Enhanced four-row cylindrical roller bearing

A cylindrical roller bearing, enhanced technology, applied in the direction of roller bearings, bearing components, shafts and bearings, etc., can solve problems such as large rolling force, exceeding the bearing load limit, and poor bearing working conditions, so as to solve the problem of bearing capacity Low, meet the use requirements, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

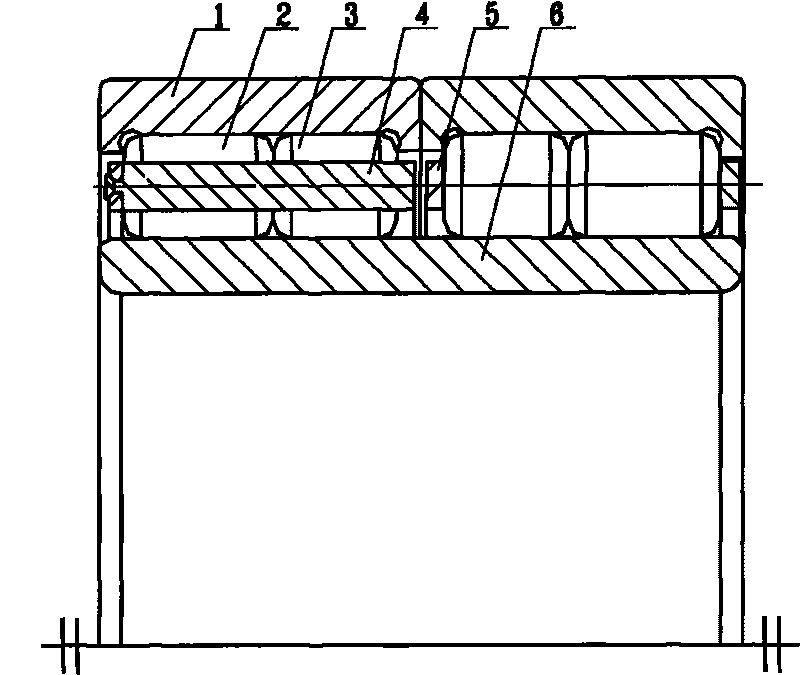

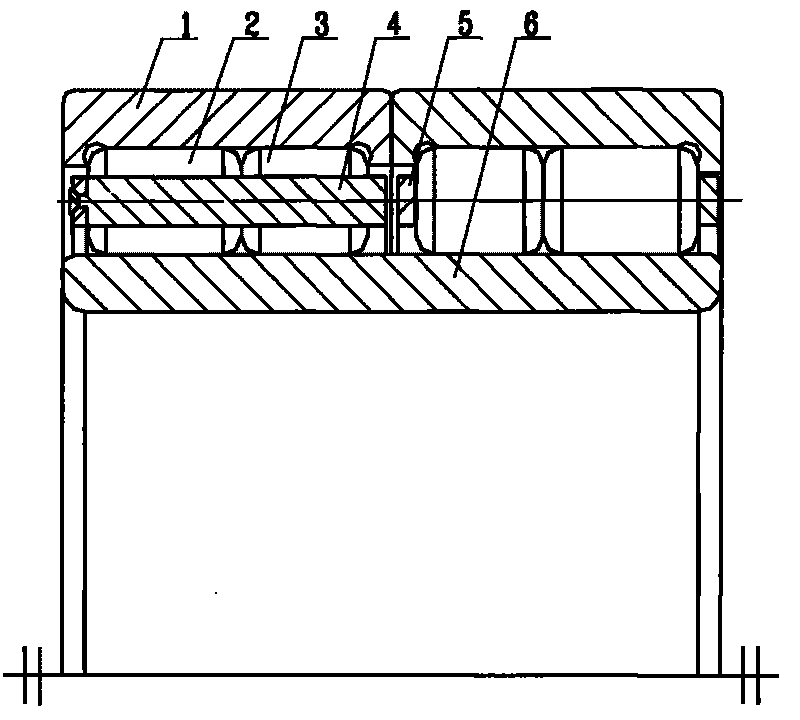

[0010] Such as figure 1 As shown, the reinforced four-row cylindrical roller bearing includes outer ring 1, long roller 2, short roller 3, cage seat 4, cage cover 5 and inner ring 6. The long rollers 2 and short rollers 3 are installed in the outer ring 1 alternately, the cage seat 4 separates the long rollers 2 and the short rollers 3 evenly, the cage seat 4 and the cage cover 5 are riveted, and the outer ring 1. Long roller 2, short roller 3, cage seat 4, and cage cover 5 form the outer assembly, and the inner ring 6 is freely installed in the outer assembly to form a complete set of bearings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com