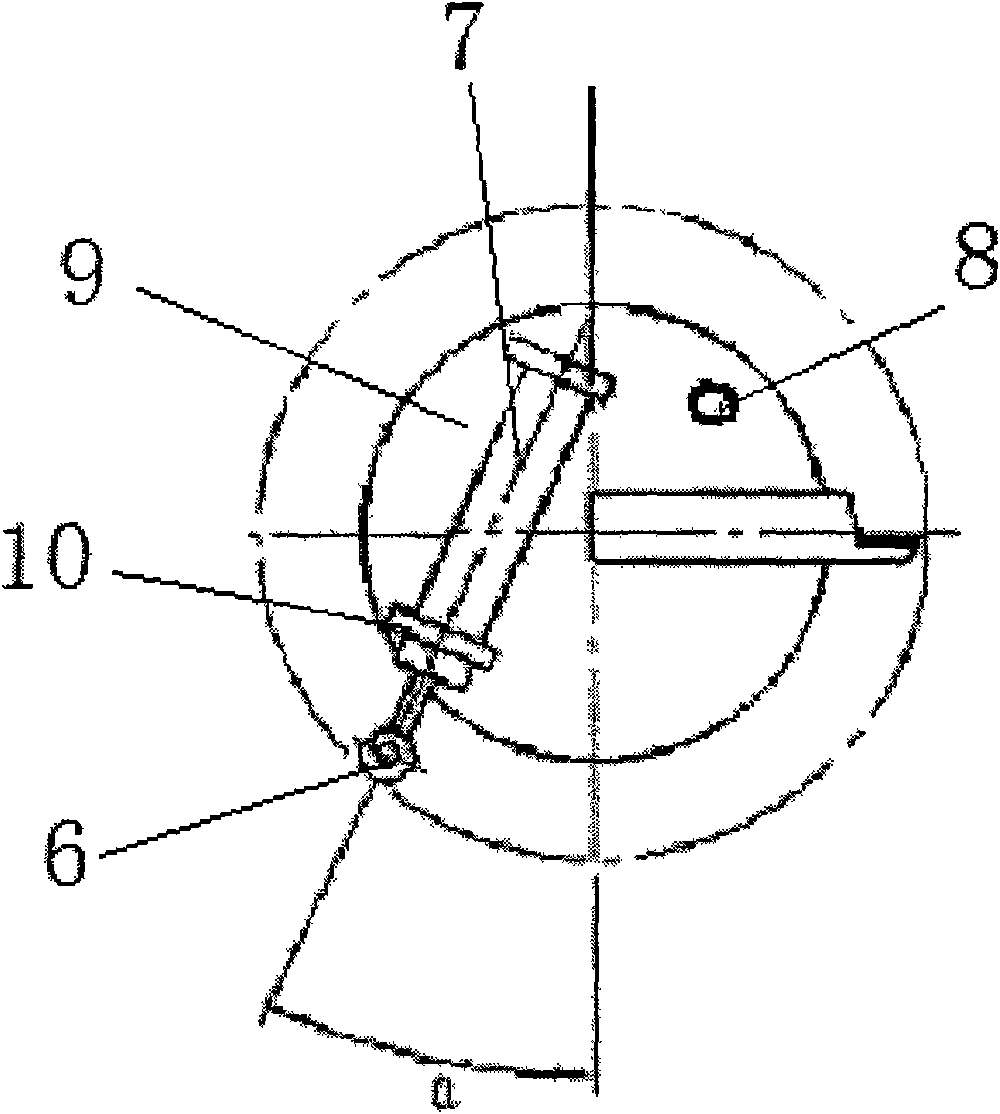

Pneumatic support device for steady operation of overlong boring cutter bar

ActiveCN101637871ASolve rigid problemsFix flutterPositioning apparatusBoring/drilling componentsDiameter ratioCutting force

The invention provides a pneumatic support device for steady operation of an overlong boring cutter bar. In the device, two support plates of a cylinder support (3) are fixed on a base plate, and thedistance between the two support plates meet the mounting requirements of a cylinder (7); a connecting line between cylinder mounting holes on the two support plates and the central line of the base plate form an included angle alpha; and the degree of the included angle alpha is consistent with the direction of resultant cutting force. Two ends of the cylinder (7) are fixed on the cylinder support (3); and the cylinder support is fixed on an end face of a boring cutter bar (1); the boring cutter bar (1) is provided with an air tube mounting groove, one end of an air tube (8) is communicated with the cylinder, and the other end thereof is communicated with a pressure regulating / stabilizing unit (4) and an air tube switch (5). A piston rod of the cylinder extends to prop on the inner wall of a bottom hole and support the boring cutter bar when compressed air enters the cylinder. The pneumatic support device solves the problems of cutter relieving and vibration due to insufficient cutterbar rigidity in precision boring of hole parts with large length-diameter ratio, is applicable to boring of holes with large length-diameter ratio, and has the advantageous of simple structure, convenient operation, reliable operation, low cost and no pollution.

Owner:AECC AVIATION POWER CO LTD

A rigid support method for machining thin-walled cavity parts

ActiveCN110712047BKeep it steadyFix flutterPositioning apparatusMetal-working holdersMechanical engineeringThin walled

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

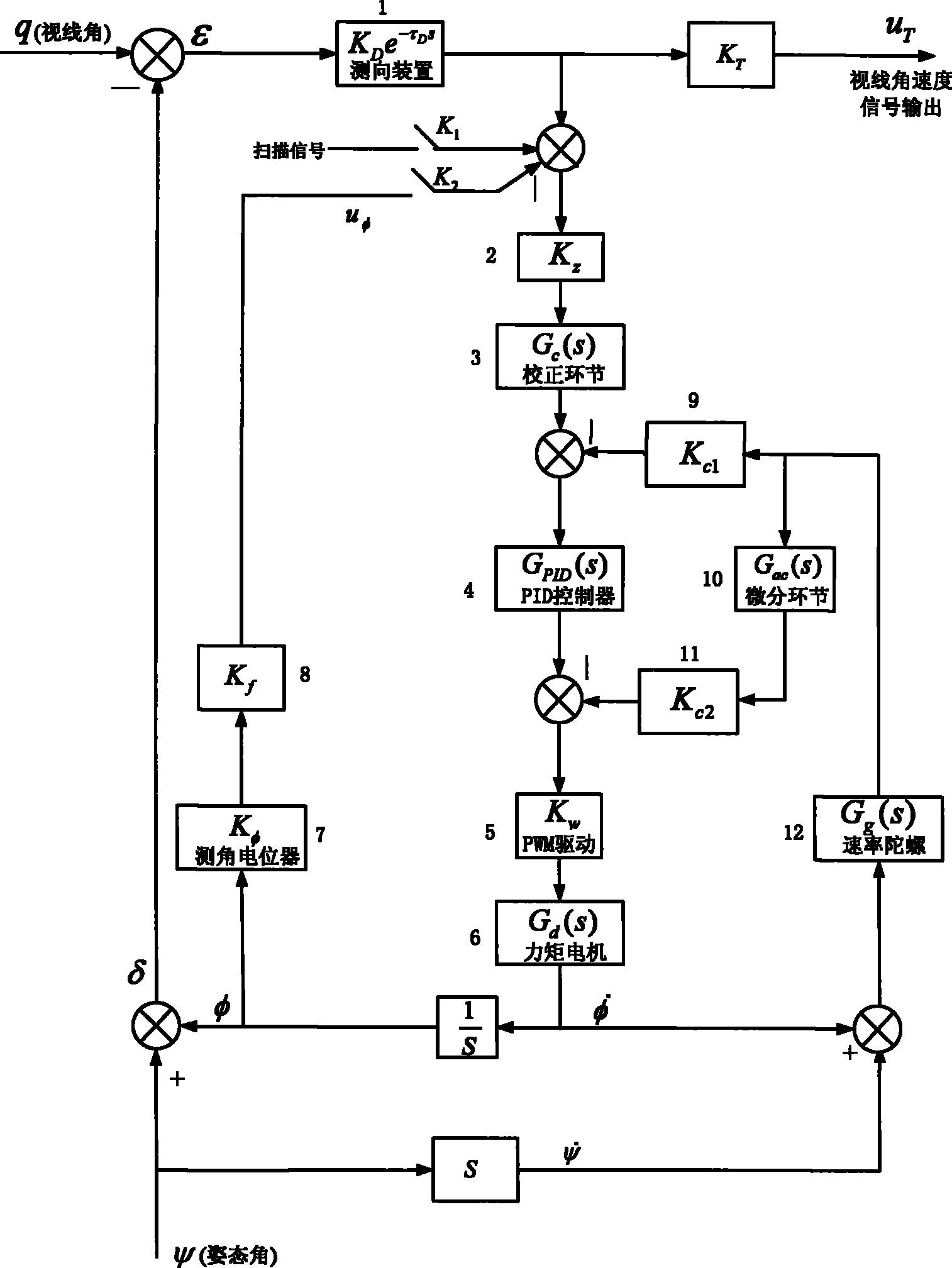

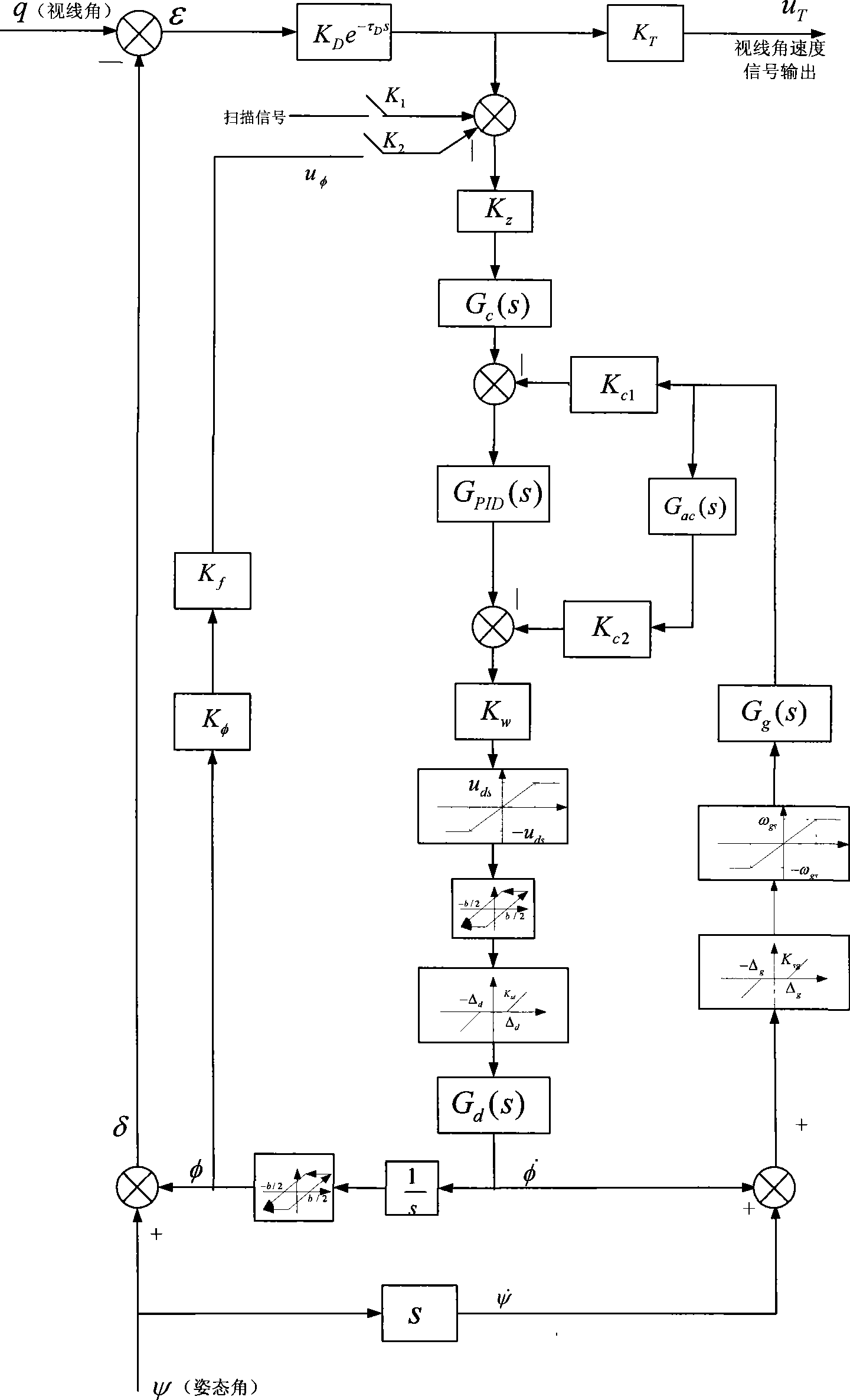

Rate gyro stabilizing platform type antenna followup system

The invention provides a follow-up tracking system of a rate gyroscope stabilized platform type antenna, which comprises a direction-finding device, an adjustment link, a PID controller, a PWM driver, a moment motor, an angle measuring potentiometer, an angular rate gyroscope and a differential link. The PWM driver, the moment motor, the angular rate gyroscope and the differential link are connected in sequence to form an angular acceleration negative feedback loop; the PID controller, the PWM driver, the moment motor and the the angular rate gyroscope are connected in sequence to form an angular rate negative feedback loop; the direction-finding device, a preamplifier, the adjustment link and the angular rate negative feedback circuit form an angular position negative feedback loop; the angle measuring potentiometer, the preamplifier, the adjustment link and the angular rate negative feedback loop form an angle searching loop. The follow-up tracking system is an antenna follow-up system which is used for realizing the follow-up tracking technology of stably tracking, searching and isolating the angular motion of a carrier in the direction-finding devices, such as radars, optical imaging, and the like, in moving carriers so as to realize high precision, weak coupling, anti-turn-off performance, fastness and stabilization and realize proportional guidance.

Owner:HARBIN ENG UNIV

Machining method of thin-wall heterogenic titanium alloy part

ActiveCN102909573BImprove rigidityIncrease stiffnessPositioning apparatusMetal-working holdersDomain analysisCutting force

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

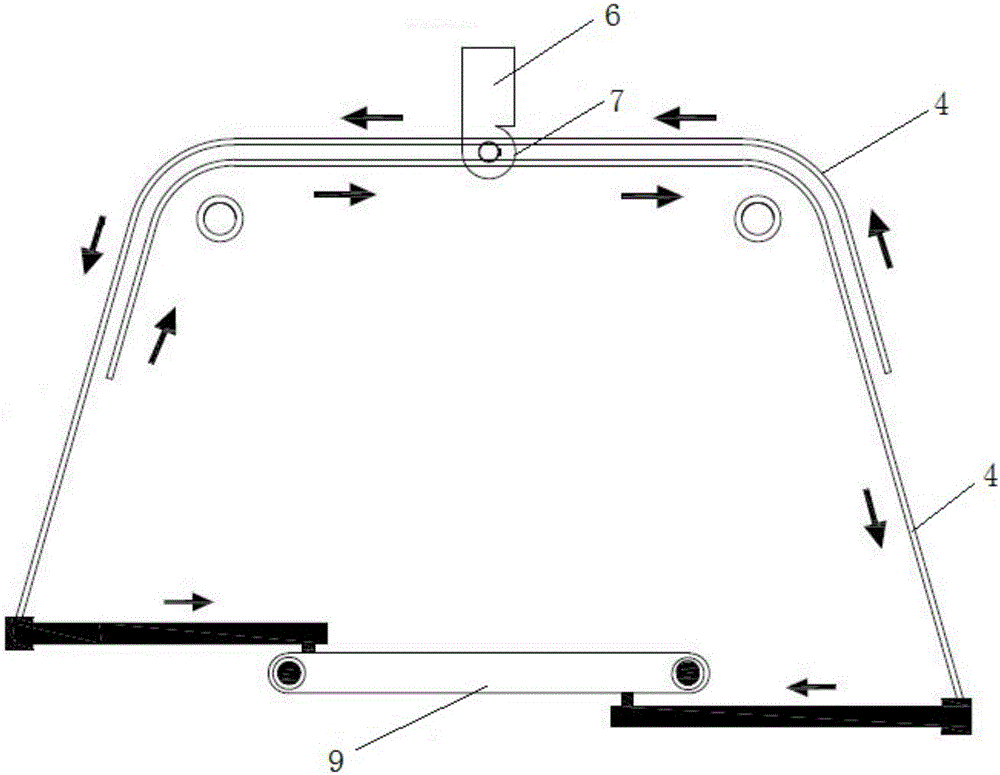

Arc-shaped guide rail cab sun-shading device

InactiveCN106004358AImprove performanceFix flutterAntiglare equipmentLight protection screensSynchronismEngineering

The invention provides an arc-shaped guide rail cab sun-shading device which comprises a motor module, a roller shutter assembly, guide rails, flexible shafts and up-and-down limiting devices. Guide rails at different radians are adopted according to different vehicle body steel structures, the sun-shading device can well adapt to and increase space in a cab, power is transmitted through the high-performance flexible shafts, and synchronism and the same direction are guaranteed; the flexible shafts are made of compact fixed structure steel pipes, and the stability, coordination and balance of a sun-shading curtain overall system are guaranteed; the purpose that under limitation of the existing compact space and shape, the sun-shading device occupies small space in order to increase the space of the cab is achieved; high efficiency, stability and high strength are achieved, sun-shading requirements under various vehicle body shapes are met, loading is convenient, performance is reliable, and no jamming or twisting phenomenon exists.

Owner:QINGDAO VICTALL RAILWAY CO LTD

A Bearing Structure Using Supercritical Carbon Dioxide Lubrication

ActiveCN108223557BSolve the problem of low carrying capacityFix flutterShaftsBearing componentsEngineeringMechanical engineering

Owner:DONGFANG TURBINE CO LTD

Machining method of thin-wall heterogenic titanium alloy part

ActiveCN102909573AImprove rigidityIncrease stiffnessPositioning apparatusMetal-working holdersDomain analysisCutting force

The invention discloses a machining method of a thin-wall heterogenic titanium alloy part. The part is clamped by a rigidity reinforced tool in an internal and external opposite pushing manner, and placed on a base of the rigidity reinforced tool, a machining position of the part is clamped by the rigidity reinforced tool in an external opposite pushing manner, and the interior of the part adopts a main beam of the rigidity reinforced tool as a force transmission device. The method aims at improving the rigidity of the part to be machined, and the rigidity reinforced tool is designed to reinforce supporting and improve the body rigidity of the part. For the selection of machining parameters of titanium alloy, the entire oscillation stability domain analysis based on cutter part equipment is adopted, and appropriate cutting parameters are selected; for a shape forming method of the cut part, the cutter base plane modeling is adopted; a cutting tool adopts a circular inserted cutter; the strength of the cutter is improved; a cutting angle is controlled by a cutting depth; and a cutting force and cutting heat are reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

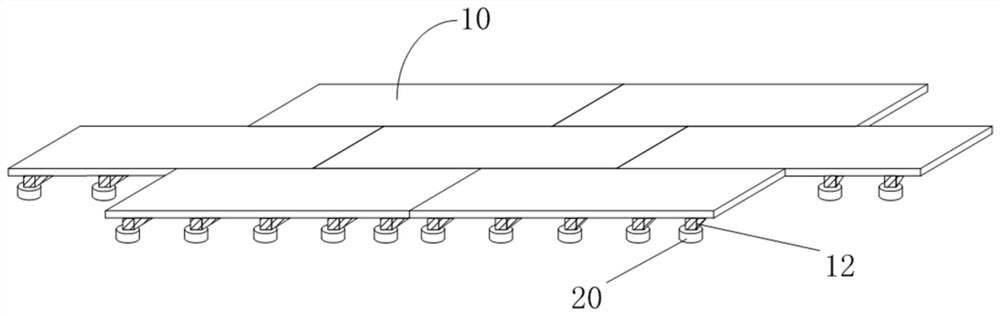

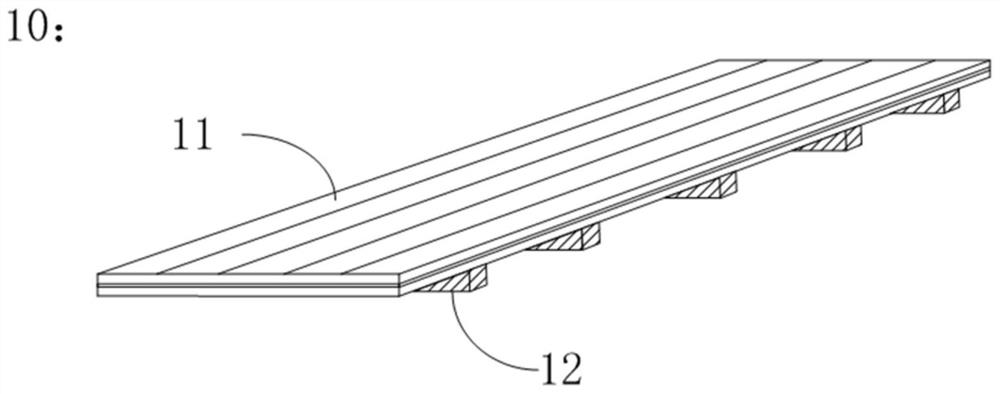

Solid wood floor comprising multiple floor blocks and leveling devices and preparation method

Disclosed is a solid wood floor. The solid wood floor comprises a plurality of floor blocks and leveling devices arranged below the floor blocks, and is characterized in that each floor block comprises a plurality of single floors spliced with one another and keels arranged below the single floors and fixedly connected with the single floors; the keels extend to the edges of the floor blocks and are connected with the keels of the adjacent floor blocks in an adjacent mode; and the leveling devices are arranged below the adjacent keels. By means of the structure, the multiple single floors and the multiple single floors and the keels are stably connected in sequence, deformation of the solid wood floor can be effectively prevented, and therefore the problems of tile deformation, bulging, warping and the like are solved. In addition, through the arrangement of the leveling devices, the heights of the adjacent floor blocks can be adjusted in sequence very conveniently, the ground height difference is eliminated, and therefore the solid wood floor can adapt to complex sites.

Owner:辽宁耐步体育发展有限公司

A Method for Optimizing Static Aeroelasticity and Flutter of an All-Motion Stabilizer

ActiveCN111125829BImprove matchSatisfy the static aeroelasticity problemGeometric CADDesign optimisation/simulationElement modelAeroelasticity

Owner:JIANGXI HONGDU AVIATION IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com