Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Solving the Recycling Dilemma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating and regenerating reuse building waste

ActiveCN101099974AAvoid excessive cement slurry contentAvoid Excessive Water DemandSolid waste managementSolid waste disposalPrillBrick

The present invention discloses building waste treating and reusing process, which includes the following steps: classifying building wastes into waste concrete, waste stone material, waste ceramic, waste sintered brick and waste lime-sand brick; crushing separately into coarse grains and eliminating metal, timber and other impurity; milling into 5 mm below regenerated fine aggregate; sorting 0.15 mm below high quality fine aggregate and milling into regenerated fine powder material of 250-600 sq m / kg specific surface area; and preparing mortar, concrete, asphalt concrete and other building material with the regenerated fine aggregate and the regenerated fine powder.

Owner:SOUTH CHINA UNIV OF TECH

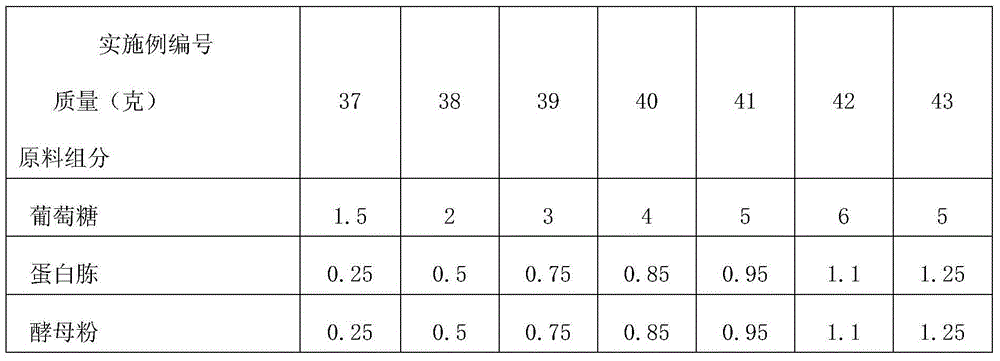

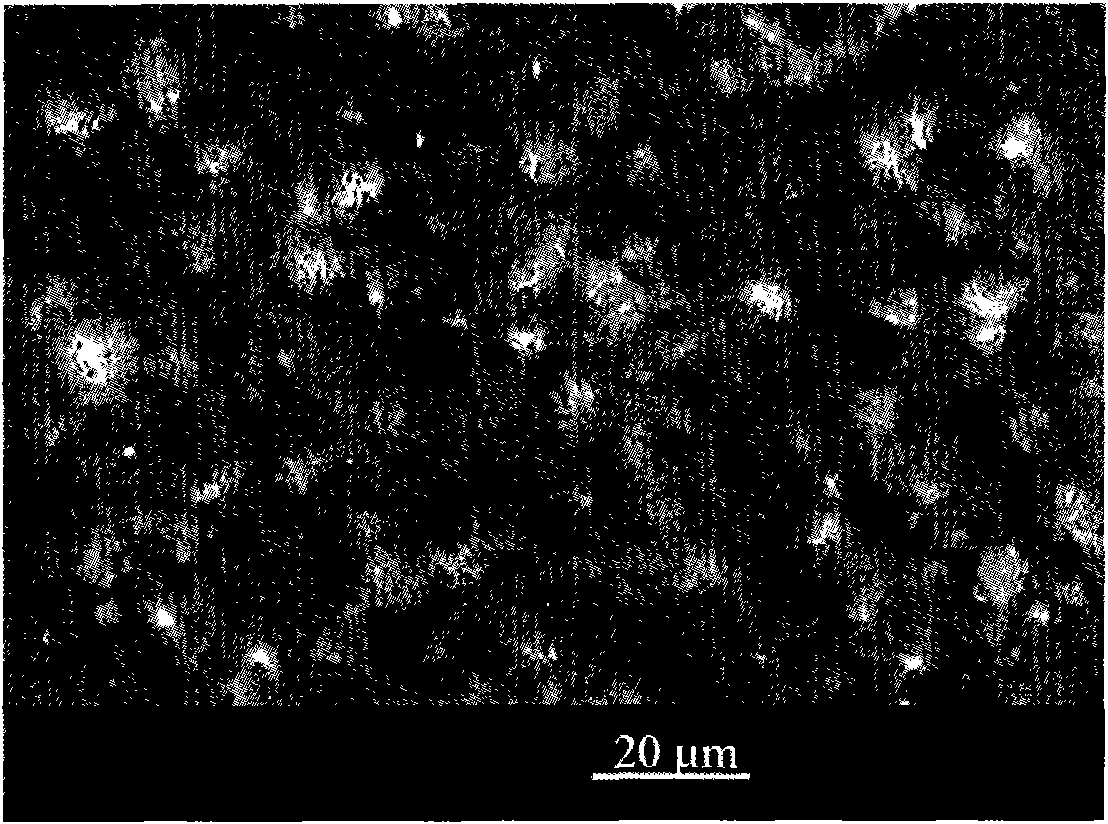

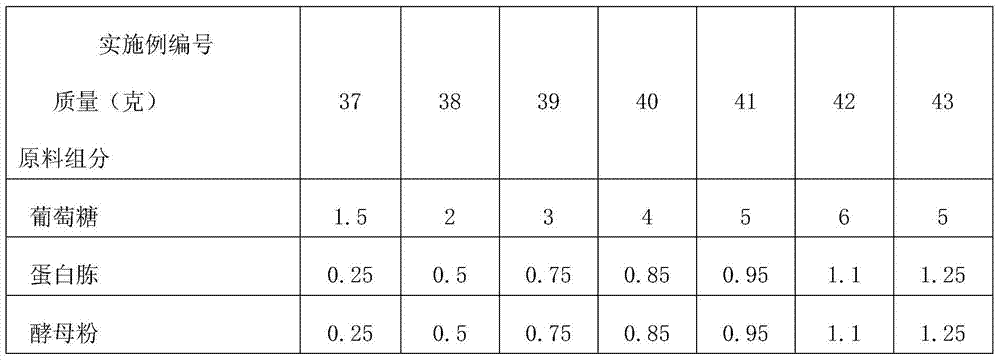

Preparation method of hypha/nanoparticle composite sphere material

InactiveCN104785216AHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationFreeze-drying

The invention discloses a preparation method of a hypha / nanoparticle composite sphere material. The preparation method is characterized by comprising steps as follows: preparing a culture medium; adding 4-20 ml of a nanoparticle aqueous solution containing 1-10 mg of nanoparticles per milliliter to the sterilized liquid culture medium, evenly mixing the mixture, inoculating the mixture with strains, culturing the mixture for 48-96 h under conditions that the temperature is 15-35 DEG C and rotating oscillation is performed at the speed of 80-200 r / min to form a hypha / nanoparticle composite sphere material, performing filtration to remove a liquid, soaking solids, namely, hypha / nanoparticle composite spheres, with a sodium hydroxide aqueous solution for 12 h, washing the spheres with deionized water until the spheres are neutral, and then performing freeze-drying to prepare the hypha / nanoparticle composite sphere material. The composite sphere material prepared with the method is applicable to fields of industrial catalysis, wastewater treatment, biomedicine and the like and has the characteristics of low cost, high activity, easiness in recovery and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

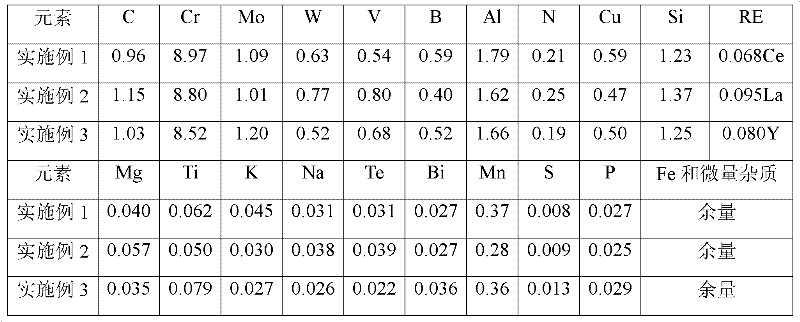

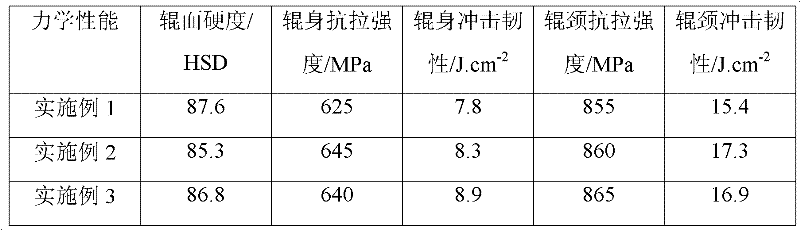

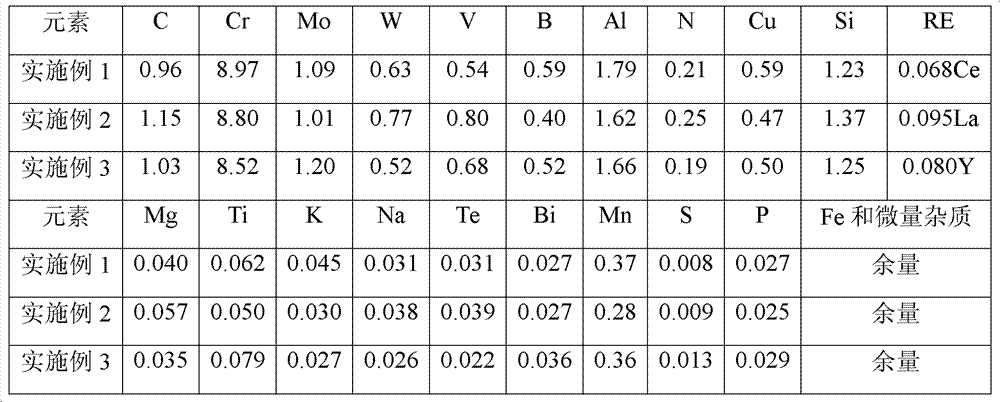

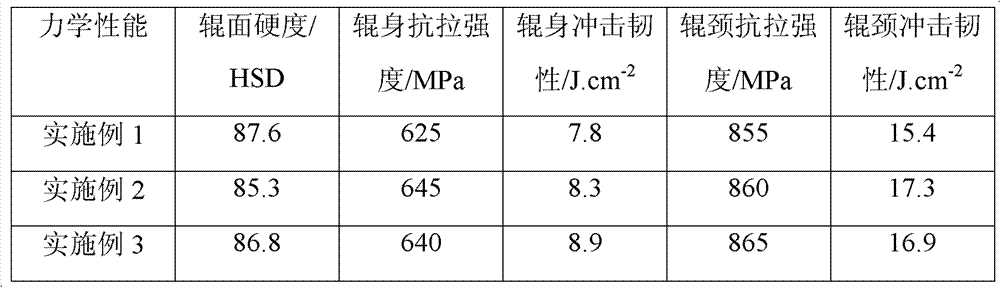

Boron-containing high speed steel roller and preparation method thereof

InactiveCN102409267ASimple production processImprove macro hardnessFurnace typesHeat treatment furnacesBoron containingWear resistance

The invention relates to a boron-containing high speed steel roller and a preparation method thereof, and belongs to the technical field of steel rolling. The steel roller comprises the following chemical components, by mass, 0.95-1.15% of C, 8.5-9.0% of Cr, 1.0-1.2% of Mo, 0.5-0.8% of W, 0.5-0.8% of V, 0.4-0.6% of B, 1.6-1.8% of Al, 0.18-0.25% of N, 0.4-0.6% of Cu, 1.2-1.4% of Si, 0.06-0.10% of RE ,0.03-0.06% of Mg, 0.04-0.08% of Ti, 0.025-0.045% of K, 0.025-0.045% of Na, 0.02-0.04% of Te, 0.02-0.04% of Bi, less than 0.5% of Mn, less than 0.025% of S, less than 0.030% of P, and the balance of Fe and inevitable trace impurities. The boron-containing high speed steel roller of the present invention can be produced by an electric furnace, and has advantages of high roll surface hardness, good wear resistance, high roll neck strength, good toughness and the like.

Owner:BEIJING UNIV OF TECH

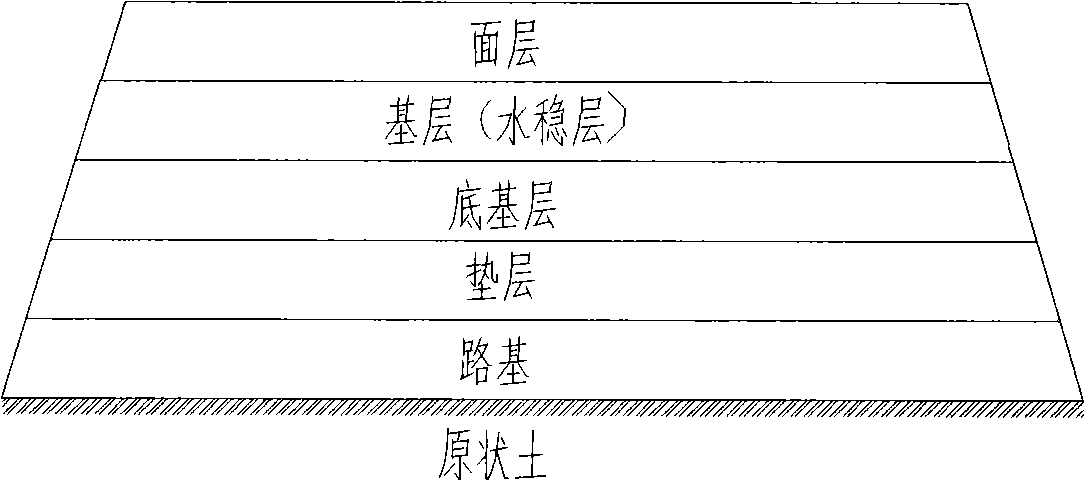

Method for preparing regenerative road material by using waste building material and construction method thereof

InactiveCN101255040ALarge amount of materialEasy to useSolid waste managementImpurityMaterials science

Owner:KUNMING UNIV OF SCI & TECH

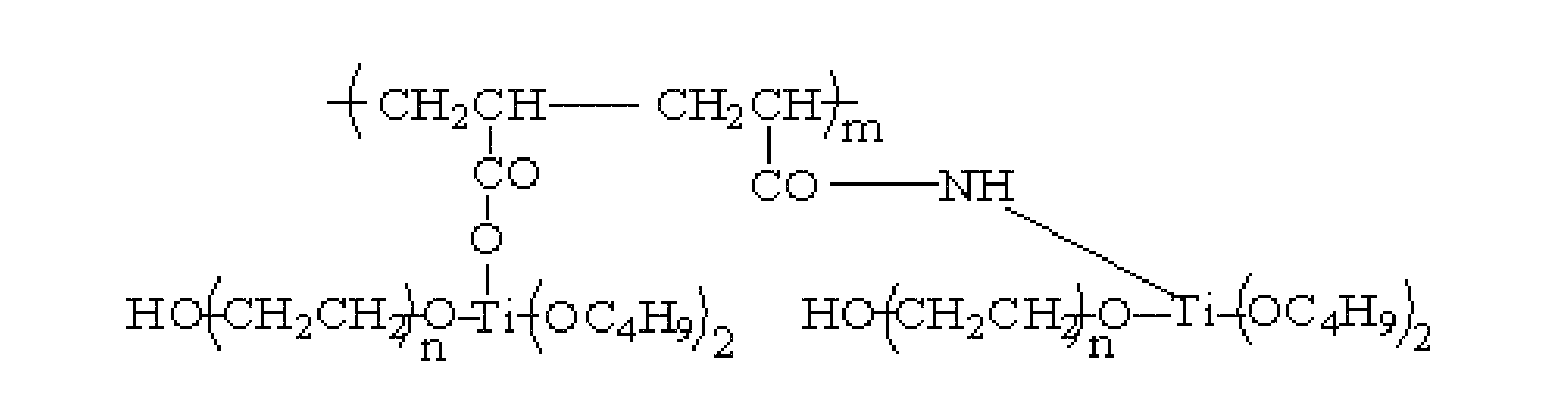

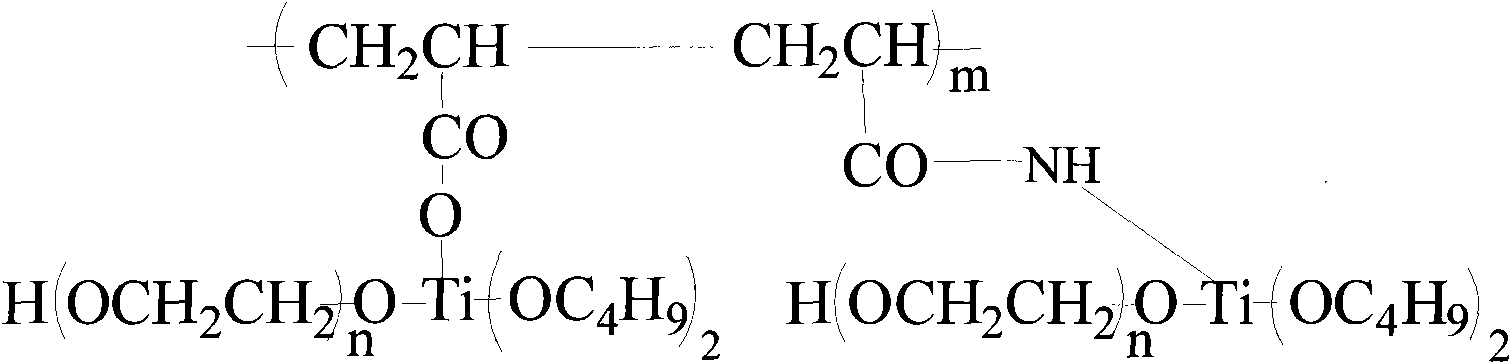

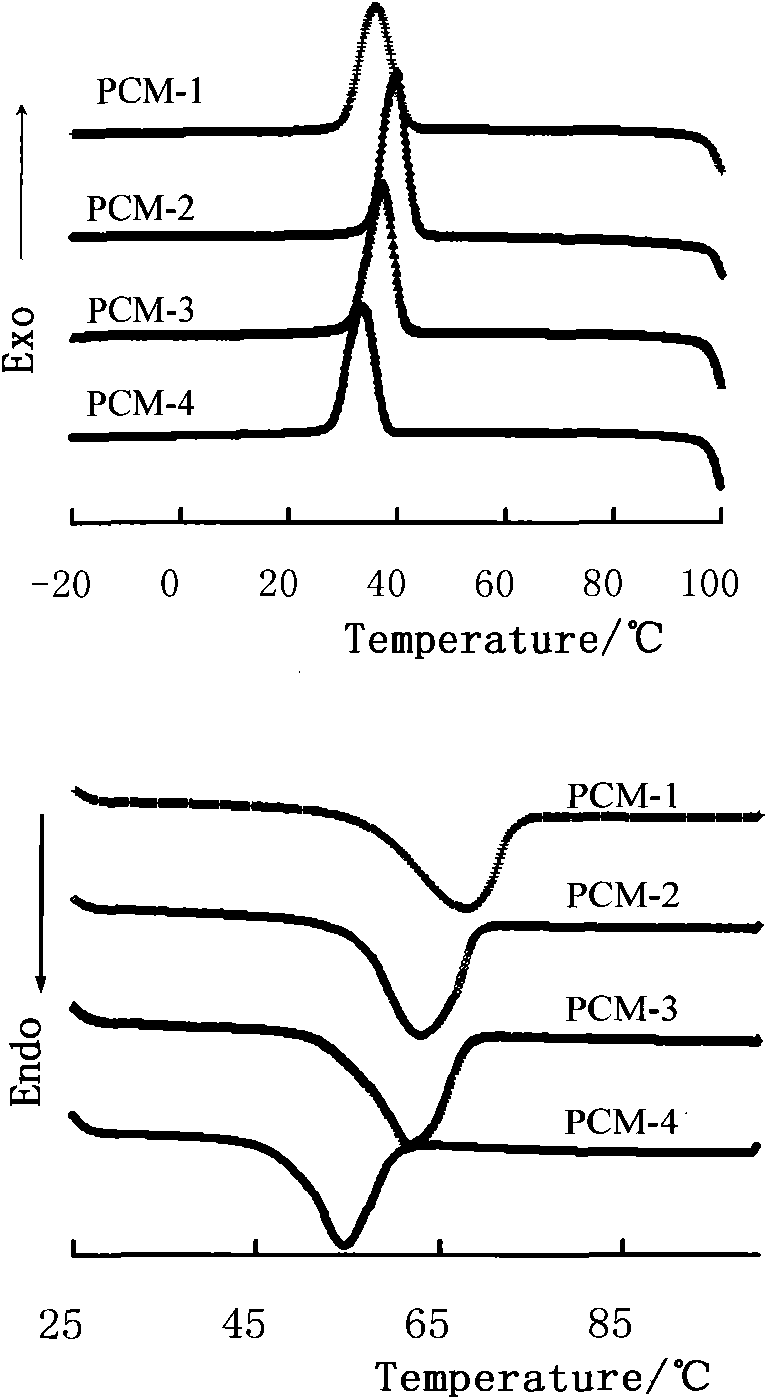

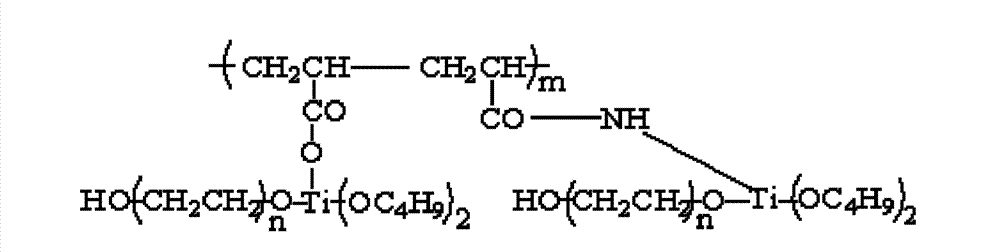

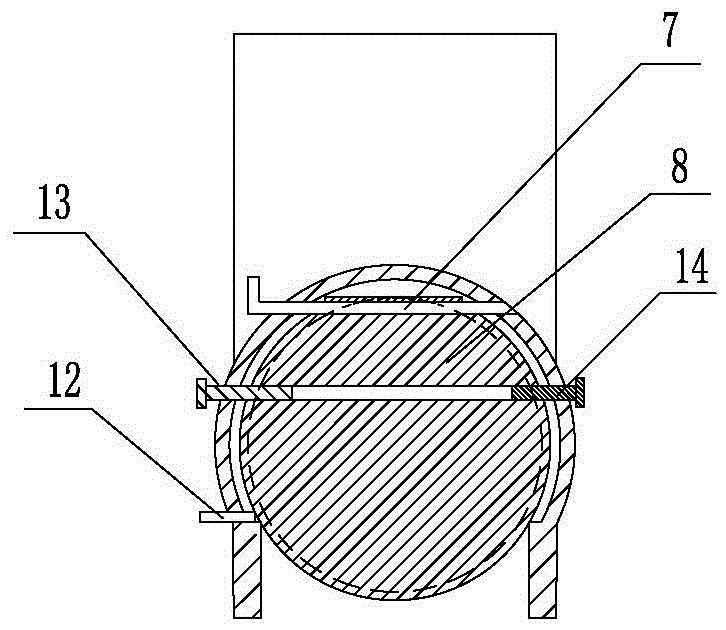

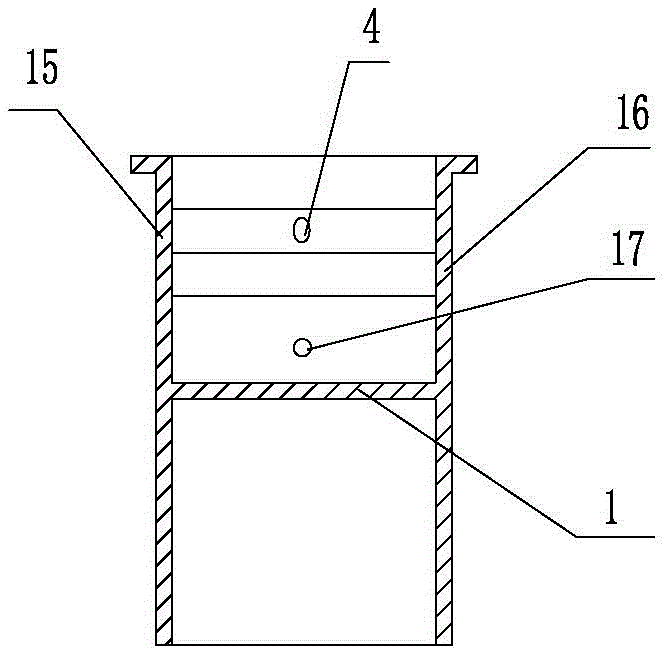

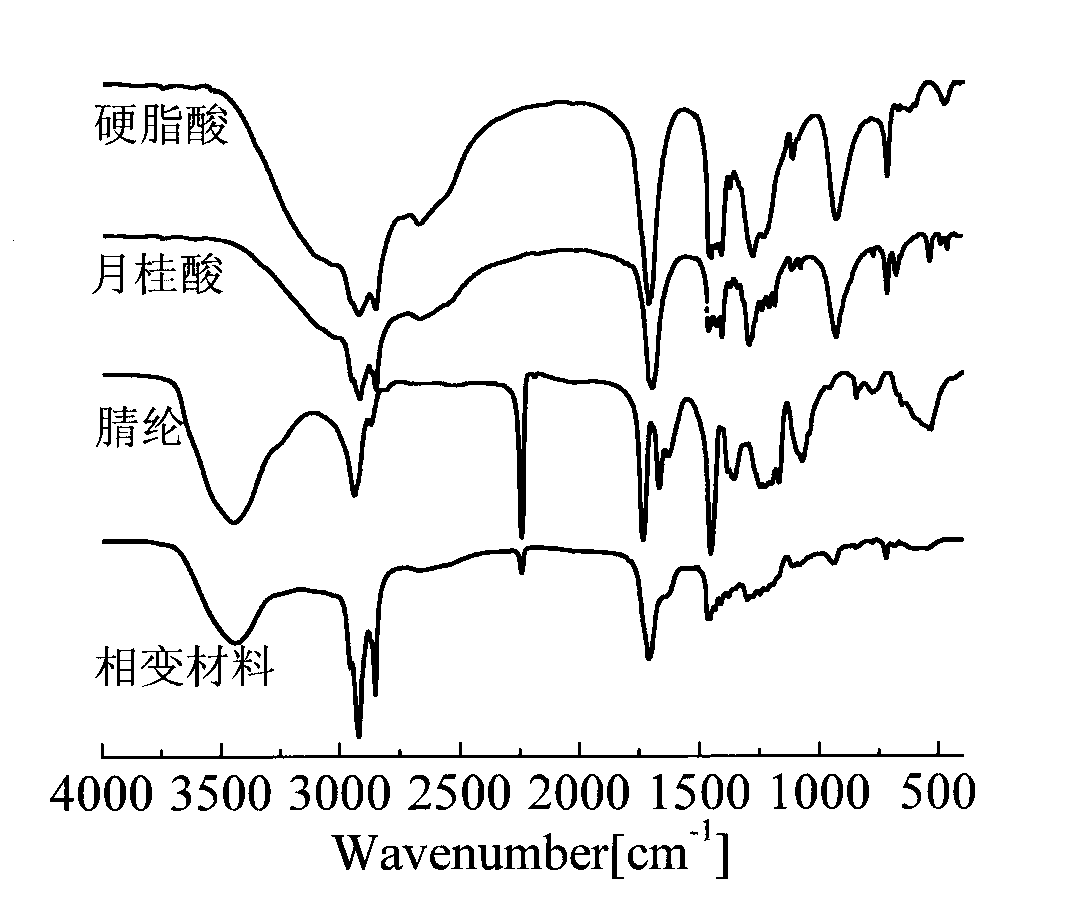

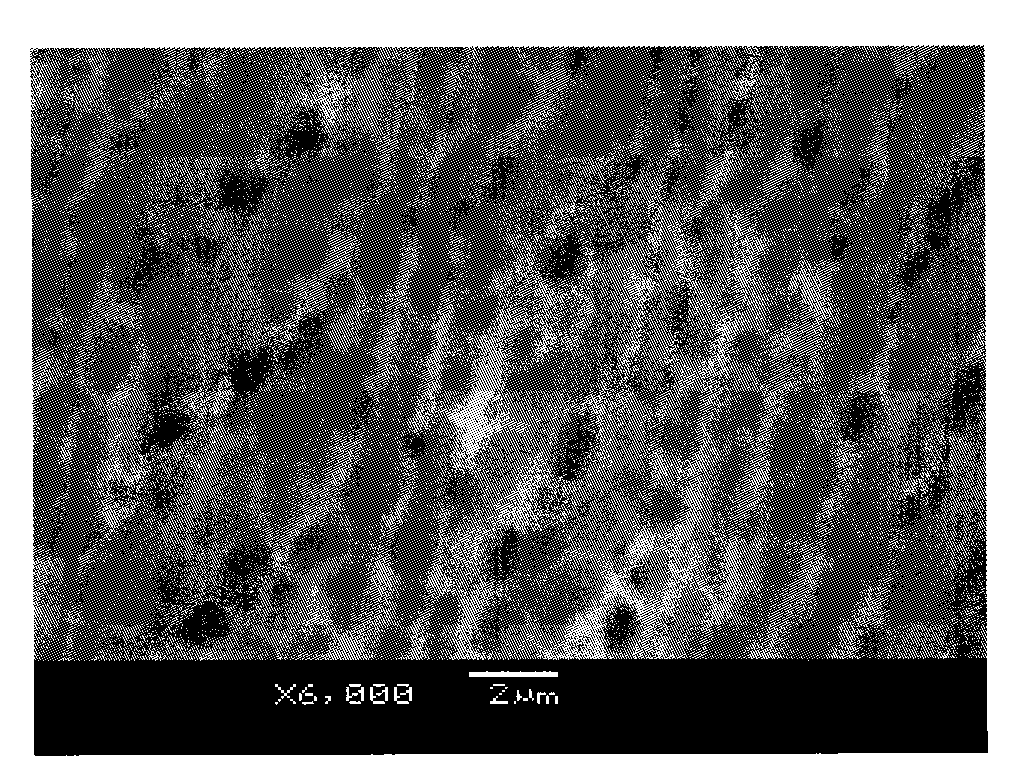

Method for preparing high phase transition enthalpy phase transition temperature-adjusting fiber from hydrolysis products of waste acrylic yarn

InactiveCN102220660ASolving the Recycling DilemmaReduce pollutionHeat-exchange elementsMonocomponent synthetic polymer artificial filamentYarnPolymer science

The invention relates to a method for preparing high phase transition enthalpy phase transition temperature-adjusting fiber from hydrolysis products of waste acrylic yarn, comprising the following steps of: reacting the hydrolysis products of the waste acrylic yarn, such as hydrolysis polyacrylonitrile and polyethylene glycol, according to proportion to prepare graft copolymer polyethylene glycolgrafted hydrolysis polyacrylonitrile; completely dissolving the polyethylene glycol grafted hydrolysis polyacrylonitrile in water, adding boric acid, stirring and completely dissolving, standing and defoaming to obtain a spinning stock solution; and preparing the spinning stock solution into high phase transition enthalpy phase transition temperature-adjusting fiber through wet spinning. Comparedwith the existing phase transition temperature-adjusting fiber, the phase transition temperature-adjusting fiber prepared by the method has the advantages of high phase transition enthalpy, stable phase transition and excellent durability and the like, and can be widely applied to the fields of textile and apparel, energy-saving building materials and certain special fields such as military industry, aerospace, etc.

Owner:DALIAN POLYTECHNIC UNIVERSITY

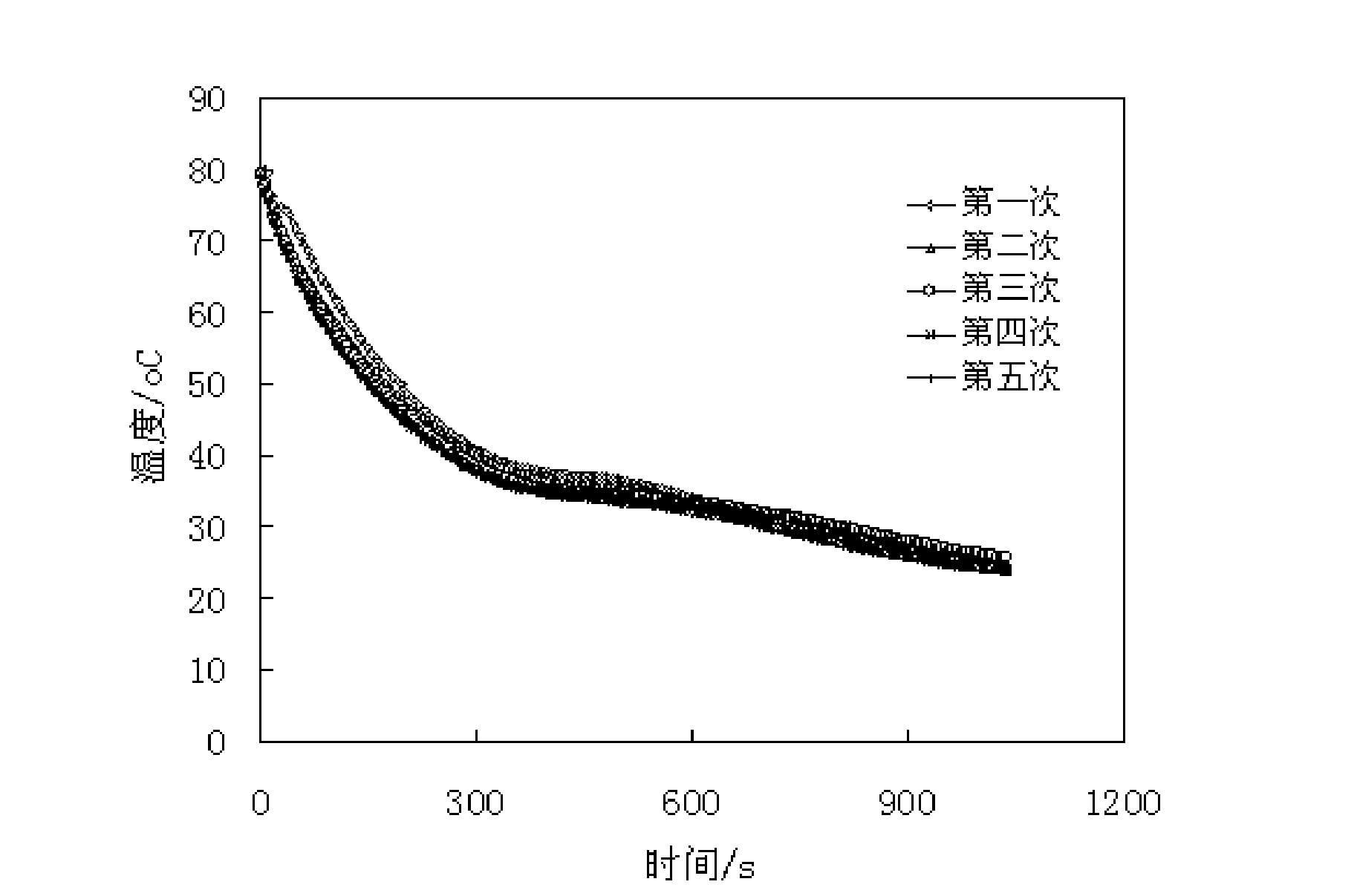

Method for preparing regenerative road material by using waste concrete and construction method thereof

InactiveCN101255044AImprove performanceLarge amount of materialSolid waste managementContinuous/uninterruptedWater reducer

A regeneration road material produced with waste concrete is used as a subbase material of roads and construction service roads and comprises waste concrete particles, cement, admixture, water reducer, expansion agent and water. The preparation method includes: separating; removing impurities, removing waste concrete contaminated by radioactive materials, heavy metals and other harmful impurities; crashing and screening; adding admixtures, water reducer, expansion agents, cement and water for mixing into a cement stable waste cement regeneration road material. The construction method of the regeneration road material produced with waste concrete includes: preparing feed according to the designed particle size and evenly mixing the cement and regeneration materials after adding water and paving in equilibrium continuously and uninterruptedly; rolling by using rollers to roll and shape the paving surface and compacting to the design required compaction degree; sprinkling for curing and sweeping away the soil sundries from the subbase surface and spraying prime coat asphalt with asphalt spray car. The invention makes full use of waste concrete to produce road materials, thereby expanding the sources of construction materials and solving the problem of recycling of waste concrete, so that the environment pollution is reduced and the natural construction resources are fully utilized.

Owner:KUNMING UNIV OF SCI & TECH

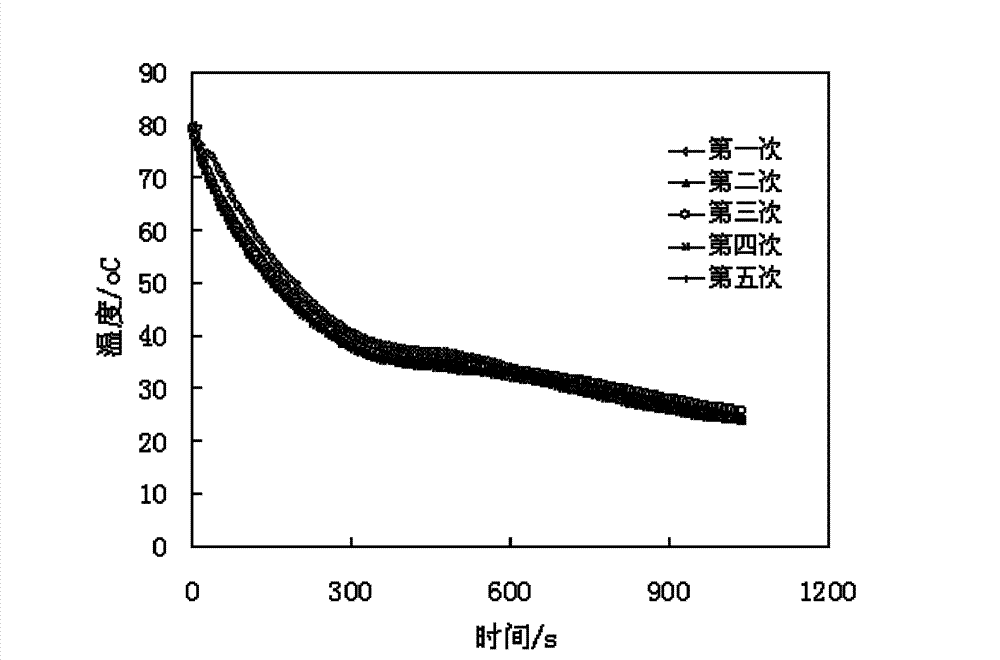

Method for preparing shape-stabilized phase change material by using acrylic fiber waste silks

The invention relates to a method for preparing a shape-stabilized phase change material by using acrylic fiber waste silks. The method comprises the following steps of: hydrolyzing the acrylic fiber waste silks into alkali liquid, obtaining an acrylic fiber hydrolysis product through ethanol precipitation, and then swelling and dissolving the acrylic fiber hydrolysis product; and mixing and reacting the acrylic fiber hydrolysis product and a mixture of polyethylene glycol, chain extender, catalyst and solvent to obtain a graft copolymer of the acrylic fiber hydrolysis product and the polyethylene glycol, wherein the graft copolymer has the solid-solid phase change characteristic. The shape-stabilized phase change material prepared by the method has the advantages of high heat enthalpy value, excellent thermal stability, simple preparation method, low cost, reclamation and recycle of the solvent and the like; and the method is a technique capable of realizing resource reutilization, energy conservation and environmental protection, and has broad market application space.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for treating and regenerating reuse building waste

ActiveCN101099974BImprove water absorptionExpand sourceSolid waste managementSolid waste disposalBrickImpurity

The present invention discloses building waste treating and reusing process, which includes the following steps: classifying building wastes into waste concrete, waste stone material, waste ceramic, waste sintered brick and waste lime-sand brick; crushing separately into coarse grains and eliminating metal, timber and other impurity; milling into 5 mm below regenerated fine aggregate; sorting 0.15 mm below high quality fine aggregate and milling into regenerated fine powder material of 250-600 sq m / kg specific surface area; and preparing mortar, concrete, asphalt concrete and other building material with the regenerated fine aggregate and the regenerated fine powder.

Owner:SOUTH CHINA UNIV OF TECH

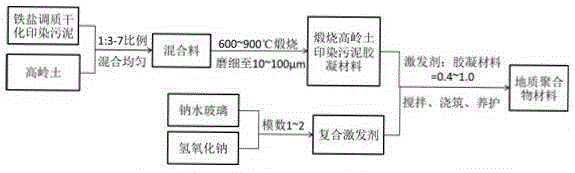

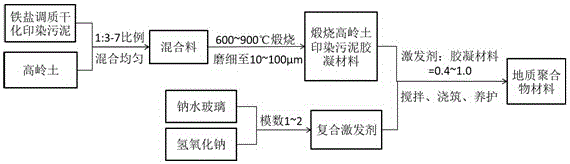

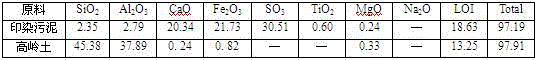

Kaolin dyeing sludge geopolymer material and preparation method therefor

The invention relates to a kaolin dyeing sludge geopolymer material which comprises a cementing material and a compound activator in a mass ratio of 1:(0.4-1.0); the cementing material is a blended calcined product of kaolin and dried dyeing sludge, wherein the mass ratio of the dried dyeing sludge and kaolin is 1:(3-7); the dried dyeing sludge is the dyeing sludge which is obtained through quenching and high-temperature tempering with lime and ferric salts and drying; the compound activator is prepared from sodium water glass and sodium hydroxide, and the modulus of the compound activator is 1-2. The invention provides an effective path to solve the problems in recycling and utilization of incremental components of the dyeing sludge after chemical quenching and high-temperature tempering and drying, so that the dyeing sludge becomes the geopolymer material rather than a simple filling material, and heavy metal pollutants are sealed.

Owner:JIANGSU GUOHAO REFRACTORY TECH

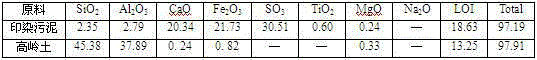

Method for selecting asbestos from asbestos-like minerals by wet process by using ultrasonic waves

The invention discloses a method for selecting asbestos from asbestos-like minerals by a wet process by using ultrasonic waves, which is characterized by comprising the following steps: pulp preparingby stirring, dispersing, desanding, dehydrating, separating and collecting; specifically, adding the asbestos-like minerals and water into a stirred tank, fully dissolving the asbestos-like mineralsby stirring and dispersing the asbestos-like minerals in water to form asbestos pulp, then leading the asbestos pulp into an ultrasonic dispersion slot to be dispersed in an ultrasonic manner, fully dispersing asbestos fibers and simultaneously precipitating sand and stones in the asbestos pulp at the bottom of the ultrasonic dispersion slot naturally. The method causes no damage on the original ecological length of the asbestos, ensures low energy consumption and zero pollution, can be used for extracting the asbestos from asbestos mines, asbestos tailings, asbestos production dregs and marketable chrysotile. By the method, the extraction efficiency of the asbestos is high, the extraction ratio of the asbestos is close to 100%, the production efficiency is high and the production cost islow. The method uses no chemical assistants, thus avoiding water from being polluted by the chemical substances adopting the surfactants for mineral separation.

Owner:重庆市万隆石棉密封材料厂

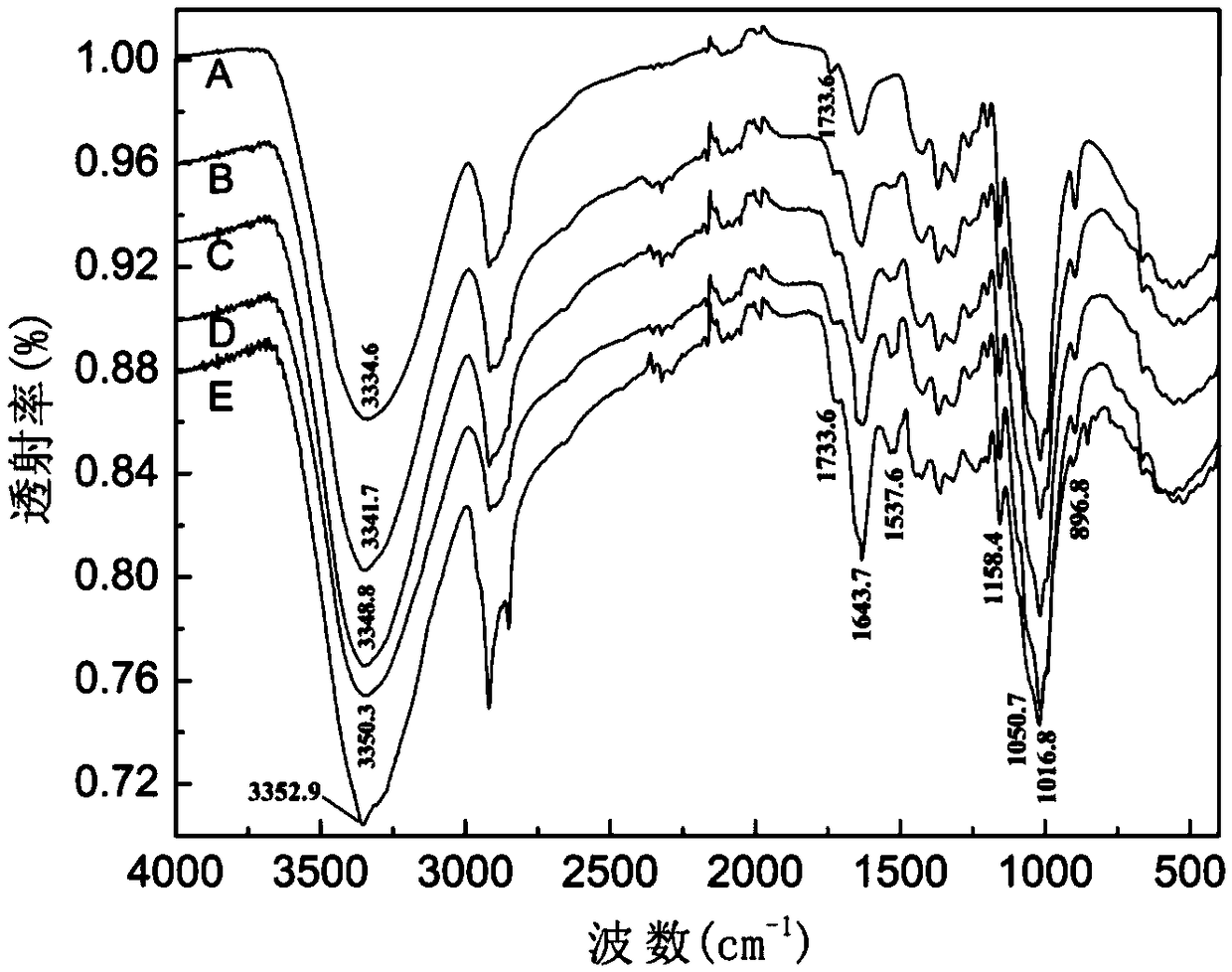

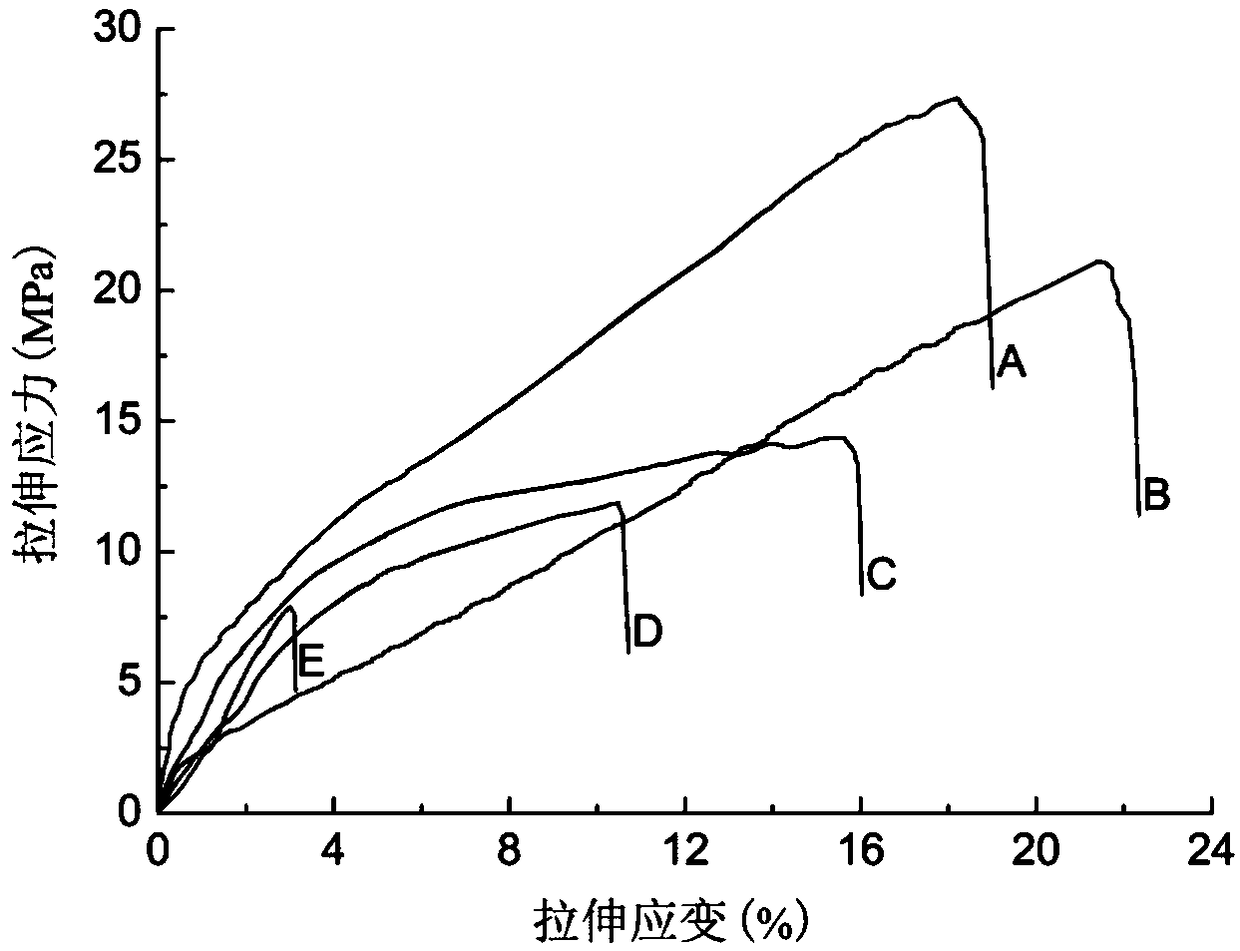

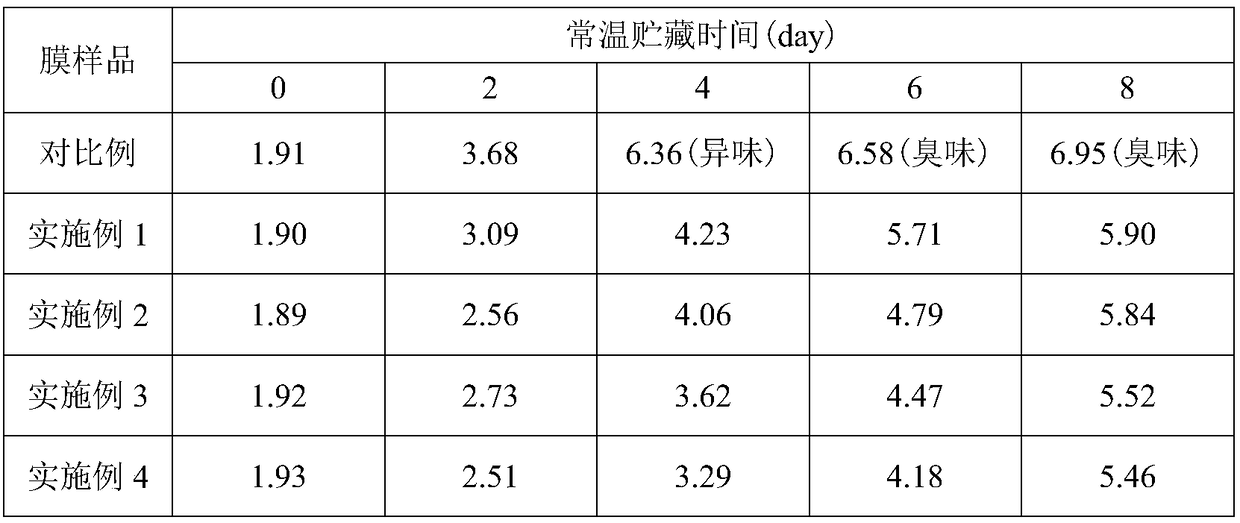

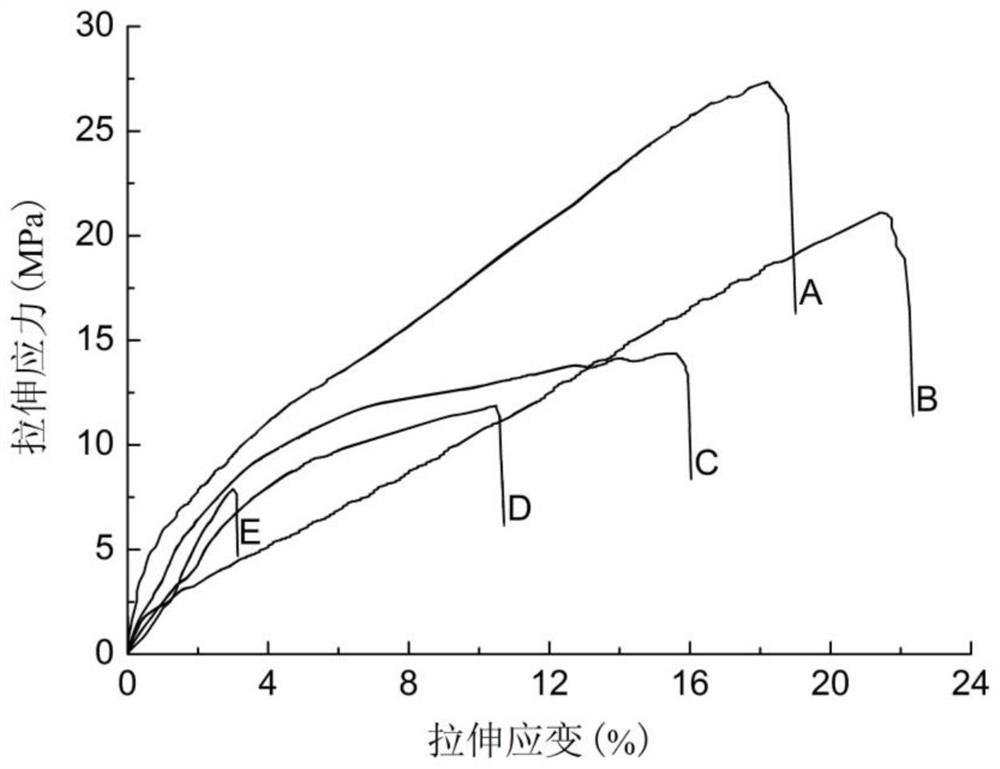

Tea leaf residue modified oxidized cellulose composite film, and preparation method and application thereof

ActiveCN109293959AWide variety of sourcesLow priceMeat/fish preservation using chemicalsChemical reactionComposite film

The invention discloses a tea leaf residue modified oxidized cellulose composite film, and a preparation method and an application thereof. The tea leaf residue modified oxidized cellulose composite film is obtained by an imine chemical reaction of an aldehyde group in a selectively oxidized cellulose molecule and an amino group in tea leaf residue. The tea leaf residue modified oxidized cellulosecomposite film prepared in the invention has good mechanical strength, biodegradability and anti-oxidation performance, is safe and sanitary, can be used for fresh-keeping of fresh pork at room temperature, and can prolong the shelf life of foods.

Owner:ANHUI AGRICULTURAL UNIVERSITY

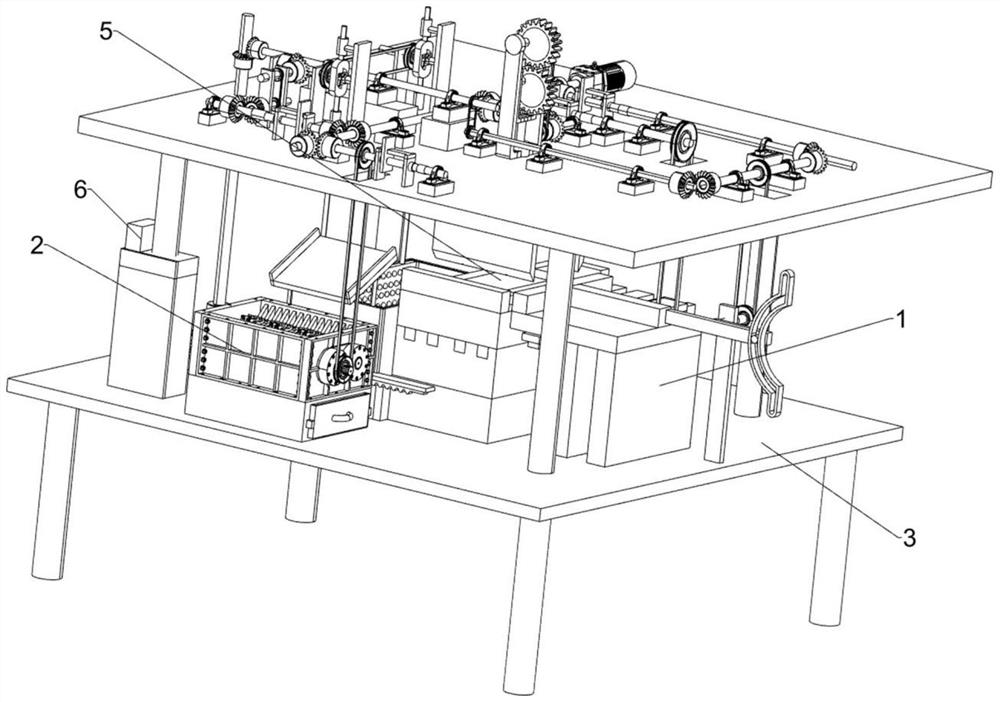

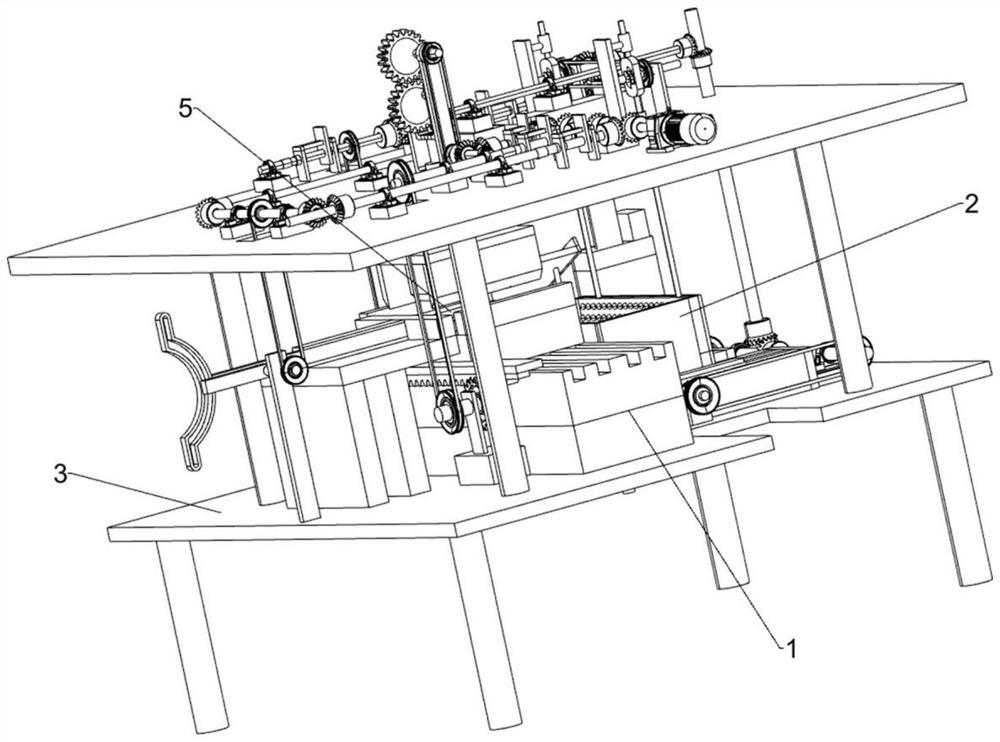

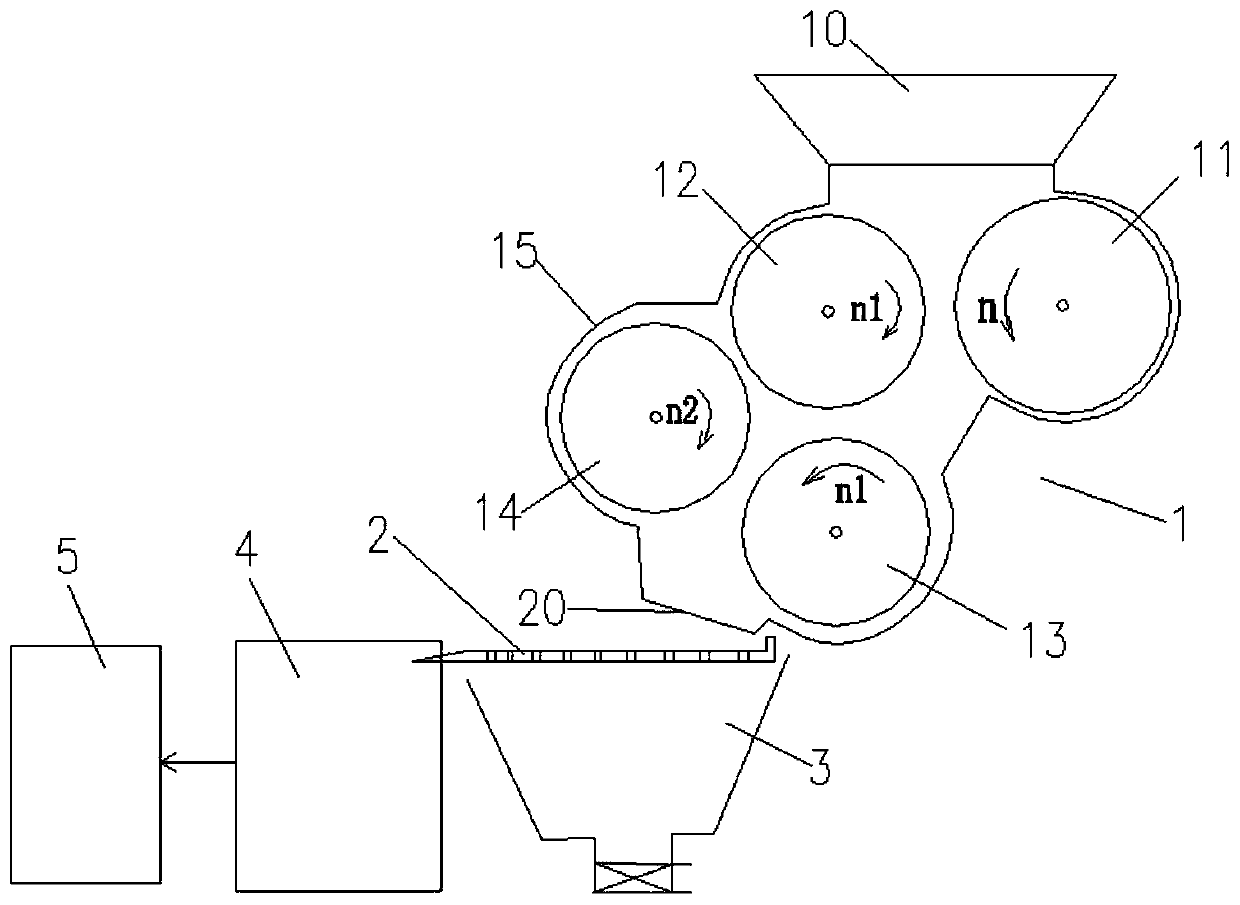

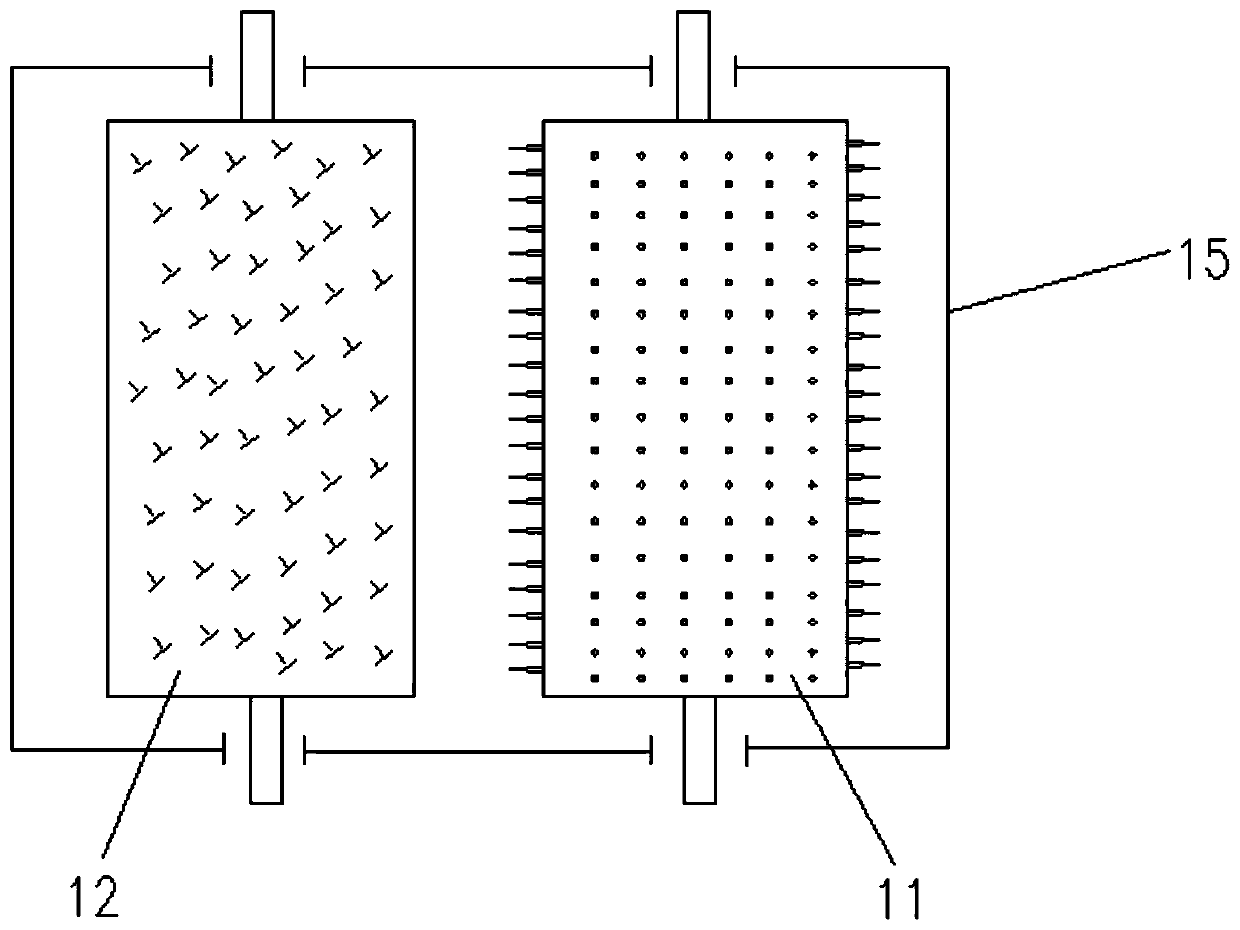

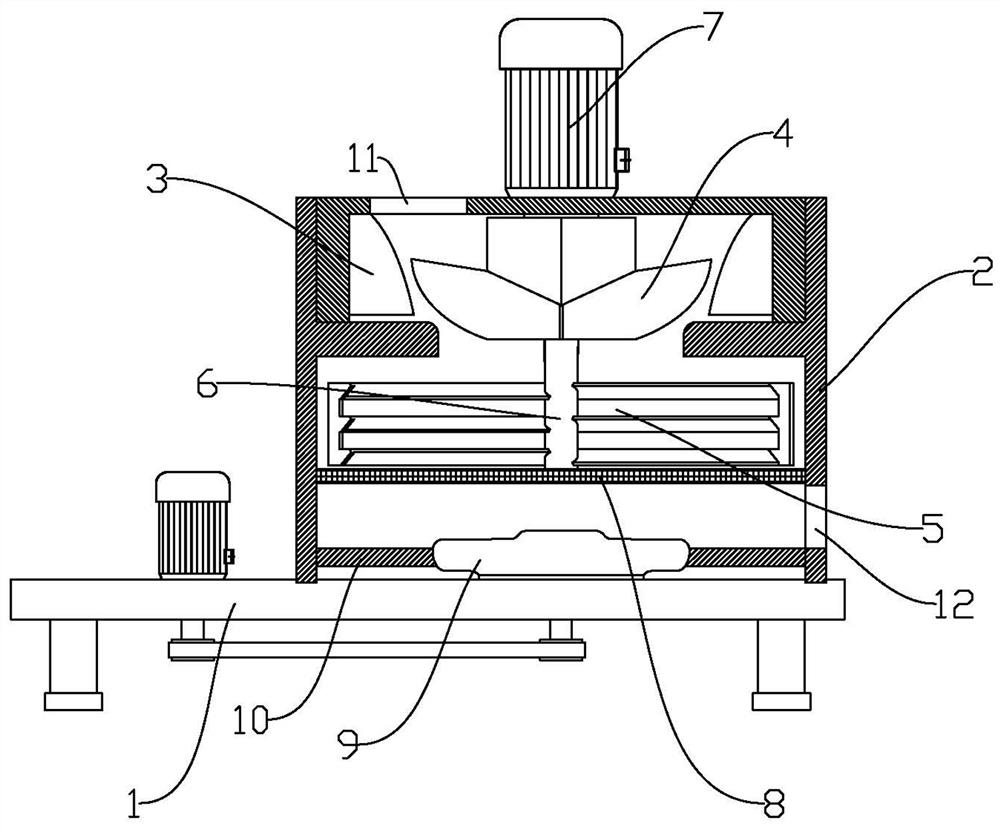

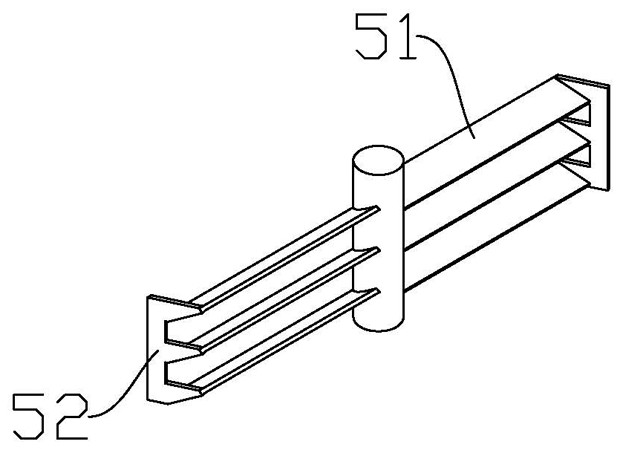

Recycling device of oiliness plastic bag

InactiveCN111844533AAchieve reuseTo achieve the effect of repeated usePlastic recyclingMechanical material recoveryOil separationProcess engineering

The invention relates to the field of environment-friendly recycling, in particular to a recycling device of an oiliness plastic bag. The technical problem to be solved is to provide a recycling device of an oiliness plastic bag. The recycling device of the oiliness plastic bag includes a transporting cutting mechanism, a deoiling separation breaking mechanism, a working table, a device protectiveshell, a plastic bag, and a control display screen. The transporting cutting mechanism and the deoiling separation breaking mechanism are arranged in the working table, the upper part of the workingtable is connected with the device protective shell, the transporting cutting mechanism is connected with the plastic bag, and the working table is connected with the control display screen. Accordingto the device, the problem that the oiliness plastic bag can not separate inner oiliness liquid so that the oiliness plastic bag can not be recycled is solved, and the purpose of protecting an environment can be achieved.

Owner:郭芸

Corrosion-resistant and scratch-resistant additive for crystal waste residue extraction coating materials, and preparation process thereof

The invention provides a corrosion-resistant and scratch-resistant additive for crystal waste residue extraction coating materials, wherein the component of the formula comprises 100% of crystal waste residue. According to the present invention, the additive is extracted from crystal waste residue, the main component is crystal glass powder, the particles are fine, and the hardness of the crystal glass powder is up to 7 Mohs hardness; the additive further contains emery, cerium oxide and other powder, wherein the hardness of the powder is up to 9.5 Mohs hardness and is only inferior to diamond, and the powder is dispersed in the coating material so as to be uniformly distributed, such that the hardness, the impact resistance, the wear resistance, the scratch resistance and the corrosion resistance of the paint film can be improved; the cerium component in the crystal waste residue has the anti-ultraviolet effect and can protect the substance covered under the paint film; the crystal waste residue recovery and utilization problem is solved, and the crystal waste residue becomes the valuable resource again; and the corrosion-resistant and scratch-resistant additive prepared from the crystal waste residue has advantages of low cost and good effect, can replace the same product, and can save a lot of mining resources.

Owner:赵君雄

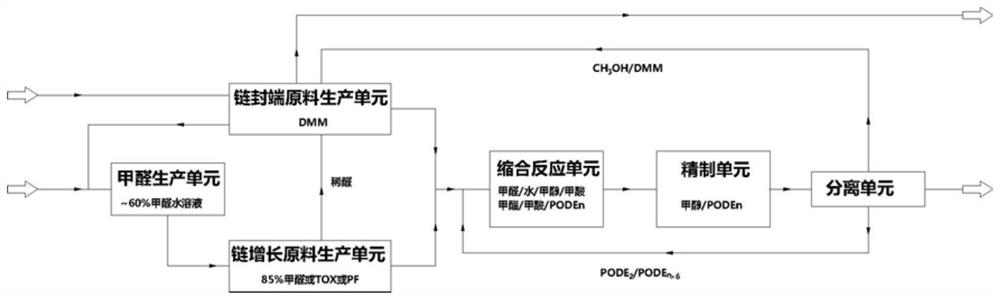

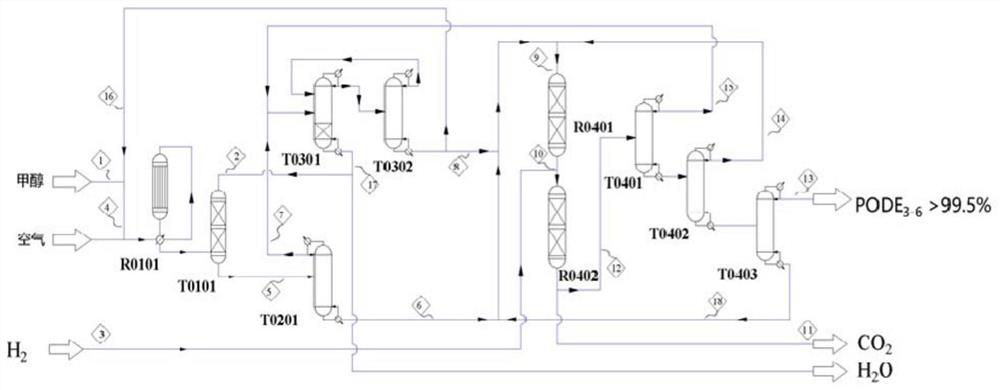

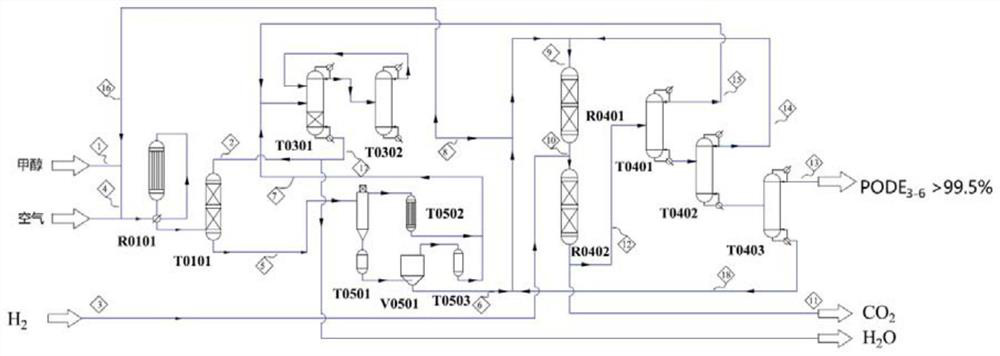

Preparation process for preparing polyoxymethylene dimethyl ether by taking methanol as raw material

PendingCN111978161ASolving the Recycling DilemmaImprove utilization efficiencyOrganic chemistryOrganic compound preparationPolymer scienceCatalytic oxidation

The invention relates to a preparation process for preparing polyoxymethylene dimethyl ether (PODE) by using methanol as a raw material, which comprises the following steps: by using methanol and methylal as raw materials, carrying out catalytic oxidation to prepare concentrated formaldehyde with the concentration of 50% or above; dehydrating the concentrated formaldehyde to prepare a chain extension raw material; preparing a chain-terminated raw material methylal with the water content of less than 0.5% through reactive distillation by taking a chain extension raw material byproduct dilute aldehyde and a light-boiling circulating material flow of a separation unit as raw materials; after the chain extension raw material and the chain-terminated raw material are subjected to a condensationreaction, converting formaldehyde, water, formic acid and methyl formate of a condensation product polyoxymethylene dimethyl ether crude product into methanol through catalytic refining by one-step multi-effect refining; and separating the refined product to obtain PODE<3-6>. By adopting the preparation process, the utilization rate of methanol and dilute aldehyde can be effectively improved, multi-element azeotropic impurities are removed, the product quality is improved, and the stability of a device is improved.

Owner:CHENGDU ZHONGKE CATALYSIS TECH CO LTD +1

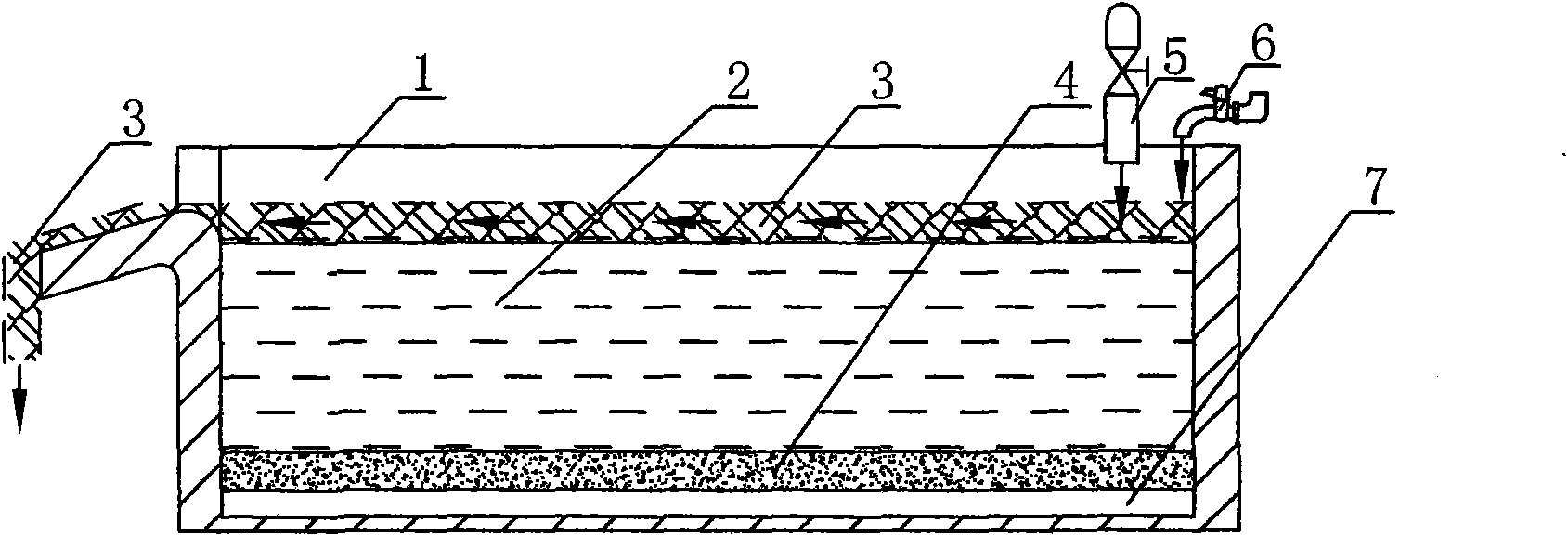

Treatment facility for comprehensively recycling excrements of high-rise building

InactiveCN106343913ASuitable for useGuaranteed Organic IngredientsBathroom accessoriesEngineeringHigh rise

The utility model relates to a treatment facility for comprehensively recycling high-rise feces, which belongs to the field of waterless toilets. It includes a toilet. The inner wall of the toilet is divided into a front wall, a side wall, a rear wall and a bottom wall. The bottom wall is provided with a feces outlet. It is characterized in that: it also includes a feces pipe, and the feces outlet is located behind the rear wall of the toilet; For setting, the bottom wall gradually lowers from the lower end of the front wall of the toilet to the position of the excrement outlet, the excrement outlet is connected to the excrement pipe, and the excrement pool is arranged below the excrement pipe. In the present invention, since the bottom wall is gradually lowered, and the feces outlet is located at the rear of the rear wall, the feces can directly fall into the feces outlet under the action of gravity when going to the toilet to enter the feces pipeline. The feces produced on each floor of the building fall from the feces pipe into the septic tank. This process does not need to be flushed with water. The feces entering the feces pipe does not contain water, which ensures its organic content and can be recycled as farmland fertilizer. This structure is suitable for It is used by building residents.

Owner:淄博正邦知识产权企划有限公司

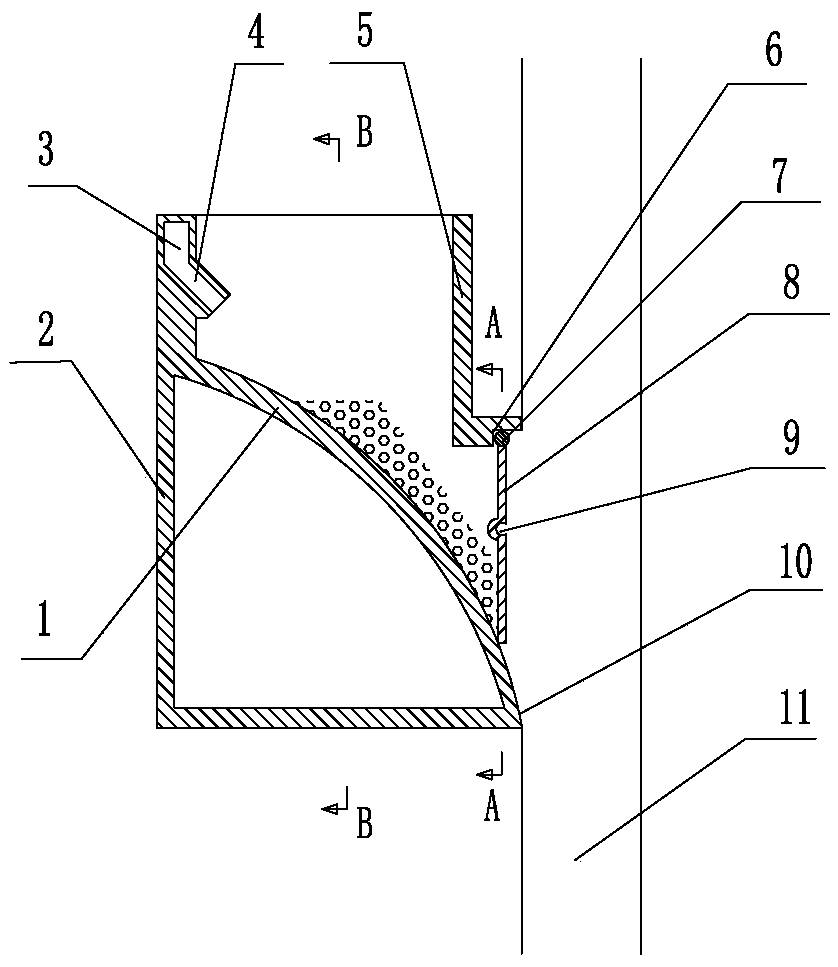

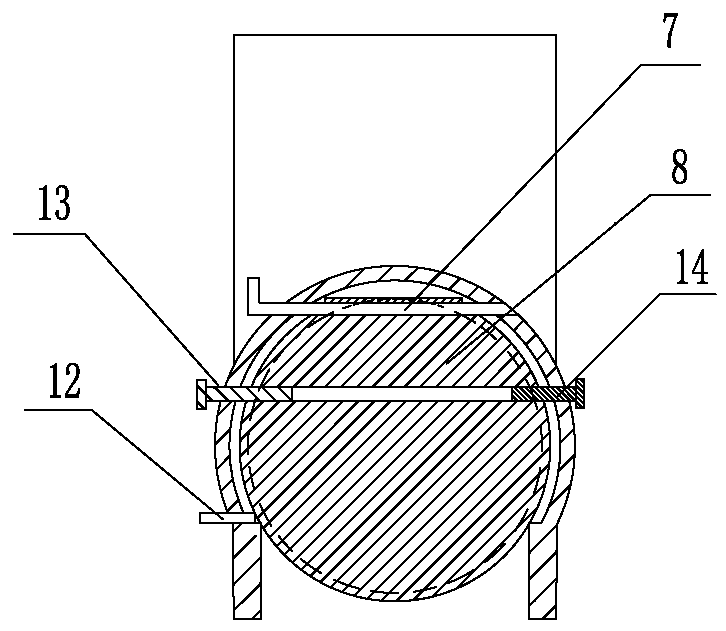

Recycling device and method of waste fiber type heat preservation materials

ActiveCN111389494ASolving the Recycling DilemmaImprove recycling ratesSievingScreeningThermodynamicsProcess engineering

The invention provides a recycling device and method of waste fiber type heat preservation materials. The recycling device comprises a fiber decomposing device, a vibrating screen device and a useable-fiber recycling processing device which are sequentially connected. The fiber decomposing device is used for decomposing / combing the to-be-processed waste fiber type heat preservation materials intomixed fiber, and the mixed fiber comprise aged and brittle fragmented fiber which is crushed in the decomposing / combing process and useable fiber with tenacity. The mixed fiber is output to the vibrating screen device. The vibrating screen device is used for separating the fragmented fiber from the useable fiber with tenacity in the mixed fiber. The useable-fiber recycling processing device is used for recycling the useable fiber. The recycling device and method of the waste fiber type heat preservation materials can efficiently conduct sufficient fibration on the waste heat preservation materials and respectively recycle the aged fragmented fiber and the useable fiber with tenacity, the processing capacity is high, the recycling rate is high, and the difficult problem of recycling of thewaste fiber type heat preservation materials can be effectively solved.

Owner:珠海市中信保温材料厂有限公司

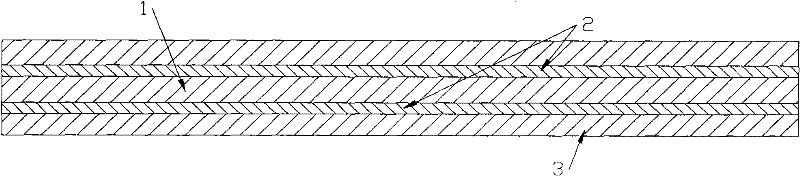

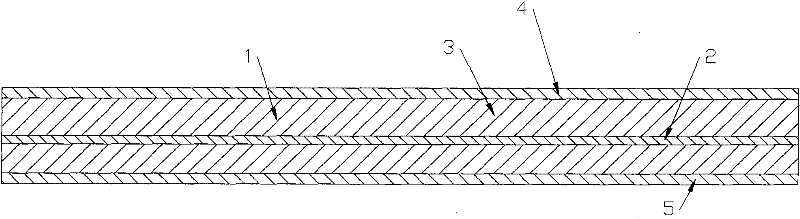

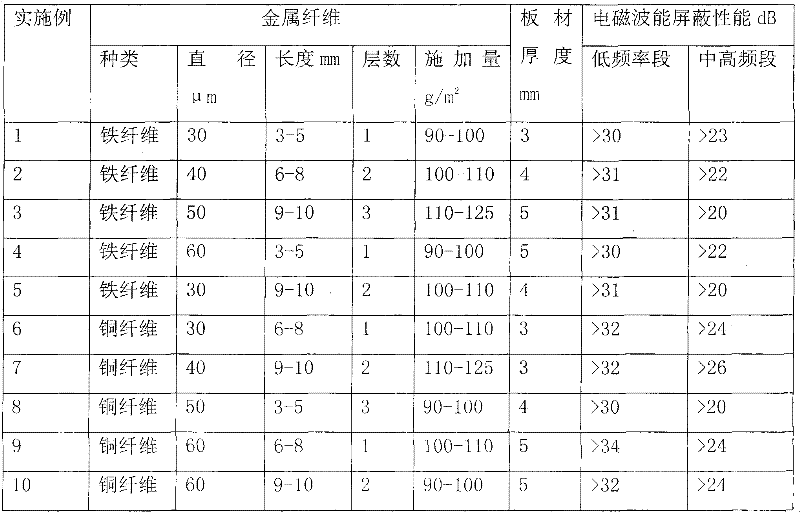

Electromagnetic shielding plate and manufacturing method thereof

ActiveCN102065672BSolving the Recycling DilemmaImprove shielding effectMagnetic/electric field screeningFilling materialsMetal fibers

The invention provides a method for manufacturing an electromagnetic shielding plate by effectively recycling Tetra Pak wastes. The manufacturing method comprises the following steps of: crushing the Tetra Pak wastes to obtain a mixture of paper / plastic / aluminum fibers; with the mixture of paper / plastic / aluminum fibers as a base material and metal fibers with diameter of 30-60 mu m and length of 3-10 mm as a filling material, laying to form a green compact; laying at least one metal fiber layer in the green compact, wherein the addition quantity of the metal fibers in the green compact per square meter is 90-125g; and finally pressing the green compact into a plate. The method is simple and feasible, is convenient to implement and has low cost. The prepared plate has an excellent shielding effect and good physical mechanical properties.

Owner:NANJING FORESTRY UNIV +1

Sand blast material extracted from crystal waste residues and preparation technique thereof

A sandblasting material extracted from crystal waste residue, the formula is: 100% crystal waste residue. It is extracted from crystal waste residue. The main component is crystal glass powder with a hardness of up to 7 Mohs hardness. There are also some powders such as corundum and cerium oxide with a hardness of 9.5 Mohs hardness, which is second only to diamond. It can be used as a sandblasting material. It produces good impact and cutting effect, and is suitable for sandblasting on the surface of glass, plastic, acrylic and metal parts. Moreover, the present invention solves the problem of recycling crystal waste, making crystal waste a valuable resource again. The sandblasting material extracted from crystal waste described in the present invention is cheap and effective, and can replace similar products, saving a lot of mining resources.

Owner:赵君雄

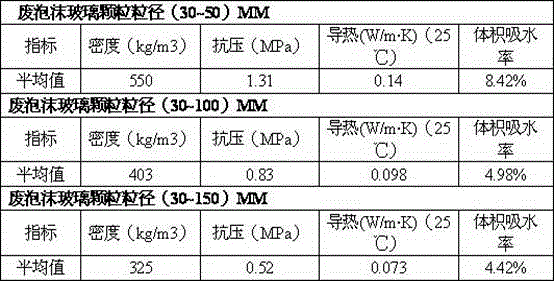

A method of making insulation board by using foam glass waste

ActiveCN104045278BSolving the Recycling DilemmaDecreased thermal insulationSolid waste managementWater-setting substance layered productSocial benefitsCellulose

The invention discloses a method for manufacturing a heat-preservation plate by using a foam glass waste material. The method is characterized by comprising the following steps: uniformly stirring foam glass fragments, foam glass powder, cellulose, rubber powder, cement and lime by using water, pouring to obtain a rectangular body by using a mold, naturally drying, and then slitting into a platy reclaimed material finished product, wherein the weight percentage of the foam glass fragments is 60-65%; the block diameter of each foam glass fragment is 30-150mm; the weight percentage of the foam glass powder is 15-17%; the weight percentage of cellulose is 0.2-0.3%; the weight ratio of the rubber powder is 0.1-0.15%; the weight percentage of the cement is 14-16%; the weight percentage of lime is 4-5%; meanwhile, a reclaimed material and a non-reclaimed material are compounded, so that each performance index can be further improved, and more application requirements can be met. More importantly, the method disclosed by the invention is used for creatively solving the difficulties of recycling foam glass fragment wastes, and has economic and social benefits.

Owner:JIAXING AOTAI NEW BUILDING MATERIALS CO LTD

A kind of preparation method of hyphae/nanoparticle composite ball material

InactiveCN104785216BHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsLiquid mediumNanoparticle Complex

The invention discloses a method for preparing mycelium / nanoparticle composite spherical material, which is characterized in that it comprises: preparing a culture medium; adding 1 to 10 milligrams of nanoparticle to the sterilized liquid culture medium in a concentration of 1 to 10 milligrams per milliliter of solution 4-20 ml of aqueous solution of nanoparticles, mixed evenly, inoculated with strains, and cultured for 48-96 hours at a temperature of 15-35°C and 80-200 rpm rotating and oscillating to form mycelium / nanoparticle composite ball materials , filtered to remove the liquid, and the solid matter, that is, the mycelia / nanoparticle composite ball was soaked in sodium hydroxide aqueous solution for 12 hours, washed with deionized water until neutral, and then freeze-dried to obtain the mycelium / nanoparticle composite ball material . The composite ball material prepared by the invention is suitable for industrial catalysis, waste water treatment, biomedicine and other fields, and has the characteristics of low cost, high activity, easy recycling and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing high phase transition enthalpy phase transition temperature-adjusting fiber from hydrolysis products of waste acrylic yarn

InactiveCN102220660BSolving the Recycling DilemmaReduce pollutionMonocomponent synthetic polymer artificial filamentHeat-exchange elementsYarnPolymer science

The invention relates to a method for preparing high phase transition enthalpy phase transition temperature-adjusting fiber from hydrolysis products of waste acrylic yarn, comprising the following steps of: reacting the hydrolysis products of the waste acrylic yarn, such as hydrolysis polyacrylonitrile and polyethylene glycol, according to proportion to prepare graft copolymer polyethylene glycolgrafted hydrolysis polyacrylonitrile; completely dissolving the polyethylene glycol grafted hydrolysis polyacrylonitrile in water, adding boric acid, stirring and completely dissolving, standing and defoaming to obtain a spinning stock solution; and preparing the spinning stock solution into high phase transition enthalpy phase transition temperature-adjusting fiber through wet spinning. Comparedwith the existing phase transition temperature-adjusting fiber, the phase transition temperature-adjusting fiber prepared by the method has the advantages of high phase transition enthalpy, stable phase transition and excellent durability and the like, and can be widely applied to the fields of textile and apparel, energy-saving building materials and certain special fields such as military industry, aerospace, etc.

Owner:DALIAN POLYTECHNIC UNIVERSITY

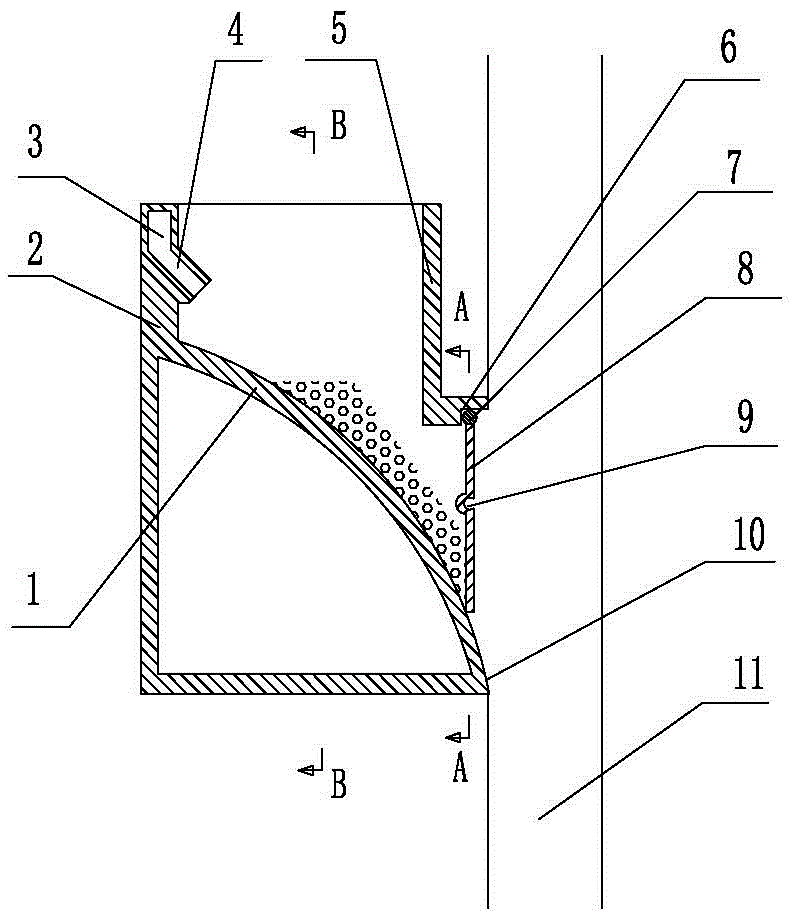

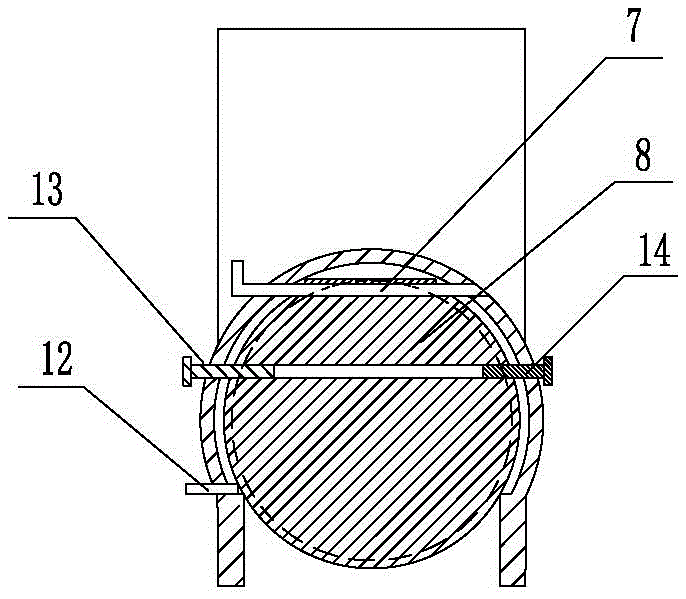

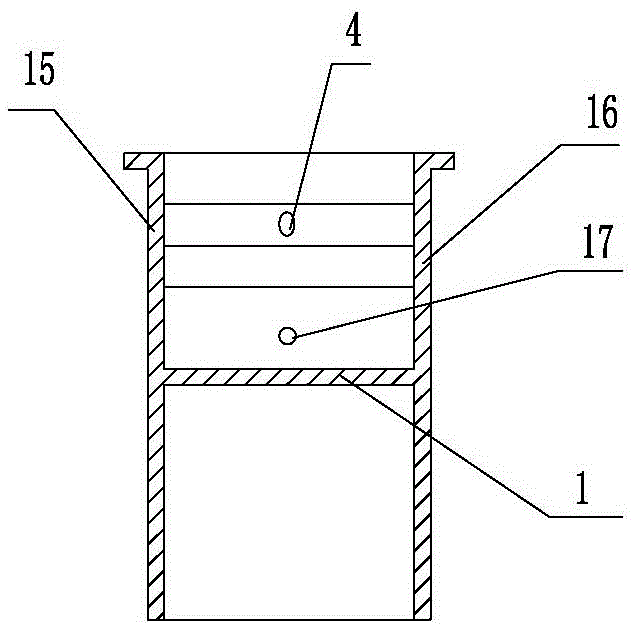

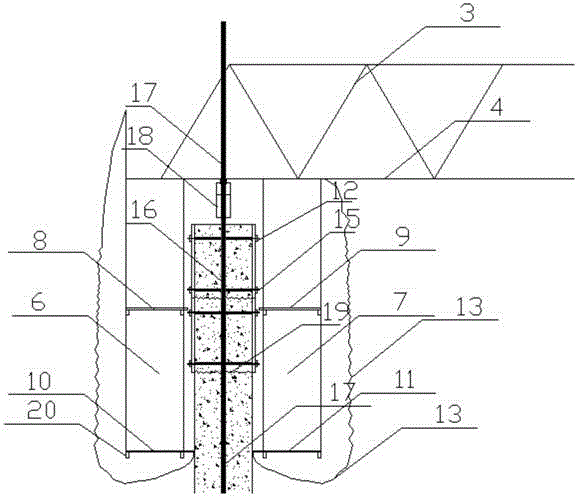

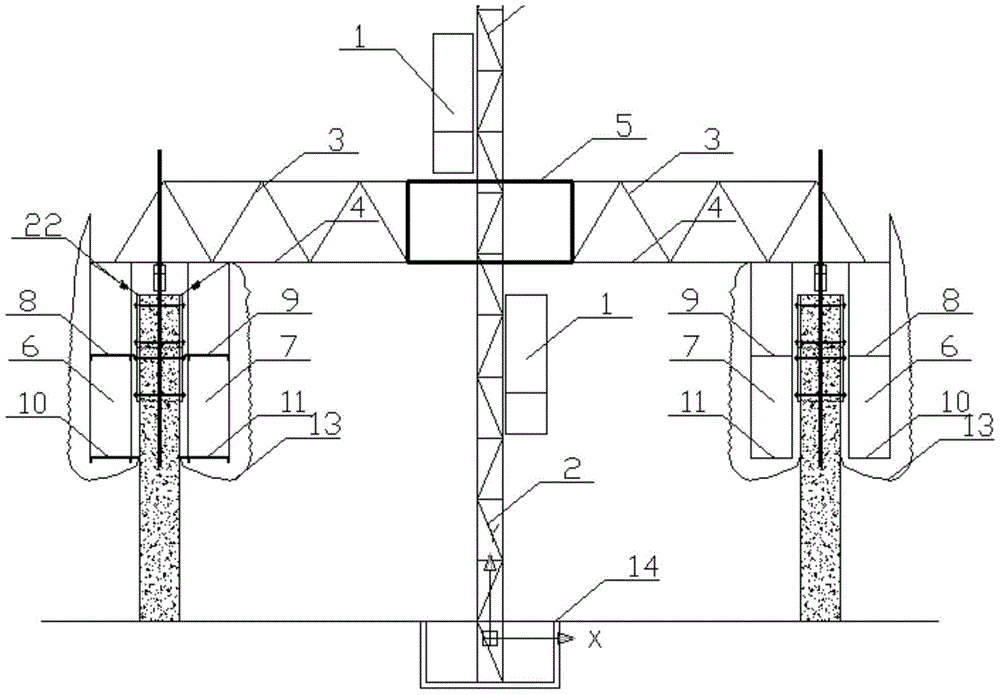

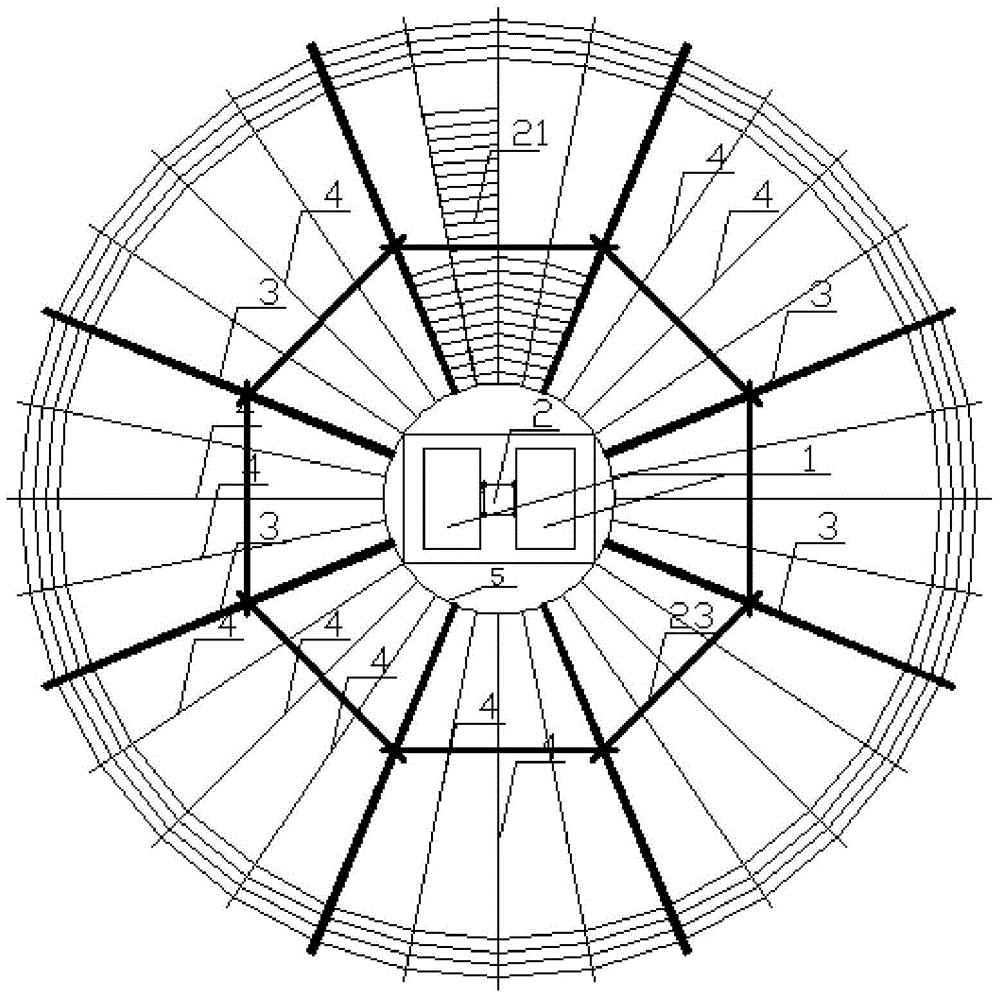

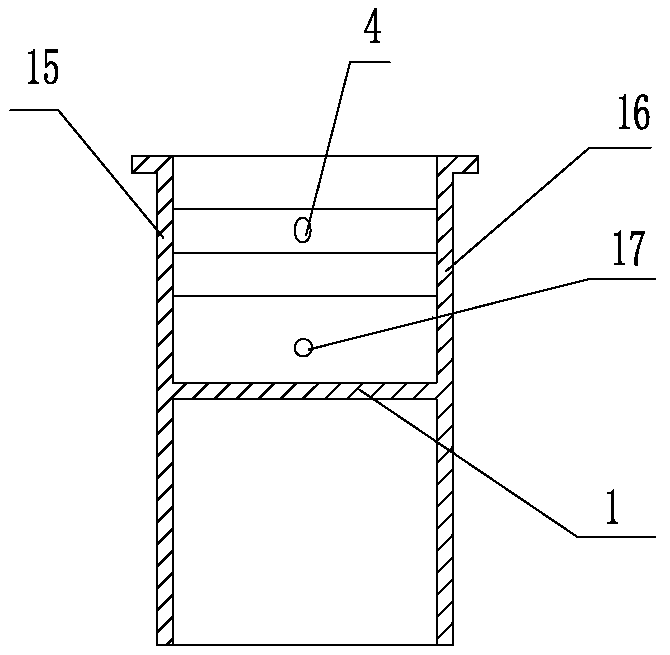

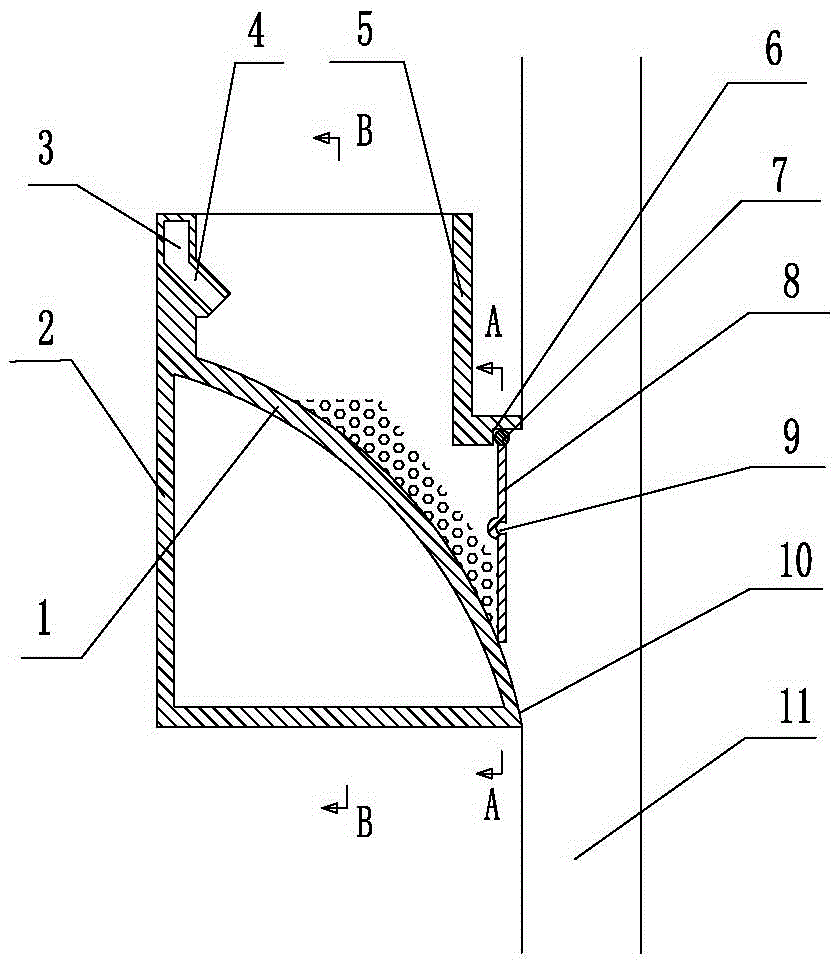

A construction method of circular reinforced concrete chimney wall inverted formwork

ActiveCN104712143BSolving the Recycling DilemmaModerate labor intensityForms/shuttering/falseworksBuilding material handlingFalseworkReinforced concrete

The invention relates to a reversed mould construction method for the circular reinforced concrete chimney wall. The method comprises the steps that a pre-embedded part is embedded; a scaffold is erected at the central position of the chimney wall, steel ring raw materials for connecting primary trusses and a secondary radiation beam are transported into the chimney, and steel rings are assembled on the ground; a central drum ring is installed; a cross-core jack is installed on a climbing rod, the cross-core jack is installed in a released state, and the cross-core jack is adjusted to the corresponding elevation; the primary trusses, the secondary radiation beam and forward-spin connecting rods of the primary trusses are installed, the assembled steel rings are lifted to the bottom of the secondary radiation beam, and the junctions of the secondary radiation beam and downward-spin rods of the primary trusses are connected through a stud and a clamp plate; a foot plank of an operation platform is paved; the normal operation of a chimney cylinder body is conducted. According to the reversed mould construction method for the circular reinforced concrete chimney wall, two formworks are adopted, and a layer of template is omitted compared with a normal condition; the labor intensity of the construction of a hydraulic reversed mould device is moderate, the lifting work of a railway mould is omitted, the labor intensity is reduced, the construction progress is obviously quickened through the dynamic and continuous operation, and the construction period is shortened obviously.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

Kaolin printing and dyeing sludge geopolymer material and preparation method thereof

The invention relates to a kaolin dyeing sludge geopolymer material which comprises a cementing material and a compound activator in a mass ratio of 1:(0.4-1.0); the cementing material is a blended calcined product of kaolin and dried dyeing sludge, wherein the mass ratio of the dried dyeing sludge and kaolin is 1:(3-7); the dried dyeing sludge is the dyeing sludge which is obtained through quenching and high-temperature tempering with lime and ferric salts and drying; the compound activator is prepared from sodium water glass and sodium hydroxide, and the modulus of the compound activator is 1-2. The invention provides an effective path to solve the problems in recycling and utilization of incremental components of the dyeing sludge after chemical quenching and high-temperature tempering and drying, so that the dyeing sludge becomes the geopolymer material rather than a simple filling material, and heavy metal pollutants are sealed.

Owner:JIANGSU GUOHAO REFRACTORY TECH

Tea dregs modified oxidized cellulose composite film and its preparation method and application

ActiveCN109293959BWide variety of sourcesLow priceMeat/fish preservation using chemicalsPolymer sciencePork meat

The invention discloses a tea dregs modified oxidized cellulose composite film and its preparation method and application, which is obtained by imine chemical reaction between the aldehyde group in the selective oxidized cellulose molecule and the amino group in the tea dregs. The tea dregs modified oxidized cellulose composite film prepared by the invention has good mechanical strength, biodegradability and oxidation resistance, is safe and hygienic, can be used for keeping fresh pork at room temperature, and can prolong the shelf life of food.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Solid powder antistatic agent and preparation method thereof

The invention discloses a solid powder antistatic agent and a preparation method thereof, and belongs to the technical field of powder antistatic assistants, the solid powder antistatic agent comprises the following raw materials: paint slag, conductive carbon black and graphene according to a mass ratio of (25-50): (25: 50): (1-2). The used graphene is few-layer graphene and / or multi-layer graphene with the carbon content not lower than 95%, and the paint slag is waste slag generated in the paint spraying process or residues of waste paint. The preparation method of the antistatic agent comprises the following steps: removing impurities from paint slag, and performing high-temperature pretreatment; then mixing with conductive carbon black and graphene at a high speed, and carrying out ball milling for 2-4 hours; and finally, sieving with a 600-mesh sieve. By adopting the technology provided by the invention, the paint slag is used for replacing conductive carbon black in a large proportion, so that the problem of environmental pollution caused by carbon black production is effectively reduced, and the problem of paint slag recycling is solved; the antistatic agent with a good antistatic effect is prepared.

Owner:SHENYANG JIANZHU UNIVERSITY

Filling wood-plastic forming method for waste packages

InactiveCN112060529ASolving the Recycling DilemmaNo pollution in the processPlastic recyclingMechanical material recoveryPlasticultureProcess engineering

The invention discloses a filling wood-plastic forming method for Tetra Pak package wastes, and belongs to the technical field of wood-plastic co-extrusion. The filling wood-plastic forming method forthe Tetra Pak package wastes comprises the following steps: breaking the Tetra Pak package wastes by using a granulator to form aggregates from the Tetra Pak package wastes; carrying out breaking treatment or crushing treatment on the aggregates by using a breaker or a crusher to obtain small particles; adding the small particles and other additives into a main extruder, melting, plasticizing andextruding, extruding a coating structure from a co-extrusion coating section, entering a cooling section of a die, and then extruding from a die orifice of the die to obtain a wood-plastic co-extrusion coated floor. The filling wood-plastic forming method for the Tetra Pak package wastes has the advantages of being simple and feasible, convenient to implement, low in cost, environment-friendly, free of pollution, and the like.

Owner:ANHUI SENTAI WPC GRP CO LTD

A waterless toilet suitable for comprehensive recycling of feces

ActiveCN106388673BSuitable for useGuaranteed Organic IngredientsBathroom accessoriesVertical planeGravitational force

The invention relates to a waterless closestool suitable for comprehensively recycling excrement and belongs to the field of waterless toilets. The waterless closestool comprises a closestool body, the inner wall of the closestool body is divided into a front wall, a lateral wall, a rear wall and a bottom wall, and an excrement outlet is formed in the bottom wall; the waterless closestool is characterized in that the lateral wall and the rear wall are both vertical planes, the excrement outlet is arranged behind the rear wall, the bottom wall is obliquely arranged, and the bottom wall gradually lowers from the lower end of the front wall to the position of the excrement outlet. As the lateral wall and the rear wall of the closestool body are both vertical, the bottom wall lowers gradually and the excrement outlet is arranged behind the rear wall, the excrement can directly fall into the excrement outlet under the gravity force action and then fall into an excrement pipeline in defecation; water flush is avoided in the process, the excrement in the excrement pipeline contains no water, the organic ingredients are guaranteed, and the excrement can be recycled to be used as a farmland fertilizer; as the water flush is avoided, a lot of water is saved; furthermore, the waterless closestool is suitable for building residents to use.

Owner:平邑县经发信息服务有限公司

Boron-containing high speed steel roller and preparation method thereof

InactiveCN102409267BSimple production processImprove macro hardnessFurnace typesHeat treatment furnacesBoron containingWear resistance

The invention relates to a boron-containing high speed steel roller and a preparation method thereof, and belongs to the technical field of steel rolling. The steel roller comprises the following chemical components, by mass, 0.95-1.15% of C, 8.5-9.0% of Cr, 1.0-1.2% of Mo, 0.5-0.8% of W, 0.5-0.8% of V, 0.4-0.6% of B, 1.6-1.8% of Al, 0.18-0.25% of N, 0.4-0.6% of Cu, 1.2-1.4% of Si, 0.06-0.10% of RE ,0.03-0.06% of Mg, 0.04-0.08% of Ti, 0.025-0.045% of K, 0.025-0.045% of Na, 0.02-0.04% of Te, 0.02-0.04% of Bi, less than 0.5% of Mn, less than 0.025% of S, less than 0.030% of P, and the balance of Fe and inevitable trace impurities. The boron-containing high speed steel roller of the present invention can be produced by an electric furnace, and has advantages of high roll surface hardness, good wear resistance, high roll neck strength, good toughness and the like.

Owner:BEIJING UNIV OF TECH

Waterless closestool suitable for comprehensively recycling excrement

ActiveCN106388673ASuitable for useGuaranteed Organic IngredientsBathroom accessoriesVertical planeGravitational force

The invention relates to a waterless closestool suitable for comprehensively recycling excrement and belongs to the field of waterless toilets. The waterless closestool comprises a closestool body, the inner wall of the closestool body is divided into a front wall, a lateral wall, a rear wall and a bottom wall, and an excrement outlet is formed in the bottom wall; the waterless closestool is characterized in that the lateral wall and the rear wall are both vertical planes, the excrement outlet is arranged behind the rear wall, the bottom wall is obliquely arranged, and the bottom wall gradually lowers from the lower end of the front wall to the position of the excrement outlet. As the lateral wall and the rear wall of the closestool body are both vertical, the bottom wall lowers gradually and the excrement outlet is arranged behind the rear wall, the excrement can directly fall into the excrement outlet under the gravity force action and then fall into an excrement pipeline in defecation; water flush is avoided in the process, the excrement in the excrement pipeline contains no water, the organic ingredients are guaranteed, and the excrement can be recycled to be used as a farmland fertilizer; as the water flush is avoided, a lot of water is saved; furthermore, the waterless closestool is suitable for building residents to use.

Owner:平邑县经发信息服务有限公司

Method for preparing waste acrylic fiber and fatty acid combined phase change material

InactiveCN102002342BSolving the Recycling DilemmaReduce pollutionHeat-exchange elementsPolymer scienceNew energy

The invention relates to a method for preparing a waste acrylic fiber and fatty acid combined phase change material, which comprises: preparing uniform polymer solution by stirring waste acrylic fibers and fatty acid in a solvent; and allowing the polymer solution to precipitate in a precipitator quickly. Macro molecules of polyacrylonitrile and molecules of fatty acid are agglomerated together through the intermolecular forces, so that the phase change material does not seeps out even the outside temperature reaches 100 DEG C. The amorphous phase change material prepared by the method has the advantages that: the enthalpy value and thermal stability are high; the preparation method is simple; the cost is low; the solvent can be recycled; and the like. The method realizes waste fiber recycling, reduces environmental pollution and provides a new energy-saving material for the society. The invention is a new project with low cost, high profit and sufficient resources, and has a bright development prospect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com