Nanometer treatment method for stainless steel

A treatment method, stainless steel technology, applied in the field of stainless steel surface treatment, can solve the problems of high cost of the method, insufficient etching uniformity, etc., achieve the effect of uniform hole depth, mild reaction, and save time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

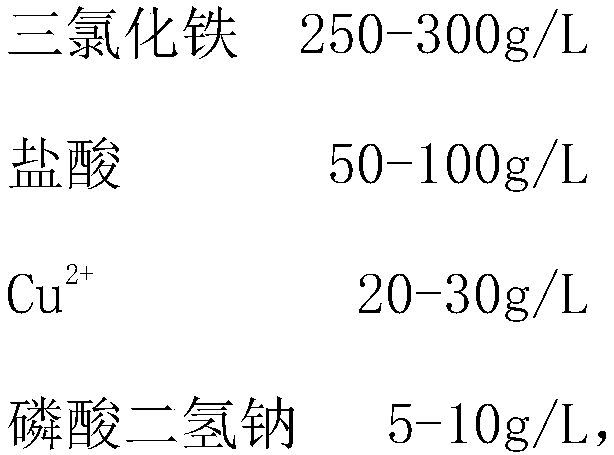

[0023] A stainless steel nano treatment method, the steps include degreasing, hot water cleaning, dry ice cleaning, nano treatment, water washing, dry ice cleaning, alkali etching, double water cleaning, neutralization, water washing, the selected medicament and dosage of the nano treatment step for:

[0024]

[0025]

[0026] The temperature of nano treatment is 20°C, and the time is 60s.

Embodiment 2

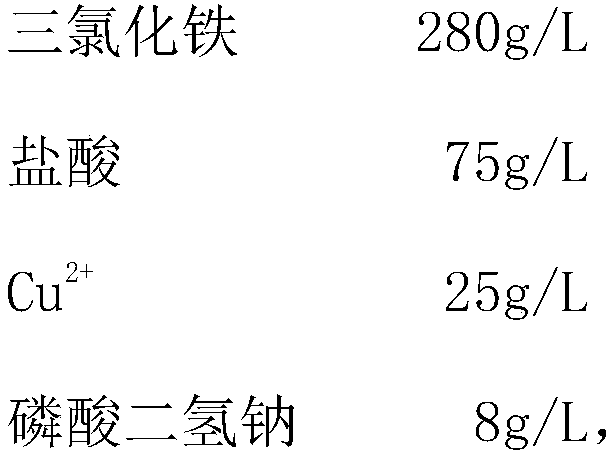

[0028] A stainless steel nano treatment method, the steps include degreasing, hot water cleaning, dry ice cleaning, nano treatment, water washing, dry ice cleaning, alkali etching, double water cleaning, neutralization, water washing, the selected medicament and dosage of the nano treatment step for:

[0029]

[0030] The temperature of the nano treatment is 40°C and the time is 120s.

Embodiment 3

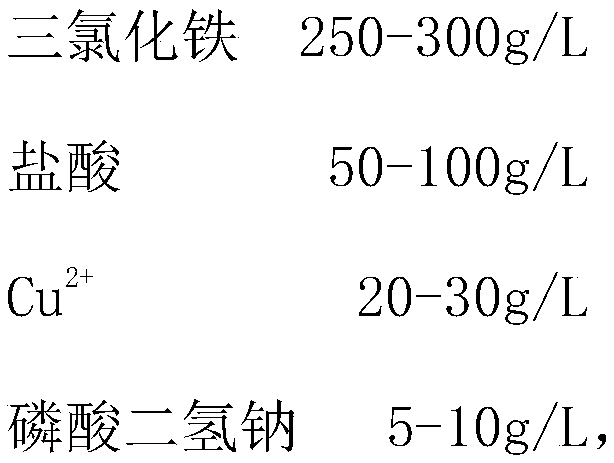

[0032] A stainless steel nano treatment method, the steps include degreasing, hot water cleaning, dry ice cleaning, nano treatment, water washing, dry ice cleaning, alkali etching, double water cleaning, neutralization, water washing, the selected medicament and dosage of the nano treatment step for:

[0033]

[0034] The temperature of the nano treatment is 60°C and the time is 240s.

[0035] Cu in the above-mentioned each embodiment 2+ It is a mixed reagent of copper sulfate and copper sulfate.

[0036] The degreasing step in each of the above embodiments is specifically to treat the surface of stainless steel at 35° C. for 10 min with a degreasing and degreasing solution with a mass concentration of 5%.

[0037] The formula of the degreasing and degreasing solution in the above-mentioned embodiments comprises 12% of sodium carbonate, 6% of sodium hydroxide, 3% of sodium silicate, 3% of potassium pyrophosphate, 2% of sodium chloride, benzotriazole 0.2%, nonylphenol eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com