Method for selecting asbestos from asbestos-like minerals by wet process by using ultrasonic waves

An ultrasonic and asbestos technology, which is applied in the field of asbestos mineral wet ultrasonic cotton separation, can solve the problems of difficulty in ensuring the length of asbestos fibers, low quality grades of asbestos products, and low asbestos beneficiation rate, and achieve the elimination of waste slag pollution and production The effect of low cost and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

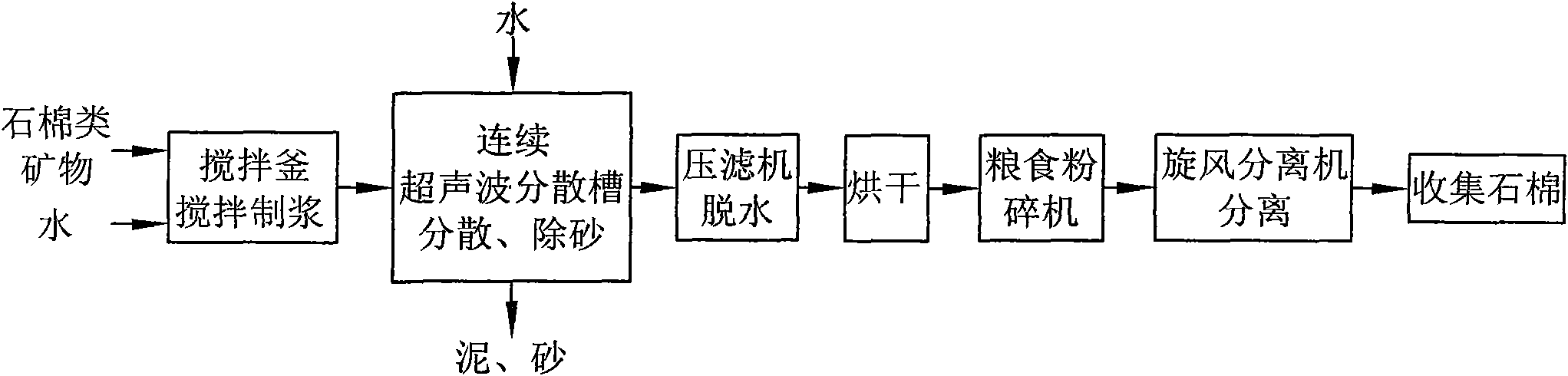

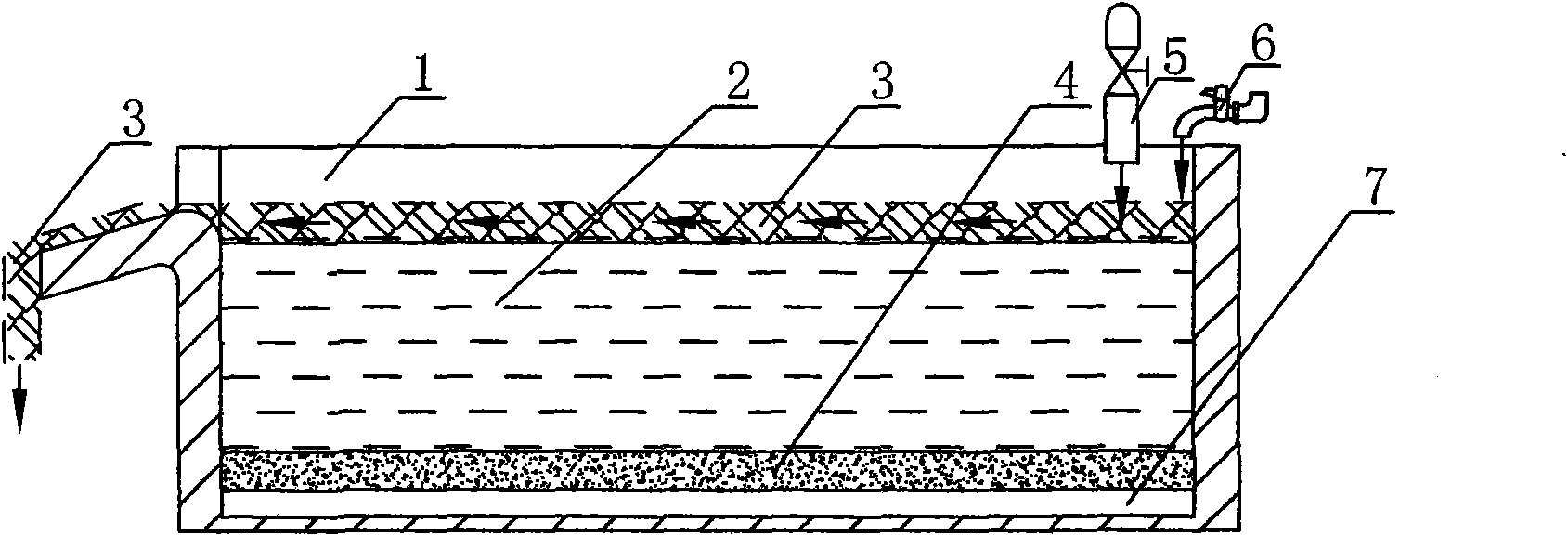

[0023] see figure 1 , figure 2 , a method for asbestos mineral wet ultrasonic cotton selection, comprising the steps of stirring and pulping, dispersing, desanding, dehydration, separation, and collecting; said stirring and pulping is asbestos ore by water: asbestos ore=1000:2 The weight ratio is added in the stirring tank, and the asbestos ore is fully dissolved under stirring, and dispersed in water to form asbestos slurry; the dispersion and sand removal are to introduce the above-mentioned asbestos slurry from the pipeline 5 into the ultrasonic dispersion tank 1, and at the same time, the asbestos slurry is introduced by the water inlet valve. 6 Inject water into the ultrasonic dispersion tank 1, start the ultrasonic generator 7 to generate ultrasonic waves, use water 2 as the medium, and disperse the ultrasonic waves for 5 to 15 minutes to fully disperse the asbestos fibers 3 and at the same time make the sand and stones 4 in the asbestos slurry settle naturally At the ...

Embodiment 2

[0025] see figure 1 , figure 2 , the stirring pulping is that asbestos tailings are added into the stirring tank according to the weight ratio of water: asbestos tailings=1000:6, and the others are the same as in embodiment 1.

Embodiment 3

[0027] see figure 1 , figure 2 , the stirring pulping is that asbestos production waste slag is added to the stirring tank according to the weight ratio of water: asbestos production waste slag=1000:8, and the others are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com