Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Work normally for a long time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

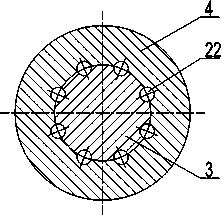

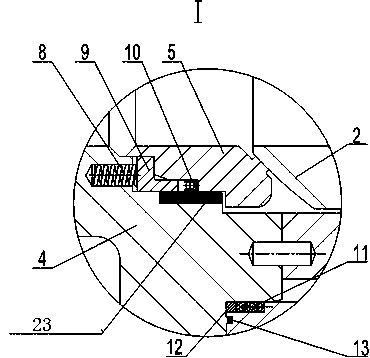

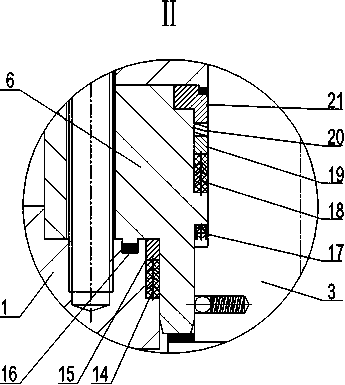

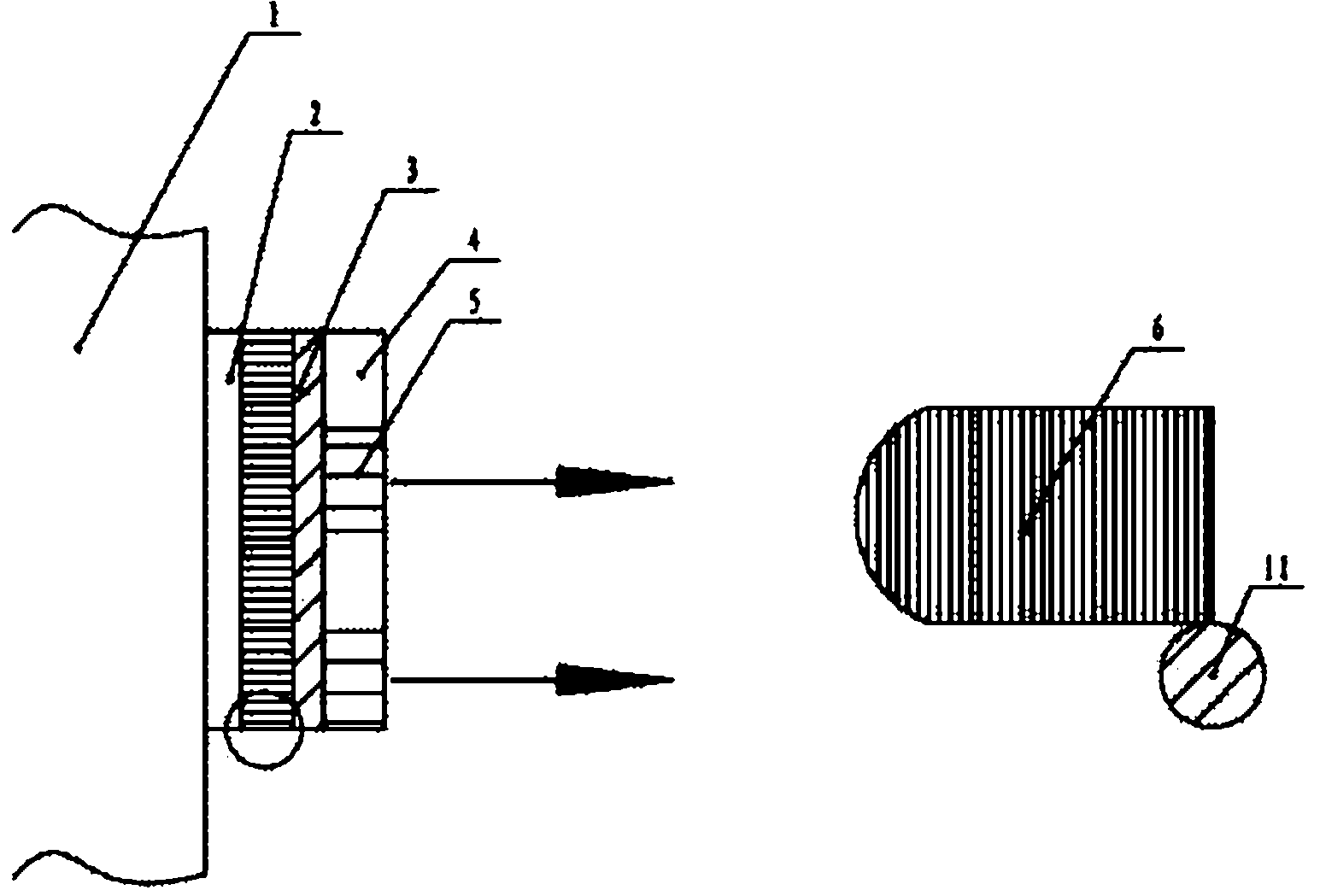

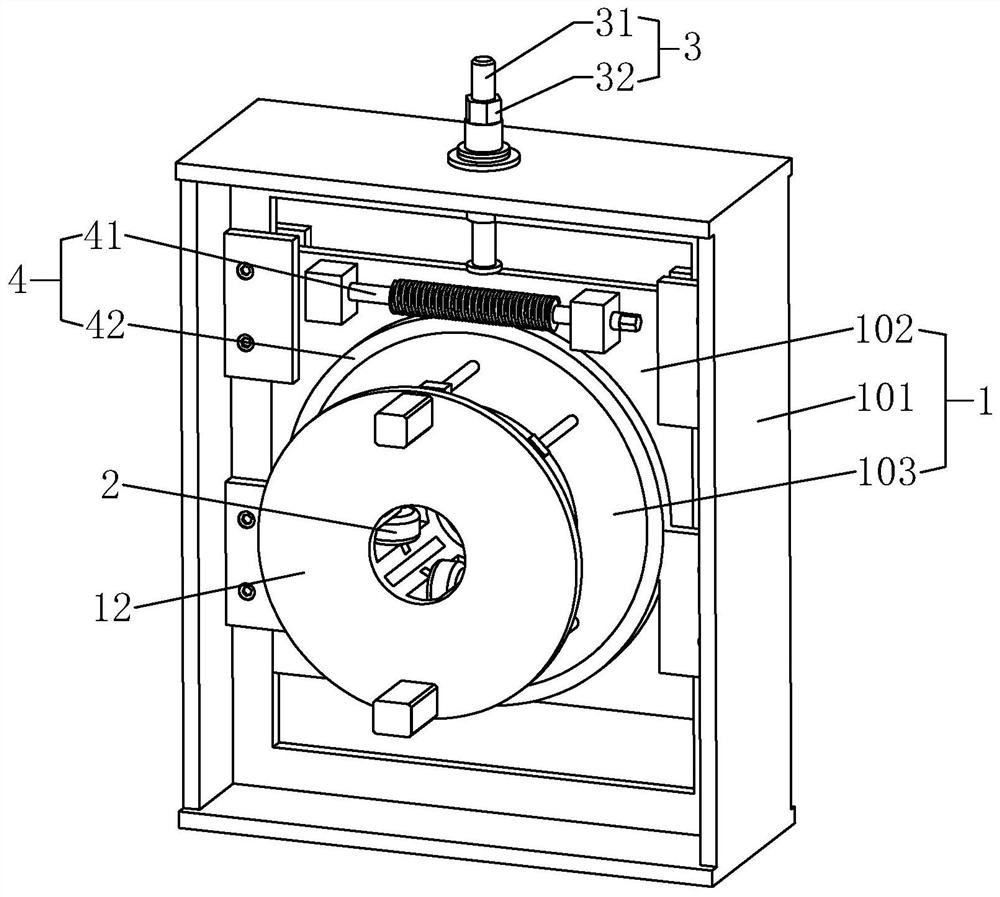

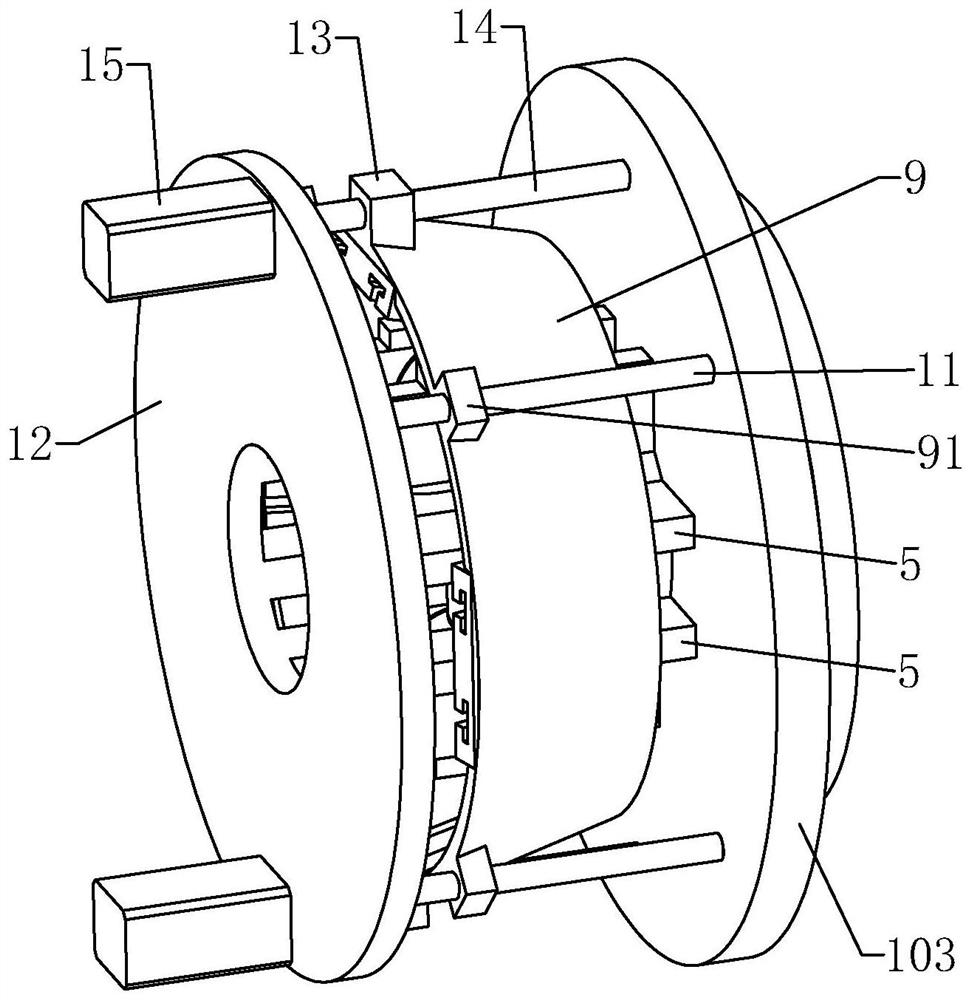

Metal rigidity seal ball valve

PendingCN108895175AGuaranteed service lifeWork normally for a long timePlug valvesValve housingsElastic componentEngineering

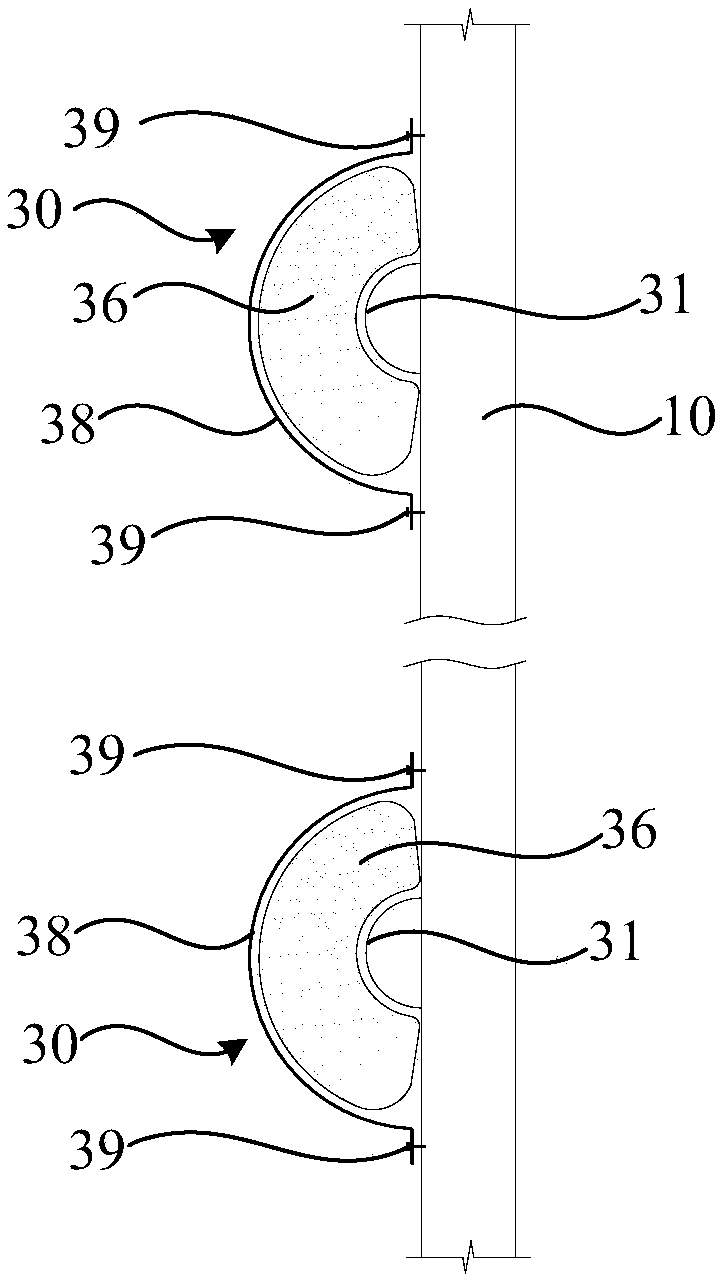

The invention discloses a metal rigidity seal ball valve which comprises a valve, a valve seat, a valve stem and a ball. The ball is positioned in a ball cavity in the valve; the valve seat comprisesa left valve seat and a right valve seat, the left valve seat and the right valve seat are symmetrically arranged on two sides of the ball, and scraper mechanisms are arranged at the positions, whichare butted to the ball, of the valve seat; seal surfaces between the valve seat and the valve are in the shapes of multiple levels of steps which are matched with one another, and a first sealing assembly is arranged between every two corresponding seal surfaces; each first seal assembly comprises a first elastic component, a clamping component and a first seal ring; the clamping components are provided with L-shaped axial sections, two ends of each first elastic component are butted to the valve and a vertical arm of the corresponding L-shaped clamping component, a corner of each L-shaped clamping component is clamped on one of the levels of steps of the corresponding seal surface of the valve seat, the first seal rings are mounted between the tail ends of transverse arms of the L-shapedclamping components and the seal surfaces of the valve seat, and metal protection layers are arranged on the seal surfaces of the valve and are positioned on the outer sides of the first seal rings. The metal rigidity seal ball valve has the advantages that seal structures on the seal surfaces are improved, accordingly, seal effects can be enhanced, the service lives of seal components can be prolonged, elastic components can be protected, and the metal rigidity seal ball valve is particularly applicable to working conditions with crude oil used as a medium.

Owner:KUSN WEISA VALVE

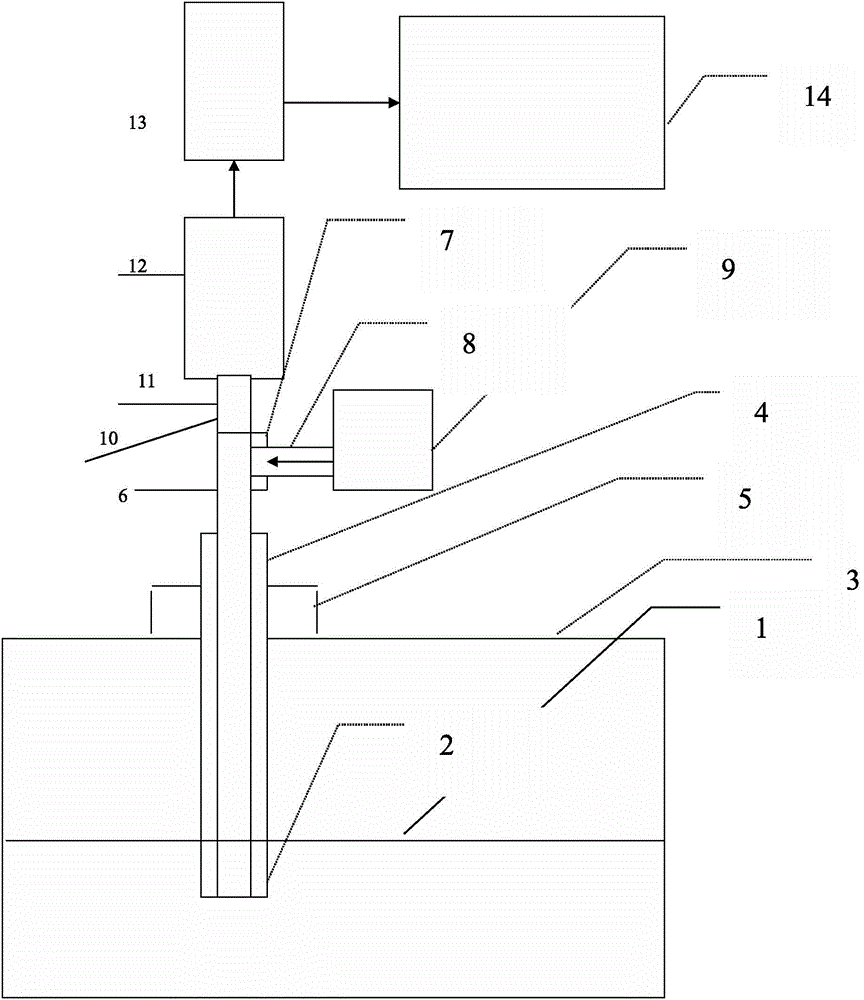

Self-powered wireless temperature field measuring device in closed rotating shaft

InactiveCN102384793AWork normally for a long timeLong term workThermometers using electric/magnetic elementsUsing electrical meansInfraredMicro structure

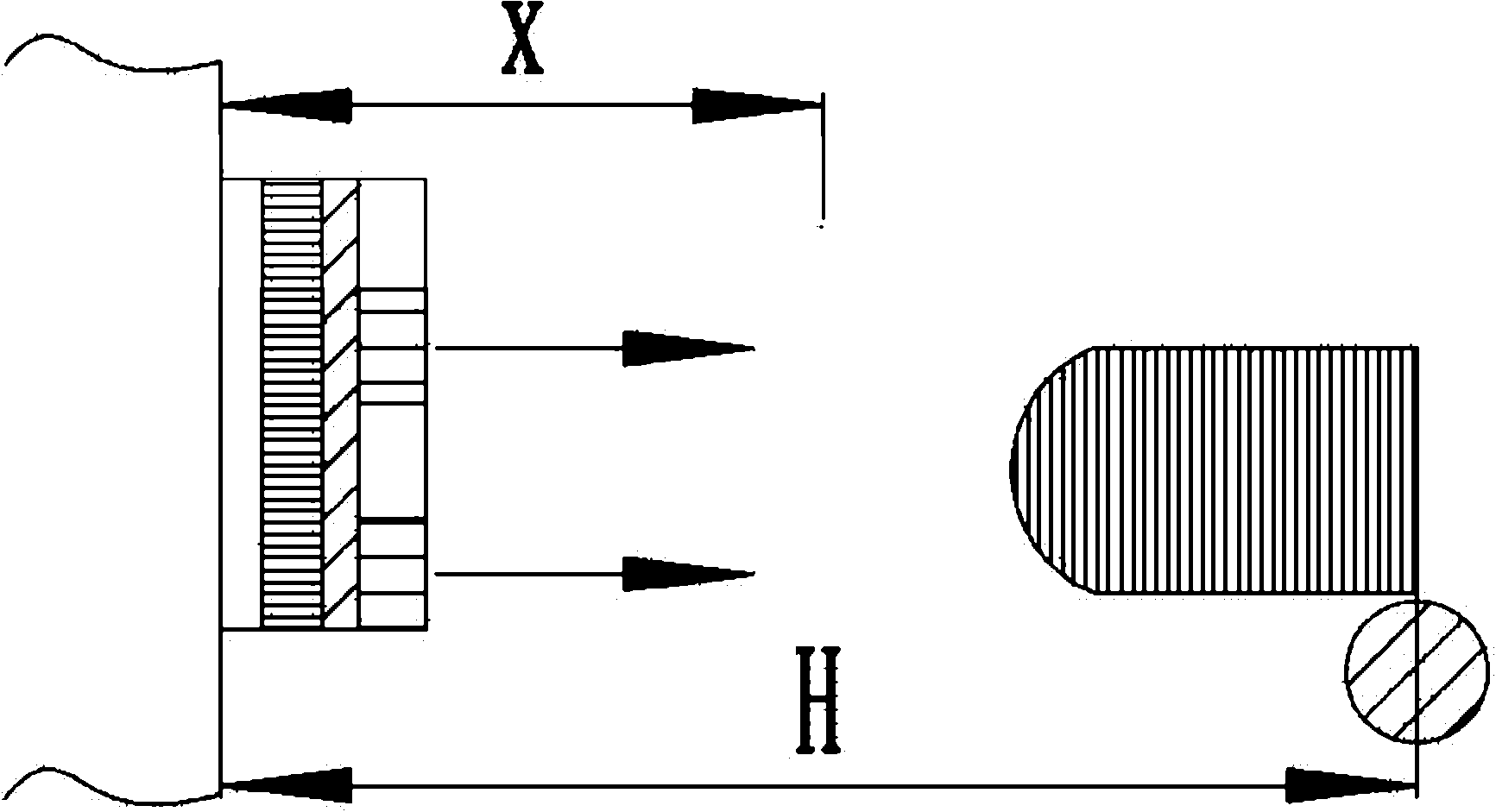

The invention discloses a self-powered wireless temperature field measuring device in a closed rotating shaft. The device comprises a hot end tightly attached to the inner surface of the closed rotating shaft, a cold end exposed in the air and connected with a radiator, a self-powered component arranged between the hot end and the cold end and consisting of a closed loop formed by connecting n semiconductor pairs in series, an infrared transmitter for transmitting infrared signals of fixed wavelength, an infrared receiving device provided with a reference temperature sensor and a calculation and output device. By adopting a micro structure design, the device can be conveniently arranged on the inner surface of a closed shaft series part; and measurement of the radial temperature field in the high-speed closed rotating shaft is realized by self-powered wireless transmission, a power supply for supplying energy is not needed, and the measuring device can work normally for a long term under an unattended environment by using heat energy.

Owner:ZHEJIANG UNIV

Contact totally closed contactor

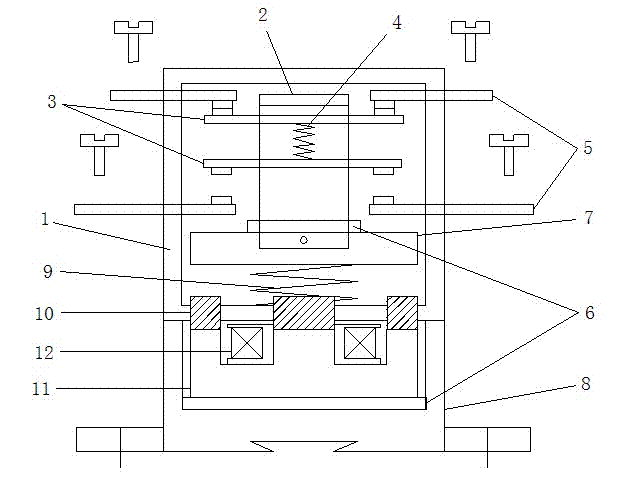

InactiveCN103247478ASolve the problem of magnetic field conductionAvoid enteringElectromagnetic relay detailsEngineeringMethane gas

The invention discloses a contact totally closed contactor which comprises movable contacts, a movable contact bracket, a movable contact spring, fixed contacts, an armature, a base, a buffer spring, a static iron core and electromagnetic coils, and further comprises a housing, wherein the movable contacts, the movable contact bracket, the movable contact spring, the armature and the buffer spring are sealed in the housing; one end of each of the fixed contacts extends into the housing, and the other end thereof extends out of the housing; a magnetic transitional iron core is arranged between the housing and the base; and the lower end of the magnetic transitional iron core penetrates the housing to be in contact with the static iron core, and the upper end penetrates the housing to be protruded below the armature. According to the invention, the movable contacts, the movable contact bracket, the movable contact spring, the armature and the buffer spring are sealed in the housing, the magnetic transitional iron core serves as a magnetic field conduction mechanism, so as to isolate the interior of the contactor from the outside, which in turn avoids entering of dusts and other impurities; and accordingly, the spark generated during contact of the contacts can not ignite methane gas and other inflammable and explosive gases so as to avoid potential safety hazards.

Owner:田春

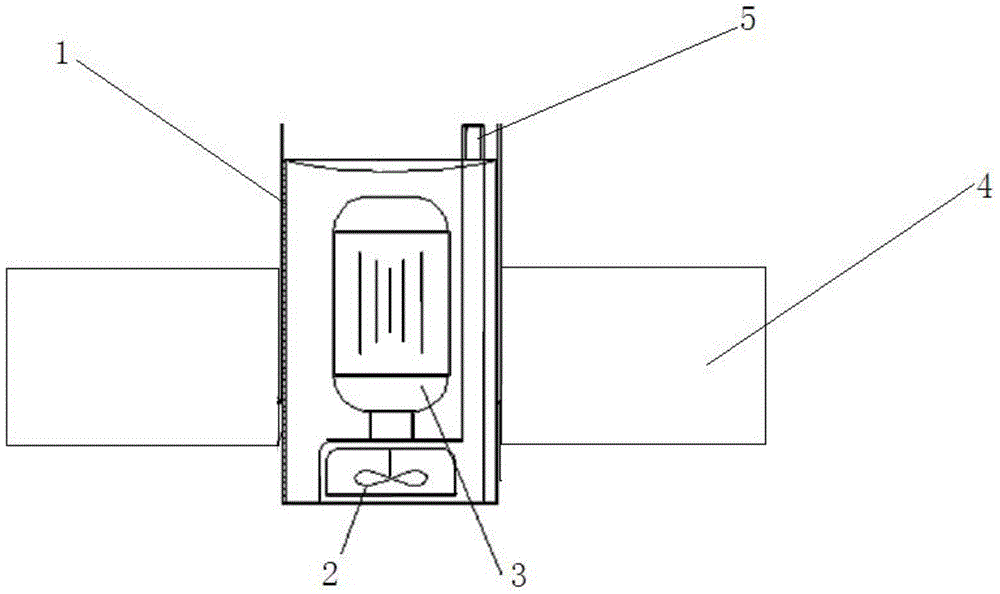

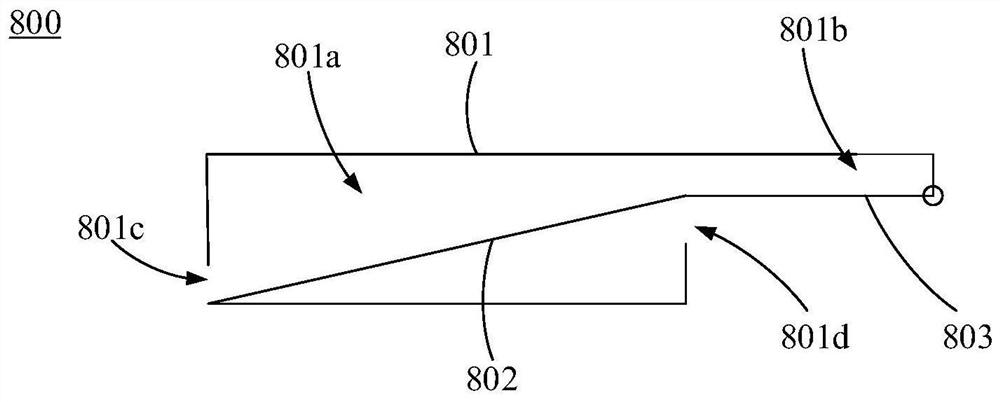

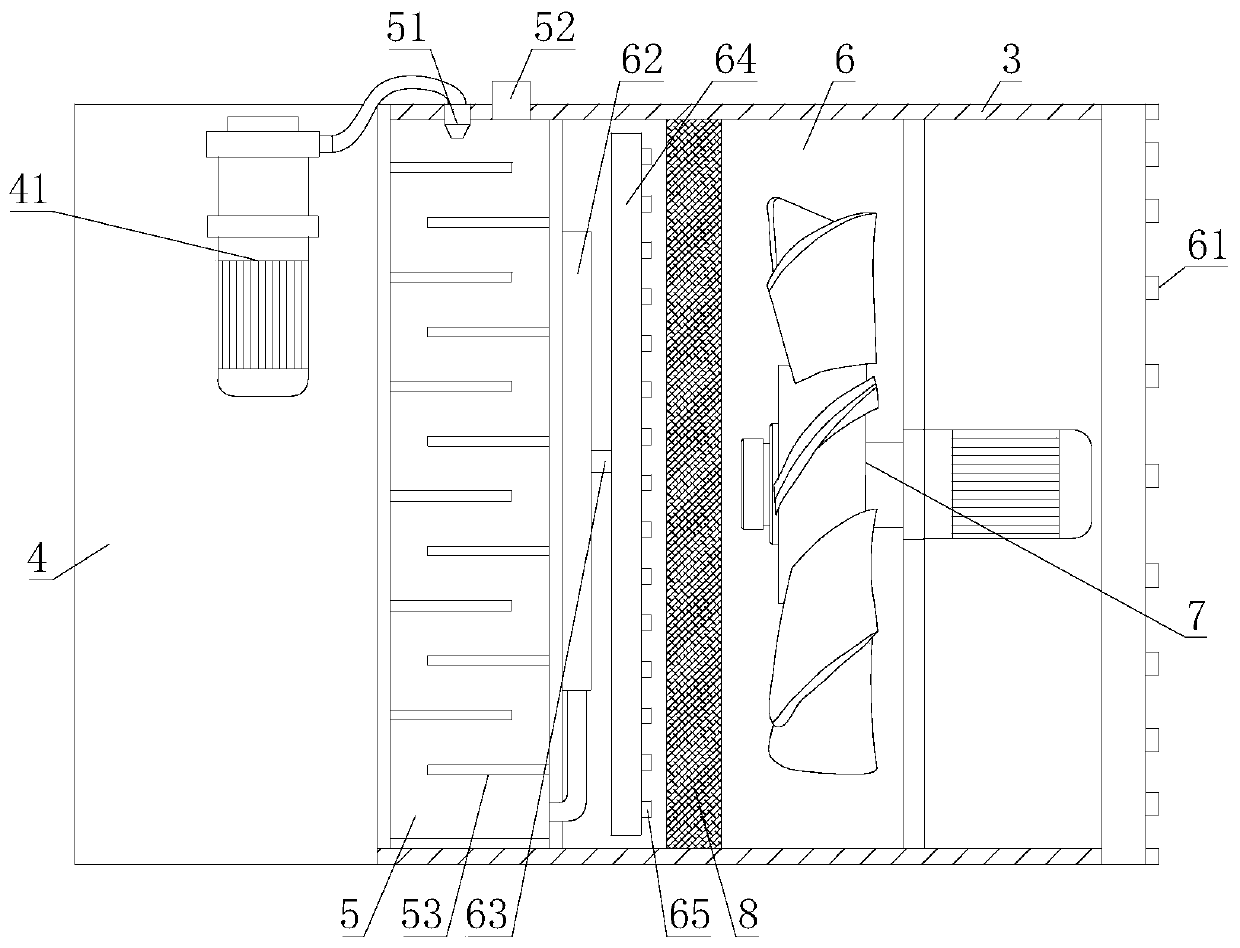

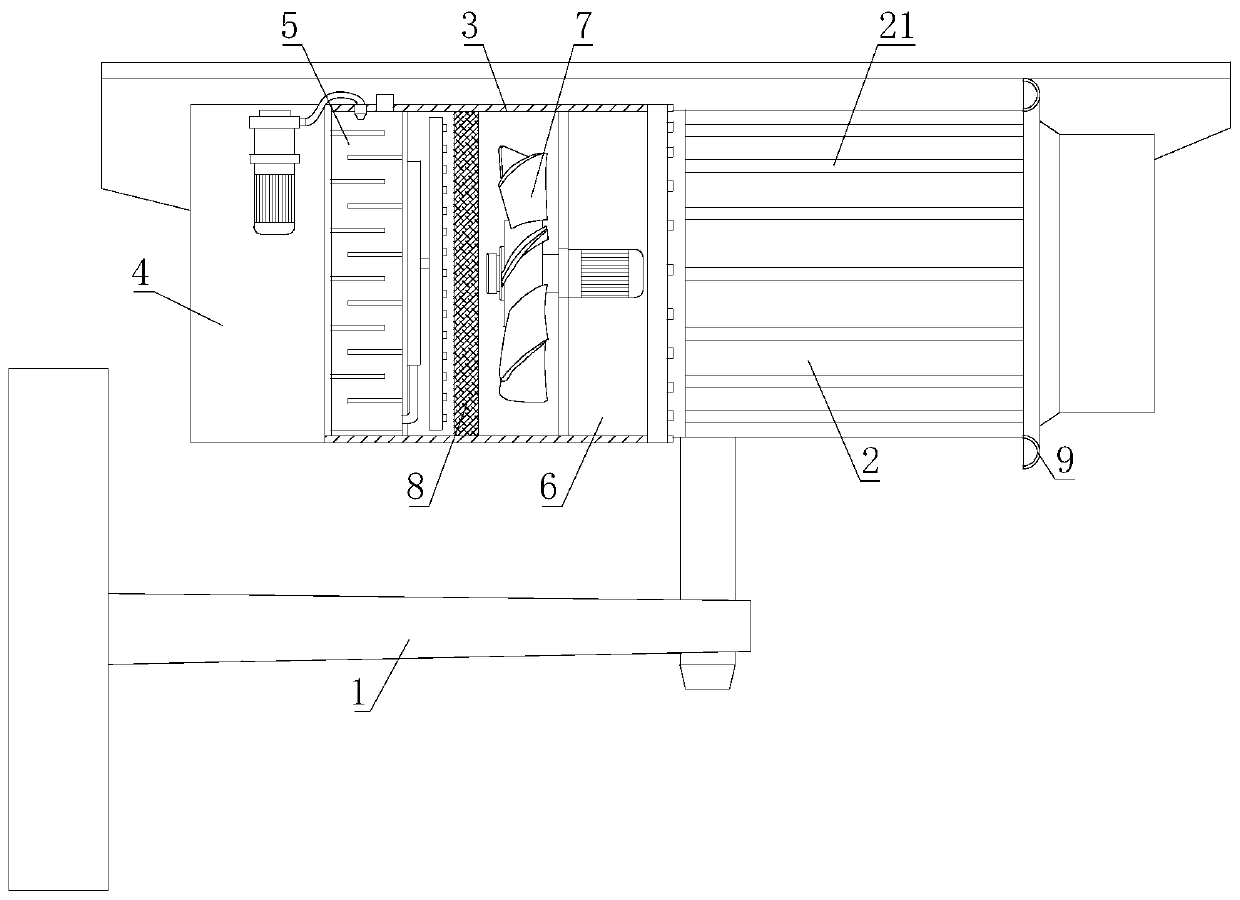

Floating oil collector

InactiveCN104420448AImprove collection efficiencyImprove work performanceWater cleaningGeneral water supply conservationPolyvinyl chlorideDrive motor

The invention discloses a floating oil collector. The floating oil collector comprises a collecting bucket, an oil suction pump and a driving motor, wherein the oil suction pump is fixedly arranged in the collecting bucket and is in drive connection through the driving motor in the collecting bucket; an oil outlet end of the oil suction pump is connected to an oil outlet in the top of the collecting bucket, and an oil inlet end of the oil suction pump is arranged at the bottom of the collecting bucket; floating blocks are arranged on the two sides of the outer wall of the collecting bucket. Further, the mounting height of the floating blocks is higher than the bottom of the collecting bucket. Further, the driving motor is a water-proof motor. Further, the floating blocks are made of anti-corrosion PVC (Polyvinyl Chloride). The independently arranged floating blocks float on the liquid level to collect floating oil in cooperation with the collecting bucket lower than the floating blocks, the working performance of the collector is stable, the floating oil collection efficiency is high, and the collector is safe in use, can work normally for a long time, has high practicability and is suitable for overwater spill oil recovery and large-sized oil-water separation operation.

Owner:天津今誉源科技发展有限公司

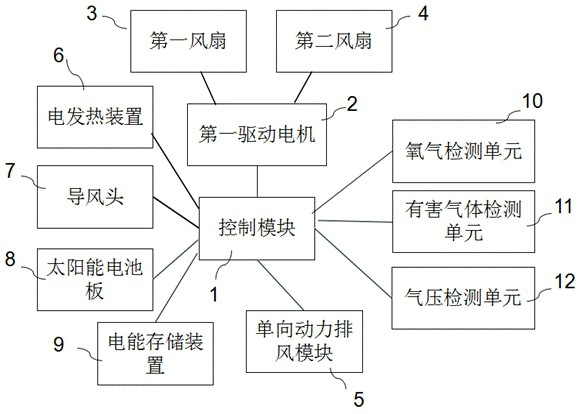

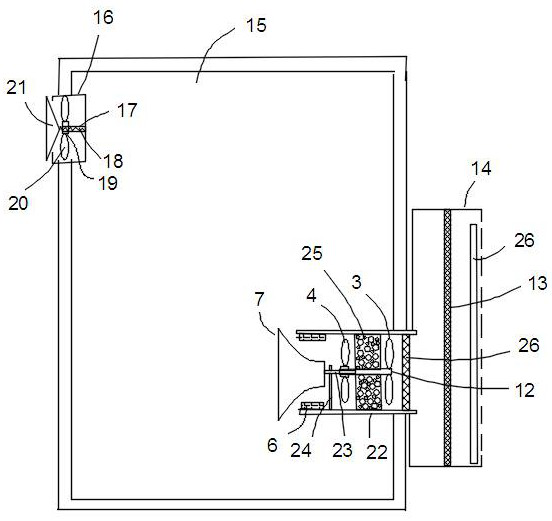

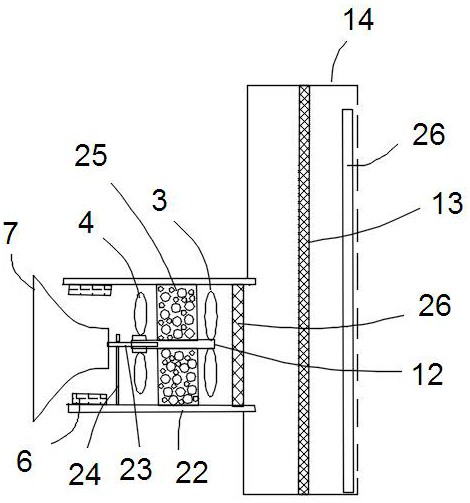

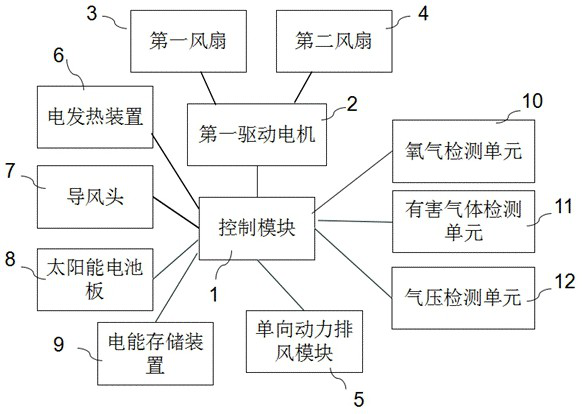

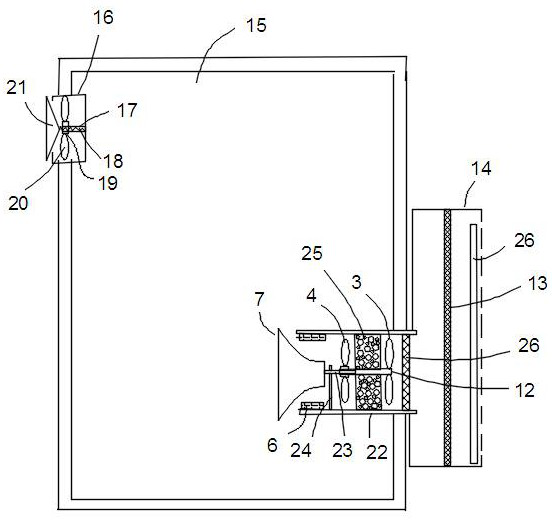

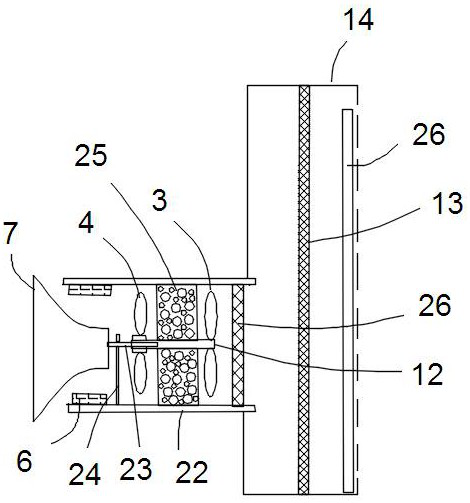

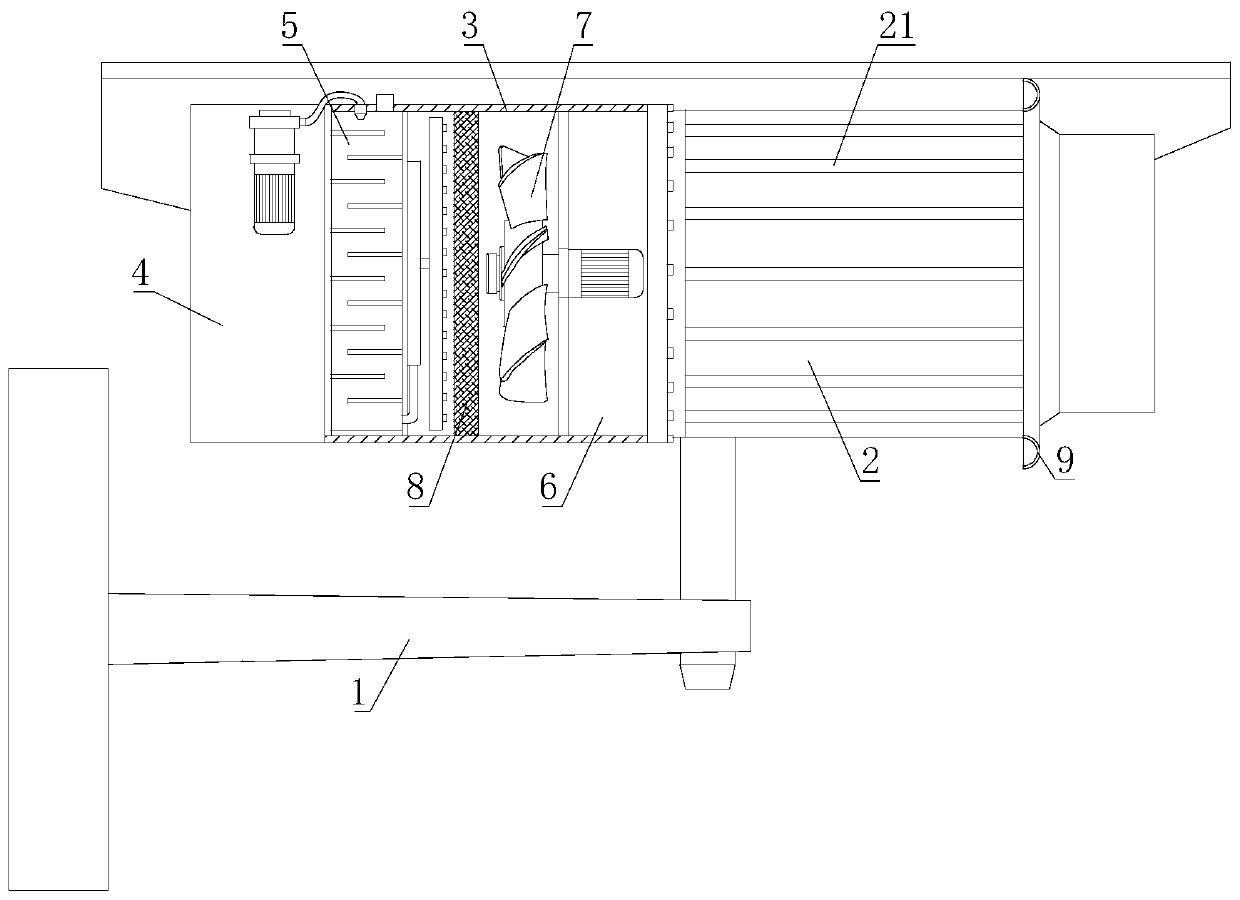

Ventilation system and method

ActiveCN112556061AAvoid failureExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsHoneycomb

The invention provides a ventilation system and method which are applied to a three-dimensional space with people or animals. The ventilation system comprises an air inlet module, a one-way power airexhaust module, an air detection module and a control module, wherein the air inlet module comprises an air inlet box, a power air inlet mechanism and an air guide head; a first interception net plateis arranged in the air inlet box; the power air inlet mechanism comprises an air inlet pipe, and a second interception net plate, a first fan, a porous honeycomb filter layer and a second fan which are sequentially arranged in the air inlet pipe according to the air inlet direction; the area of the air passing face of the first interception net plate is larger than the area of the air passing face of the second interception net plate; the air guide head is movably arranged at an air outlet of the air inlet pipe; and the control module is used for controlling starting and stopping of the firstfan, the second fan and the one-way power air exhaust module according to the air pressure and the preset type of gas concentration. Compared with the prior art, the filter effect is better, the ventilation efficiency is higher, the service life is longer, and the biological safety is better.

Owner:深圳博强建设开发有限公司

Waterproof and corrosion-proof cable material

The invention discloses a waterproof and corrosion-resistant cable material, which comprises the following raw materials in parts by weight: 70-100 parts of EPDM rubber, 3-6 parts of zinc stearate, 60-80 parts of zinc borate, and alkylated diphenylamine 6‑10 parts, 2‑4 parts of vinyltrimethoxysilane, 5‑7 parts of copper sulfate, 5‑10 parts of glass fiber, 3‑10 parts of crosslinking agent, 10‑20 parts of waterproofing agent. The composition of the invention has a reasonable composition of raw materials, good corrosion resistance and waterproof performance, can work normally for a long time in a water environment, has strong wear resistance and aging resistance, and has a long service life.

Owner:彭兰娟

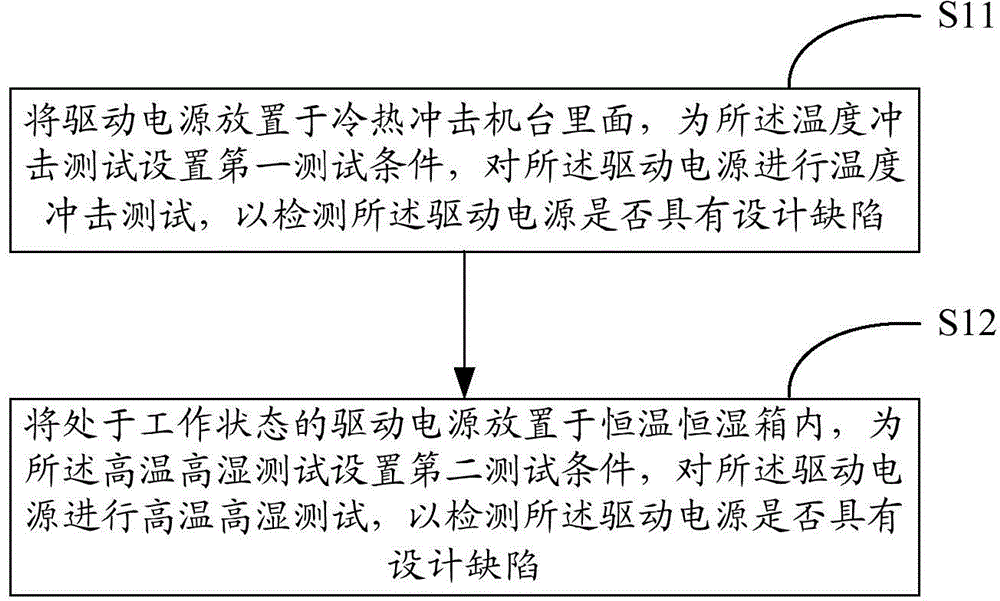

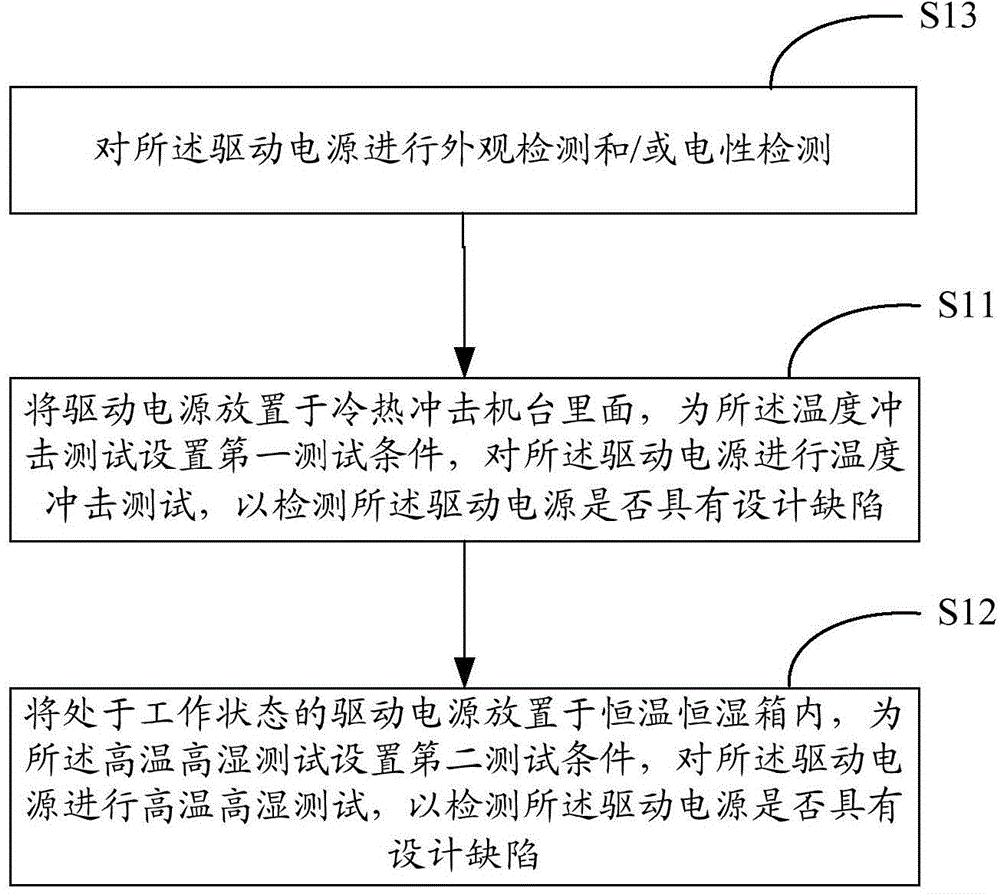

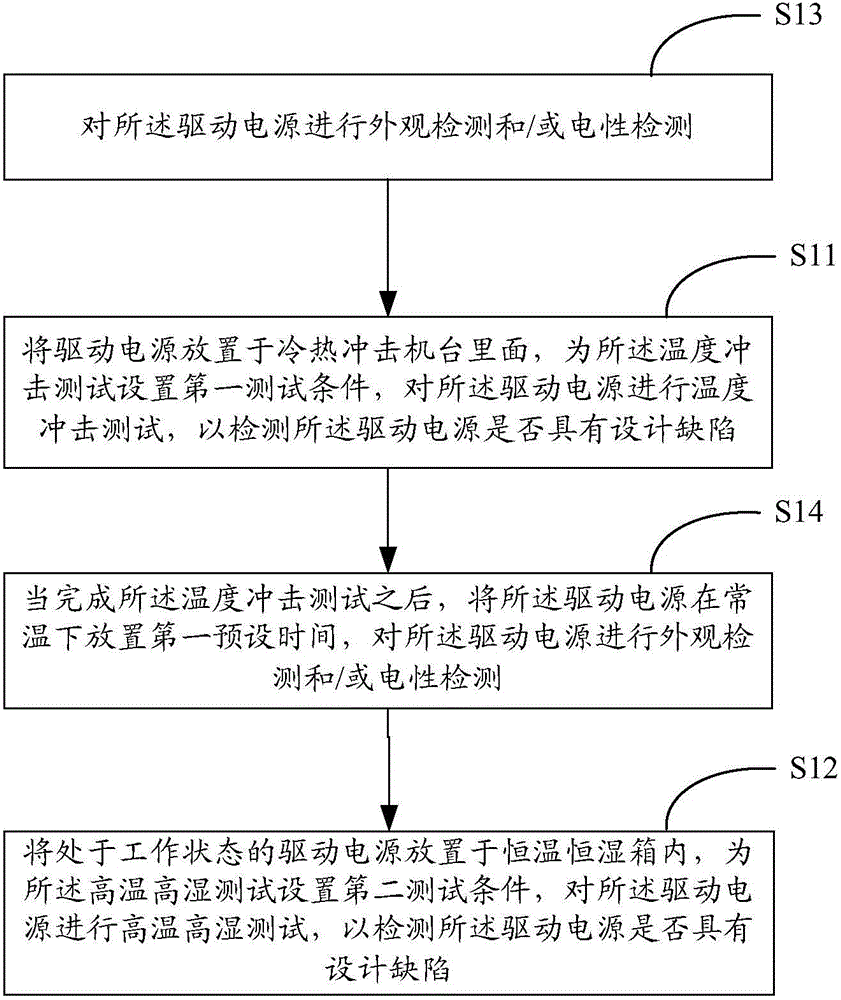

Method for detecting design defects of driving power supplies

InactiveCN104656036AExposing design flawsWork normally for a long timeOptically investigating flaws/contaminationPower supply testingTest setupThermal shock

The invention is suitable for the field of tests of driving power supplies and provides a method for detecting welding defects of driving power supplies. The method comprises the following steps: placing the driving power supplies in a thermal shock tester, setting a first condition for a temperature shock test and carrying out the temperature shock test on the driving power supplies to detect whether the driving power supplies have design defects; placing the driving power supplies which are in working state in a constant-temperature constant-humidity box, setting a second test condition for a high-temperature high-humidity test and carrying out the high-temperature high-humidity test on the driving power supplies to detect whether the driving power supplies have design defects; screening the driving power supplies with design defects and retaining the driving power supplies without design defects so as to ensure that the detected driving power supplies can normally work for a long time.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

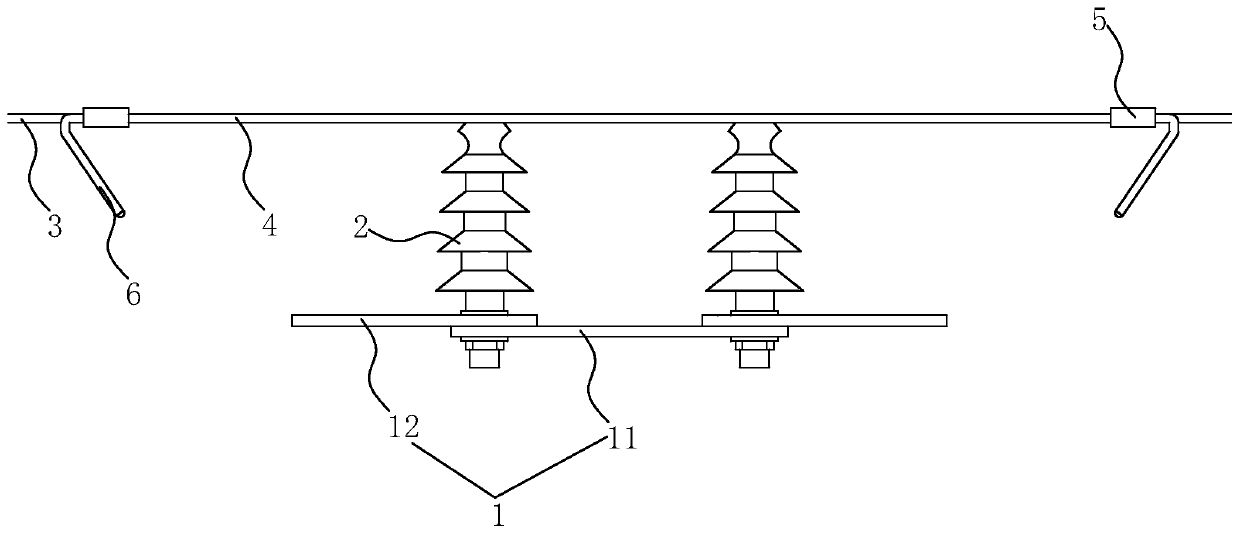

Bidirectional lightning-proof wire breakage protection method and device for insulated wire

ActiveCN111293661AWill not disconnectImprove flow capacityConnection to earthDischarge by conduction/dissipationLightning strokesControl theory

The invention discloses a bidirectional lightning-proof wire breakage protection method and device for an insulated wire. A grounding electrode is arranged at the low-voltage end of an insulator; an insulated wire and a current guide line are arranged at the high-voltage end of the insulator; the current guide line is connected with the insulated wire in parallel through puncture wire clamps; arcstriking electrodes are arranged on the two sides of the current guide line; protection gaps are formed between the arc striking electrodes and the grounding electrode. According to the bidirectionallightning-proof wire breakage protection method and device for the insulated wire of the invention, two sides of the insulator are each provided with one discharge protection gap; when any side is subjected to lightning overvoltage, both of the discharge protection gaps act and discharge; during discharging, the two wire clamps jointly provide fault current; the insulated wire, the current guide line and the arc striking electrodes are integrated; the structures of the protection gaps are stable; and therefore, the device of the invention has the advantages of stable performance, reliable action, strong through-current capability and the like, can effectively prevent the occurrence of lightning stroke disconnection faults of the insulated wire, ensures the safety of the insulated wire, andsolves the technical problems of poor power frequency follow current capability, unstable gap distances and low reliability of a single discharge protection gap.

Owner:国网浙江武义县供电有限公司 +4

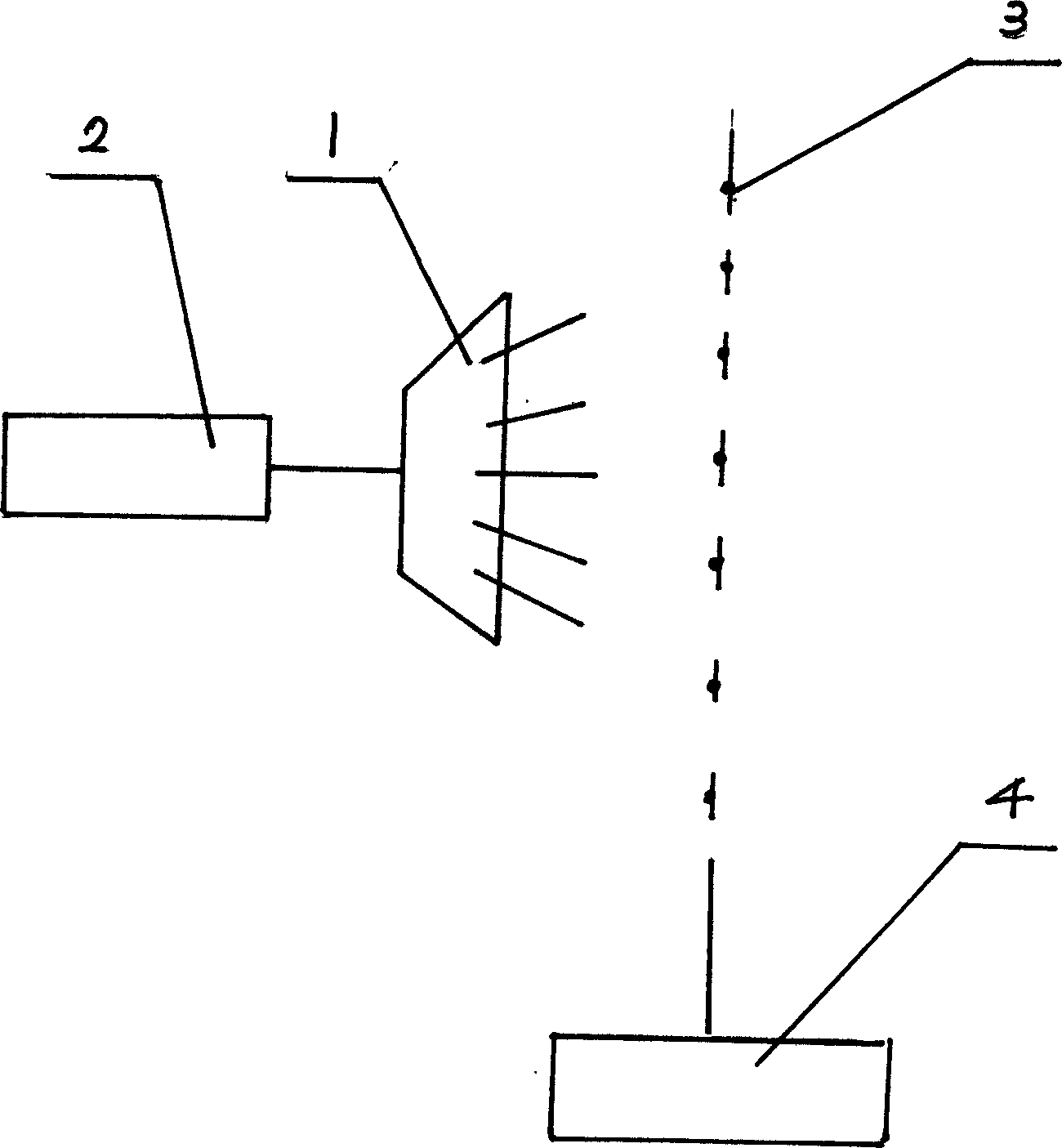

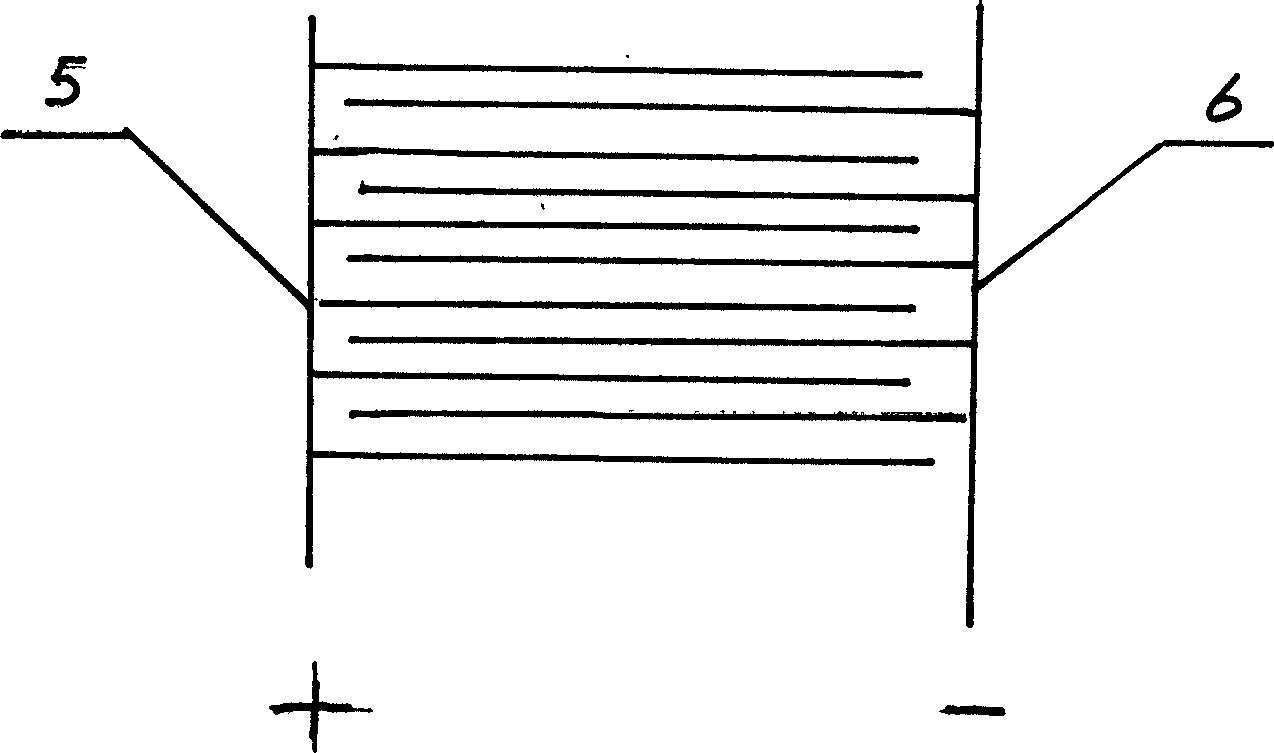

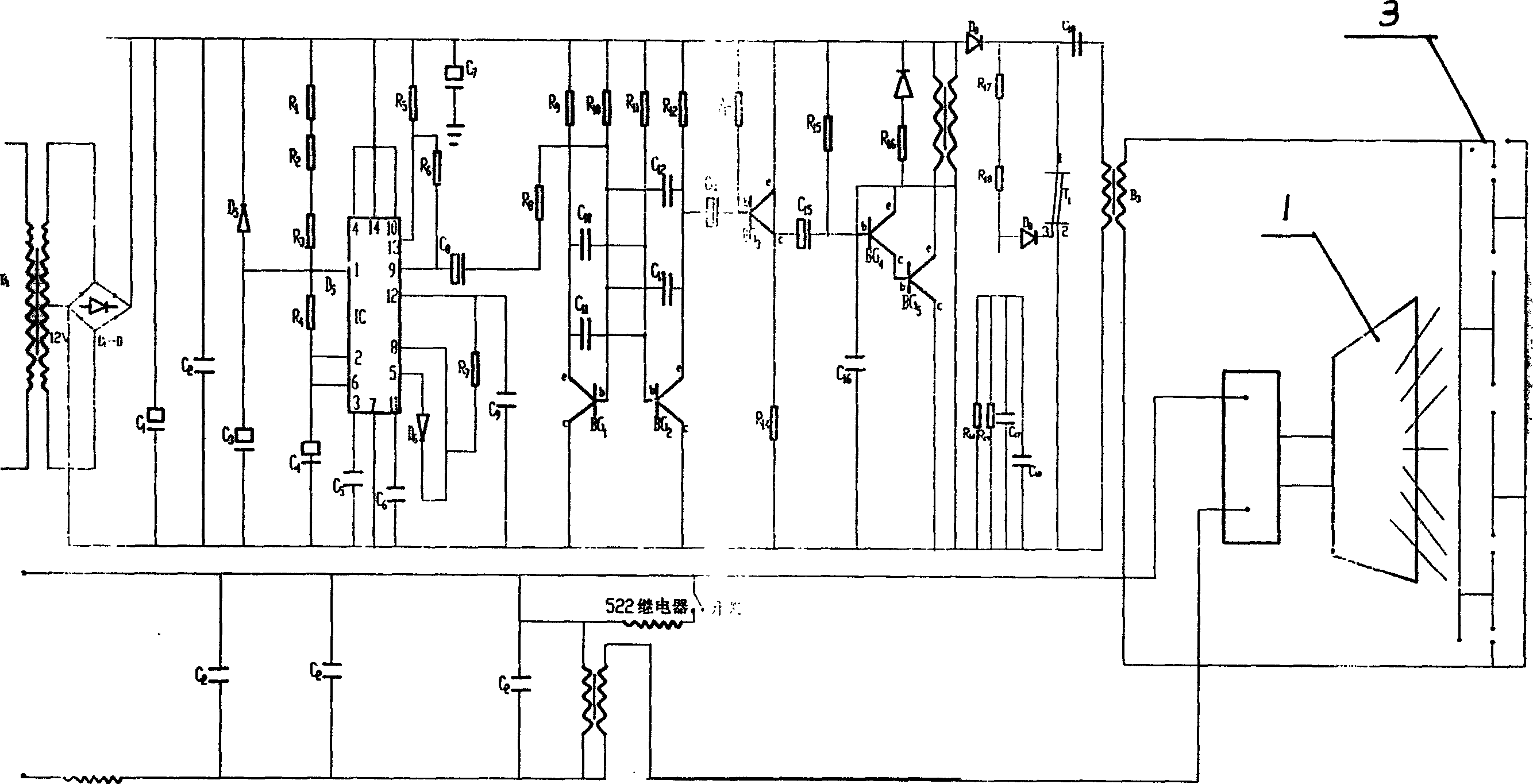

Physical pest killing machine

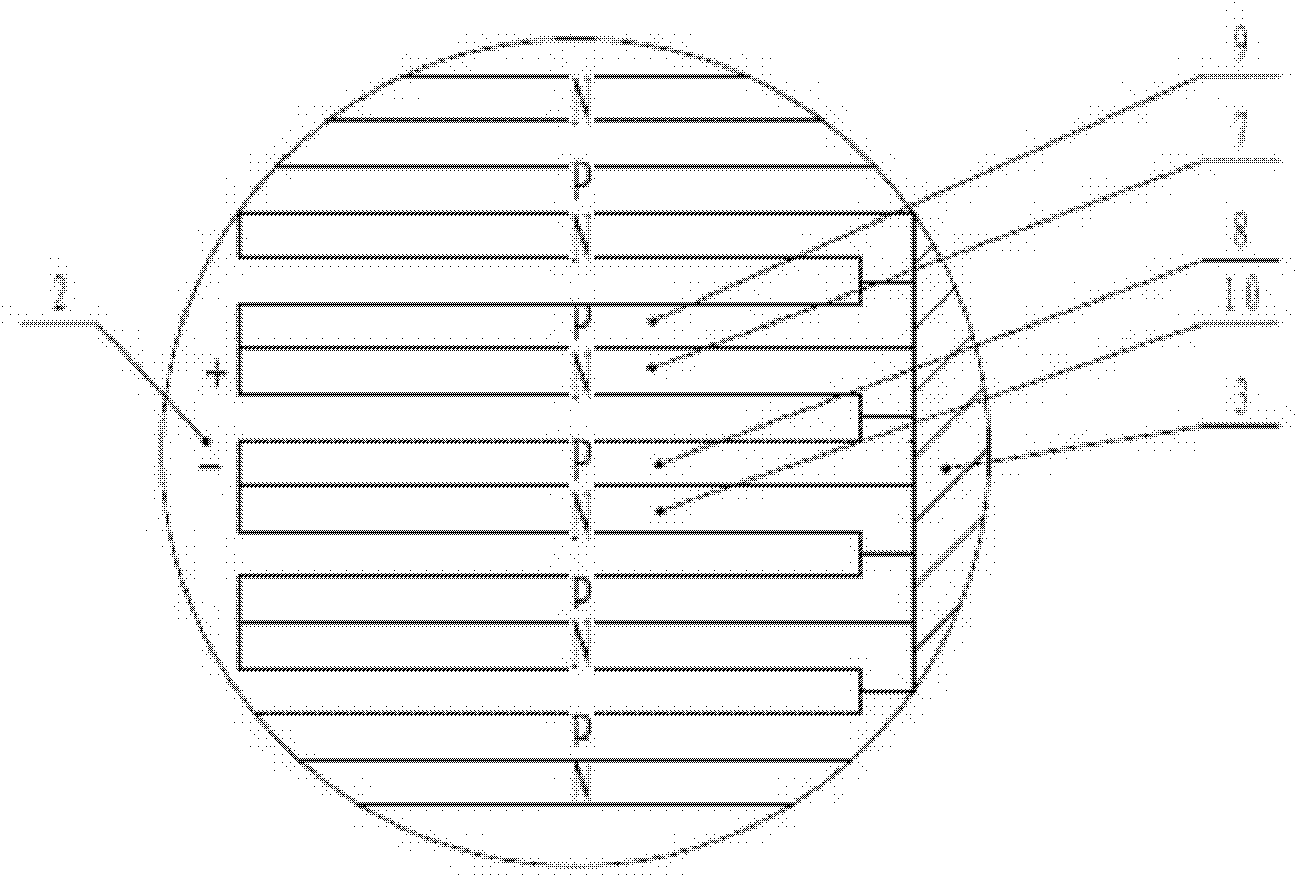

InactiveCN1172587CStrong penetrating powerEfficient killingInsect catchers and killersUltravioletElectric field

The physical pest killing machine consists of sub-ultraviolet ray source and light valve and features that the wavelength of the sub-ultraviolet ray source is 430-620 nm and the light valve consists of metal net electrodes and drive circuit. The positive and negative metal net electrodes are arranged alternately in one identical plane and have intermittent high frequency and high voltage electric field of 1200-3000 Hz and 2000-3500 V in between. The physical pest killing machine is operated together with low frequency electromagentic wave and supersonic wave. It can be used reliably in heavily dusty field, has long killing distance, large killing ragne and high fly pest killing effect, and can kill pests in piles and soil effectively without using fumigant and other pesticide.

Owner:ZHONGHE PHYSICAL NEW TECH APPL HUBEI

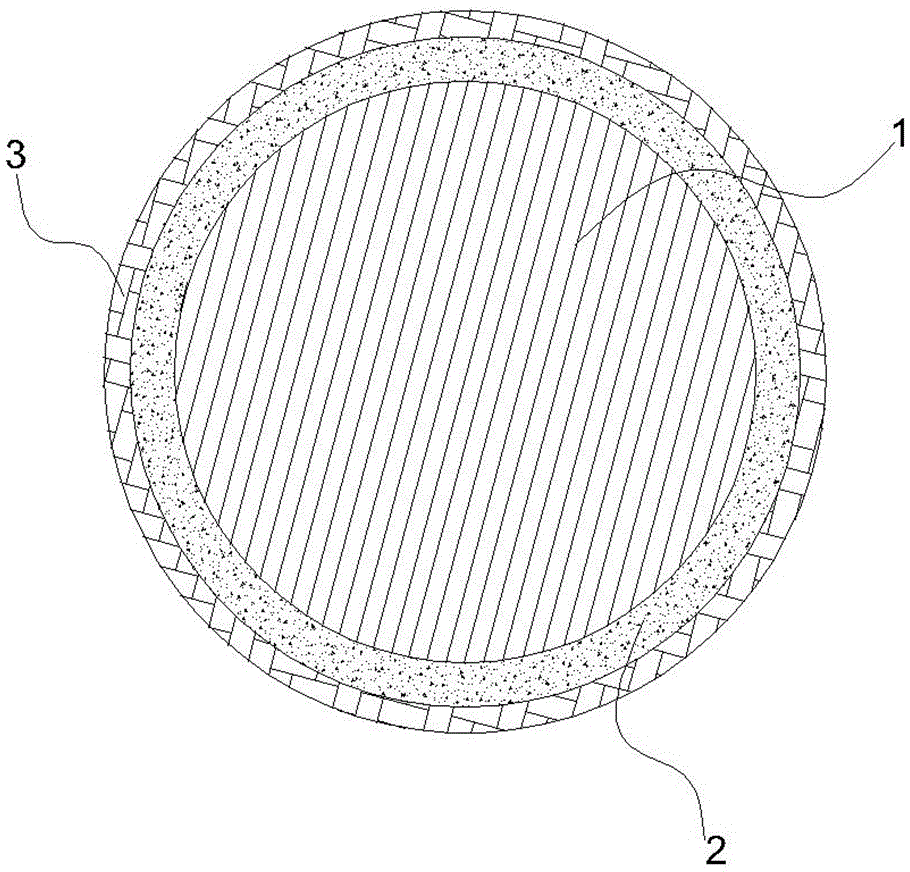

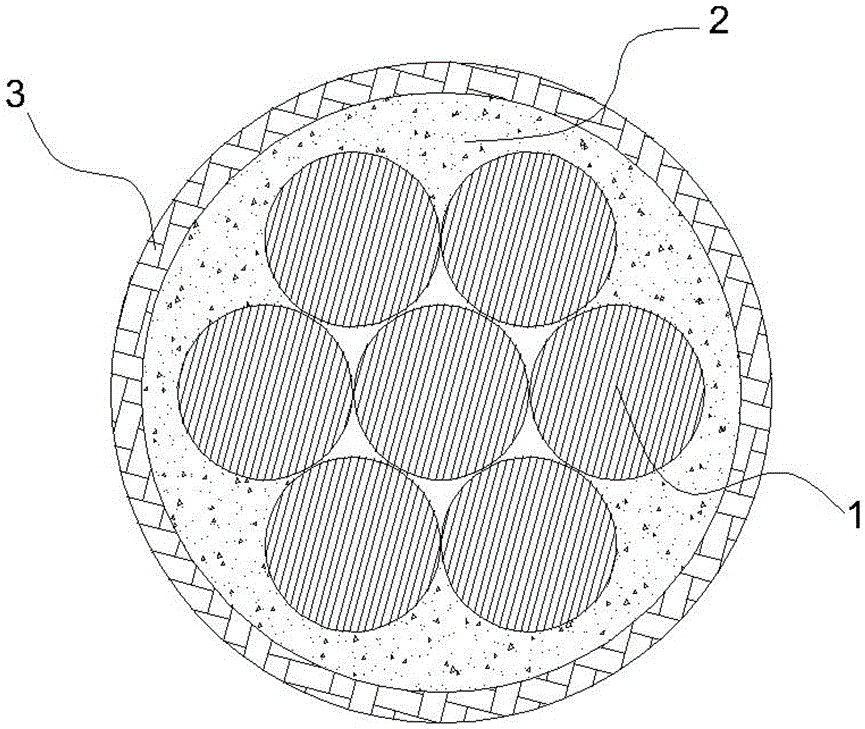

High temperature resistance diving motor winding wire and preparation technology

InactiveCN105161170AImprove electrical performanceImprove mechanical propertiesInsulated cablesCable/conductor manufactureCopper conductorInsulation layer

The invention discloses a high temperature resistance diving motor winding wire and a preparation technology. The winding wire comprises a single-wire copper conductor and an intertwisted conductor which is obtained through intertwisting at least seven copper conductors; an ethane-tetrafluoroethene copolymer insulating layer and a polyamide sheath layer. The preparation technology comprises steps of drawing a copper wire to form soft copper wires of various models through a drawbench, enabling the drawn soft copper wire or the intertwisted wire to pass through a cable extruding machine, wherein the insulation layer made of the ethane-tetrafluoroethene copolymer and having thickness of 0.50-1.20mm wraps the outside of the drawn soft copper wire or the interteisted wire, passing the soft copper wire wrapped with the insulation layer through a caber extruding machine, wrapping the outside surface of the insulation layer with the sheath layer which is made of polyamide and has a thickness og 0.2-0.3mm. After performing the above steps, the high temperature diving motor winding wire is obtained. The wiring wire disclosed by the invention has characteristics of resisting oil, resisting acid and alkali and general solvent, can be used as a winding wire used under special environment like the high temperature oil pump, the sewage pump and the frequency conversion pump.

Owner:HOUMA ECONOMIC DEV ZONE XINXIN CABLE CO LTD

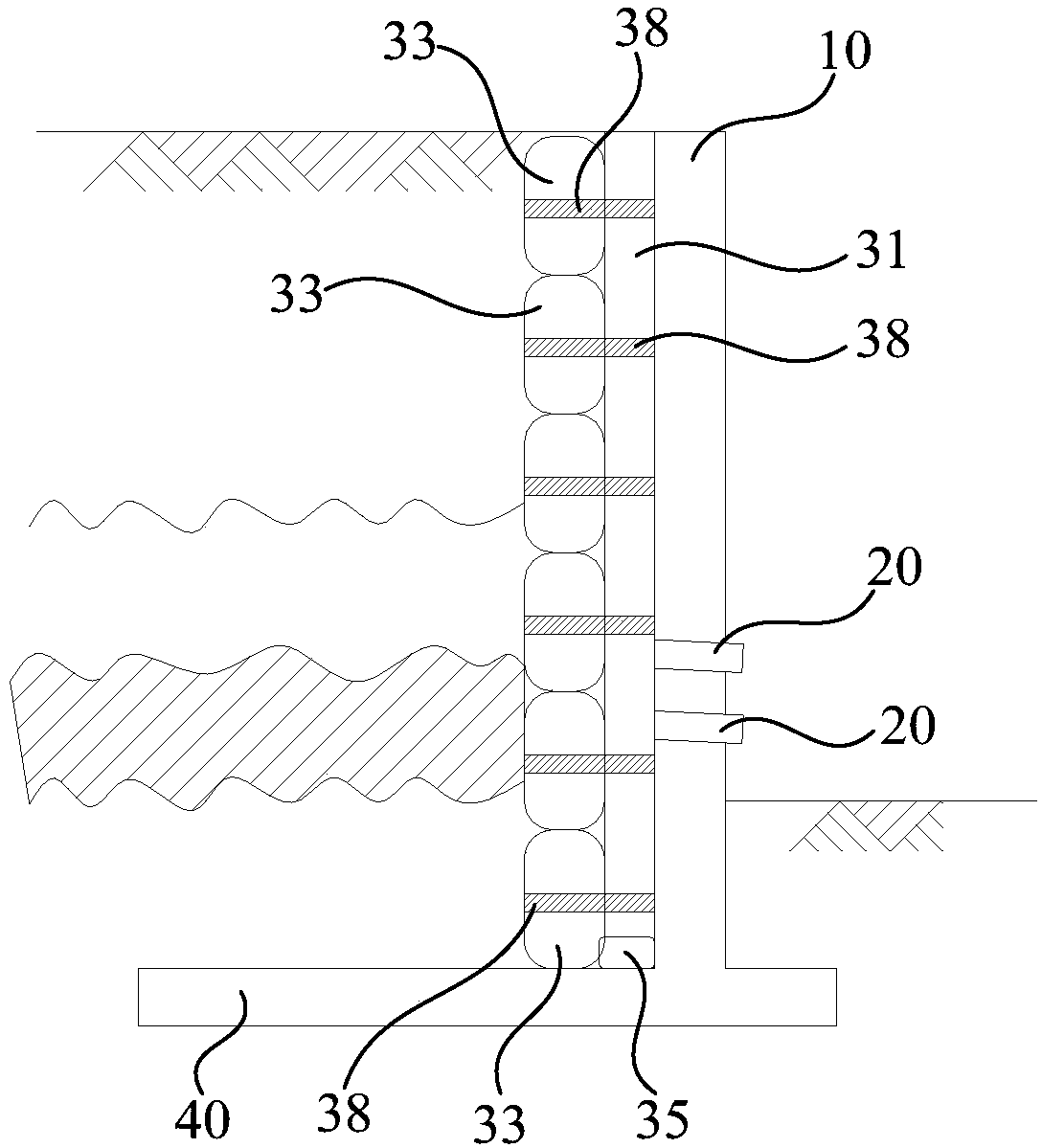

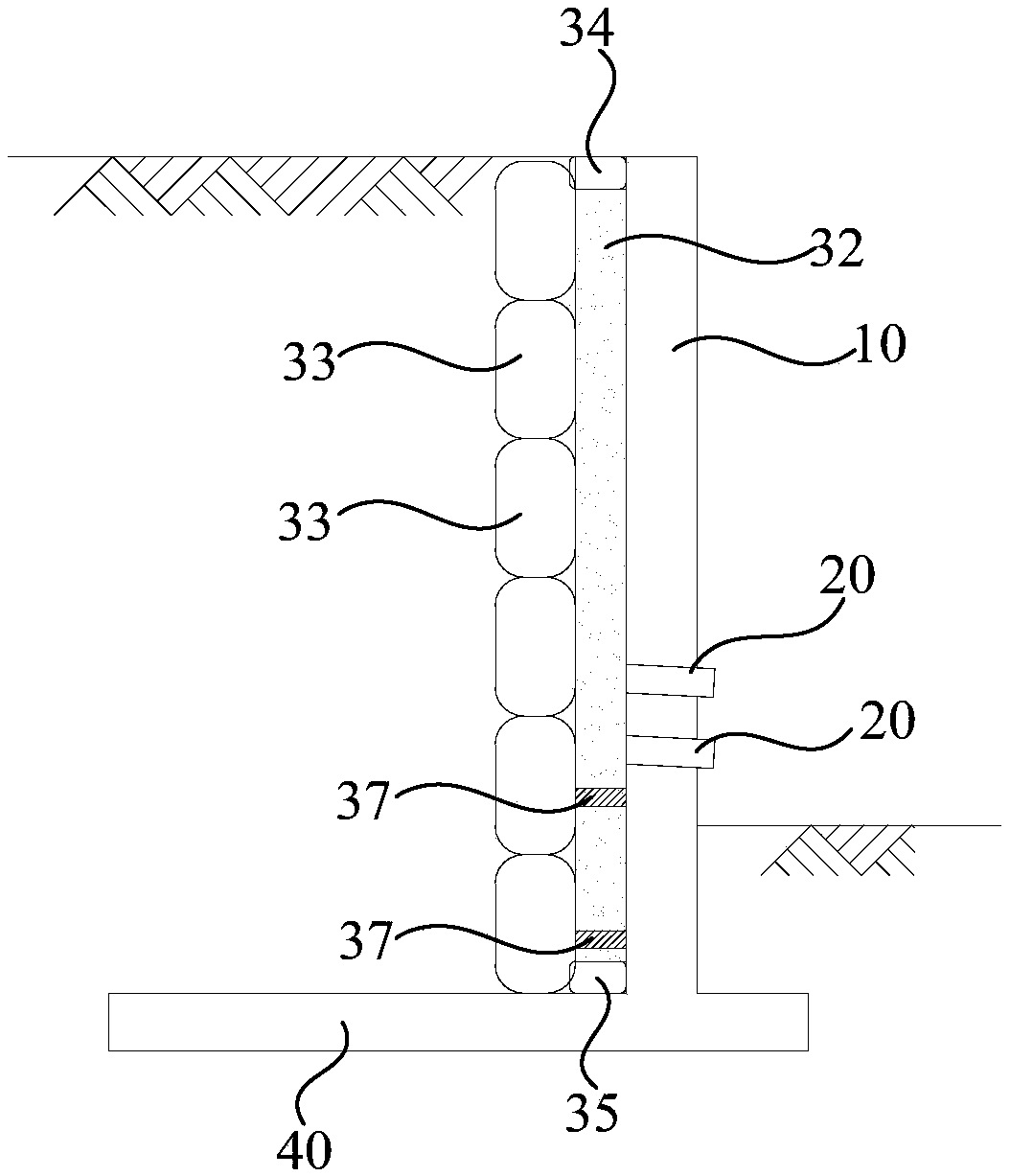

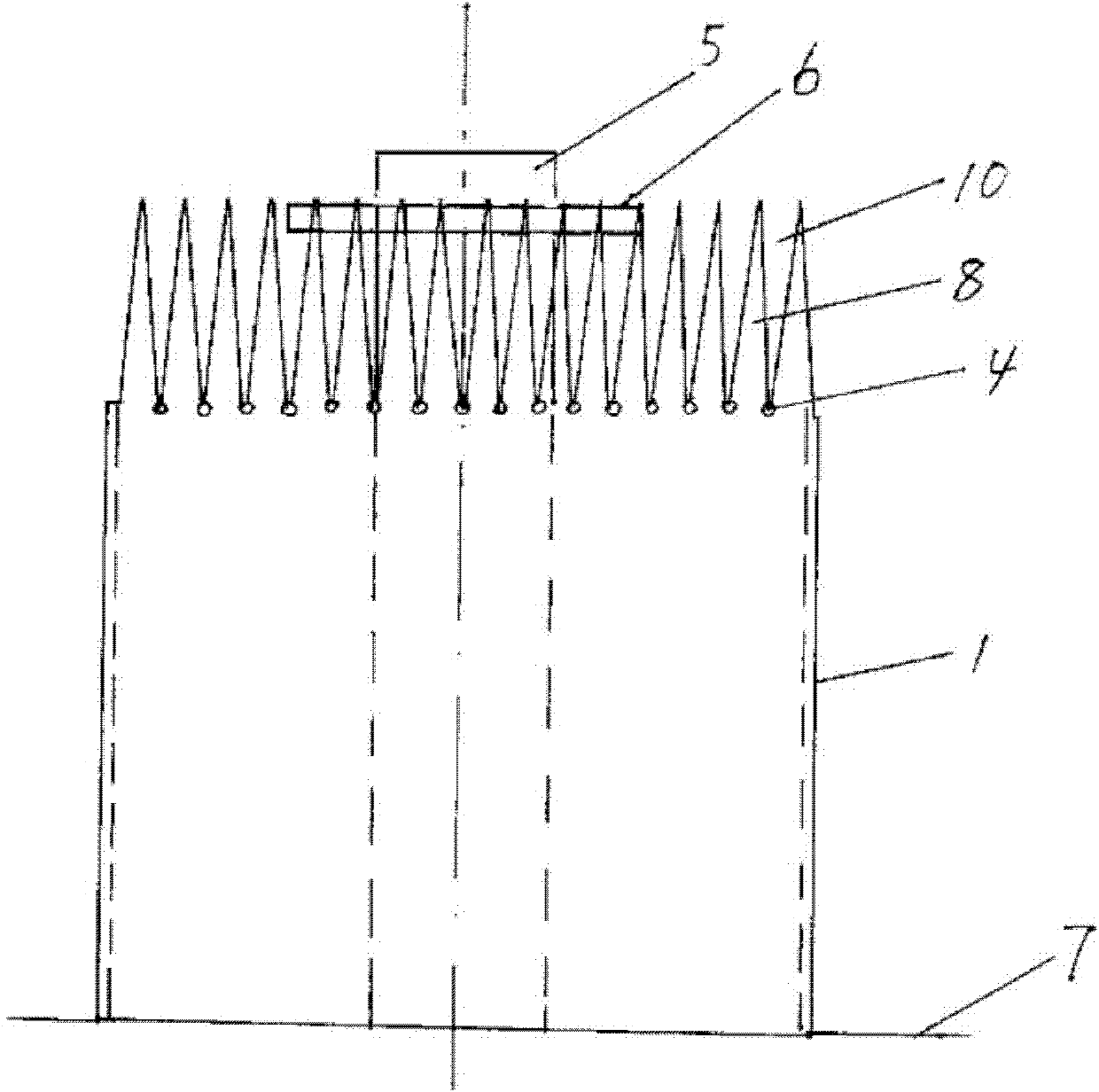

Retaining wall water drainage system

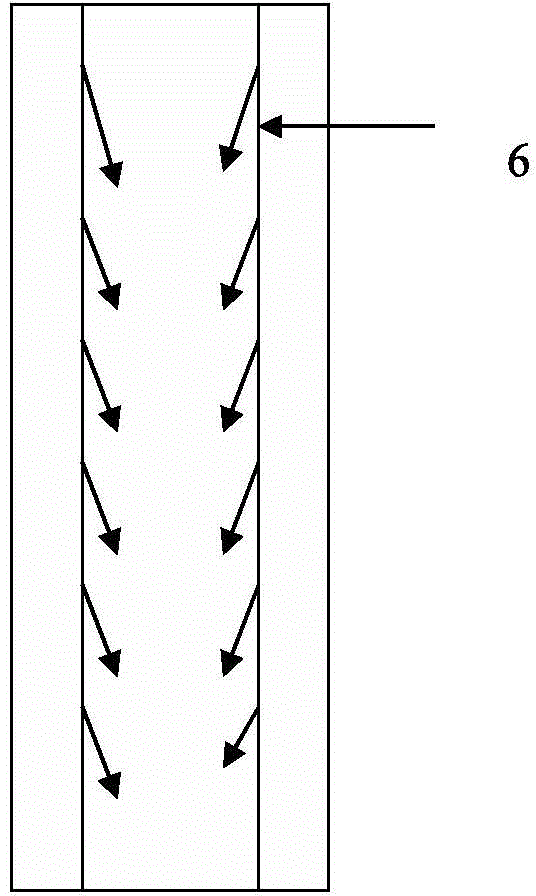

PendingCN108716223AAvoid standing waterWork normally for a long timeArtificial islandsUnderwater structuresInverse filterRetaining wall

The invention relates to a retaining wall water drainage system. The system comprises a retaining wall, water drainage pipes and a vertical inverse filtering water drainage body; water drainage holesare formed in the bottom of the retaining wall, the water drainage holes penetrate to the other side wall of the bottom of the retaining wall from one side wall of the bottom of the retaining wall, the water drainage pipes are arranged on the water drainage holes, the vertical inverse filtering water drainage body is fixedly arranged on the side wall, facing the soil behind wall, of the retainingwall, the vertical inverse filtering water drainage body vertically and downwards extends to the bottom of the retaining wall from the top of the retaining wall, and the vertical inverse filtering water drainage body communicates with the water drainage holes; according to the retaining wall water drainage system, after the retaining wall is completed for a certain time, even if the soil behind the wall is sunken, the vertical inverse filtering water drainage body makes direct contact with the soil, within the different depth ranges, behind the retaining wall all the time, soil on different depths is collected to the vertical inverse filtering water drainage body in a diving manner, the vertical inverse filtering water drainage body drains the water outwards through the water drainage pipes, the water accumulation behind the retaining wall can be avoided, the retaining wall is kept in the long-term normal work all the time under the light load condition, and the service life of the retaining wall is prolonged as much as possible.

Owner:广州市设计院集团有限公司

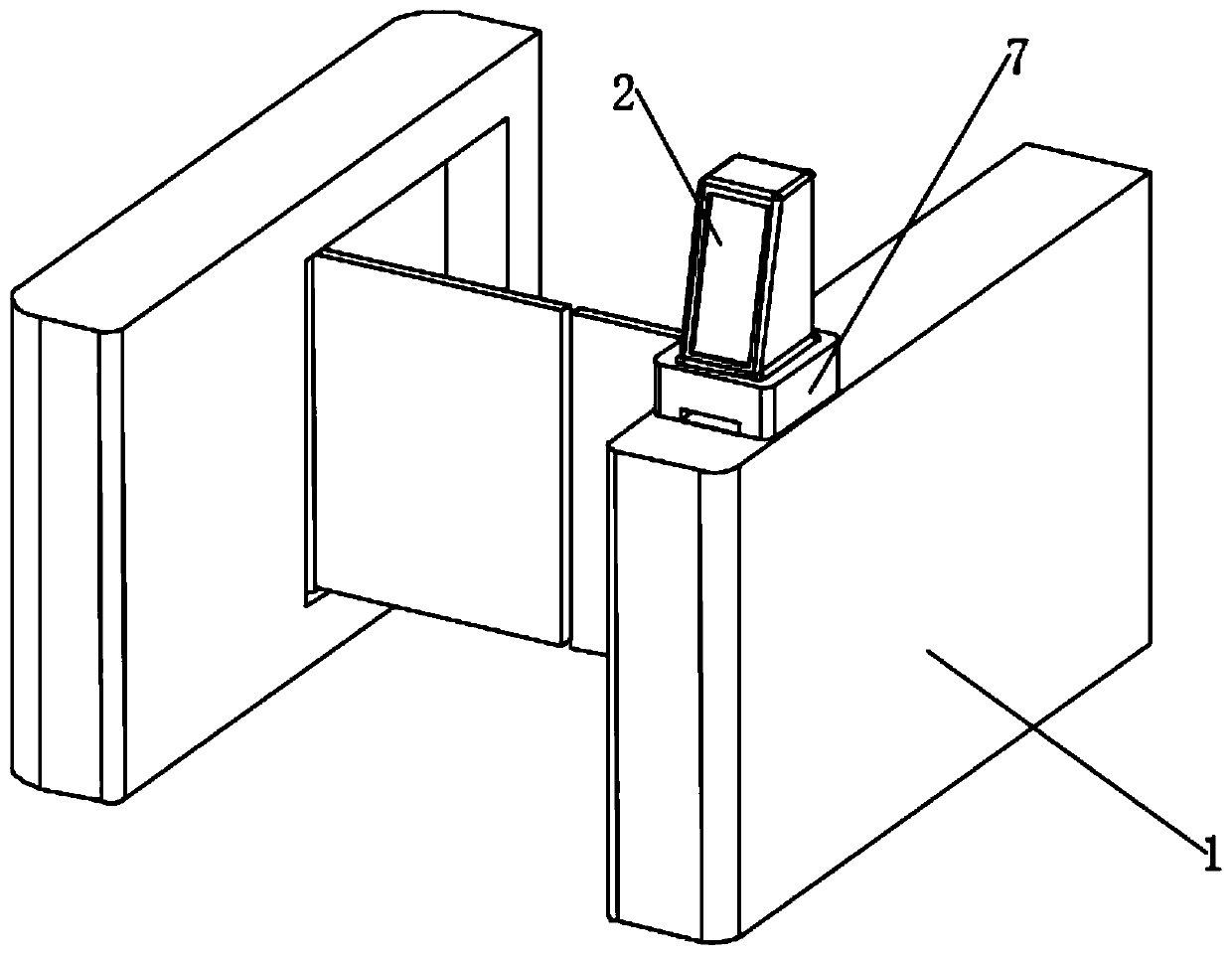

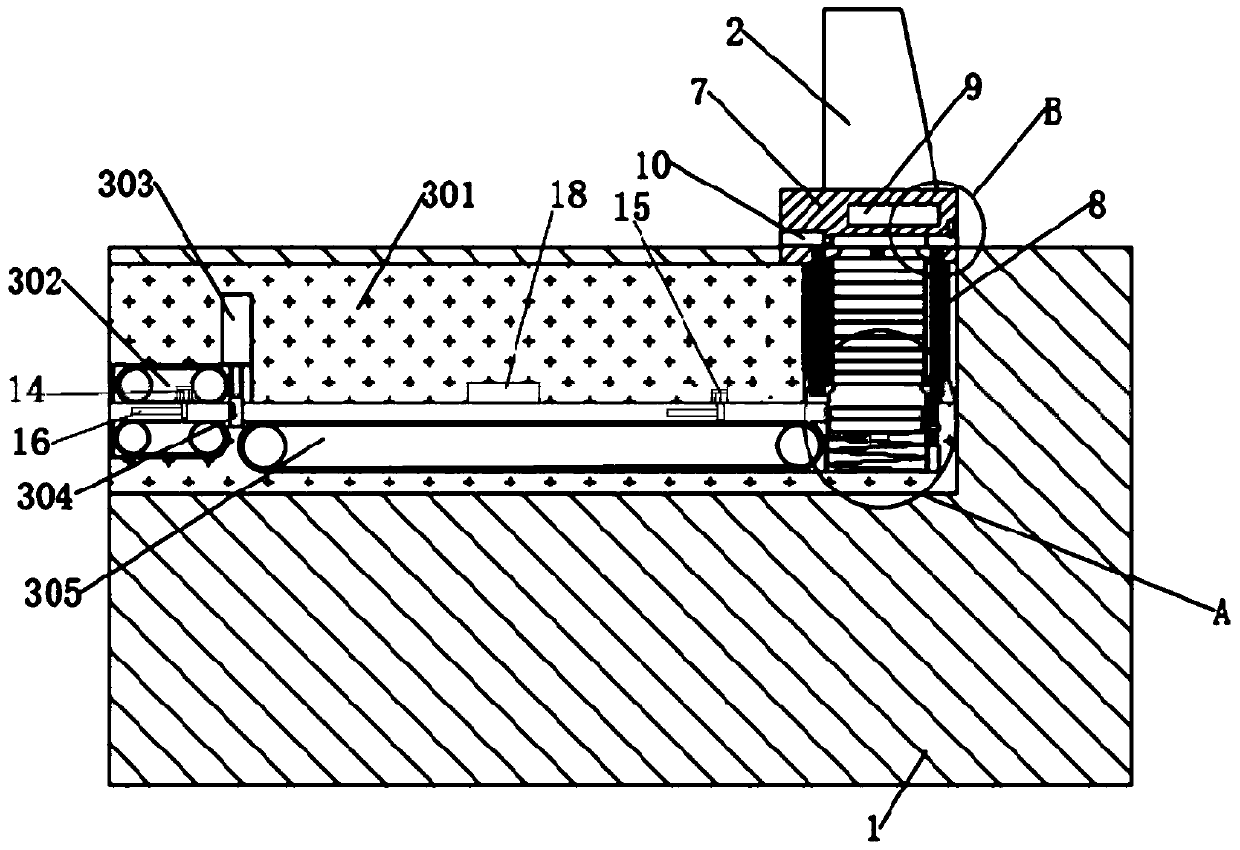

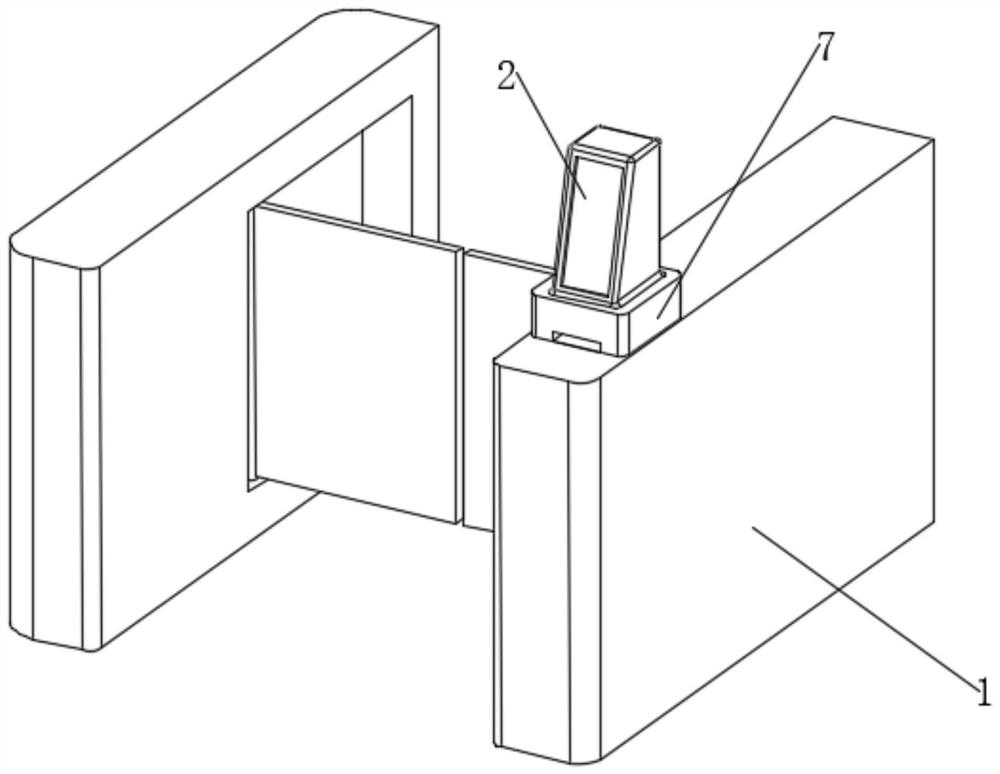

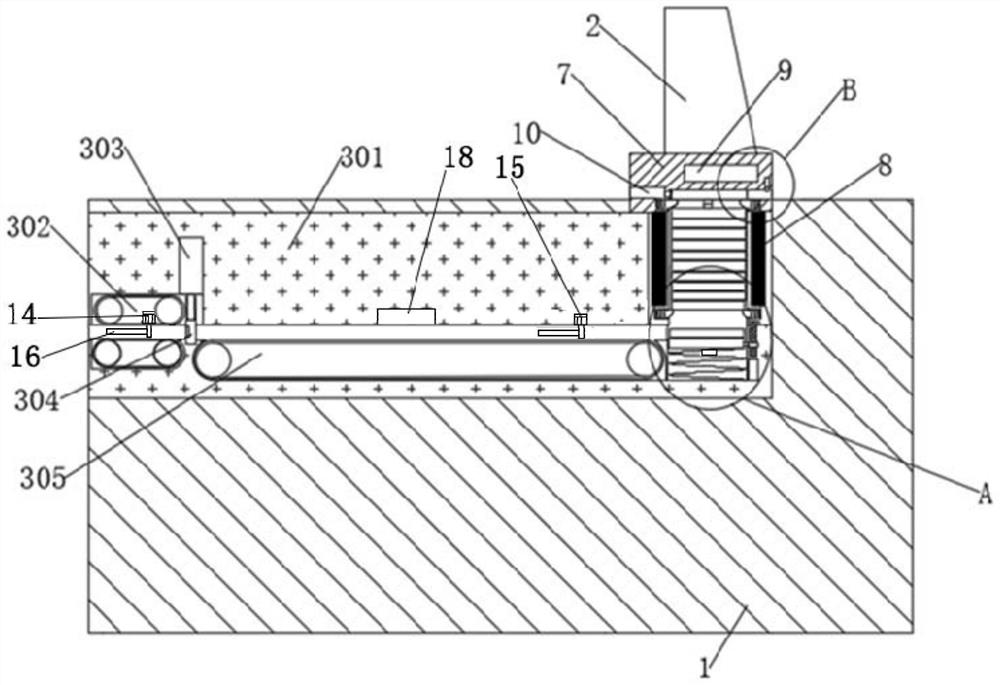

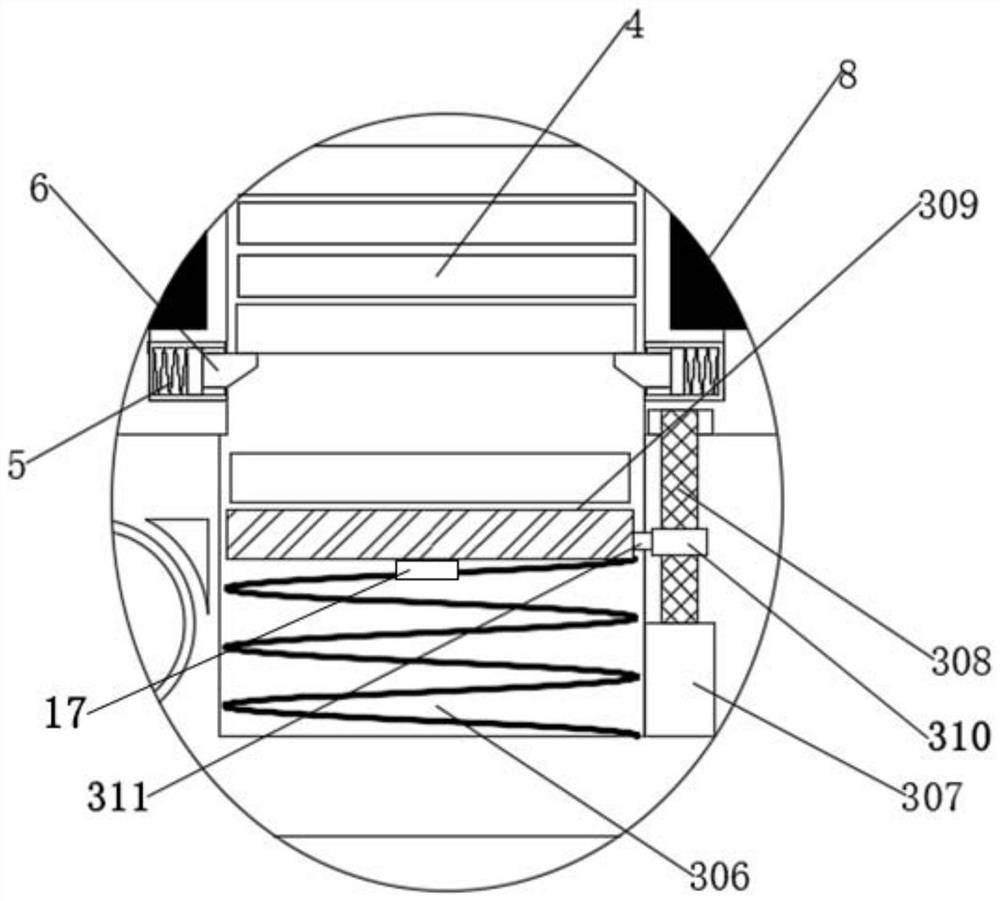

Intelligent face recognition access control device

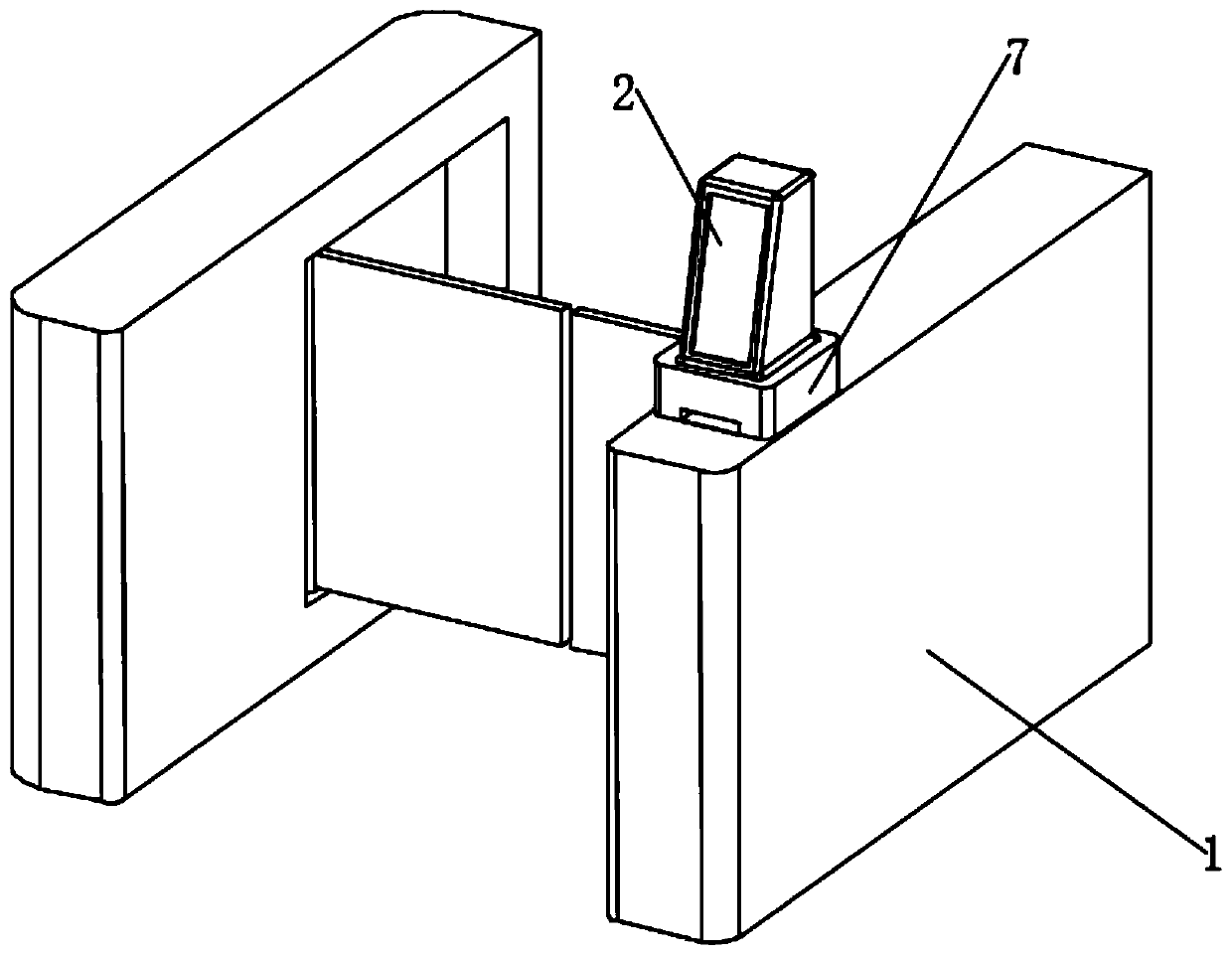

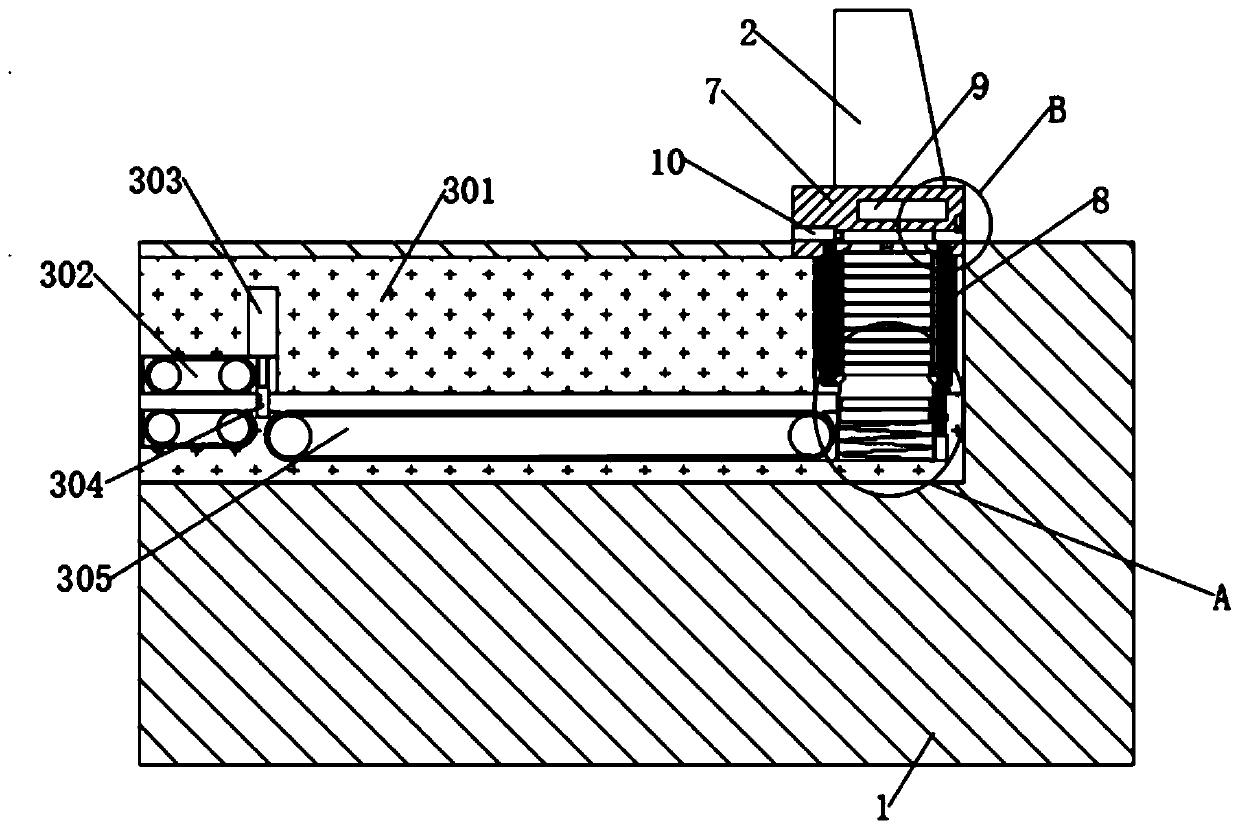

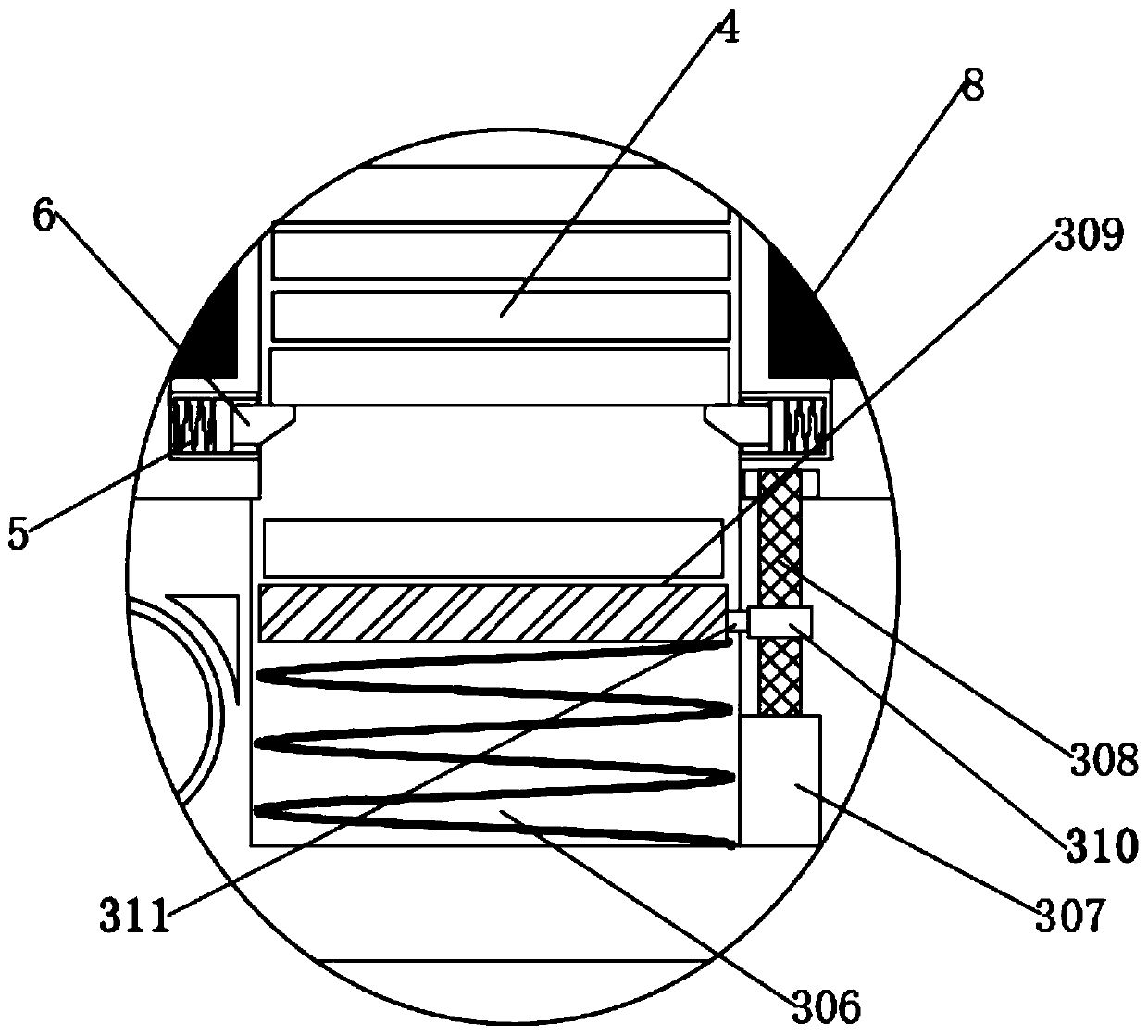

ActiveCN111540098AEasy to store and outputEasy to useCircuit arrangementsIndividual entry/exit registersElectrical and Electronics engineeringMechanical engineering

The invention discloses an intelligent face recognition access control device, and belongs to the field of access control. The intelligent face recognition access control device comprises an entranceguard gate main body, wherein the upper end of the entrance guard gate main body is fixedly connected with a shell; the shell is connected with a face recognition device; a card gate machine is connected into the access control gate machine main body; a feeding cavity communicated with the card gate machine is dug in the upper end of the access control gate machine main body; two pairs of spring grooves are dug in the two ends of the upper side of the inner wall of the feeding cavity. A clamping block is slidably connected into the spring groove; a second compression spring is fixedly connected between the clamping block and the bottom end of the spring groove; a plurality of positioning clamps are clamped between the two pairs of clamping blocks and are connected with a visitor authoritymanagement system. According to the scheme, the visitor information is obtained through face recognition, the visitor information is input into the positioning card after the visitor is authorized, the visitor carries the positioning card to carry out area finding, the management of the visitor can be facilitated, the visitor entering the area can be positioned, and help seeking can be carried outin time when the visitor gets lost.

Owner:湖南奇谷智能科技有限公司

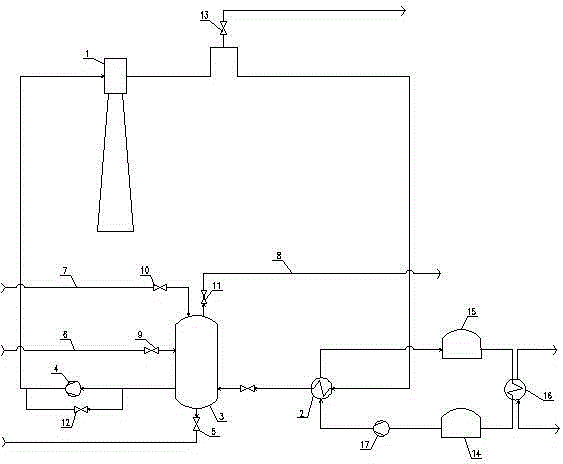

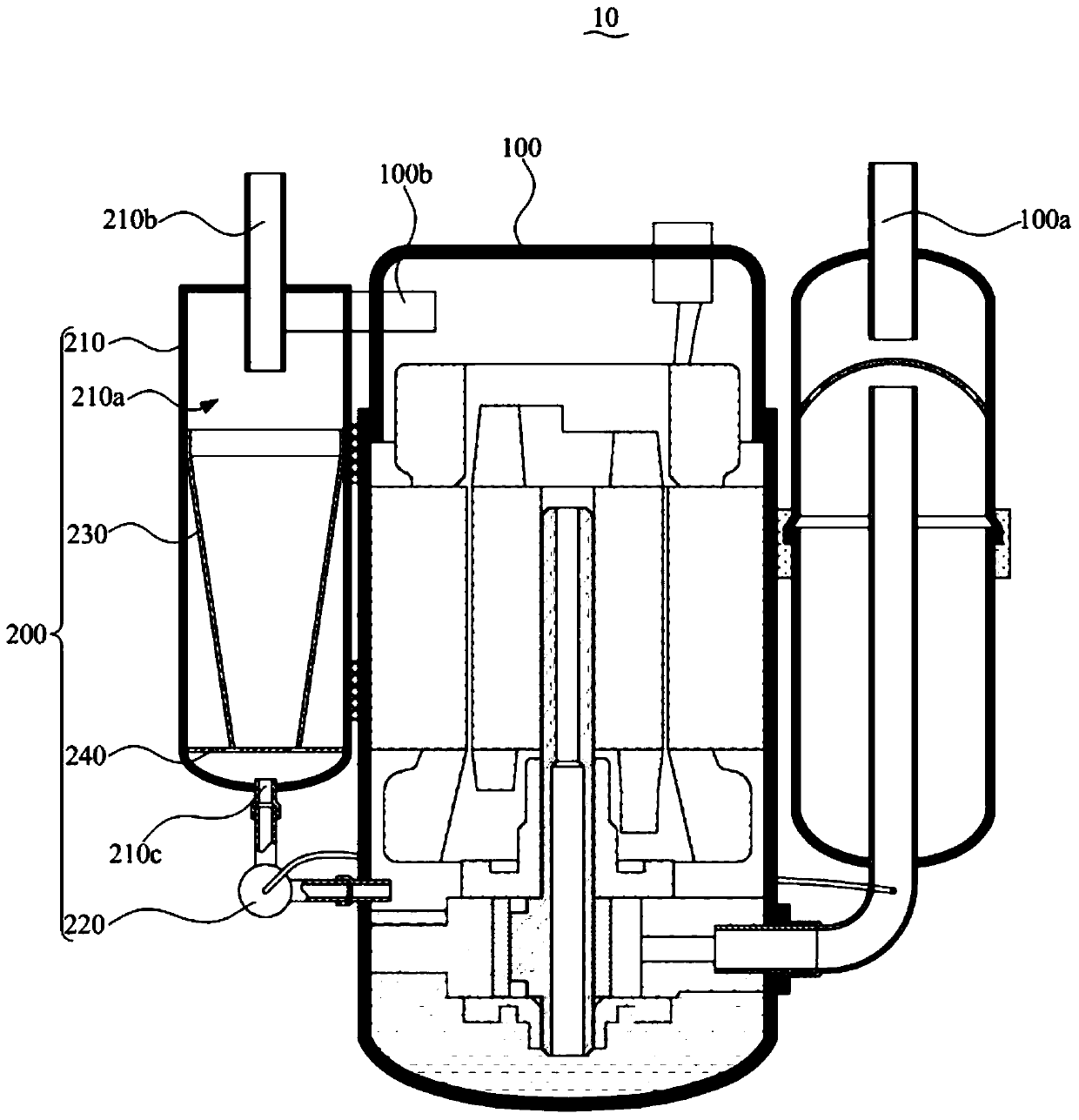

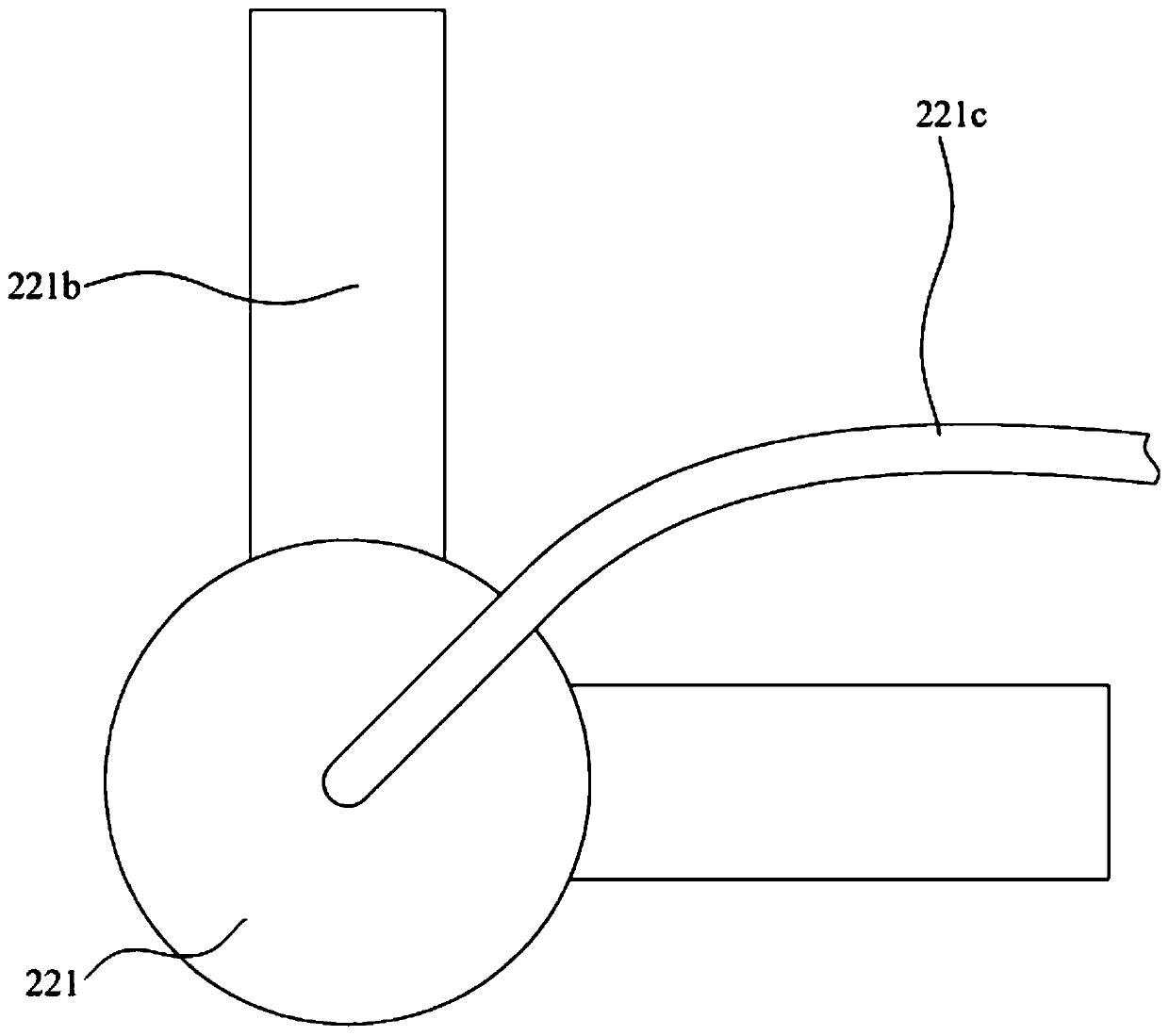

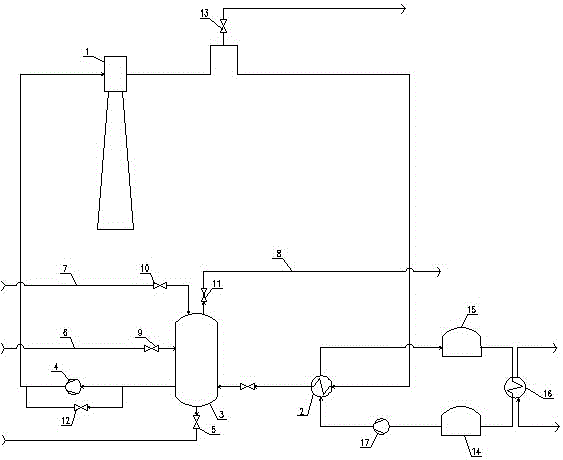

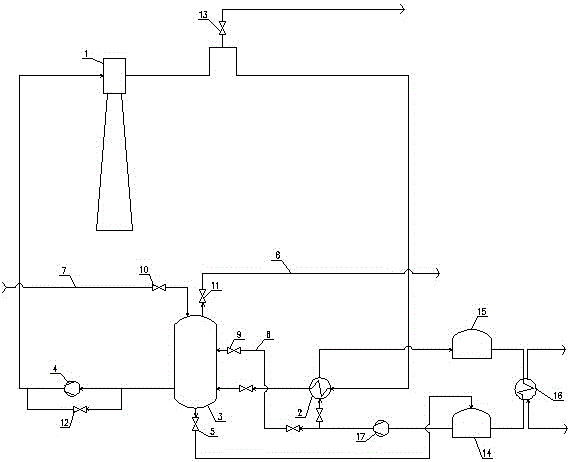

Tower-type solar closed under-pressure heat absorption system and method

ActiveCN105180475AShort startup timeLow investment costSolar heat devicesSolar thermal energy generationBlowoff valveStart time

The invention discloses a tower-type solar closed under-pressure heat absorption system which comprises a heat absorber at the high position and a heat exchanger located at the low position. An outlet of the heat absorber is connected with an inlet of the heat exchanger through a pipeline. The tower-type solar closed under-pressure heat absorption system is characterized by further comprising a storage buffer tank located at the low position; a heat absorption medium adding pipe is connected to the storage buffer tank; an air inlet pipe and an exhaust pipe are connected to the storage buffer tank higher than the heat absorption medium adding pipe; the air inlet pipe, the exhaust pipe and the heat absorption medium adding pipe are each provided with a valve; one side of the storage buffer tank is connected with an outlet of the heat exchanger through a pipeline, and the other side of the storage buffer tank is connected with an inlet of a circulating pump through a pipeline; an outlet of the circulating pump is connected with an inlet of the heat absorber through a pipeline; and the heat absorber is connected with a blowoff valve through a pipeline, and the blowoff valve is higher than the heat absorber. The invention further discloses the heat absorption method. The tower-type solar closed under-pressure heat absorption system has the beneficial effects of being low in investment cost and operation cost, good in safe and short in heat absorber starting time and ensures the long-term normal working.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

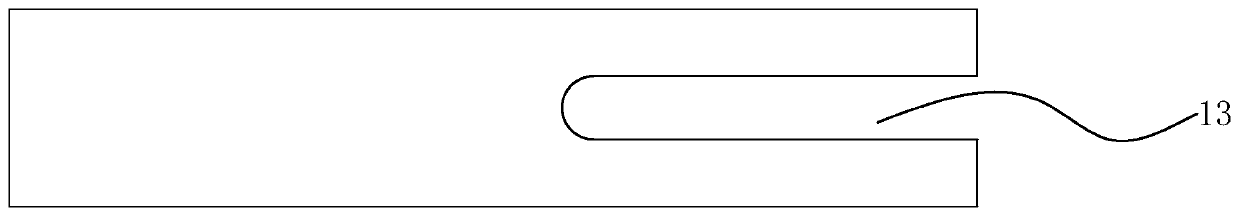

A catheter for peritoneal dialysis

ActiveCN110090328BAvoid cloggingEasy to observe positionMaterial analysis by electric/magnetic meansMedical devicesPeritoneal dialysis catheterPeritoneal cavity

A peritoneal dialysis catheter, comprising a catheter body, a glucose monitoring probe and a strip-shaped liquid bag, one end of the catheter body is a dialysis area, and a plurality of dialysis holes are opened on the dialysis area, the other end is connected to an external dialysis fluid bag, and the catheter body is provided with a dialysis hole One end of the strip-shaped liquid bag is connected with the glucose monitoring probe, and the strip-shaped liquid bag is set in the inner cavity of the catheter body, and the length is not less than the length of the dialysis area on the catheter body. The catheter body is connected to one end of the external dialysate bag, and a rubber stopper is provided at the opening of the liquid injection port. The invention has the advantages that the peritoneal dialysis catheter does not float, has good sealing performance, does not block the dialysis hole, and can monitor the glucose concentration of the dialysate in the peritoneal cavity in real time.

Owner:THE SECOND XIANGYA HOSPITAL OF CENT SOUTH UNIV

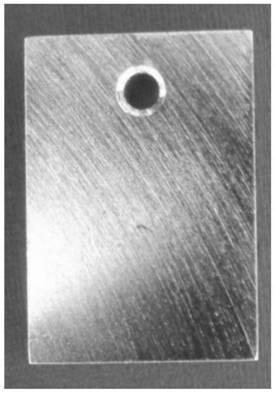

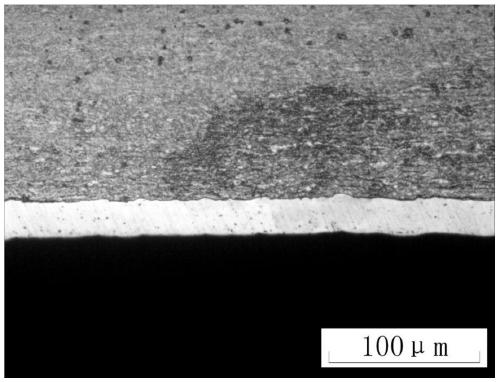

Modifying method for improving performance of stainless steel pump material

InactiveCN109868463AImprove work efficiencyExtended service lifeLiquid/solution decomposition chemical coatingChemical platingDehydrogenation

The invention discloses a modifying method for improving performance of a stainless steel pump material. The modifying method comprises the steps that the surface of a flow passage component of a stainless steel centrifugal pump is plated with a Ni-P amorphous plating film by a chemical plating technology, and the thickness of the plating film is 10-100 [mu]m. The modifying method comprises the specific steps that a test piece is subjected to pretreatment such as cleaning, alkaline washing, acid pickling, activation and pre-plating treatment; the test piece is subjected to chemical nickel-phosphorus plating treatment, the test piece is placed in a plating solution, and film plating is carried out under the environment that the temperature is 80-100 DEG C, the PH is 4.5-5.0, and the platingspeed is 12 [mu]m / h; and plating film thermal treatment is carried out, specifically, firstly, annealing dehydrogenation and stress releasing treatment are carried out at the temperature of 200 DEG C, then thermal treatment is carried out according to different performance requirements, and the temperature range is 300 DEG C-400 DEG C. According to the modifying method for improving the performance of the stainless steel pump material, bonding of the plated Ni-P amorphous plating film and a stainless steel substrate is good, when the thickness of the plating layer is 10-100 [mu]m, the hardness HV is 550-1100 ( which equals to HRC 55-72), and the bonding strength is greater than 15 kg / mm<2>; and the anti-corrosion property of the amorphous plating film is greatly better than stainless steel, and the working efficiency of the centrifugal pump is improved, and the service life is prolonged.

Owner:大连四方佳特流体设备有限公司 +1

Liquid temperature measuring method

InactiveCN104864965AAccurate measurementOvercoming contactRadiation pyrometryLiquid temperatureMeasuring instrument

The invention provides a liquid temperature measuring method which is applied to a liquid temperature measuring system. The liquid temperature measuring system comprises an optical measuring system, a gas source controller, a spectrum temperature measuring instrument, a data recorder and a large-screen display, wherein the optical measuring system comprises a metal optical tube, a measuring window and an optical lens. The liquid temperature measuring method comprises the following steps: the optical measuring system collects spectrum signals of a liquid target surface in the metal optical tube, and transferring the collected spectrum signals to the spectrum temperature measuring instrument; the spectrum temperature measuring instrument converts the received spectrum signals into electric signals, converts the electric signals into temperature data, and then outputs the temperature data to the data recorder; the temperature data is displayed on the large-screen display. The liquid temperature measuring method integrates the advantages of high precision of contact-type temperature measuring and high response of non-contact temperature measuring, so that not only can the defect of low response speed caused by the thick protection pipe wall of the conventional online temperature measuring system be overcome, but also the characteristics of both high precision and high response can be achieved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

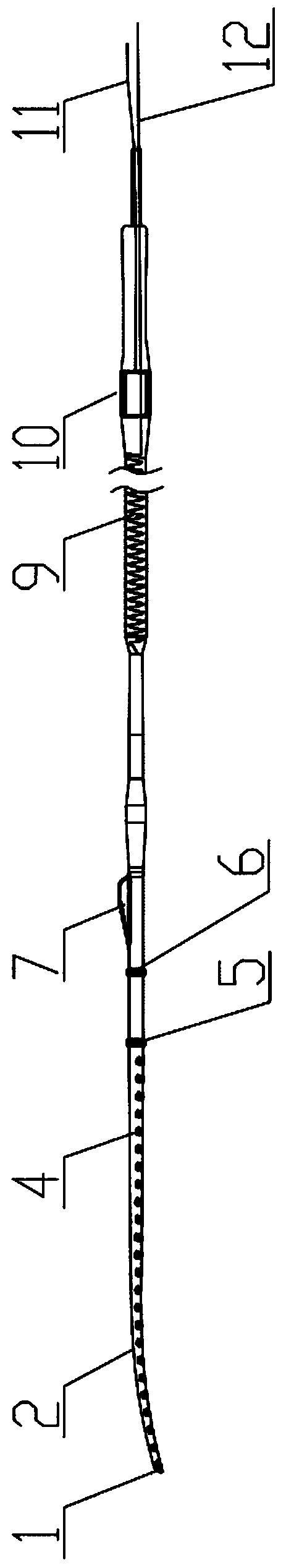

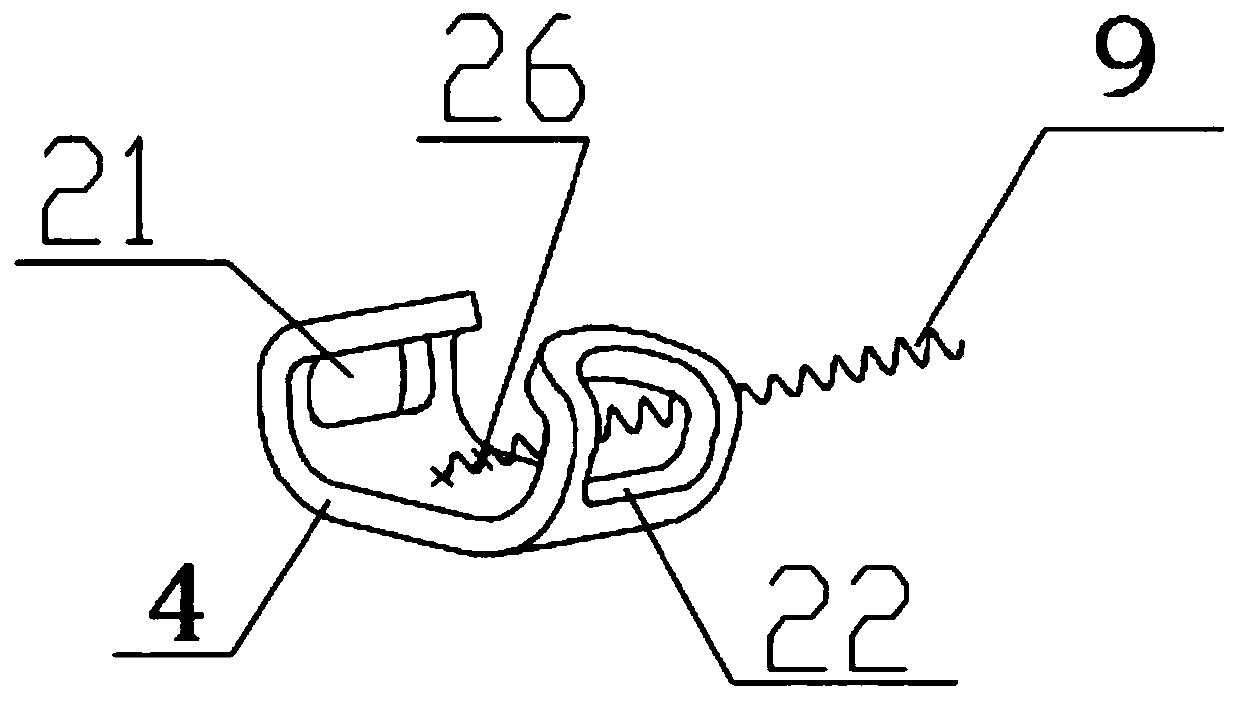

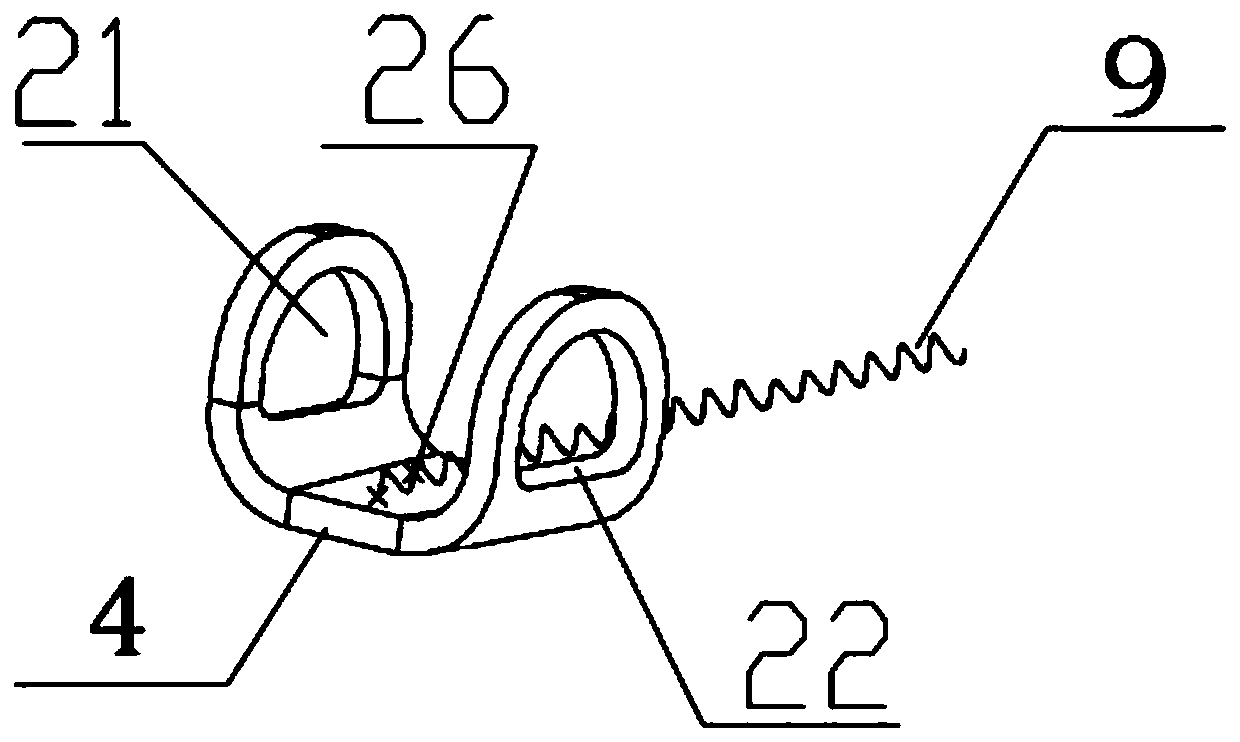

Graphene oxide artificial cochlea electrode and manufacturing method thereof

The invention discloses a graphene oxide artificial cochlea electrode and a manufacturing method thereof. The graphene oxide artificial cochlea electrode comprises an electrode tip point, an electrodecarrier, an electrode contact point, a first positioning ring, a second positioning ring, a boosting part, an electrode wire, a loop electrode, a loop wire electrode and a wire array, wherein the electrode tip point is arranged at the front part of the artificial cochlea electrode; the electrode carrier is silica gel grafted with graphene oxide; the electrode carrier is used for packing the wireelectrode and semi-packing the electrode contact point in one-to-one connection with the wire electrode; the electrode carrier is entirely in the shape being micro-bending; and the wire electrode andthe electrode contact point are in one-to-one connection, and after passing the first positioning ring, the second positioning ring and the boosting part, the wire electrode is in the spiral shape. The methyl ethylene silica gel is adopted, after activating treatment, a silica gel coupling agent namely rrimethoxy silane is used for grafting the graphene oxide to the silica gel, and a hydrophilic antibacterial polymer is obtained, so that the hydrophilicity of the silica gel is improved, the silica gel has antibacterial properties, and besides, the cytotoxicity is reduced.

Owner:ZHEJIANG NUROTRON BIOTECH +1

Square tube roller device and square tube squaring machine applying same

InactiveCN111774419ASatisfy the production operationGuarantee molding qualityMetal rolling stand detailsRollsSteel tubeIndustrial engineering

The invention discloses a square tube roller device and a square tube squaring machine applying the same, and relates to steel tube machining equipment. The square tube roller device comprises a mounting base, four rollers and four roller shafts rotationally erected on the mounting base, wherein the rollers are evenly distributed in the circumferential direction, any roller shaft is arranged in the direction of the connecting line of the corresponding roller and the circle center of the circumference in a sliding mode, and an adjusting assembly used for driving the roller shafts to move synchronously is further arranged on the mounting base; and a square tube squaring machine comprises a machine table and a plurality of square tube roller devices, wherein the square tube roller devices areevenly arranged at intervals in the length direction of the machine table, and the square tube roller device is movably and adjustably arranged in the width direction of the machine table. The squaretube roller device and the square tube squaring machine applying the same are stable in work, convenient and fast to operate, capable of conveniently producing square tubes of various sizes and specifications and beneficial to improving the production efficiency and the square tube forming quality.

Owner:天津仁和聚科技发展有限公司

Security entrance guard identification system with anti-jamming self-detection function

ActiveCN111540097AHigh degree of automationImprove long-term operational stabilityBatteries circuit arrangementsElectric powerElectric machineryEmbedded system

The invention discloses a security entrance guard identification system with an anti-jamming self-detection function. By arranging a first anti-jamming motor, a second anti-jamming motor, a weight sensor and the like, the system can achieve the automatic self-detection and automatic blockage clearing on two most common jamming positions of a positioning card, so the automation degree of the systemis improved, the frequency of manual startup maintenance is reduced, and the long-term operation stability of the system is improved.

Owner:西安悦泰科技有限责任公司

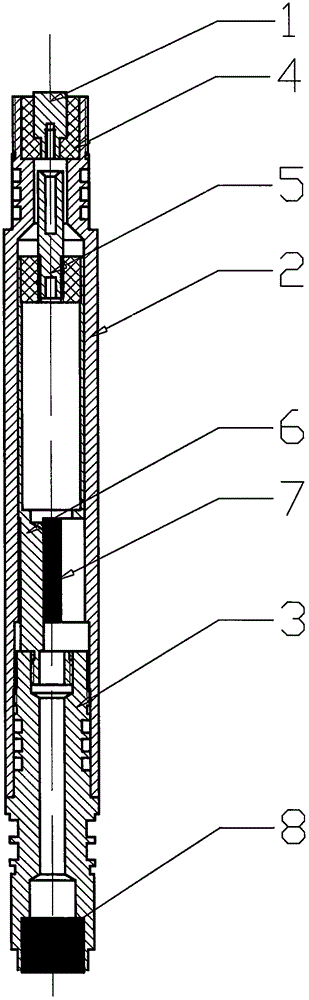

Oil production system of reciprocating submersible electric pump driven by sand-proof linear motor

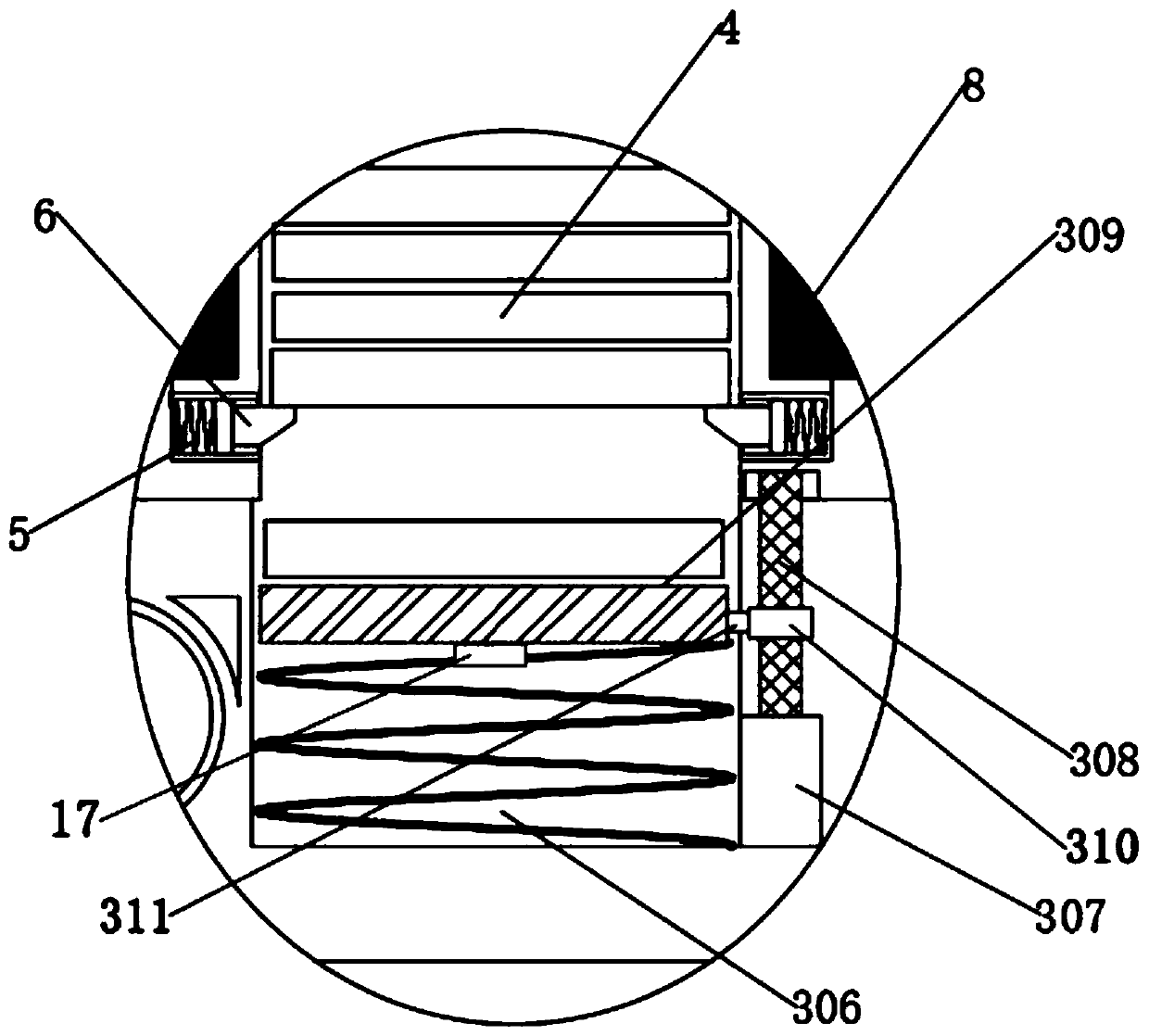

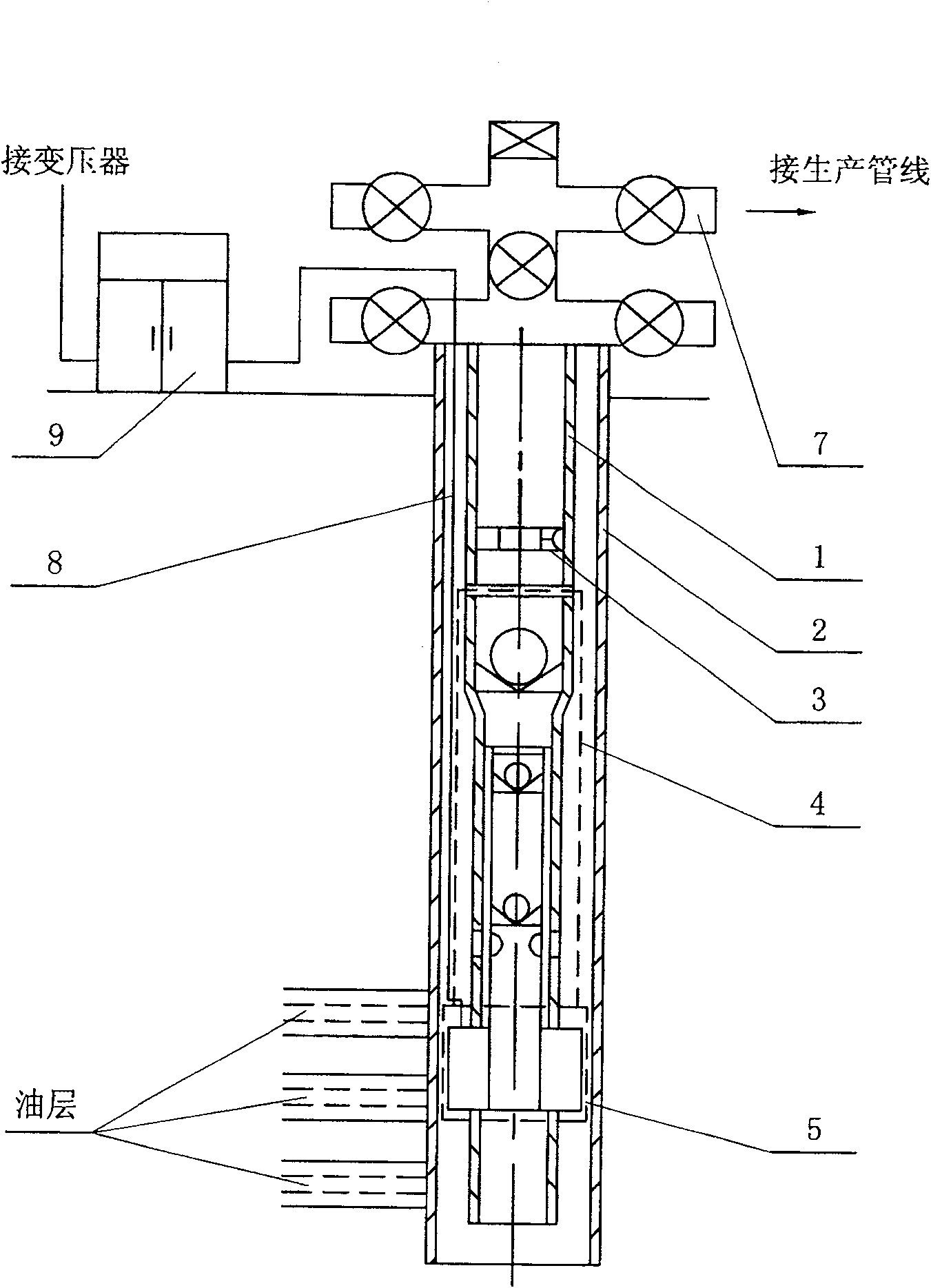

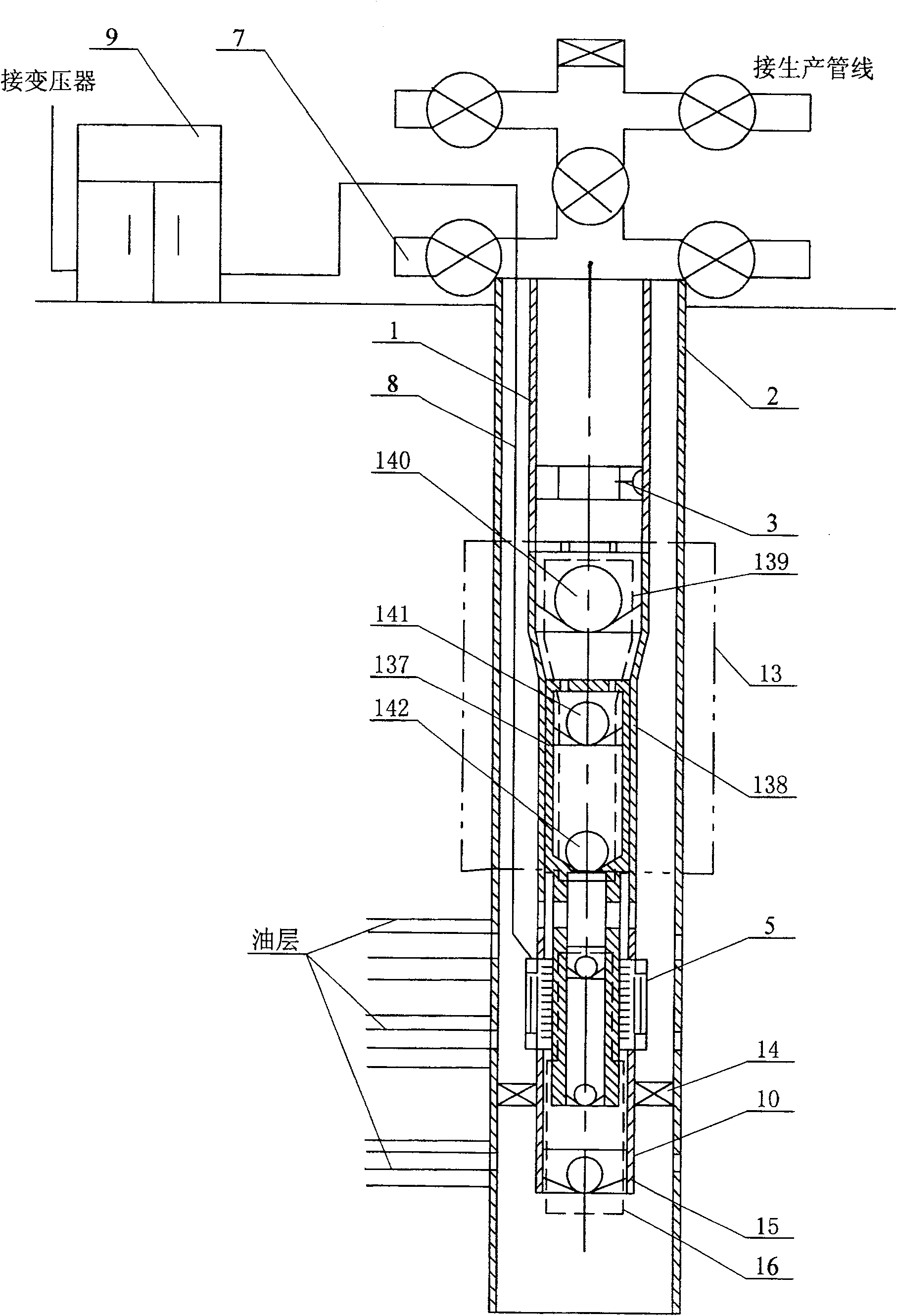

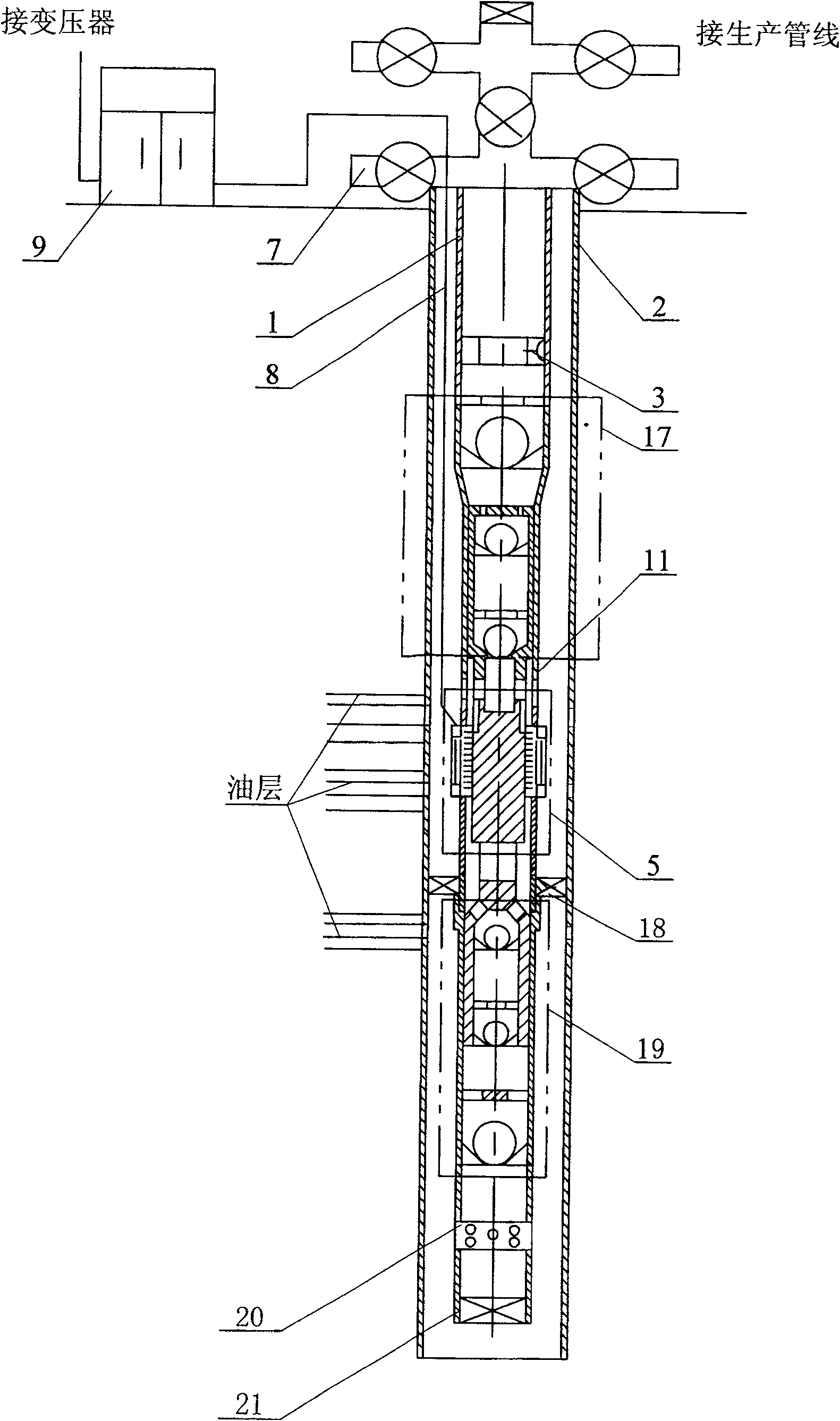

InactiveCN100567700CWork normally for a long timeTo achieve the purpose of anti-cardFlexible member pumpsFluid removalTubular linear motorElectric machine

A reciprocating electric submersible pump oil production system driven by a sand control linear motor relates to a submersible electric pump oil production system driven by a linear motor. For the reciprocating submersible electric pump oil production system driven by linear motors, since the linear motors used do not have sand control functions, the sand in the well fluid is easy to enter the gap between the mover and stator of the linear motors, affecting the reciprocating submersible electric pumps. Problems with the normal operation of the pump oil production system. The oil pipe is equipped with a drainer, the two ends of the reciprocating plunger pump are fixedly connected with the oil pipe and the linear motor respectively, and the two ends of the cable are respectively connected with the linear motor and the frequency conversion speed control device; the reciprocating plunger pump is a reciprocating split It is one of the plunger pump for stratified mining, reciprocating double pumping plunger pump for stratified mining or reciprocating double-acting plunger pump. The linear motor is a sand control linear motor. The oil production and sand prevention linear motor of the present invention drives the reciprocating electric submersible pump to work, thereby achieving the purpose of preventing the linear motor from jamming and ensuring the normal operation of the reciprocating electric submersible pump oil production system.

Owner:DAQING OILFIELD CO LTD

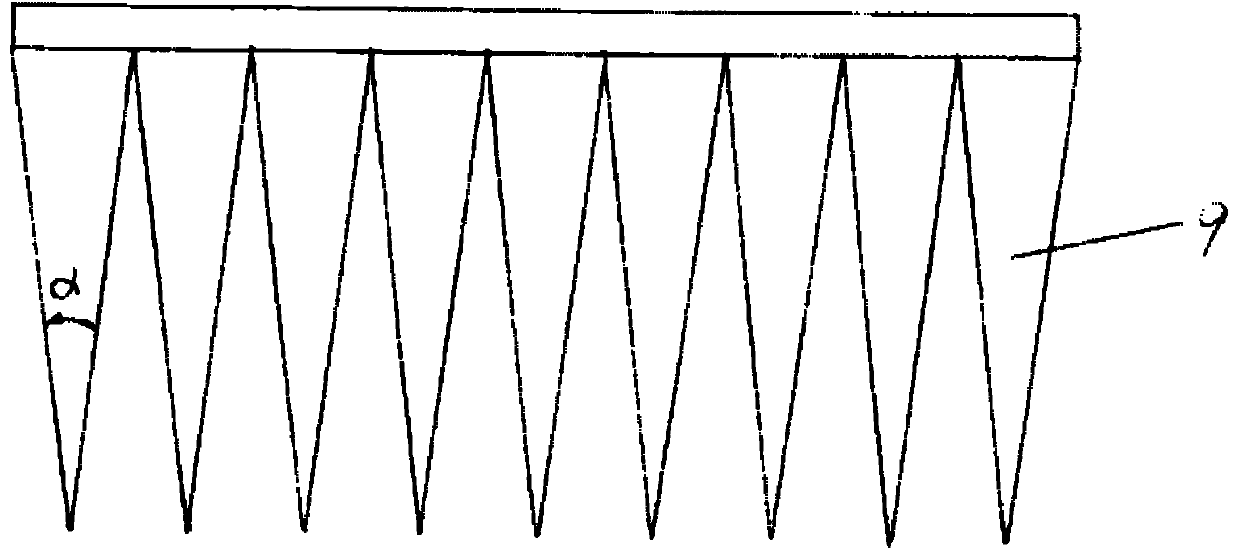

Method for manufacturing buoy of air valve of hydroelectric generating unit

The invention relates to a method for manufacturing components of a mixed flow type generating set in a power plant, namely a method for manufacturing a buoy of an air valve of a hydroelectric generating unit. The method comprises the following steps of: taking a stainless steel tube of which the diameter is equal to that of the buoy, wherein the length of the stainless steel tube is equal to thesum of the height of a round tube section of the buoy and the length of a beveled edge of a tapered section; drawing triangles side by side from the upper end to the lower end on the circumferential surface of the stainless steel tube; cutting an inverted triangle in a stripping way to obtain a spaced rack shape, and treating by using an angle grinder; vertically welding a central rod of which the upper end is provided with a central disc to a flat base steel plate and sleeving the stainless steel tube on the central rod and the central disc, wherein the diameter of the central disc is equal to that of an upper opening of the buoy and the height of the central disc is equal to that of the buoy; and heating racks through gas welding, bending the racks on the central disc in turn, performing spot welding among the racks through electric welding, taking down the stainless steel tube, connecting the racks through electric welding, and polishing to form the buoy with the upper opening. Themethod has the characteristics that: the buoy is reasonable in process, hard to rust and long in service life, and normal work of a main valve is guaranteed.

Owner:YUNFENG POWER PLANT

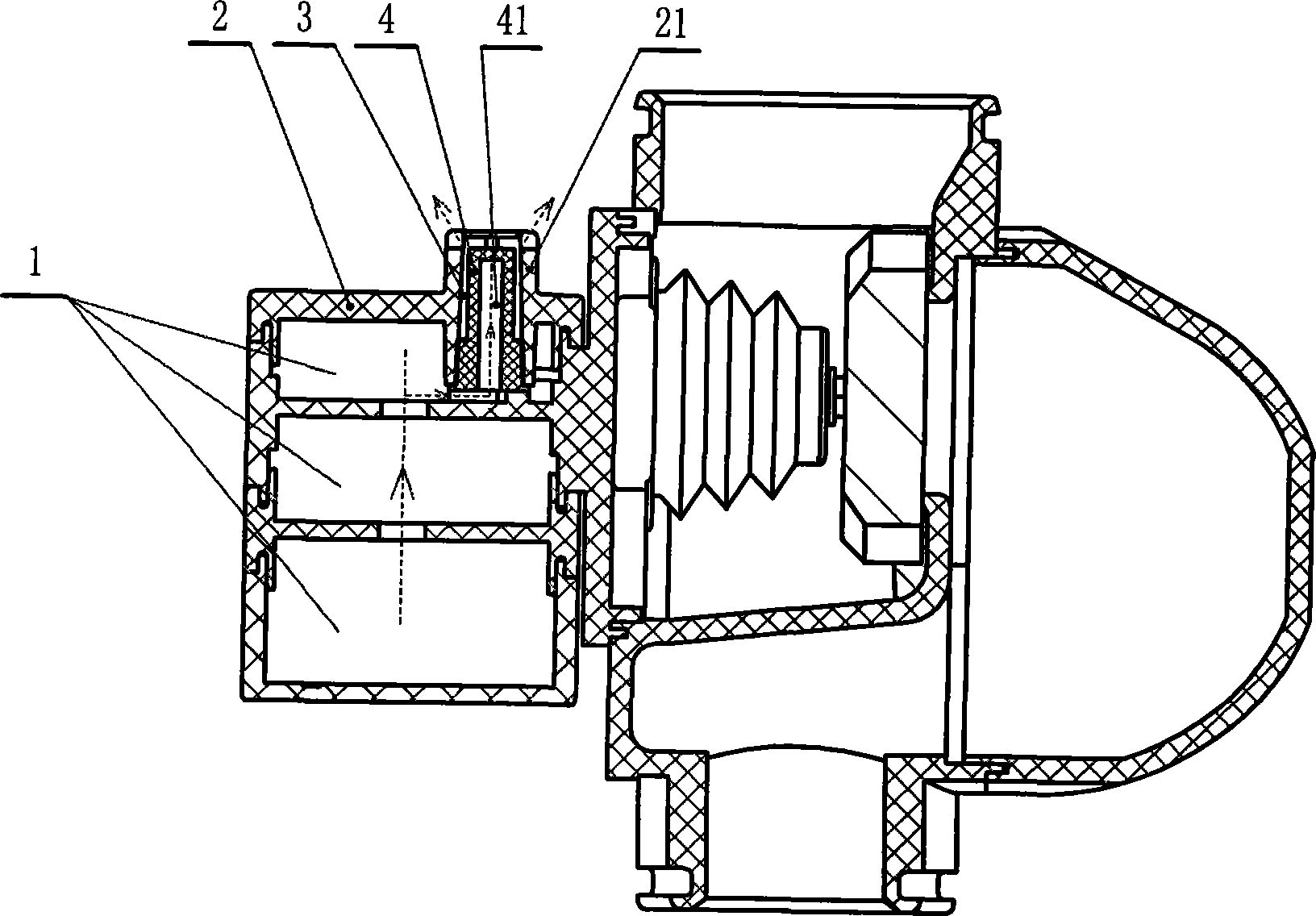

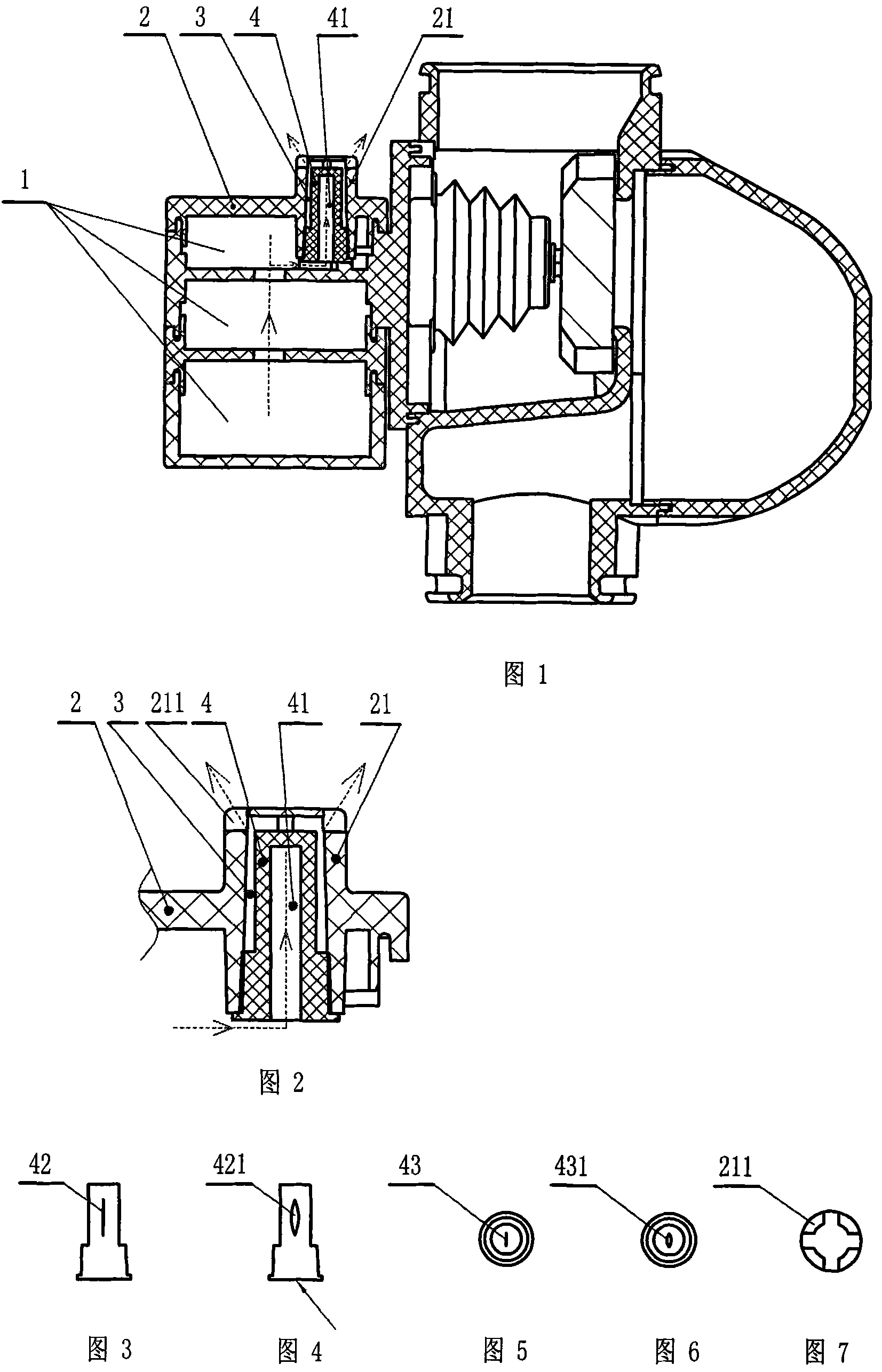

Exhaust for gas meter valve

InactiveCN101424353BTimely exclusionAvoid situations where it cannot be openedEqualizing valvesSafety valvesGas meterBody cavity

The invention provides an exhaust device for gas meter valves, which can prevent pressure in a cavity of a gas meter valve from increasing and guarantee the long-term normal work of the valve. A sealing cover with a through hole is arranged on a valve body cavity; an exhaust plug (4) is inlaid in the through hole of the sealing cover; the exhaust plug is provided with a blind hole (41) which has the inner end opened and is communicated with the valve body cavity (1); the upper part of the exhaust plug is provided with an exhaust gap (42); the inner mouth of the exhaust gap (42) is communicated with the blind hole of the exhaust plug; and the outer mouth of the exhaust gap (42) is communicated with the external environment of the cavity (1). The exhaust device is suitable to be arranged onthe gas meter valve so as to ensure that the valve can normally work for a long time.

Owner:宣国平

A ventilation system and method

ActiveCN112556061BAvoid failureExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsHoneycomb

The invention provides a ventilation system and method, which are applied to a three-dimensional space with people or animals, including an air intake module, a one-way power exhaust module, a gas detection module and a control module. The air intake module includes an air intake box, a power The air inlet mechanism and the air guide head, the first intercepting screen is arranged in the air inlet box, the power air inlet mechanism includes the air inlet pipe and the second intercepting screen, the first fan, and the porous honeycomb are arranged in the air inlet pipe in sequence according to the air inlet direction. body filter layer, the second fan, the area of the wind passing surface of the first intercepting net plate is greater than the area of the wind passing surface of the second intercepting net plate, the air guide head is movably arranged at the air outlet of the air inlet pipe, and the control module is used It is used to control the start and stop of the first fan, the second fan and the one-way power exhaust module according to the air pressure and the gas concentration of the preset type. Compared with the existing technology, better filtering effect, higher ventilation efficiency, longer service life and better biological safety are achieved.

Owner:深圳博强建设开发有限公司

A security access control identification system with anti-card self-detection function

ActiveCN111540097BHigh degree of automationImprove long-term operational stabilityBatteries circuit arrangementsElectric powerElectric machineryEmbedded system

The invention discloses a security access control identification system with an anti-jamming self-detection function. By setting a first anti-jamming motor, a second anti-jamming motor and a weight sensor, etc., it can automatically locate the jamming in the two most common jamming positions. Self-inspection and automatic blockage removal improve the degree of automation of the system, reduce the frequency of manual start-up maintenance, and improve the long-term operation stability of the system.

Owner:西安悦泰科技有限责任公司

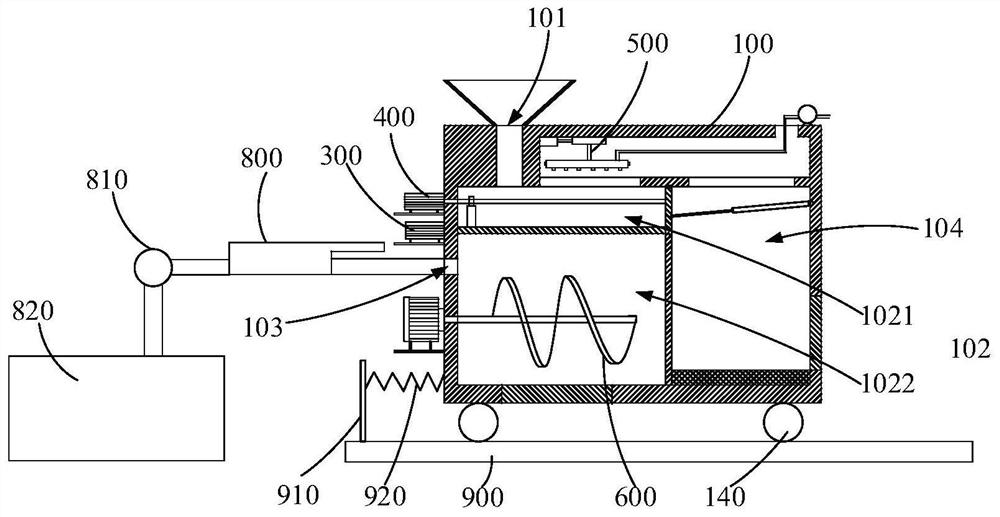

Building appliance

InactiveCN112829059AAvoid blockingWork normally for a long timeCement mixing apparatusLiquid ingredients supply apparatusArchitectural engineeringMoving parts

The invention discloses a building appliance, which comprises a stirring box provided with a stirring cavity and a water injection port communicated with the stirring cavity; a stirring mechanism connected with the stirring box and used for stirring materials in the stirring cavity; a filtering assembly comprising a shell, a filtering part and a moving part; the shell is provided with a water passing cavity, a water inlet communicated with the water passing cavity and a water outlet communicated with the water passing cavity; the water outlet is communicated with the water injection port; the filtering part is arranged in the water passing cavity and located between the water inlet and the water outlet, and the filtering part is further provided with a filtering hole communicated with the water inlet and the water outlet; and the moving part is arranged on the filtering part and used for moving substances located on the side, close to the water inlet, of the filtering part so that the substances can avoid the filtering hole. The building appliance provided by the invention can prevent impurities from blocking the filtering hole, and it is guaranteed that the filtering part can work normally for a long time.

Owner:湖南弘运建筑有限公司

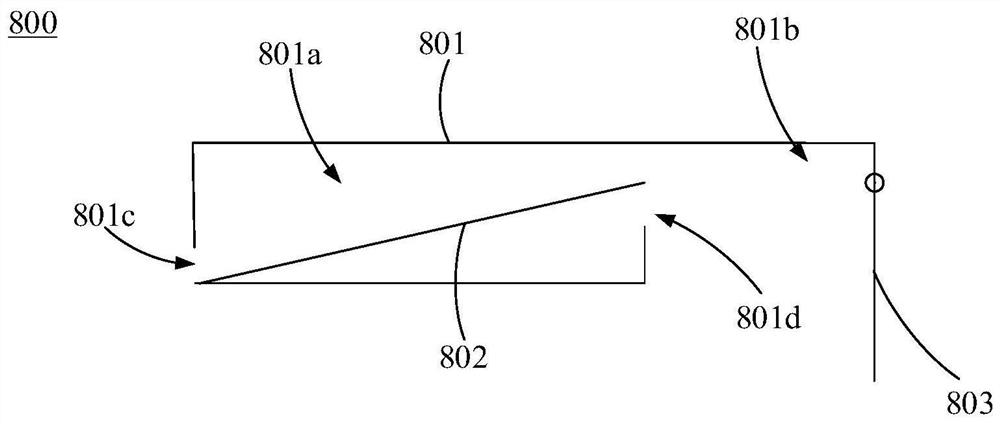

Totally closed downhole pressure gauge

The invention discloses a totally closed downhole pressure gauge and mainly solves the problems that a conventional pressure gauge has poor airtightness and cannot keep long-term effective airtightness in environments with high pressure, high temperature and strong aggressive gas. The totally closed downhole pressure gauge is characterized in that a welding insulation ring (4) is arranged between a welding electrode (1) and a welding sleeve (2) for mutual welding connection, a circuit bracket (6) is arranged in the welding sleeve (2), the upper end of the circuit bracket (6) is in circuit communication with the welding electrode (1) through a rotary connector (5), an attitude detection circuit (7) and a battery are arranged in the circuit bracket (6), the attitude detection circuit (7) is in data communication with the outside through the rotary connector (5) and the welding electrode (1), the upper end of a sensor welding bracket (3) is connected with the circuit bracket and welded with the welding sleeve (2), and the lower end is in welding connection with a pressure sensor (8). The totally closed downhole pressure gauge has the characteristics that instrument working states are controlled through attitude detection and good airtightness can be still kept when the downhole pressure gauge is placed at a high pressure, at a high temperature and in strong aggressive gas.

Owner:方永和

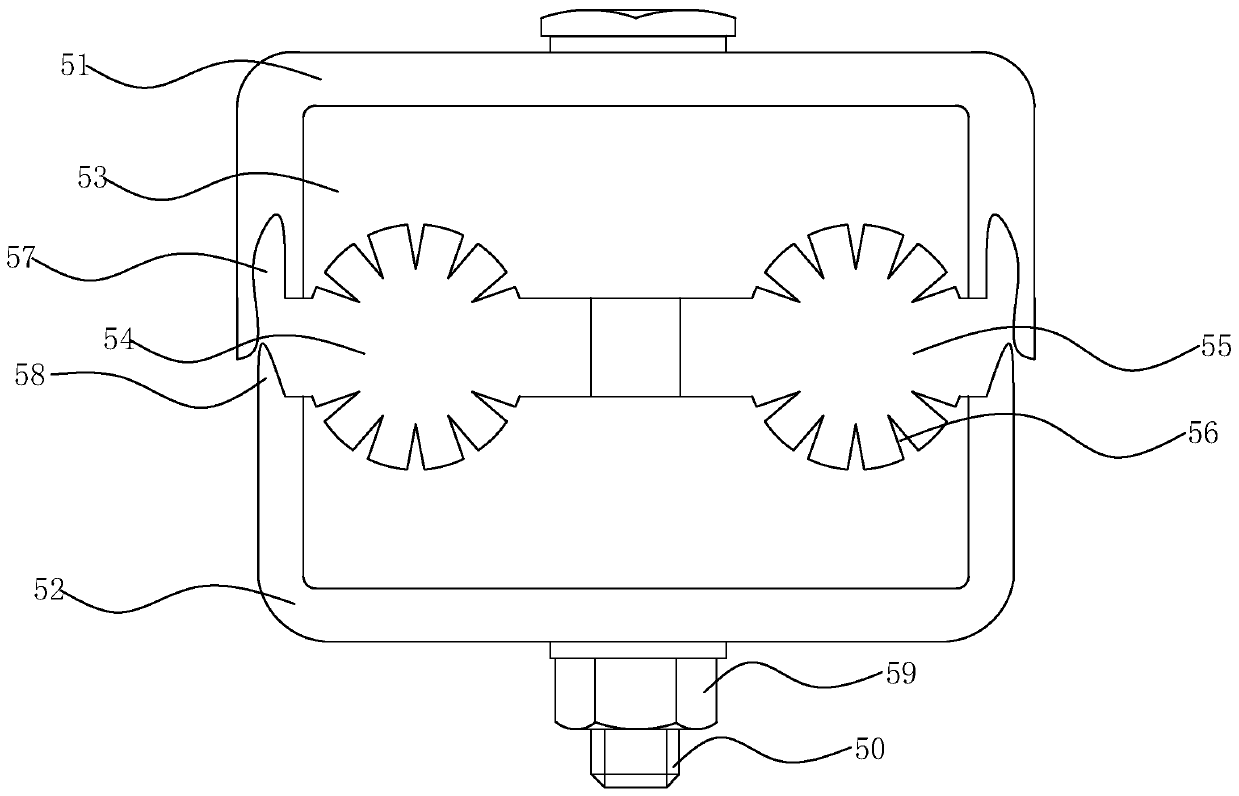

Efficient heat dissipation bus monitoring device

InactiveCN111132522AAdequate heat dissipationEfficient heat dissipationCooling/ventilation/heating modificationsEngineeringTransit bus

The invention relates to the technical field of bus monitoring devices, and particularly relates to an efficient heat dissipation bus monitoring device. According to the technical scheme, the efficient heat dissipation bus monitoring device comprises a support, and a monitoring camera is installed on the support; one end, away from a lens, of the monitoring camera is connected with a heat dissipation box; a water box, an atomization cavity and an air draft cavity are sequentially arranged in the heat dissipation box, and one side, away from the atomization cavity, of the air draft cavity is connected with the monitoring camera; a micro water pump is included, a water inlet of the micro water pump is connected with the water box, a water outlet pipe of the micro water pump is connected withan atomizing nozzle, the atomizing nozzle is installed in the atomization cavity, an air inlet is arranged in the atomization cavity, and the atomization cavity is connected with the air draft cavity; and an exhaust fan is installed in the air draft cavity, and a plurality of cooling air holes are arranged in the side, close to the monitoring camera, of the air draft cavity. The invention provides the bus monitoring device capable of cooling the cooling air to improve cooling efficiency during air cooling, and a problem that an existing bus monitoring device is difficult to obtain reliable heat dissipation is solved.

Owner:新疆天亿智远电子科技有限公司

Modification method of improving performance of stainless steel material

InactiveCN111254381ASimple processingImprove wear resistanceSolid state diffusion coatingLiquid/solution decomposition chemical coatingCarburizingCorrosion

The invention provides a modification method of improving the performance of stainless steel material. The treatment process is simple and effective, nitriding and oxidation treatment is carried out on the surface of the stainless steel material, and a compact compound layer with sufficient depth and a diffusion layer with corresponding length are formed on the surface of a workpiece, so that thewear resistance, corrosion resistance and fatigue resistance of the metal surface are greatly improved; a black oxidation film is formed on the surface of the workpiece to improve the antirust performance of the workpiece, and the workpiece appearance can be beautified; in addition, the compound layer can be oxidized to increase oxygen content of the compound layer so as to passivate the compoundlayer, so that the corrosion resistance is greatly improved, the energy consumption is reduced, and the service life of a product is prolonged; and the technology is simple, the cost is low, and the treatment technology including high-frequency quenching, carburizing and quenching, hard chrome plating, ion nitriding and the like can be substantially replaced.

Owner:江苏拓展新材料科技有限公司

Compressor and air conditioner

PendingCN111271256AReduce oil contentImprove heat transfer efficiencyPositive displacement pump componentsPositive-displacement liquid enginesReflux valveRefrigerant

The invention discloses a compressor and an air conditioner applying the same. The compressor comprises a main machine, the main machine is provided with an air inlet and an air outlet, low-temperature and low-pressure refrigerant gas enters the main machine from the air inlet, after the main machine compresses the low-temperature and low-pressure refrigerant gas, high-temperature and high-pressure refrigerant gas is formed and discharged outwards from the air outlet, a separation cylinder of a gas-liquid separation assembly is provided with a separation cavity, an exhaust port and a backflowport, the exhaust port and the backflow port communicate with the separation cavity, the separation cavity communicates with the air outlet, an exhaust port is arranged above the backflow port, and abackflow valve communicates with the backflow port and a main machine lower cavity. According to the technical scheme of the compressor and the air conditioner applying the same, lubricating oil in arefrigerant is collected at the bottom of the separation cavity of the separation cylinder by adopting the separation cylinder, so that the oil content in a circulating pipeline is reduced, and the heat exchange efficiency and the overall performance of a heat exchanger of the air conditioner are improved.

Owner:北海职业学院

A tower-type solar closed pressure heat absorption system and method

ActiveCN105180475BShort startup timeLow investment costSolar heat devicesSolar thermal energy generationBlowoff valveStart time

The invention discloses a tower-type solar closed under-pressure heat absorption system which comprises a heat absorber at the high position and a heat exchanger located at the low position. An outlet of the heat absorber is connected with an inlet of the heat exchanger through a pipeline. The tower-type solar closed under-pressure heat absorption system is characterized by further comprising a storage buffer tank located at the low position; a heat absorption medium adding pipe is connected to the storage buffer tank; an air inlet pipe and an exhaust pipe are connected to the storage buffer tank higher than the heat absorption medium adding pipe; the air inlet pipe, the exhaust pipe and the heat absorption medium adding pipe are each provided with a valve; one side of the storage buffer tank is connected with an outlet of the heat exchanger through a pipeline, and the other side of the storage buffer tank is connected with an inlet of a circulating pump through a pipeline; an outlet of the circulating pump is connected with an inlet of the heat absorber through a pipeline; and the heat absorber is connected with a blowoff valve through a pipeline, and the blowoff valve is higher than the heat absorber. The invention further discloses the heat absorption method. The tower-type solar closed under-pressure heat absorption system has the beneficial effects of being low in investment cost and operation cost, good in safe and short in heat absorber starting time and ensures the long-term normal working.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com