Method for manufacturing buoy of air valve of hydroelectric generating unit

The technology of a hydroelectric unit and its production method is applied in the field of production of mixed-flow generator unit components in power plants. It can solve problems such as failure to use the original process, unsuitable finished products, and large welding deformation, so as to solve the problem of buoy corrosion and ensure long-term normal operation. smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

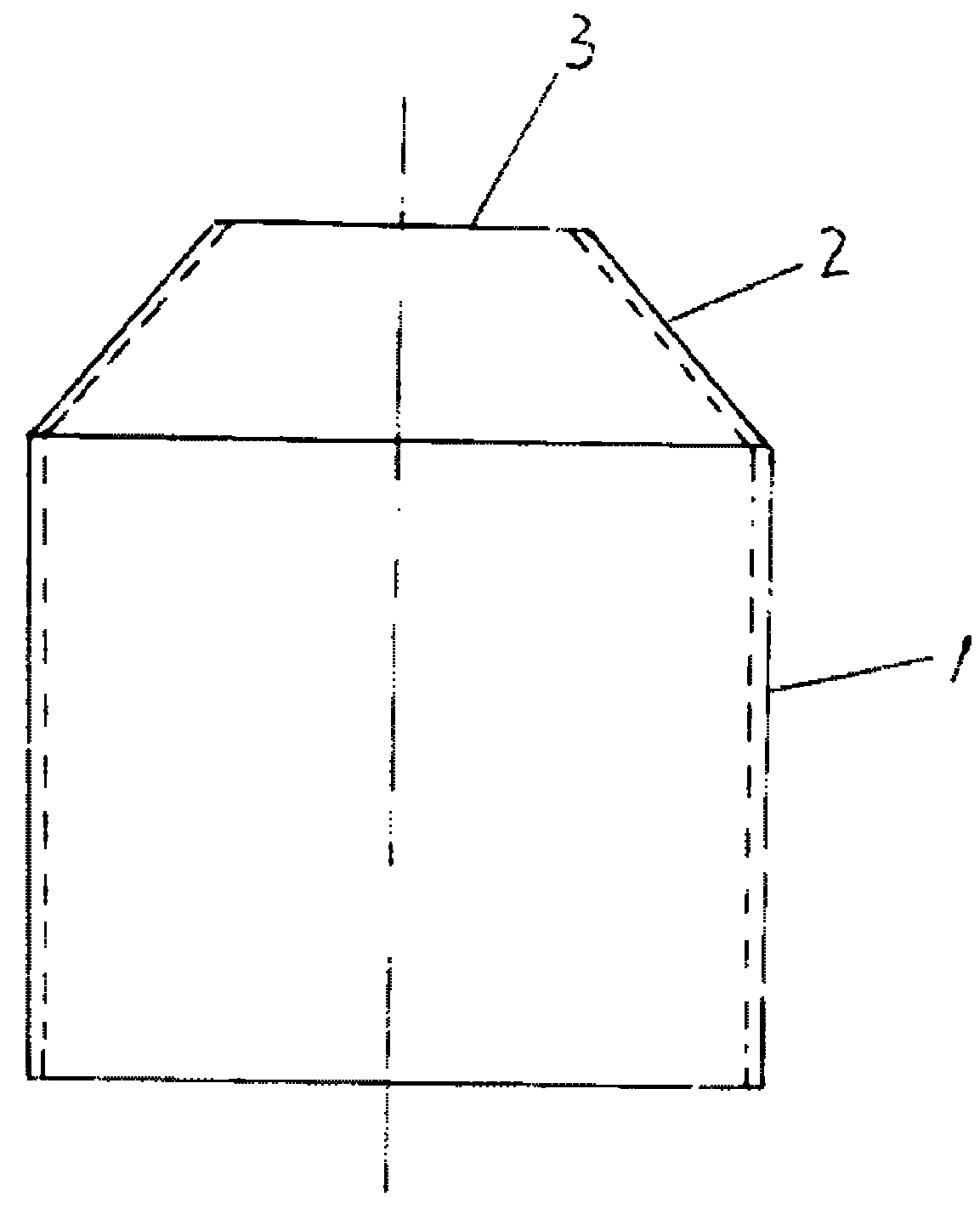

[0015] see figure 1 , the air valve buoy is a cylindrical structure in which a circular tube 1 (or called a cylinder) and a tapered tube 2 are connected as one. The upper part has an opening 3. It consists of a Φ600mm, wall thickness 10mm, 300mm long circular tube 1 and a 147mm long tube. , Bottom Φ600, top Φ280 conical tube 2 welded.

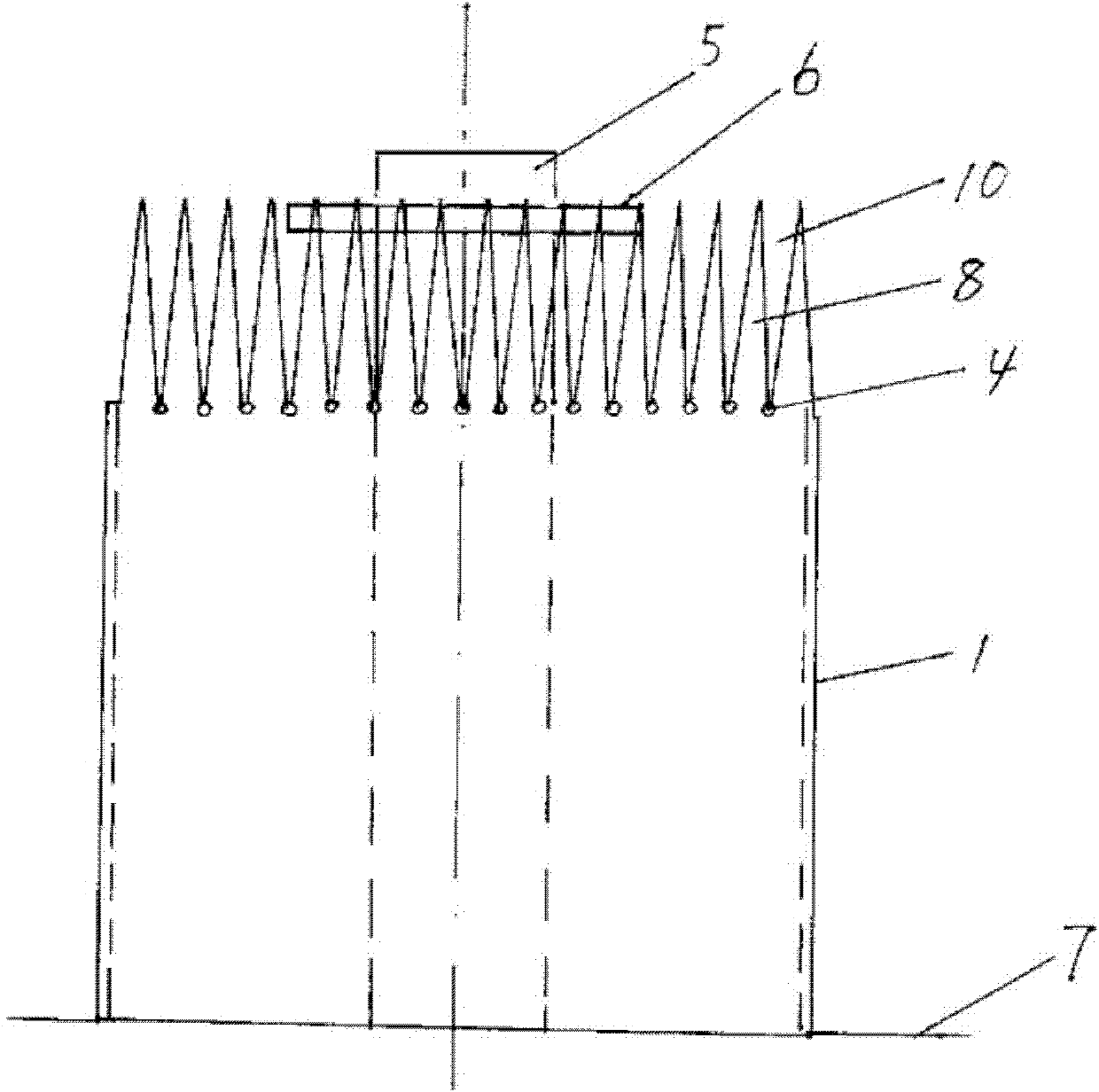

[0016] see figure 2 , 3 , the manufacturing method of the hydroelectric unit air valve buoy comprises the following steps:

[0017] 1. Purchasing a Φ600 stainless steel pipe with a wall thickness of 10mm according to the drawing of the air valve, and cutting a section of round pipe with a height of 447mm.

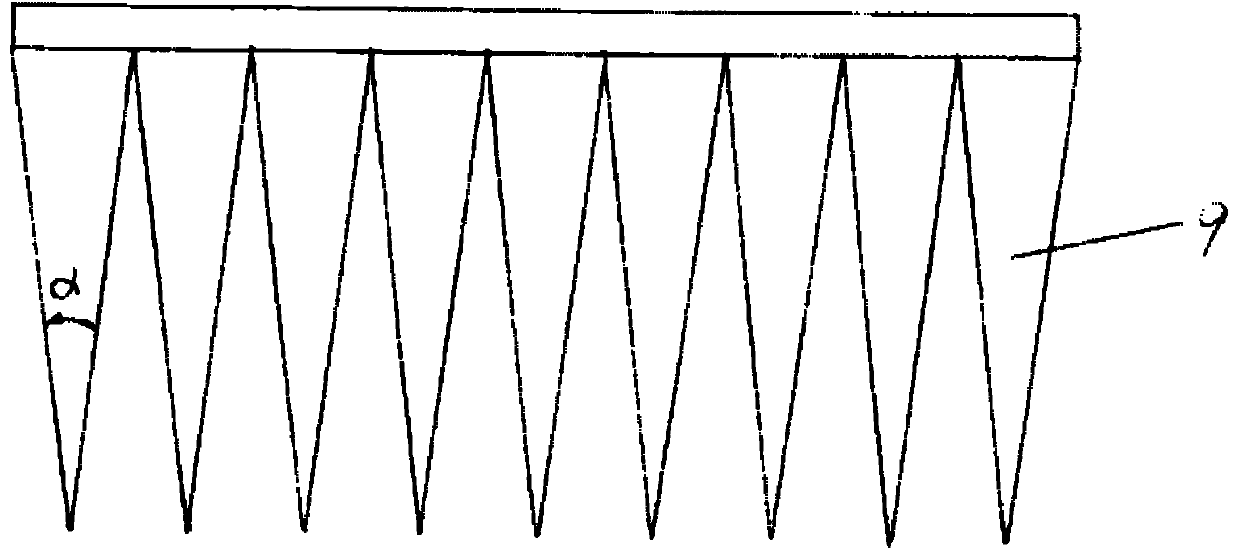

[0018] 2. To make a variable-diameter sample, expand the soft plastic plate with a length of 1884mm (equal to the circumference of a Φ600 round tube) and a width of 220mm (see figure 2 ). There are 24 triangles 9 in total, and the cone angle α is 15°. The height of triangle 9 is 198mm (equal to the hypotenuse length of 2 sections of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com