Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Uniform shade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dispersing/reducing printing process for polyester/cotton blended fabric

InactiveCN102852013AImprove efficiencyFast and efficientDry-cleaning apparatus for textilesDyeing processPolyesterCooking & baking

The invention discloses a dispersing / reducing printing process for a polyester / cotton blended fabric, which belongs to the technical field of printing of polyester / cotton blended fabrics. The process comprises the following successive steps: reception of a sample from a customer; color separation; draft drawing; preparation of a net; inspection of a gray fabric; sewing; singeing; desizing and scouring and bleaching; mercerizing; performing; printing; primary drying; baking; rolling of reduction liquid; rapid vat ageing; primary washing; oxidation; ventilation; oxidation; secondary washing; soaping; ternary washing; secondary drying; shaping; inspection; and inspection of a finished product. The dispersing / reducing printing process for the polyester / cotton blended fabric provided by the invention has the advantages of a good printing effect, low cost and simple process.

Owner:SHAOXING UNIVERSITY

Color-light consistent pure cotton bleached bright adhesive interlining and production method thereof

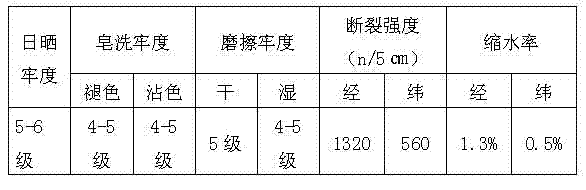

ActiveCN105133314AUniform shadeReduce freeSucessive textile treatmentsGarmentsCoated surfaceInterlining

The invention discloses a color-light consistent pure cotton bleached bright adhesive interlining and a production method thereof; the adhesive interlining is uniform and consistent in color and light, and the surface of a coating layer is bright; the content of free and hydrolyzed formaldehyde is not more than 35 mg / kg; the adhesive interlining stripping strength is not less than 20 N; the dimensional change rate in the warp and weft direction after water washing is -0.8% to +0.5%. The adhesive interlining is uniform and consistent in color and light and bright in surface, the quality grade of the adhesive interlining is enhanced, point leakage, coating leakage and other defect points can be easily detected during visual inspection, so as to ensure that defective products are not produced due to point leakage and coating leakage during clothing pressing, the content of free and hydrolyzed formaldehyde is low, the adhesive interlining stripping strength is high, the shrinkage rate in the warp and weft direction is small, and the production method is easy to operate.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

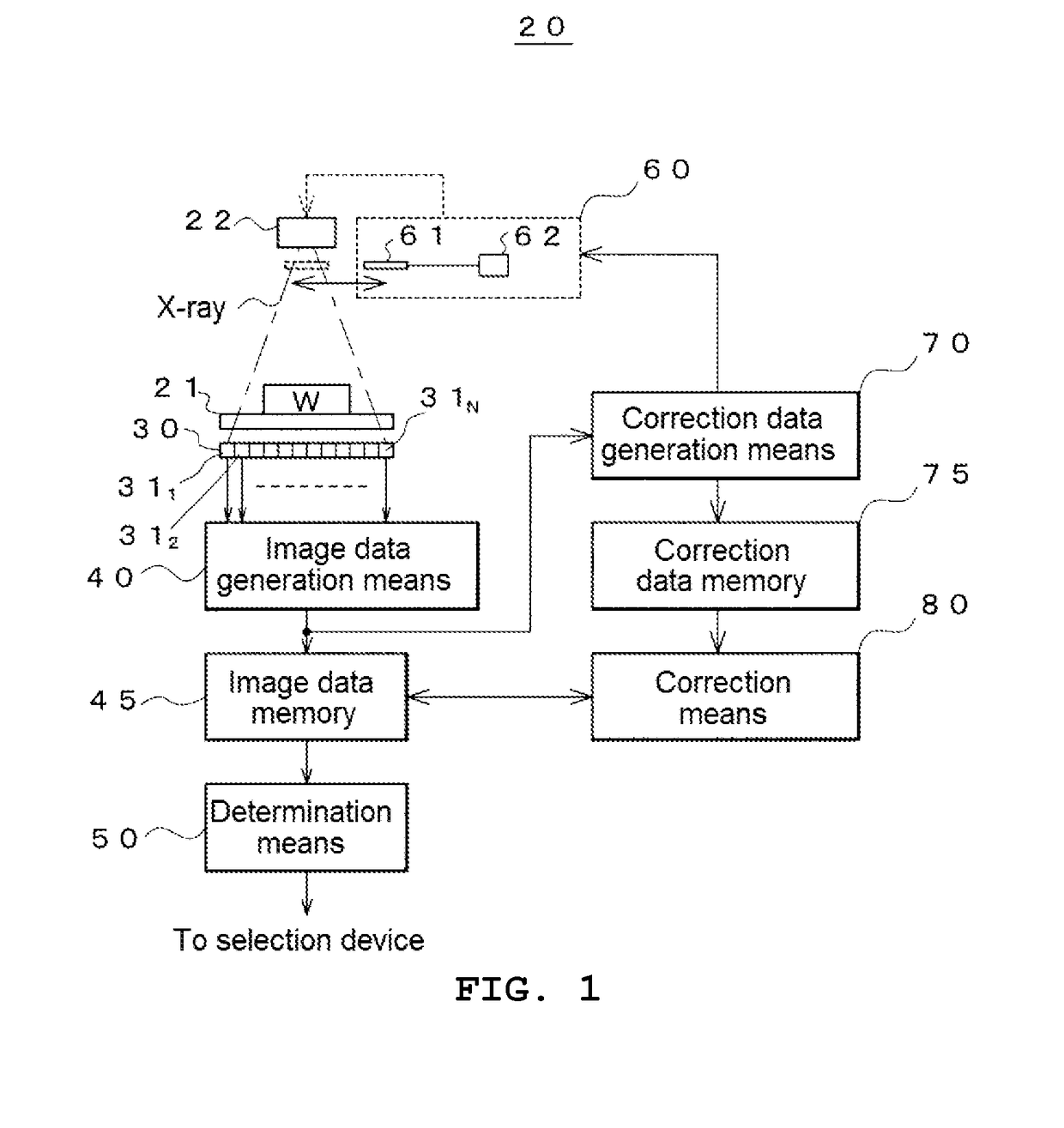

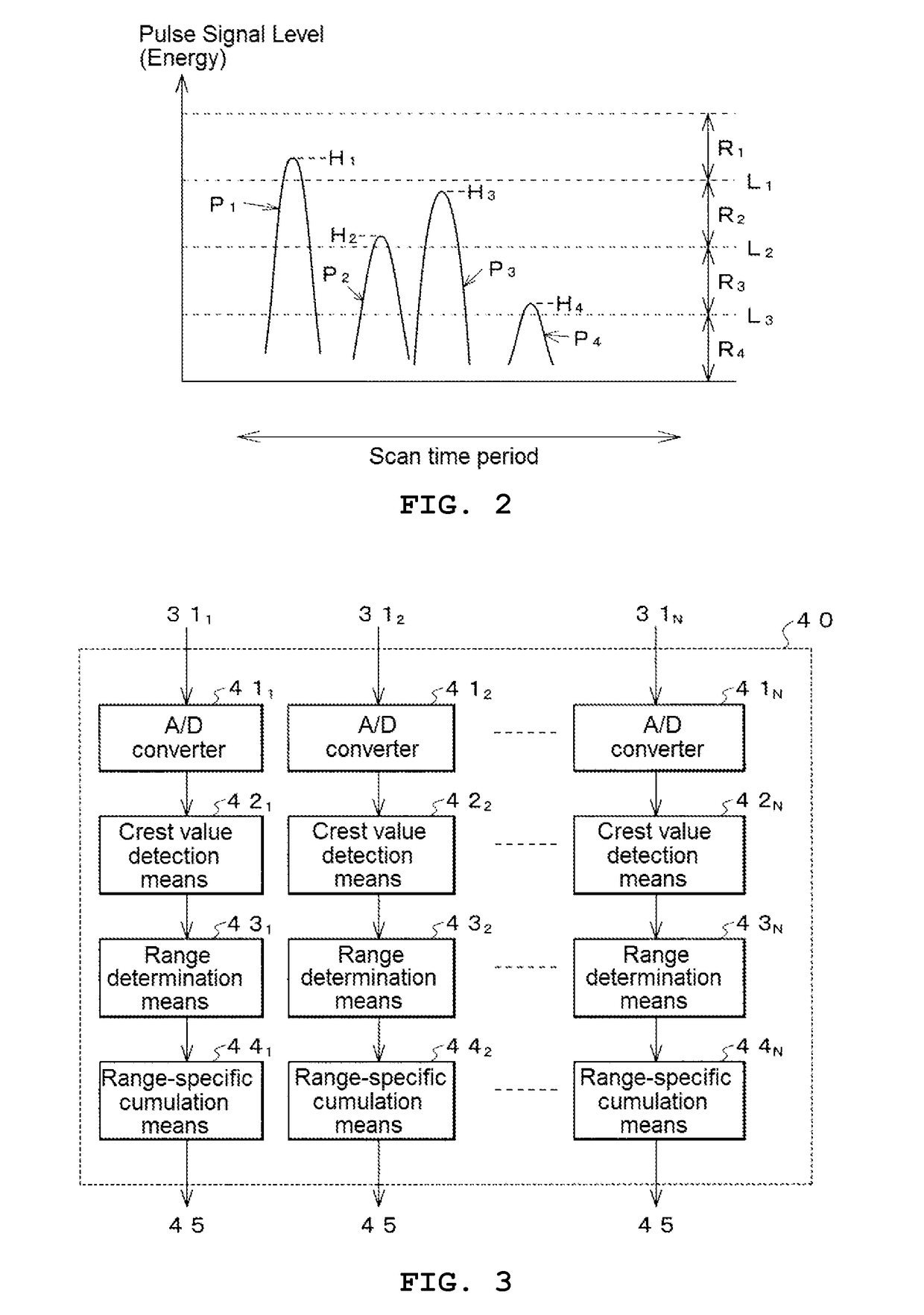

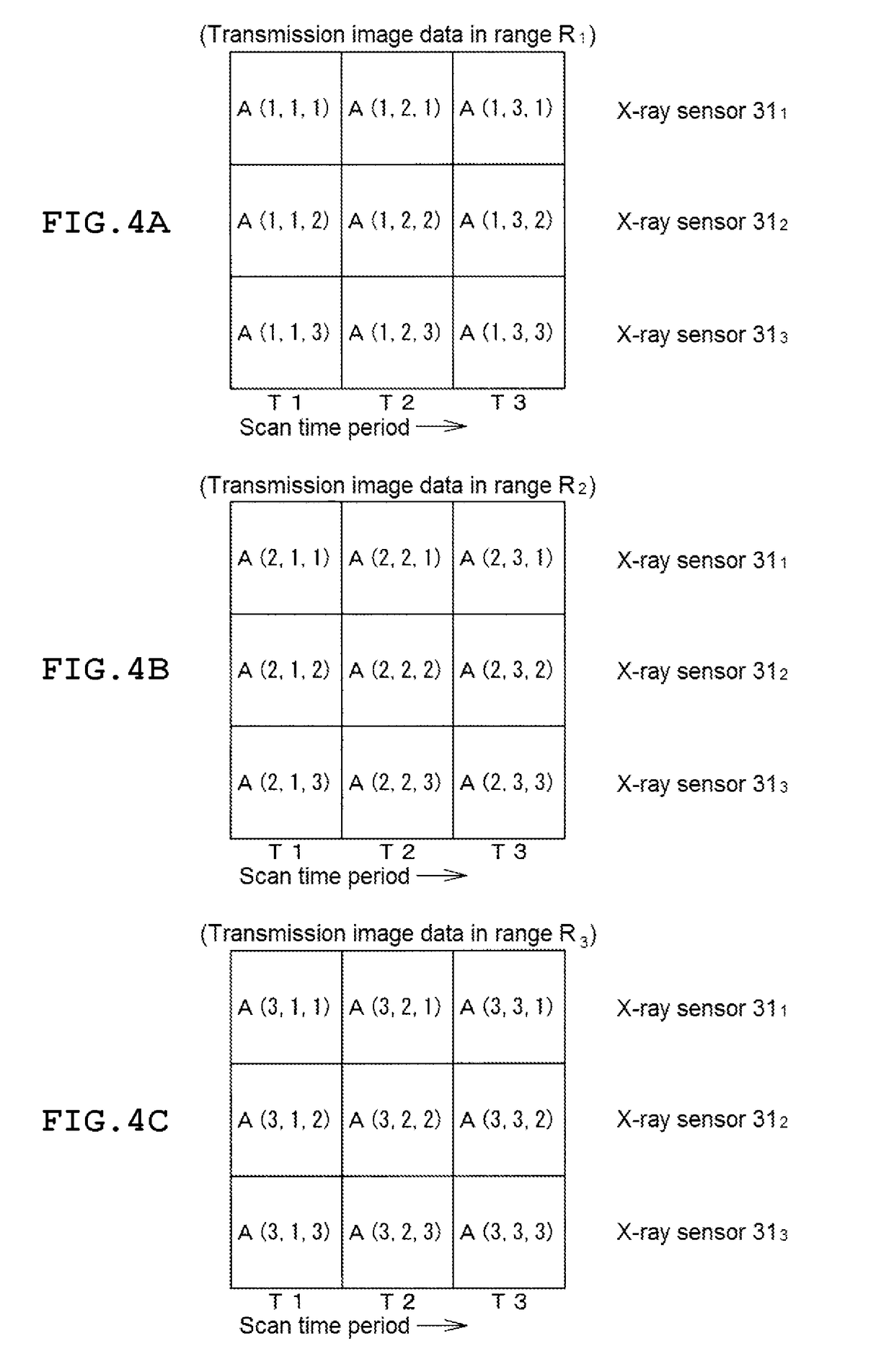

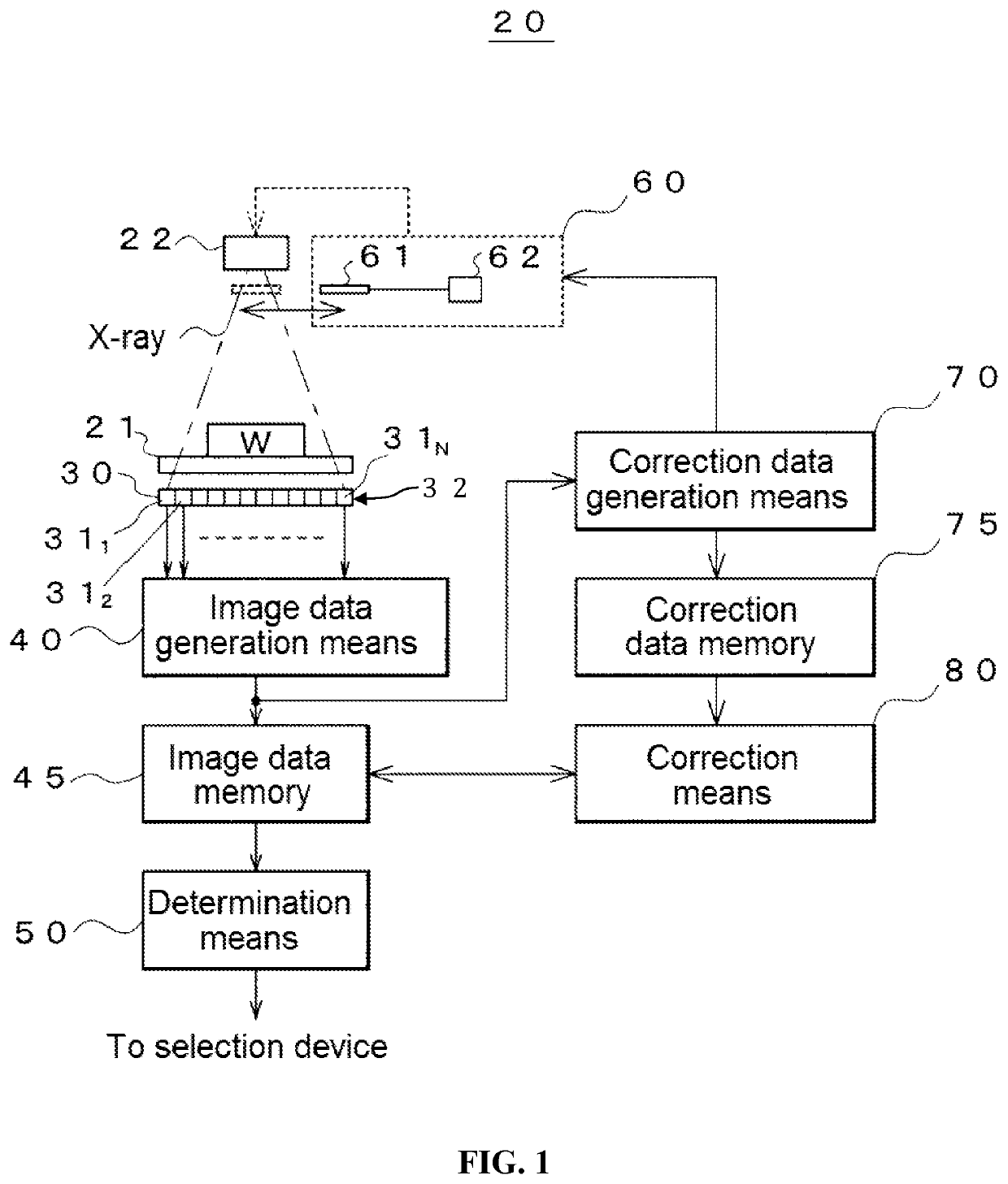

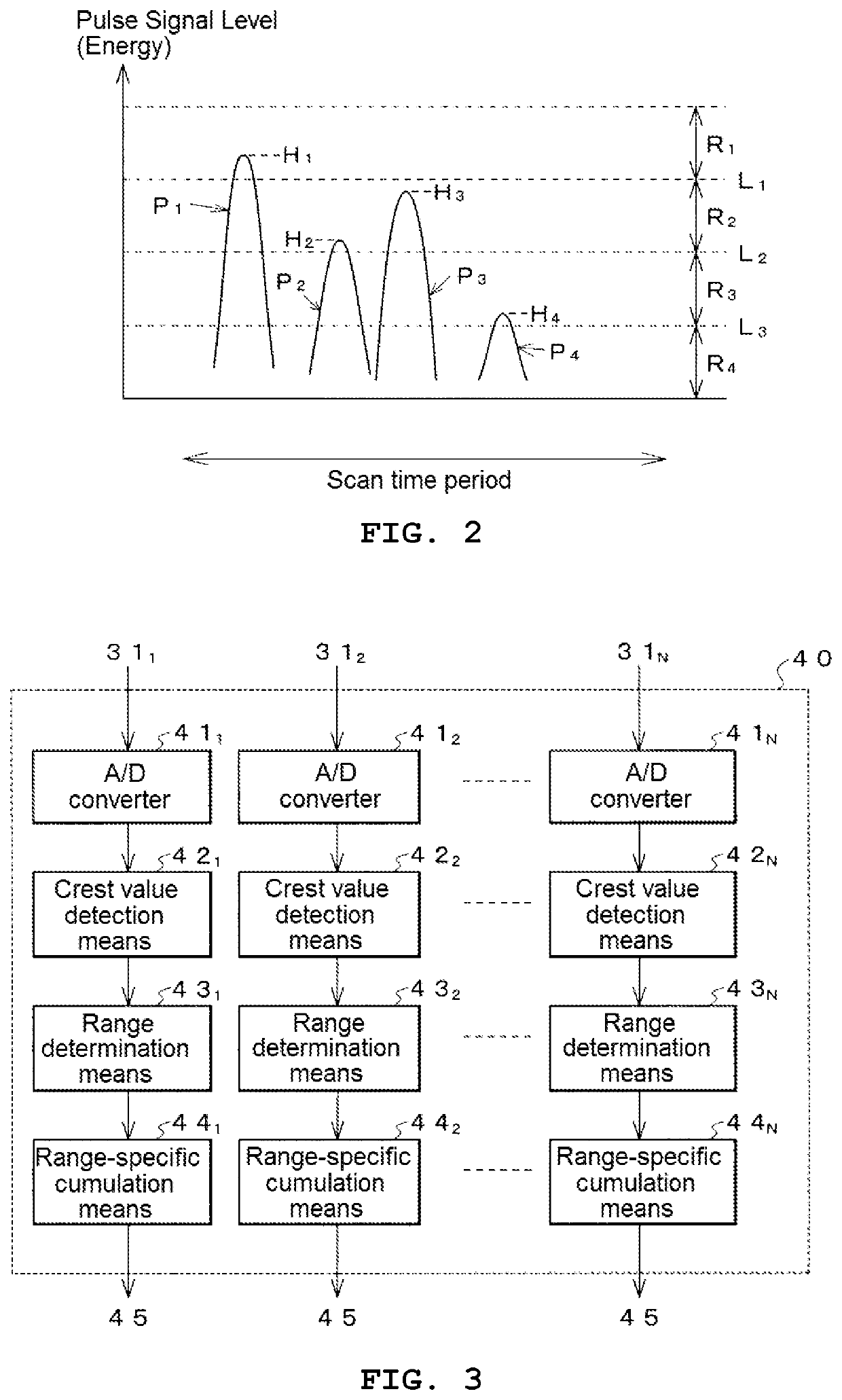

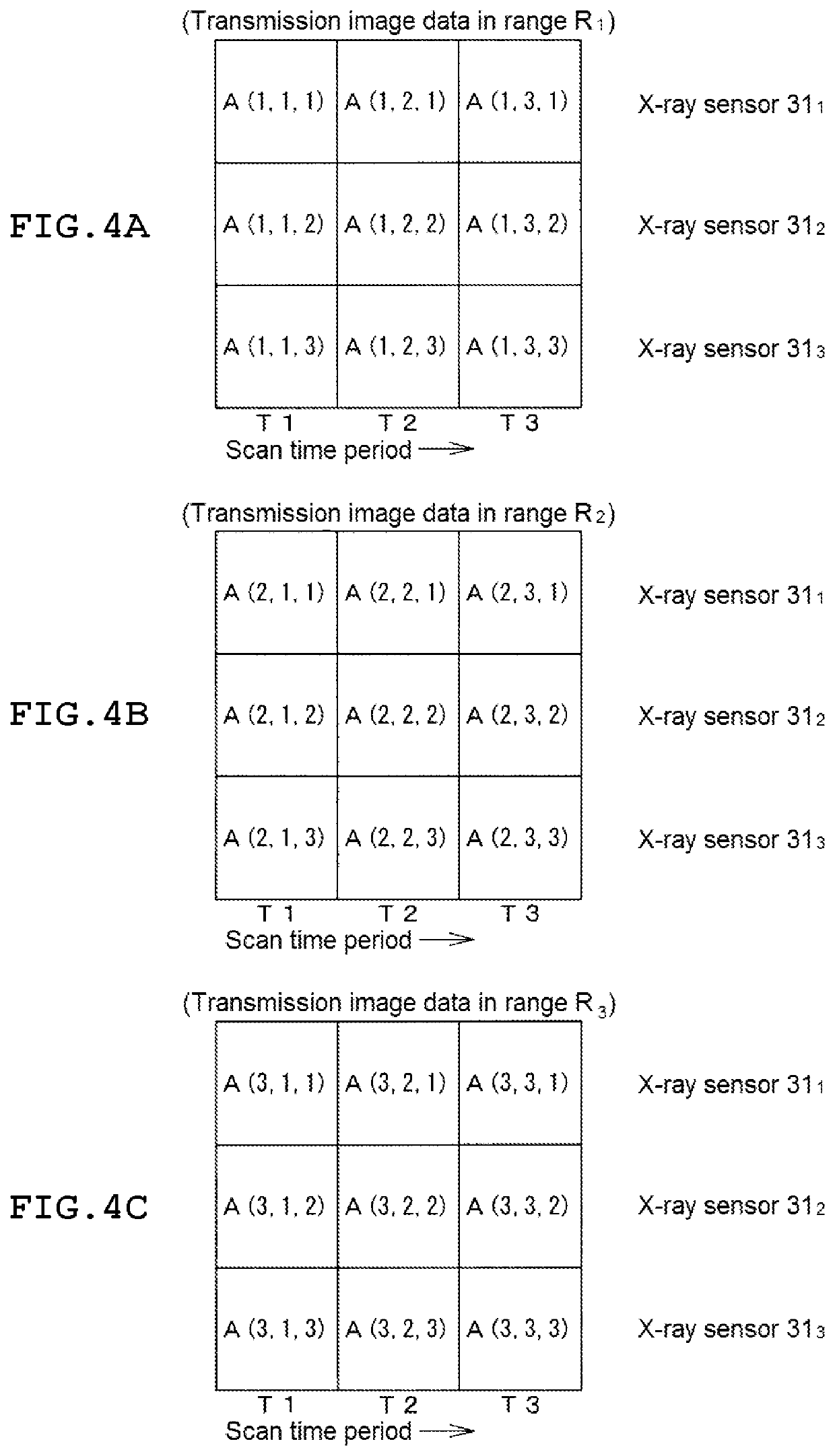

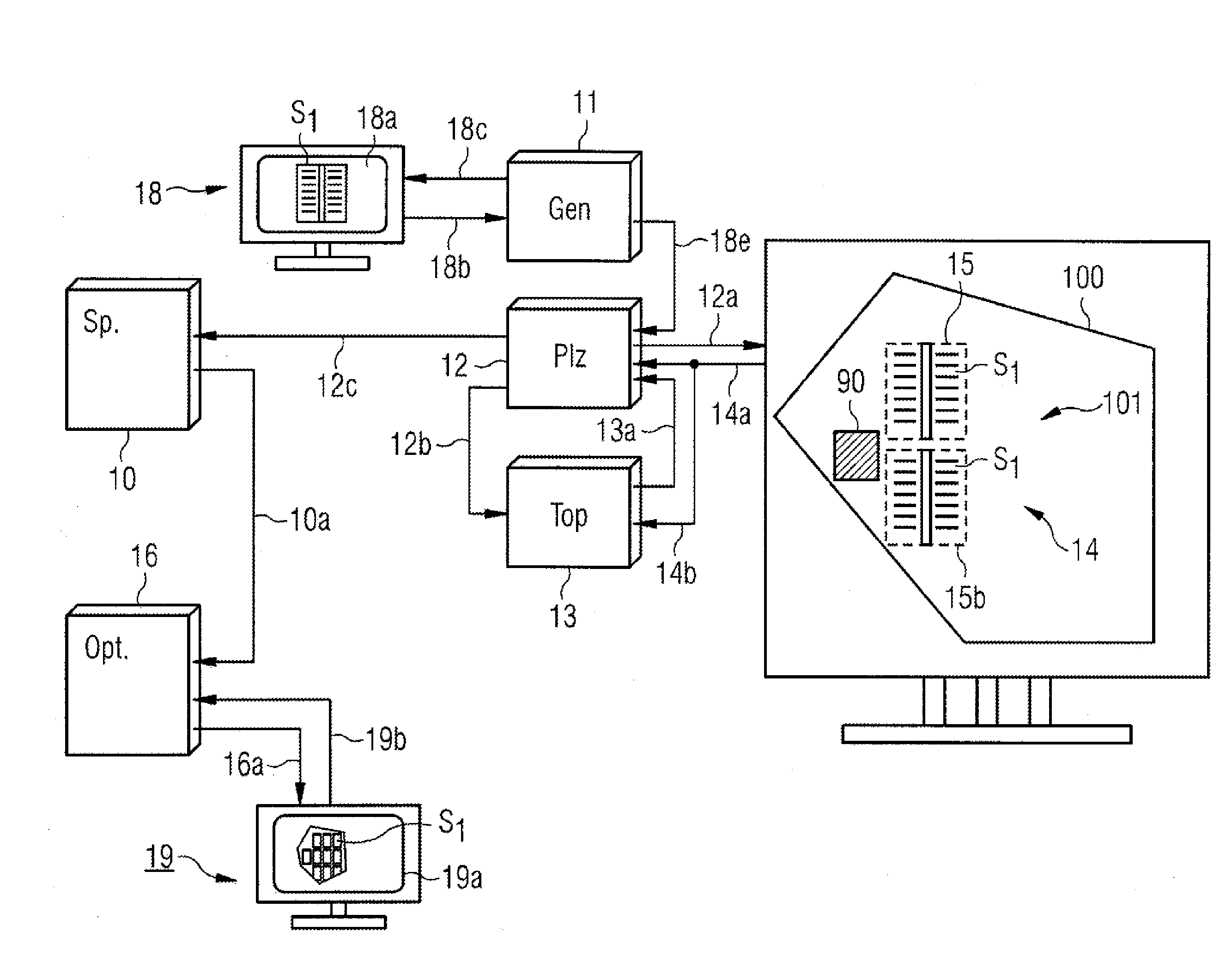

X-ray inspection apparatus and correction method for x-ray inspection apparatus

ActiveUS20190003989A1Uniform shadeImprove accuracyImage analysisMaterial analysis by transmitting radiationSoft x rayX-ray

To correctly acquire image data of an inspected article by preventing a difference in shade between images caused by a difference in position or sensitivity between sensor elements. An X-ray generation source irradiates an inspection region where an inspected article passes with an X-ray. X-ray detection means receives the X-ray passing through the inspection region using a plurality of sensor elements. Image data generation means generates image data of the inspected article from an output of the X-ray detection means. Incidence condition changing means changes two or more kinds of X-ray incidence conditions common for all of the sensor elements of the X-ray detection means in a state of absence of the inspected article in the inspection region. Correction data generation means acquires correction data that is needed for making a shade of an image uniform for each incidence condition.

Owner:ANRITSU CORP

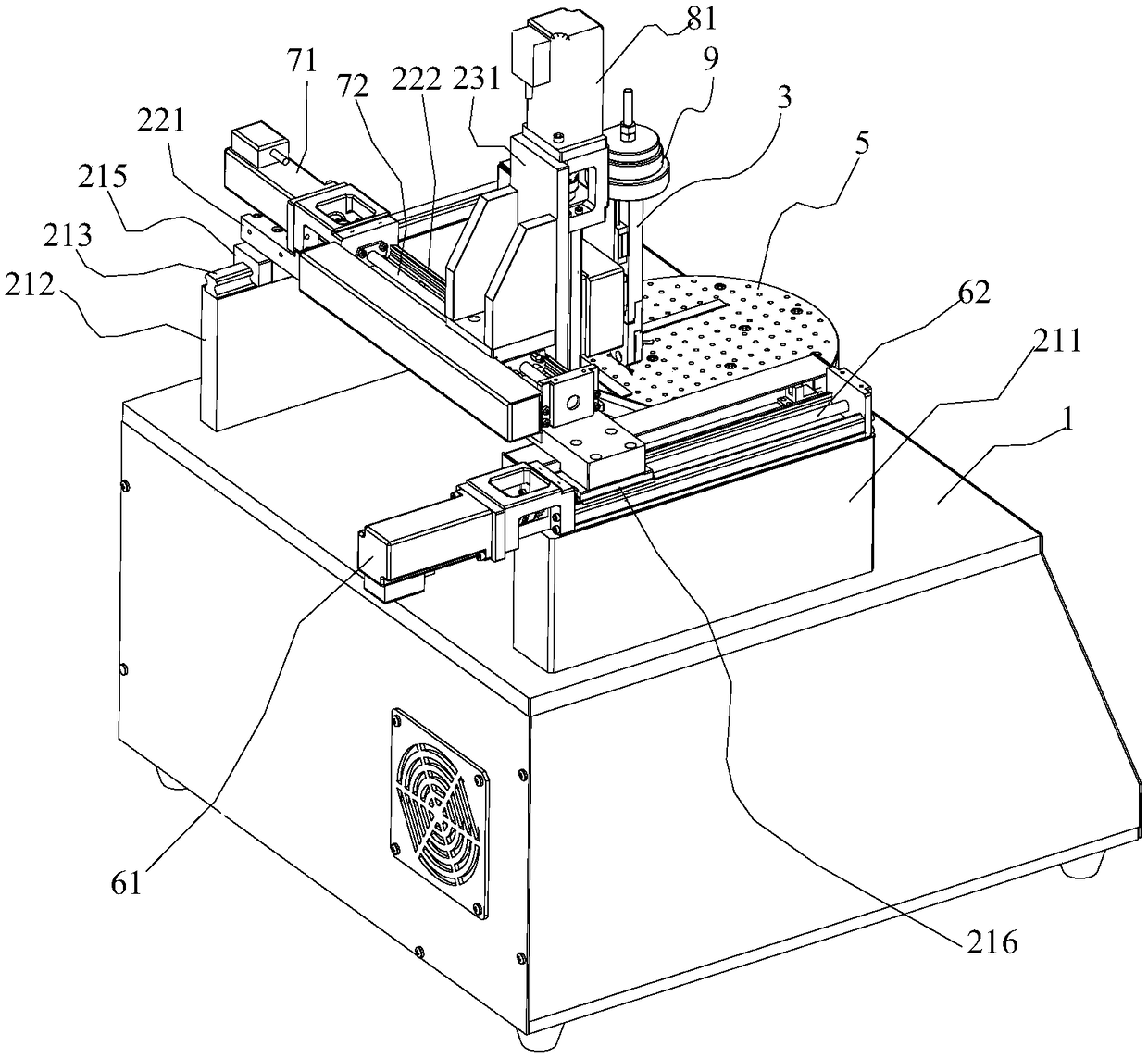

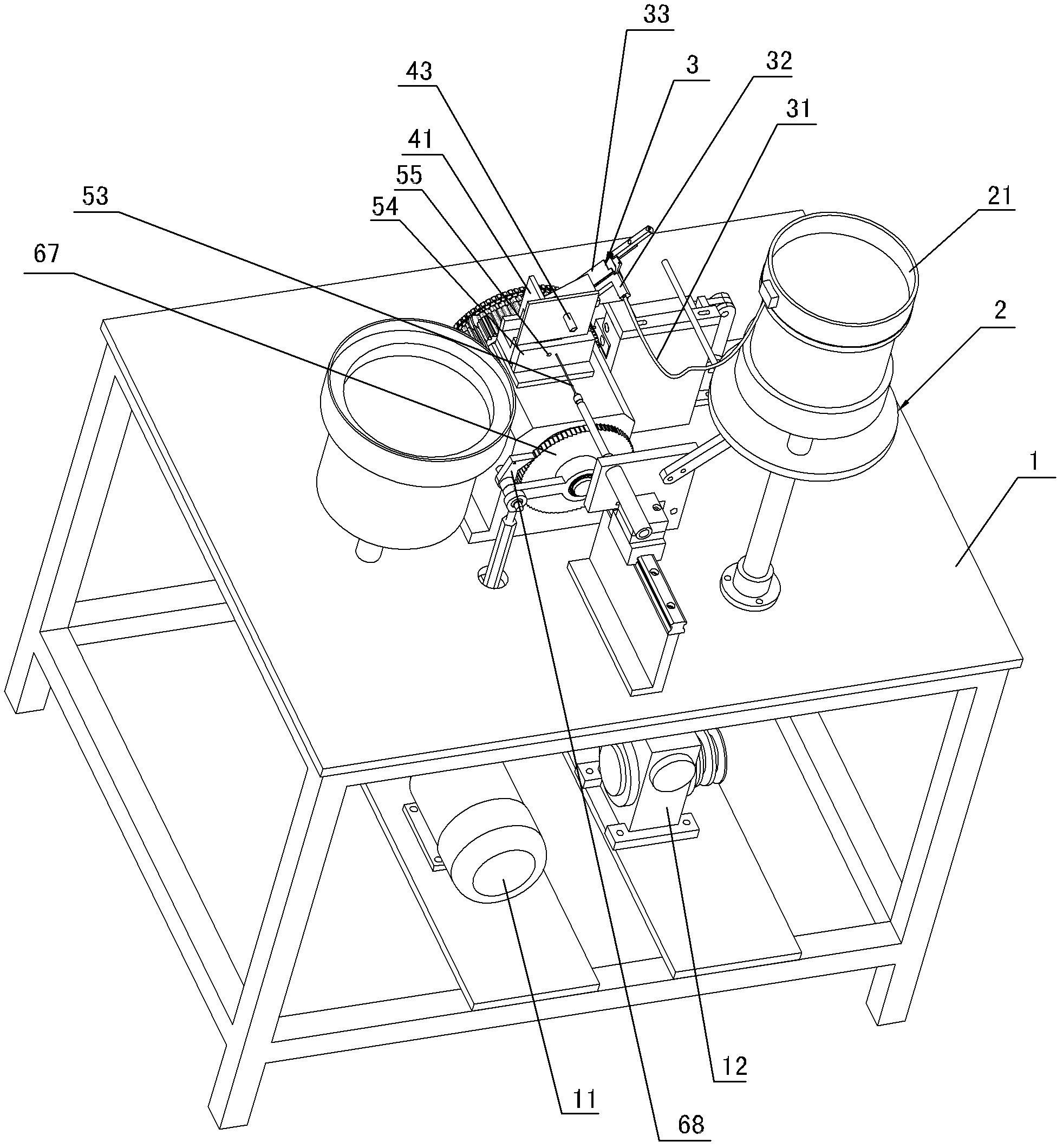

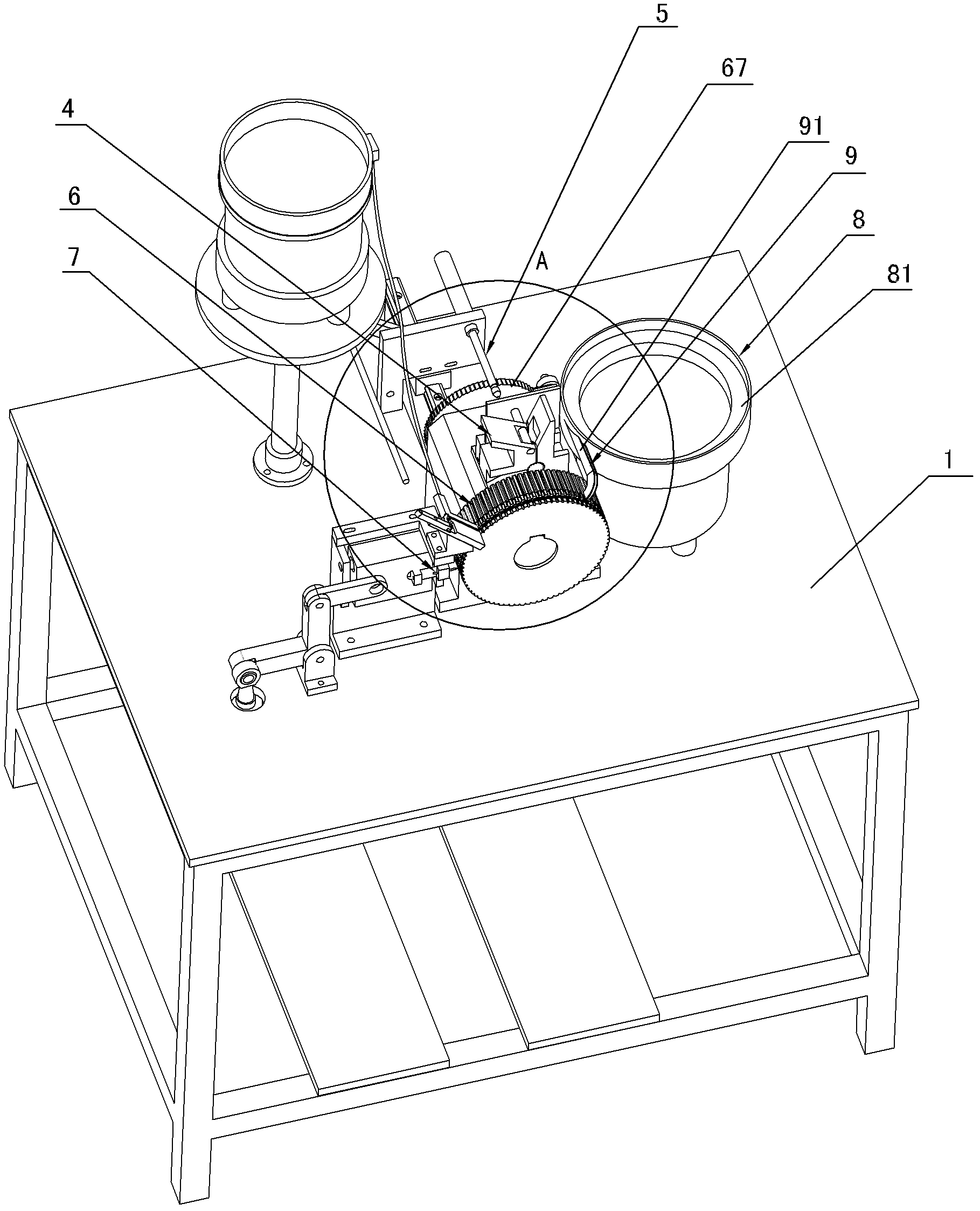

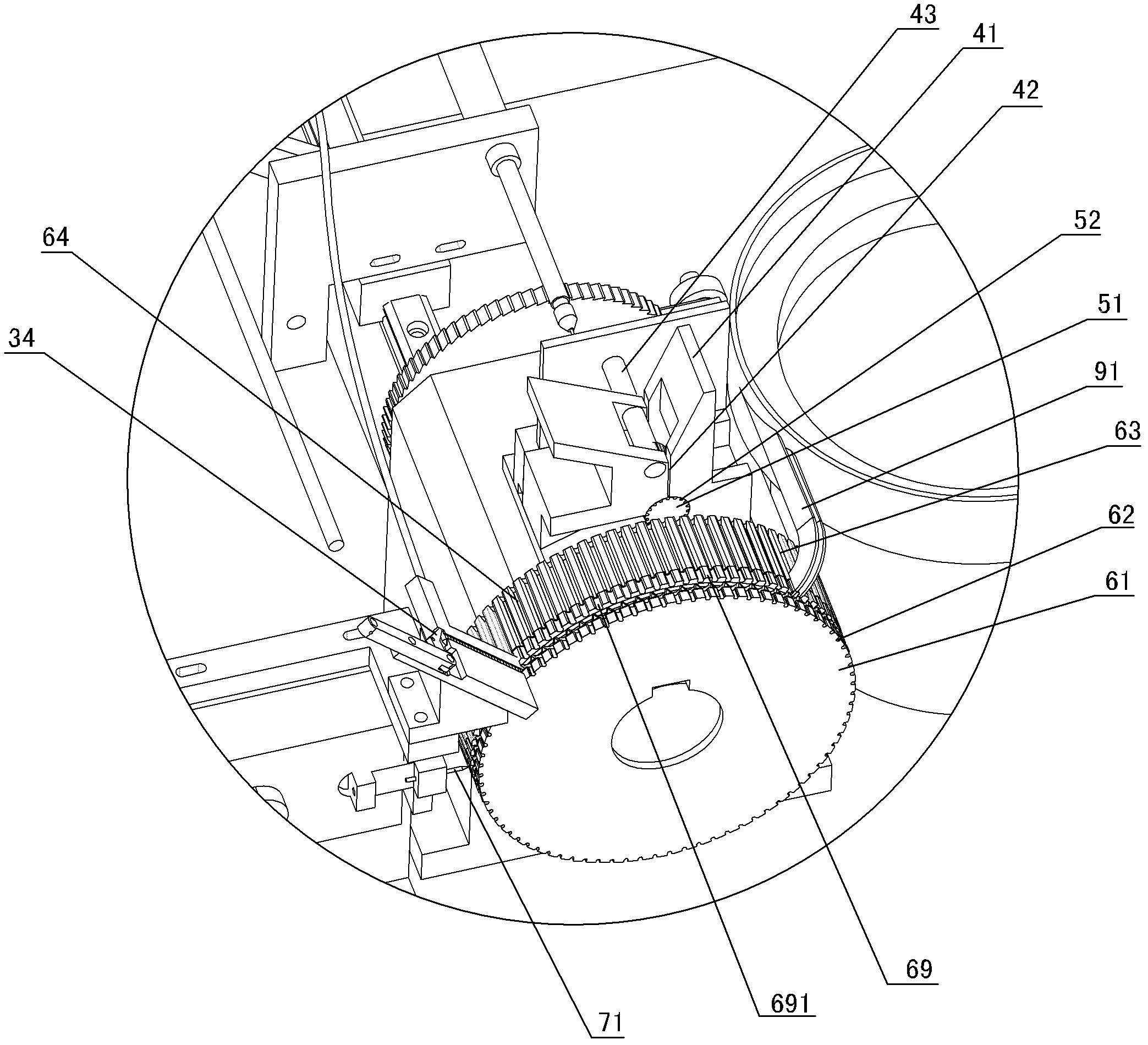

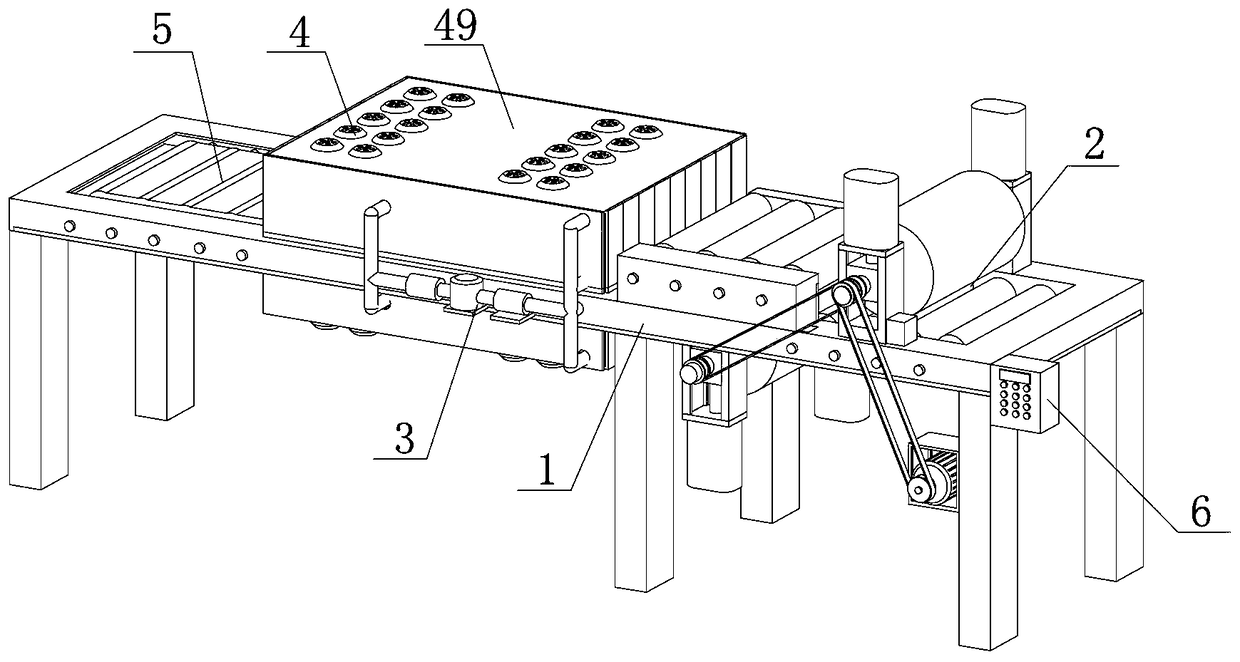

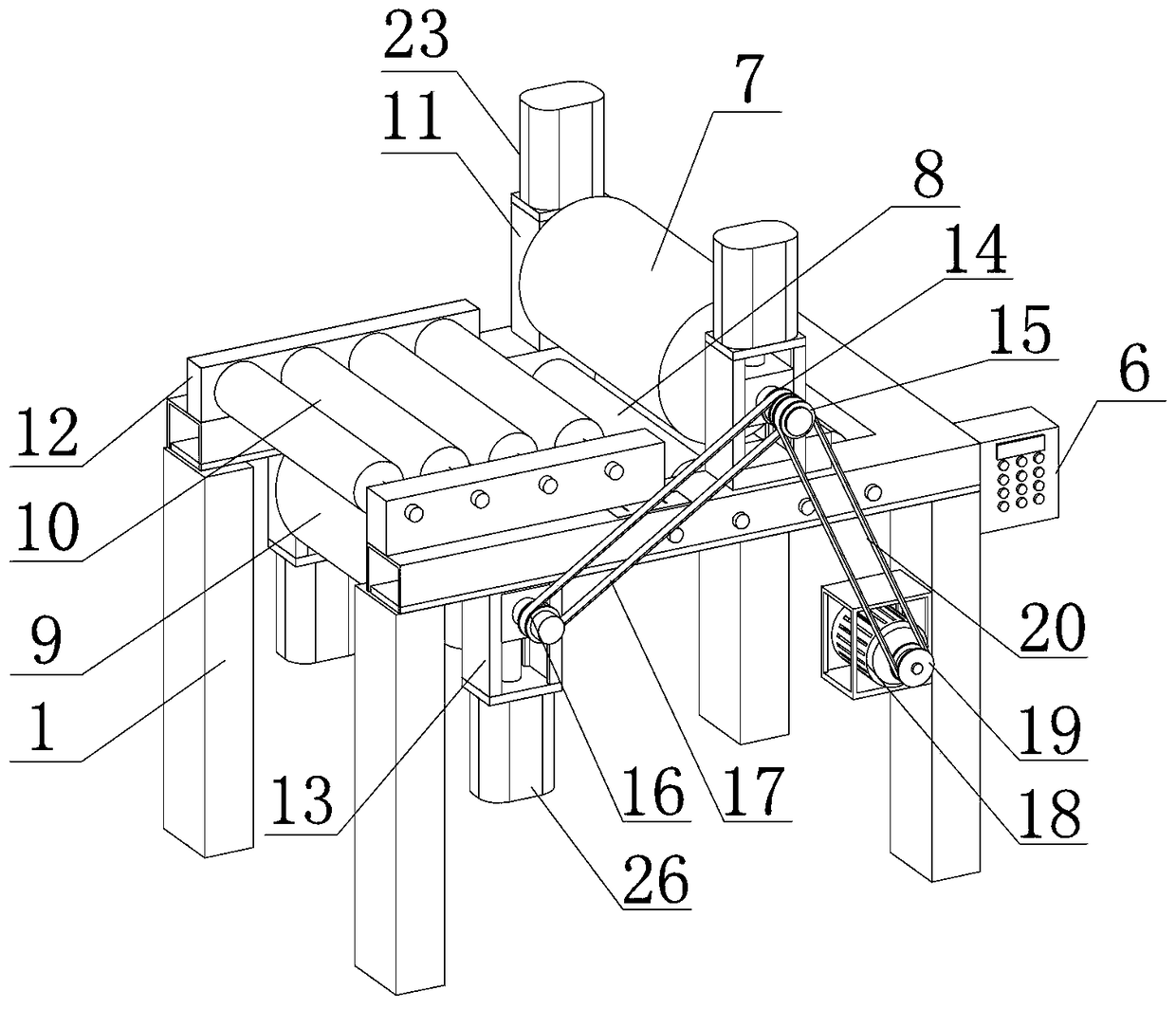

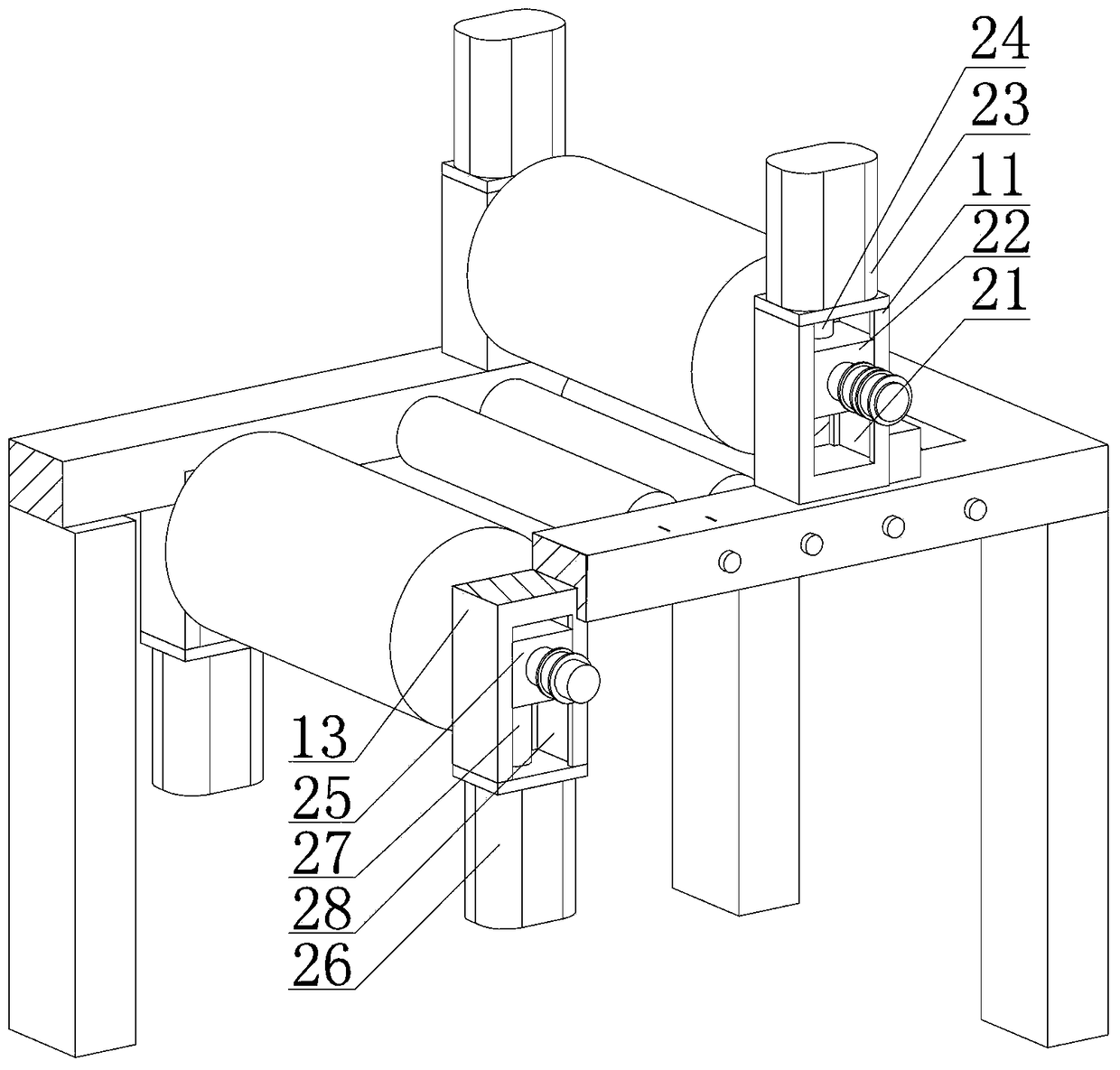

Scribing machine

InactiveCN109129386AOvercoming errors such as uneven artificial force and uneven depth of marking linesOvercoming errors such as uneven depth of scribing linesOther workshop equipmentTest sampleComputer engineering

The invention provides a scribing machine. The scribing machine comprises a machine table, a scribing knife shifting device and a scribing knife device, wherein the scribing knife shifting device is fixed to the surface of the machine table, the scribing knife device is connected with the scribing knife shifting device and is used for scribing on the surface of a test sample. The scribing knife shifting device comprises an X-direction horizontal sliding device, a Y-direction horizontal sliding device and a Z-direction vertical sliding device. The scribing knife device is fixedly arranged at the position of the Z-direction vertical sliding device, and an object stage is further arranged on the surface of the machine table and used for supporting and fixing the test sample. The scribing machine can realize full-automatic scribing on the surface of the test sample, and the grid-scribing speed is high and the entire process is uniform in force.

Owner:BIEL OPTIC HUIZHOU

Injection ampoule bottle non-contact type automatic bottle opener for medical care

InactiveCN111483961AFree from lateral extrusionAvoid it happening againOpening closed containersBottle/container closureBottle neckInjections needle

The invention belongs to the technical field of medical care apparatuses, and relates to an injection ampoule bottle non-contact type automatic bottle opener for medical care. An ampoule bottle is manually put in, a bottle body without a nipple is taken down, a first fixed parallel gas claw drives two first clamping blocks to closely press two V-shaped groove assemblies, and the two V-shaped groove assemblies closely clamp the bottle body of the ampoule bottle. An annular cutting parallel gas claw drives a cutting part and a balance part to clamp a bottle neck of the ampoule bottle. An annularcutting driving cylinder drives the combination of a flexible connecting part, the annular cutting parallel gas claw, the cutting part and the balance part to rotate by one cycle. A cutting edge in an internal arc shape performs annular cutting on the bottle neck by one cycle. A breakage cylinder drives a flexible push plate to push the nipple of the ampoule bottle, so that the nipple can burst into a waste bucket. The automation level is high, work efficiency is greatly improved, operation steps are greatly simplified, glass fragments are avoided, medical staff is prevented from being hurt,safety is improved, and the ampoule is prevented from being crushed.

Owner:杜宗英

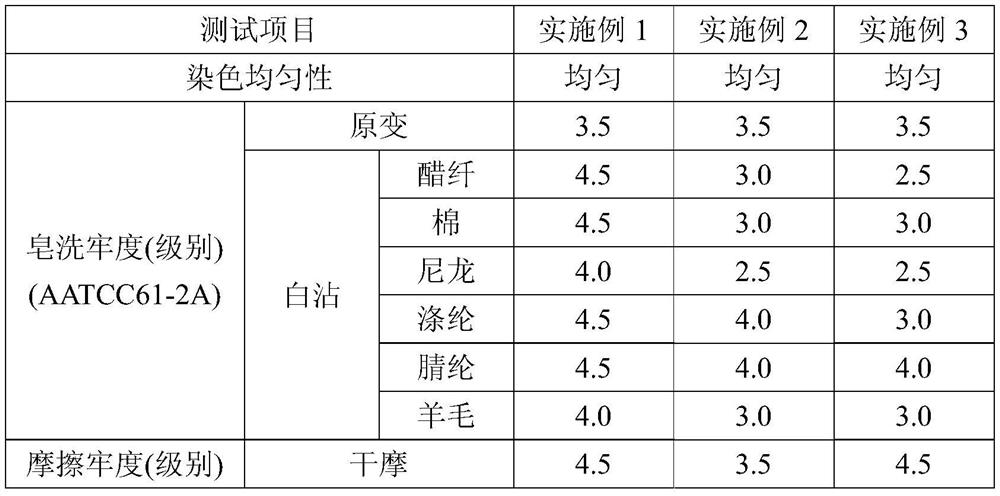

Colored light consistent cold pad-batch dyeing pure cotton wide fabric and production method thereof

The invention discloses a colored light consistent cold pad-batch dyeing pure cotton wide fabric and a production method thereof. The pure cotton wide fabric is uniform and consistent in colored light; the soaping fastness is greater than or equal to grade 4; the rubbing fastness is greater than or equal to grade 3-4; the warp and weft direction dimensional change rate after washing is -3.0%-+1.0%; when cold pad-batch dyeing starts, part of dye is additionally added into a roll groove, so that the fabric is uniform and consistent in colored light before and after dyeing; besides, the conventional water glass is replaced with low temperature cold-batch fixation alkali EW-956, and a common soaping agent is replaced with a high-concentration low temperature anti-staining soaping agent ANT, the color fastness of the fabric after dyeing reaches the quality grade of a superior product. According to the colored light consistent cold pad-batch dyeing pure cotton wide fabric and the production method thereof, provided by the invention, the production process is reasonable, the operability is high, the product quality is stable, and the production method is an energy-saving and emission-reducing clean production process.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

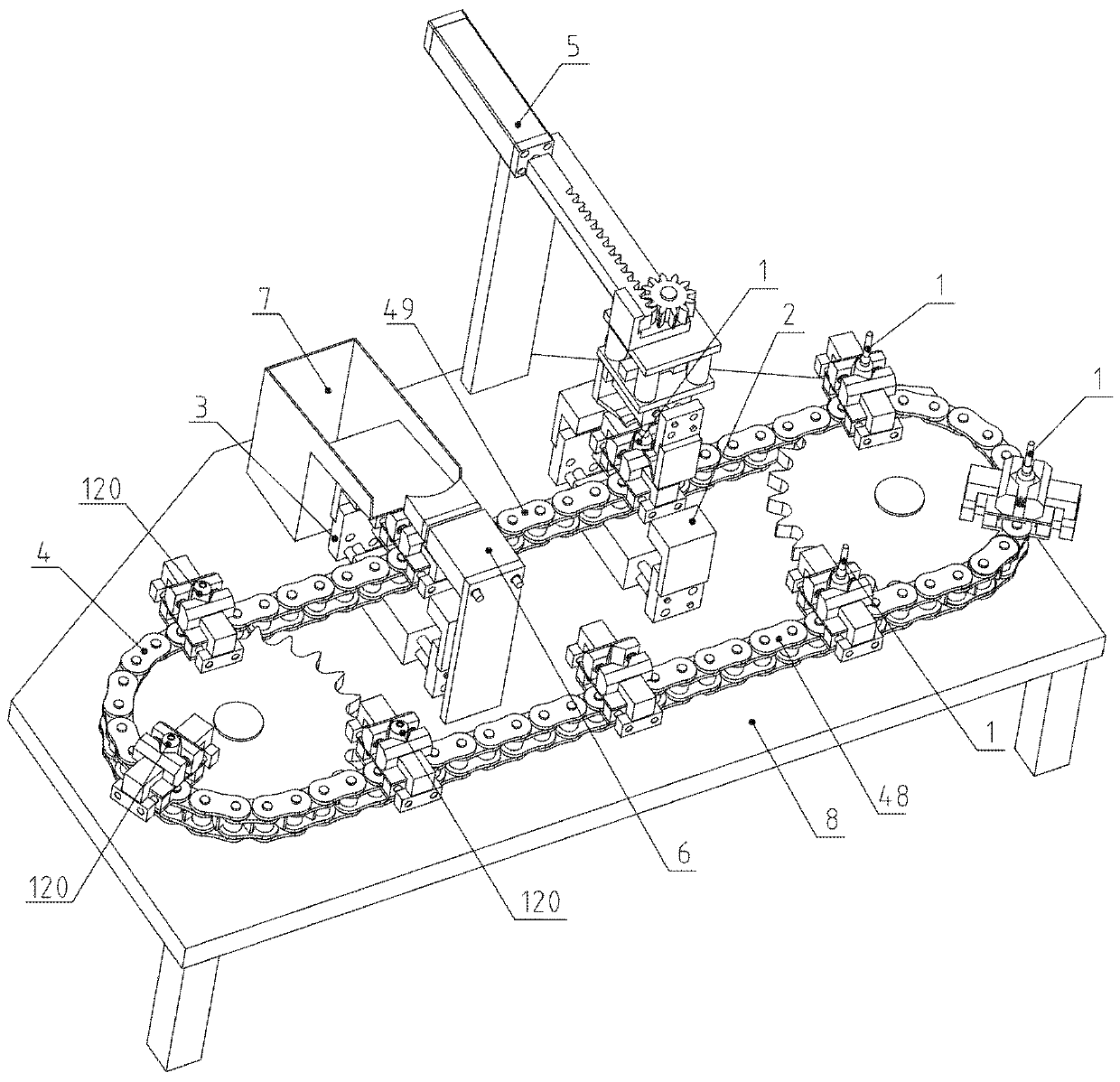

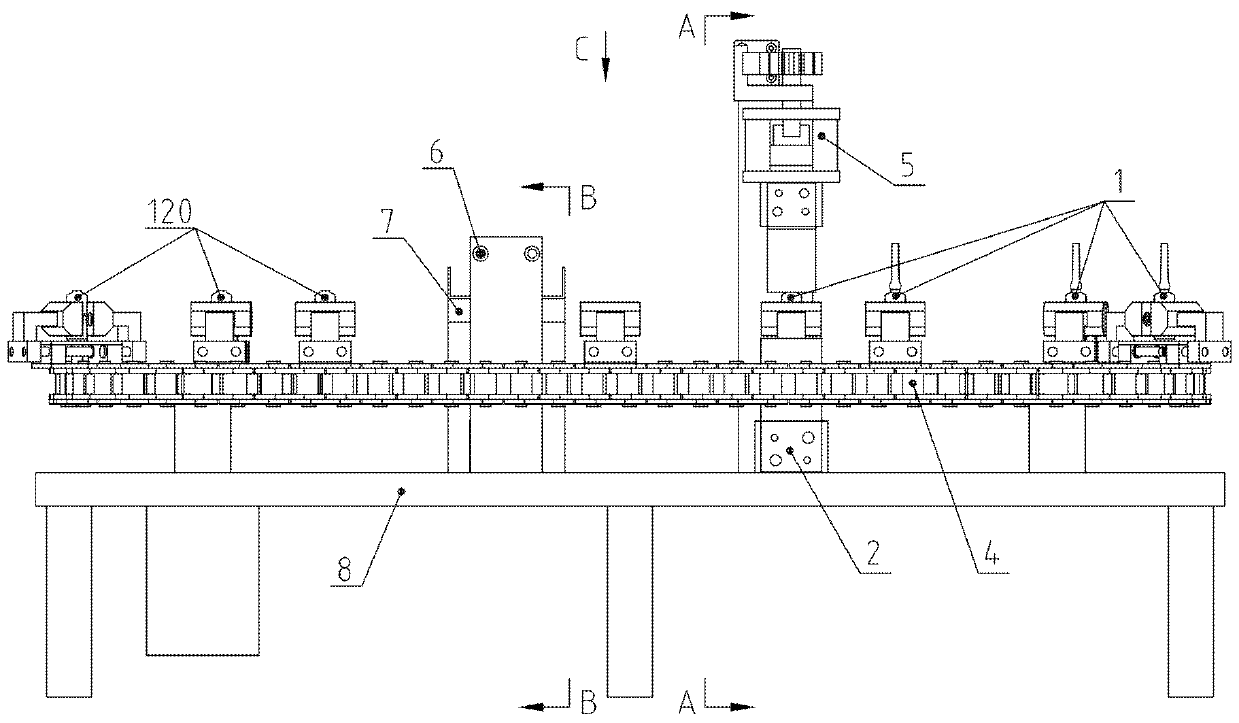

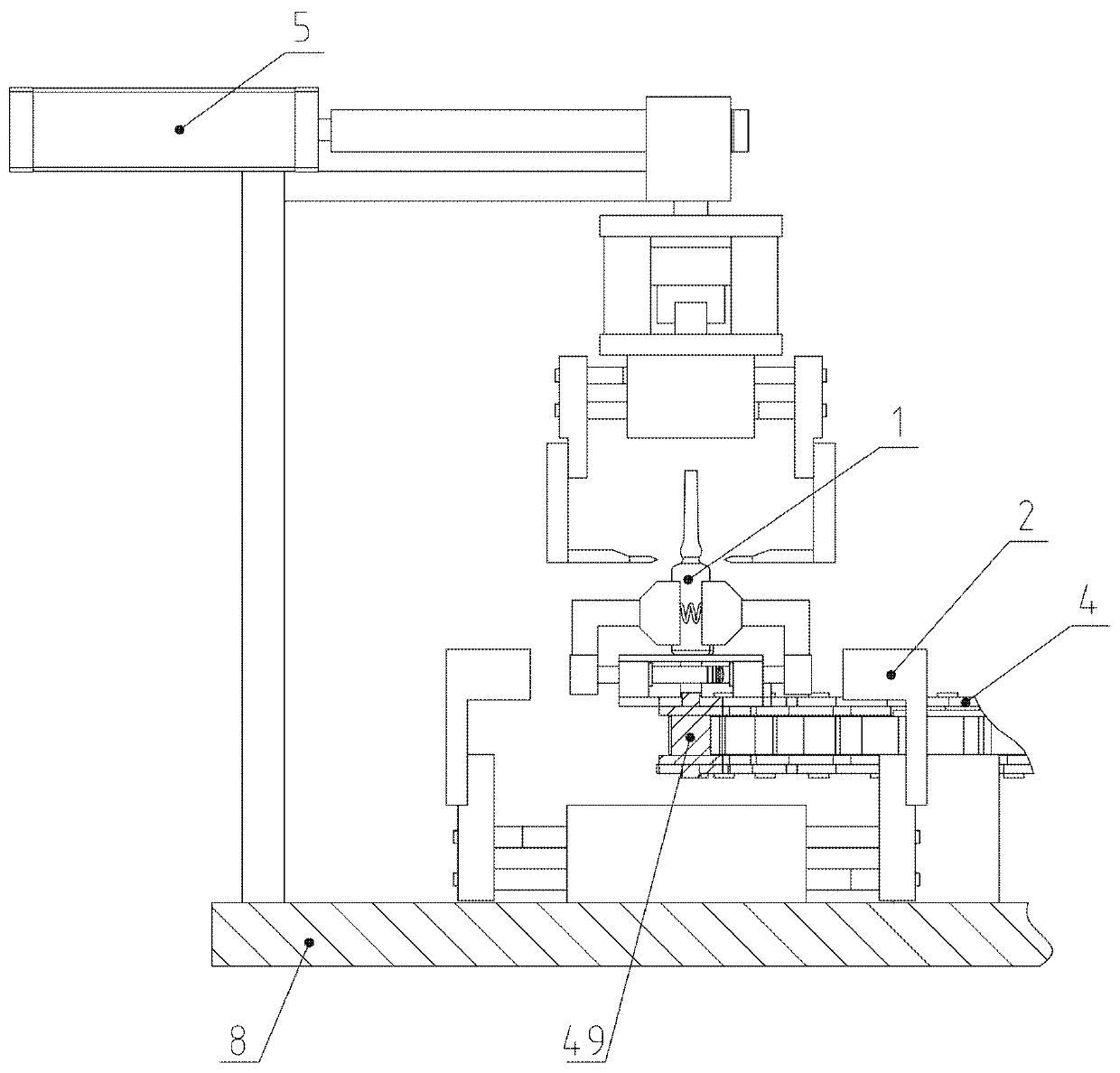

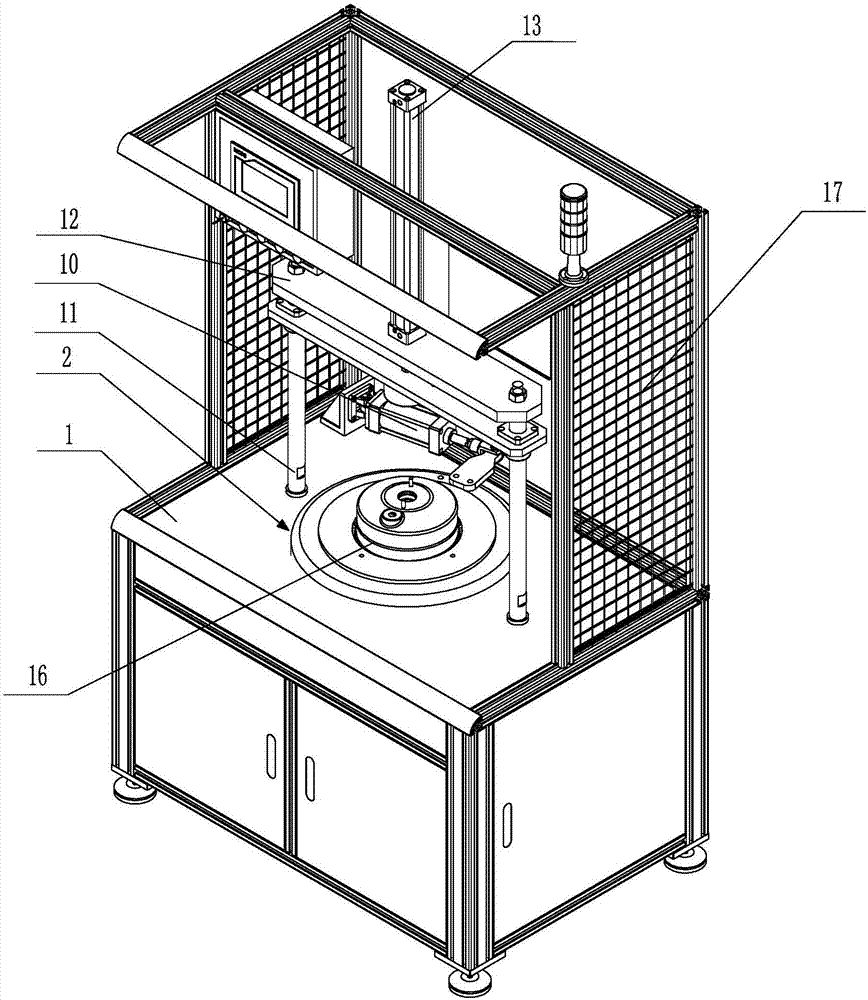

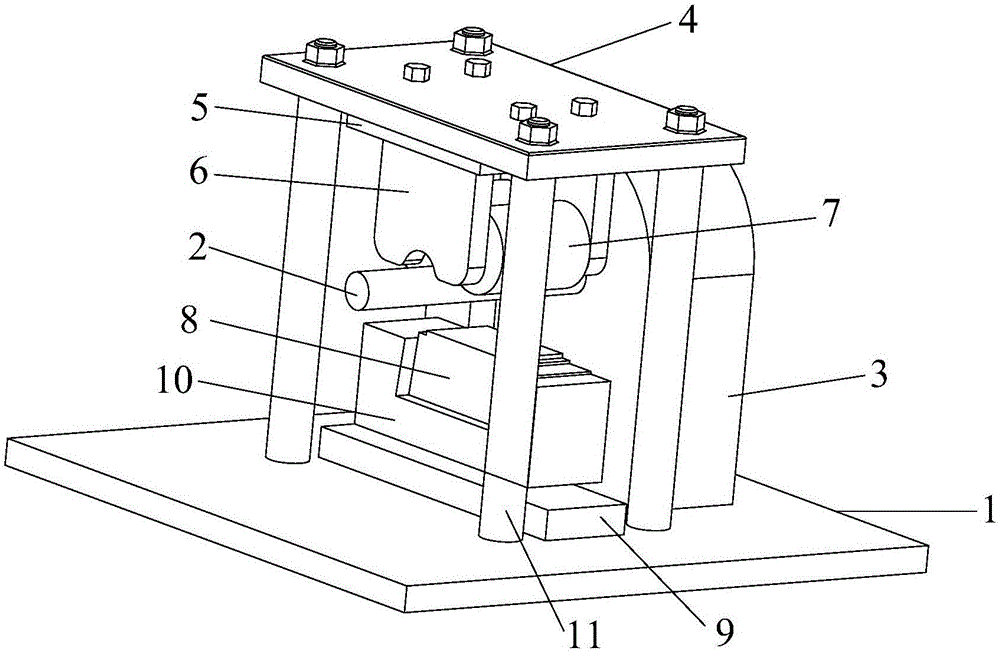

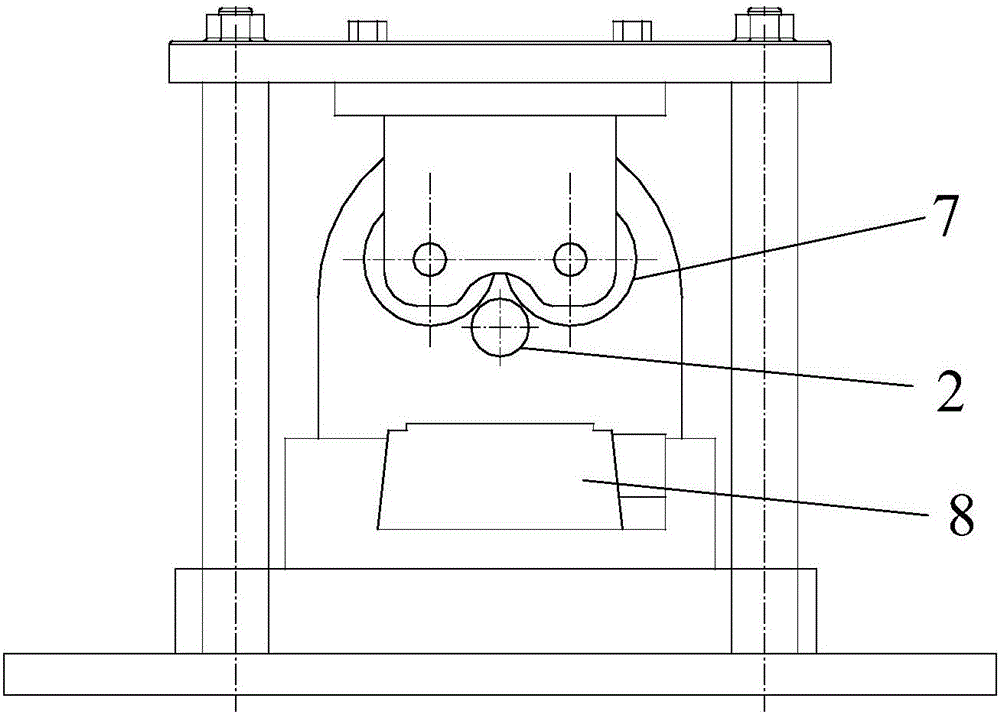

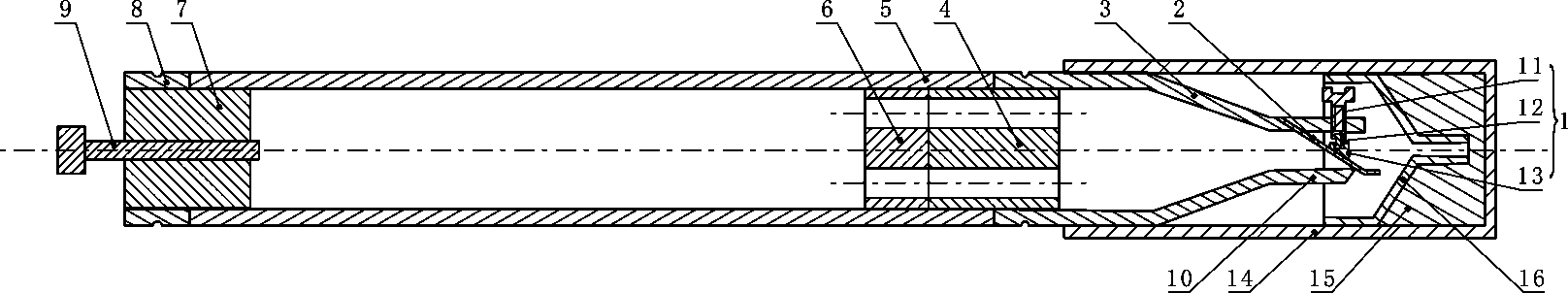

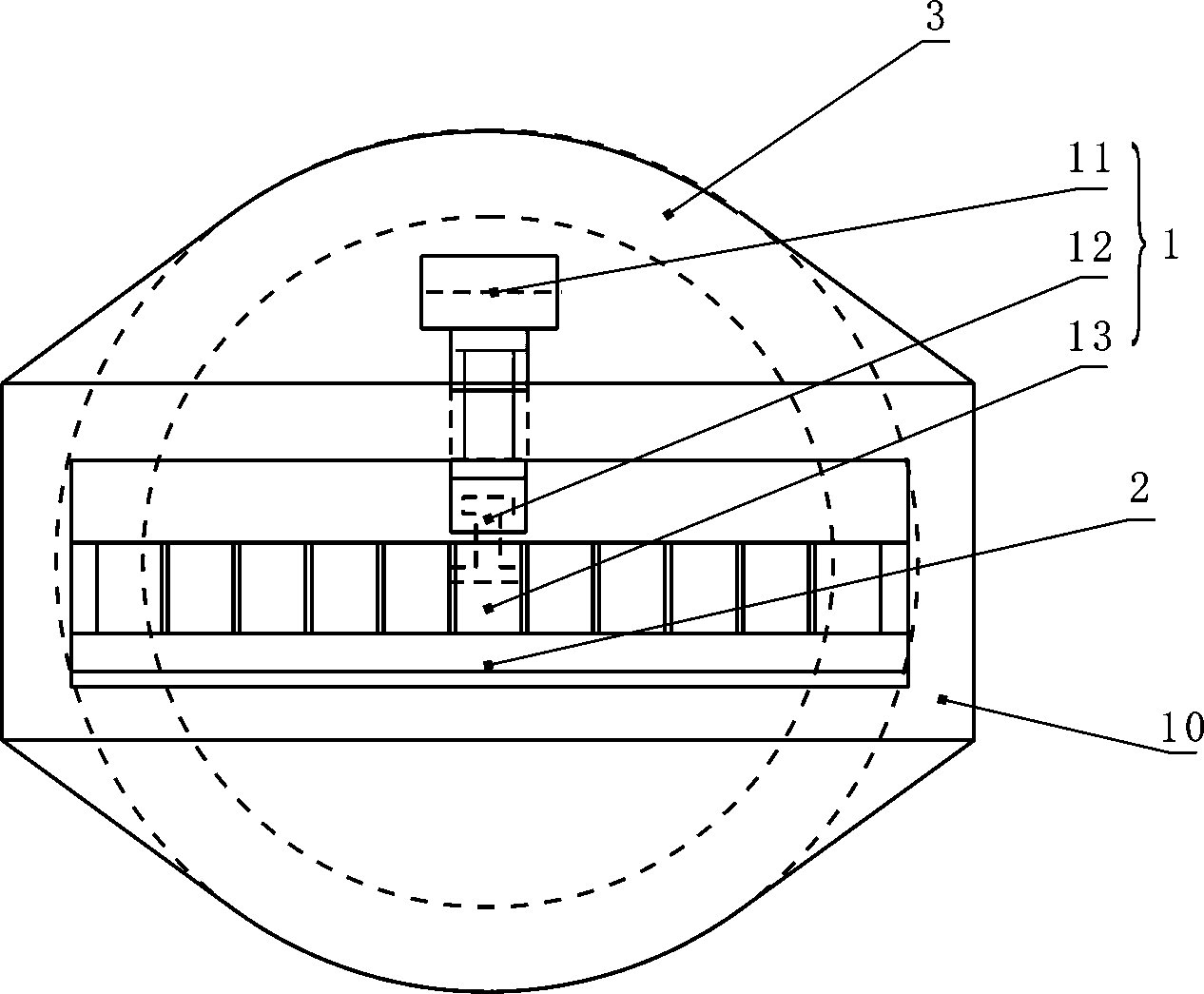

Pen point dotting machine

ActiveCN102529506AGuaranteed connection reliabilityUniform shadePen repairingMechanical engineeringEngineering

The invention discloses a pen point dotting machine, comprising a rack, a pen point feeding mechanism, a pen point transmitting mechanism, an ink guiding core feeding mechanism, an ink guiding core transmitting mechanism, an assembling mechanism and a dotting mechanism, wherein the pen point feeding mechanism, the pen point transmitting mechanism, the ink guiding core feeding mechanism, the ink guiding core transmitting mechanism, the assembling mechanism and the dotting mechanism are arranged on the rack. The pen point feeding mechanism is used for continuously feeding metal pen points to the pen point transmitting mechanism. The pen point transmitting mechanism is used for receiving and loading the metal pen points which are continuously fed by the pen point feeding mechanism, and transmitting the metal pen points to the assembling mechanism. The ink guiding core feeding mechanism is used for continuously feeding ink guiding cores to the ink guiding core transmitting mechanism. The ink guiding core transmitting mechanism is used for receiving and loading the ink guiding cores which are fed by the ink guiding core feeding mechanism, and transmitting to the assembling mechanism. The assembling mechanism is used for assembling and machining the metal pen points which are transmitted by the pen point transmitting mechanism and the ink guiding cores which are transmitted by the ink guiding core transmitting mechanism. Meanwhile, the dotting mechanism is used for dotting the metal pen points which is integrally assembled and is connected with the ink guiding cores. The depth of dotted groove can be effectively ensured to be uniform due to automatic operation, so that the connection reliability of the metal pen points and the ink guiding cores can be ensured.

Owner:NINGBO BEIFA GRP CO LTD

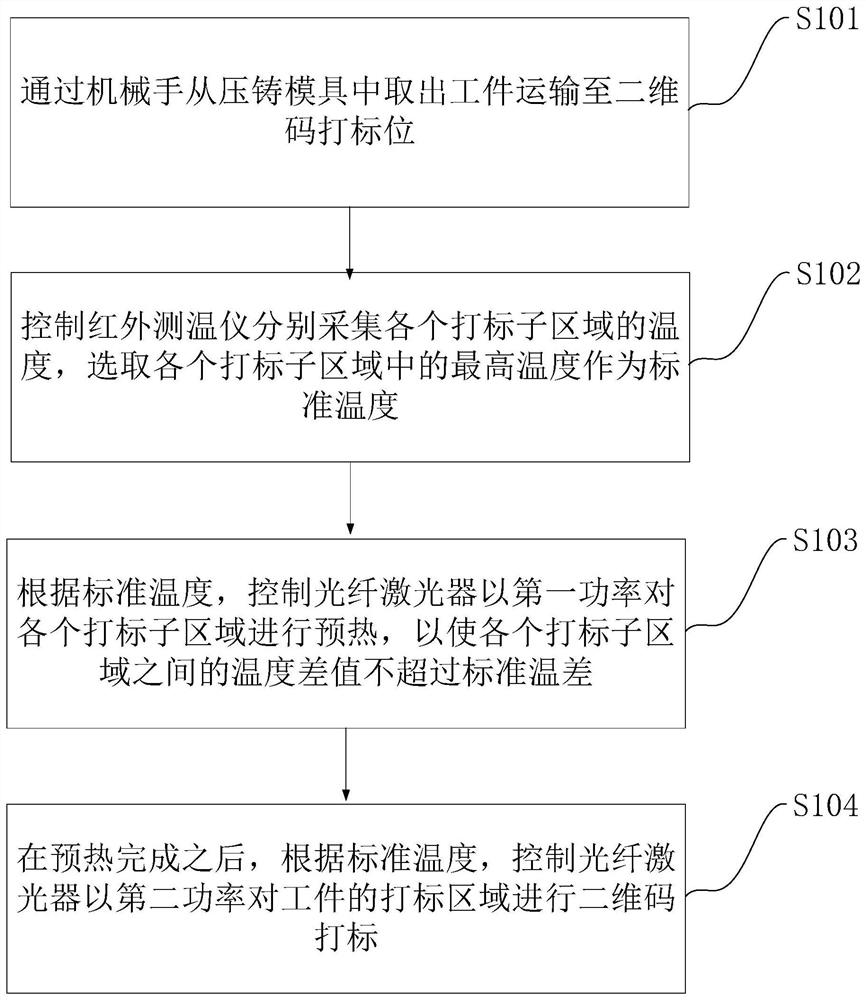

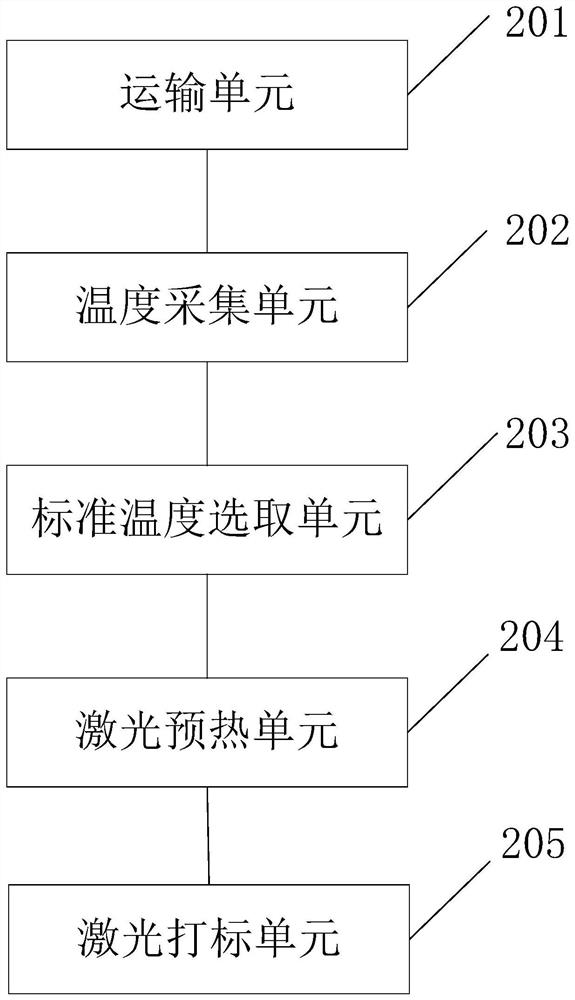

Optical fiber laser assembly line two-dimensional code marking method and system

PendingCN114273785AUniform shadeImprove accuracyLaser beam welding apparatusInfrared thermometrySoftware engineering

The invention discloses a fiber laser assembly line two-dimensional code marking method and system, and the method comprises the steps: taking out a workpiece from a die-casting die through a manipulator, and conveying the workpiece to a two-dimensional code marking position; wherein the workpiece comprises a marking area corresponding to a two-dimensional code marking position, and the marking area comprises marking sub-areas divided according to the size of two-dimensional code pixel points; an infrared thermometer is controlled to collect the temperature of each marking sub-area, and the highest temperature in each marking sub-area is selected as the standard temperature; according to the standard temperature, an optical fiber laser is controlled to preheat all the marking sub-areas with first power, so that the temperature difference value between all the marking sub-areas does not exceed the standard temperature difference value; and after preheating is completed, according to the standard temperature, the optical fiber laser is controlled to conduct two-dimensional code marking on the marking area of the workpiece with second power. According to the invention, the two-dimensional code can be uniformly marked, and the recognition accuracy of the two-dimensional code is ensured.

Owner:莆田市鑫镭腾科技有限公司 +1

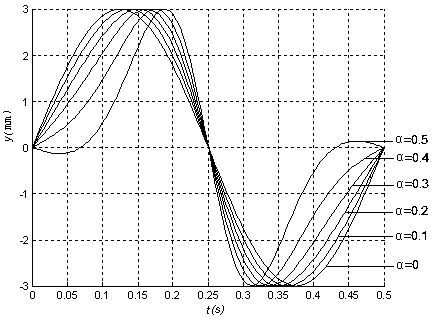

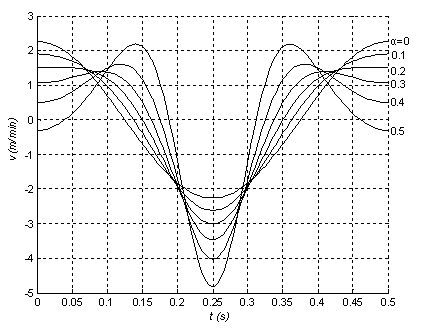

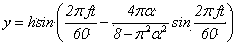

Hydraulic vibration method for continuous casting mold

The invention relates to the field of steel-making casting, in particular to a vibration method for a continuous casting mold during casting. In the hydraulic vibration method for the continuous casting mold, the continuous casting mold vibrates during casting according to the following curve, and the vibration curve is in accord with a vibration curve equation expressed by displacement (img file = 'dest_path_image002.TIF' wi = '16 'he = '16' / ) and speed (img file = 'dest_path_image004.TIF' wi = '13 'he = '16' / ). According to the hydraulic vibration method for the continuous casting mold provided by the invention, a precisely set non-sinusoidal vibration curve model is given, and parameters in the vibration curve model can be adjusted according to the required quality of casting blanks and problems in production through the vibration curve model, so that the quality of the casting blanks is improved; the actual production shows that the vibration marks of the casting blanks obtained by casting are uniform in depth, the distance between the vibration marks is reduced by 20%, the depth of the vibration marks is reduced by more than 30%, and the lubrication of the casting mold is favorable; meanwhile, the tensile stress of blank shells is reduced, the pull crack is reduced, and the quality of the casting blanks is effectively improved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

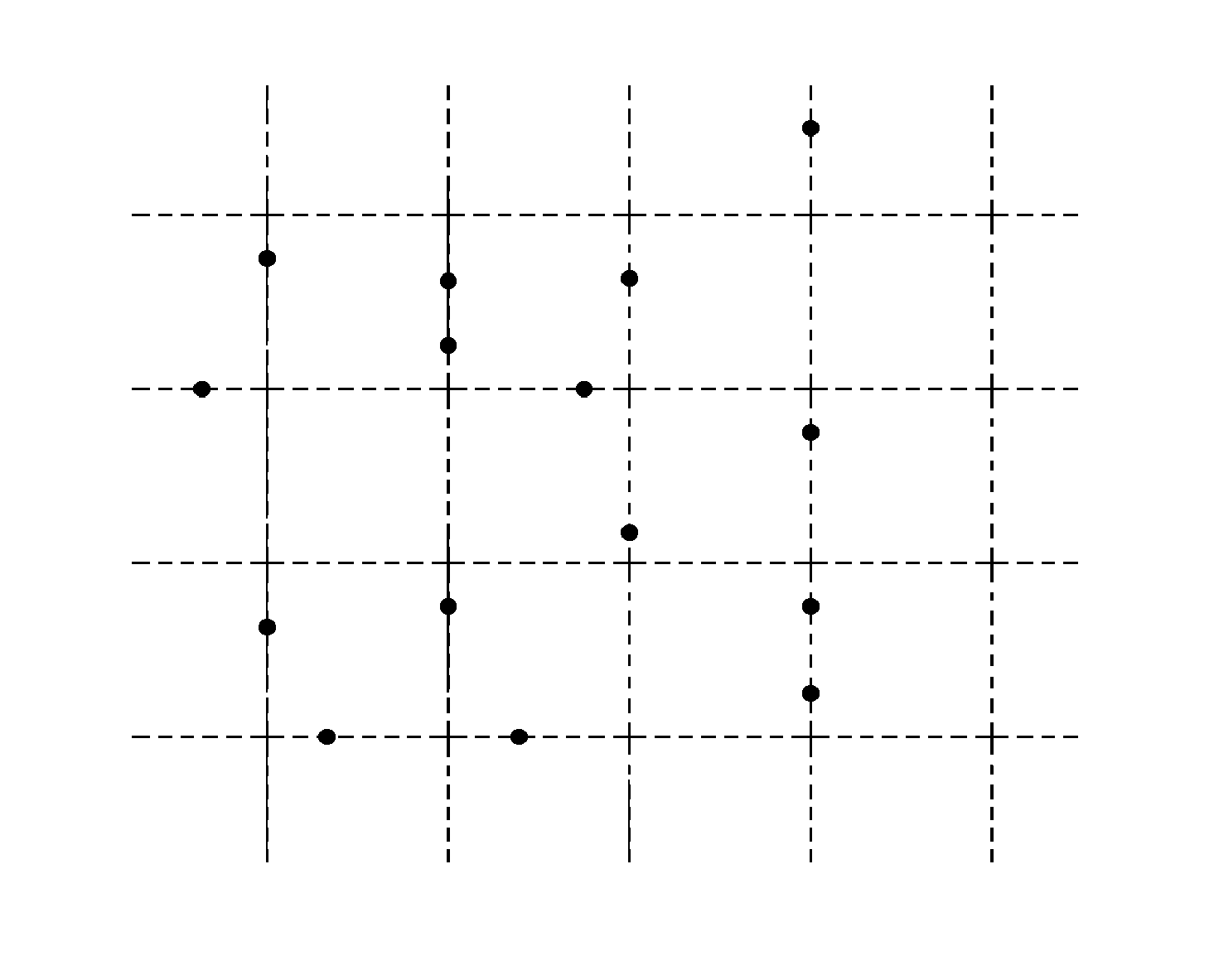

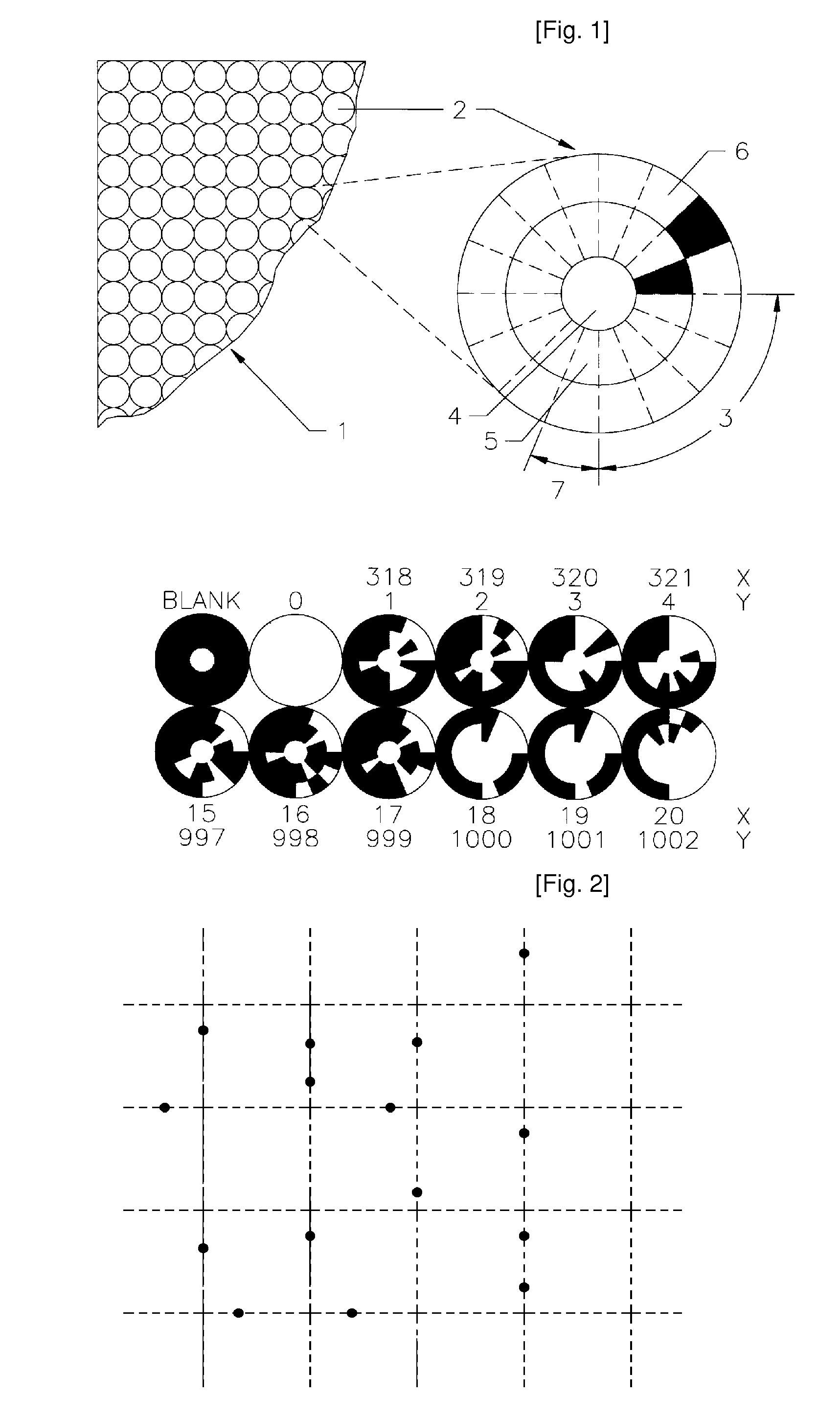

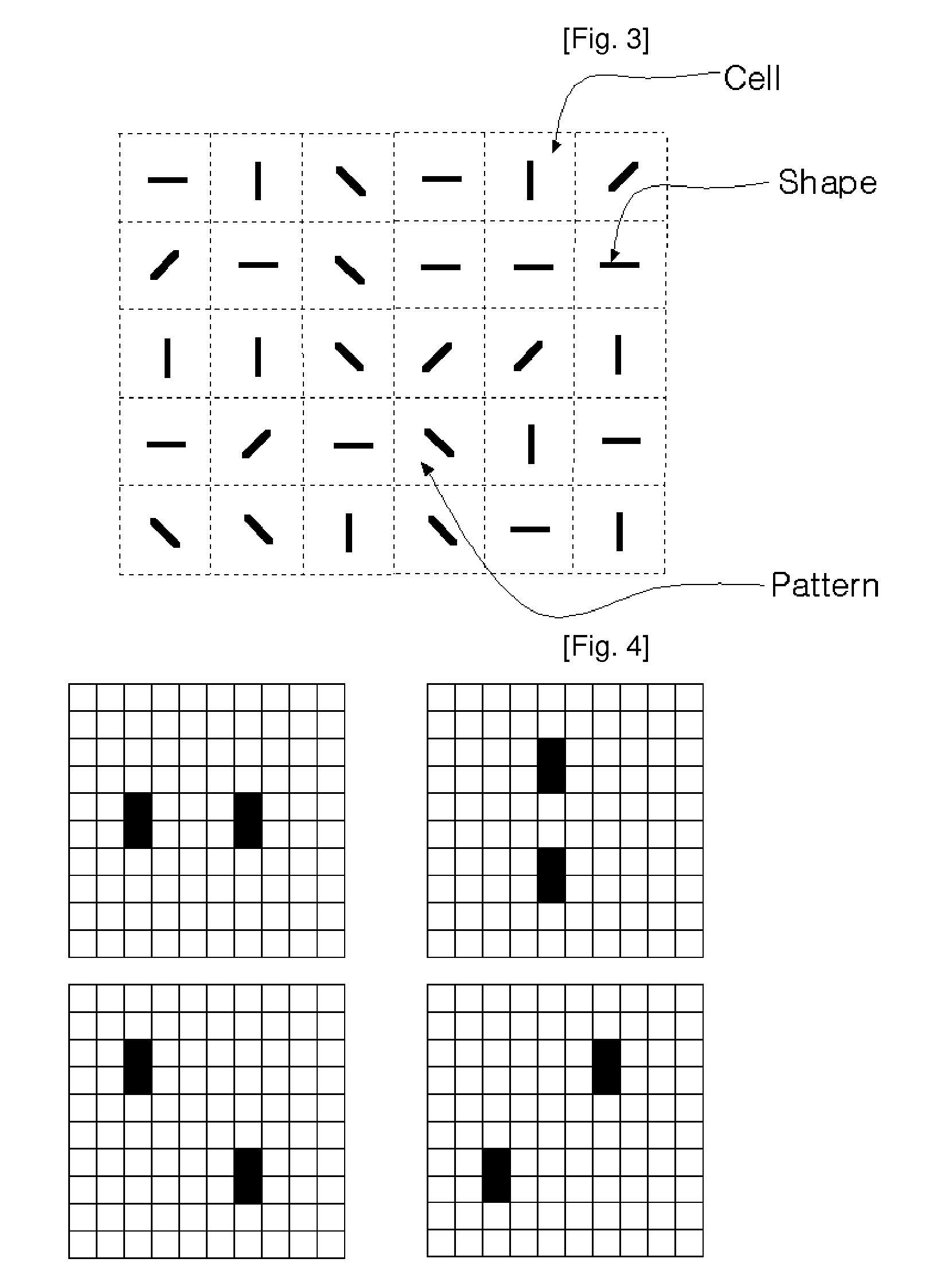

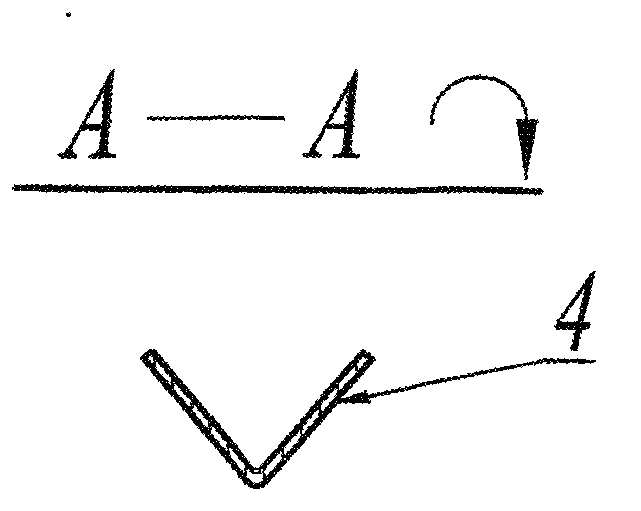

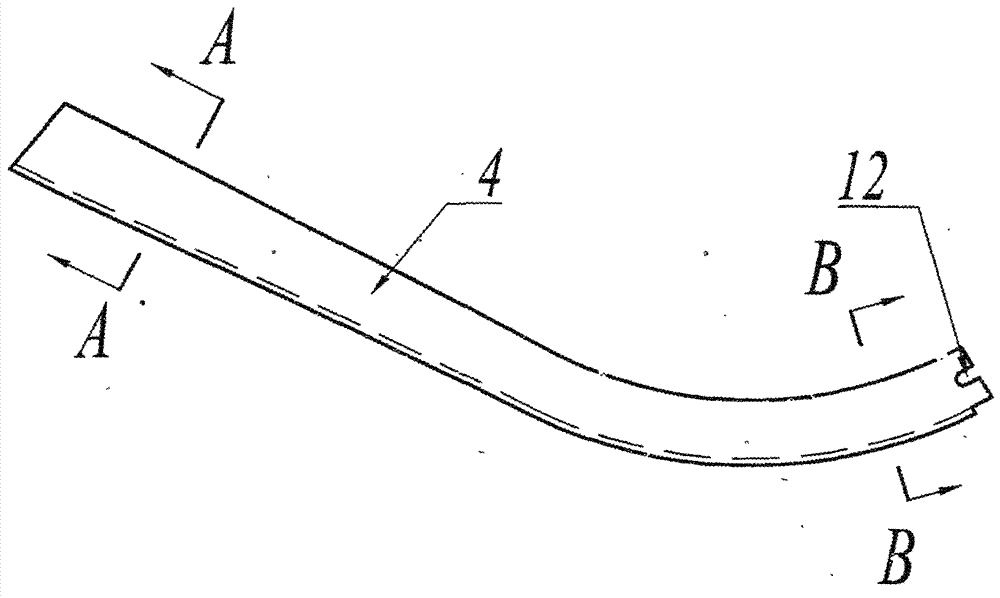

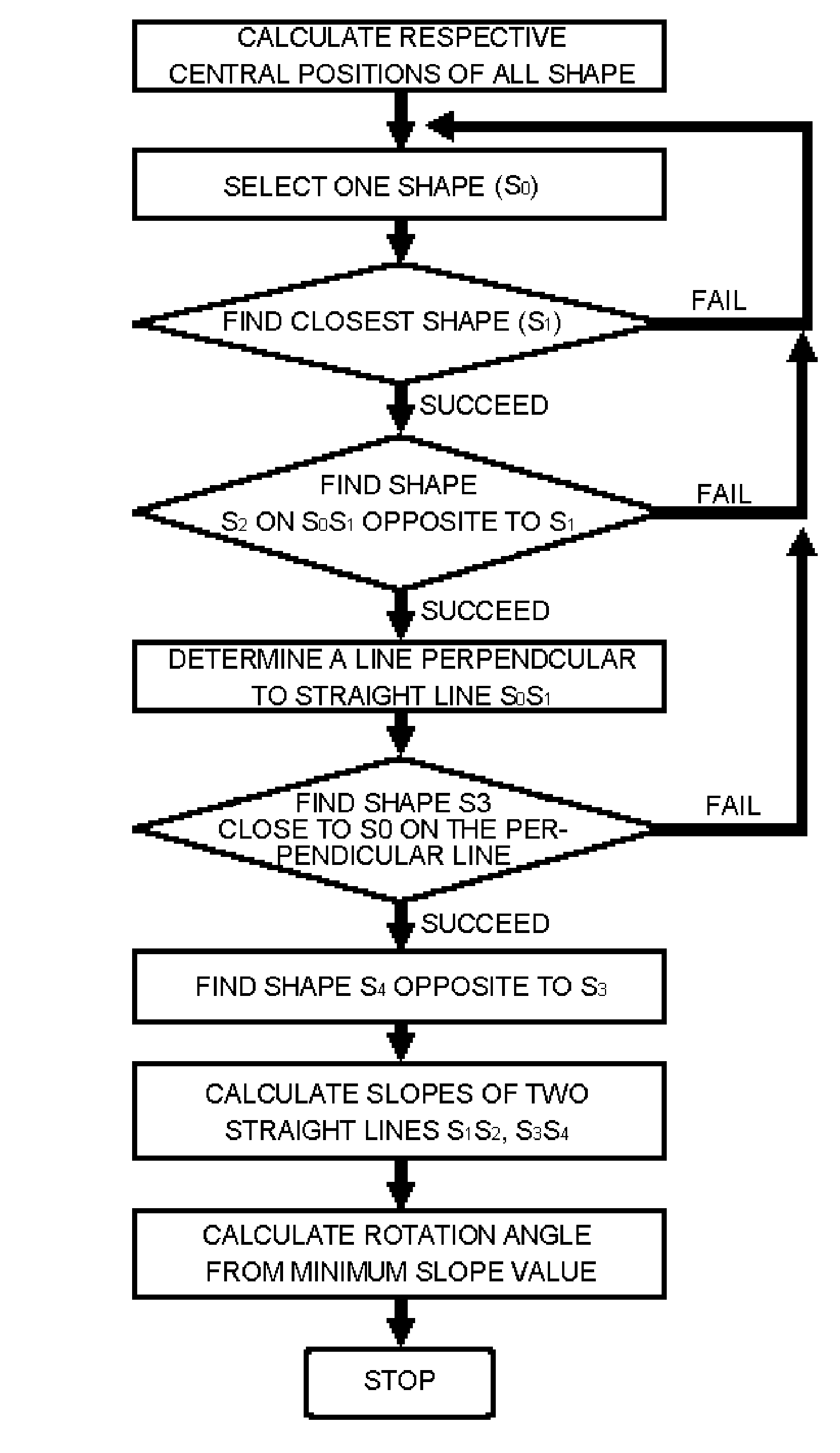

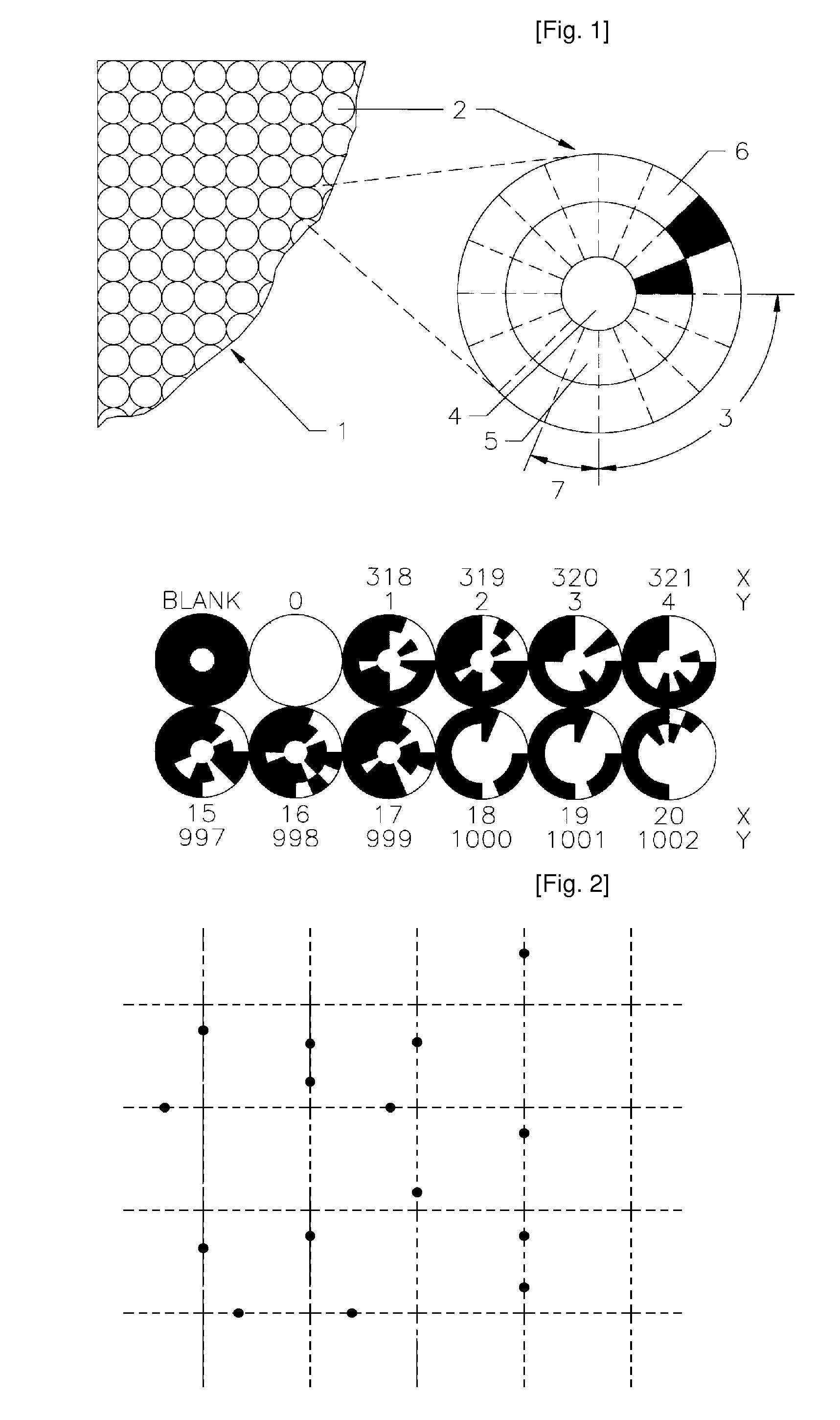

System and method of detecting absolute coordinates

ActiveUS8270775B2Pattern recording mediumConstantTransmission systemsCharacter and pattern recognitionImage resolutionSignal processing

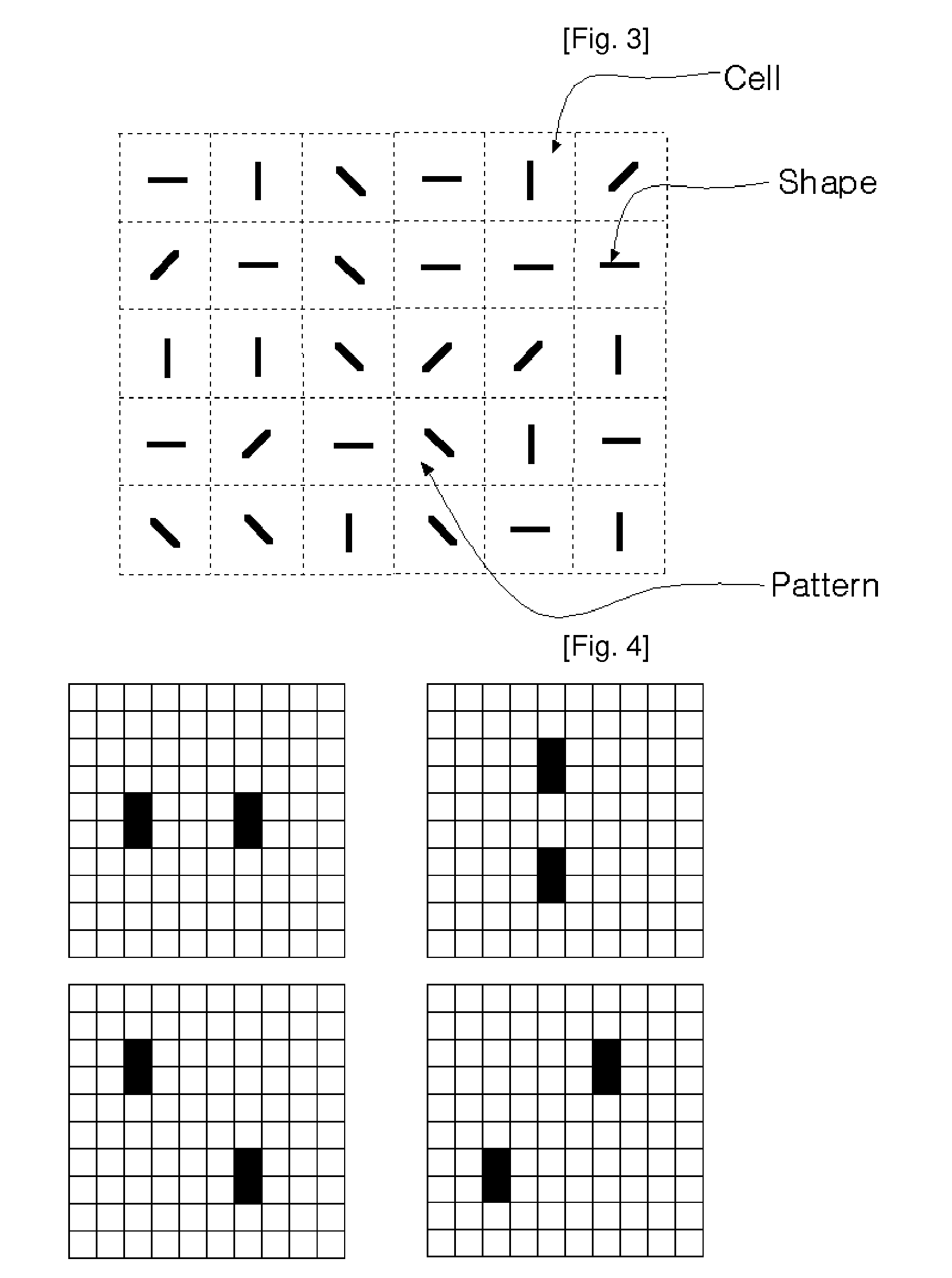

A system and method of recognizing absolute coordinates are provided. The absolute coordinate recognition system includes: a pattern recording medium in which each cell is diagrammatized, and a predetermined microcode is allocated to the pattern formed by each arrangement of the diagrammatized cells; a pattern sensing unit recognizing the microcode by sensing the pattern; and a signal processing unit calculating the position of the pattern sensing unit on the pattern recording medium, from the sensed pattern. By constructing the simpler patterns of the pattern recording medium, the absolute coordinate recognition system and method therefor enable imaging system and image sensor with not-high resolutions to recognize the patterns.

Owner:FINGER SYST

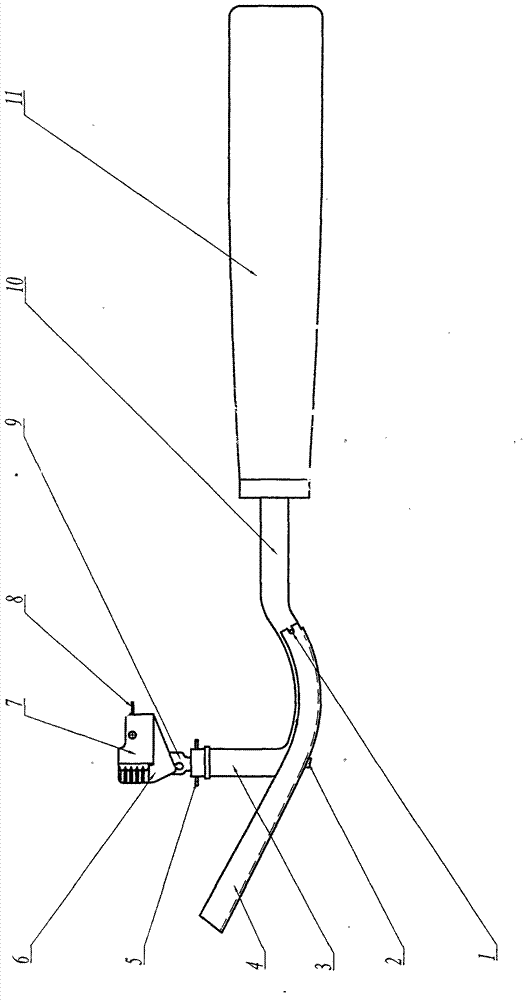

Scraper knife

The invention discloses a scraper knife, which comprises a knife handle, a scraper knife body, a plane cutter body, a vertical cant hook and a handle cant hook. The scraper knife is characterized in that the scraper knife body is arranged at the bottom of the vertical cant hook; the bottom of the handle cant hook is provided with a first pivot pin; the scraper knife body is movably arranged at a second pivot pin, can change a position and can be folded; the plane cutter is provided with a plane cutter holder and a blade; the plane cutter holder is connected with a plane cutter support holding strip; the plane cutter support holding strip is connected to the vertical cant hook; and the longitudinal and vertical position of a plane cutter is adjusted by a universal head so as to plane bark. The scraper knife moves forwards to make a new bark opening, and the blade moves on the bark longitudinally and vertically to finish multidirectional bark planning. The scraper knife makes new gum openings in consistent specification and depth, the plane cutter planes the marks in adjustable depth and adjustable direction, and the scraper knife can be operated freely on concave-convex trunks, can be folded, is convenient to carry, ensures that a great amount of resin glue is tapped and easy to collect, and is easily operated by a worker.

Owner:王缉兰

System and Method of Detecting Absolute Coordinates

ActiveUS20080123965A1Uniform shadeError minimizationCharacter and pattern recognitionInput/output processes for data processingImage resolutionSignal processing

A system and method of recognizing absolute coordinates are provided. The absolute coordinate recognition system includes: a pattern recording medium in which each cell is diagrammatized, and a predetermined microcode is allocated to the pattern formed by each arrangement of the diagrammatized cells; a pattern sensing unit recognizing the microcode by sensing the pattern; and a signal processing unit calculating the position of the pattern sensing unit on the pattern recording medium, from the sensed pattern. By constructing the simpler patterns of the pattern recording medium, the absolute coordinate recognition system and method therefor enable imaging system and image sensor with not-high resolutions to recognize the patterns.

Owner:FINGER SYST

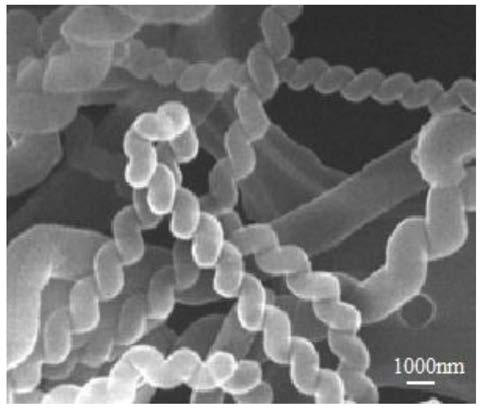

Preparation process of spiral yarn

InactiveCN111270344AUniform shadeReasonable designArtificial filament heat treatmentMelt spinning methodsYarnPolymer science

The invention discloses a preparation process of a spiral yarn. The spiral yarn is prepared from 8-12 parts of a carbon fiber intercalated graphene composite material, 30-40 parts of PET fiber, 60-70parts of PTT fiber and 0.8-2 parts of a catalyst through melt spinning and heating treatment. The preparation process of the spiral yarn specifically comprises the steps of preparation of carbon fibers, preparation of the carbon fiber intercalated graphene composite material, melt extrusion preparation of the spiral yarn and heat treatment of the spiral yarn. The preparation process is reasonablein design, the operation process is simple and feasible, the obtained spiral yarn is PET / PTT fiber reinforced by the carbon fiber intercalated graphene composite material, the crimp rate reaches 48%,a tensile fracture experiment proves that the tensile strength of the spiral yarn is enhanced by 15-20 %, the tensile ratio is increased to 1.6 from 1.2, and the strip shadow property of the cloth face of a fabric prepared by using the spiral yarn product is uniform.

Owner:绍兴天普纺织有限公司

X-ray inspection apparatus and correction method for X-ray inspection apparatus

ActiveUS10718725B2Uniform shadeImprove accuracyImage analysisMaterial analysis by transmitting radiationRadiologyEngineering

To correctly acquire image data of an inspected article by preventing a difference in shade between images caused by a difference in position or sensitivity between sensor elements. An X-ray generation source irradiates an inspection region where an inspected article passes with an X-ray. X-ray detection means receives the X-ray passing through the inspection region using a plurality of sensor elements. Image data generation means generates image data of the inspected article from an output of the X-ray detection means. Incidence condition changing means changes two or more kinds of X-ray incidence conditions common for all of the plurality of sensor elements of the X-ray detection means in a state of absence of the inspected article in the inspection region. Correction data generation means acquires correction data that is needed for making a shade of an image uniform for each incidence condition.

Owner:ANRITSU CORP

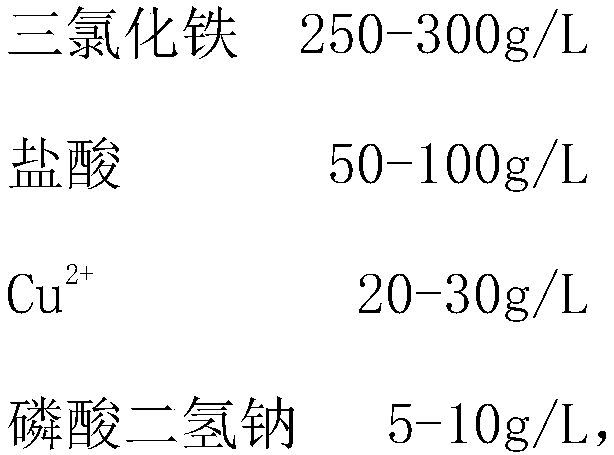

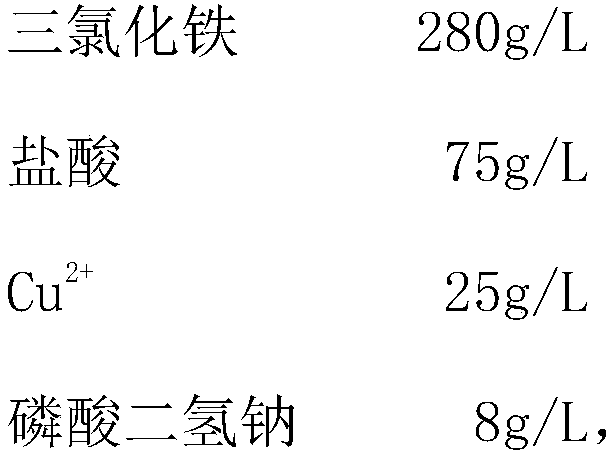

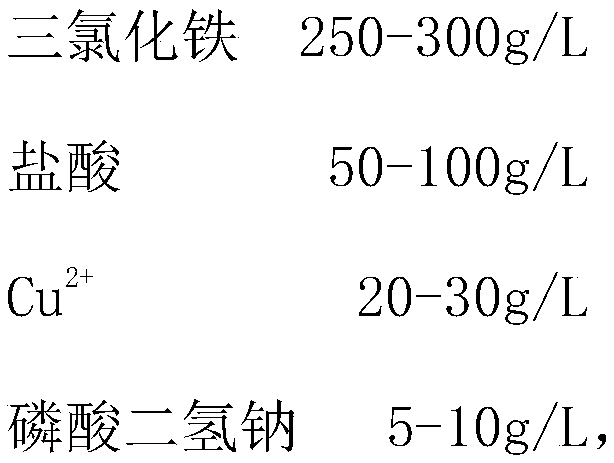

Nanometer treatment method for stainless steel

The invention discloses a nanometer treatment method for stainless steel. The nanometer treatment method comprises the steps of degreasing, hot water cleaning, dry ice cleaning, nanometer treatment, water washing, dry ice cleaning, alkaline etching, twice successive water cleaning, neutralization and water washing. In the nanometer treatment step, 250-300 g / L of ferric trichloride, 50-100 g / L of hydrochloric acid, 20-30 g / L of Cu2+ and 5-10 g / L of sodium dihydrogen phosphate are selected to be used. Nanometer treatment is conducted for 60-240 seconds at the temperature of 20-60 DEG C. The nanometer treatment method is mild in reaction and uniform in etching speed; pits at the nanometer scale can be formed in the surface of the stainless steel, and the formed pits are uniform; and the process is completed by one step, so that the time cost is saved. Copper ions are used, and therefore, etching can be implemented steadily; formed holes are uniform in depth; the formed pits are filled with resin in the injection molding process, so that tight connection is achieved between the resin and the surface of the stainless steel; and the bonding strength between the resin and the steel is improved.

Owner:安徽新合富力科技有限公司

Acrylic fabric cationic dyeing pad dyeing process

The invention relates to the technical field of acrylic fabric dyeing, in particular to an acrylic fabric cationic dyeing pad dyeing process. The acrylic fabric cationic dyeing pad dyeing process comprises the following steps of (1) padding a fabric in a heated dye liquor, wherein the dye liquor is a cationic dye solution with the concentration of 1-130 g / L, the pH value of the dye liquor is 4-5, and the amount of liquid carried by the fabric after padding is 30%-80%; (2) directly steaming the fabric padded with the dye liquor, wherein the steaming temperature is 100-102 DEG C; (3) washing; and (4) drying. According to the process, continuous dyeing processing is adopted, the production efficiency is high, the production period can be shortened, the process is suitable for dyeing of large-batch fabrics, and acrylic fabric products which are consistent in colored light, full in cloth cover and excellent in color fastness index can be obtained through the process. In addition, the process does not affect the dye uptake and color fastness of other fibers in the blended fabric.

Owner:HUAFANG +1

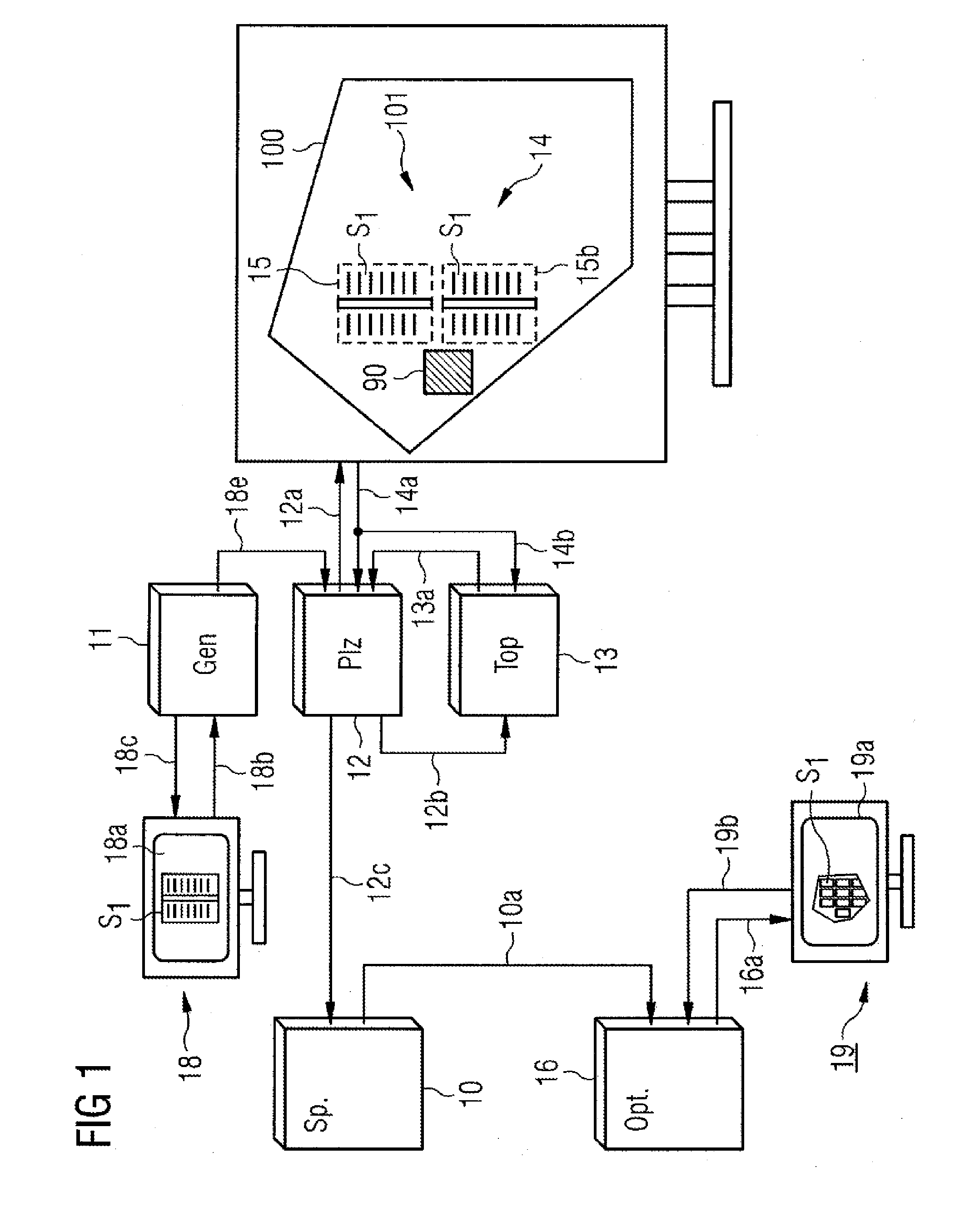

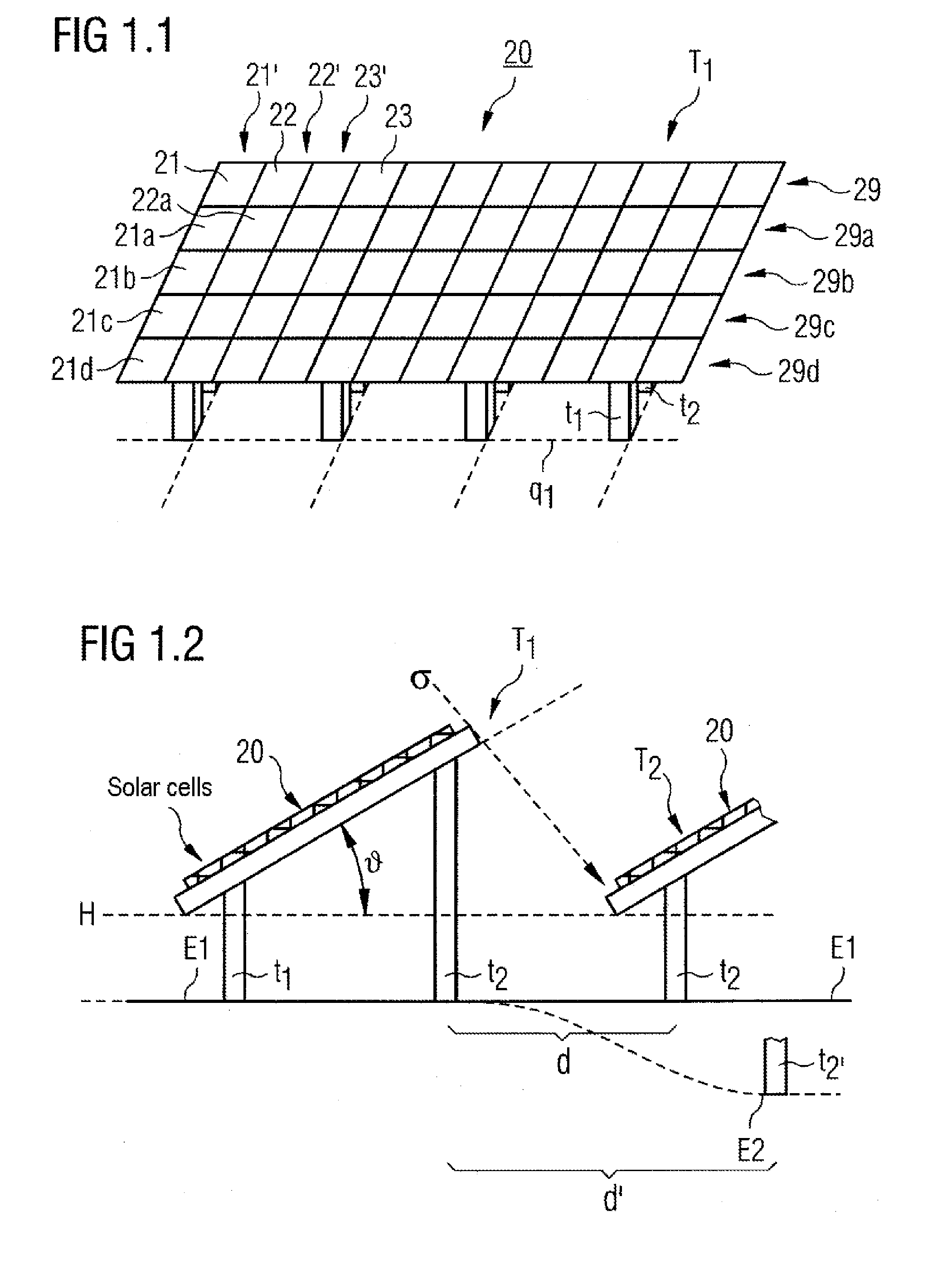

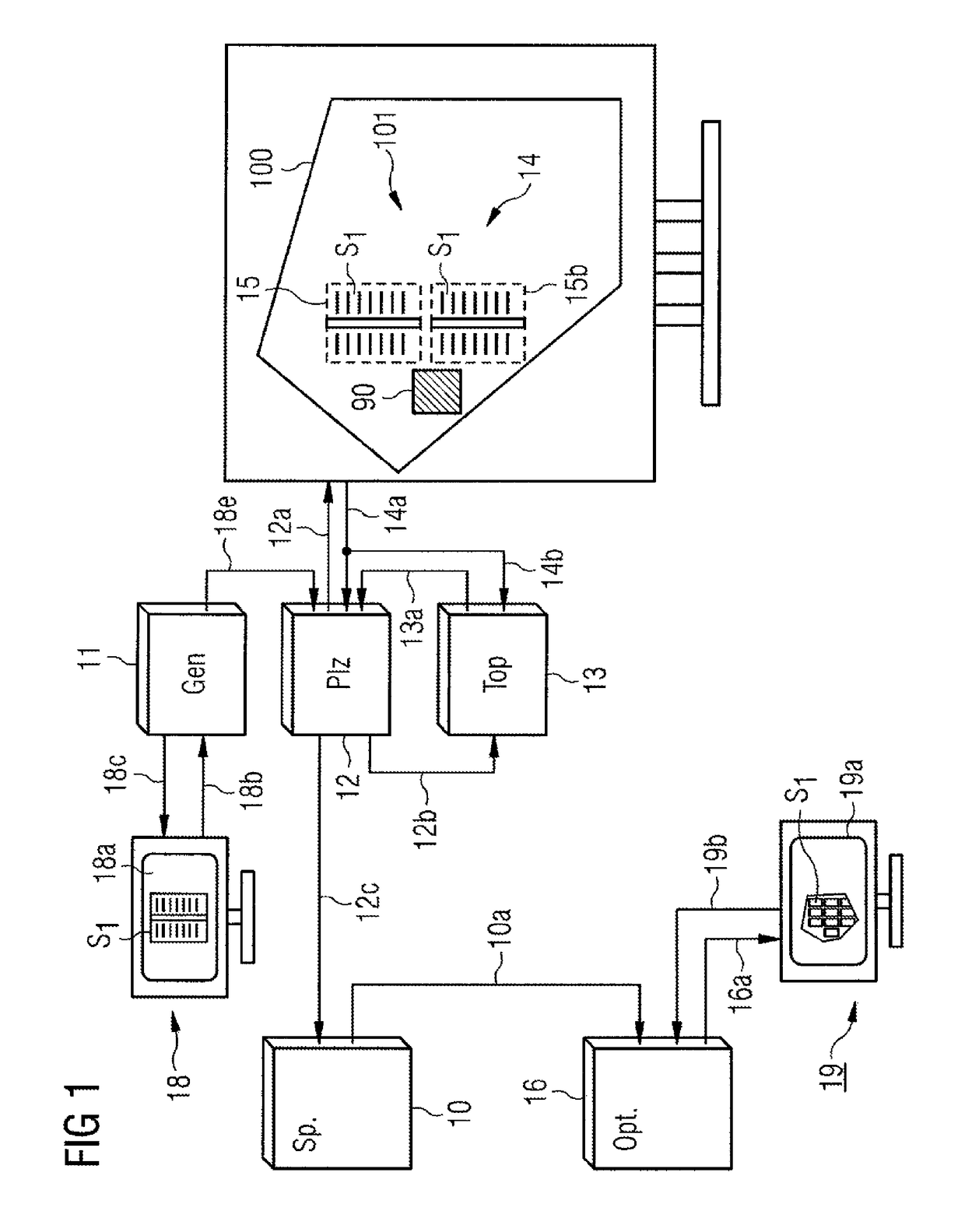

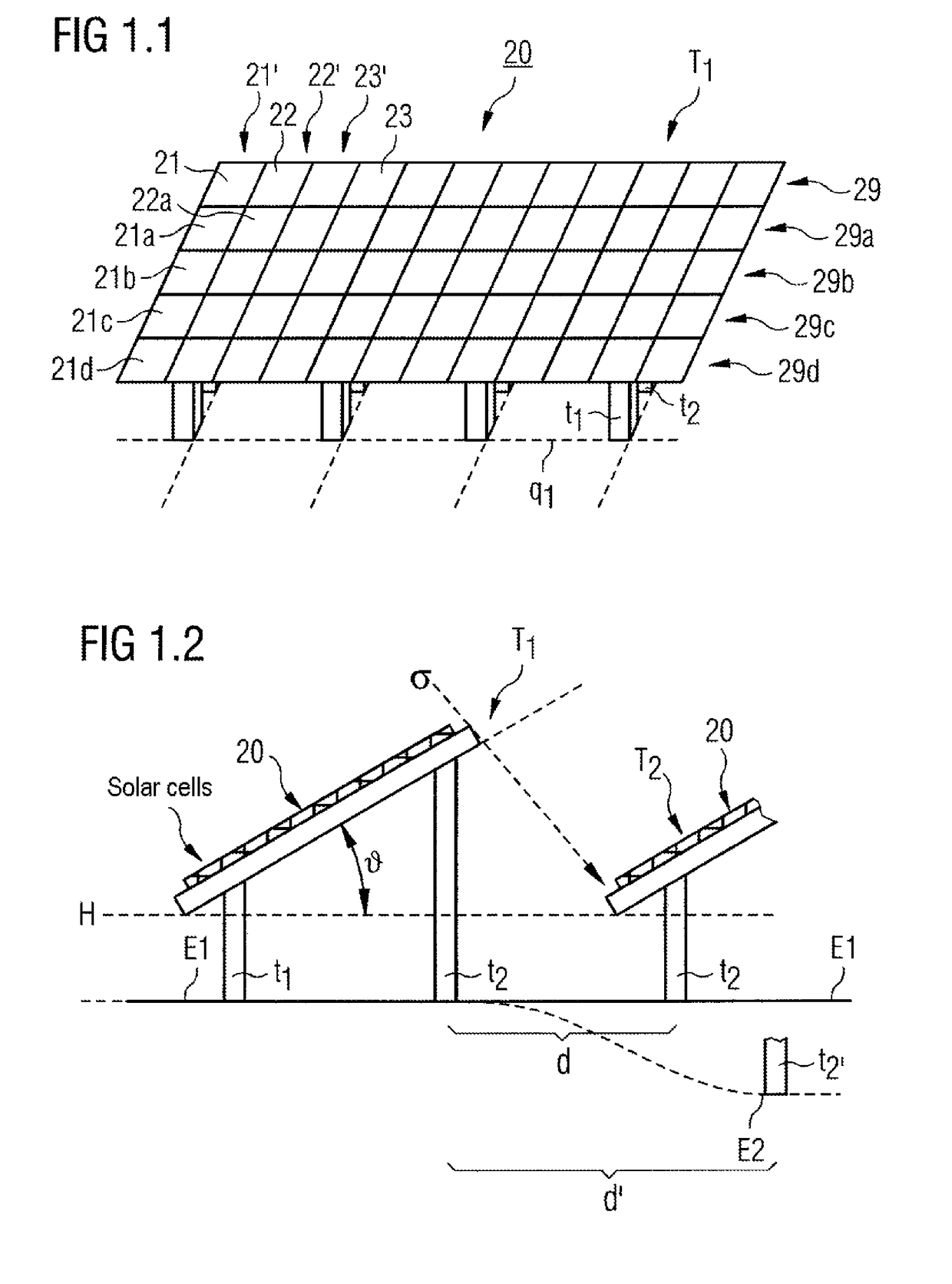

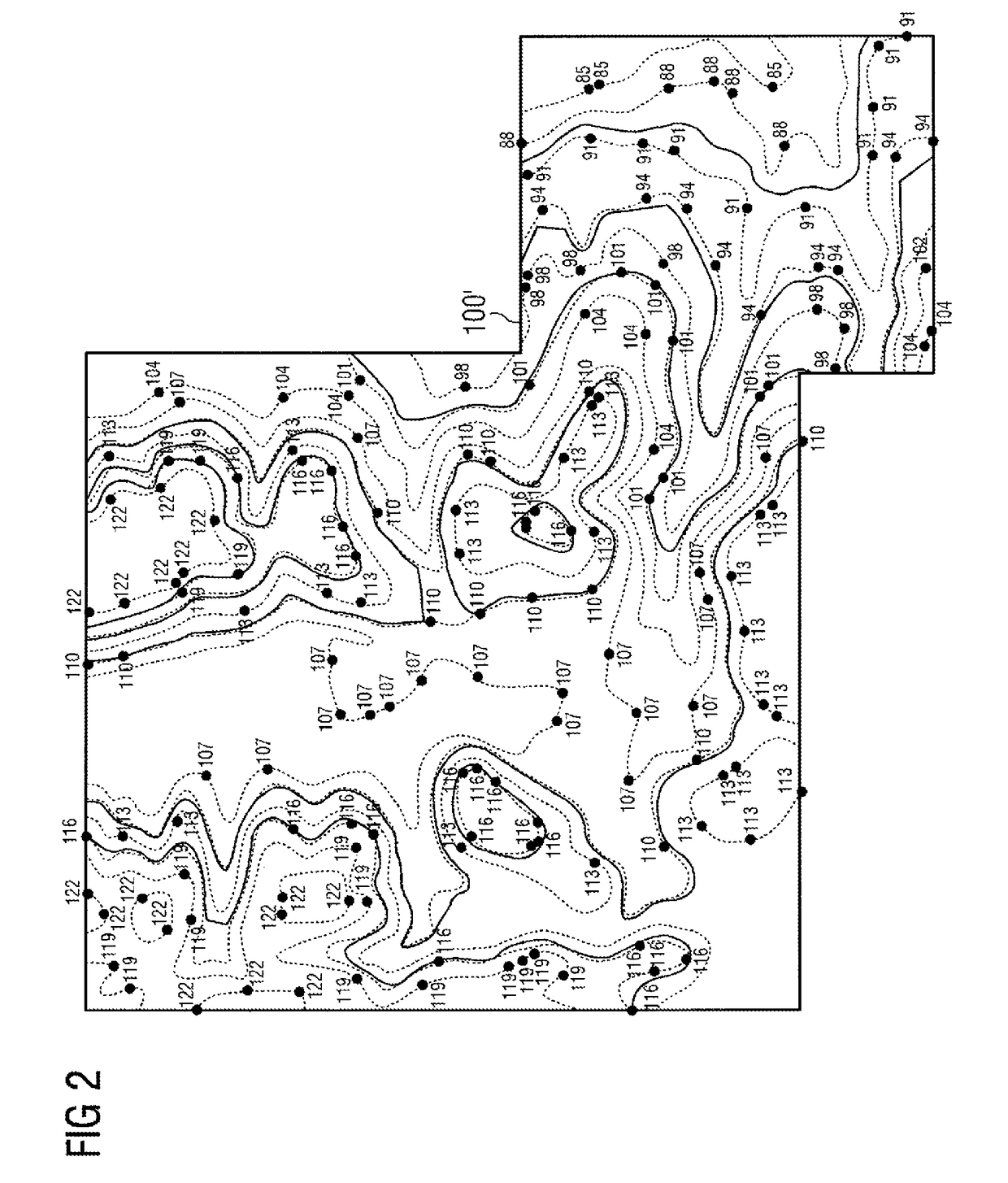

Simplified construction of a photovoltaic system with a consecutively placed system block

ActiveUS20150006118A1Sure easyTime taken to generate a wide variety of potential (useful) photovoltaic systemsPhotovoltaic supportsForecastingLocal topologyPhotovoltaic system

A method for defining a structure of a photovoltaic system on a system surface with a local topology is provided, including: first placement of a block at a location on the system surface with the local topology; placing additional blocks at additional locations on the system surface without overlapping previously placed blocks, wherein prior to each placement, row spacing of the solar panels of each additional block is adapted to the topology at the location at which the respective additional block was placed, resulting in a change in the extension of the additional block in the direction of the column of solar panels of the additional block, and ending the placement of additional blocks if, by the placement of an additional block, the nominal capacity of a photovoltaic system corresponding to the structure were to be exceeded, or if no additional block can be placed without overlapping previously placed blocks.

Owner:SIEMENS AG

Producing process of bleached hydrophilic toweling

The invention discloses a producing process of bleached hydrophilic toweling. The producing process comprises steps of: (1) putting toweling into a prepared bleaching solution; (2) heating the bleaching solution to 95-100 DEG C and maintaining the temperature for 25 min; (3) adding a whitening liquid into the solution in the step (2); (4) heating the solution in the step (3) to 150-170 DEG C and maintaining the temperature for 40 min; (5) washing the toweling in the step (4) with cold water; and (6) drying the toweling in a drier and finishing. The process is simple and easily understood. The processed fabric is natural in color, uniform in colored light and nonirritating to skin and achieves natural whiteness and good using performances.

Owner:QINGDAO TONGGUANWANG IND

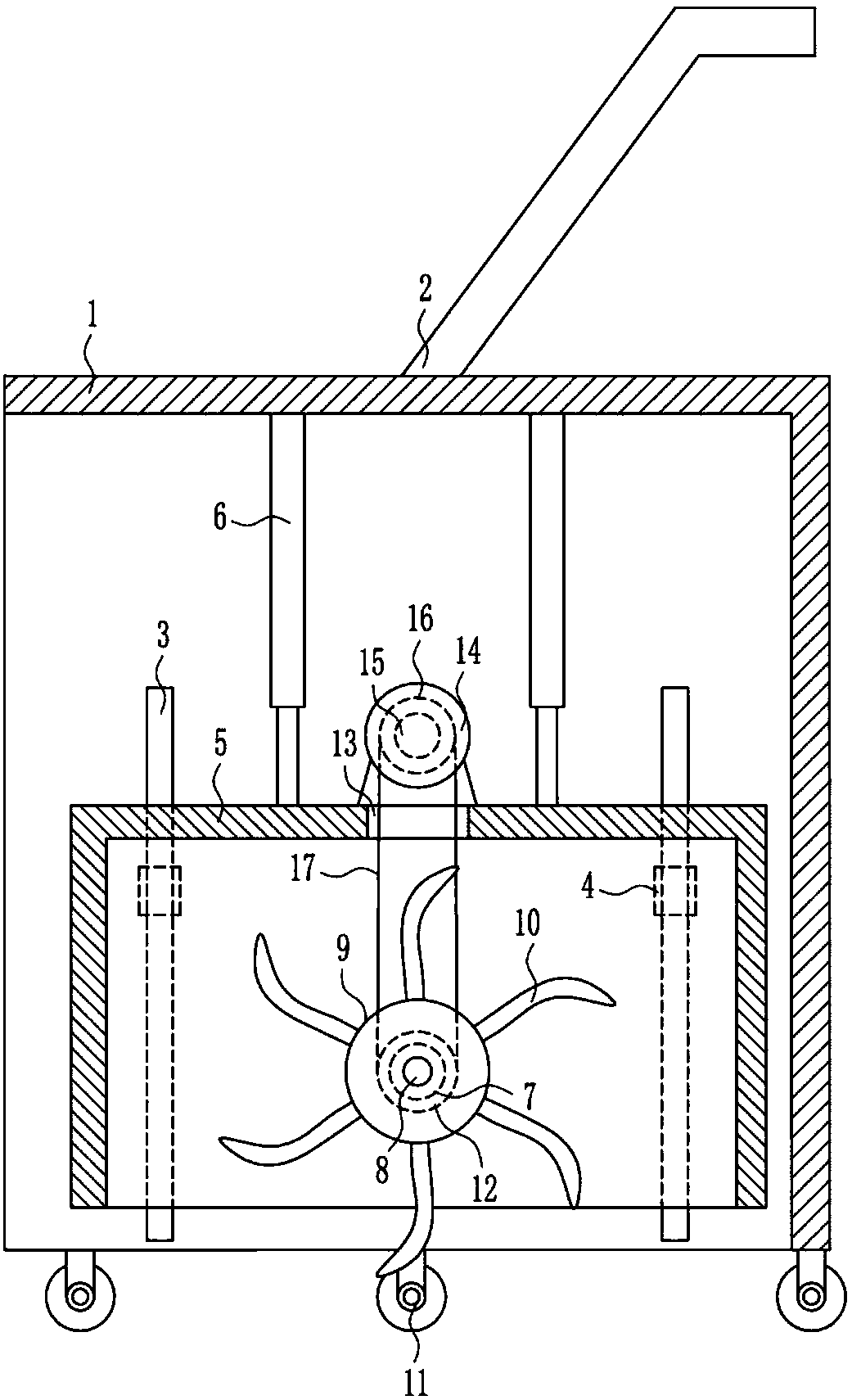

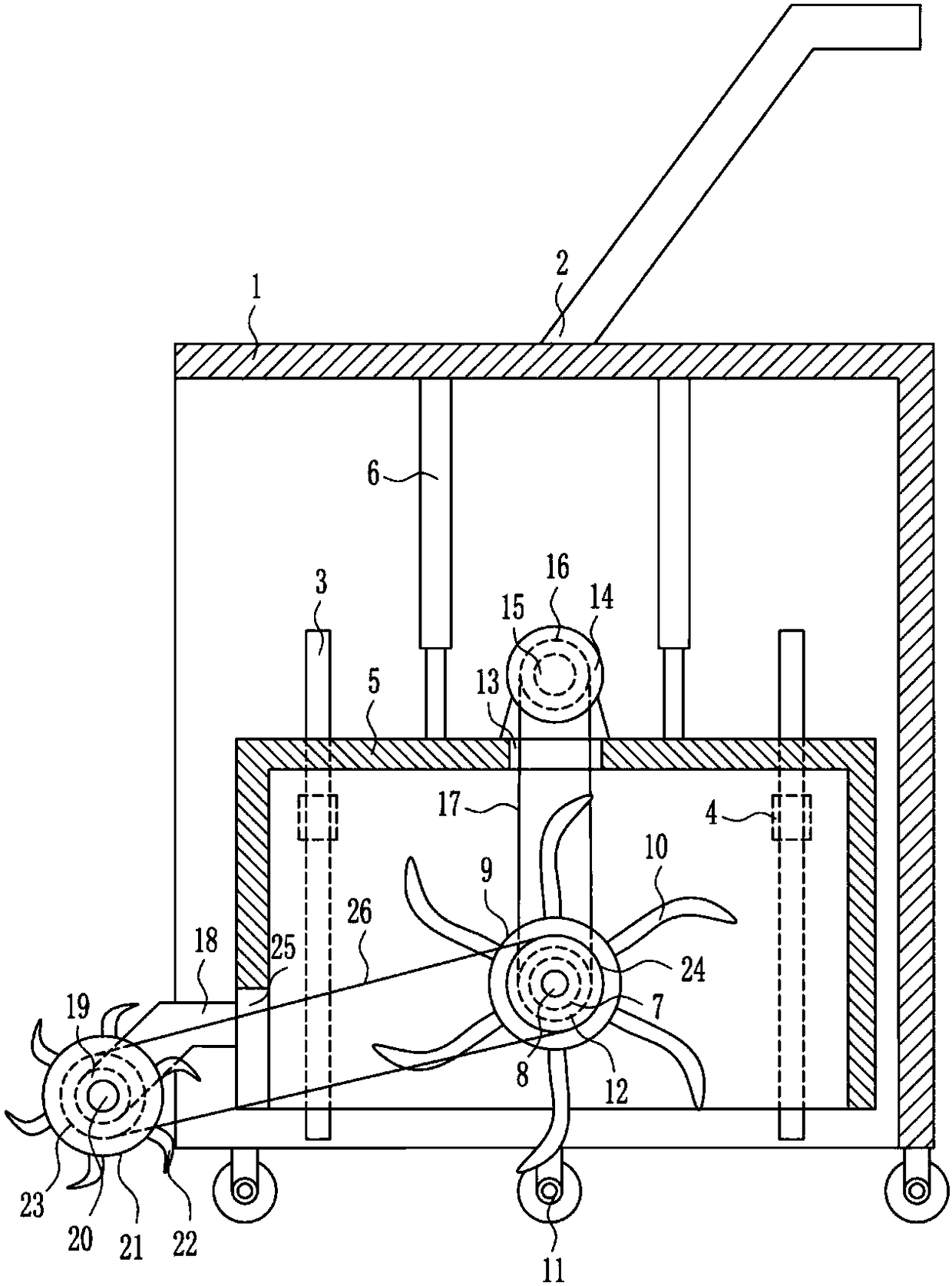

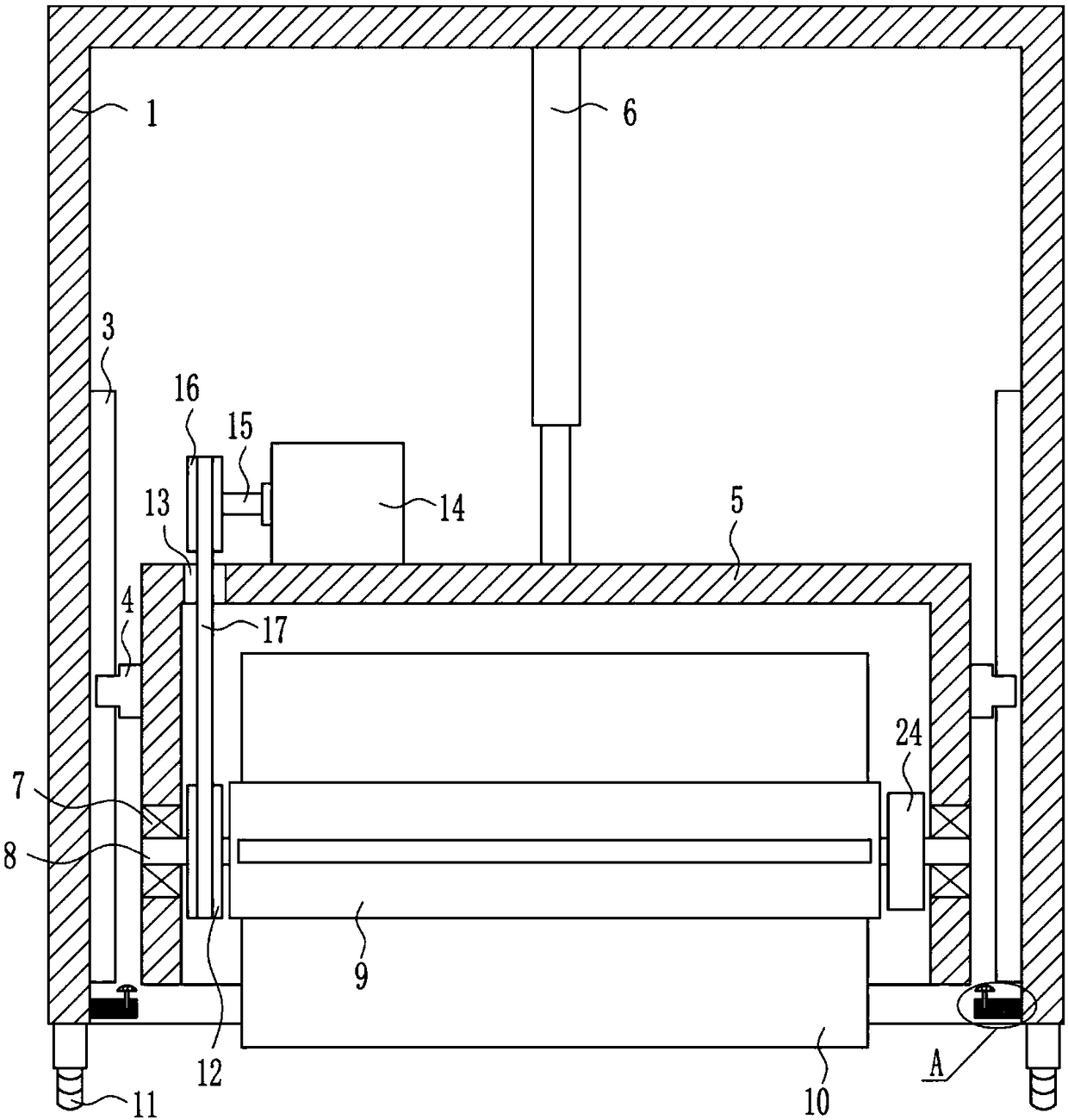

Ditching equipment for paving discharge pipe

The invention relates to ditching equipment, in particular to ditching equipment for paving a discharge pipe. The invention aims to provide the ditching equipment for paving the discharge pipe, wherein the ditching speed is high and the depths of the ditched furrows are relatively uniform. The invention provides the ditching equipment for paving the discharge pipe. The ditching equipment for paving the discharge pipe comprises a frame, a pushing hand, slide rails, slide blocks, a frame body, air cylinders, a first bearing pedestal, a first rotating shaft and the like, wherein the pushing had is mounted on the top of the outer side of the frame; the two slide rails are mounted on the front and back sides in the frame; the slide blocks are slidably arranged on the inner side face of each slide block; the frame body is mounted between the front and back slide blocks; and the two air cylinders are mounted in the top of the frame. Driven by a first motor, a roller can be driven to rotate soas to drive a doctor blade to rotate. An operator then pushes the ditching equipment to ditch furrows on the ground. Small chutes are ditched first through the doctor blade first, so that the ditching efficiency can be improved. Therefore, the effects that the ditching speed is high and the depths of the ditched furrows are relatively uniform are achieved.

Owner:嘉兴市迅程信息技术有限公司

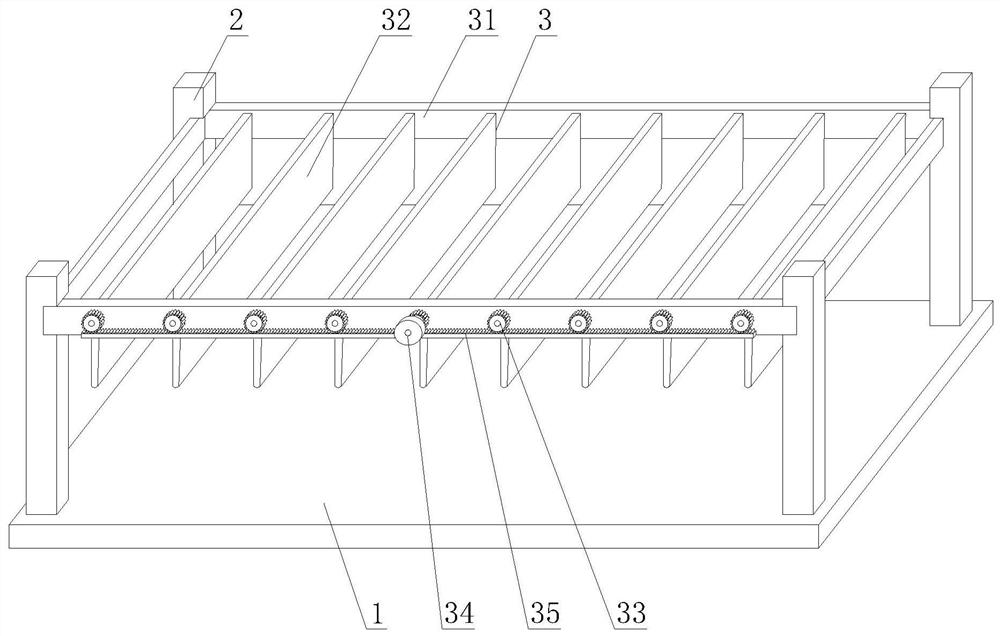

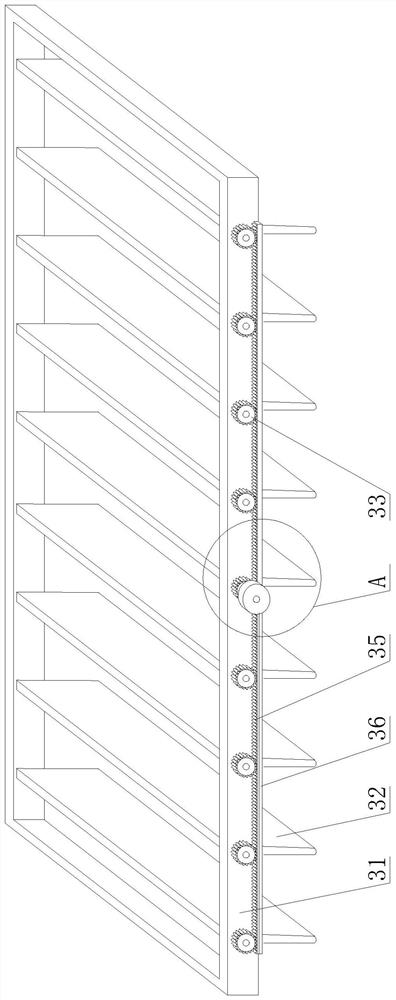

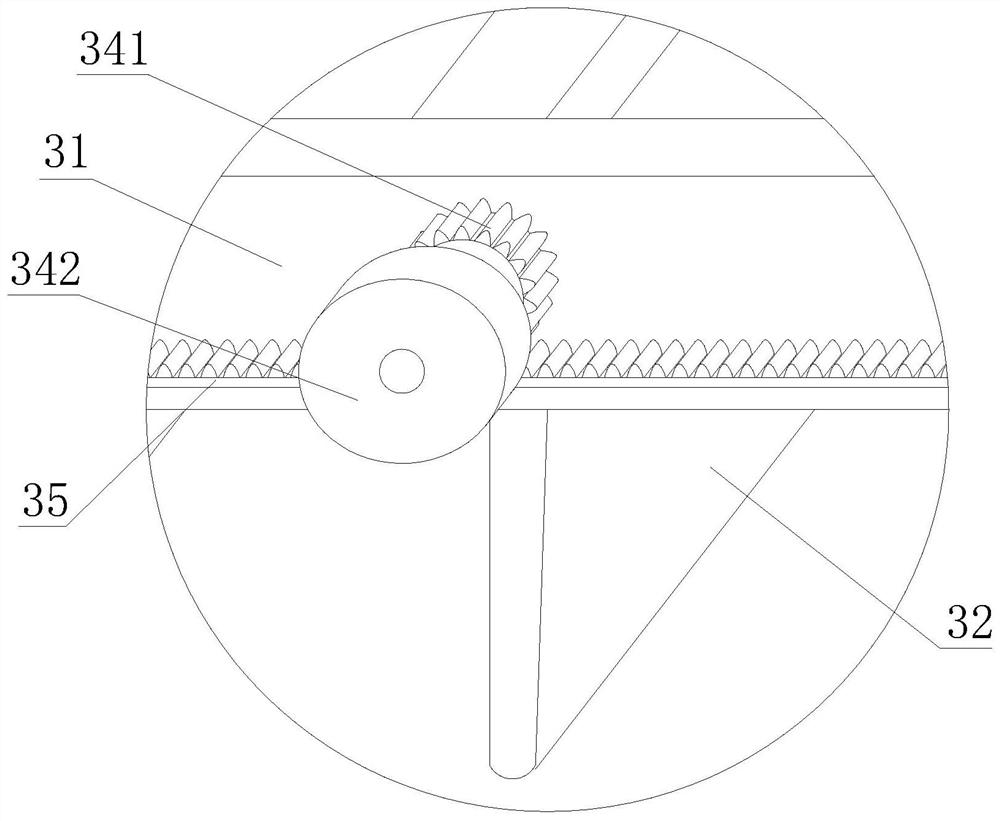

Strawberry planting shading and transplanting device and implementation method thereof

InactiveCN112042341AEasy to adjustRegulation stabilityTransplantingPlant protective coveringsFragariaGear wheel

The invention discloses a strawberry planting shading and transplanting device and an implementation method thereof. The strawberry planting shading and transplanting device comprises bottom frames and supporting columns, wherein the supporting columns are installed at the four corners of the bottom frames, a shading assembly is connected to the supporting columns through rectangular limiting grooves, and the shading assembly comprises a frame, shading blades, driven gears, a driving adjusting structure, a rack, an extending strip and short shafts. The plurality of bottom frames can be stackedtogether to facilitate overall movement of the bottom frames, the supporting columns are connected with the shading assembly through the rectangular limiting grooves, the shading assembly can effectively shade strawberry seedlings, and when the driving adjusting structure is driven to rotate, the rack can slide left and right, the rack drives the driven gears to rotate while sliding, and the driven gears can drive the shading blades, so that the shading blades deflect, the purpose of adjusting the shading effect is achieved, the whole strawberry planting shading and transplanting device is simple and convenient to adjust, and meanwhile, the adjusted shading effect is uniform and good in practicability.

Owner:马鞍山鑫发农业发展股份有限公司

Pre-treatment process of fluorescence-free bleached towel

InactiveCN1974919ANatural colorUniform shadeBiochemical fibre treatmentBleaching apparatusFluorescencePre treatment

The pre-treatment process of fluorescence-free bleached towel includes the working procedures of accepting fabric, refining, bleaching, dewatering and stoving. The working procedures of refining and bleaching includes the following steps: circulating the towel in the refining liquid with biological enzyme in 1-2 g / L and surfactant in 0.3-0.8 g / L at 40-60 deg.c for 30-50 min, and conventional water washing; circulating in bath with hydrogen peroxide in 2 g / L and hydrogen peroxide stabilizer in 1 g / L and of pH 10-11 at 90-98 deg.c for 20-40 min; and high temperature water washing at over 95 deg.c and cold water washing. The process is simple and reasonable, and can eliminate commensals from pure cotton towel and endow towel with natural whiteness and excellent wearability.

Owner:QINGDAO XIYINGMEN GRP

Modified polyester composite filament durable elastic woolen sweater and preparation method thereof

InactiveCN114016198AIncrease elasticityFlexible and controllableWeft knittingDyeing processYarnPolymer science

The invention discloses a modified polyester composite filament durable elastic woolen sweater and a preparation method thereof. PET and PTT polyester composite filaments and wool or wool blended spun yarns are doubled to form composite yarns serving as a core, and the PET and PTT polyester composite filaments are stock solution colored or white self-crimping filaments; and the wool fabric has 10-40% tensile elasticity in the warp and weft directions. The woolen sweater has the advantages of stable and lasting elasticity, strong woolen feeling and simplicity and convenience in processing. The wool fabric with lasting elasticity, controllable elasticity, hank dyeing, wool feeling, strong force and high cost performance can be provided, and aiming at the problems that the existing wool spandex elastic fabric is easy to loosen and expose white, and the wool / high-temperature dyeable polyester elastic filament fabric is difficult to dye and easy to dye, the low-temperature dyeable self-crimping composite elastic white filament is adopted, through a Sirofil spinning or doubling twisting mode, by controlling the off-machine size of a flat knitting machine and the temperature, time and bath ratio of drying and washing, and by combining key process control such as spinning, hank dyeing and the like, the product is prepared.

Owner:JIANGSU JIANLU WOOLEN

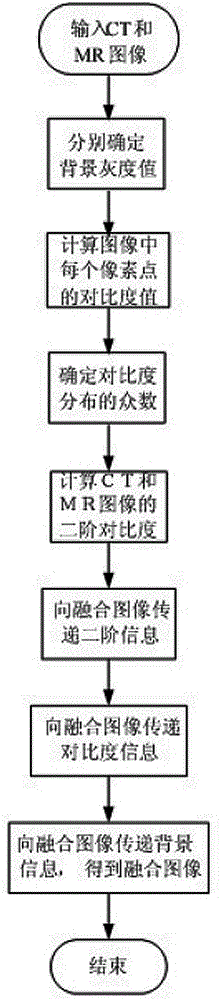

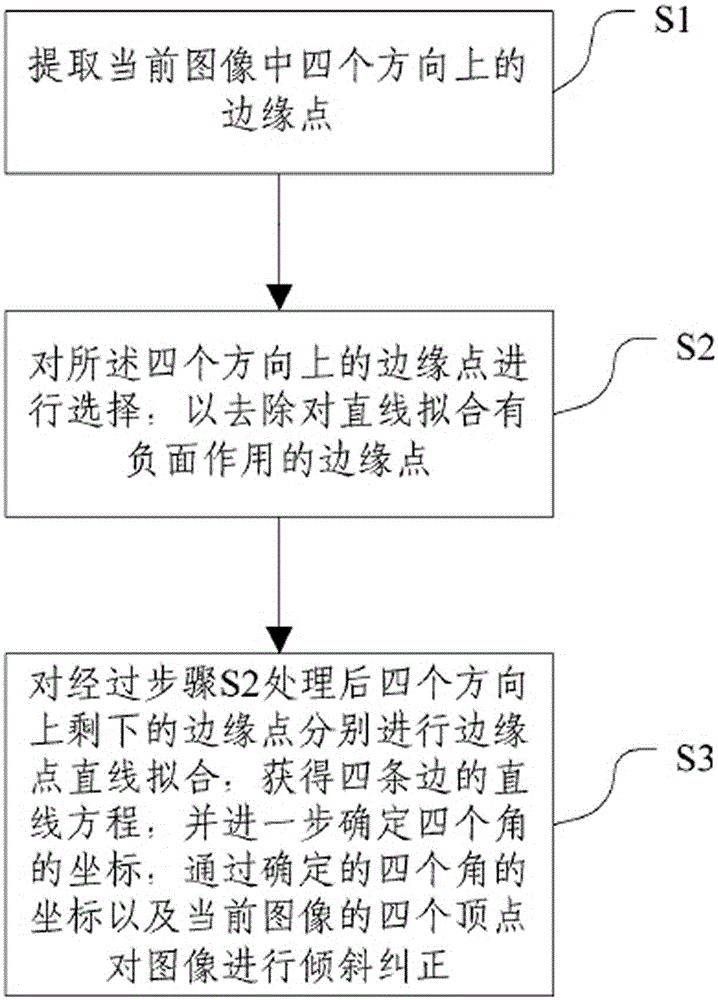

Panoramic photo automatic uploading and splicing method

InactiveCN106530211AUniform shadeSave human effortGeometric image transformationGyroscopeComputer vision

The invention discloses a panoramic photo automatic uploading and splicing method, which belongs to the panoramic photo processing technology field. The panoramic photo automatic uploading and splicing method is advantageous in that labor and time are saved, and checking is facilitated. The panoramic photo automatic uploading and splicing method comprises steps that (1) after images are uploaded by a panorama camera, the images are spliced and fused into a panorama according to the parameters of the panorama camera; (2) according to the gyroscope data of the camera, the spliced panorama is corrected, and the panorama, which is shot inclinedly a little bit, is corrected to the panorama, which is shot horizontally; (3) projection on a ball body is defined by the panorama via an image around the two dimensional surface of the ball body, and at the same time, is divided into different levels.

Owner:STATE GRID LIAONING ELECTRIC POWER CO LTD SHENYANG POWER +1

An integrated production line for wood floor embossing, spraying, drying

InactiveCN104275727BImprove processing efficiencySolve the problem of uneven embossing strengthWood compressionProduction lineIntegrated production

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Lithol red preparing method

The invention provides a lithol red preparing method and relates to the technical field of pigments. The lithol red preparing method comprises the following steps of (1) preparing a coupling fluid bymixing and dissolving, by weight part, 3-5.6 parts of liquid alkali, 3-5 parts of ethyl naphthol and 0.6-1.5 parts of anionic surfactant; (2) preparing a diazonium solution by uniformly mixing, by weight part, 3-4.5 parts of liquid alkali, 3-4 parts of tobias acid, 3-4 parts of sulfonated tobias acid and 2-4 parts of cold distributing acid and then adding in 0.6-3 parts of hydrochloric acid and 1.5-2.8 parts of sodium nitrite for diazo reaction; (3) mixing, by weight part, 2-4 parts of liquid alkali and 2-3 parts of rosin to obtain a rosin solution; (4), mixing the coupling fluid and the diazonium solution for coupling reaction, then adding in the rosin solution and saturated barium chloride solution, adjusting the pH to 7.5-8.0 and adding in aluminum chloride to obtain lithol red. The prepared lithol red can avoid flocculation in a system when applied to ink and paint, and is free from separation, uniform in color darkness, fined in pigment particles and small in grain size.

Owner:宣城英特颜料有限公司

Simplified construction of a photovoltaic system with a consecutively placed system block

ActiveUS10204179B2Time taken to generate a wide variety of potential (useful) photovoltaic systemsSystem area) can be reducedPhotovoltaic supportsForecastingLocal topologyPhotovoltaic system

A method for defining a structure of a photovoltaic system on a system surface with a local topology is provided, including: first placement of a block at a location on the system surface with the local topology; placing additional blocks at additional locations on the system surface without overlapping previously placed blocks, wherein prior to each placement, row spacing of the solar panels of each additional block is adapted to the topology at the location at which the respective additional block was placed, resulting in a change in the extension of the additional block in the direction of the column of solar panels of the additional block, and ending the placement of additional blocks if, by the placement of an additional block, the nominal capacity of a photovoltaic system corresponding to the structure were to be exceeded, or if no additional block can be placed without overlapping previously placed blocks.

Owner:SIEMENS AG

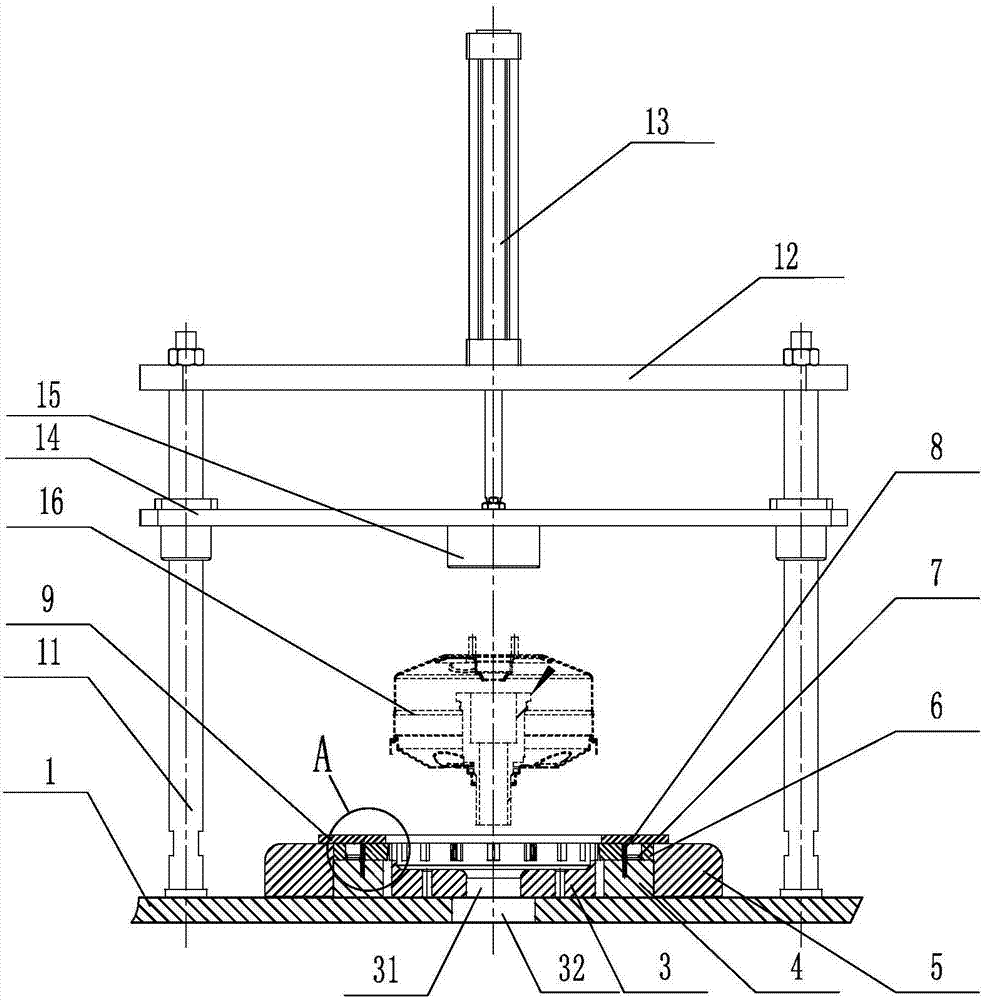

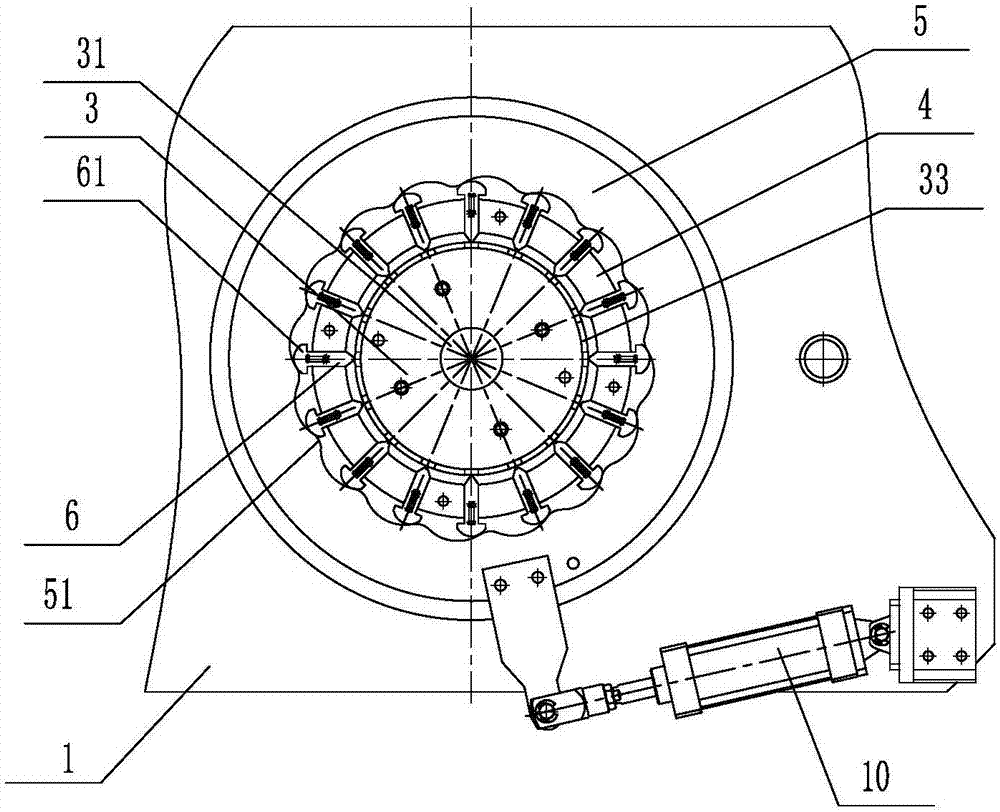

Special riveting machine for vacuum booster

The invention discloses a special riveting machine for a vacuum booster. The special riveting machine comprises a rack, wherein a riveting device is arranged on the rack; the riveting device comprises a location disc installed on the rack and used for placing the vacuum booster; a riveting guide device is fixedly installed at the outer side of the location disc in a sleeving manner; radially-sliding riveting knives are distributed on the riveting guide device in the circumferential direction; the riveting knives are connected with a return limit device; an outer riveting disc is rotationally installed at the outer side of the riveting guide device in a sleeving manner; riveting bulges corresponding to the outer ends of the riveting knifes are distributed on the inner circumferential wall of the outer riveting disc in a bulging manner in the circumferential direction; and a riveting propelling device is arranged between the rack and the outer riveting disc. The special riveting machine disclosed by the invention is capable of realizing simultaneous feeding of the riveting knifes, thereby ensuring the same riveting time for parts and the same depth of riveting points of riveting parts of a vacuum booster product, and effectively ensuring the sealing performance and the appearance quality of the riveting points.

Owner:SHANDONG AOYOU AUTOMOBILE BRAKING SYST

Character rolling device suitable for vibration reducer outer cylinder and vibration reducer outer cylinder character rolling method

The invention discloses a character rolling device suitable for a vibration reducer outer cylinder. The device comprises a core rod rotationally arranged and used for mounting the vibration reducer outer cylinder, and further comprises a character rolling template movably arranged below the core rod and a pressing mechanism for providing pressing force, of keeping the core rod in a horizontal state, to the core rod. The character rolling device suitable for the vibration reducer outer cylinder is provided with the pressing mechanism for keeping the core rod and the vibration reducer outer cylinder mounted on the core rod in the horizontal state during character rolling, so that the depths of rolled characters on the surface of the vibration reducer outer cylinder are uniform, and the characters are clear. The invention further discloses a vibration reducer outer cylinder character rolling method.

Owner:WUHU TIANYOU AUTOMOBILE TECH CO LTD

Blue glaze and preparation method thereof

The invention discloses a blue glaze and a preparation method thereof. The blue glaze is prepared from, by weight, 40-48% of albite, 18-25% of quartz powder, 8-12% of kaolin and 21-25% of wollastonite. The glaze enables a porcelain fired by the glaze to be dark in color and luster, uniform in concentration, stable in color generation, non-flowing and non-cracking in glaze surface, smooth in hand feeling, durable, wear-resistant, good in smoothness and thermal stability, wide in firing range, suitable for medium-temperature oxidizing atmosphere and high-temperature reducing atmosphere and suitable for wide popularization.

Owner:景德镇市乐陶陶瓷原料有限公司

Tongue-type multi-line brushing device of leather adhesive

InactiveCN102319658BAdjustable flowHow many linesLiquid surface applicatorsCoatingsShoe industryAdhesive

The invention discloses a leather adhesive tongue-type multi-line brushing device, which consists of an adhesive control plug, a tongue, a tongue tube, an adhesive control column A, an agent container outer tube, an adhesive control column B, It consists of a rear cover plug, a rear cover ring, an air needle, and a casing sleeve. The lower part of the container outer tube is fixedly equipped with the adhesive control column B, the lower part of the adhesive control column A is fixedly installed in the upper port of the tongue tube, and the upper part is movably connected to the lower port of the container outer tube; Column A and Adhesive Control Column B are made with two through holes for controlling the flow of adhesive liquid; the middle and lower part of the tongue tube is made into a funnel shape, and the tail of the funnel is the tongue mouth; a tongue is arranged in the tongue mouth; A threaded hole is made at the center point of the top, and a control adhesive plug is set in the hole, and the bottom surface of the control adhesive plug is crimped with the tongue. The device can save more than 80% of the adhesive than the brush, and does not pollute the upper surface and the environment. It is especially suitable for brush combination, sliver, drawing and other adhesives in the leather shoe industry and various repairing adhesive processes.

Owner:卿太辉 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com