Waterless closestool suitable for comprehensively recycling excrement

A technology for waterless toilets and feces, applied in applications, household appliances, sanitary equipment, etc., can solve problems such as large water consumption, blockage, and loss of fertilizer sources for humans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] When the present invention is in use, the side facing the toilet user is defined as the front, the side facing away is defined as the rear, and the side below the toilet is defined as the bottom wall accordingly.

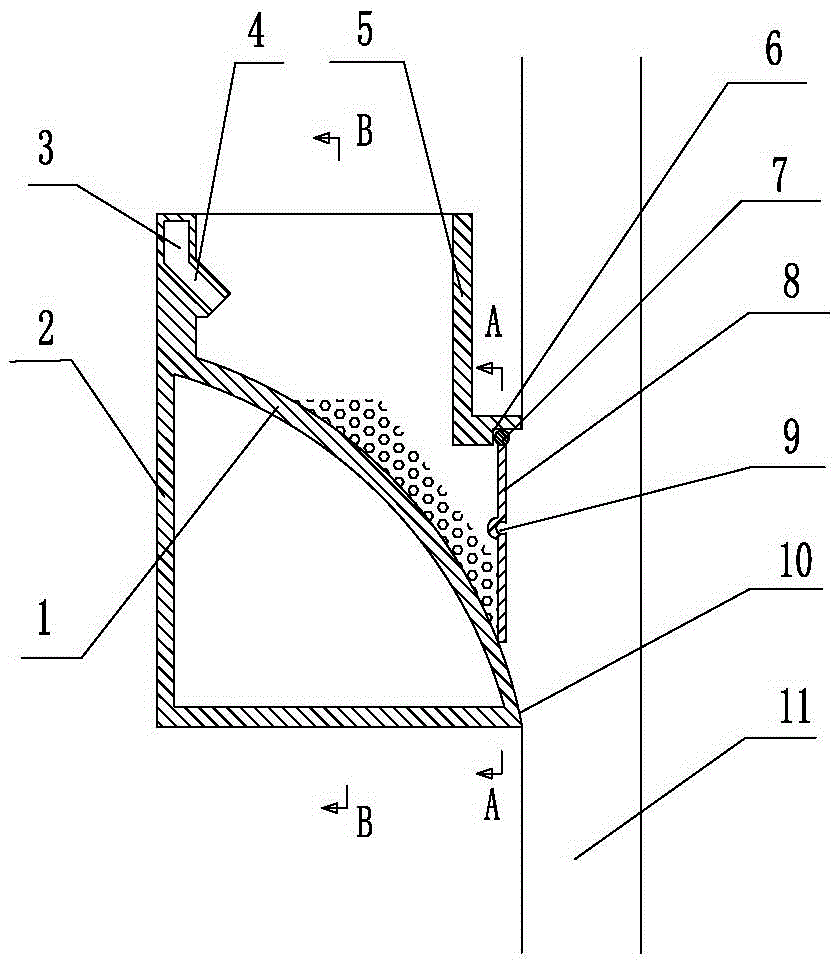

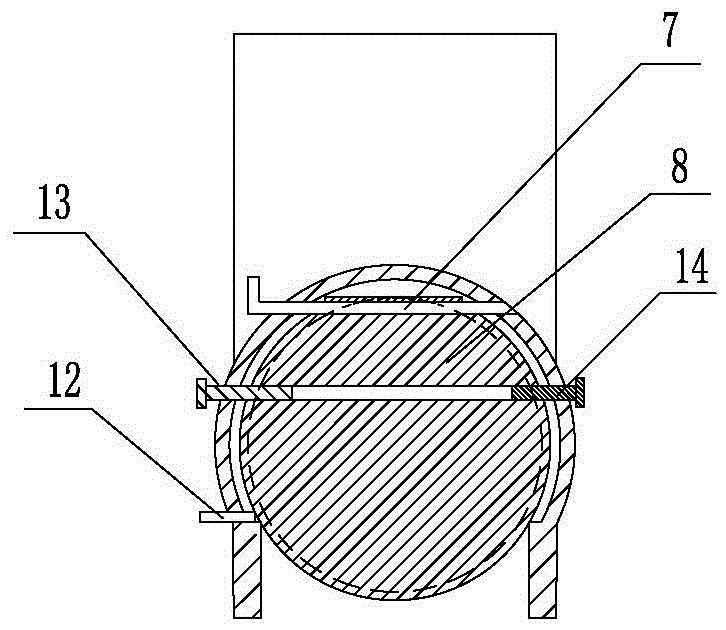

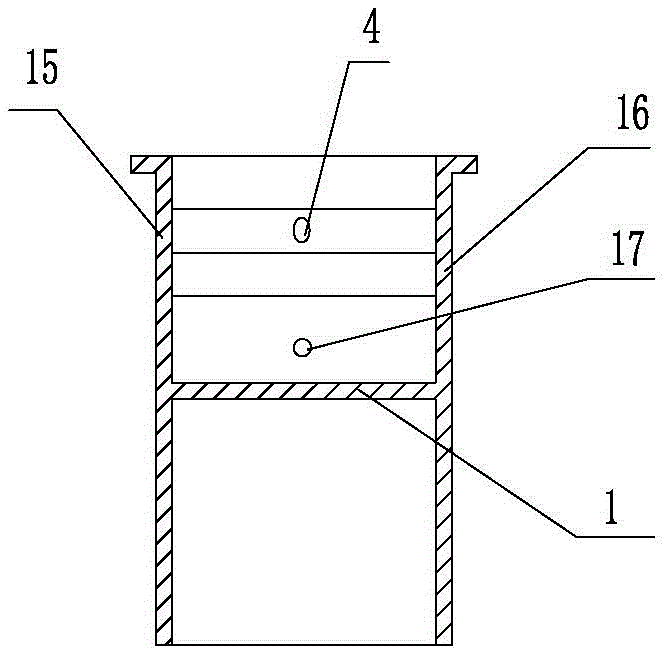

[0031] Such as Figures 1 to 3 Shown, the inwall of the toilet body is divided into front wall 2, side wall 15 and side wall 16, rear wall 5 and bottom wall 1, offers feces outlet 10 on the bottom wall 1, and feces outlet 10 is positioned at the rear of rear wall 5. The side wall 15, the side wall 16, and the rear wall 5 are all vertical surfaces, and the bottom wall 1 is inclined, and the bottom wall gradually decreases from the lower end of the front wall 2 to the position of the excrement outlet 10 . A step mouth 6 is set at the position of the feces outlet 10 , and the upper end of the sealing sheet 8 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com