Filling wood-plastic forming method for waste packages

A wood-plastic and waste technology, which is applied in the field of wood-plastic co-extrusion, can solve the problems of poor core board quality, insufficient core board strength, and difficulty in Tetra Pak waste, and achieve high elastic modulus and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

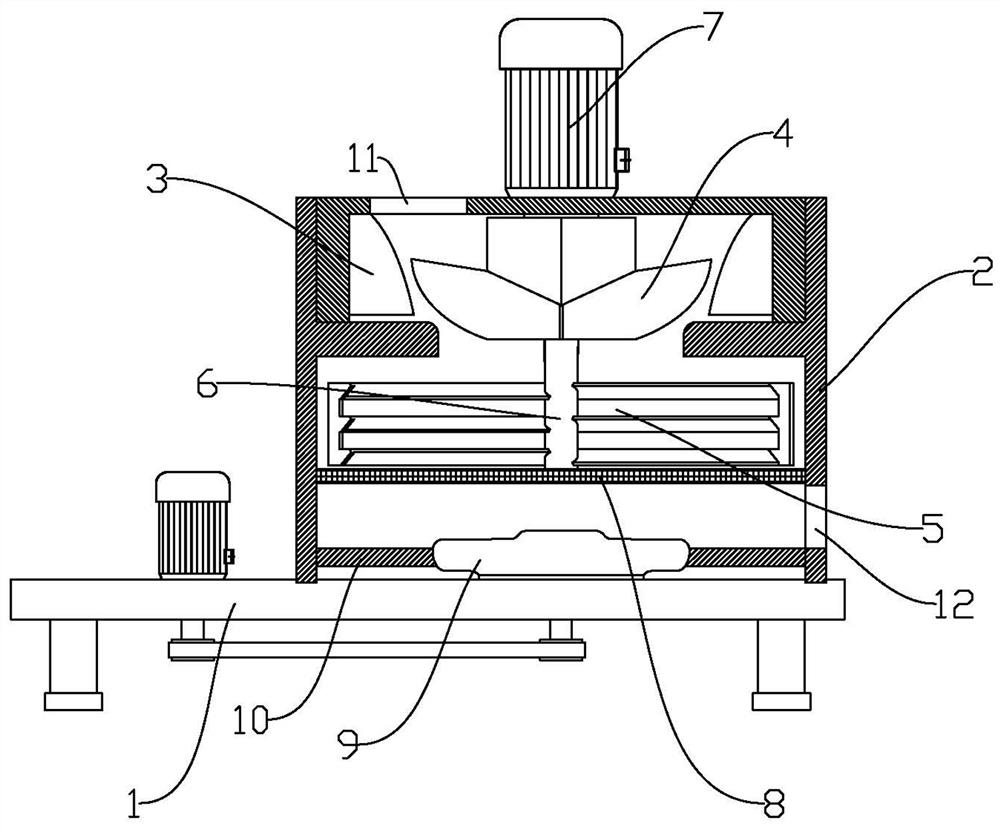

Image

Examples

Embodiment 1

[0040] A method for filling wood-plastic molding with waste packaging, the specific steps include:

[0041] a. Add the recovered Tetra Pak packaging waste to the agglomerator, the amount of Tetra Pak packaging waste added is 2 / 3 of the internal capacity of the agglomerator; open the agglomerator, so that the agglomerator can break the Tetra Pak packaging waste into Fragments, continue to use the agglomerator to agglomerate the fragments, during which the temperature is controlled at 100~120°C, specifically: when the temperature rises to about 100°C, the rotational speed of the rotating blade of the agglomerator is controlled at 500~700rpm during the stable period, And stop for 30 seconds every working 5 minutes, after continuous treatment for 20 minutes in this way, the pellets of Tetra Pak packaging waste are obtained; the pellets have the following properties: the pellets are a homogeneous mixture, and the pellets can It is a hard non-stick solid when it is hot, and it is a ...

Embodiment 2

[0057] A method for filling wood-plastic molding with waste packaging, the specific steps include:

[0058] a. Add the recovered Tetra Pak packaging waste to the agglomerator, the amount of Tetra Pak packaging waste added is 2 / 3 of the internal capacity of the agglomerator; open the agglomerator, so that the agglomerator can break the Tetra Pak packaging waste into Fragments, continue to use the agglomerator to agglomerate the fragments, during which the temperature is controlled at 100~120°C, specifically: when the temperature rises to about 100°C, the rotational speed of the rotating blade of the agglomerator is controlled at 500~700rpm during the stable period, And stop for 30 seconds every working 5 minutes, after continuous treatment for 20 minutes in this way, the pellets of Tetra Pak packaging waste are obtained; the pellets have the following properties: the pellets are a homogeneous mixture, and the pellets can It is a hard plastic non-sticky solid when it is hot, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com