Semi-automatic five-shaft dividing and cutting machine

A semi-automatic, shaft-splitting technology, used in metal processing and other directions, can solve problems such as chatter vibration and let the knife, and achieve the effect of solving chatter vibration, reducing processing time and improving cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

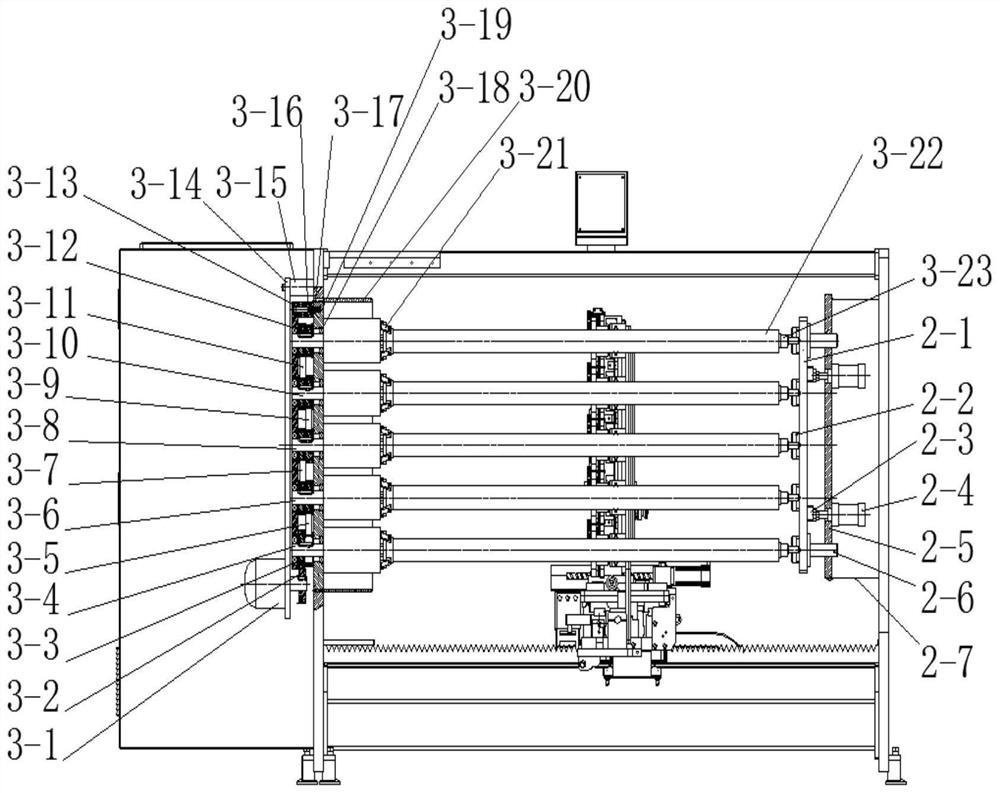

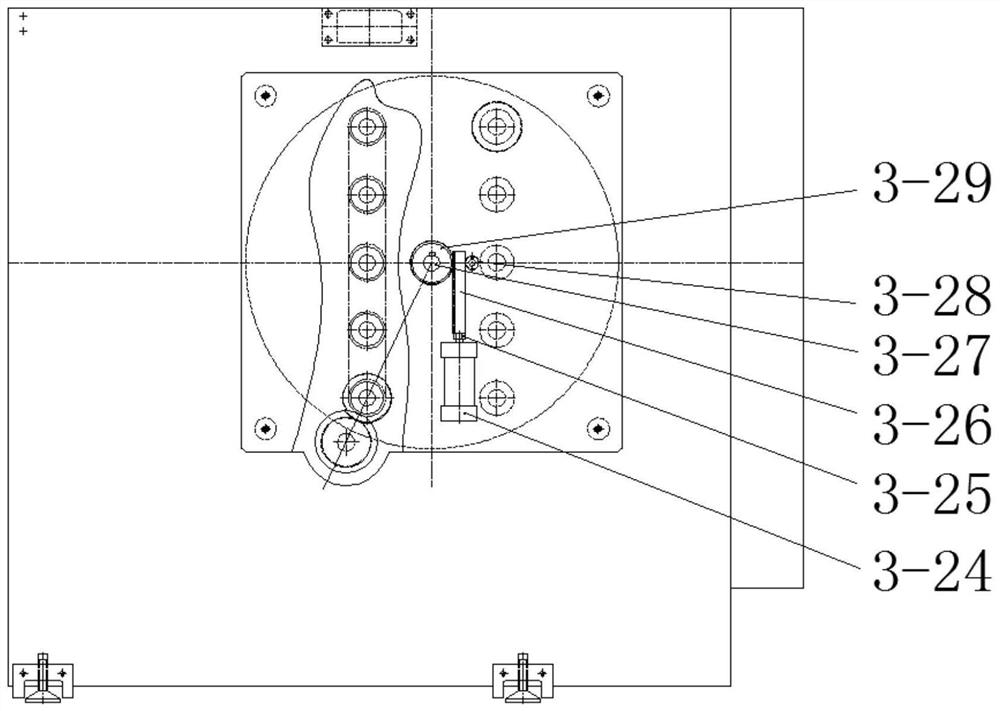

[0024] Attached below Figure 1-4 The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

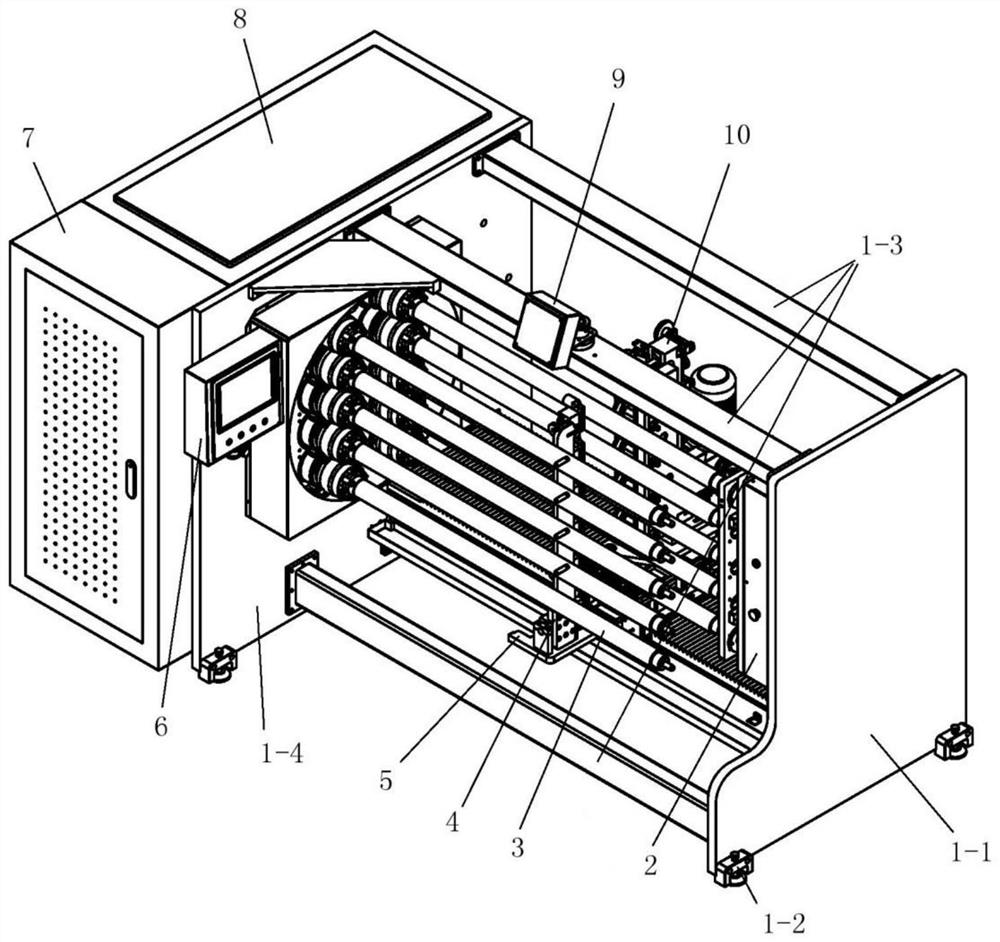

[0025] A semi-automatic five-axis slitting machine, comprising a frame 1, a shaft support member 2, a rotating shaft member 3, a support wheel member 4, a cutting mobile platform 5, a control panel 6, an electrical box 7, a drive box 8, a display 9, a cutting Part 10, the frame 1 is connected by three square pipes 1-3 to the right wall panel 1-1 and the left wall panel 1-4, and the left end of the rotating shaft part 3 is installed on the left wall panel 1-4 of the frame 1 In the large round hole on the upper side, the shaft support member 2 is arranged on the right wall panel 1-1 of the frame 1, the support wheel member 4 is adapted to the cutting member 10, and the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com