High temperature resistance diving motor winding wire and preparation technology

A submersible motor, winding wire technology, used in cable/conductor manufacturing, circuits, insulated cables, etc., can solve the problems of short service life, can not work normally, can not meet the accurate transmission of signals, etc., to improve electrical performance and mechanical performance, Avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

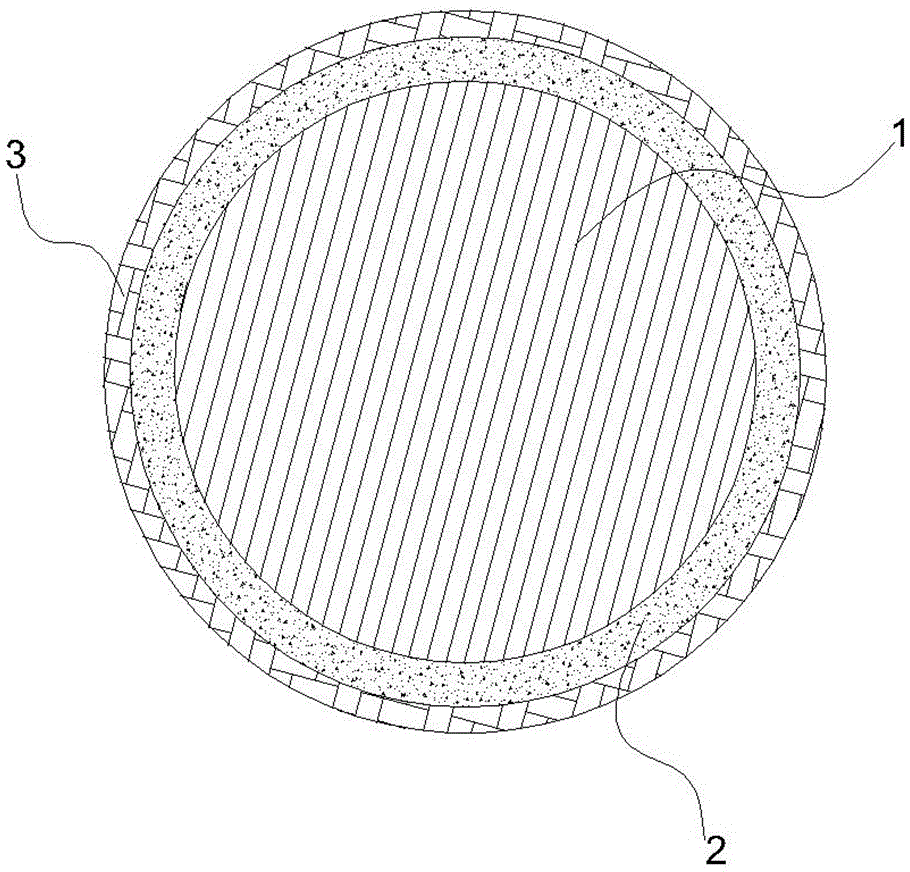

[0021] A high temperature resistant submersible motor winding wire, such as figure 1 As shown, the winding wire includes a single-wire copper conductor 1, the diameter of the single-wire copper conductor is 1.00mm, and an insulating layer 2 and a sheath layer 3 are sequentially wrapped outside the single-wire copper conductor, and the material of the insulating layer 2 It is ethylene-tetrafluoroethylene copolymer, the thickness of the insulating layer 2 is 0.50 mm, the material of the sheath layer 3 is polyamide, and the thickness of the sheath layer 3 is 0.30 mm.

Embodiment 2

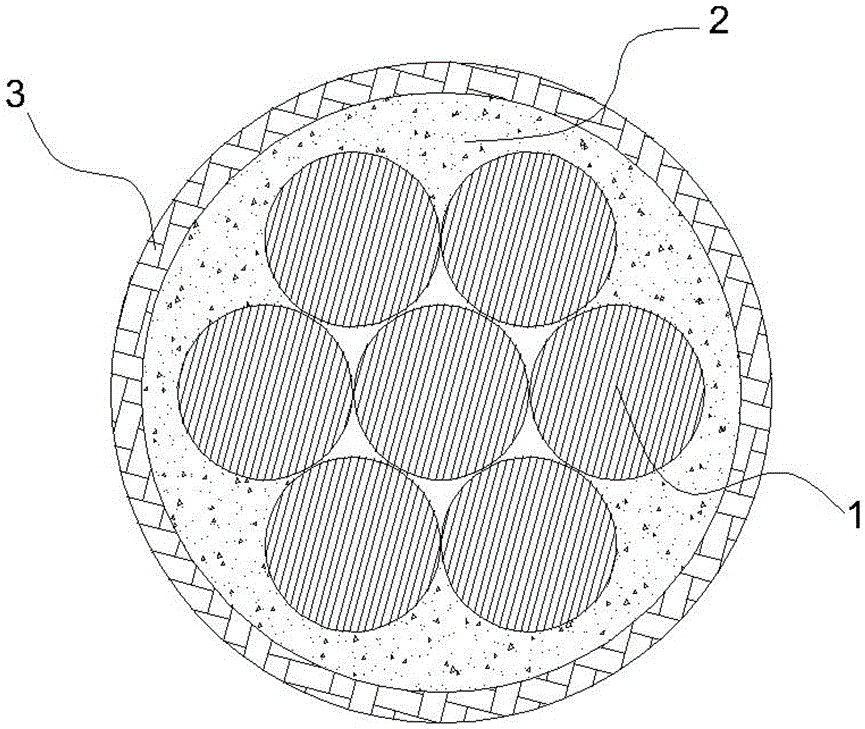

[0023] A high temperature resistant submersible motor winding wire, such as figure 2 As shown, the winding wire is a stranded conductor 1 formed by twisting 7 copper conductors with a diameter of 1.12 mm, and the outer surface of the stranded conductor is wrapped with an insulating layer 2 and a sheath layer 3 in sequence, so The material of the insulating layer 2 is ethylene-tetrafluoroethylene copolymer, and the thickness of the insulating layer 2 is 1.00 mm. The material of the sheath layer 3 is polyamide, and the thickness of the sheath layer 3 is 0.3 mm.

[0024] The winding wires can be made into various models, such as 7 / 0.60-7 / 3.00mm, 19 / 0.60-19 / 1.50mm.

[0025] The winding wires of the above two embodiments have been tested by a high temperature test, and the winding wires will not be broken down at a high temperature of 200±5°C for 30 minutes and then switched to a power frequency of 50HZ and 2500V for 1 minute.

[0026] The preparation process of the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com