A Bearing Structure Using Supercritical Carbon Dioxide Lubrication

A carbon dioxide and supercritical technology, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of low viscosity, low bearing capacity, flutter of pad viscosity medium structure, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

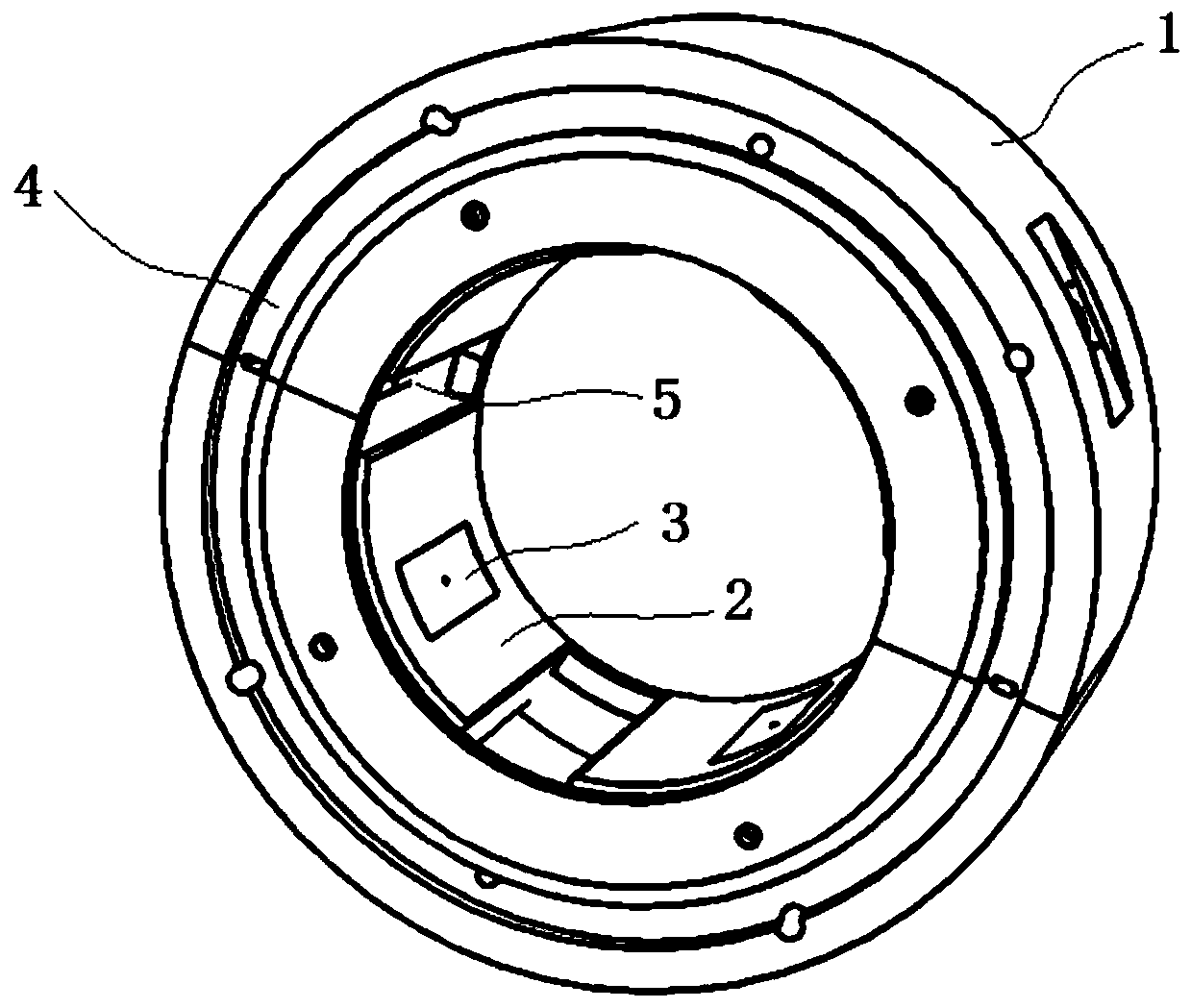

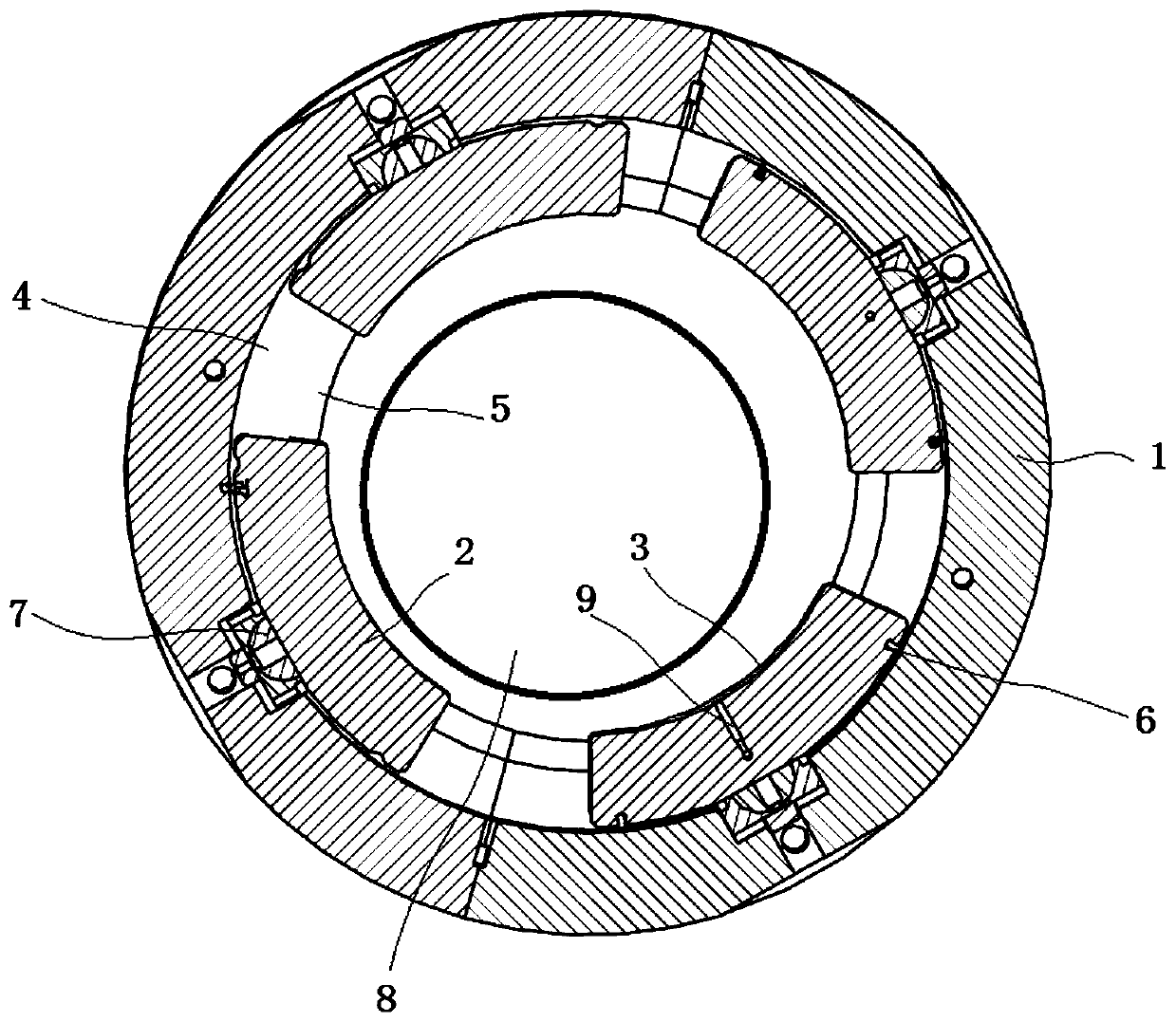

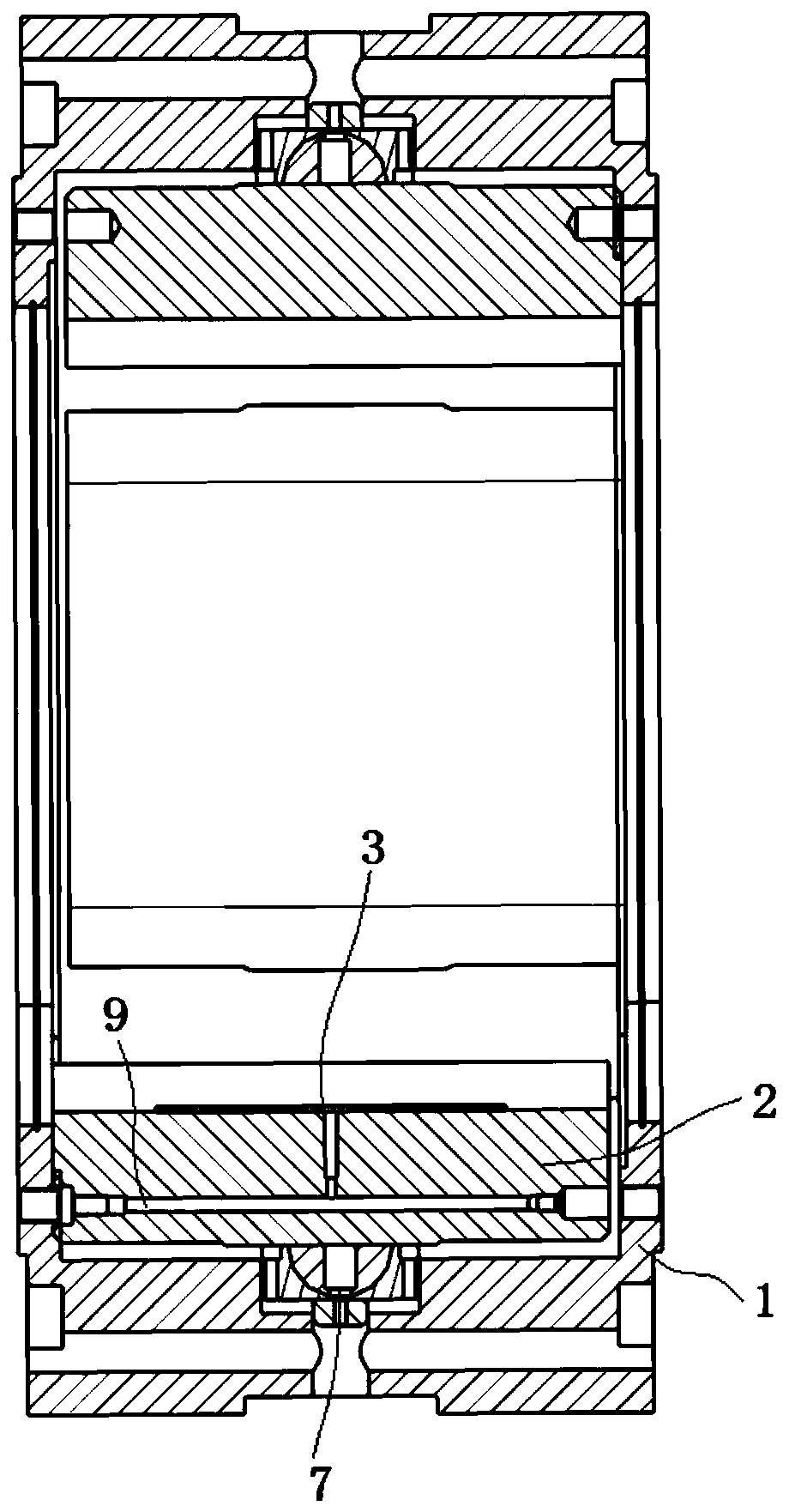

[0019] Such as Figure 1 to Figure 5 Shown: a bearing structure lubricated by supercritical carbon dioxide, including a bushing 1 and a tilting pad 2, the tilting pads 2 are four, arranged in the inner ring of the bushing 1; the lower part of the bearing can be tilted A controllable open support static pressure mechanism is installed on the tile block 2 . The controllable open support static pressure mechanism includes a static pressure bag 3 and a pressurized supercritical carbon dioxide channel 9; One end passes through the tiltable pad 2 and communicates with the static pressure bag 3, and the other end is connected with an adjustable pressurizing device.

[0020] The middle part of the back of the tiltable tile 2 is installed with a tile swing mechanism 7; the two ends behind the tiltable tile 2 are respectively equipped with swing damping blocks 6. The swing damping block 6 is a V-shaped rubber damping structure. There is a lubricating liquid inlet 5 between the tiltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com