Rotary piston cylinder

A technology of rotating pistons and cylinders, applied in the field of piston cylinders, can solve the problems of low energy conversion efficiency, high sealing difficulty, low power frequency, etc., and achieve the effects of excellent clutch braking performance, wide torque output range and wide power range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

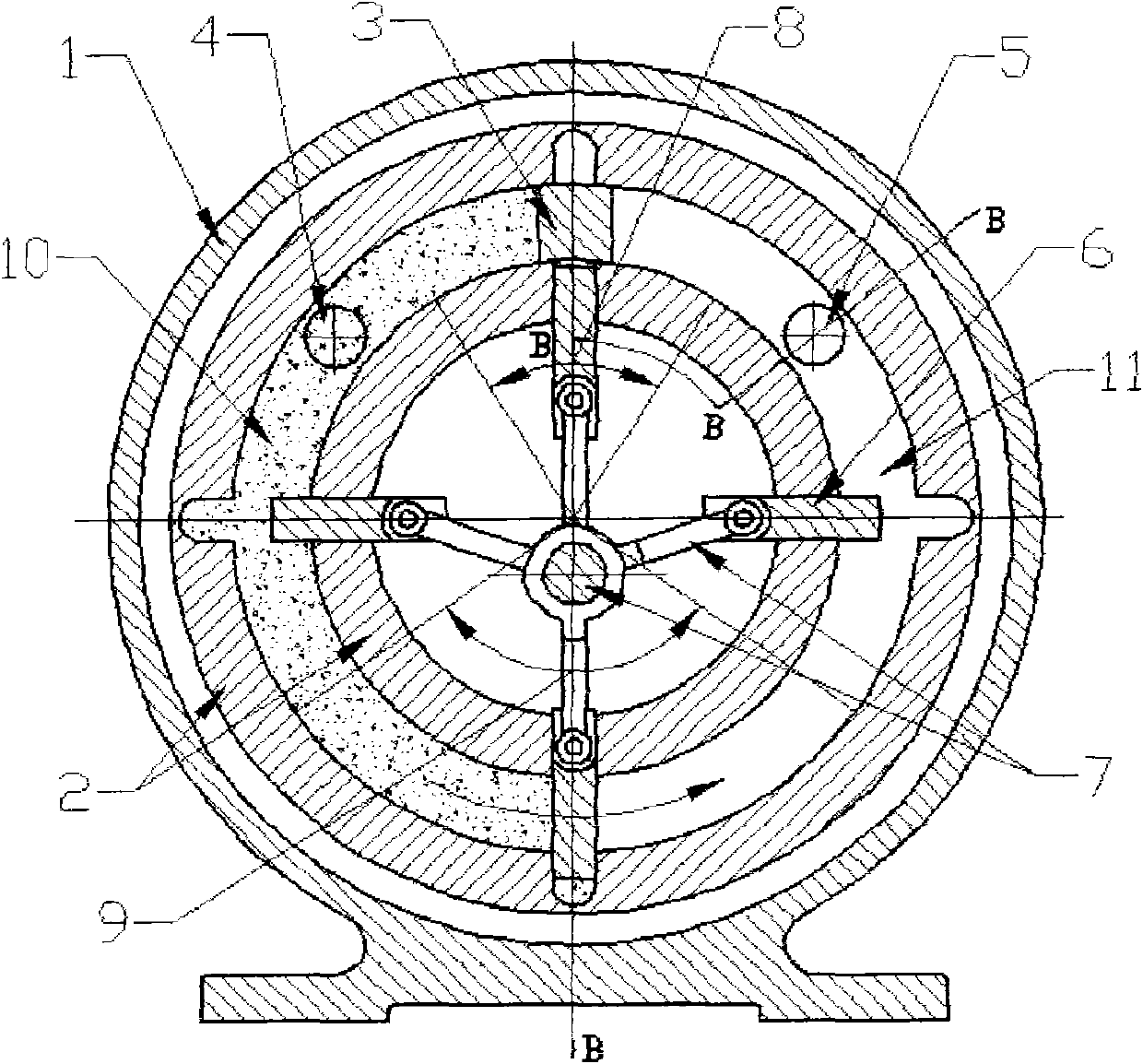

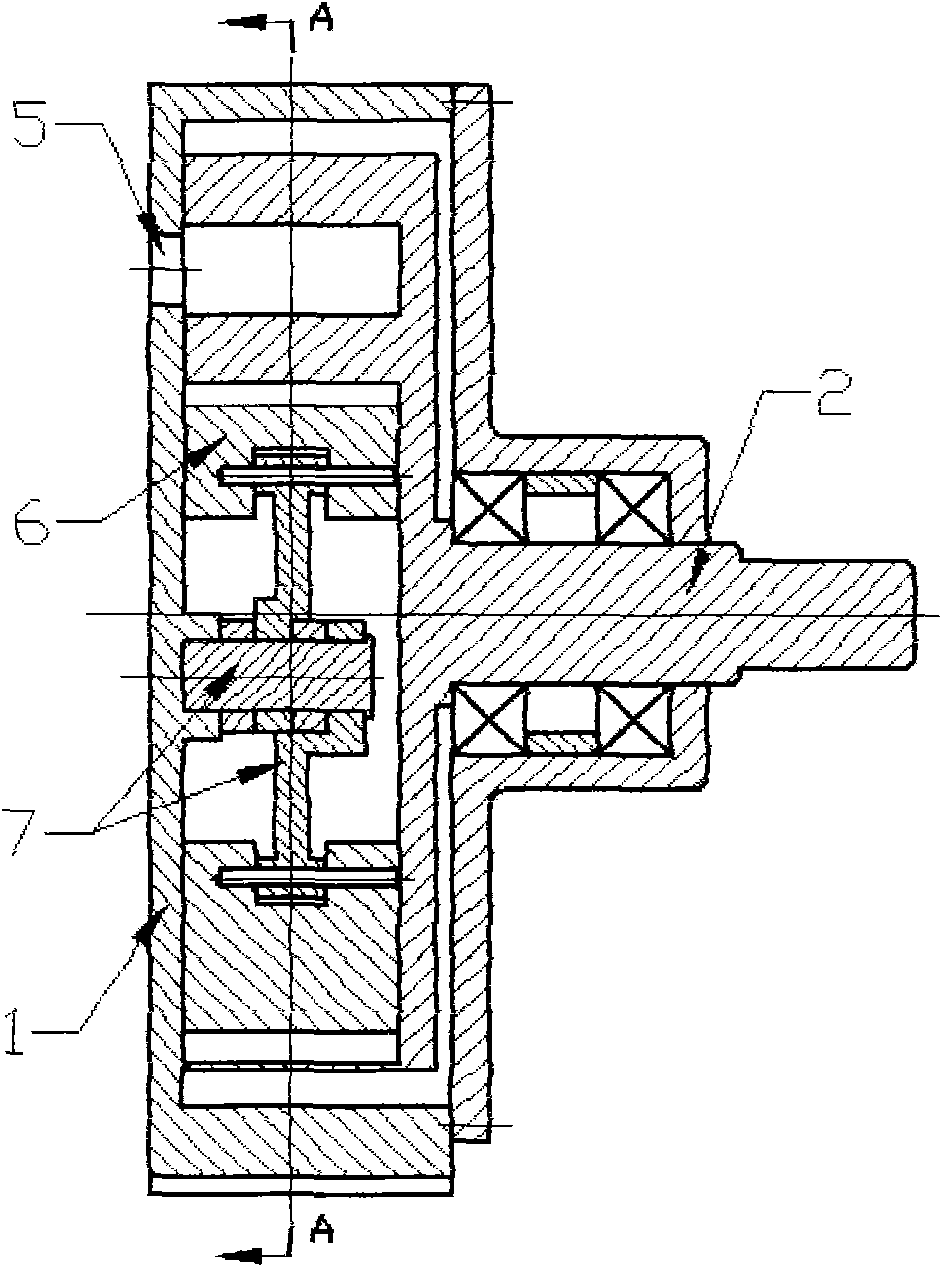

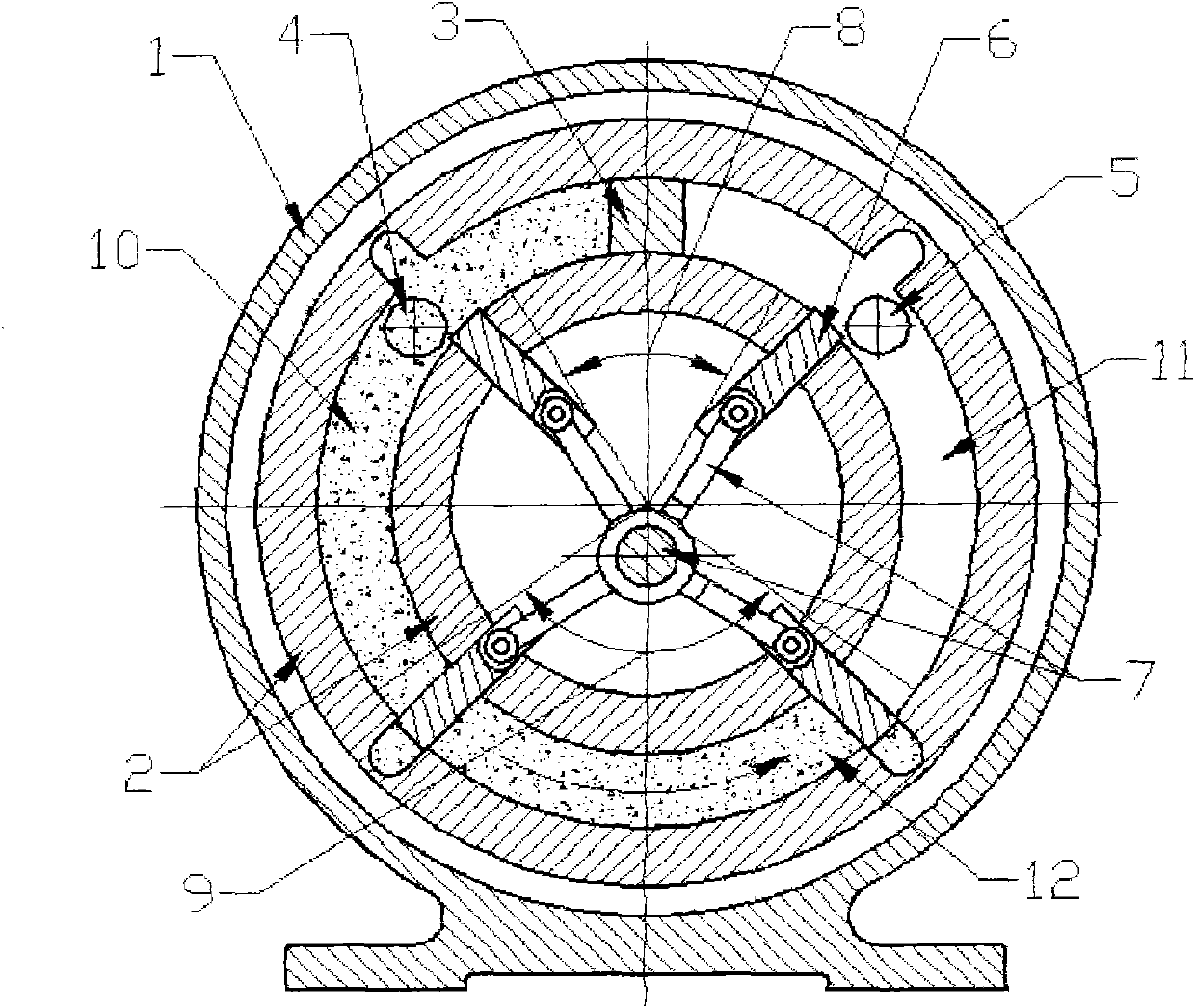

[0022] Such as figure 1 figure 2 As shown, because when the rotary piston 6 is outside the packing angle 9, the radial pressure will generate reaction torque through the crankshaft linkage mechanism 7, which will cause fluctuations in the output, and increase the normal effective bearing area and radial area of the rotary piston 6 Increasing the ratio of the connecting rod length to the eccentricity will reduce the magnitude of this effect; increasing the number of rotary pistons 6 can reduce the eccentricity and the size of the body, but more than 3 will increase the magnitude of the fluctuation and the difficulty of processing And cost, so the number of rotary piston 6 is advisable with 3 or 4.

[0023] Rotary ring 6 is set in a sheet shape, with small radial anti-torque, stable output, and large load-carrying capacity; however, the ease of processing, sealing and lubricity are slightly worse than those of the columnar shape.

[0024] The partition plate 3, the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com