Preparation process of spiral yarn

A preparation technology, a helical technology, is applied in the field of helical yarn preparation technology, which can solve the problems of limited preparation methods, need for further improvement, and uneven cloth and noodle shadow, and achieve simple and easy operation, reasonable design, uniform shadow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

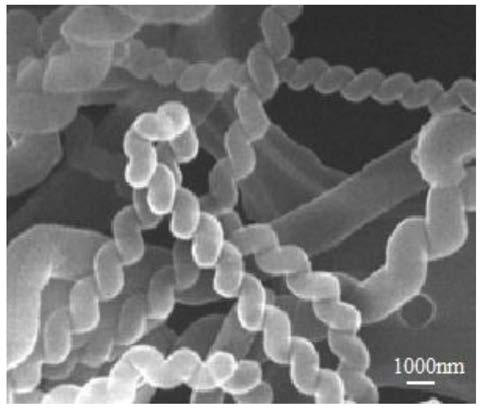

Image

Examples

Embodiment 1

[0017] A preparation process of a helical yarn, which is prepared by heat treatment after melt spinning by 8 parts of carbon fiber intercalated graphene composite material, 30 parts of PET fiber, 60 parts of PTT fiber, and 0.8 part of catalyst. The preparation process of the wire includes the following steps:

[0018] Step 1, preparation of carbon fibers: place cellulose nanofibers in a tube furnace, then pass through the protective gas argon, raise the temperature to 250°C at a heating rate of 2°C / min and keep it for 2h, and then heat it up at a heating rate of 5°C / min The heating rate is raised to 600°C and kept for 1 hour. After the carbon fiber synthesis reaction is completed, it is naturally cooled to room temperature under vacuum conditions, and finally the product is taken out to obtain carbon fiber;

[0019] Step 2, preparation of carbon fiber intercalated graphene composite material: dispersing cellulose nanofibers in an aqueous solution to prepare a 1wt% dispersion, ...

Embodiment 2

[0024] A preparation process of a helical yarn, prepared by heat treatment after melt spinning by 10 parts of carbon fiber intercalated graphene composite material, 35 parts of PET fiber, 65 parts of PTT fiber, and 1.2 parts of catalyst, the helical yarn The preparation process of the wire includes the following steps:

[0025] Step 1, preparation of carbon fibers: place cellulose nanofibers in a tube furnace, and then pass in protective gas nitrogen, raise the temperature to 265°C at a heating rate of 3°C / min and keep it for 2 hours, and then raise the temperature at a rate of 8°C / min Raise the temperature to 700°C and keep it warm for 1 hour. After the carbon fiber synthesis reaction is completed, it is naturally cooled to room temperature under vacuum conditions, and finally the product is taken out to obtain carbon fiber;

[0026] Step 2, preparation of carbon fiber intercalated graphene composite material: disperse cellulose nanofibers in an aqueous solution to prepare a ...

Embodiment 3

[0031] A preparation process for a helical yarn, which is prepared from 12 parts of carbon fiber intercalated graphene composite materials, 40 parts of PET fibers, 70 parts of PTT fibers, and 2 parts of catalysts through heat treatment after melt spinning, the helical yarn The preparation process of the wire includes the following steps:

[0032] Step 1, preparation of carbon fibers: place cellulose nanofibers in a tube furnace, then pass through the protective gas argon, raise the temperature to 280°C at a heating rate of 5°C / min and keep it for 1h, and then heat it up at a heating rate of 10°C / min The heating rate is raised to 600°C and kept for 1 hour. After the carbon fiber synthesis reaction is completed, it is naturally cooled to room temperature under vacuum conditions, and finally the product is taken out to obtain carbon fiber;

[0033] Step 2, preparation of carbon fiber intercalated graphene composite material: disperse cellulose nanofibers in aqueous solution to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com