Dispersing/reducing printing process for polyester/cotton blended fabric

A printing process and cotton blending technology, which is applied in the field of dispersion/reduction printing process of polyester/cotton blended fabrics, can solve the problems of poor air permeability of paint printing, poor fastness to friction and washing, and not widely used, so as to achieve good printing effect and improve gloss Degree, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

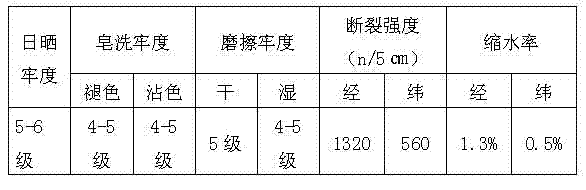

Examples

Embodiment 1

[0052] The dispersion / reduction printing process of polyester / cotton blended fabrics of the present invention comprises the following steps: sample from customer → color separation → drawing → net making → gray fabric inspection → sewing → singeing → deboiling and bleaching → mercerizing → presetting → printing → The first drying→baking→rolling reducing solution→rapid reduction and steaming→the first washing→oxidation→ventilation→oxidation→the second washing→soaping→the third washing→the second drying→setting→ Inspection → finished product inspection.

[0053] Among them, the singeing process adopts two fronts and two reverses, and the vehicle speed is 100m / min.

[0054] In the printing process, rotary screen printing is adopted, the mesh is 80 mesh, and the speed is 30m / min. The color paste used in the printing process is prepared from the following raw materials by weight percentage: printing paste 50%, vat dye 5%, disperse dye 5%, sodium alginate 2%, and the ba...

Embodiment 2

[0061] The dispersion / reduction printing process of polyester / cotton blended fabrics of the present invention comprises the following steps: sample from customer → color separation → drawing → net making → gray fabric inspection → sewing → singeing → deboiling and bleaching → mercerizing → presetting → printing → The first drying→baking→rolling reducing solution→rapid reduction and steaming→the first washing→oxidation→ventilation→oxidation→the second washing→soaping→the third washing→the second drying→setting→ Inspection → finished product inspection.

[0062] Among them, the singeing process adopts two fronts and two reverses, and the vehicle speed is 110m / min.

[0063] In the printing process, rotary screen printing is adopted, the mesh is 100 mesh, and the speed is 40m / min. The color paste used in the printing process is prepared from the following raw materials in weight percentage: printing paste 60%, vat dye 20%, disperse dye 10%, sodium alginate 2%, and the...

Embodiment 3

[0070] The dispersion / reduction printing process of polyester / cotton blended fabrics of the present invention comprises the following steps: sample from customer → color separation → drawing → net making → gray fabric inspection → sewing → singeing → deboiling and bleaching → mercerizing → presetting → printing → The first drying→baking→rolling reducing solution→rapid reduction and steaming→the first washing→oxidation→ventilation→oxidation→the second washing→soaping→the third washing→the second drying→setting→ Inspection → finished product inspection.

[0071] Among them, the singeing process adopts two fronts and two reverses, and the speed is 105m / min.

[0072] In the printing process, rotary screen printing is adopted, the mesh is 90 mesh, and the speed is 35m / min. The color paste used in the printing process is prepared from the following raw materials in weight percentage: printing paste 55%, vat dye 10%, disperse dye 8%, sodium alginate 2%, and the balance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com