Method for preparing shape-stabilized phase change material by using acrylic fiber waste silks

A technology for shaping phase change material and acrylic fiber waste silk, which is applied in the field of phase change energy storage materials, can solve problems such as phase change material leakage, achieve low production cost, good morphological stability and thermal stability, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The first step, preparation of acrylic waste silk hydrolyzate: add 5g of PAN waste silk, 5g of sodium hydroxide, and 95ml of deionized water into a 250ml three-neck flask, stir and reflux at 130°C, wait until the waste silk is completely dissolved, and cool to room temperature , add 20ml of 95% ethanol for precipitation, and use 0.1mol / L hydrochloric acid to adjust the pH value of the precipitate to be slightly less than 7, stir for 30min, then wash with ethanol until neutral, and vacuum dry at 95°C for later use.

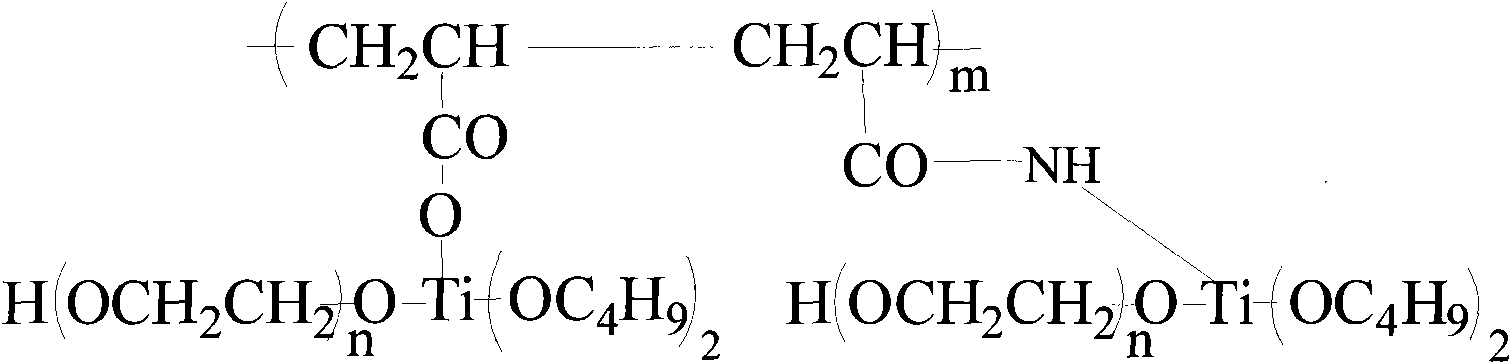

[0027] The second step, preparation of phase change material: Weigh 2g of acrylic fiber waste hydrolyzate in 150mL conical flask A, add solvent N, N-dimethylformamide (DMF) 20ml to dissolve and swell for 2h; weigh polyethylene Diol (6000) 5g, chain extender tetrabutyl phthalate (TBT) 0.8g, catalyst dibutyltin dilaurate 0.015g In another 150mL Erlenmeyer flask B, add DMF 20ml, and stir magnetically at 90°C for 60 Minutes, then pour the solution of acrylic fib...

Embodiment 2

[0032] The first step, preparation of acrylic waste silk hydrolyzate: add PAN waste silk 5g, sodium hydroxide 10g, and deionized water 90ml into a 250ml three-neck flask, stir and reflux at 150°C, wait until the waste silk is completely dissolved, and cool to room temperature , add 20ml of 95% ethanol for precipitation, and use 0.1mol / L hydrochloric acid to adjust the pH value of the precipitate to be slightly less than 7, stir for 30min, then wash with ethanol until neutral, and vacuum dry at 95°C for later use.

[0033] The second step, preparation of phase change material: Weigh 2g of acrylic fiber waste hydrolyzate in 150mL Erlenmeyer flask A, add 20ml of N,N-dimethylformamide (DMF) to dissolve and swell for 2h; weigh polyethylene glycol Alcohol (2000) 5g, chain extender tetrabutyl phthalate (TBT) 0.4g, catalyst dibutyltin dilaurate 0.007g in another 150mL Erlenmeyer flask B, add DMF 20ml, magnetically stir at 80°C for 1h, Then pour the solution of the hydrolyzate of acryl...

Embodiment 3

[0035] The first step, the preparation of acrylic waste silk hydrolyzate: add PAN waste silk 5g, sodium hydroxide 10g, and deionized water 90ml into a 250ml three-neck flask, stir and reflux at 140°C, wait until the waste silk is completely dissolved, and cool to room temperature , add 20ml of 95% ethanol for precipitation, and use 0.1mol / L hydrochloric acid to adjust the pH value of the precipitate to be slightly less than 7, stir for 30min, then wash with ethanol until neutral, and vacuum dry at 95°C for later use.

[0036]Preparation of phase change material: Weigh 4g of acrylic fiber waste hydrolyzate in 150mL Erlenmeyer flask A, add 20ml of N,N-dimethylformamide (DMF) to dissolve and swell for 2h; weigh polyethylene glycol (4000) 5g, chain extender tetrabutyl phthalate (TBT) 0.8g, catalyst dibutyltin dilaurate 0.015g in another 150mL Erlenmeyer flask B, add DMF20ml, magnetically stir at 80°C for 1h, then acrylic fiber waste The solution of the silk hydrolyzate was poured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com