A packaging equipment suitable for high-generation liquid crystal glass substrates

A technology for liquid crystal glass substrates and glass substrates, applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of large floor space and high construction costs, reduce production line costs, speed up loading, and save construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

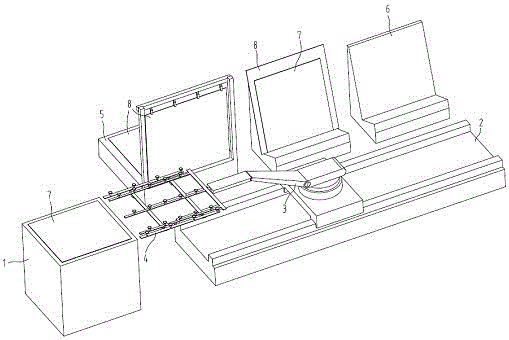

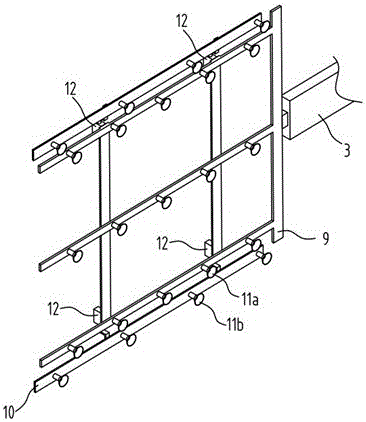

[0014] A packaging equipment suitable for high-generation liquid crystal glass substrates, including a glass substrate loading platform 1, a robot sliding table 2, a robot 3, a robot arm 4 connected to the robot, a paper loading mechanism 5, an A-frame 6, the robot arm 4 It includes a glass substrate suction cup holder 9 and a paper suction cup holder 10. The two holders are respectively provided with a glass substrate suction cup 11a and a paper suction cup 11b; the paper loading mechanism 5 includes a paper loading table 13, a bracket 14 with a guide, and a gripper moving Cross beam 15, air claw mounting bracket 16, air claw 17; the A-frame 6 is fixed on the ground by a positioning device.

[0015] The suction cup holder 10 is connected to the glass substrate suction cup holder 9 through the expansion cylinder 12.

[0016] The paper loading mechanism 5 and the A-frame 6 are arranged on the side of the robot sliding table 1.

[0017] Two or more of the A-frames 6 are arranged.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com