Automatic horn assembling device and control method thereof

A technology for automatic assembly and installation of devices, applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of lack of qualitative improvement in production efficiency, different assembly processes, and large space occupation, and achieve production efficiency and The effect of improving the qualification rate of products, high degree of automation and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

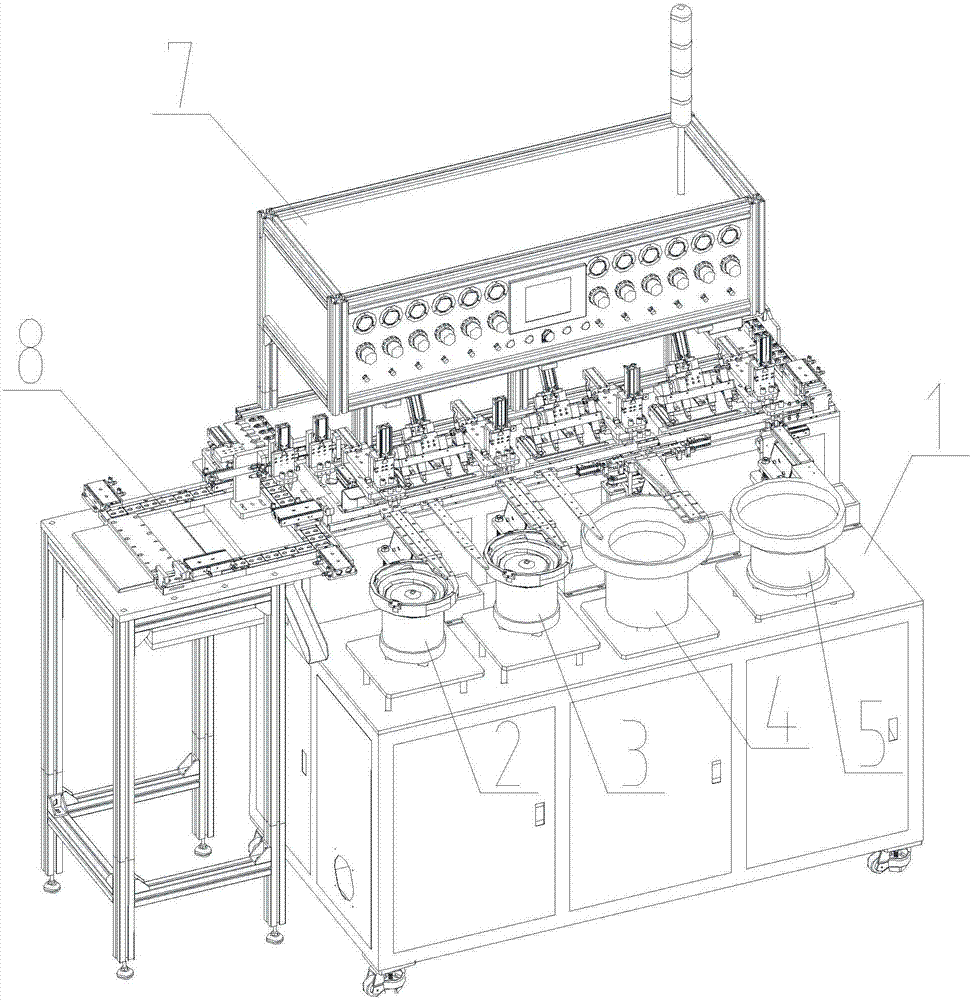

[0042] Such as figure 1 , figure 2 As shown, an automatic speaker assembly device is provided in the embodiment, including a speaker automatic assembly device, which is characterized in that it includes a main base 1, a first installation device 2, a second installation device 3, and a third installation device 4 , the fourth installation device 5, the circular conveying track 6, and the controller 7, the first installing device 2, the second installing device 3, the third installing device 4, and the fourth installing device 5 are arranged on one side of the circulating conveying track 6 in sequence , the second installation device 3, the third installation device 4, the fourth installation device 5, and the circulation conveying track 6 are all fixed on the top of the main base 1, and the controller 7 is connected with the first installation device 2, the second installation device 3, The third installation device 4, the fourth installation device 5, and the circular conve...

Embodiment 2

[0052] A control method for the above-mentioned horn automatic assembly device is provided, which is implemented according to the following steps:

[0053] S01: The controller 7 controls the metal gasket vibrating plate 21 to transfer the metal gasket to the output track 211 of the metal gasket vibrating disk 21, and then controls the component suction nozzle 221 of the metal gasket retrieving mechanism 22 to transfer the metal gasket from the metal gasket The output track 211 of the vibrating plate 21 is sucked up;

[0054] S02: the controller 7 controls the component suction nozzle 221 of the metal gasket retrieving mechanism 22 to move to the stage 9, and after reaching the designated position, place the metal gasket on the stage 9;

[0055] S03: the controller 7 controls the stage 9 to move to the bottom of the metal gasket dispenser 23, and the metal gasket dispenser 23 dispenses glue on the metal gasket;

[0056] S04: The controller 7 controls the magnetic metal block v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com