Hydrostatic nut pair with internal variable throttling function

A nut pair, static pressure technology, applied in the direction of transmission, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of unstable throttling characteristics, affecting transmission accuracy, increasing nut length, etc., to achieve throttling performance Good, avoid the oil supply line, reduce the length of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

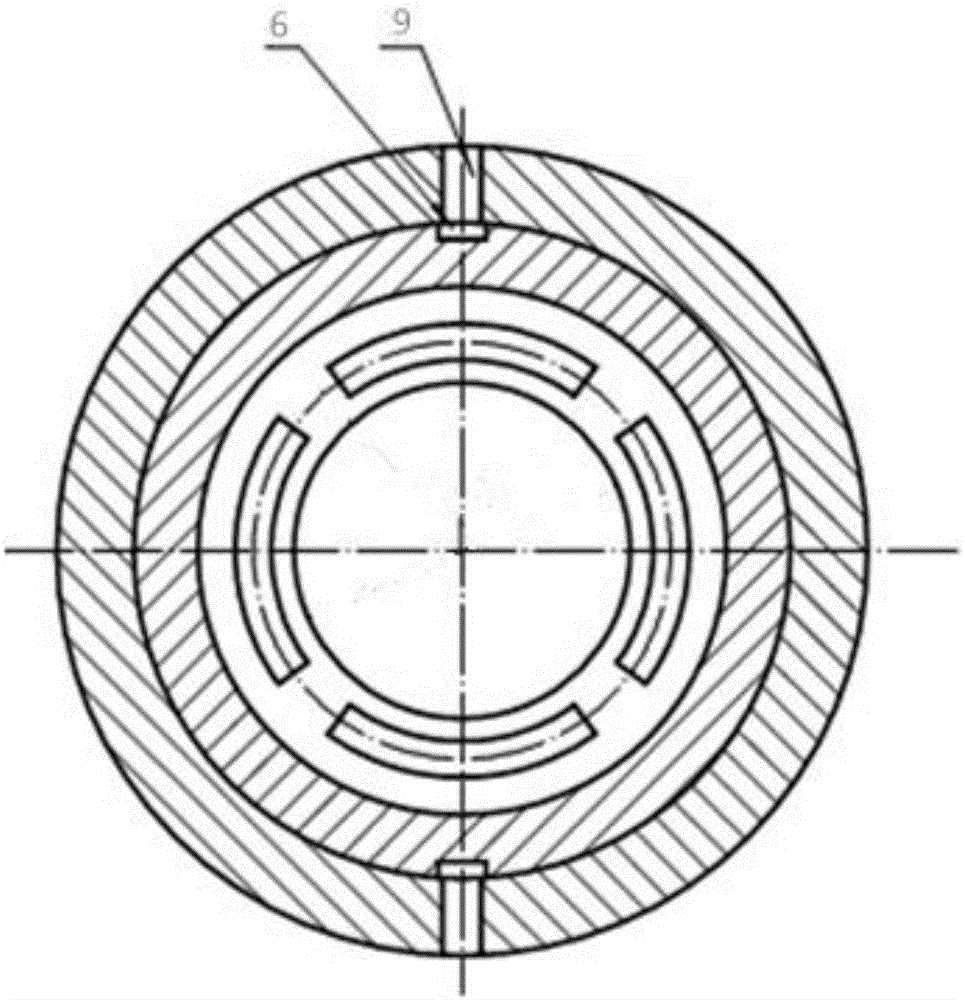

[0029] The invention provides an internal variable throttle static pressure nut pair, such as Figure 1-2 As shown, including matching lead screw 1 and nut 2, wherein:

[0030] The two sides of each internal thread tooth surface of the nut 2 have a first oil chamber 3 and a second oil chamber 4 respectively. A hydrostatic oil film is formed between the sides;

[0031] The first oil chamber 3 and the second oil chamber 4 are projected into a trapezoidal sector in the radial cross-section, and grooves 5 communicating with the first oil chamber 3 and the second oil chamber 4 are provided on the outer circle of the nut 2 at the teeth of the internal thread. A movable throttling part 7 is installed in the groove 5, and the throttling part 7 includes a slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com