Pen point dotting machine

A technology of inking machine and nib, which is applied in the repairing, printing, writing utensils and other directions of ink pens, can solve the problems of strength effect, uneven depth and shallowness of concave holes, affecting the reliability of the connection between the metal nib and the ink guide core, etc. Achieve the effect of ensuring connection reliability and uniform depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

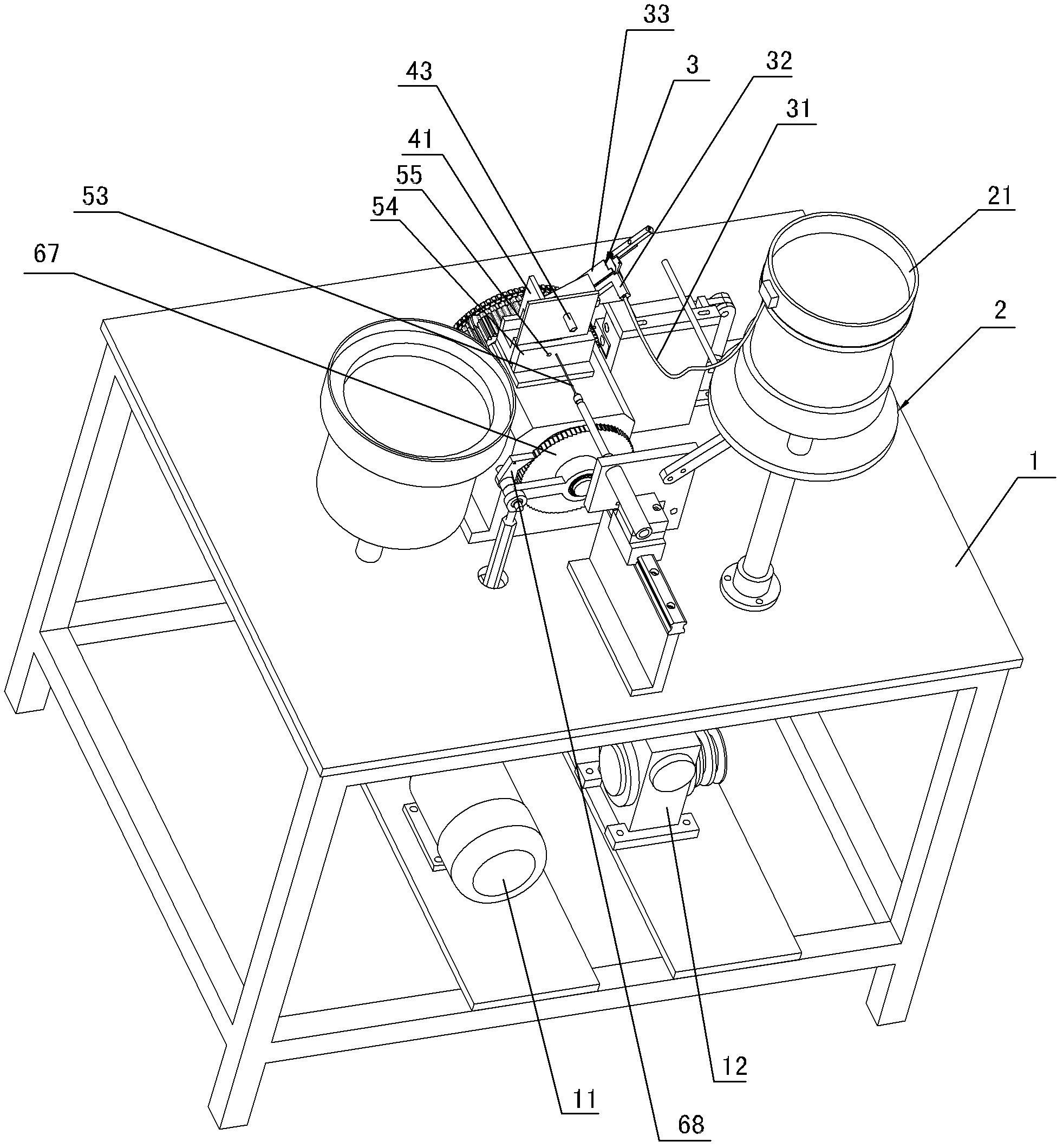

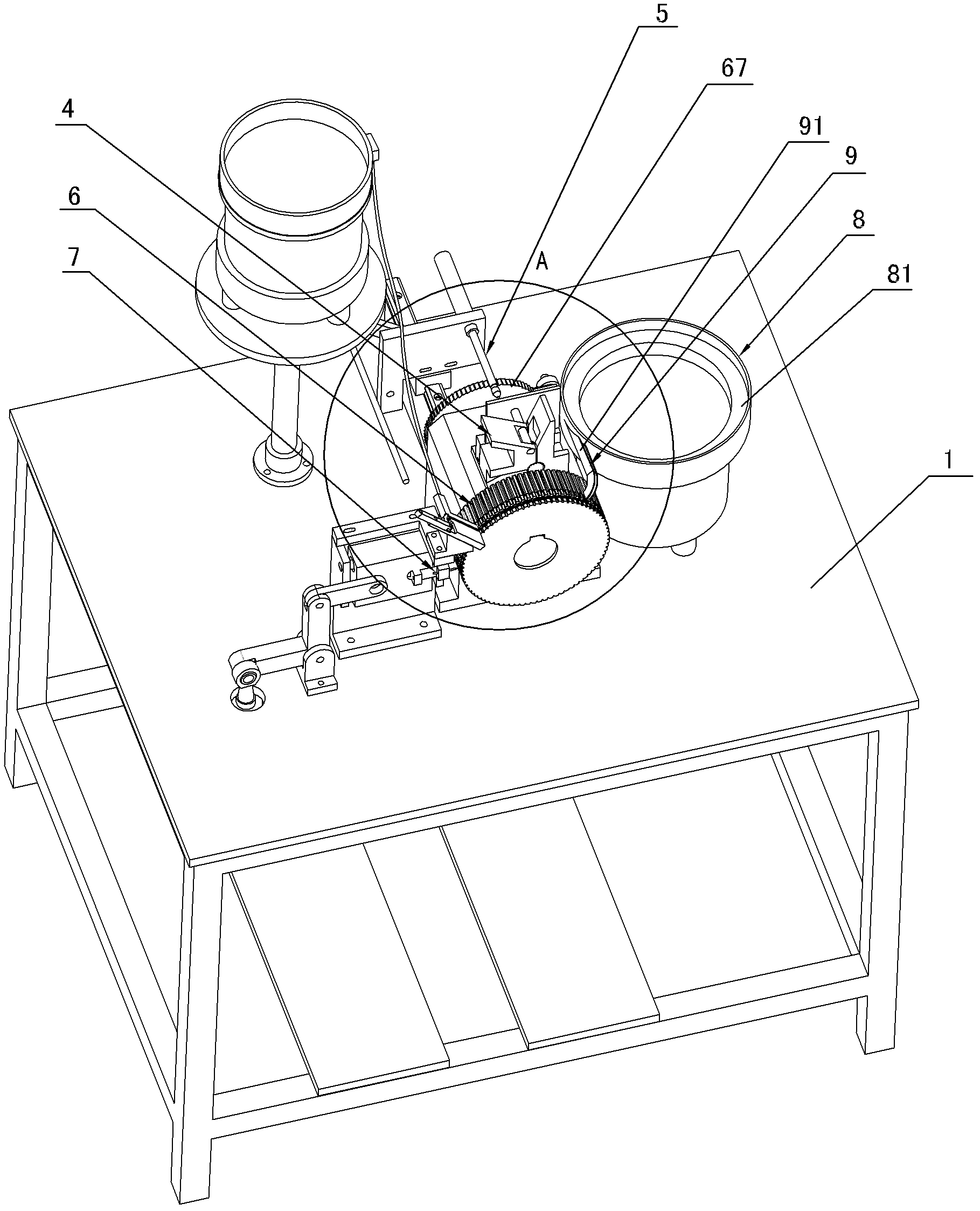

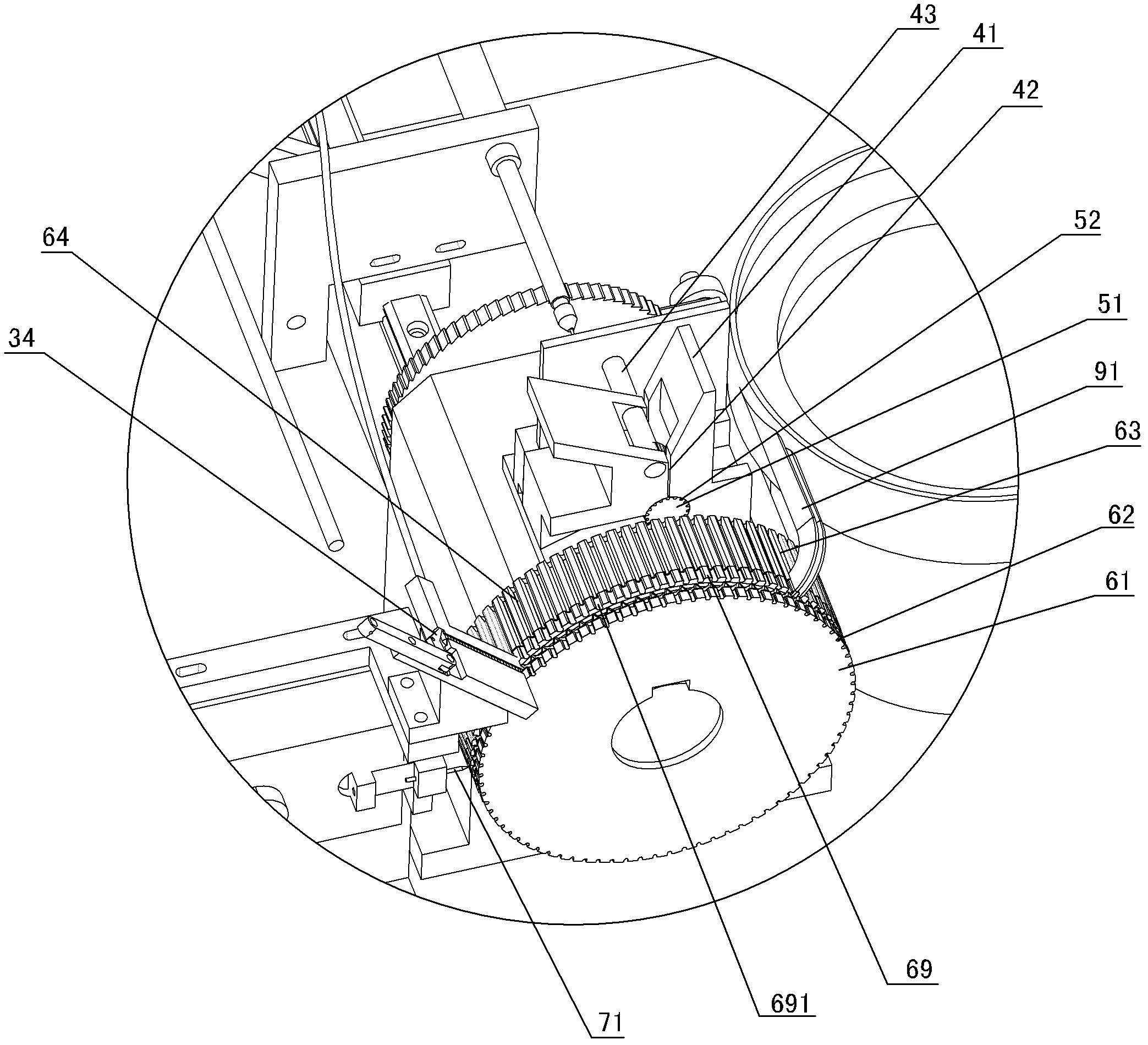

[0019] A nib dotting machine, as shown in the figure, it includes a frame 1, a first motor 11 arranged under the frame 1, a reducer 12 connected to the first motor 11, and a nib feeding mechanism arranged on the frame 1 2. Pen tip transmission mechanism 3, ink core feeding mechanism 4, ink core transmission mechanism 5, assembly mechanism 6, dotting mechanism 7 and synchronous linkage mechanism, reducer 12, pen tip transmission mechanism 3, ink core transmission mechanism 5, The assembly mechanism 6 and the dotting mechanism 7 are all connected with the synchronous linkage mechanism, the nib feeding mechanism 2 continuously puts metal nibs into the nib delivery mechanism 3, and the nib delivery mechanism 3 receives and carries the metal nibs continuously dropped by the nib feeding mechanism and transmits them to the assembly Mechanism 6, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com