Neutron Generators for Measurements While Drilling

A neutron generator and measurement-while-drilling technology, which is applied in oil and natural gas drilling fields, to achieve the effect of prolonging working time, solving the instability of neutron production and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

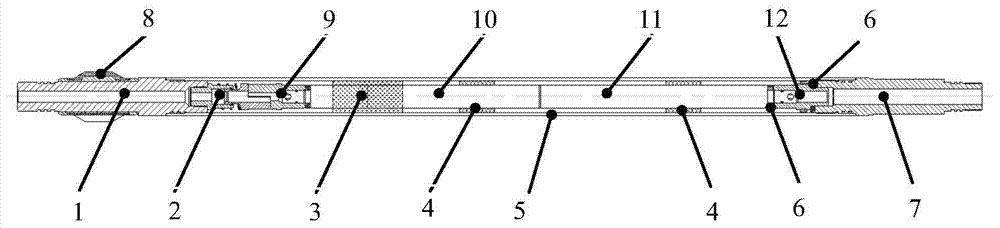

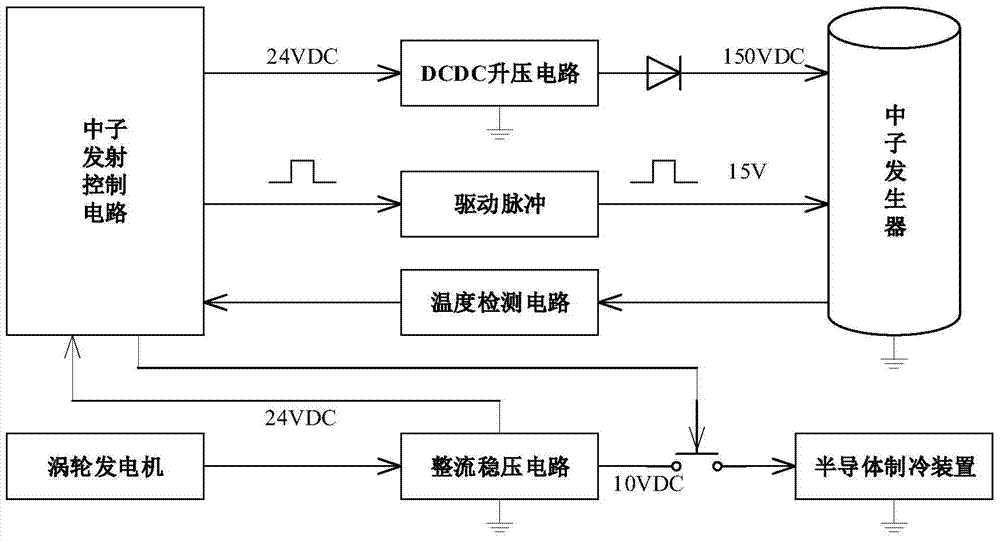

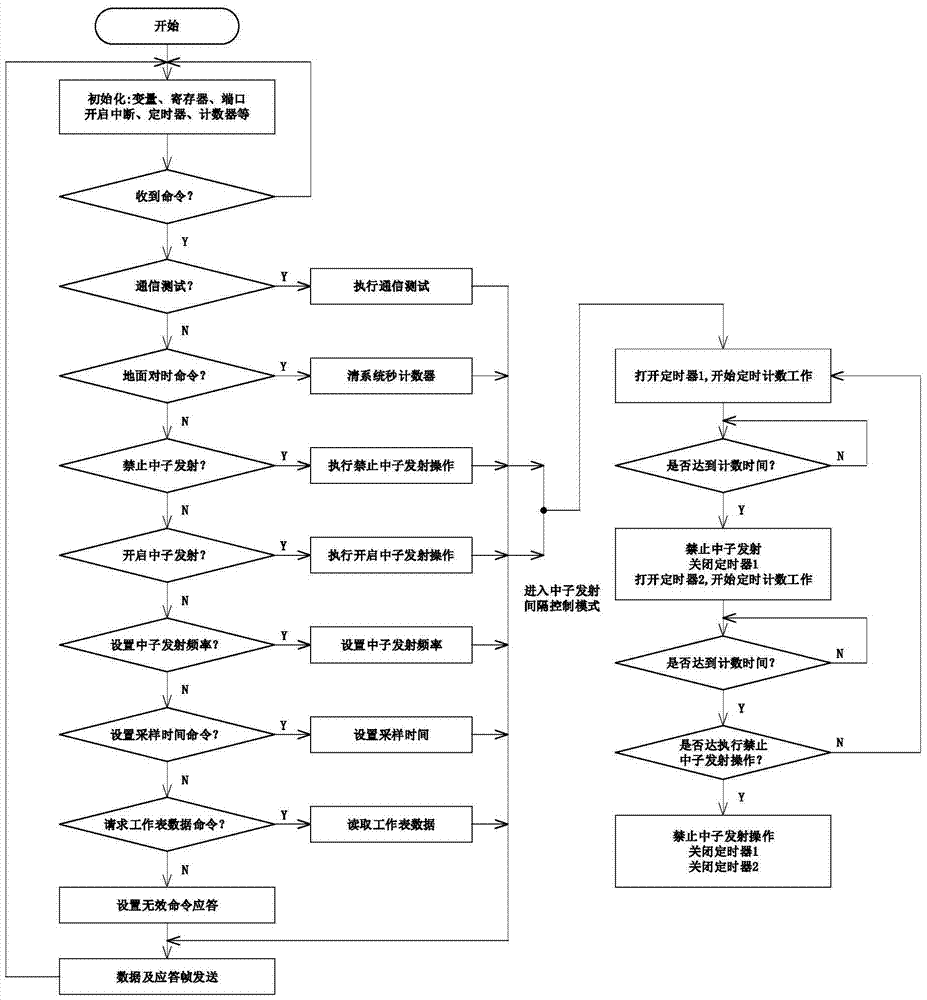

[0014] Hereinafter, the implementation of the technical solution will be further described in detail with reference to the accompanying drawings.

[0015] Those skilled in the art can understand that although the following description relates to many technical details related to the embodiments of the present invention, this is only an example for illustrating the principle of the present invention, and does not imply any limitation. The present invention can be applied to occasions other than the technical details exemplified below, as long as they do not deviate from the principle and spirit of the present invention.

[0016] In addition, in order to avoid limiting the description of this specification to cumbersomeness, in the description of this specification, some technical details that can be obtained in the prior art materials may be omitted, simplified, modified, etc., which is important to the technology in the field. It is understandable for personnel, and this will not a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com