Numerical control card-less rotary cutter

A technology of rotating motors and clamping mechanisms, which is applied in the manufacture of veneer, wood processing equipment, manufacturing tools, etc. It can solve the problems of round wood bending and vibration semi-automatic state, and achieve the effect of convenient operation and high wood utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

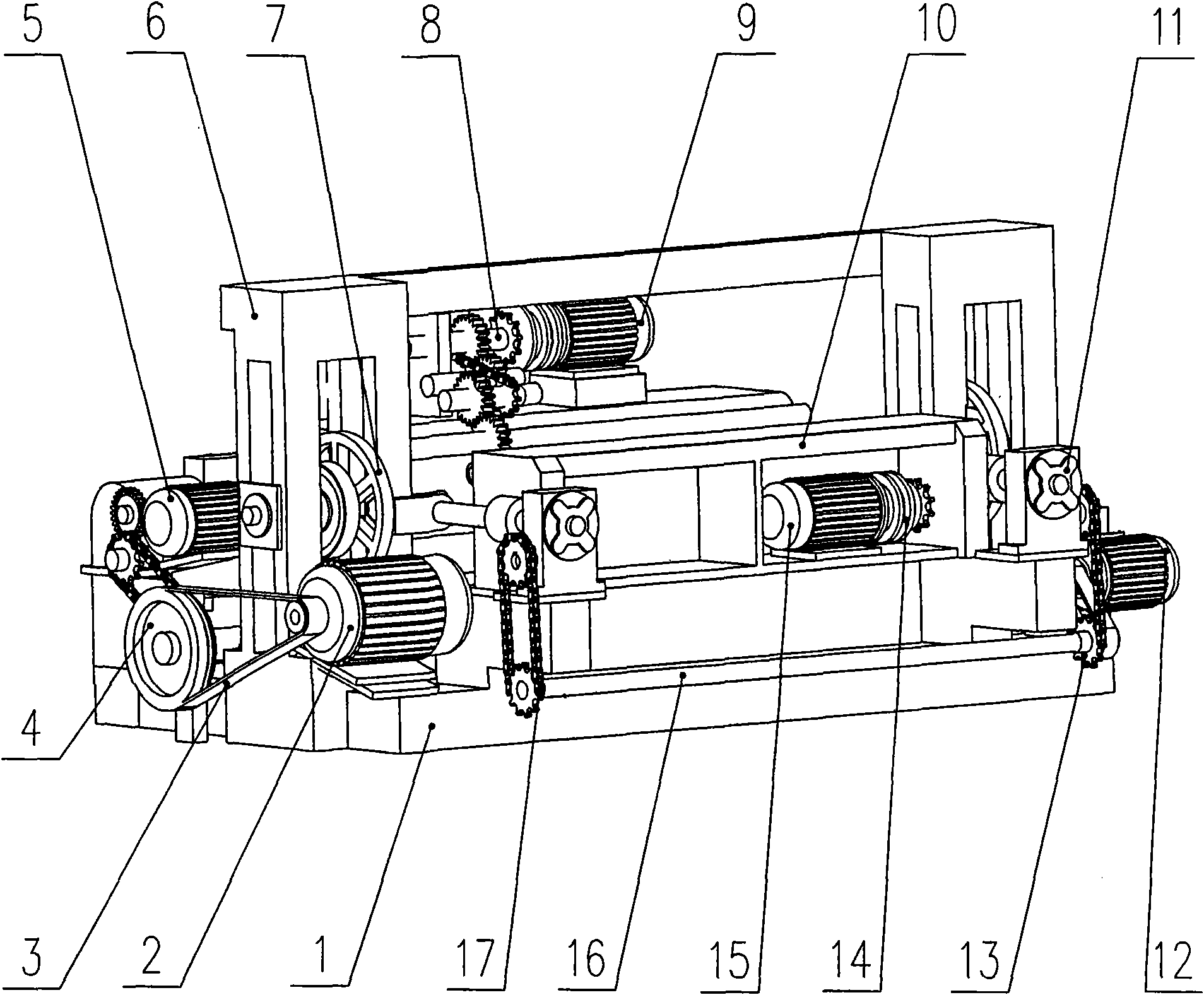

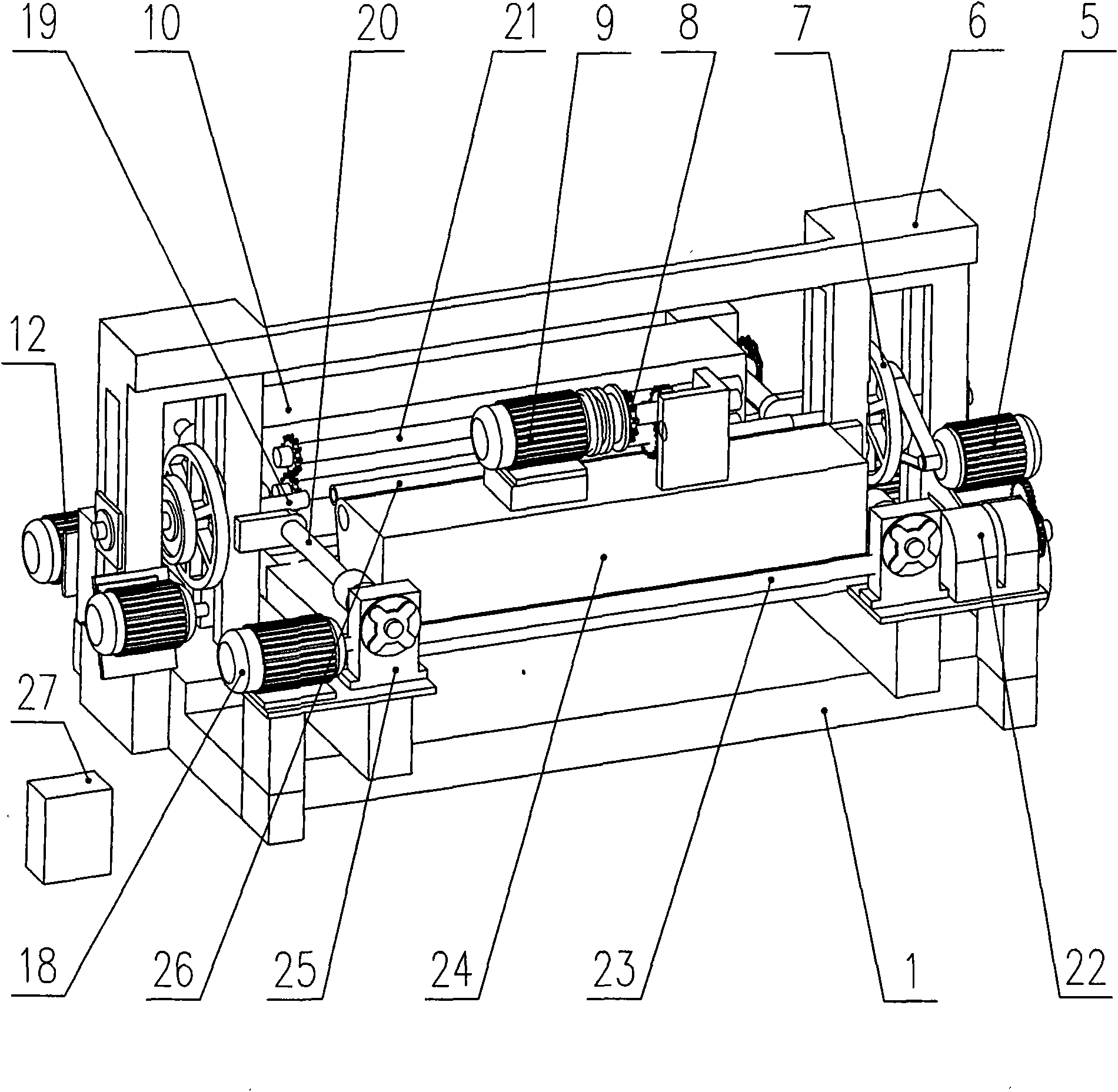

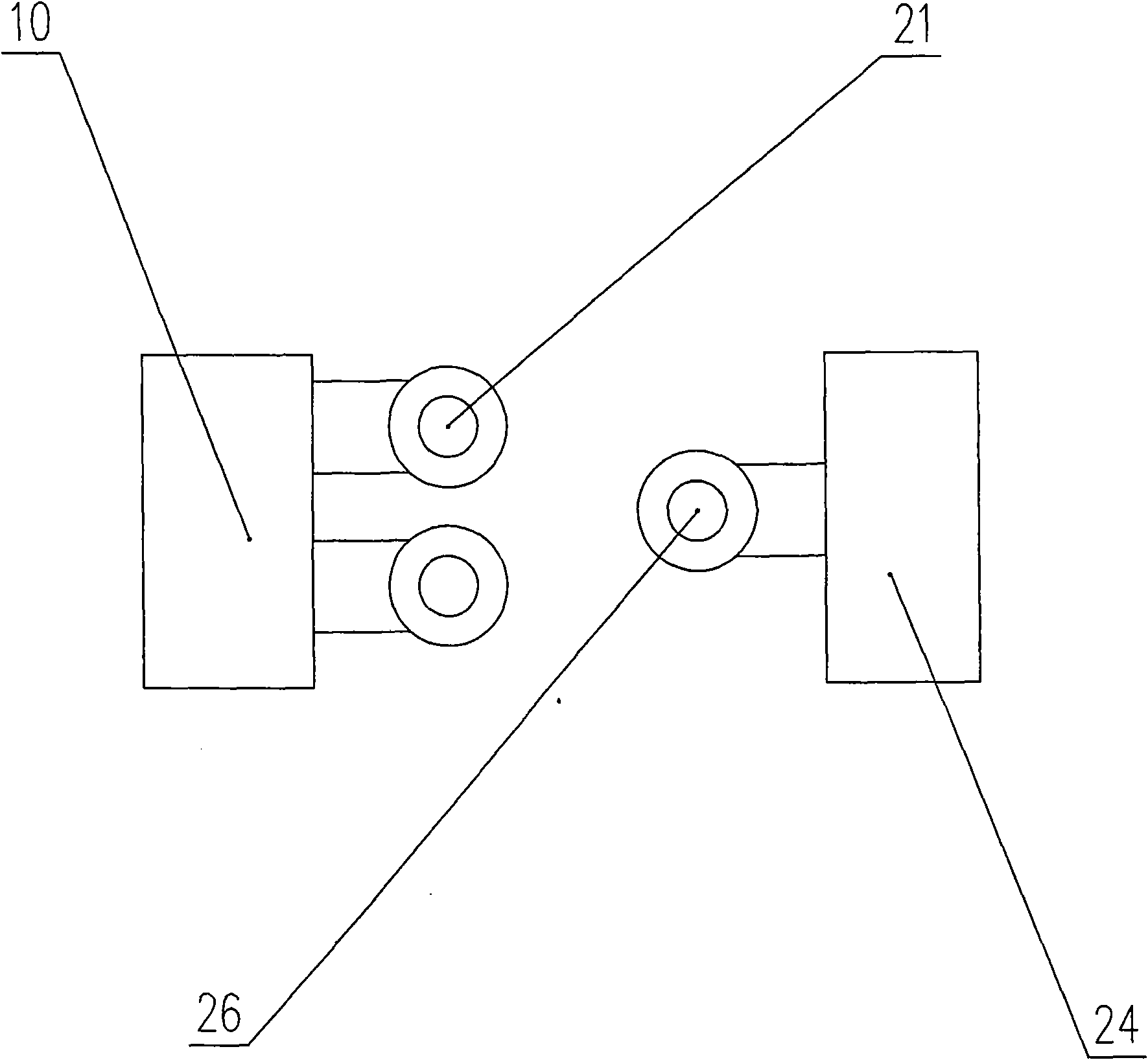

[0012] according to figure 1 , figure 2 and image 3 , the present invention comprises base 1, front and rear knife rests 10, 24, front and rear knife rest motion motors 12, 18, pressure rollers 21, 26, pressure roller speed change system 8 and pressure roller rotation motor 9; The vertical support 6 is provided with a log clamping mechanism composed of a clamping motor 5 and a clamping body 19 respectively on the vertical support 6, and the clamping motor 5 is connected with the clamping body 19 through a transmission shaft; the base 1 is provided with a knife table Slide rails, the two ends of the front and rear knife tables 10 and 24 are respectively arranged on the knife table slide rails through sliders, the sliders are set on the sliding screw 20, and the pressure roller speed change system 8 and the pressure roller rotation motor 9 are arranged on the rear knife table 24; the pressure roller is provided with two in parallel on the front knife table 10, and is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com