Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Achieving Adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

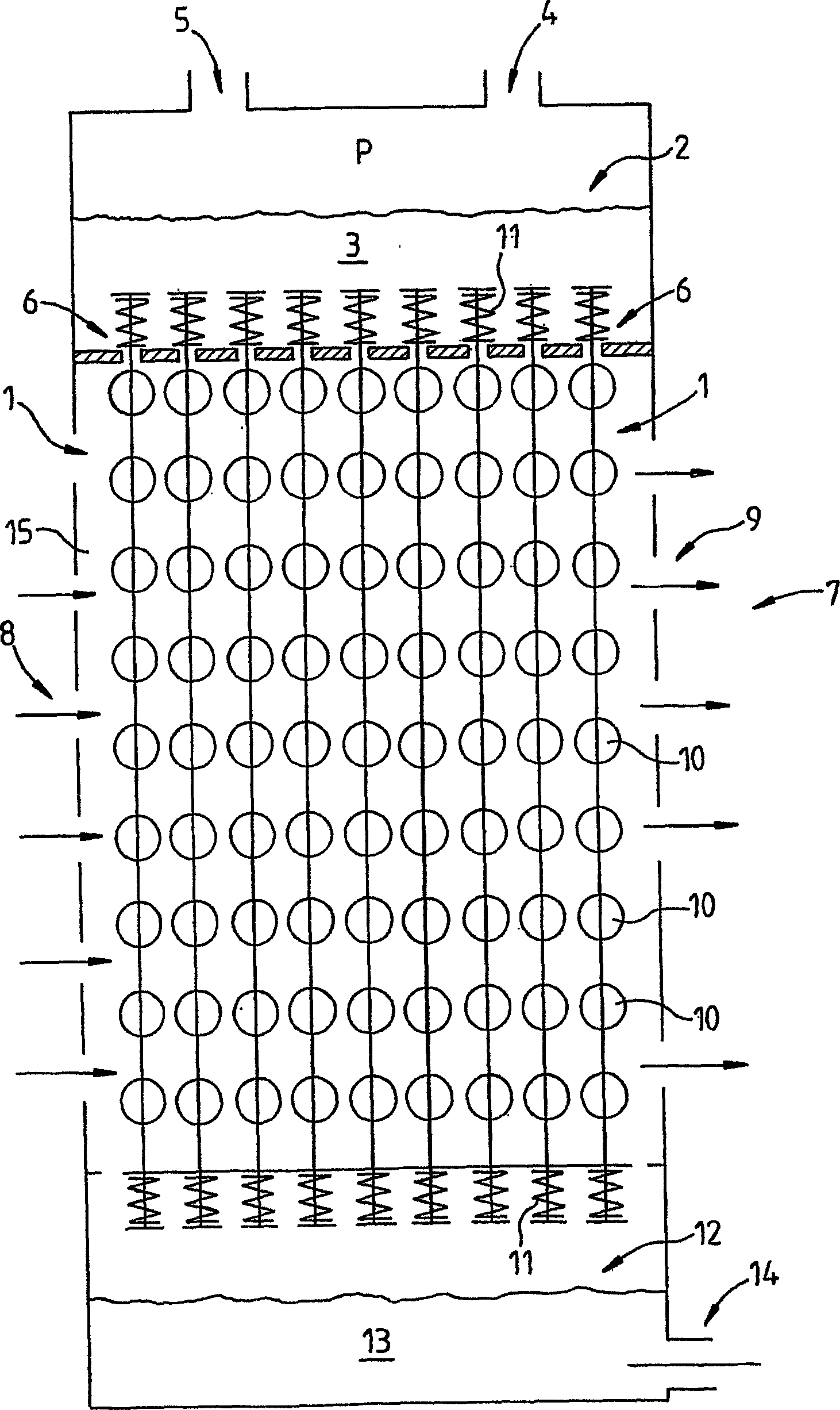

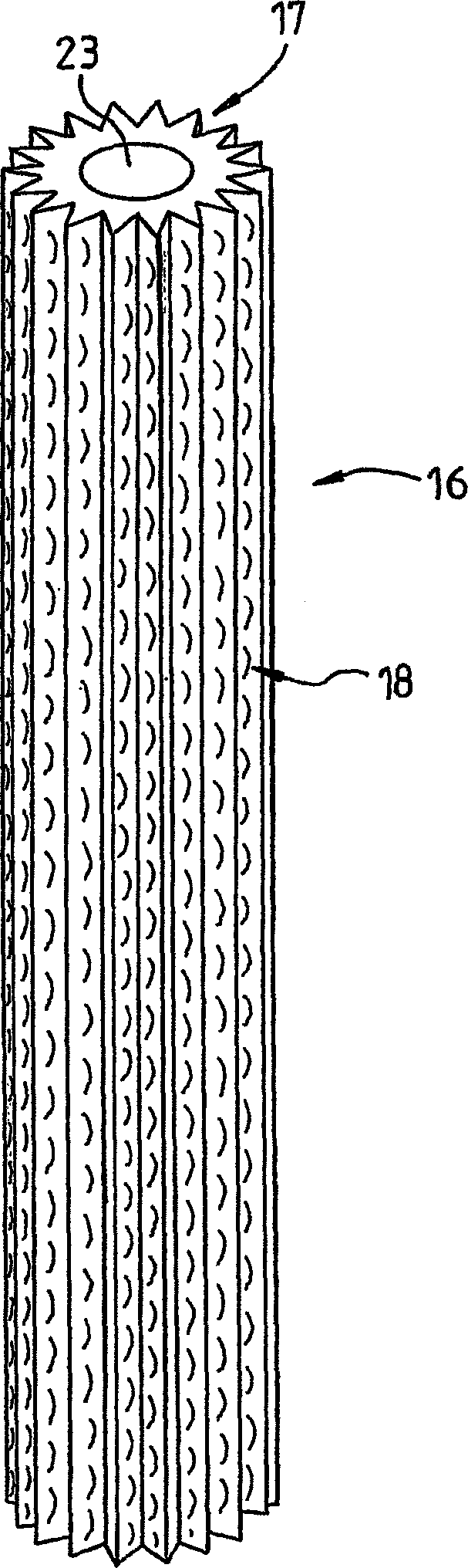

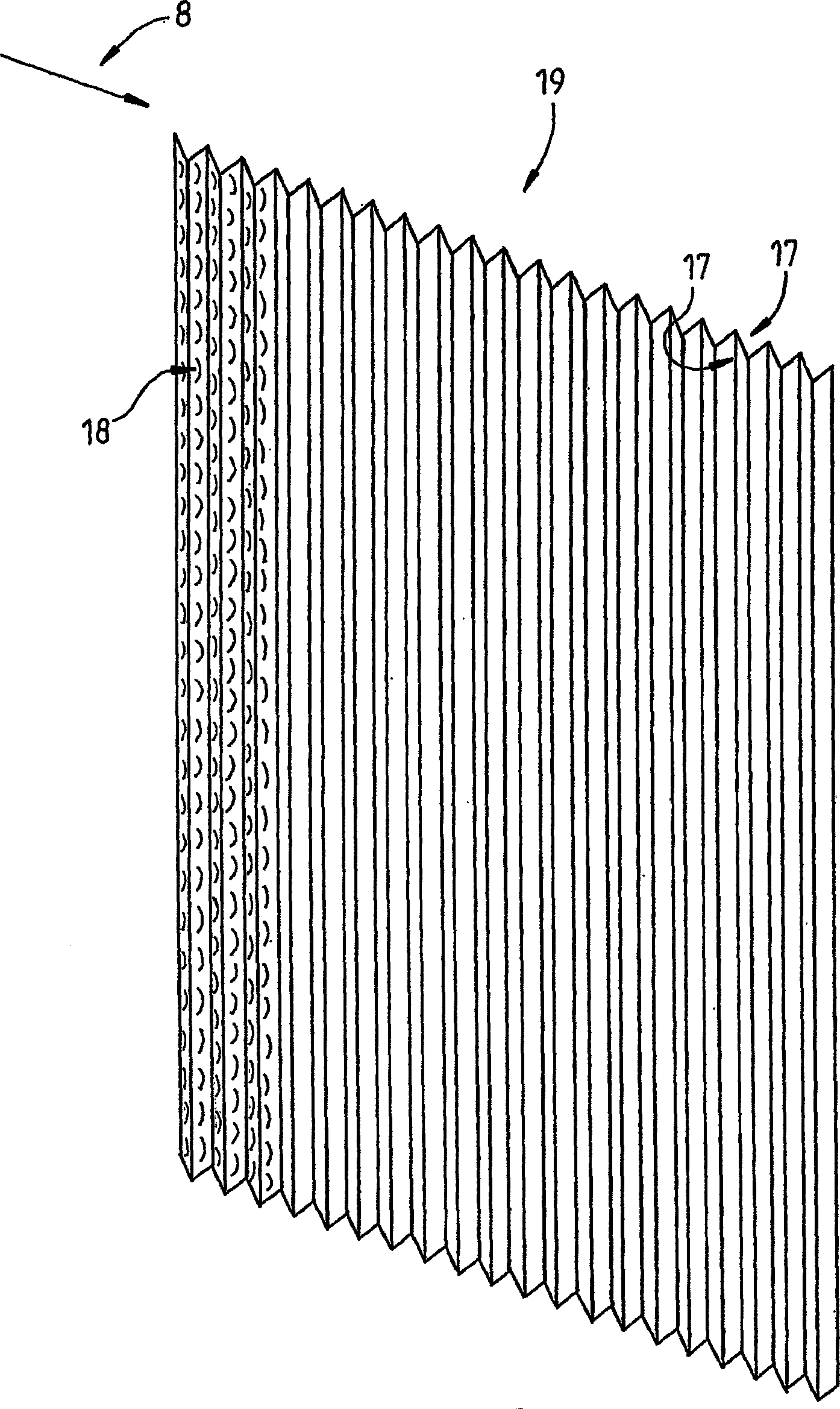

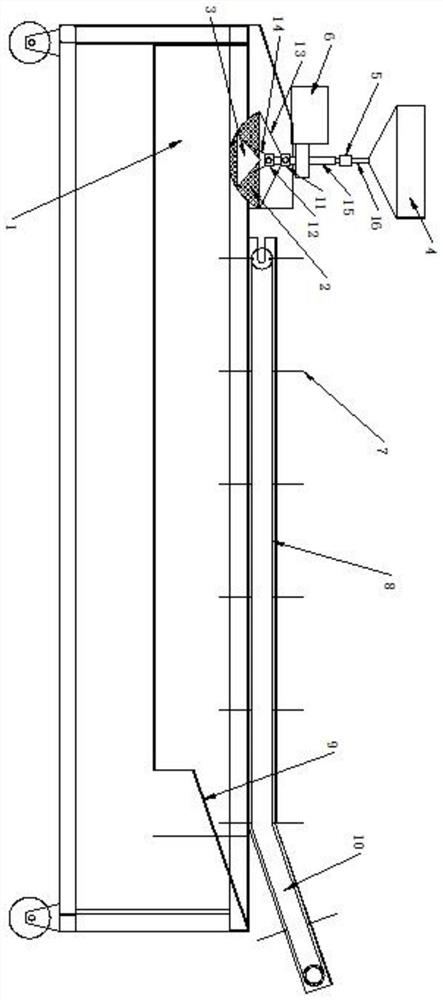

Device for the extraction of water from atmospheric air

InactiveCN1829845AAchieve adhesionAchieving AdhesionDrinking water installationSorbentAtmospheric air

The invention relates to a device for the extraction of water from atmospheric air (8), with a flowing adsorbent or absorbent, in particular a saline solution (3), comprising a hygroscopic salt for the adsorption or absorption of the water, whereby the adsorption or absorption occurs along an adsorption or absorption path (7). A reduction in the assembly requirements and an increased yield of (potable) water per volume unit of the construction or absorbent / adsorbent (3) can be achieved, whereby the flowing adsorbent (3, 13) or absorbent (3, 13) is arranged, at least along the adsorption or absorption path (7), essentially on a guide element (1, 16, 19, 22, 24) for guiding the adsorbent (3) or absorbent (3) particularly along a given track.

Owner:LOGOS INNOVATIONEN

High-transparency polyvinyl alcohol hydrogel as well as preparation method and application thereof

ActiveCN112646206ATransparent highImprove adhesionAerosol deliveryOintment deliveryInorganic saltsPolymer science

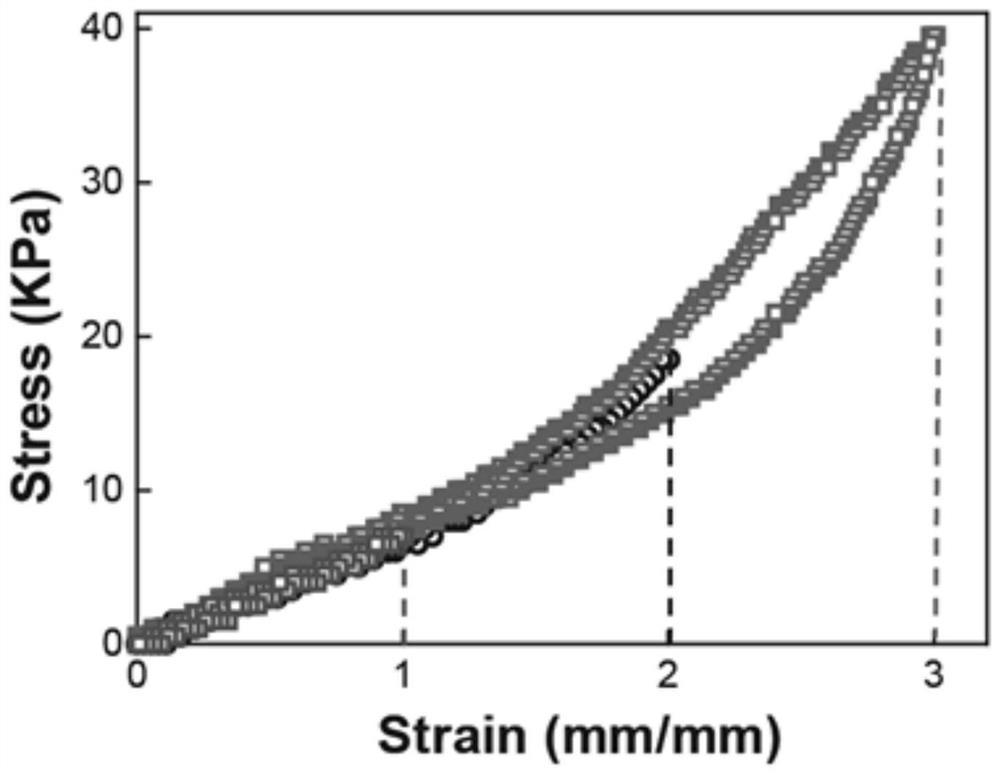

The invention provides high-transparency polyvinyl alcohol hydrogel as well as a preparation method and application thereof. According to the high-transparency polyvinyl alcohol hydrogel, polyvinyl alcohol and inorganic salt are used as raw materials, water is used as a solvent, the concentration of the polyvinyl alcohol is 3-30 wt%, and the concentration of the inorganic salt is 0.5-29.9 wt%. The method disclosed by the invention is green and environment-friendly, and the prepared polyvinyl alcohol hydrogel has high transparency, adhesion and ultralow-temperature freezing resistance, and has elasticity, ductility, ionic conductivity and moisture retention, so that the problems of non-transparency, no adhesion, no freezing resistance and the like of the polyvinyl alcohol hydrogel during application are solved, and the prepared polyvinyl alcohol hydrogel can be applied to the fields of medicines, materials and sensors.

Owner:QINGDAO UNIV

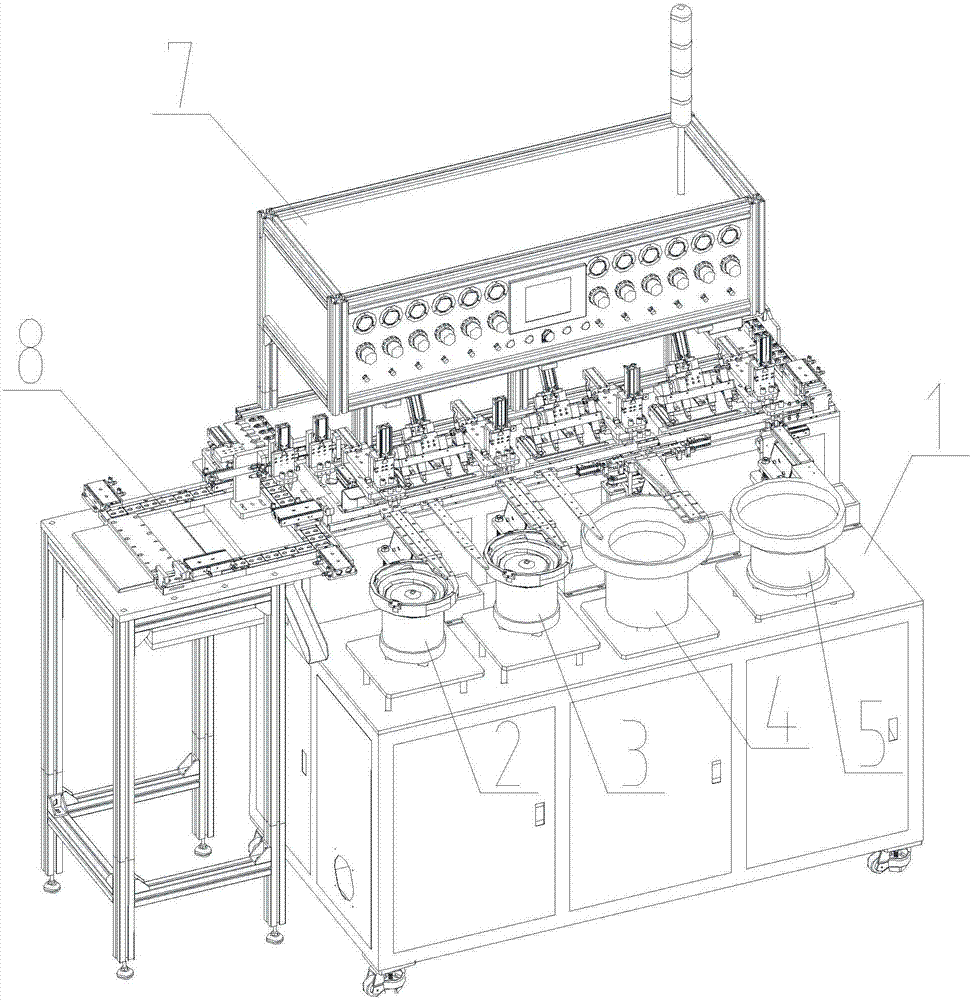

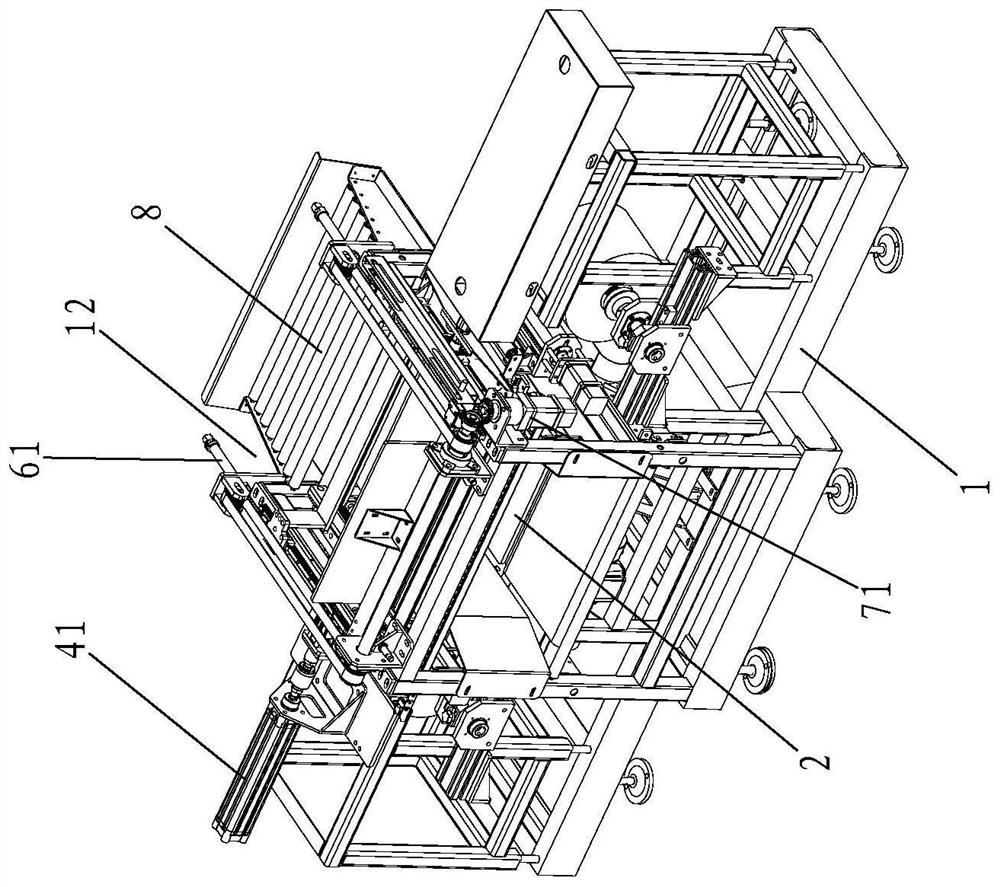

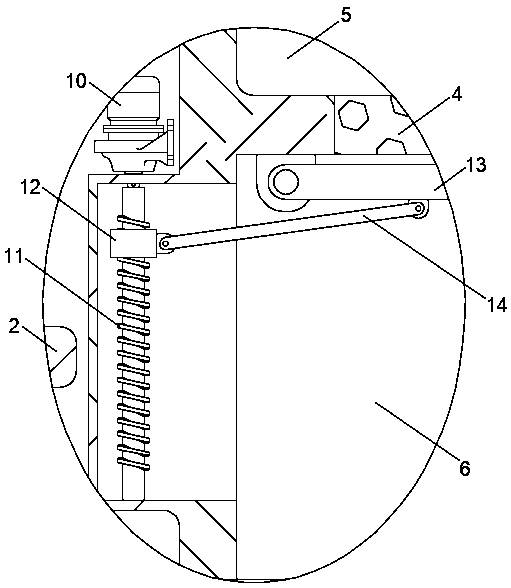

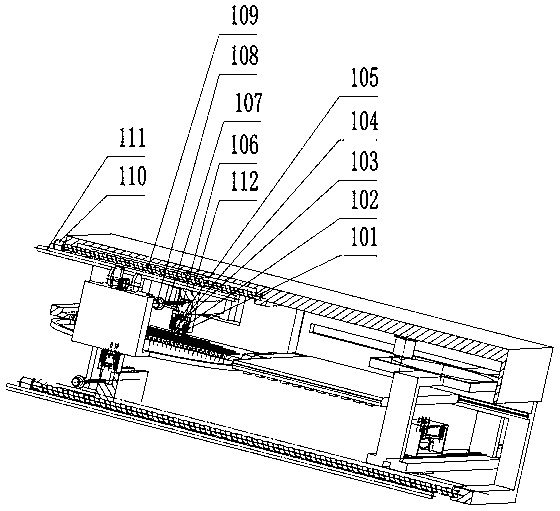

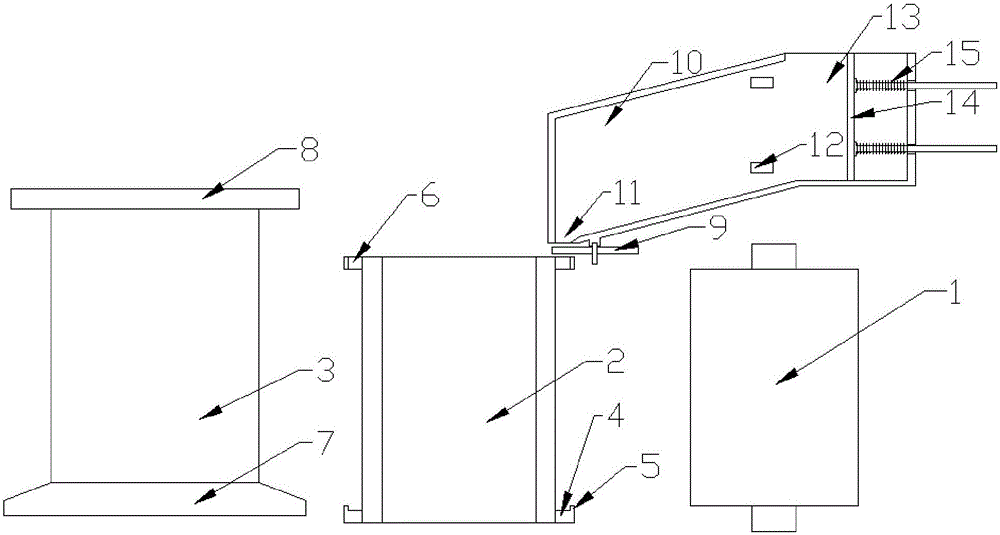

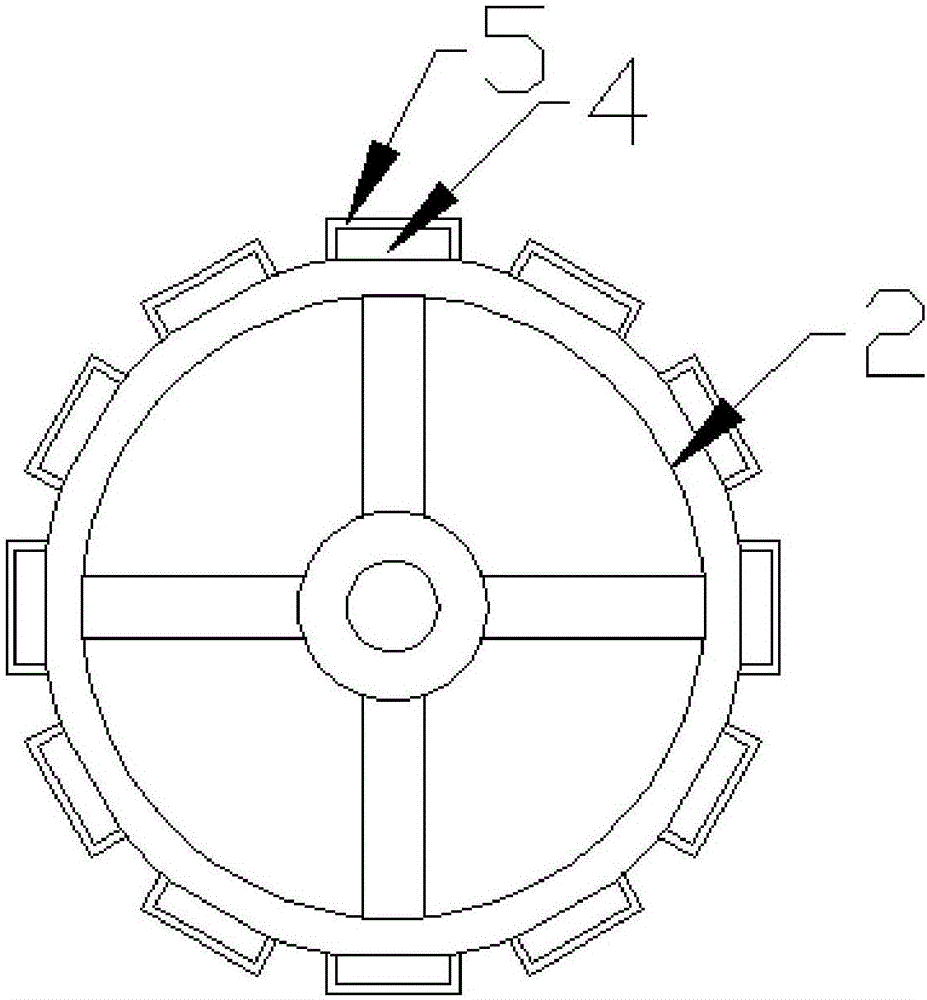

Automatic horn assembling device and control method thereof

ActiveCN107243742AHigh degree of automationRealize automatic feeding processAssembly machinesProcess engineeringMechanical engineering

The invention discloses an automatic horn assembling device and belongs to the field of automatic assembling devices. The automatic horn assembling device comprises a main base, a first installation device, a second installation device, a third installation device, a fourth installation device, a circulatory conveying rail, a controller and a magnetizing device. The invention further discloses a control method for the automatic horn assembling device. The automatic horn assembling device can automatically convey workpieces needing machining and sticking, sequentially conduct feeding, sequentially conduct automatic adhesion and replace manual conveying operation, a whole set of complete automatic horn assembling technologies is provided, and the automatic horn assembling device has the advantages of being high in work efficiency, accurate in alignment and the like.

Owner:江西迪迪工业智能设备有限公司

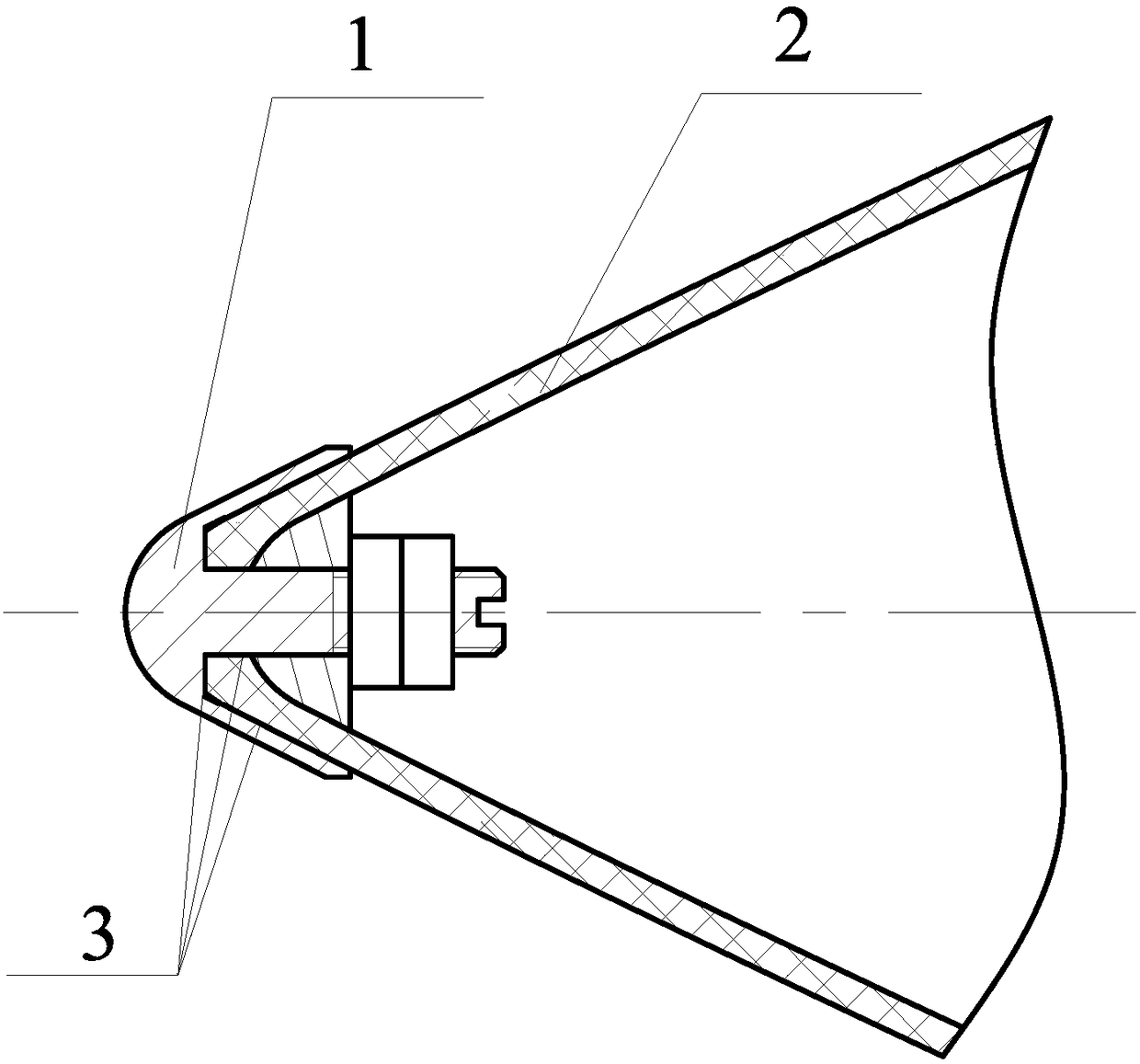

High-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing and preparation method thereof

ActiveCN108148548ASolve temperature resistanceAchieving adhesionNon-macromolecular adhesive additivesRadiating element housingsEpoxyAdhesive

The invention provides a high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing and a preparation method thereof. The high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing comprises an antenna housing body and a rainfall-erosion head, wherein the rainfall-erosion head is connected to the antenna housing body through a high-temperature-resistant wave transmission adhesive; the high-temperature-resistant wave transmission adhesive comprises epoxy-modified organic resin, mica powder, fumed silica, a silane coupling agent and an imidazole curing agent; the mica powder, the fumed silica, the silane coupling agent and the imidazole curing agent are sequentially added to the epoxy-modified organic resin. According to the high-temperature-resistant and rainfall-erosion-resistant wave transmission antenna housing, a special intermediate-temperature normal-pressure curing type high-temperature-resistant wave transmissionadhesive is adopted, so that the rainfall erosion head and the housing body can be adhered in high temperature environment; the temperature resistance and reliability of the rainfall erosion head andthe housing body in connection are ensured; and the influence of the mounted rainfall erosion head on the electric performance of a wideband antenna housing can be overcome.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Automatic hand strap penetrating and pressing device

InactiveCN103144351AHigh control precisionHigh degree of integrationPaper-makingBox making operationsElectric machineryEngineering

The invention discloses an automatic hand strap penetrating and pressing device which comprises a strap feeding part, a strap cutting part, a strap penetrating part and a pressing and bonding part, wherein the strap feeding part is arranged on one side of the strap penetrating part and is used for automatically transmitting the hand strap to the strap penetrating part; the strap cutting part is arranged above the position between the strap feeding part and the strap penetrating part and is used for cutting off the hand strap; the strap penetrating part is used for allowing the hand strap to be subjected to strap penetration and for pressing the hand strap to be arc-shaped; and the pressing and bonding part is arranged above the strap penetrating part and is used for bonding the end part of the hand strap to the surface of an objected to be bonded and exerting downward pressure to press the hand strap onto the object to be bonded. According to the utility model, a linear servomotor and a rotary servomotor are adopted to serve as a power device, therefore the automatic hand strap penetrating and pressing device provided by the invention has the advantages of high control precision, convenience in installation, small occupied area, and compact structure, and more importantly, has the advantages of high integration degree, energy conservation, environmental protection, high operating efficiency and high openness, and can realize full automation of strap penetrating operation, so as to avoid traditional labor operation.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

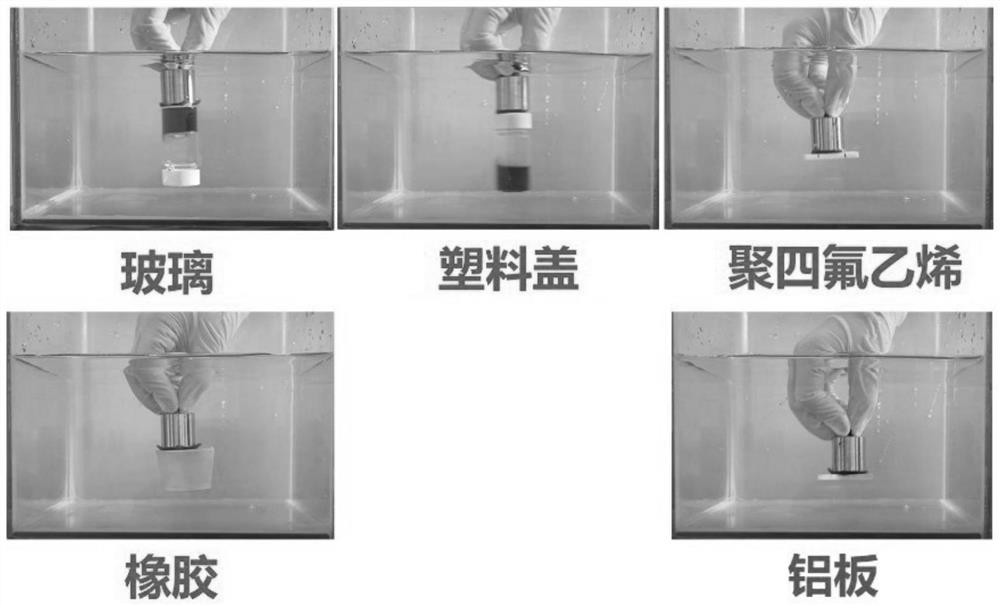

Hydrogel with wet-state adhesion property as well as preparation method and application thereof

InactiveCN113754830AImprove mechanical propertiesImprove adhesionNon-macromolecular adhesive additivesGraft polymer adhesivesXylanCross linker

The invention discloses hydrogel with wet-state adhesion property as well as a preparation method and application thereof. The hydrogel with the wet-state adhesion property is prepared from the following raw materials in parts by mass: 100 parts of acrylic acid, 10 parts to 30 parts of quaternized xylan, 3 parts to 6 parts of tannic acid, 0.1 part to 1 part of a cross-linking agent, 0.1 part to 1 part of an initiator, and 150 parts to 400 parts of water. The hydrogel disclosed by the invention has excellent mechanical property and underwater adhesion property, and is environment-friendly, the preparation method is simple, and industrial large-scale production is easy to realize.

Owner:SOUTH CHINA UNIV OF TECH

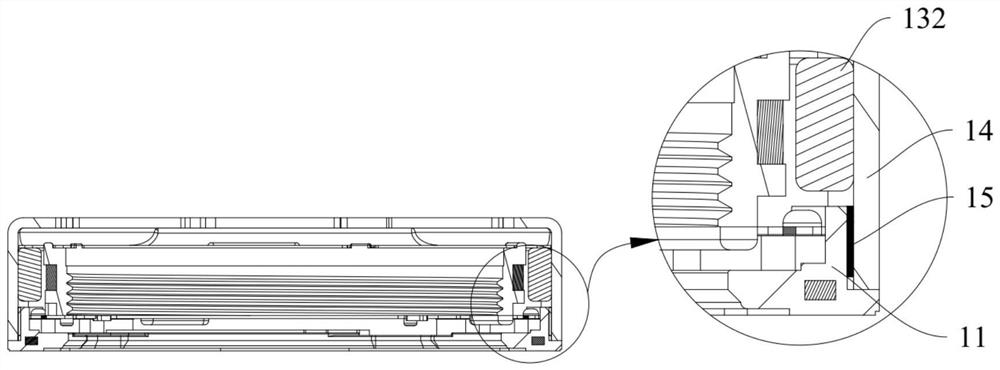

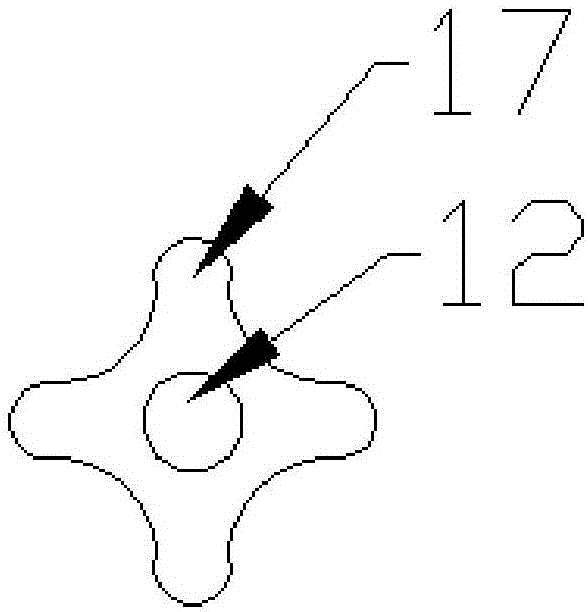

Active adhesion and desorption variable-rigidity self-adaptive gecko-like leg, robot and method

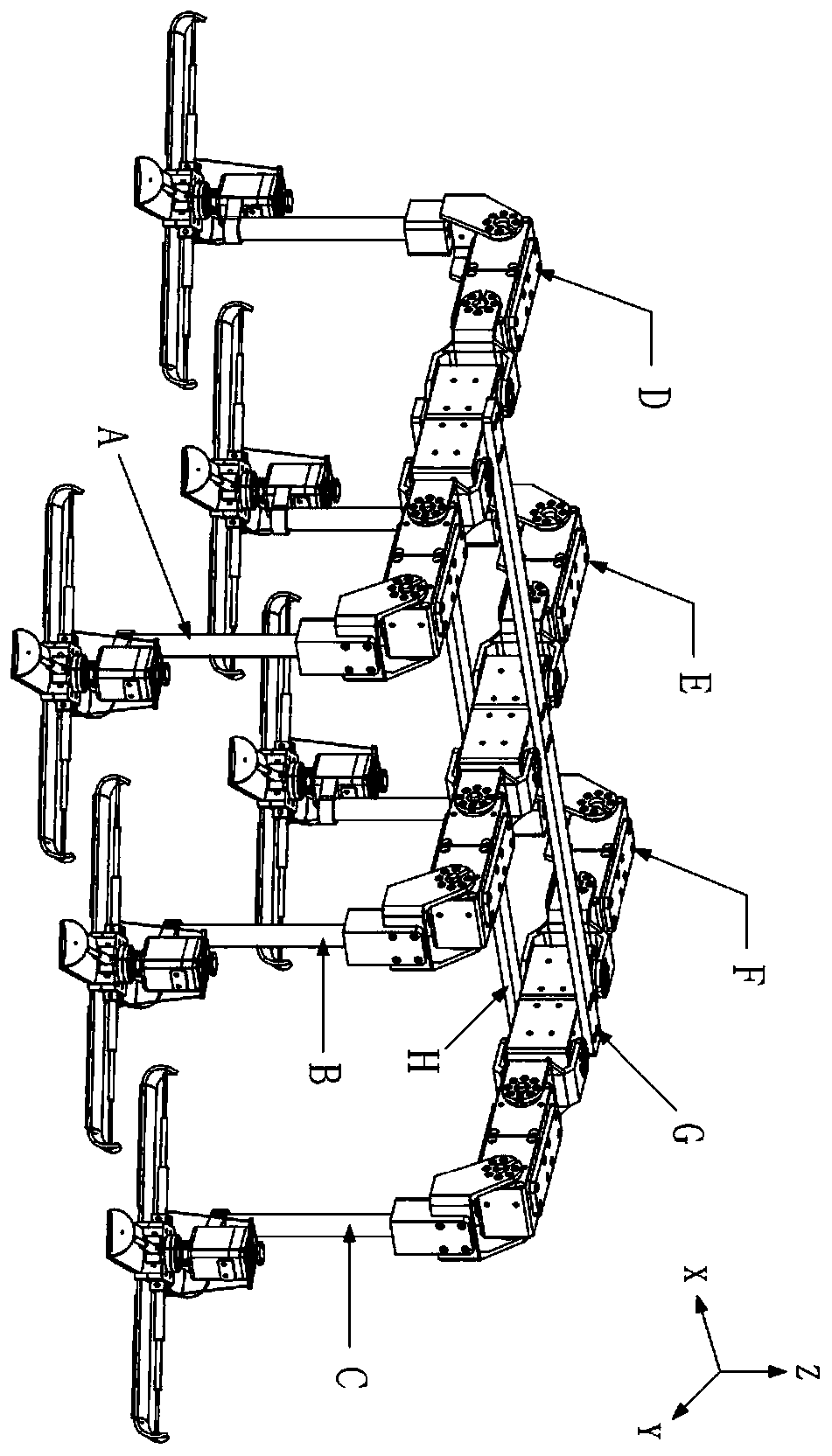

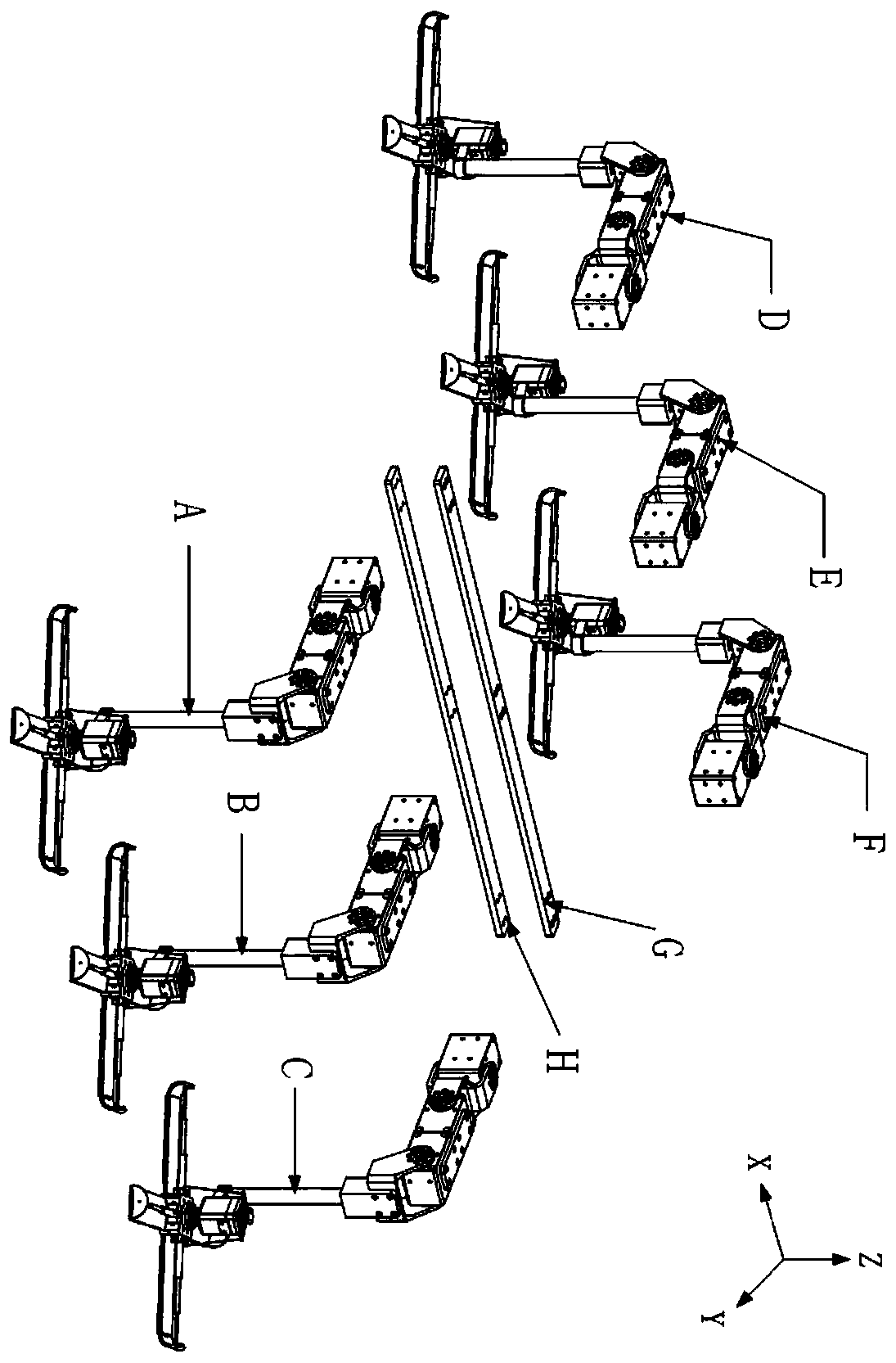

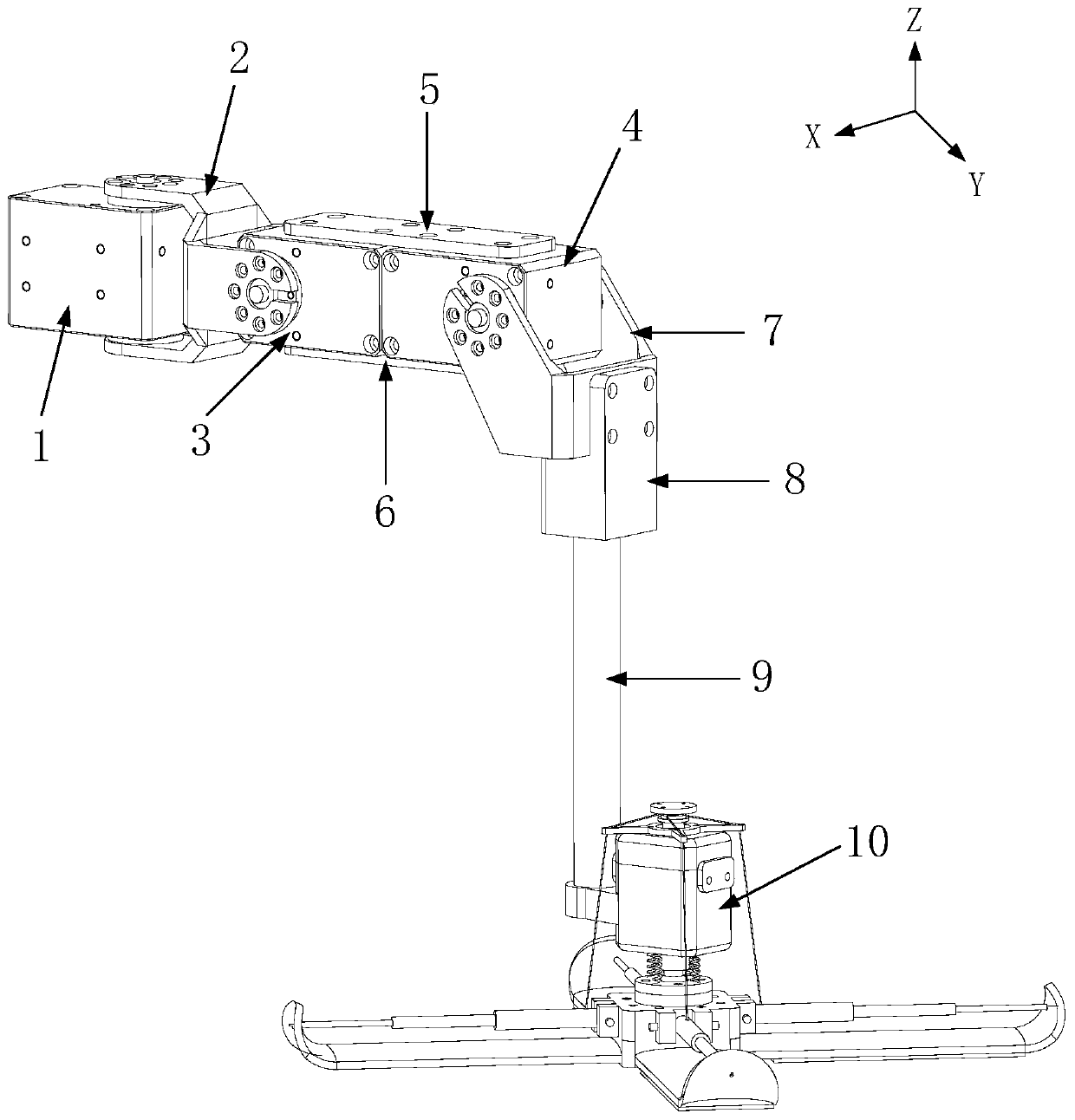

ActiveCN111422276AQuickly return to the initial postureReturn to the original postureVehiclesClassical mechanicsEngineering

The invention relates to an active adhesion and desorption variable-rigidity self-adaptive gecko-like leg, a robot and a method, and belongs to the technical field of robot application. The variable-rigidity self-adaptive gecko-like leg is mainly characterized by comprising a bionic foot sole (10). The bionic foot sole (10) comprises a wire pulling steering engine (11), a wire pulling steering engine upper end fixing piece (12), a wire pulling steering engine lower end fixing piece (13), a rotary supporting frame (14), a rotary flange (15), a ball head (16), a ball joint upper cover (17) and afoot sole fixing piece (18), and also comprises N foot sole units uniformly arranged on a circle of the foot sole fixing piece (18) and having the same structure; wherein N is a natural number from 3to 9. The self-adaptive gecko-like leg and the robot have active adhesion and desorption movement functions, meet the self-adaptive requirement of the space surface, and can be applied to the structural design of a micro-miniature adhesion foot type robot.

Owner:JIANGSU POLICE INST

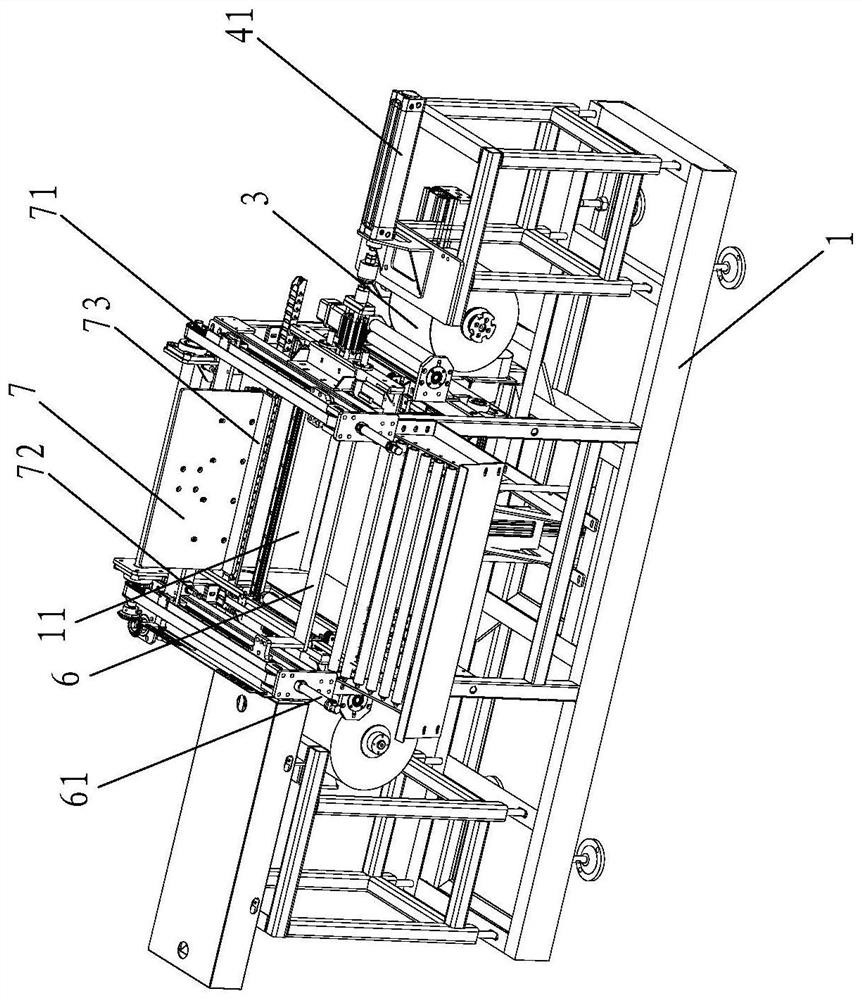

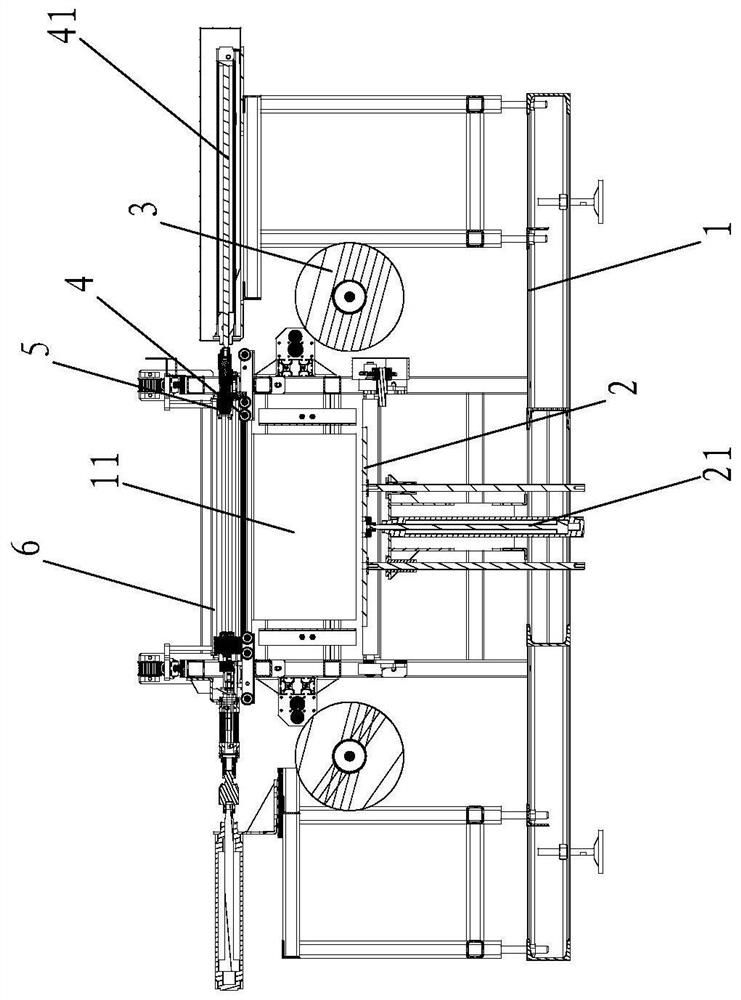

Cigarette carton wrapping, sealing and cutting device and cigarette carton wrapping, sealing and cutting process

PendingCN113044269ANot easy to scatterSimple processWrapping material feeding apparatusWrappingCartonStructural engineering

The invention relates to the field of cigarette carton packaging, in particular to a cigarette carton wrapping, sealing and cutting device which comprises a rack, a lifting channel, a lifting platform and a lifting driving mechanism, unwinding mechanisms are arranged on the rack, a guide mechanism is arranged on the rack, wrapping films of the two unwinding mechanisms are connected with each other after winding around the guide mechanism, a guide driving mechanism is arranged on the rack, the rack is provided with a sealing and cutting mechanism used for sewing and cutting off the wrapping films, the rack is provided with a sealing and cutting driving mechanism used for driving the sealing and cutting mechanism to stretch into the lifting channel so that the sealing and cutting mechanism can get close to the lifting channel, a bearing plate used for supporting cigarette cartons is arranged on the rack and located above the sealing and cutting mechanism and located on one side or two sides of the lifting channel, and the rack is provided with a bearing driving mechanism used for driving the bearing plate to stretch into the lifting channel so as to achieve cigarette carton bearing. The technical problems that a sealing device with a sleeve film is high in cost and low in working efficiency are solved. The invention further provides a cigarette carton wrapping, sealing and cutting process.

Owner:福建科盛智能物流装备有限公司

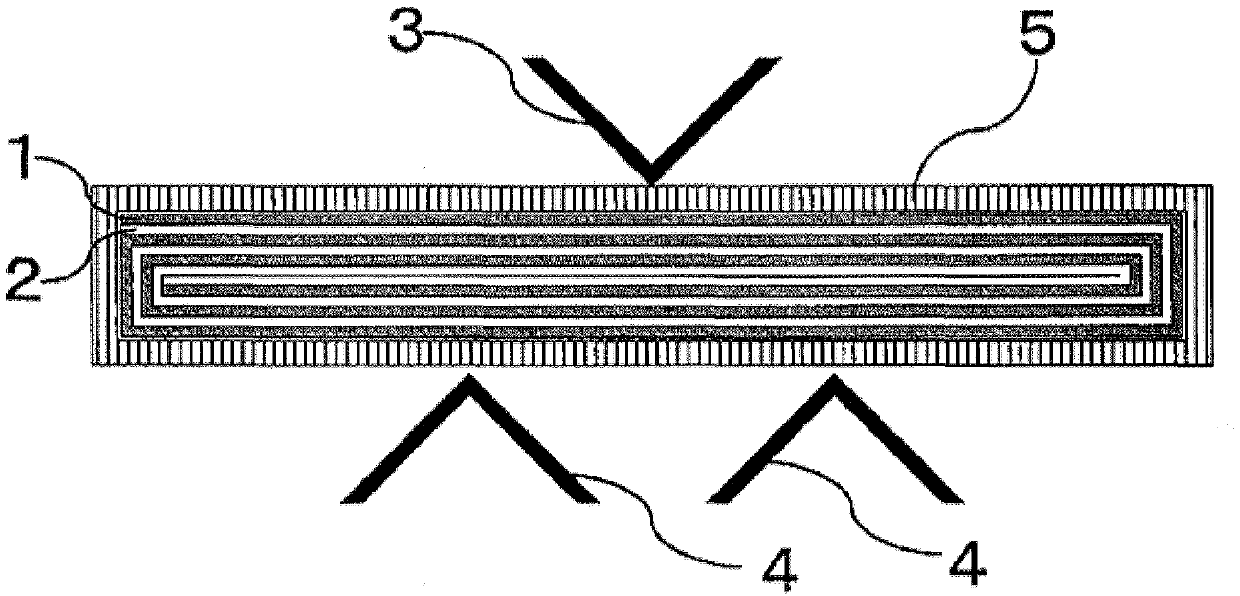

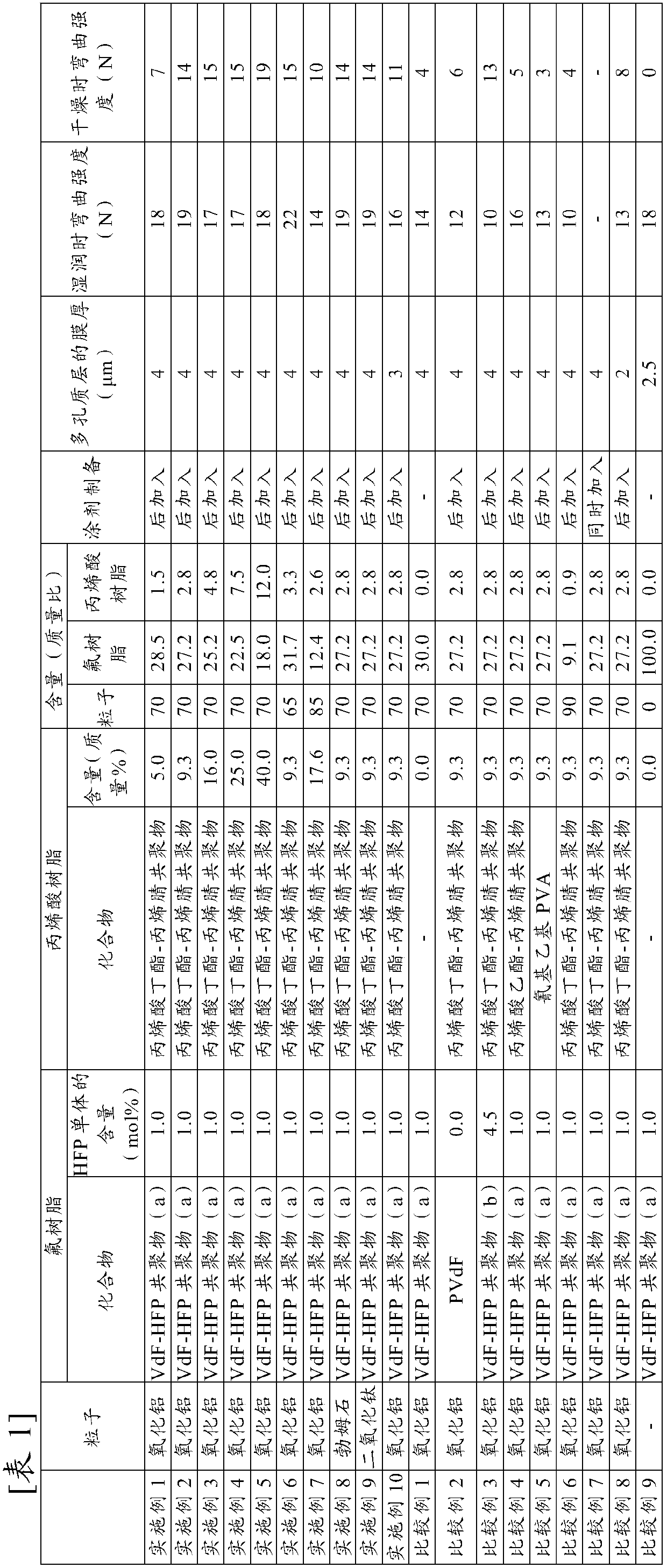

Battery separator

ActiveCN107925036AAchieving adhesionCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous layerAcrylic resin

It is the aim of the present inventors to provide a battery separator with excellent dry-time adhesion, which is a new problem resulting from an expected increase in battery size in the future, and wet-time adhesion, without deterioration in air impermeability. The battery separator is provided with a microporous membrane and a porous layer disposed at least on one side of the microporous membrane, wherein the porous layer includes vinylidene fluoride-hexafluoropropylene copolymer and acrylic resin, the vinylidene fluoride-hexafluoropropylene copolymer includes a monomer unit with a hydrophilic group and 0.3 mole% or more and 3 mole% or less of a hexafluoropropylene monomer unit, and the acrylic resin includes a butylacrylate monomer unit.

Owner:TORAY IND INC

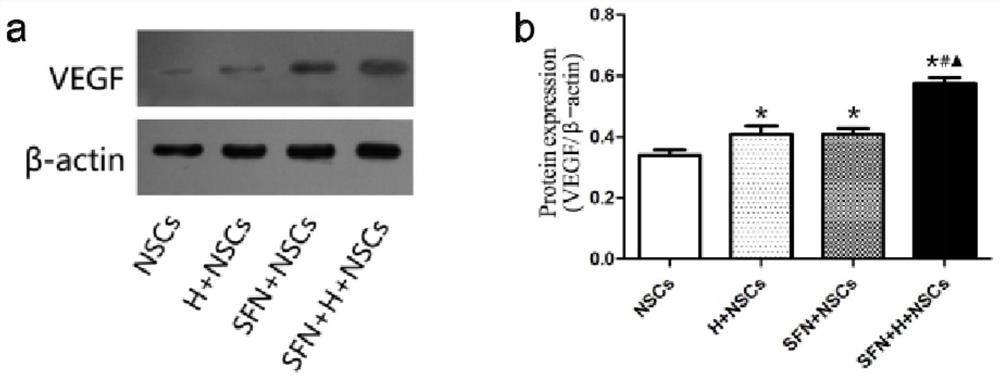

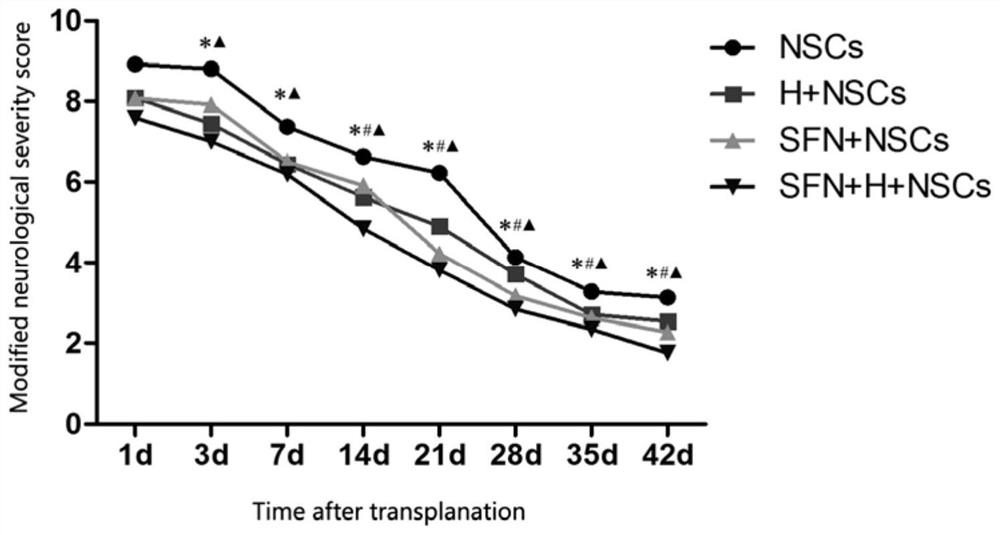

Hydrogel/fibroin nanofiber/neural stem cell integrated transplant for promoting VEGF secretion as well as preparation method and application thereof

ActiveCN112494727AReturn to normal structureRestoration of mechanical propertiesPharmaceutical delivery mechanismTissue regenerationDirected differentiationCerebral ischaemia

The invention discloses a hydrogel / fibroin nanofiber / neural stem cell integrated transplant capable of promoting VEGF secretion as well as a preparation method and application thereof, and belongs tothe technical field of biological tissue medical engineering. The method comprises the following step: polysaccharide-based hydrogel / neural stem cell gel are adhered to a fibroin nanofiber scaffold through dopamine to form a polysaccharide-based hydrogel / fibroin nanofiber / neural stem cell integrated transplant, wherein the polysaccharide-based hydrogel is a self-healing injectable polysaccharide-based hydrogel. According to the invention, the polysaccharide-based hydrogel embedded with the neural stem cells is adhered to a gap between fibroin nanofiber scaffolds through dopamine to construct the polysaccharide-based hydrogel / fibroin nanofiber / neural stem cells integrated transplant, so that the cells can be promoted to secrete VEGF and fill the defect part, and provide required microenvironment for adhesion, proliferation and directional differentiation of the neural stem cells into neurons, and the neural stem cells can be applied to the field of treatment of cerebral ischemia injuryand promotion of neural stem cell amplification and differentiation.

Owner:SHAANXI UNIV OF SCI & TECH +1

Bonding system of PU artificial leather and rubber foxing strips for shoes as well as preparation method and use method of bonding system

InactiveCN107841255AImprove adhesionAchieving adhesionNatural rubber adhesivesNon-macromolecular adhesive additivesRubber shoesAdhesive

The invention discloses a bonding system of PU artificial leather and rubber foxing strips for shoes as well as a preparation method and a use method of the bonding system. A unique bonding system prepared from an artificial PU leather treatment agent, a bonding agent and high-viscosity adhesive layer foxing strips can be used for realizing the bonding performance of rubber shoe foxing strips andPU artificial leather materials by virtue of a specific use method. Because the bonding strength of the bonding system is good, the wearing life of the rubber shoes is prolonged. The methods disclosedby the invention are simple and easy to industrialize.

Owner:JIHUA 3537 SHOE MAKING

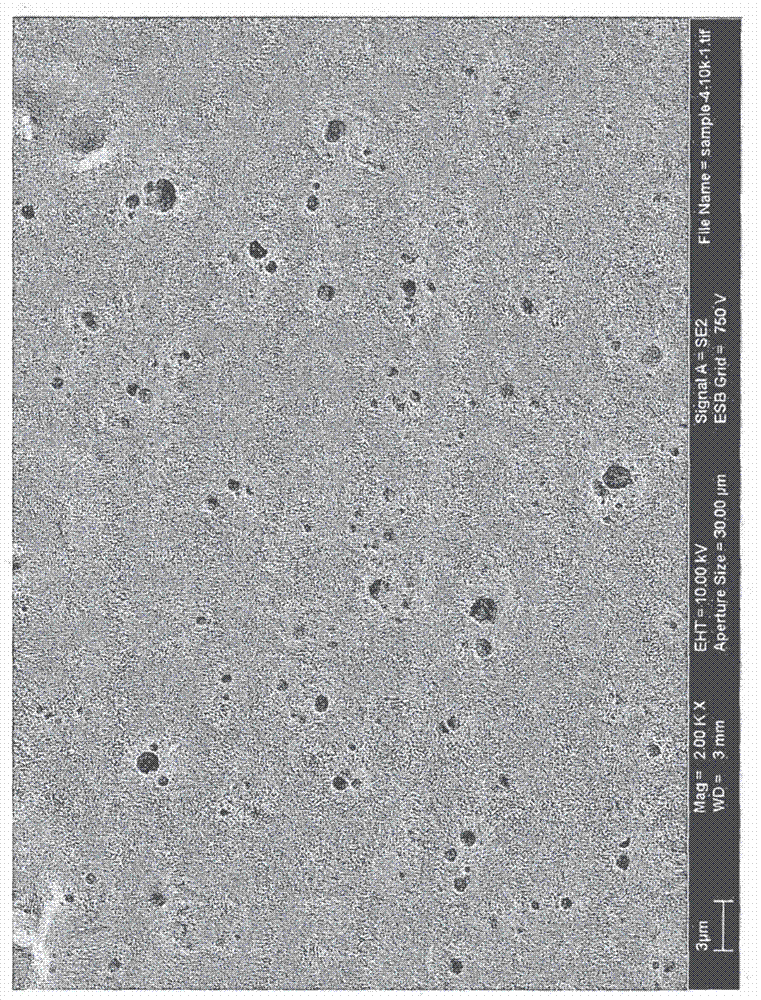

Method for manufacturing toner, toner and image forming method

ActiveCN103930831AAchieving AdhesionSufficient image densityElectrographic process apparatusDevelopersOrganic solventCharge control

A method for manufacturing a toner, including at least: dissolving or dispersing a toner material including at least any one of a binder resin and a precursor of a binder resin in an organic solvent which is dispersed in a dispersant-including aqueous medium; forming particles by removing the organic solvent; washing the particles; forming voids in the particles by heating to a temperature T while or after dispersing the particles in an aqueous medium; forming toner base particles by adding a charge controlling agent; and adding an external additive to the toner base particles to obtain toner particles, wherein the T is between a glass transition temperature Tg of the toner particles and Tg + 25 DEG C, and the toner has a cross-sectional void fraction Sp / St of 0.1% to 15.0%, where St is a cross-sectional area of the toner particles, and Sp is a cross-sectional area of the voids.

Owner:RICOH KK

Firing method capable of improving strength of ceramic tableware green body as well as firing kiln

The invention discloses a firing method capable of improving the strength of a ceramic tableware green body as well as a firing kiln. The method comprises the following steps: S1, putting ceramic tableware into the firing kiln. A rotating shaft and a turntable which are driven by a first-level motor to rotate are arranged in an upper cavity, so that the ceramic tableware is supported to horizontally rotate in a kiln body; the lower end of a filtering plate is connected with a sealing plate through a pin shaft, a screw rod which is driven by a second-level motor to rotate is arranged in a lowercavity, and the rotating screw rod enables a nut moving up and down to perform traction supporting on the sealing plate through a supporting rod, so that sequential temperature rise and fall of the ceramic tableware in the kiln body is realized under the condition that a furnace body is not extinguished; the ceramic tableware is fired step by step, and a sprayer provides uniform and comprehensiveadhesion spraying for the ceramic tableware doing rotary motion, so that the own adhesiveness is improved; and sequential temperature rise and fall is realized through step-by-step firing, so bubblesand damage to the green body of the ceramic tableware caused by temperature sudden rise and sudden fall in the traditional firing technology can be avoided.

Owner:广东明宇科技股份有限公司

Environment-friendly type wood and plastic composite material

The invention discloses an environment-friendly type wood and plastic composite material, and relates to the technical field of novel materials. The environment-friendly type wood and plastic composite material is prepared from the following components of modified wood powder, polyethylene resin, polyvinyl alcohol, calcium carbonate, mulberry leaf powder, a lubricant, epoxy soybean oil, and an organosilane coupling agent. The environment-friendly type wood and plastic composite material is obtained after multiple times of design of raw materials and components and massive experiment data, andhas the advantage that the modified wood powder can be bound with polyethylene plastic, so that the strength of wood and plastic material is obviously enhanced.

Owner:合肥旭亚新材料科技有限公司

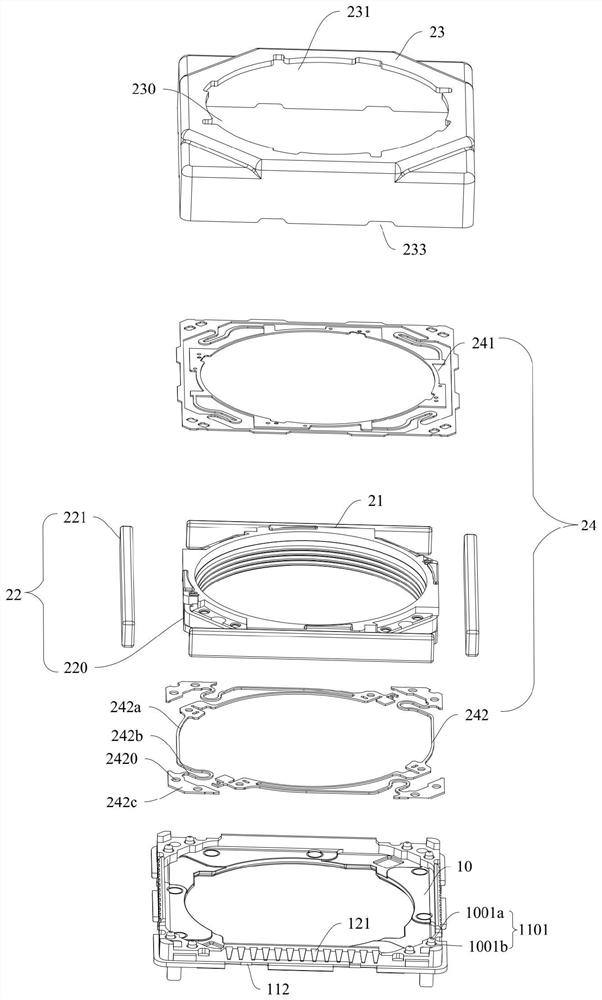

Driving device, camera module and electronic equipment

PendingCN112987226ASimple structural designAchieving a glue connectionTelevision system detailsPrintersImaging qualityEngineering

The invention discloses a driving device, a camera module and electronic equipment, wherein the driving device comprises a base, a carrier, a power assembly and a shell, the carrier is arranged on the base, the power assembly is arranged on the periphery of the carrier and used for driving the carrier to move, and the shell is provided with a hollow space and covers the periphery of the base; the shell is provided with an avoiding notch communicated with the hollow space, an adhesive layer is arranged between the shell and the base, and the adhesive layer at least corresponds to the receding notch so as to prevent dust from entering the hollow space from the receding notch. According to the driving device, the camera module and the electronic equipment disclosed by the embodiment, when the shell and the base are bonded together, dust and external water entering through the receding notch can be blocked by the glue layer, so that the dust and the external water cannot enter the hollow space of the shell; therefore, dust and external water can be prevented from entering the hollow space of the housing to influence the imaging quality of the lens assembly arranged in the housing.

Owner:NEW SHICOH MOTOR CO LTD

Preparation and synchronous modification method of novel multifunctional embolism

The invention discloses a preparation and synchronous modification method of a novel multifunctional embolism, and particularly relates to research and development of embolism microspheres which are stable in structure, proper in size and capable of coating an imaging object with polydopamine, and visualization is realized on the basis of enhancing adhesion and treatment effects. In-vitro experiments prove the biocompatibility and the X-ray imaging capability of the material. The microspheres can also load chemotherapeutic drugs, and animal experiments prove that the microspheres have good embolism effects. The design embodies an excellent novel method for synthesizing the multifunctional embolism.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL +1

Method for producing gypsum plaster by using desulfurized gypsum

The invention discloses a method for producing gypsum plaster by using desulfurized gypsum. The method comprises the following steps of: S1, calcining, grinding, cooling and storing desulfurized gypsum; S2, taking the cooled desulfurized gypsum, mixing the cooled desulfurized gypsum with an additive and water, and then putting the mixture into a grinding tool to wait for solidification forming; and S3, after solidification forming, connecting the product with surface protection paper through glue, and carrying out solidification forming and drying treatment; In the step S1, the calcining temperature is 180 DEG C, and the calcining time is when the content of crystal water is detected to be 8-10%; In the step S2, the additive comprises 3-8 parts by weight of konjaku flour, 5-10 parts by weight of a water reducing agent, 1-5 parts by weight of a foaming agent and 2-6 parts by weight of a coupling agent, and the weight ratio of the additive to the water to the desulfurized gypsum is 10: 60: 110. In the step S3, the drying temperature is 220-250 DEG C, and the drying time is 30 min.

Owner:四川蓝鼎新材料有限公司

Preparation method of recycled aggregate applied to laminated slab

PendingCN114380523AImprove physical impact resistanceAchieving adhesionSolid waste managementSilica fumeFiller particle

The invention discloses a preparation method of recycled aggregate applied to a laminated slab, and belongs to the technical field of recycled aggregate, and the preparation method specifically comprises the following steps: S1, collecting raw materials; s2, cleaning the raw materials; s3, grinding the raw materials; s4, screening the raw materials; s5, preparing filler particles; s6, soaking the filler particles; and S7, mixing the materials. According to the invention, the addition control capability of the water reducing agent during the preparation of the laminated slab can be improved by adjusting the infiltration particles, and the pulverized coal ash and the silicon powder of the infiltration particles can fill the pores of the recycled aggregate, so that the physical impact resistance of the prepared recycled aggregate is improved; the bonding capacity and impact strength of regenerated particles are achieved through the clay waste, the regulation and control requirements of additives for large-scale production are effectively improved, slow precipitation of the slow-release water reducing agent in the production process of laminated slab slurry is guaranteed, and the mixing control requirements of raw material water liquid are improved.

Owner:常熟市博海新型建材有限公司

Semiconductor packaging and mounting device

ActiveCN110783238AAchieve transferAchieving adhesionSemiconductor/solid-state device manufacturingSilver pasteWafer

The invention provides a semiconductor packaging and mounting device. The device comprises a thimble structure, a blue film fixing structure, a crystal block adsorption structure, a silver paste point sprinkling structure and a machine body. The blue film fixing structure is installed above the thimble structure, the crystal block adsorption structure is installed at a top of the machine body, and the silver paste point sprinkling structure is installed in front of the thimble structure. A wafer is obtained through a slicing process to ensure that a wafer block is fixed. A blue film is attached to a bottom, the wafer subjected to the slicing process is placed on a machine body. The blue film is pressed by the blue film fixing structure. A position of the crystal block adsorption structureis controllable, the crystal block adsorption structure moves downwards to adsorb a crystal block at the position with the crystal block, the thimble structure moves upwards to carry out top hit on the crystal block so that the crystal block is separated from the blue film, an adsorption rod transfers the crystal block to a front lead frame, and the silver paste point sprinkling structure dispenses silver paste on a protruding island on the lead frame so that the crystal block is fixed on the lead frame. The plurality of crystal blocks can be transferred and mounted at the same time, the positions of all structures are controllable, and efficiency is high.

Owner:MICA TECHSUZHOUCO

Ventilating member for photoelectric instrument

ActiveCN104936400AModerate pressure changes inside the cavityAchieving adhesionCasings/cabinets/drawers detailsEngineeringMechanical engineering

The invention provides a ventilating member for a photoelectric instrument. The ventilating member is mounted on an air vent of the photoelectric instrument, and comprises a ventilating film and an adhesive tape, the adhesive tape is arranged in the surrounding of the air vent, the ventilating film is fixed on the adhesive tape to cover the air vent, and the ventilating film comprises an adhesive area which can be separated from or adhered to the adhesive tape and a non-adhesive area which can cover the air vent. The non-adhesive area is recessed or protruded in the circumferential direction of the air vent with the pressure difference between the internal and external spaces of the photoelectric instrument; the adhesive area moves with the recession or protrusion of the non-adhesive area; and thus, the adhesive area is adhered to or separated from the adhesive tape.

Owner:CHANGZHOU HUADA KEJIE OPTO ELECTRO INSTR

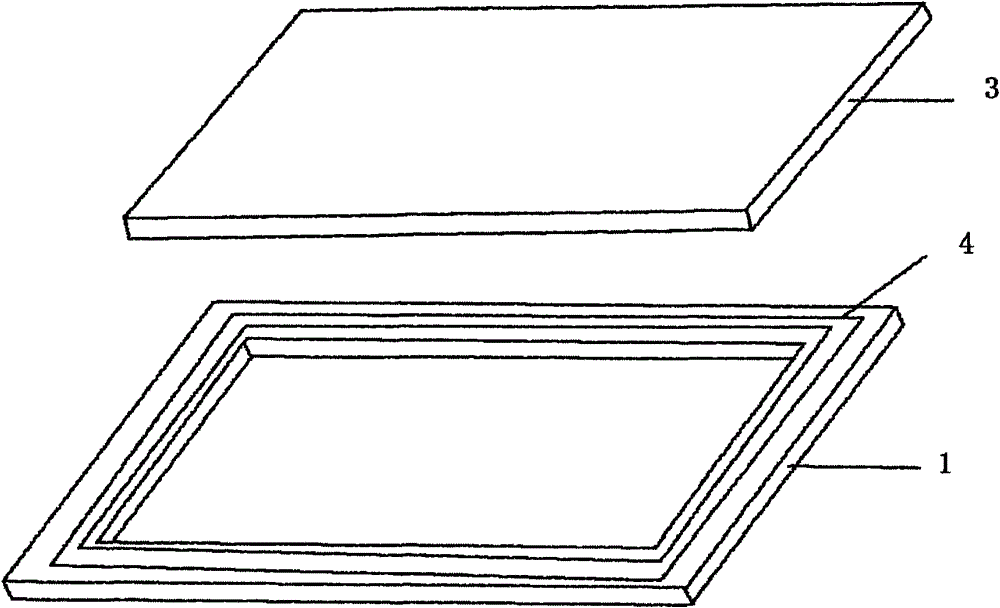

Method for depositing buffer material on framework of flat-panel display

InactiveCN102378539BFully automatedIncrease production capacityPretreated surfacesRack/frame constructionDisplay deviceFlat panel display

The invention discloses a method for depositing a buffer material on the framework of a flat-panel display. The method comprises the following steps of: (a) jetting a photo-hardening composition on the framework by utilizing a jet device; (b) performing ultraviolet irradiation and hardening on the photo-hardening composition jetted on the framework to form a photo-hardening buffer material with elasticity; and (c) bonding a transparent plate to the photo-hardening buffer material. By utilizing the technical scheme provided by the invention, the buffer material deposited on the framework of the flat-panel display can be hardened in a short time by ultraviolet irradiation, and the hardened buffer material has the elasticity, so that the automation of a framework production process is improved, the productivity is improved, the defect rate is reduced, the cost is reduced, and the defect that a conventional injection-type framework needs to the produced by the processes such as placing the transparent plate such as glass and the like on the framework after directly bonding a silicon ribbon manually and the like is overcome.

Owner:苏州天辅新型建材有限公司

Insulating paper support wood piece adhesion equipment

InactiveCN106829613AImplement automatic placementAchieving adhesionArticle deliveryDrive wheelPaper recycling

The invention relates to an insulating paper supporting wood chip bonding equipment, which comprises an insulating paper winding roller, a supporting wood chip placing roller, and an insulating paper recovery roller; the upper part of the supporting wood chip placing roller is provided with a supporting wood chip placing mechanism; The limit ring is concentrically fixed, and the outer edge of the limit ring is vertically provided with an annular retaining ring, and a number of support wood chip placement sleeves are arranged in an annular array on the top outer wall of the support wood chip placement roller; the support wood chip placement mechanism includes a flat support The wood chip placement groove is provided with a support wood chip discharge hole at one end of the support wood chip placement groove, and the support wood chip discharge hole is located at the upper position of the support wood chip placement sleeve. The upper part is synchronously fixed with an exciting motor; the bottom of the insulating paper recovery roller is provided with a circular truncated guide block, and the upper bottom of the guide block is fixedly connected with the bottom of the insulating paper recovery roller.

Owner:NANTONG ZHONGLING INSULATION MATERIALS

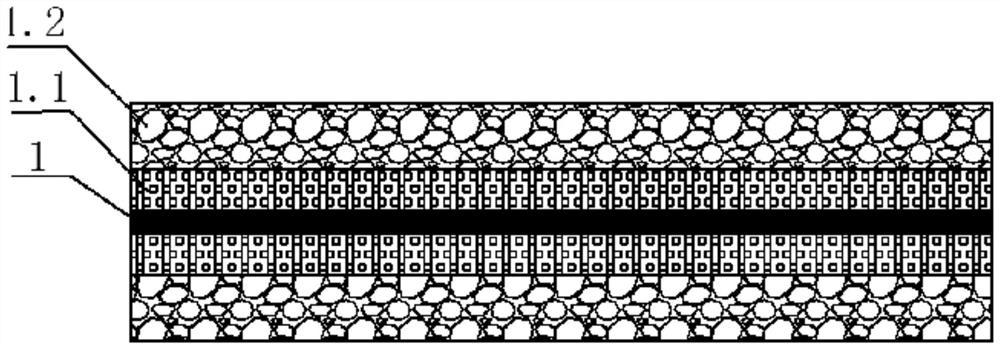

Bamboo-wood composite board using low amount of adhesive and preparation process thereof

PendingCN112757716AReduce usageImprove environmental performanceLaminationLamination apparatusThermoplasticAdhesive cement

The invention discloses a bamboo-wood composite board using a low amount of adhesive, the bamboo-wood composite board sequentially comprises an upper surface layer board, an upper reinforcing layer board, a composite core layer board, a lower reinforcing layer board and a lower surface layer board from top to bottom, the upper surface layer board and the upper reinforcing layer board are bonded through the adhesive, and the lower reinforcing layer board and the lower surface layer board are bonded through the adhesive. The composite core layer plate comprises the following raw materials in parts by weight: 30-40 parts of bamboo chips, 30-40 parts of wood chips, 20-30 parts of thermoplastic plastic and 5-10 parts of light calcium powder. The invention discloses a preparation process of the composite core layer plate. The invention relates to the technical field of bamboo-wood processing, and particularly provides a bamboo-wood composite board using a low amount of adhesive and a preparation process thereof. The bamboo-wood composite board uses less adhesive and has high connection stability among multiple layers of composite boards.

Owner:三明市尤溪县兴竹竹木制品科技有限公司

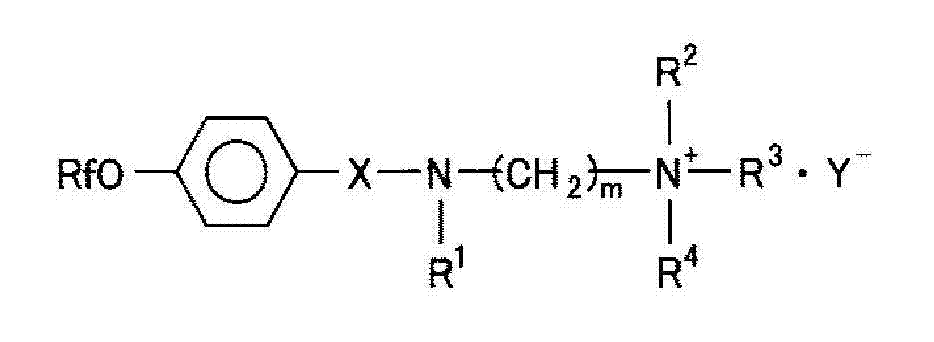

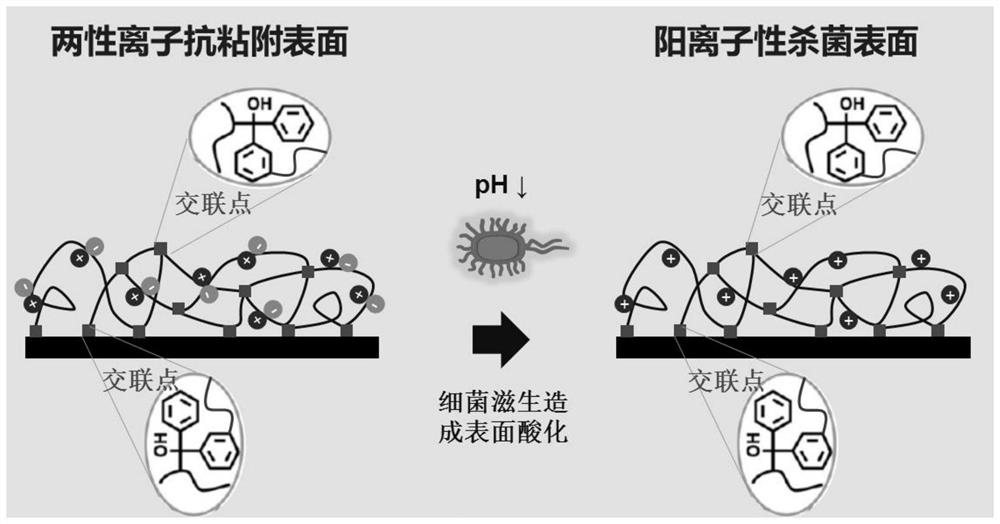

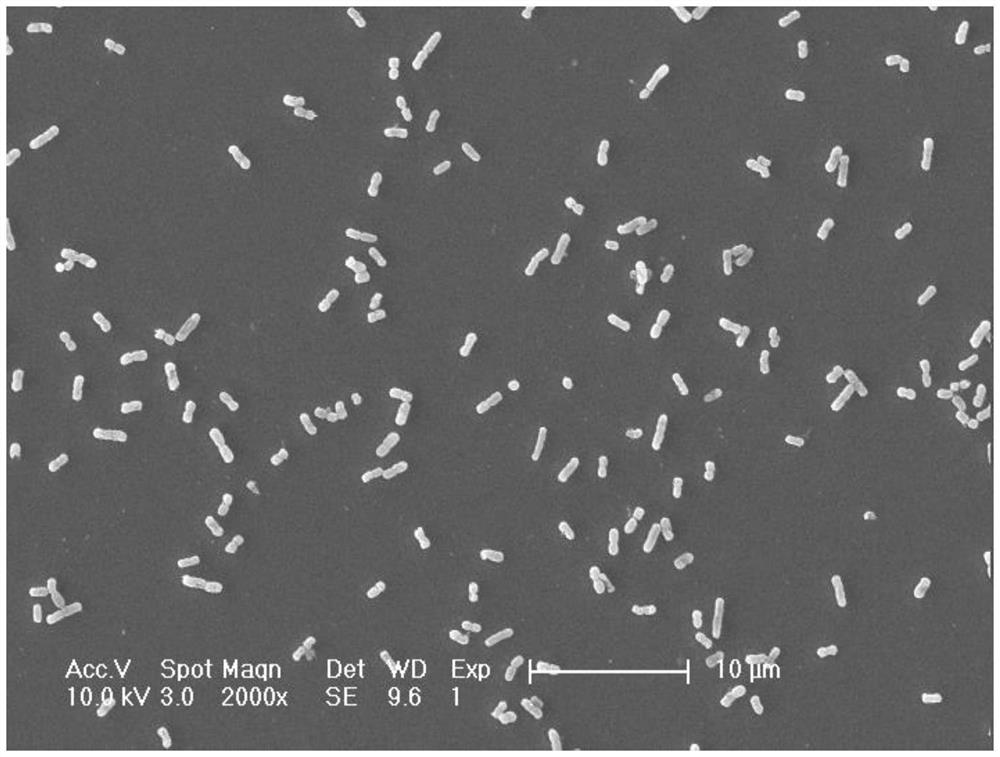

Antibacterial coating with pH response function, functional material with antibacterial coating and preparation method of functional material

ActiveCN113801568AHigh biosecurityAchieve adaptive antibacterialAntifouling/underwater paintsPharmaceutical delivery mechanismMedical equipmentBenzophenone

The invention provides an antibacterial coating. The antibacterial coating comprises a zwitterionic polymer with a structure as shown in a formula (I). The polymer designed by the invention has a pH-responsive functional group. In an acidification environment caused by bacteria, the structure of the responsive functional group is changed and a negative electricity group is removed, at the moment, the polymer shows positive electricity, the polymer shows antibacterial property, and effective sterilization aiming at the bacterial micro-environment is realized. In addition, a benzophenone derivative is introduced into the polymer as a photocuring or crosslinking group, and firm coating of the polymer on the surface of medical equipment can be achieved. According to the self-adaptive antibacterial coating provided by the invention, a photocuring group and a zwitterionic group are combined to construct a zwitterionic polymer, and the dual functions of adhesion resistance and responsive antibacterial property are realized through the polymer. The preparation process is simpler, low in equipment requirement, easy to operate and high in feasibility.

Owner:WEIGAO HLDG +2

Tempura flower frying machine

The invention relates to a tempura flower frying machine, which relates to the technical field of food processing devices and comprises a frying box, and a shaking net is rotatably mounted above the frying box. According to the invention, the problems that non-uniform force and amplitude, large adhesion and non-uniform appearance are caused by manual slurry spreading in the traditional technology; continuous automatic production cannot be realized, large labor force is occupied, and the yield is low; when the tempura is fried, the tempura is easy to be inconsistent in appearance and color, and the fried tempura needs to be fished out by an operator, so that the percent of pass is influenced; and the number of defective products is large due to the fact that the discharging flow is not constant are solved.

Owner:诸城市博康机械有限公司

Multi-column eccentric compressing shrapnel bonding device and method

InactiveCN109974539AImprove distributionEasy to installAmmunitionElectrical and Electronics engineeringExtrusion

The invention discloses a multi-column eccentric compressing shrapnel bonding device which comprises a bracket, wherein a shrapnel storage device is arranged on the bracket and is used for accommodating a shrapnel; a magnetic cylinder for rotating is arranged at the outlet of the shrapnel storage device; a gap is reserved between the shrapnel storage device and the magnetic cylinder; an output rail is arranged on one side of the magnetic cylinder; the head end of the output rail is tangent with the magnetic cylinder; a chuck is mounted on the bracket; a cartridge case is mounted through the chuck; the tail end of the output rail is used for being close to the cartridge case to enable the shrapnel to be bonded on the cartridge case along the output rail; the cartridge case is close to the tail end of a round rail plate; and a bonding layer is paved on the surface of the cartridge case. Eccentricity of the cartridge case and the rail is utilized to realize bonding and extrusion of the shrapnel, and the gravity of the shrapnel is utilized to enable the shrapnel to be closely arrayed and increase the shrapnel arraying density, so that the problems that the existing shrapnel is low in bonding efficiency, the equipment is complicated in structure and the operating steps are more are expected to be solved.

Owner:SICHUAN UNIV

Longitudinal watertight tight-buffered fiber and preparation method thereof

InactiveCN110618507AAchieving adhesionRealize the buffering effectFibre mechanical structuresFiberBare fiber

The invention relates to a longitudinal watertight tight-buffered fiber and a preparation method thereof. The longitudinal watertight tight-buffered fiber comprises a fiber body, wherein the fiber body is packaged by a waterproof layer; and the waterproof layer is packaged by a tight-buffering layer. In a preparation period, steps of paying off a fiber, coating a bare fiber, carrying out drying, carrying out extrusion tight-buffering and carrying out cooling are carried out to obtain a finished product. Independent organic silicon gel is taken as an intermediate medium. Bonding and buffering effect between the bare fiber and the tight-buffered layer is realized, and a longitudinal watertight effect is achieved. Integral construction is simple. Preparation is convenient. An application requirement for longitudinal watertight performance of 10MPa and a water depth of 1000m is satisfied.

Owner:昆山频谱电子科技有限公司

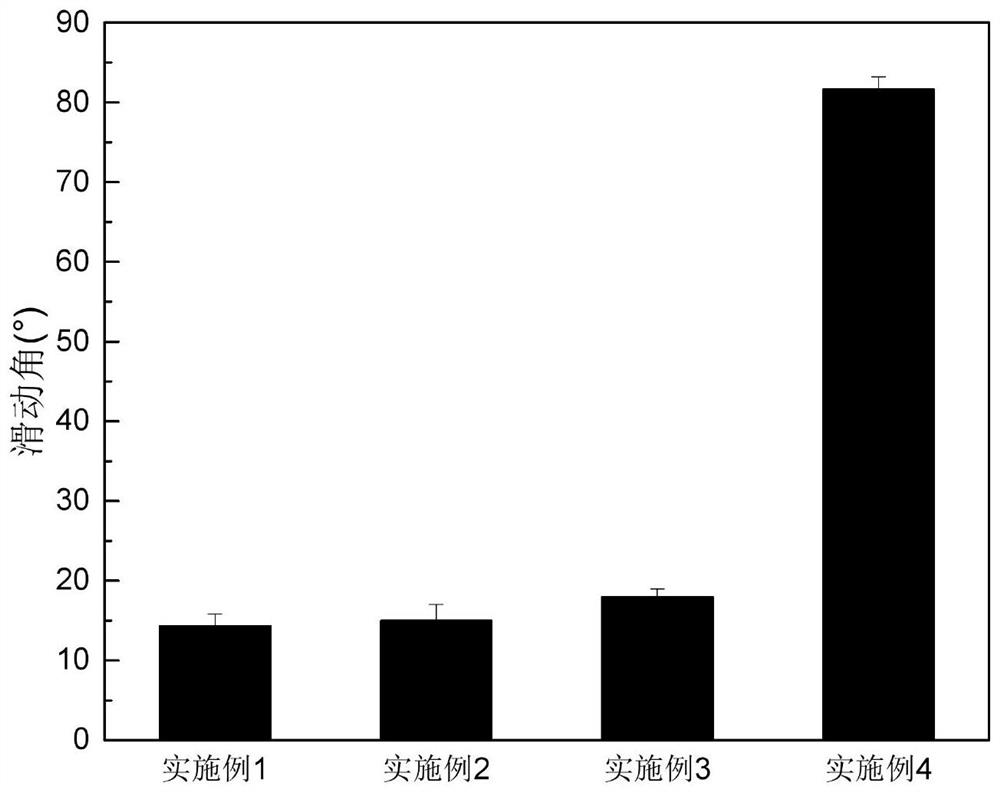

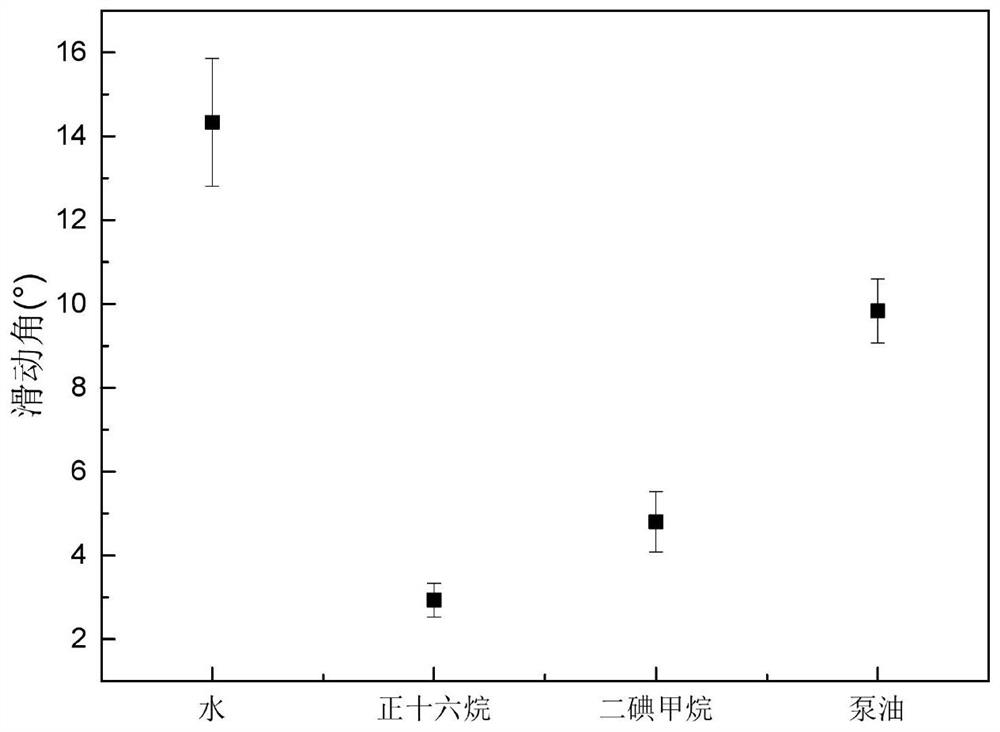

Electrophoretic paint capable of preventing adhesion of liquid and bacteria and application method of electrophoretic paint

ActiveCN114045059AImprove adhesionExcellent low adhesionAntifouling/underwater paintsPaints with biocidesSilicone fluidOrganic chemistry

The invention provides electrophoretic paint capable of preventing adhesion of liquid and bacteria. The electrophoretic paint is prepared from high-hydroxyl-value water-soluble cationic resin, a silicon-modified cross-linking component and a diluting solvent. The high-hydroxyl-value water-soluble cationic resin is obtained by polymerizing vinyl monomers in a first reaction solvent, and the vinyl monomers comprise a comonomer, a cationic monomer and a cross-linking monomer. The silicon-modified cross-linking component is obtained by reacting a silicone oil liquid low-surface-energy compound with water-dispersed or water-soluble amino resin in a second reaction solvent. The electrophoretic paint disclosed by the invention has excellent low adhesion to liquid and bacteria.

Owner:GUANGZHOU UNIVERSITY

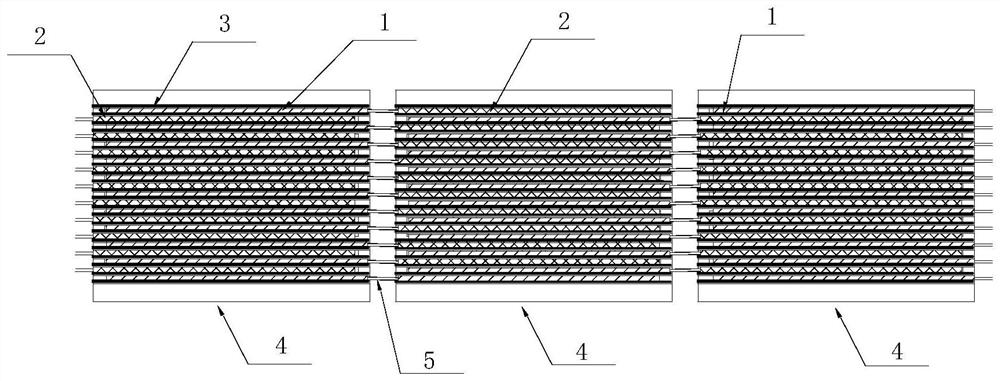

Composite separator for horizontal lead-acid battery, horizontal lead-acid battery comprising same and assembling method of horizontal lead-acid battery

PendingCN112018454ASmall self-dischargeIncrease production capacityFinal product manufactureCell component detailsEngineeringStructural engineering

The invention provides a composite separator for a horizontal lead-acid battery. The separator is of a strip-shaped structure composed of an elastic parent body and an insert wrapped in the elastic parent body, the height of the strip-shaped structure is equal to the distance between horizontal lead-acid battery polar plates, and the upper end and / or the lower end of the strip-shaped structure are / is provided with glue containing grooves / glue containing grooves which are / is through in the left-right direction and used for containing sealant. The elastic parent body is an elastic material withthe elasticity modulus being 5-50 MPa, and the insert is an acid-resistant rigid material with the elasticity modulus being larger than or equal to 200 MPa. The invention also provides a horizontal lead-acid battery comprising the composite separator and an assembling method of the horizontal lead-acid battery. The insert provides rigidity, and deformation and instability of the insert during assembly and compression are prevented; the lead wire can pass through the elastic parent body and the sealant filled in the sealant accommodating groove in a lossless manner, so that gas and liquid amongdifferent cells are isolated, efficient sealing among the cells of the horizontal lead-acid battery is realized, and the comprehensive performance of the horizontal lead-acid battery is effectively improved.

Owner:浙江图兰特储能科技有限公司

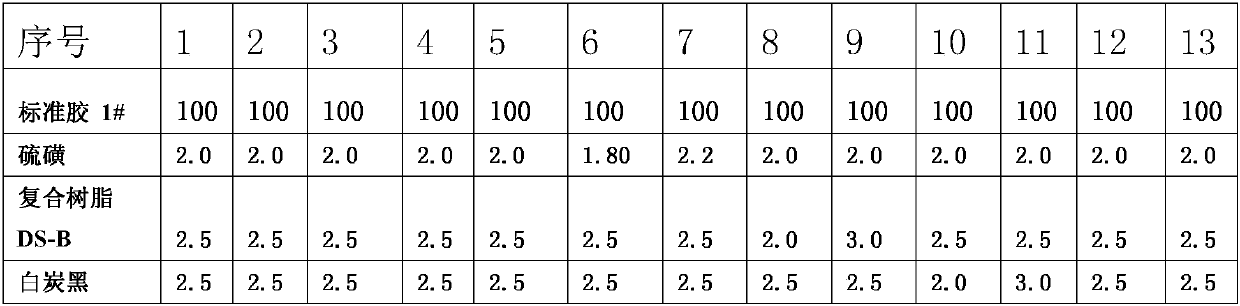

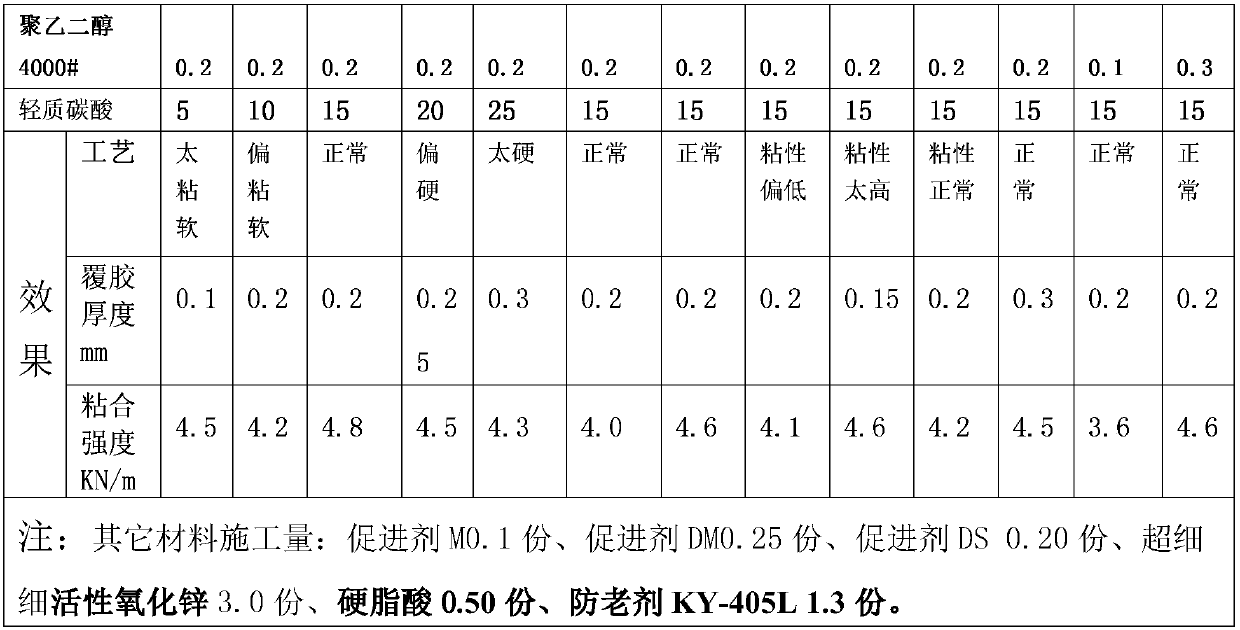

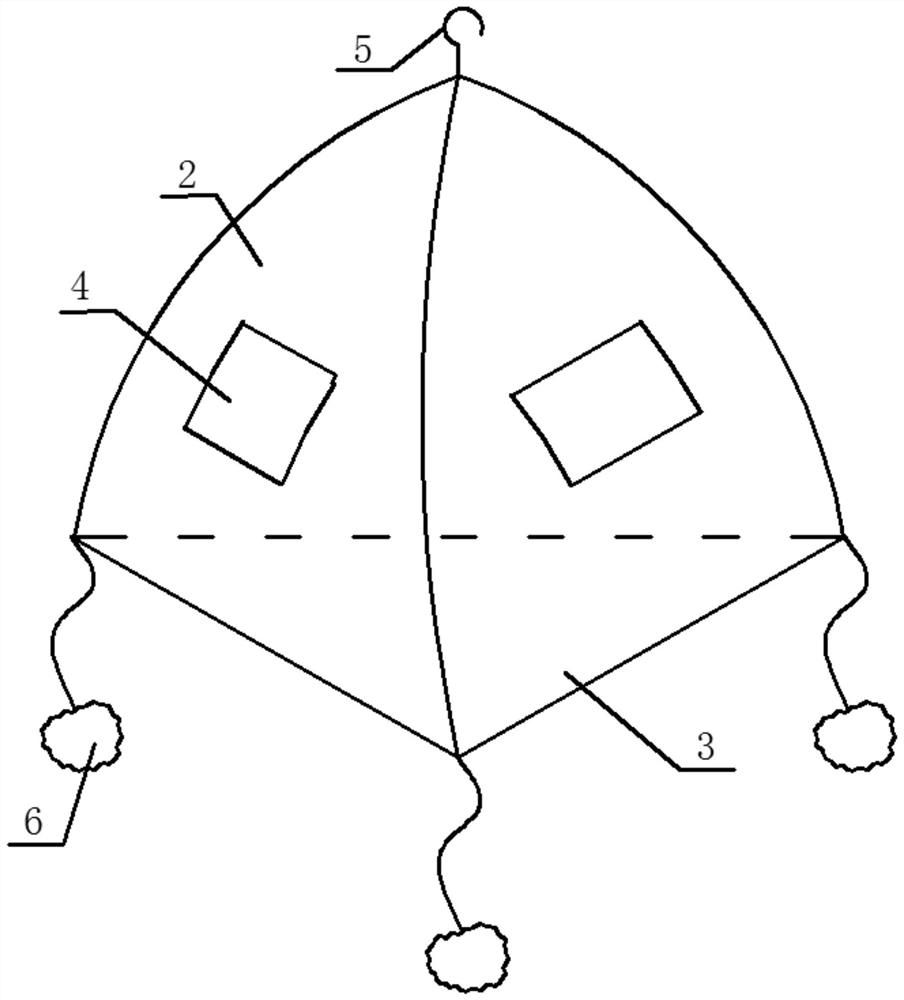

A canvas-based artificial fish reef and its preparation method

ActiveCN109530186BReduce weightImprove root stabilitySpecial surfacesCoatingsLatex rubberCrushed stone

The invention discloses a canvas-based artificial fish reef and a preparation method thereof, which is characterized in that: the artificial fish reef includes a canvas body, the outer surface of the canvas body is coated with a first protective layer, and the first protective layer The outer surface of the layer is coated with a second protective layer; the first protective layer is prepared from the following components in parts by weight: 7-10 parts of redispersible latex powder, 15-25 parts of polyurethane, 100-200 parts of cement 70-150 parts of water; the raw materials of each part by weight of the second protective layer include: 440-470 parts of cement, 30-80 parts of fly ash, 20-50 parts of mineral powder, and 910-960 parts of crushed stone , 680-730 parts of sand, 8-15 parts of soda ash, 2-5 parts of quicklime, 10-40 parts of redispersible latex powder, and 220-260 parts of water; the canvas-based artificial fish reef is a tent-like structure. It has the advantages of suitable weight, easy salvage and repair, and can effectively improve the rooting stability of seaweed, and the overall fish reef is not easy to crack and has strong toughness.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com