Hydraulic vibration method for continuous casting mold

A continuous casting mold and hydraulic vibration technology, which is applied in the field of steelmaking and casting, can solve the problems affecting the quality and production efficiency of continuous casting slabs, increase the longitudinal cracks, corner cracks, and decrease the vibration accuracy of the slabs, so as to achieve the advantages of lubrication, The effect of reducing cracking and reducing the depth of vibration marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

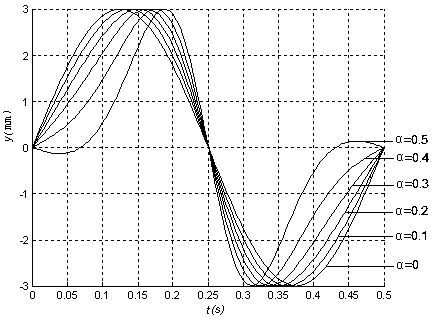

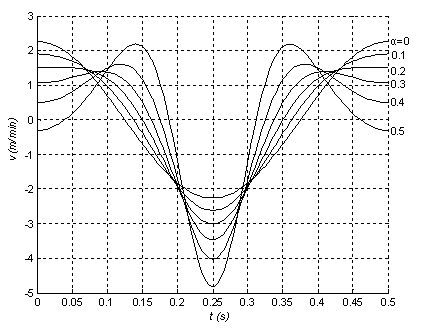

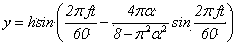

[0024] A continuous casting crystallizer hydraulic vibration method, the continuous casting crystallizer vibrates according to the following curve during casting, and the vibration curve uses displacement and speed The vibration curve equation for expression is:

[0025] (1)

[0026] (2)

[0027] In the formula: ——Displacement mm

[0028] ——Vibration speed m / min

[0029] ——Amplitude mm

[0030] ——Slope rate, which is an empirical parameter obtained from experiments

[0031] ——vibration frequency

[0032] - time s.

[0033] In the hydraulic vibration method of the continuous casting crystallizer of the present invention, the deflection rate The value of is 0~0.5, and the skew rate is an empirical parameter obtained from experiments.

[0034] In the continuous casting crystallizer hydraulic vibration method of the present invention, the amplitude The value of 1~10mm, the amplitude value and pulling speed ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com