Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Solve temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

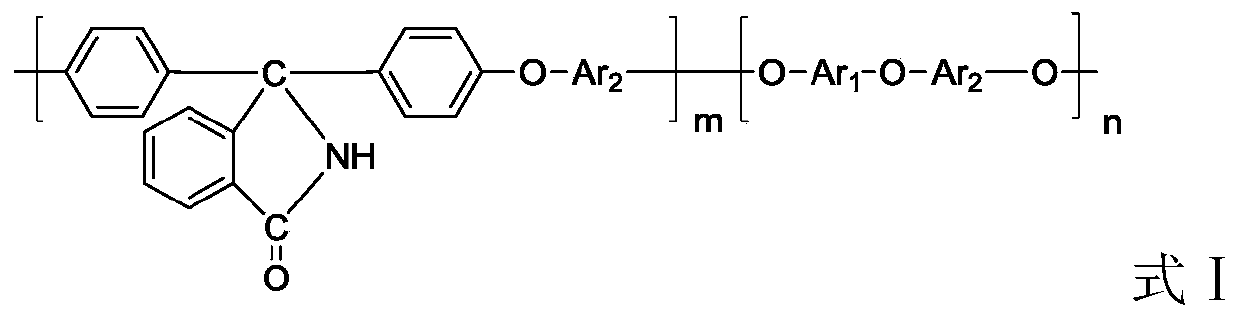

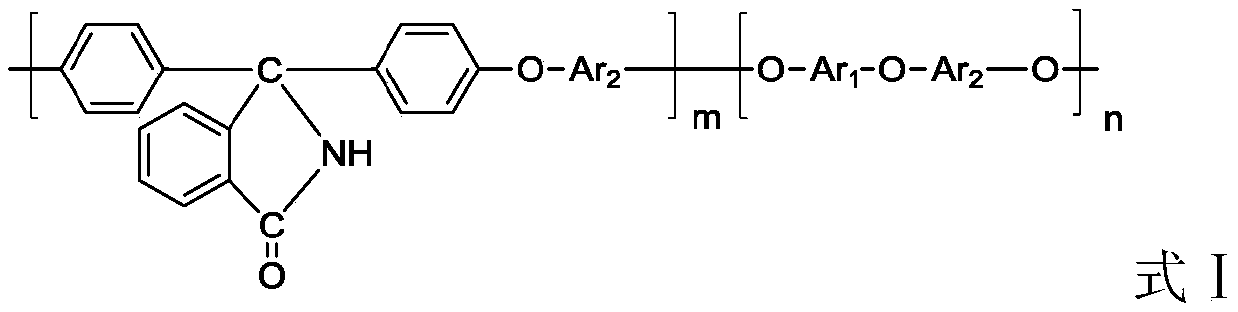

Functional polymer with surface activity as well as preparation method and application thereof

ActiveCN104693351ASolve problems such as chromatographic separation effectsSolve temperature resistanceDrilling compositionSalt resistancePolymer science

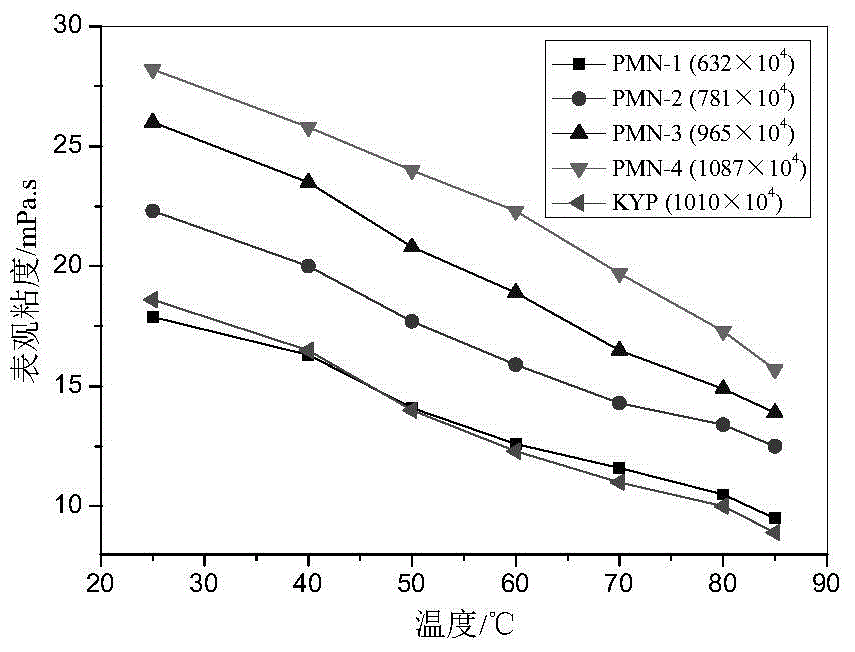

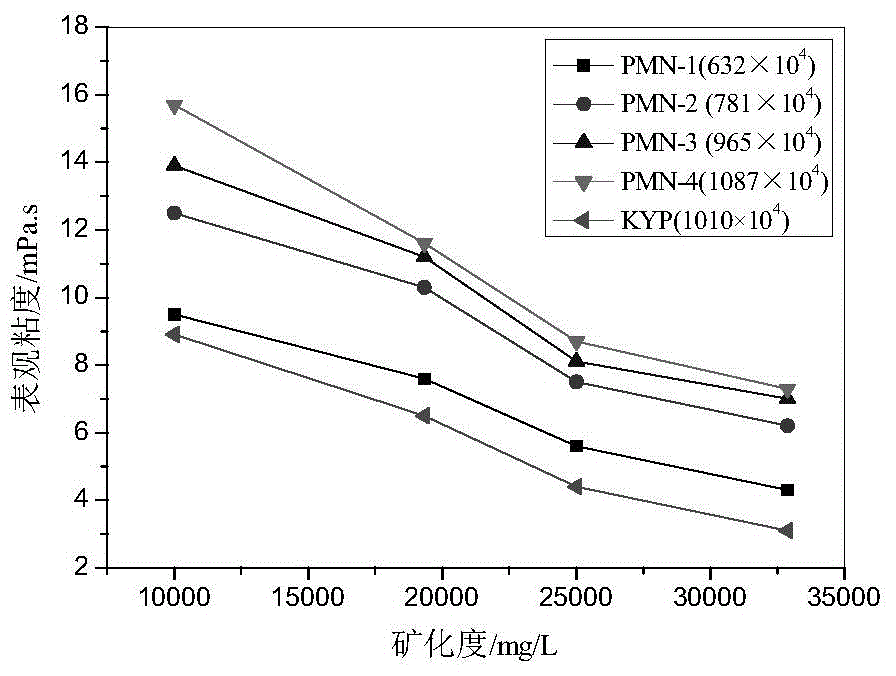

The invention provides a functional polymer with surface activity as well as a preparation method and application thereof. The functional polymer with surface activity contains a structural unit A, a structural unit B and a structural unit C, wherein the structural unit A has a structure as shown in a formula (1) in the specification; the structural unit B has a structure as shown in a formula (2) in the specification; the structural unit C has a structure as shown in a formula (3) in the specification; based on the weight of the polymer, the content of the structural unit A is 50-88wt%; the content of the structural unit B is 10-40wt%; the content of the structural unit C is 2-10wt%; the viscosity-average molecular weight of the polymer is 6-12 million. The functional polymer with surface activity has good temperature and salt resistance and a capability of thickening water media. The polymer oil displacement agent is applicable to oil reservoirs with low to medium permeability and high-temperature and high-salinity oil reservoirs and can conduce to further enhancing the oil recovery in tertiary oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

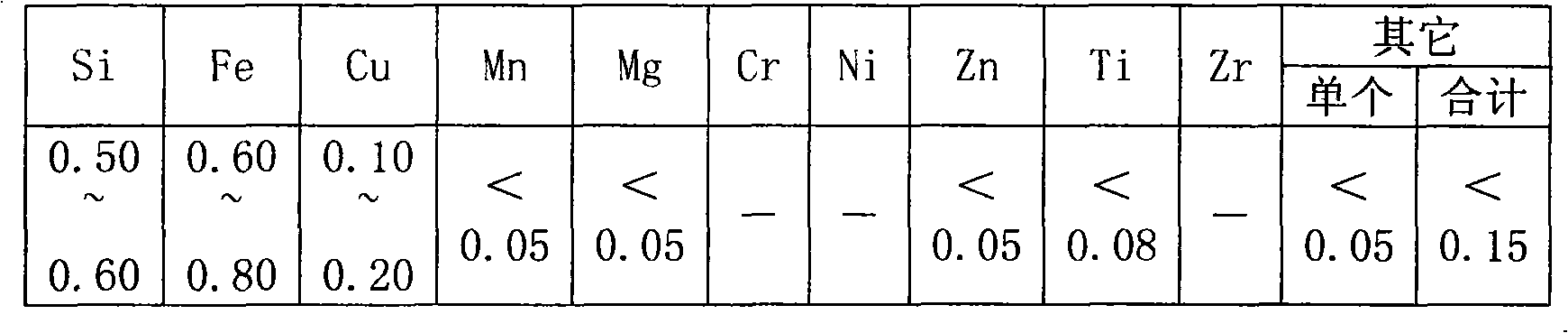

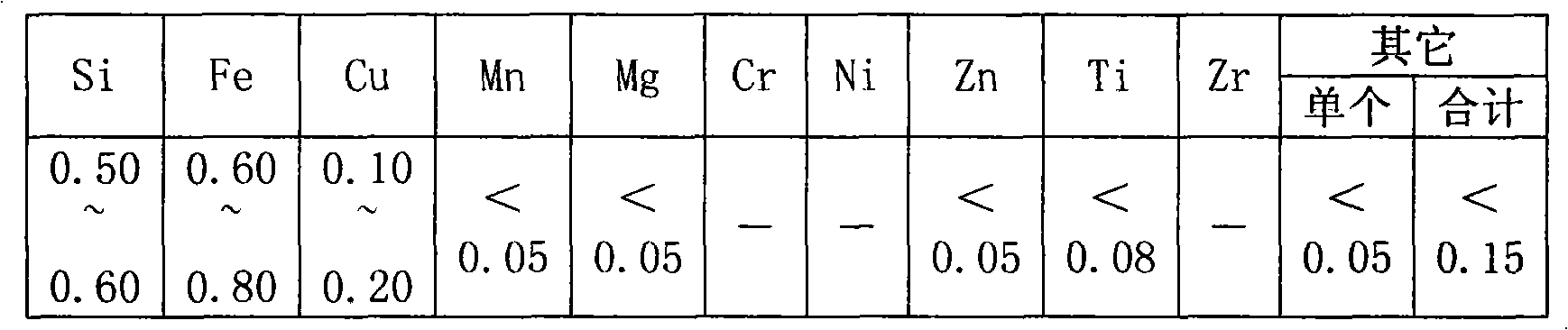

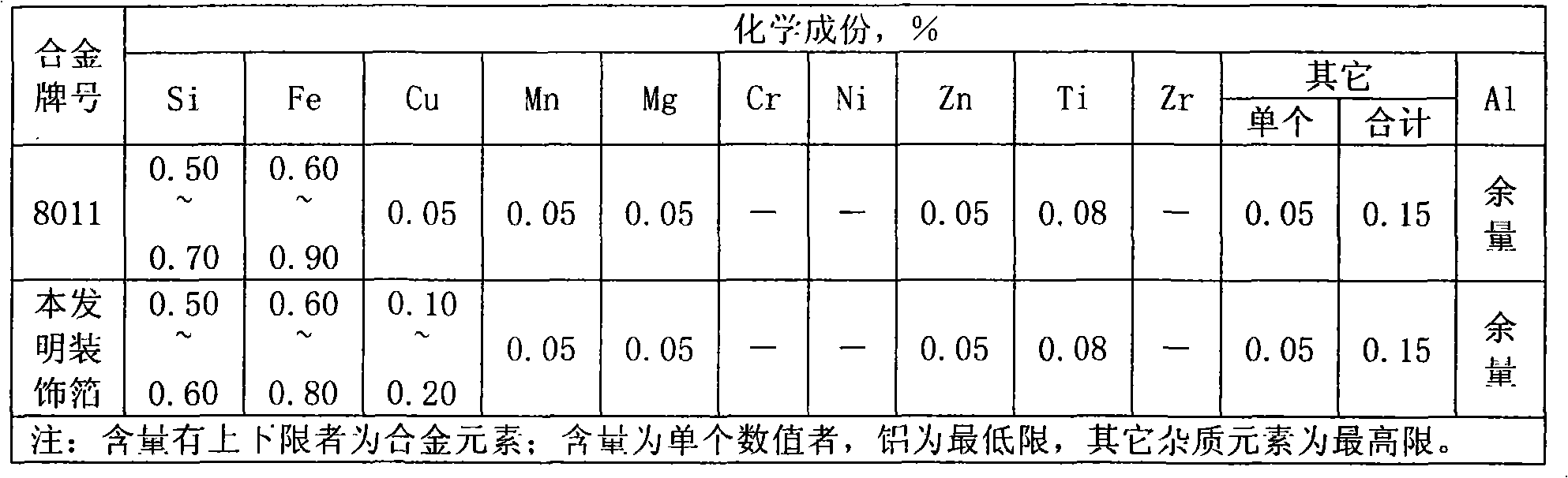

0.022 mm temperature-tolerance decoration foil and preparation method thereof

The invention relates to a 0.002 mm temperature-tolerance decoration foil and a preparation method thereof. The decoration foil is characterized by being made by adding 0.10-0.20 percent by weight of Cu element on the basis of 8011 alloy. The preparation method comprises the following process procedures: cold-rolling a cast-rolling plate into 0.44-0.85 mm from 6.0-10.0 mm, adopting an H22 status for interannealing, cold-rolling to 0.28-0.60 mm, foil-rolling to reach a finished thickness of 0.022 mm, and slitting, wherein the H22 status annealing process comprises the following steps: adopting a burner-gas temperature controlling way for annealing, namely, charging below 100 DEG C, heating 1.5 hours till the temperature reaches 350-450 DEG C, and preserving the temperature for 5-15 hours; cooling for 0.5 hour till the temperature reaches 320-380 DEG C, preserving the temperature for 5-15 hours, cooling for 1.5 hours till the temperature reaches 200 DEG C, and discharging; and achieving the total processing ratio being more than 95 percent after interannealing. The invention has good temperature tolerance and stable quality.

Owner:新疆天展新材料科技有限公司

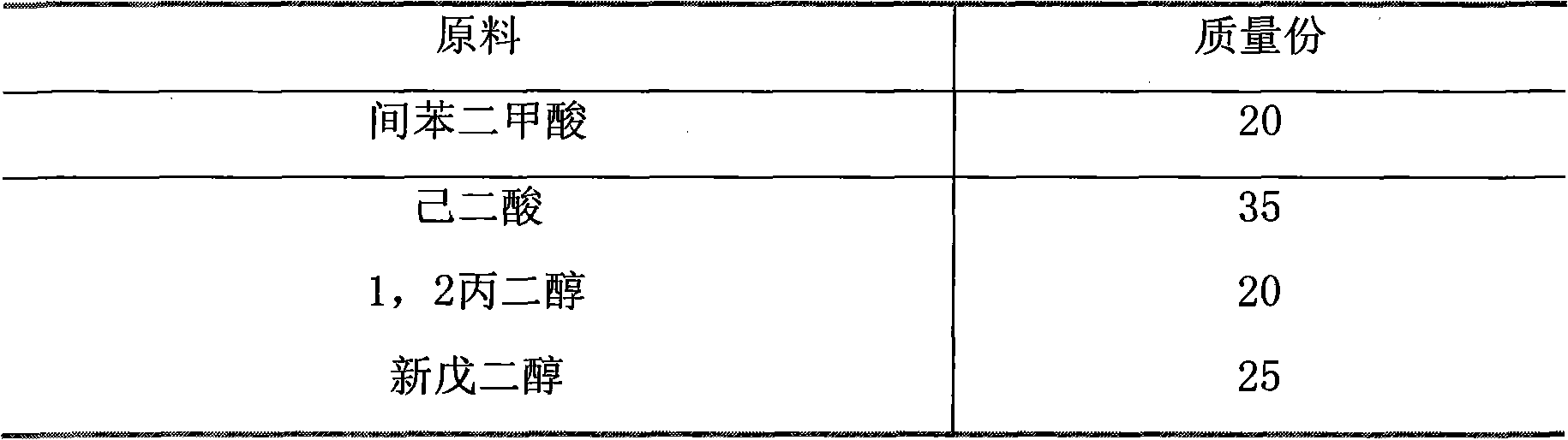

Adhesive for laminated steel and preparation method thereof

InactiveCN101928542AImprove temperature resistanceAccelerated corrosionPolyureas/polyurethane adhesivesMacromolecular adhesive additivesAdhesiveAdipic acid

The invention discloses an adhesive for laminated steel and belongs to the field of adhesives. The adhesive is prepared from the following raw materials: polyester polyol, 4,4'-diphenylmethane diisocyanate, an environment-friendly organic solvent, gamma-epoxypropoxypropyltriethoxysilane and a bisphenol A type epoxy resin, and has the synthesized solid content of 50 to 60 percent, the viscosity of3,000 to 5,000 mPa.s and the hydroxyl value of 10 to 20 mgKOH / g after reaction, wherein the polyester polyol is prepared from m-phthalic acid, 1,2 propylene glycol, adipic acid and neopentyl glycol through once esterification and polycondensation. The adhesive has the advantages of good temperature and corrosion resistance, a cup drawing test for the laminated steel product shows that the laminated steel product is unwarped at 8mm, and the problems that the conventional adhesive for the laminated steel has low temperature and corrosion resistance and the like are radically solved.

Owner:NANTONG GAOMENG NEW MATERIAL

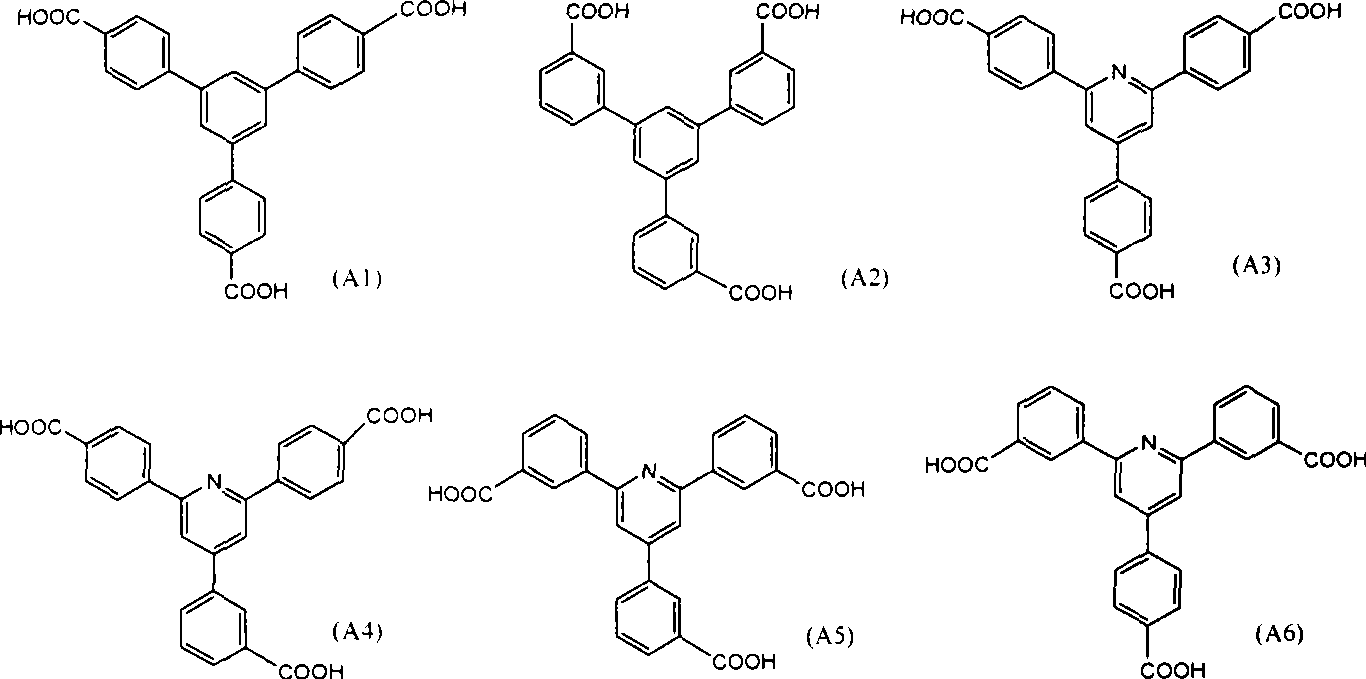

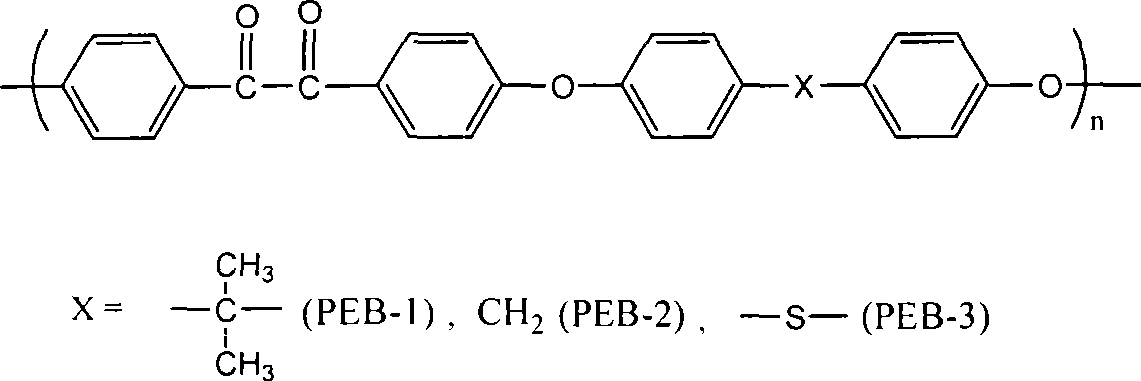

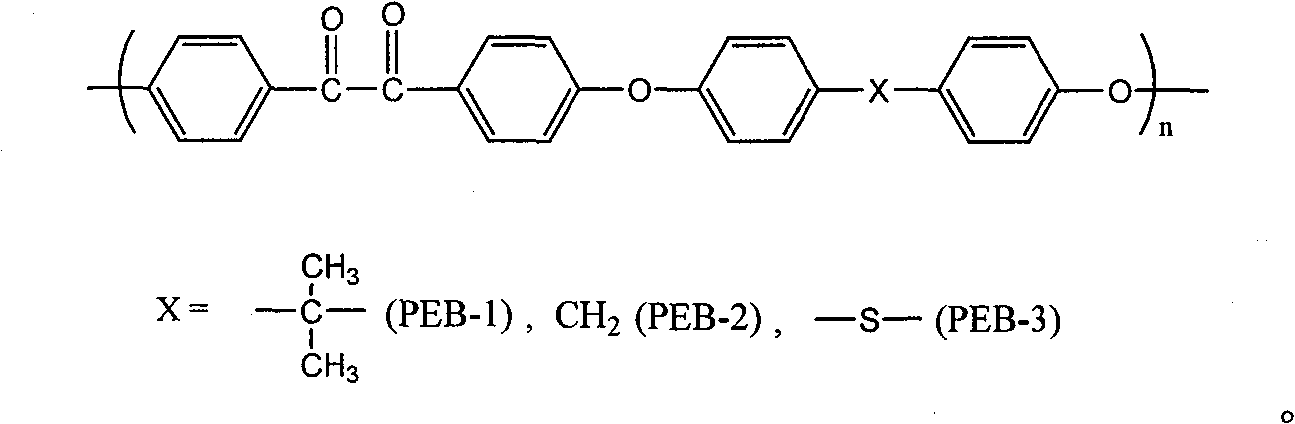

Crosslinked polybenzimidazoles thin film containing sulfonic group and preparation thereof

The invention relates to a crosslinked polybenzimidazole film containing sulfo group and a method for preparing the same. The invention is characterized in that the raw material proportions of the crosslinked polybenzimidazole film are as follows: (1) 10 proportions of 3,3',4,4'-tetraamino diphenyl ether by weight; (2) 5-10 proportions of aromatic triacid by weight; (3) 2-3 proportions of 1,2-naphthoquinone-4-ammonium sulphonate by weight; (4) 0.5-2 proportions of PEB by weight; (5) 100-200 proportions of organic solvent by weight; and (6) 200-300 proportions of polyphosphoric acid by weight. The film can effectively regulate the molecular weight of the branched polybenzimidazole and the structure of the crosslinked film by controlling the raw material proportions. The obtained polybenzimidazole has excellent solubility as well as higher thermal stability, better transparence, excellent corrosion resistance and high proton conduction rate, and the like.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

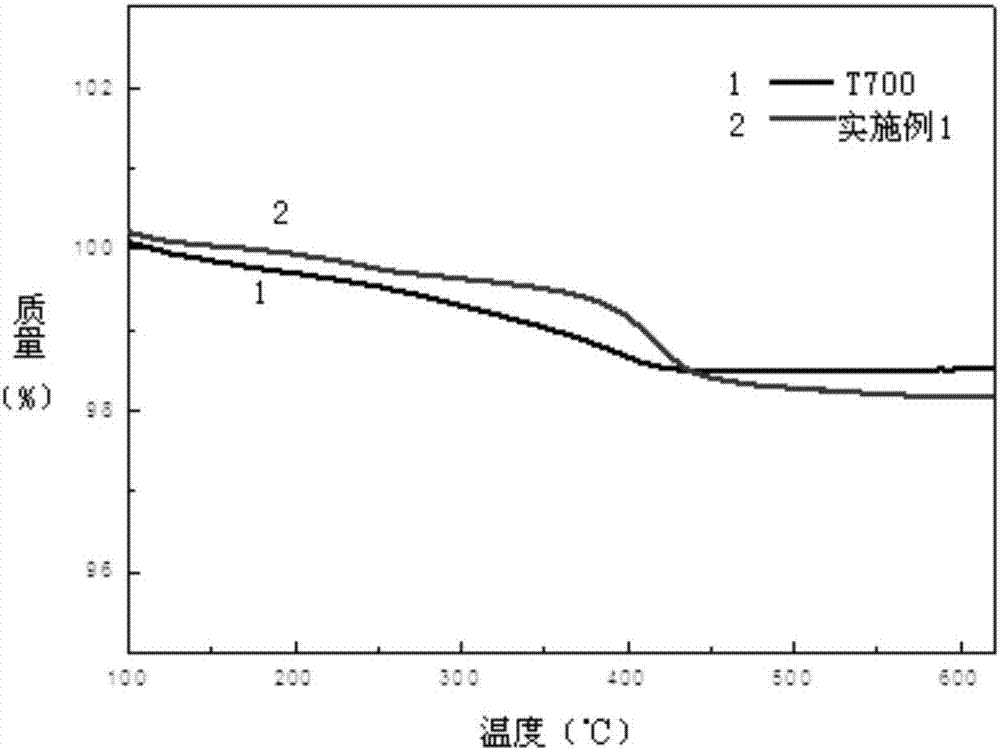

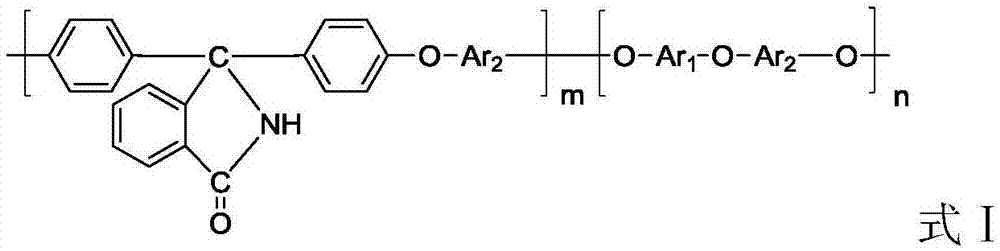

Interface-enhancement emulsion type sizing agent used for carbon fibers, and preparation method thereof

The invention provides an interface-enhancement emulsion type sizing agent used for carbon fibers, and a preparation method thereof, and belongs to the technical field of carbon fiber sizing agents. The sizing agent comprises a main slurry, an emulsifier, a coupling agent and deionized water, the main slurry comprises polyaryletherketone resin and an organic solvent according to a mass percentage ratio of (5-30):(70-95), the mass of the emulsifier is 5-20% of the mass of the main slurry, the mass of the coupling agent is 1-10% of the mass of the main slurry, and a mass percentage ratio of the deionized water to the main slurry is (60-90):(10-40). The polyaryletherketone resin having a high heat stability is used as the main component to prepare the emulsion type sizing agent for carbon fibers, so the temperature tolerance problem of the sizing agent is solved; and the polyaryletherketone resin has good compatibility with epoxy resin, and can participate in the curing reaction of the epoxy resin, so the bonding performance of the epoxy resin and the fibers is greatly improved, thereby the interlace shearing strength of a composite material is improved.

Owner:芜湖万隆新材料有限公司

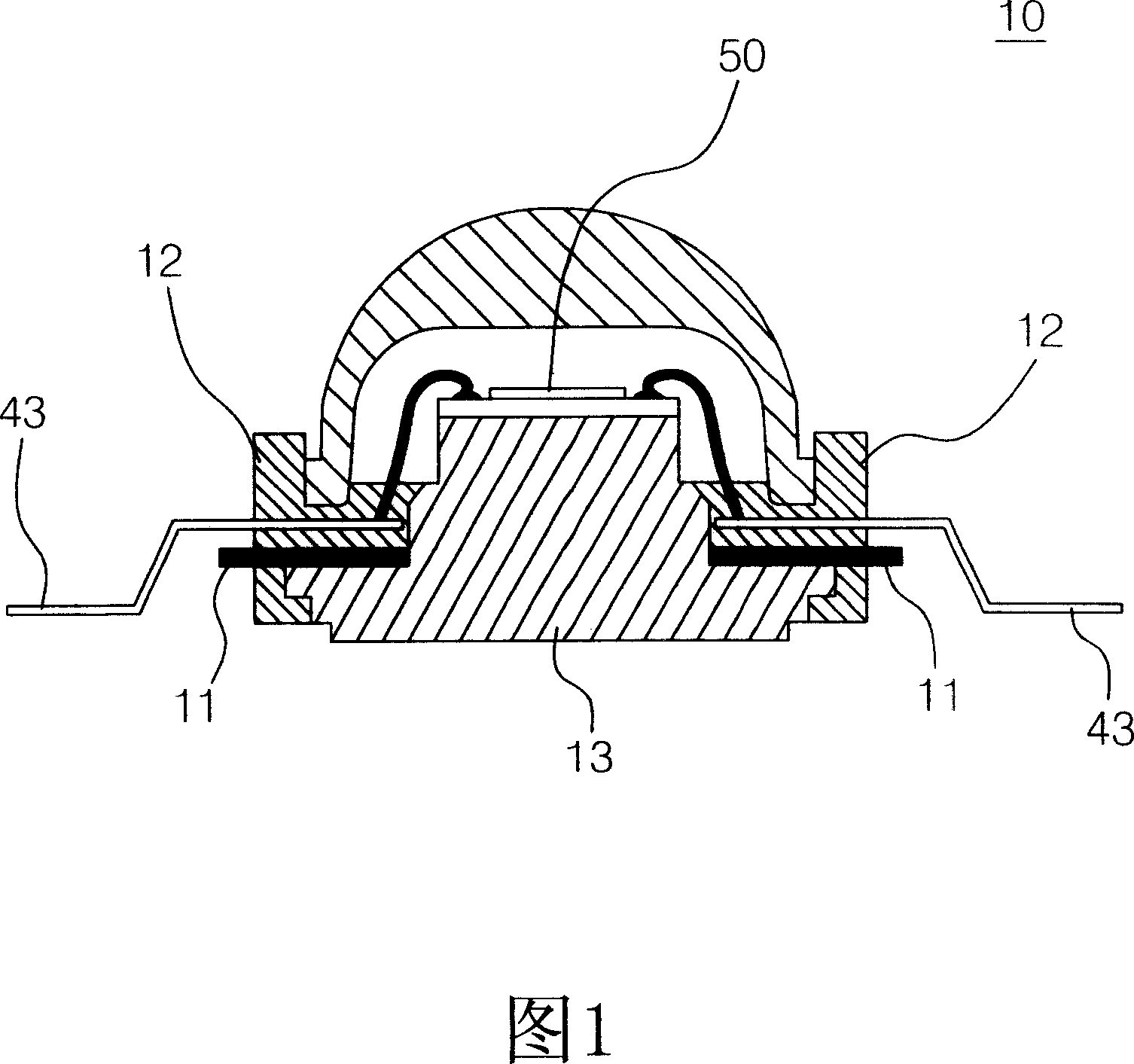

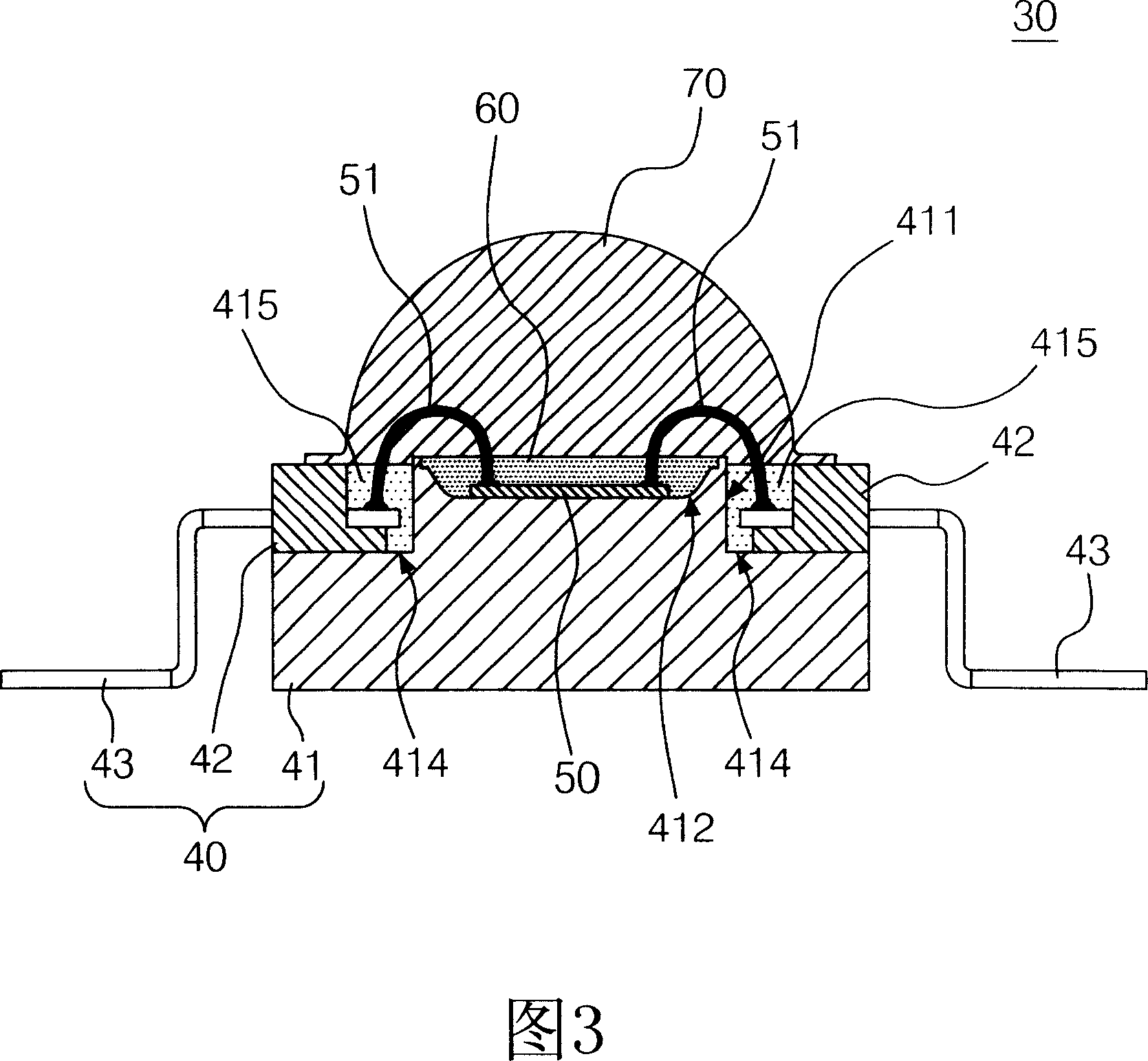

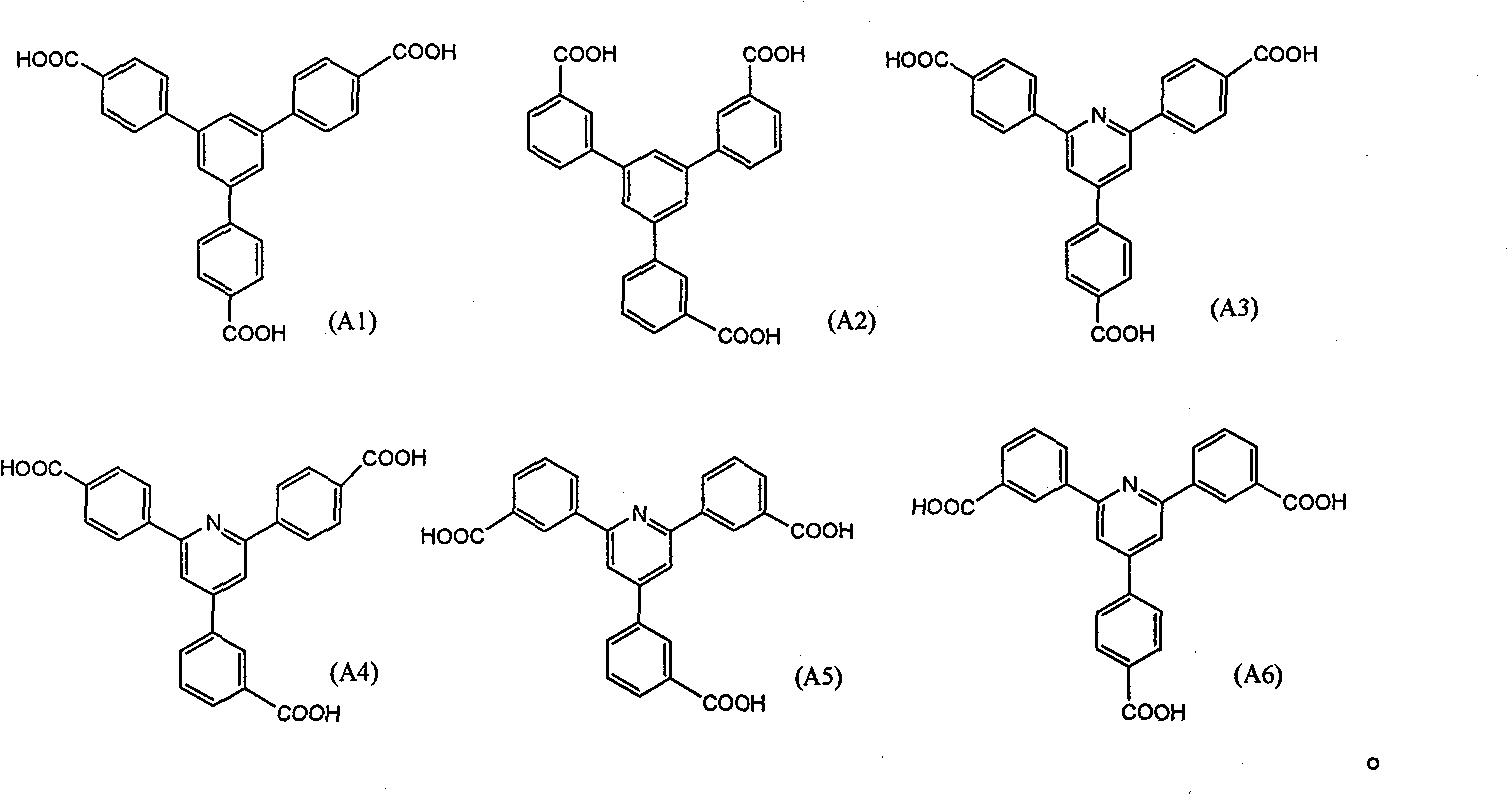

Manufacture method for diode light-emitting device and its structure

InactiveCN1953218AGood cooling efficiencyImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesThermal conductivityEngineering

The invention relates to a method for producing diode lighting device and relative structure. Wherein, said method comprises that combining the base with diode chip, wire setting and covered lighting layer on the mould filled with lens resin, or setting at least two pour holes on the base to combine the base and mould; then filling the lens resin via said pour holes into the mould. The invention can effectively improve the combine efficiency between lens and base; and the main body of lighting device is made from metal with better thermal conductivity, to improve radiate area.

Owner:TOP CRYSTAL TECH

Anticorrosive paint

InactiveCN102504674ANo change in flame retardancyConductivity unchangedAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention relates to an anticorrosive paint which comprises epoxy resin, carbon substances, metal and oxides thereof, a flame retardant, a heat insulating material, additives, a mixed solvent and a curing agent substance, wherein the epoxy resin is flame-retardant epoxy resin which is an additive flame-retardant epoxy resin formed by combination of common epoxy resin and the flame retardant or a reactive flame-retardant epoxy resin formed by combination of flame-retardant epoxy resin with a flame-retardant element and an inorganic flame retardant.

Owner:XIAN RUIJINYUAN ENERGY TECH

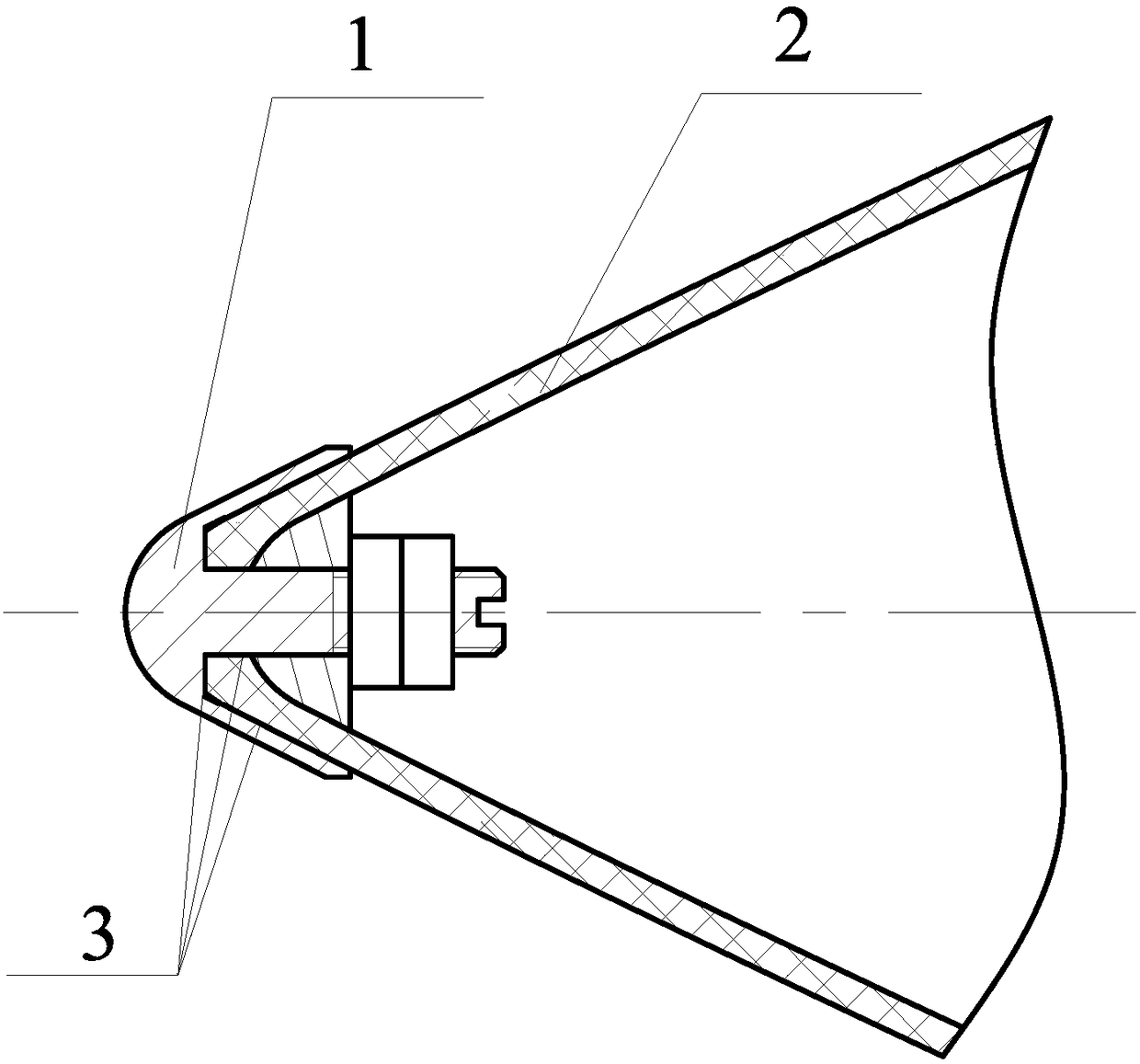

High-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing and preparation method thereof

ActiveCN108148548ASolve temperature resistanceAchieving adhesionNon-macromolecular adhesive additivesRadiating element housingsEpoxyAdhesive

The invention provides a high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing and a preparation method thereof. The high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing comprises an antenna housing body and a rainfall-erosion head, wherein the rainfall-erosion head is connected to the antenna housing body through a high-temperature-resistant wave transmission adhesive; the high-temperature-resistant wave transmission adhesive comprises epoxy-modified organic resin, mica powder, fumed silica, a silane coupling agent and an imidazole curing agent; the mica powder, the fumed silica, the silane coupling agent and the imidazole curing agent are sequentially added to the epoxy-modified organic resin. According to the high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing, a special intermediate-temperature normal-pressure curing type high-temperature-resistant wave transmissionadhesive is adopted, so that the rainfall erosion head and the housing body can be adhered in high temperature environment; the temperature resistance and reliability of the rainfall erosion head andthe housing body in connection are ensured; and the influence of the mounted rainfall erosion head on the electric performance of a wideband antenna housing can be overcome.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

PMMA ultrathin hot melt adhesive film as well as production method and application thereof

InactiveCN108003819AHigh mechanical strengthGood transparencyNon-macromolecular adhesive additivesMacromolecular adhesive additivesTemperature resistanceMethyl methacrylate

The invention relates to the application field of PMMA, in particular to a PMMA ultrathin hot melt adhesive film as well as a production method and application thereof. The hot melt adhesive film is mainly used in a traffic reflective film, and overcomes the defects that an existing hot melt adhesive film has unstable residual melting, poor high-temperature resistance, poor weatherability, and thelike. The hot melt adhesive film is prepared from the PMMA, methyl methacrylate-butadiene-styrene terpolymer, rutile type titanium dioxide and a tackifier, and the weight percentages are 80% to 90% of the PMMA, 3% to 10% of the methyl methacrylate-butadiene-styrene terpolymer, 3% to 10% of the rutile type titanium dioxide, and 1% to 10% of the tackifier. The production method and an application process of the PMMA ultrathin hot melt adhesive film are shown in the figures. The production method comprises the steps of mixing, granulation, extrusion calendering and lamination.

Owner:福建新力元反光材料有限公司

Manufacture method of high-temperature resistant glass reinforced plastics mould

The invention belongs to the field of aviation material composites and in particular relates to a manufacture method of a high-temperature resistant glass reinforced plastics mould. Due to the adoption of a glass fiber reinforced polymer based composite technology, the manufacture of a large composite part forming tool can be realized; a glass reinforced plastic forming mould which meets the cost requirement and the usage requirement is manufactured. The invention discloses a low-cost glass reinforced plastic mould capable of being cured and demoulded at 100 DEG C and resisting a temperature of 160 DEG C, so that the rigidity and the temperature resistance of the mould can meet the use requirement; meanwhile, the mould is low in cost and light in weight, and can be used repeatedly; the technical problems of temperature resistance and high cost of a large aviation composite product forming mould can be solved.

Owner:SHAANXI AIRCRAFT CORPORATION

Low-water-absorption glass fiber reinforced halogen-free flame-retardant polyamide material and preparation method thereof

The invention relates to a low-water-absorption glass fiber reinforced halogen-free flame-retardant polyamide material and a preparation method thereof, and belongs to the technical field of high polymer materials. The material comprises the following components: a polyamide resin, a graft, an alkyl phenolic vulcanized resin, glass fiber, a flame retardant, a thermal stabilizing aid, a processinglubricant and silicone oil. According to the invention, a certain amount of glass fibers and a certain amount of a flame retardant are added into a polyamide resin to carry out flame retardance and reinforcement modification on the polyamide resin, so that the final material has the advantages of environmental protection, flame retardance, high strength, good temperature resistance and the like; more importantly a certain amount of an alkyl phenolic vulcanized resin and graft are added into the polyamide resin, so that the water absorption of the finally prepared glass fiber reinforced halogen-free flame-retardant polyamide material can be effectively reduced, the problems of poor dimensional stability, poor mechanical properties, poor electrical properties and the like caused by hygroscopicity are solved, and the advantages of small addition amount, high efficiency, low cost, no influence on material properties and the like are achieved; and the preparation method of the material is simple, easy to operate, low in equipment requirement and suitable for expanded production.

Owner:重庆科聚孚新材料有限责任公司 +1

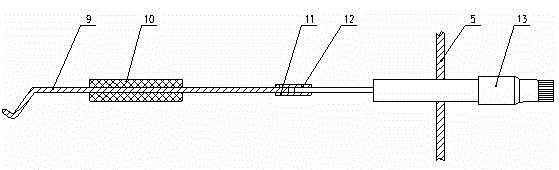

Hot air type combustor

ActiveCN105066125ASolve temperature resistanceReduce external surface temperatureGaseous fuel burnerThermal insulationFire detection

The invention discloses a hot air type combustor. The hot air type combustor comprises a fuel butterfly valve, an air ventilation door, an adjusting mechanism assembly, a cooling air inlet and a combustor shell. The combustor shell comprises an outer shell body, an inner shell body and non-asbestos alumina silicate fiber cotton. An ignition needle device comprises an ignition needle and a ceramic bar installed outside the ignition needle. The bottom of the air ventilation door is connected with a ventilation door assembly. The ventilation door assembly comprises a ventilation door frame, a ventilation door shaft, a temperature sensor and a servo adjusting motor. The combustor shell is further provided with a fire detection thermal insulation sleeve. The fire detection thermal insulation sleeve comprises a flame monitor and a thermal insulation glass cover. A combustion head adjusting barrel assembly is arranged behind the fuel butterfly valve and comprises an air pressure adjusting barrel, an adjusting pull rod and a fuel gas mixing head. The hot air type combustor achieves the aim of temperature resisting of the ignition needle and the flame monitor, the temperature of the outer surface of the combustor is reduced, and pressure adjustment on the ventilation door and the fuel combustion head of the combustor can be automatically carried out along with the temperature change.

Owner:上海凌云瑞升燃烧设备有限公司

A hot air burner

ActiveCN105066125BSolve temperature resistanceReduce external surface temperatureGaseous fuel burnerFiberGlass cover

Owner:SHANGHAI LINGYUN RUISHENG COMBUSTION EQUIP CO LTD

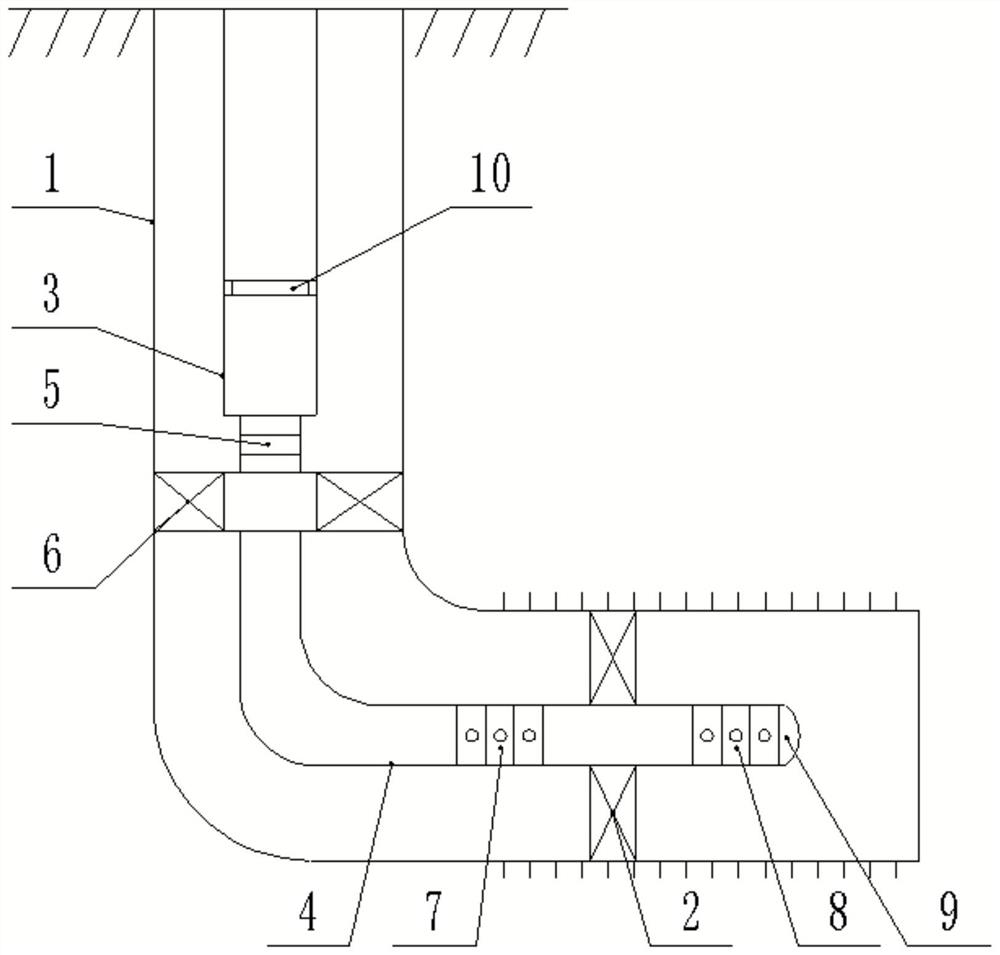

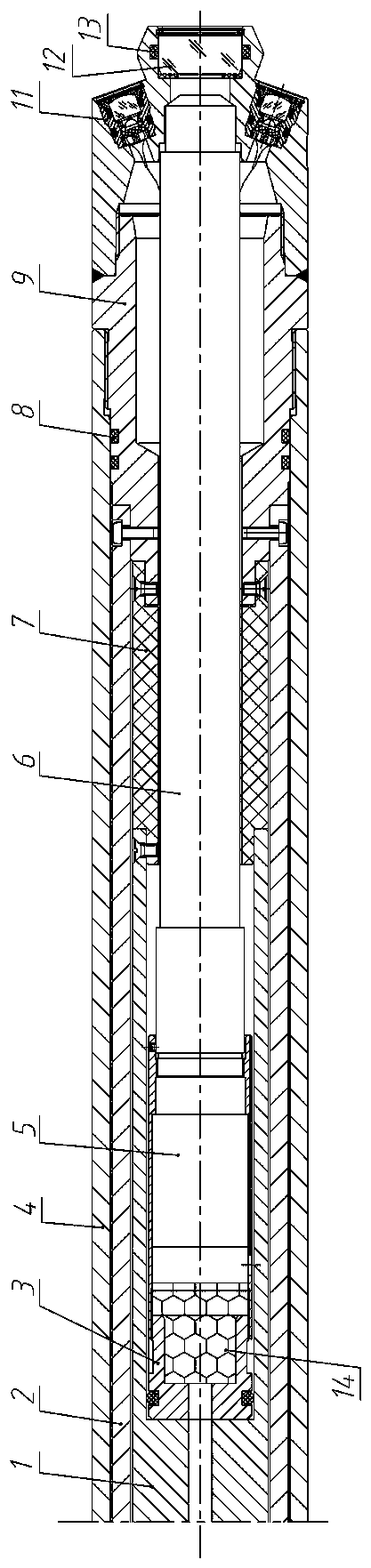

Heavy oil recovery method integrating heat injection oil production and mechanical oil production

ActiveCN109854217AReduce the temperatureSolve temperature resistanceFluid removalRecovery methodEngineering

The invention provides a heavy oil recovery method integrating heat injection oil production and mechanical oil production. The method includes the following concrete steps: S1. performing preparationwork; S2. placing a combined heat injection pipe column in a wellbore; S3. after placing the combined heat injection pipe column, installing an oil production tree, and implementing a heat injectionprocess after installing the oil production tree; S4. performing self-spraying production, measuring the temperature of produced fluid, and providing a basis for subsequent selection of a temperatureresistance level of a mechanical plucking machine tool; S5. placing the mechanical plucking machine tool; and S6. performing mechanical plucking. According to the method, the wellbore and a heat injection pipe column with large diameter are first placed, and then heat injection is performed; after the heat injection and the self-spraying production are completed, the heat injection pipe column isnot required to be moved, the oil production tree is not required to be removed, the mechanical plucking machine tool only needs to be connected by a continuous oil pipe, the mechanical plucking machine tool is sent to a predetermined position seat seal in the heat injection pipe column, then the mechanical plucking can be achieved, and so, the contradiction between temperature resistance of the mechanical plucking machine tool and high temperature of the heat injection oil production is solved well under existing technical conditions, and an important technical means is provided for development of heavy oil.

Owner:天津克睿特维科技发展有限公司

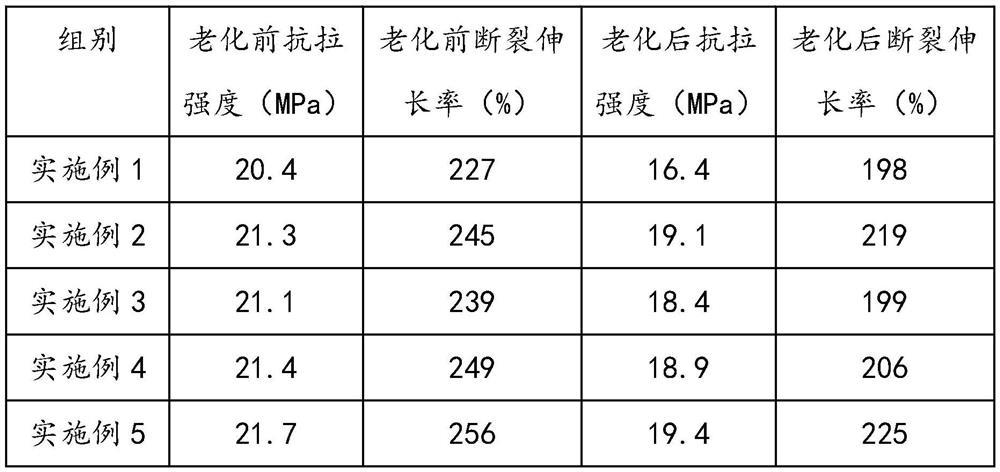

Polyvinyl chloride cable composite material and preparation method and application thereof

InactiveCN113004637ASolve wear resistanceSolve temperature resistancePlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

The invention relates to the technical field of insulated cable production, and particularly discloses a polyvinyl chloride cable composite material and a preparation method and application thereof, and the polyvinyl chloride cable composite material comprises the following raw materials: polyvinyl chloride resin, a plasticizer, nano calcium carbonate, a stabilizer, MBS resin, calcined kaolin, argil, a flame retardant and butyl stearate. Through reasonable use of various raw materials, compared with an insulation protection layer prepared from rubber, the wear resistance and the temperature resistance can be effectively improved, and the problem that an existing insulation cable cannot have good wear resistance and temperature resistance when rubber is adopted as an insulation material is solved. Moreover, the preparation method of the polyvinyl chloride cable composite material provided by the embodiment of the invention is simple, other types of insulating materials can be prepared for preparing insulated cables, and the polyvinyl chloride cable composite material has a wide market prospect.

Owner:庄飞电缆有限公司

0.022 mm temperature-tolerance decoration foil and preparation method thereof

The invention relates to a 0.002 mm temperature-tolerance decoration foil and a preparation method thereof. The decoration foil is characterized by being made by adding 0.10-0.20 percent by weight of Cu element on the basis of 8011 alloy. The preparation method comprises the following process procedures: cold-rolling a cast-rolling plate into 0.44-0.85 mm from 6.0-10.0 mm, adopting an H22 status for interannealing, cold-rolling to 0.28-0.60 mm, foil-rolling to reach a finished thickness of 0.022 mm, and slitting, wherein the H22 status annealing process comprises the following steps: adoptinga burner-gas temperature controlling way for annealing, namely, charging below 100 DEG C, heating 1.5 hours till the temperature reaches 350-450 DEG C, and preserving the temperature for 5-15 hours; cooling for 0.5 hour till the temperature reaches 320-380 DEG C, preserving the temperature for 5-15 hours, cooling for 1.5 hours till the temperature reaches 200 DEG C, and discharging; and achievingthe total processing ratio being more than 95 percent after interannealing. The invention has good temperature tolerance and stable quality.

Owner:新疆天展新材料科技有限公司

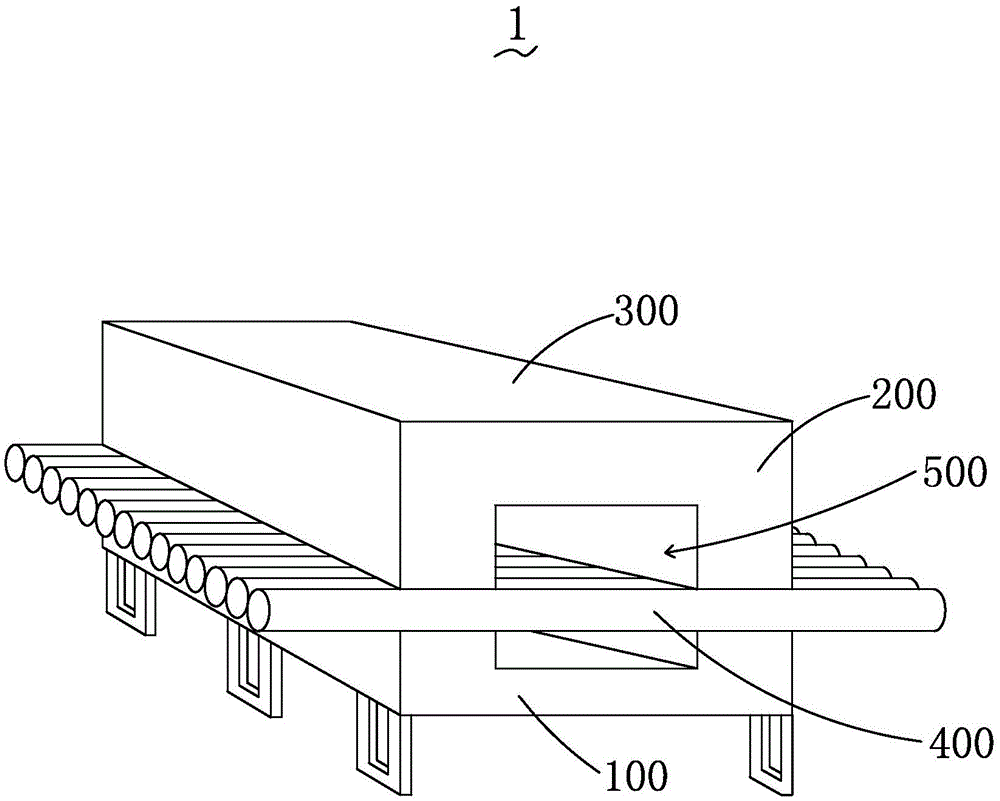

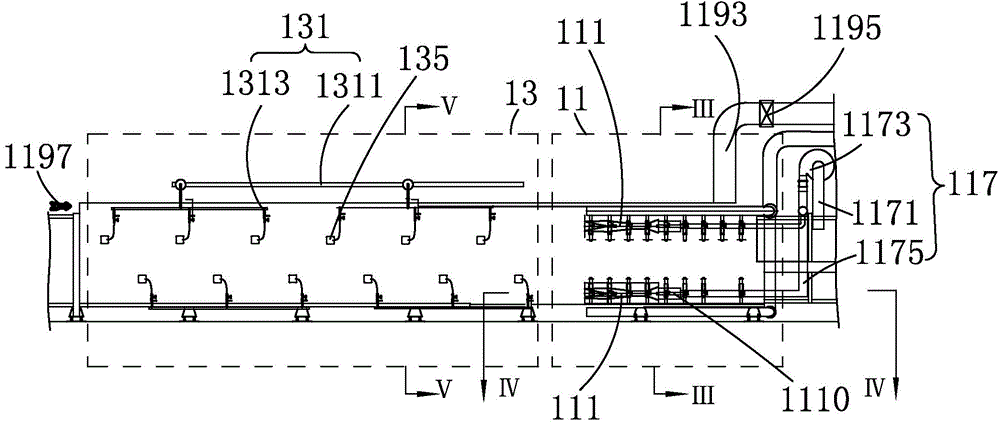

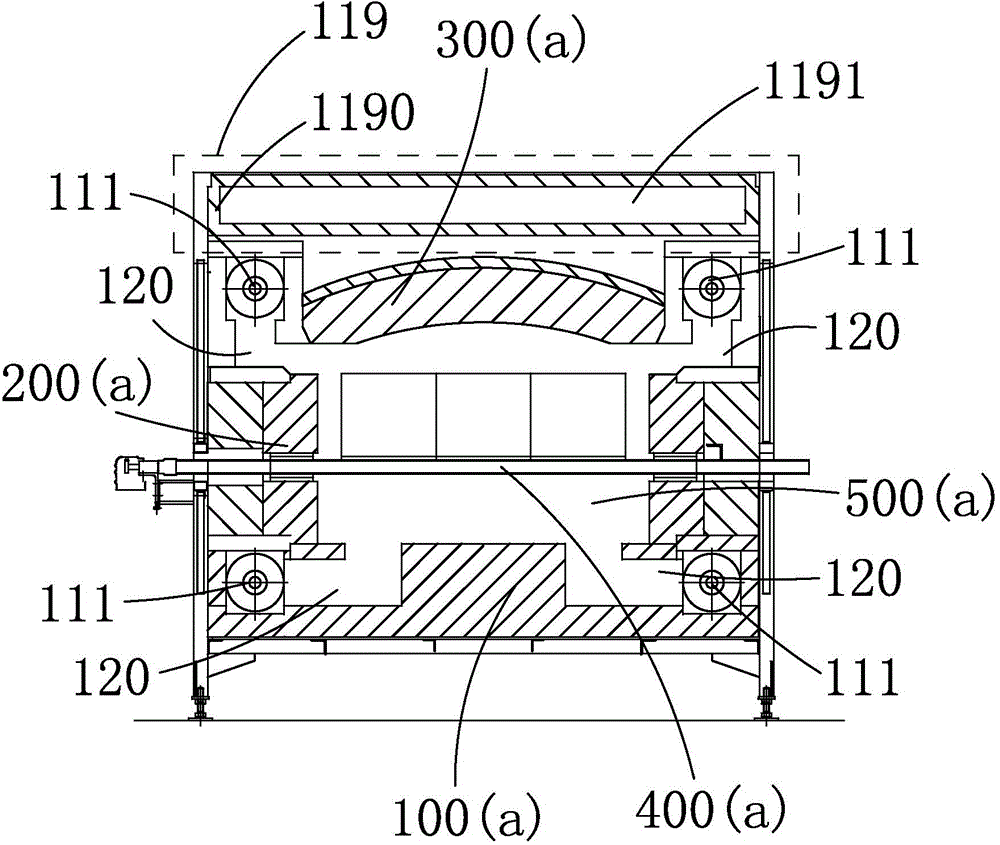

Roller kiln and working method thereof

InactiveCN104807324AMeet delivery requirementsIncrease temperatureCombustion processFurnace typesCombustorEngineering

The invention provides a roller kiln and a working method thereof. The roller kiln comprises an injection mixer, a high temperature waste heat air duct, an injection burner and a waste heat air system; the roller kiln is divided into a preheating section, a firing section and a cooling section along the direction of movement of products; the injection mixer is arranged on the cooling section; the injection burner is arranged on the firing section; the high temperature waste heat air duct is communicated with the cooling section and the firing section; the waste heat air system is arranged at the top of the firing section and the top of the cooling section; the injection mixer is of a concealed venturi tube structure and the injection burner is of a concealed venturi tube structure. According to the roller kiln and the working method thereof, the injection mixer which is of a venturi tube structure is added into the roller kiln so as to directly suck the high temperature waste heat air of a cooling zone of the roller kiln to be pressurized and conveyed to the injection burner of a firing zone and accordingly the high temperature waste heat is well utilized, the sufficient burning is ensured, the energy is saved, and the production workshop environment is improved.

Owner:HUNAN OTLAN IND EQUIP

A heavy oil recovery method integrating thermal injection recovery and mechanical recovery

ActiveCN109854217BReduce the temperatureSolve temperature resistanceFluid removalThermodynamicsCoiled tubing

The present invention is a heavy oil recovery method integrating heat injection recovery and mechanical oil recovery. The specific steps are: S1, preparatory work; S2, running a combined heat injection string in the wellbore; S3, after running the heat injection string, Install the christmas tree, and after the christmas tree is installed, implement the heat injection process; S4, self-spray production, measure the temperature of the output fluid, and provide a basis for the subsequent selection of the temperature resistance level of the mechanical mining tool; S5, lower the mechanical mining tool; S6, Machine mining. In the present invention, the large-diameter wellbore and the heat injection string are lowered first, and then heat injection is performed; after the heat injection and self-spraying production are completed, no dynamic heat injection string is required, and the oil tree is not required to be dismantled, only the coiled tubing is needed to connect The mechanical mining tools are sent to the predetermined position in the heat injection pipe string for sealing, and then the mechanical mining can be realized, which solves the contradiction between the resistance of the mechanical mining tools and the high temperature of the thermal injection oil production under the existing technical conditions. Oil development provides an important technical means.

Owner:天津克睿特维科技发展有限公司

A kind of manufacturing method of high temperature resistant glass fiber reinforced plastic mold

The invention belongs to the field of aviation material composite materials, in particular to a method for manufacturing a high-temperature-resistant glass fiber reinforced plastic mold. Using glass fiber reinforced polymer-based composite material technology, the manufacturing problem of large-scale composite material parts forming tooling is solved, and a glass fiber reinforced plastic forming mold that meets the cost and use requirements is manufactured. The invention proposes a 160°C low-cost FRP mold that can be solidified and demolded at 100°C, so that the rigidity and temperature resistance of the mold can meet the requirements of use, and the cost is low, the weight is light, and it can be used repeatedly. It solves the technical problems of high temperature resistance and high cost of forming molds for large-scale aviation composite materials.

Owner:SHAANXI AIRCRAFT CORPORATION

A kind of interface reinforcing emulsion type sizing agent for carbon fiber and preparation method thereof

The invention provides an interface-enhancement emulsion type sizing agent used for carbon fibers, and a preparation method thereof, and belongs to the technical field of carbon fiber sizing agents. The sizing agent comprises a main slurry, an emulsifier, a coupling agent and deionized water, the main slurry comprises polyaryletherketone resin and an organic solvent according to a mass percentage ratio of (5-30):(70-95), the mass of the emulsifier is 5-20% of the mass of the main slurry, the mass of the coupling agent is 1-10% of the mass of the main slurry, and a mass percentage ratio of the deionized water to the main slurry is (60-90):(10-40). The polyaryletherketone resin having a high heat stability is used as the main component to prepare the emulsion type sizing agent for carbon fibers, so the temperature tolerance problem of the sizing agent is solved; and the polyaryletherketone resin has good compatibility with epoxy resin, and can participate in the curing reaction of the epoxy resin, so the bonding performance of the epoxy resin and the fibers is greatly improved, thereby the interlace shearing strength of a composite material is improved.

Owner:芜湖万隆新材料有限公司

Kepler type light beam imaging pattern lamp

ActiveCN111720800AQuick correctionClear boundariesNon-linear opticsLight fasteningsBeam angleLiquid-crystal display

The invention discloses a Kepler type light beam imaging pattern lamp. The Kepler type light beam imaging pattern lamp comprises a shell and a built-in assembly; the built-in assembly sequentially comprises a light source assembly, a condensing lens set, a liquid crystal display assembly, an electronic refrigeration assembly and a light receiving lens set; the liquid crystal display assembly comprises a liquid crystal display screen, and miniature temperature sensors are laid around the liquid crystal display screen; the electronic refrigeration assembly is a semiconductor refrigeration sheet;the liquid crystal display assembly and the electronic refrigeration assembly are fixed through a heat conduction plate and embedded in an upper installation cavity and a lower installation cavity ofthe heat conduction plate respectively; and a control module is arranged on the side surface of the shell, and the control module is electrically connected with the liquid crystal display assembly, the electronic refrigeration assembly and a power source. According to the Kepler type light beam imaging pattern lamp, the integrated design of a beam lamp and a pattern lamp is achieved; beam angle change and pattern form change are achieved through a transparent liquid crystal screen, and pattern source data are directly written into a control module of the transparent liquid crystal screen to achieve rapid display and rapid pattern correction; and the heat conduction plate and the electronic refrigeration sheet are added as cooling devices of the transparent liquid crystal screen, and therefore the temperature resistance problem of the liquid crystal screen can be effectively overcome.

Owner:上海艾葛诺照明科技有限公司

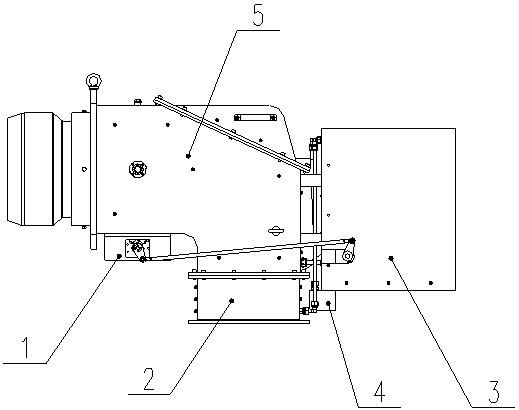

Down-hole video instrument

PendingCN110242282ASimple structureAvoid failureConstructionsGeothermal energy generationImage sensorHigh pressure

The invention relates to a down-hole video instrument, in particular to a photoelectric composite cable instrument for oil-and-gas well logging. The down-hole video instrument is mainly used for detecting whether a pipe is deformed and corroded or bubbling due to casing damage, and finishing fallen things, especially used in worse environments of the sea or oil-and-gas wells. The down-hole video instrument includes a pressure bearing outer pipe and a hollow lower joint, the lower joint is connected to one end of the pressure bearing outer pipe, and the end connected the pressure bearing outer pipe and the lower joint is the tail end of the pressure bearing outer pipe. According to the down-hole video instrument, the structure is simple, the pressure bearing outer pipe bearings high pressure of working environments, external high pressure transmitted to an image sensor in an axial direction through a lens is alleviated, the image sensor is a heating source, heat is transferred to an endothermic body by a regulating casing, and image sensor failure due to excessive temperature is avoided.

Owner:西安威盛电子科技股份有限公司

Kepler type light beam imaging pattern lamp

PendingCN113983426AQuick correctionClear boundariesLight fasteningsNon-linear opticsBeam angleLiquid-crystal display

Owner:SHANGHAI AIGENO LIGHTING TECH CO LTD

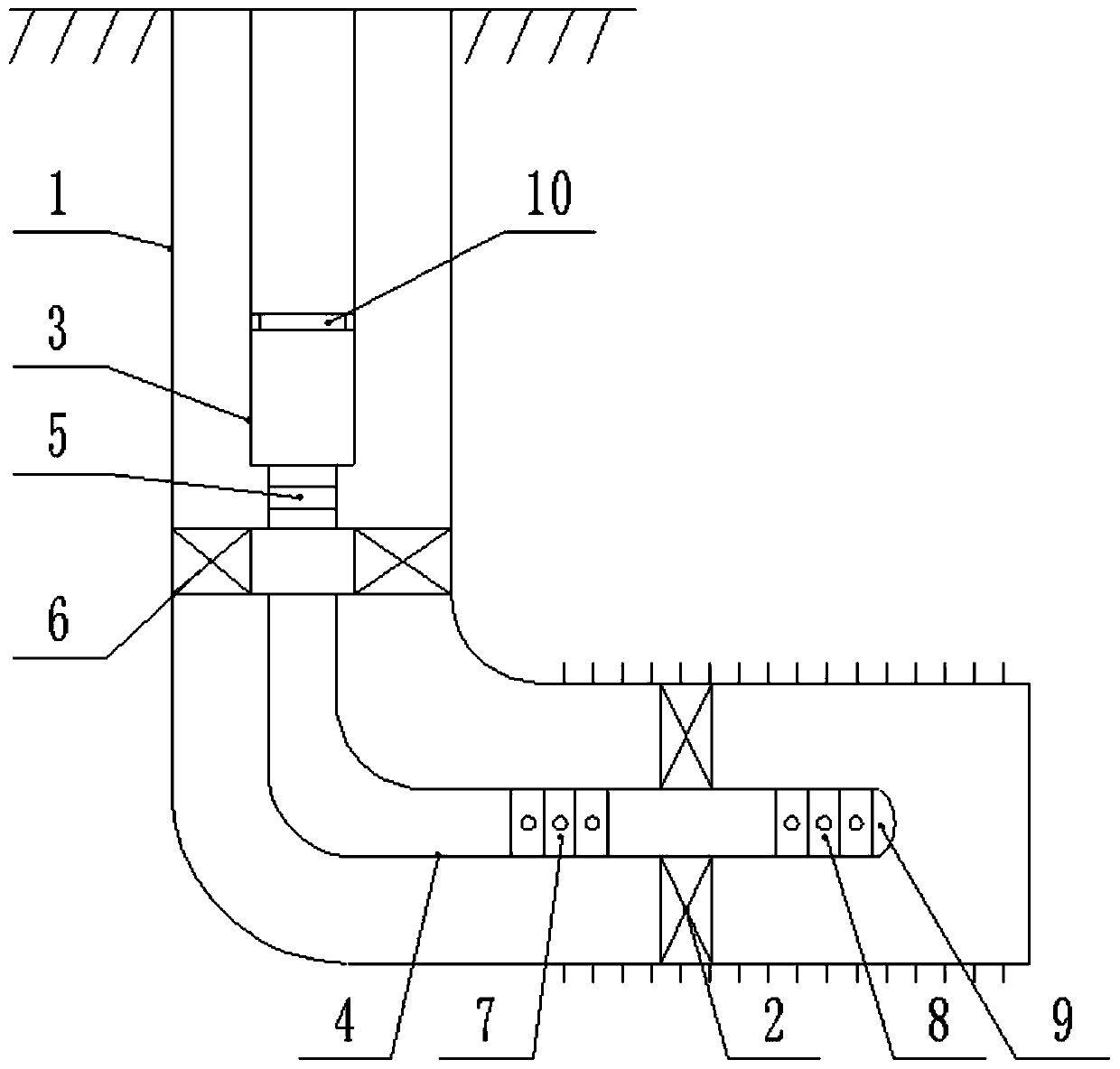

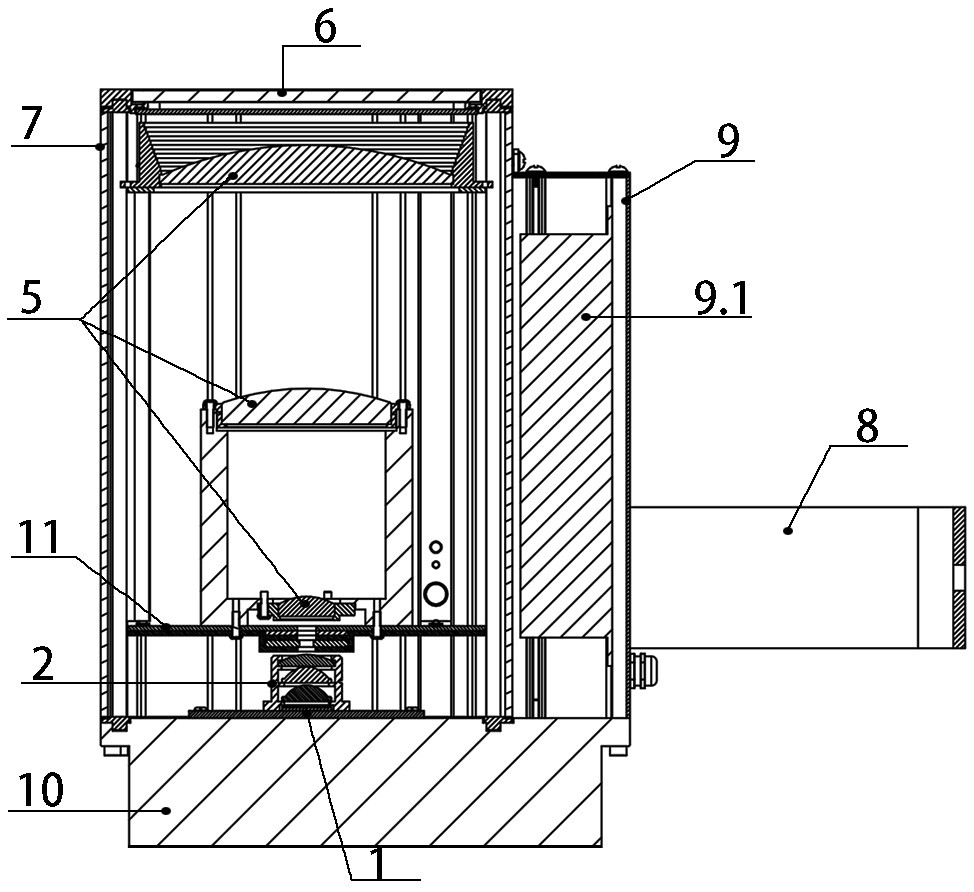

Method for utilizing waste heat of low-concentration combustible materials in tail gas of Slapple furnace

InactiveCN103604128BExtended burn timeSolve temperature resistanceIncinerator apparatusSteam generation using hot heat carriersCombustion chamberInternal resistance

The invention provides a method for utilizing waste heat of low-concentration combustible materials in tail gas of a Slapple furnace. The technical scheme includes that the low-concentration tail gas with a heat value lower than 450Kcal / m<3> flows into a 'U'-shaped settling chamber (5), is subjected to inertial separation and then flows into a secondary combustion chamber (6), air is distributed in the secondary combustion chamber by the aid of an air distribution chamber (7) and is ignited by a heat accumulator (16) with the temperature ranging from 400 DEG C to 600 DEG C, the combustible tail gas is ignited, is sufficiently combusted in a combustion chamber (8) with a long flue and is gradually expanded in the long flue, combusted high-temperature flue gas flows into a heat-pipe heat exchanger (10) at a low flow rate, internal resistance of the heat exchanger is lower than 10mmH<2>O, a coal economizer (13) performs heat exchange, the tail gas flows through desulfurization dust removal equipment (15) and then is exhausted into the atmosphere, and high-grade steam generated in a waste heat boiler (9) flows to a heat accumulation chamber (2) to be supplied to the Slapple activation furnace (1), so that activated carbon can be manufactured. The method has the advantages that the low-grade waste heat can be sufficiently utilized, pollution emission can be reduced, and a system is high in reliability and can be operated and maintained easily and conveniently.

Owner:ZHONGBEI UNIV +1

Crosslinked polybenzimidazoles thin film containing sulfonic group and preparation thereof

InactiveCN101481457BSolve temperature resistanceSolve the problem of acid lossSolubilityDiphenyl ether

The invention relates to a crosslinked polybenzimidazole film containing sulfo group and a method for preparing the same. The invention is characterized in that the raw material proportions of the crosslinked polybenzimidazole film are as follows: (1) 10 proportions of 3,3',4,4'-tetraamino diphenyl ether by weight; (2) 5-10 proportions of aromatic triacid by weight; (3) 2-3 proportions of 1,2-naphthoquinone-4-ammonium sulphonate by weight; (4) 0.5-2 proportions of PEB by weight; (5) 100-200 proportions of organic solvent by weight; and (6) 200-300 proportions of polyphosphoric acid by weight. The film can effectively regulate the molecular weight of the branched polybenzimidazole and the structure of the crosslinked film by controlling the raw material proportions. The obtained polybenzimidazole has excellent solubility as well as higher thermal stability, better transparence, excellent corrosion resistance and high proton conduction rate, and the like.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Epoxy resin binder as well as preparation method and application thereof

PendingCN114196358ASolve temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer chemistryFirming agent

The invention discloses an epoxy resin binder as well as a preparation method and application thereof. The epoxy resin binder is obtained by mixing and curing a component A and a component B, the component A is prepared from the following components in parts by weight: 100 parts of epoxy resin, 18 to 40 parts of phenolic resin, 5.5 to 14 parts of resorcinol, 3.5 to 16.5 parts of toughening agent, 15 to 45 parts of inorganic modified filler and 0.5 to 2.5 parts of reinforcing agent; the component B comprises a first curing agent and a second curing agent, and the weight ratio of the first curing agent to the second curing agent is (2-12): (0.5-2.5). The bonding strength of the epoxy resin adhesive at normal temperature is 25 MPa or above, the bonding strength is 12 MPa or above after the epoxy resin adhesive is kept at 200 DEG C for 10 minutes, the bonding strength is 6 MPa or above after the epoxy resin adhesive is kept at 280 DEG C for 10 minutes, and the problem of temperature resistance of the epoxy resin adhesive at the temperature of 250 DEG C or above within a short time can be solved.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Nylon 12 extrusion coating material for new energy automobile

The invention discloses a nylon 12 extrusion coating material for a new energy automobile, which comprises the following components: nylon 12 with 100 parts by weight of nylon 12, 50-60 parts of butadiene, 0.1-1 part of a modification additive, 5-8 parts of polytetrafluoroethylene powder, 5-25 parts of an EVA copolymer, 1-5 parts of mica powder, 2-5 parts of a wear-resistant agent, 2-3 parts of a POE elastomer and 0.2-1 part of silicone powder. The preparation method of the nylon 12 comprises the following steps: 1) preparing materials and weighing: sequentially preparing 100 parts by weight of nylon 12 and 50-60 parts by weight of butadiene; the silicone powder is selected to improve the flowability and the processability of the material, and the EVA copolymer, the polytetrafluoroethylene powder, the mica powder and the POE elastomer are selected as materials for improving the temperature resistance and the processability, so that the material has the advantage of good temperature resistance; the problems that the temperature resistance and the processability of an existing nylon 12 extrusion coating material are effectively improved, metal pieces such as copper, iron and aluminum cannot be effectively coated, and the existing nylon 12 extrusion coating material is not suitable for long-term use in a high-temperature environment are solved.

Owner:青岛瑞益信新材料科技有限公司

Manufacture method for diode light-emitting device and structure thereof

InactiveCN100481537CSolve temperature resistanceSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesEffect lightMetallic materials

The invention relates to a method for producing diode lighting device and relative structure. Wherein, said method comprises that combining the base with diode chip, wire setting and covered lighting layer on the mould filled with lens resin, or setting at least two pour holes on the base to combine the base and mould; then filling the lens resin via said pour holes into the mould. The invention can effectively improve the combine efficiency between lens and base; and the main body of lighting device is made from metal with better thermal conductivity, to improve radiate area.

Owner:TOP CRYSTAL TECH

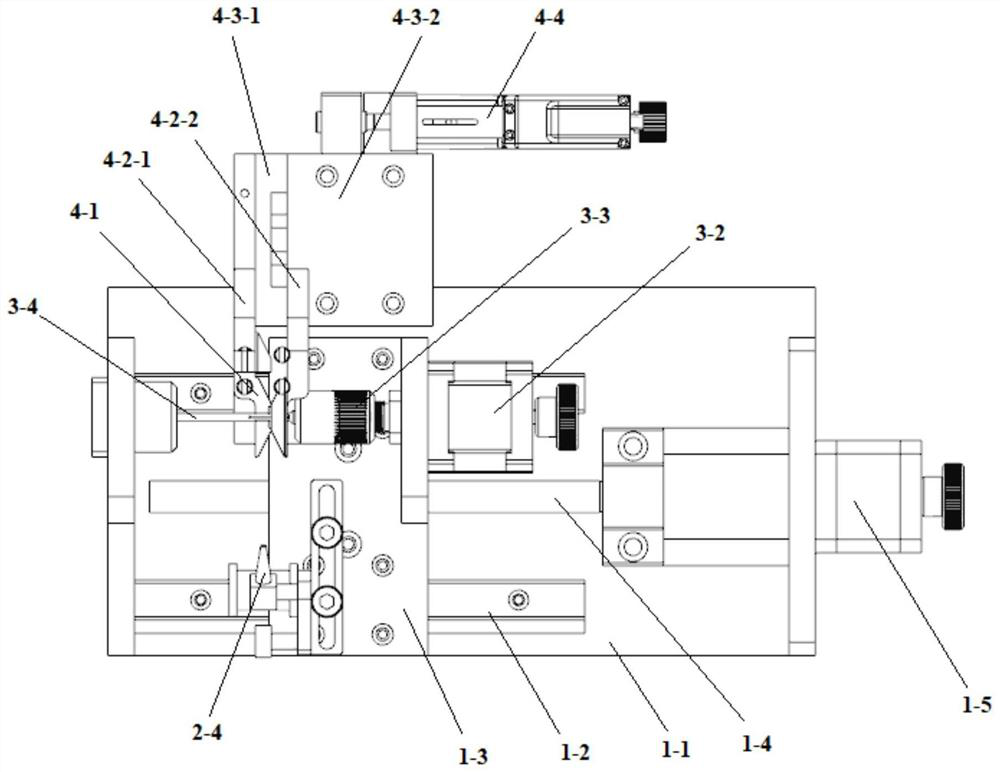

Device and method for manufacturing high temperature resistant displacement sensor probe based on planar coil

ActiveCN110864614BGuaranteed SensitivityGuaranteed measurement rangeUsing electrical meansInductances/transformers/magnets manufactureBobbinElectric machine

The invention discloses a high-temperature-resistant displacement sensor probe manufacturing device and method based on a planar coil, which includes a displacement control unit, a wire feeding unit and a winding drive unit arranged on the displacement control unit, and a detachable installation with the winding drive unit. Planar coil fixed unit. The metal wire is sent into the middle of the fixed clip through the wire feeding unit and fixed on the winding shaft. The winding motor drives the winding shaft to rotate and is wound into a planar coil between the two fixed clips. The planar coil and the ceramic sheet are bonded with ceramic glue. for encapsulation. The invention has controllable cost, high reliability, and is convenient for batch production. The coil material, wire diameter, and coil size can be independently selected to manufacture suitable planar inductance coils, and the problems of making and forming non-self-adhesive planar coils are solved. The planar inductance sensor probe made of high temperature resistant materials can be used for non-contact measurement in harsh environments above 1000°C, which solves the problem of sealing processing and temperature resistance of sensor probes in extremely high temperature environments.

Owner:西安瑞谱捷特动力技术有限公司

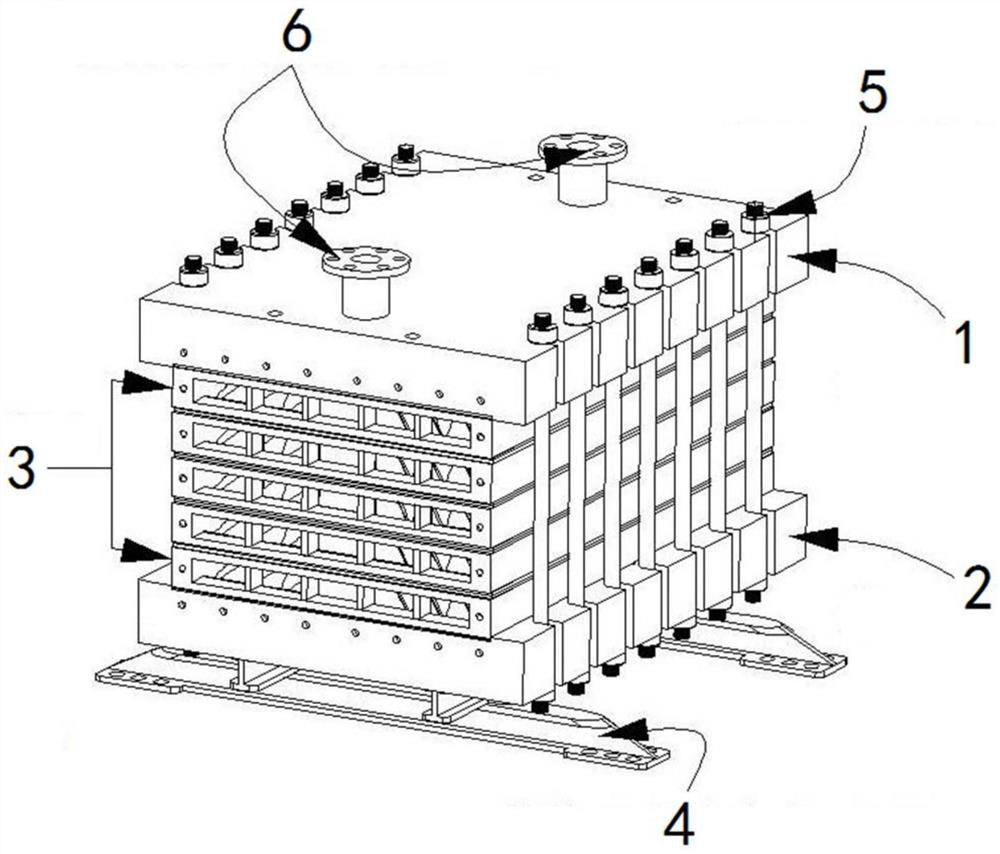

Pressure-bearing supporting type heat exchanger

PendingCN112728976AIncreased pressure rangeMeet pressure requirementsHeat exchanger casingsLaminated elementsLower faceMechanical engineering

The invention relates to a pressure-bearing supporting type heat exchanger. The pressure-bearing supporting type heat exchanger comprises a heat exchanger body, the heat exchanger body is formed by assembling a first clamping plate, a second clamping plate and a heat exchange plate bundle, and the heat exchange plate bundle is formed by superposing a plurality of pressure-bearing supporting framework combination units. Each pressure-bearing supporting framework combination unit is formed by assembling a pressure-bearing supporting framework and heat exchange plates arranged on the upper face and the lower face of the pressure-bearing supporting framework. Under the condition that the body structure of the heat exchange equipment is not changed, the purpose and the function of the equipment can be changed by additionally arranging end sockets required by the working condition at the two ends, so that the heat exchanger is manufactured in an integrated manner and assembled and maintained in a modular manner, the manufacturing cost is reduced, the manufacturing, assembling and maintaining efficiency is improved, and the service cycle of the equipment is prolonged.

Owner:张福成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com