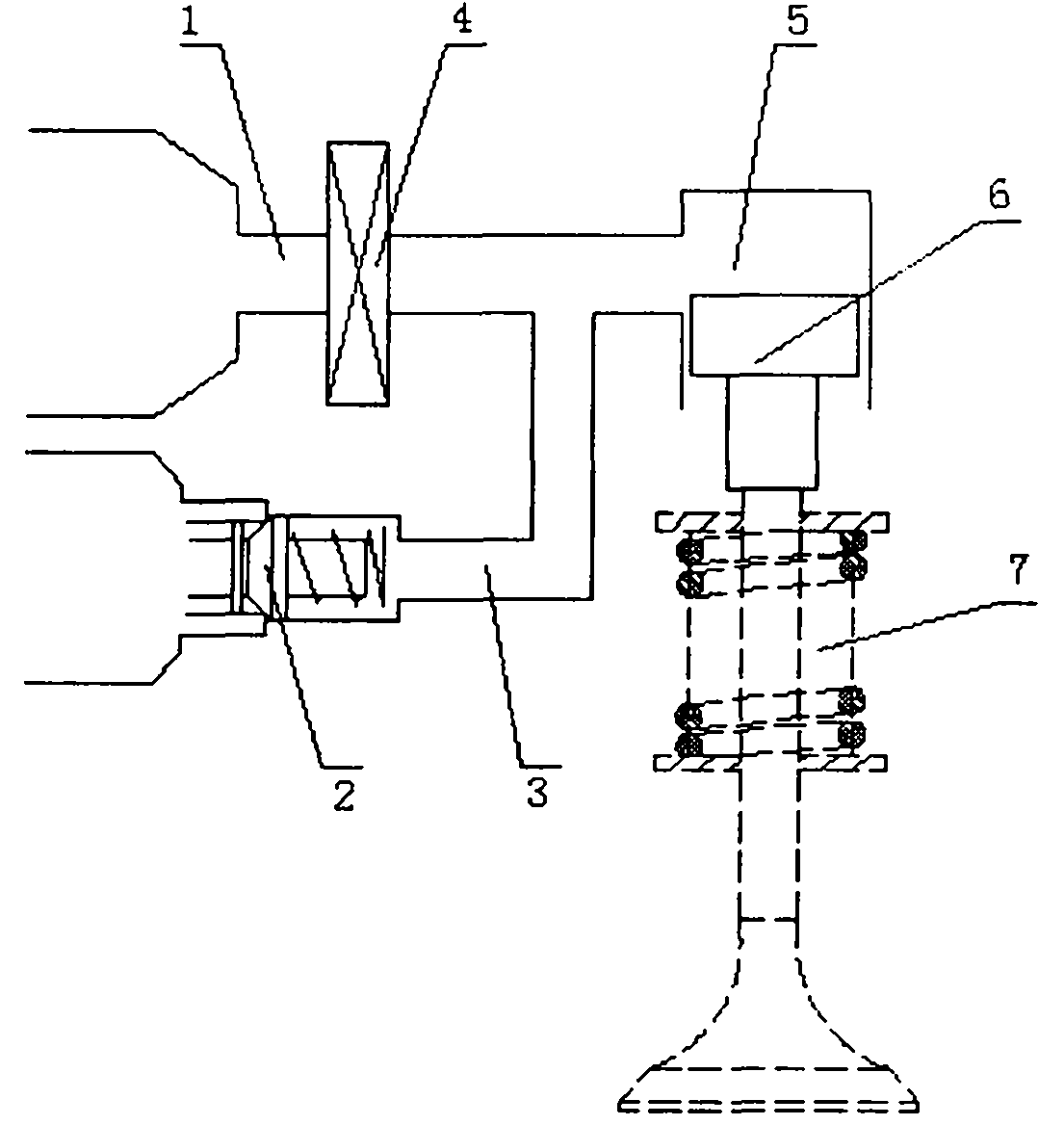

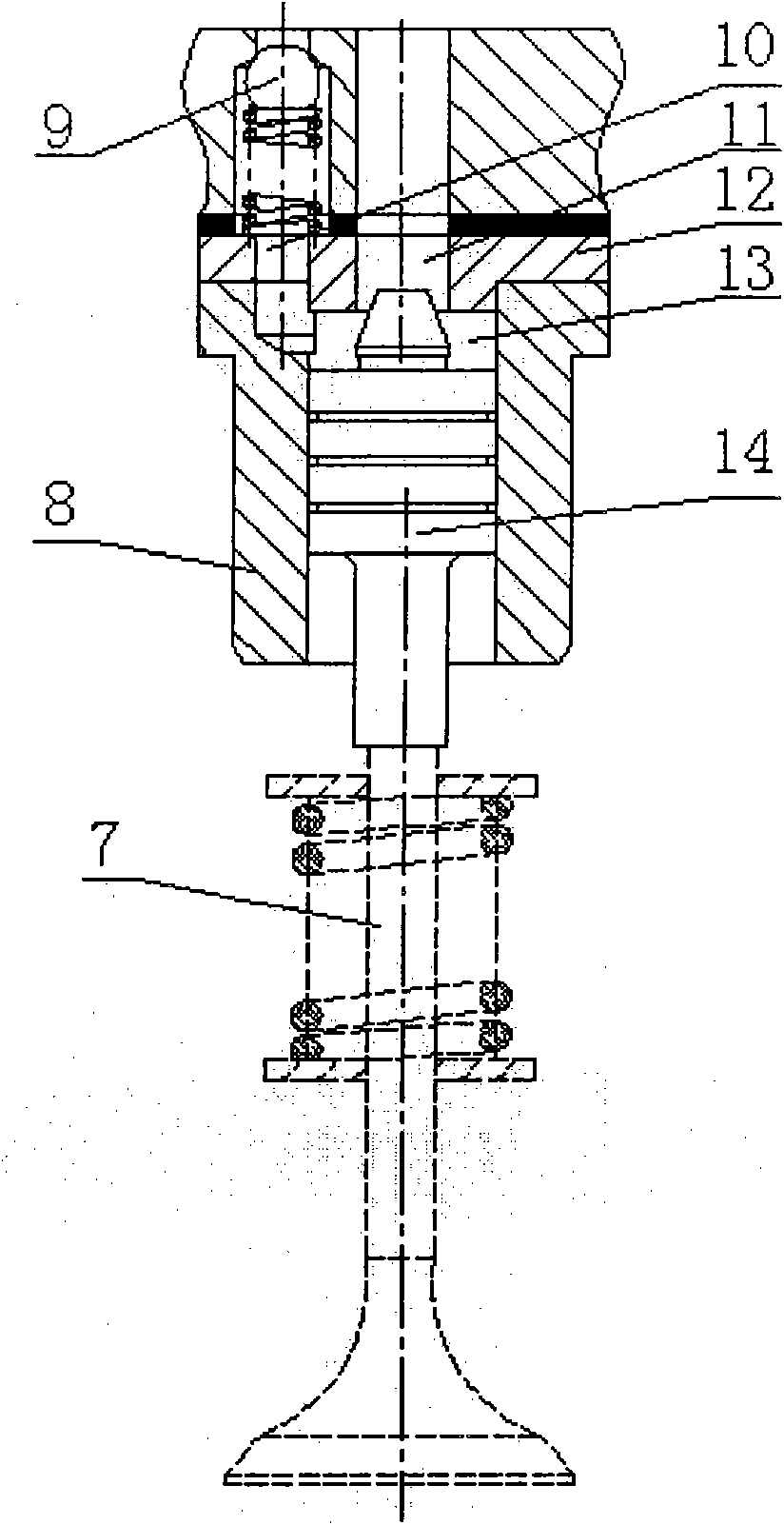

Air valve seating control device for hydraulic drive air valve mechanism of engine

A valve mechanism and control device technology, applied in engine components, machines/engines, valve devices, etc., can solve the problems of valve U-turn, high valve seating speed, valve seat impact, etc., and achieve the effect of stable seating and reasonable flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

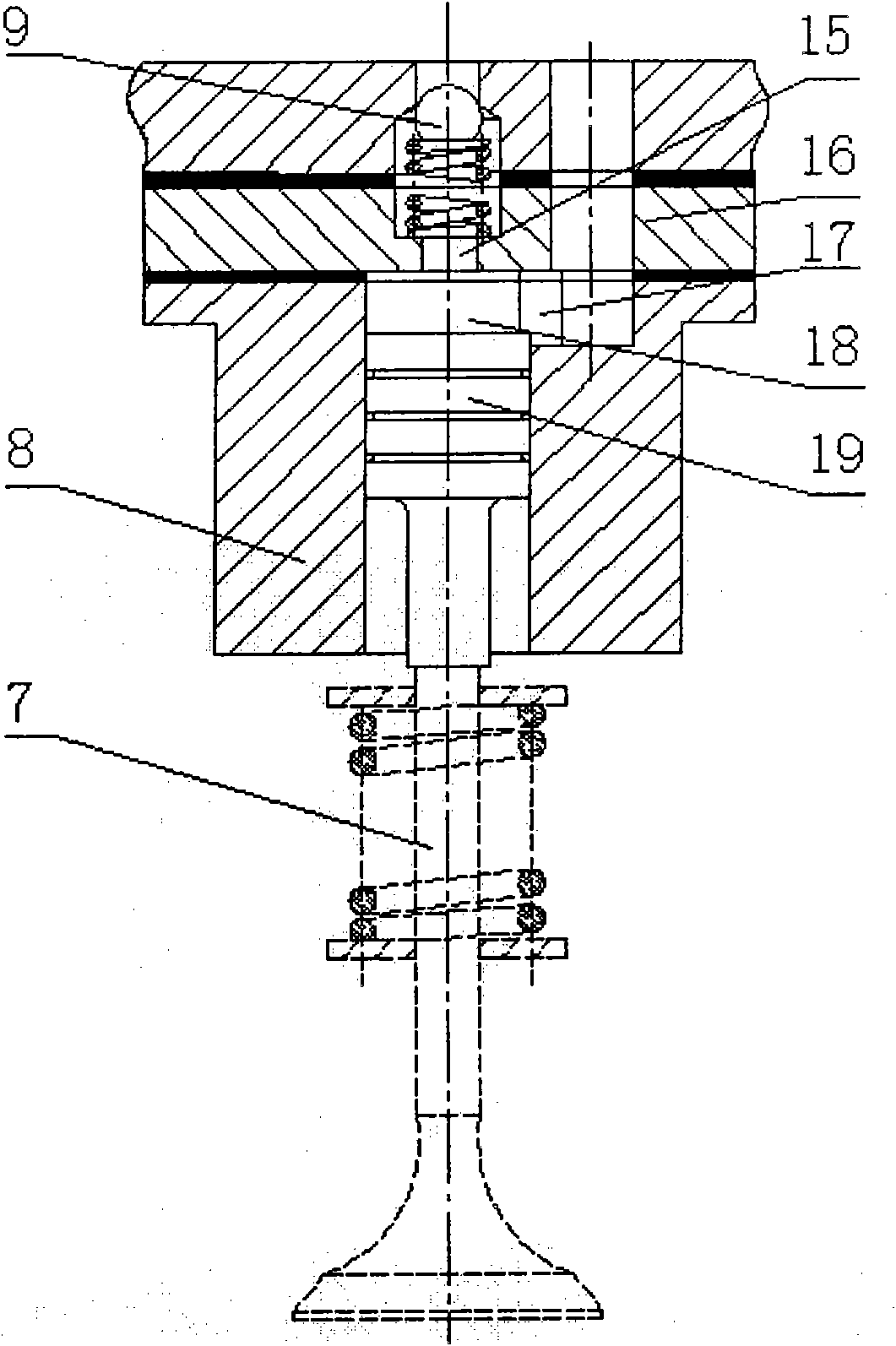

specific Embodiment 2

[0017] Such as image 3 As shown, the check valve 9 is installed in the bypass oil passage 15; the variable throttle passage is composed of the outer circular side of the flat top piston 19 and the side oil passage hole 17 on the piston sleeve 8, and controls the minimum flow area of the main oil passage ; The piston cavity 18 is formed by the piston 19, the piston sleeve 8 and the piston sleeve cover 16. The piston cavity 18 is connected with the hydraulic system through the bypass oil passage 15 and the main oil passage provided with the side oil passage hole 17 . Its specific working process is as follows:

[0018] The first stage is the valve opening process. In this process, the working process of the device can be divided into two periods. In the first period, because the piston 19 covers most of the area of the side oil passage hole 17 to form a variable throttling passage, the flow area of the variable throttling passage is small at this time, and the throttli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com