Semiconductor packaging and mounting device

A semiconductor and body technology, which is applied in the field of semiconductor packaging and chip mounting devices, can solve the problems of complex semiconductor packaging technology, imperfect semiconductor packaging technology, low efficiency of chip bonding process, etc., and achieves the effect of good controllability of the position of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

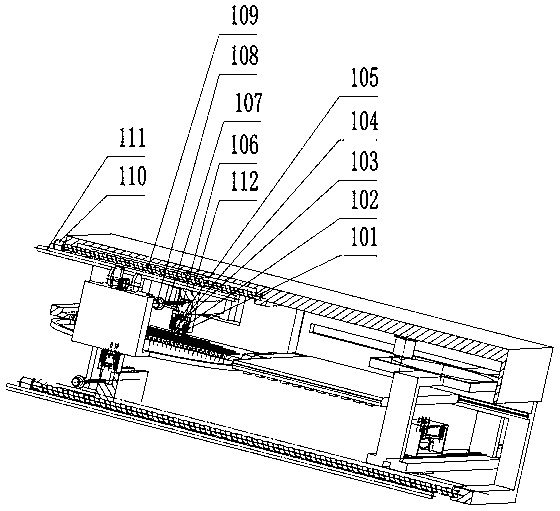

[0017] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 A semiconductor package chip loading device is shown: including a thimble structure 1 , a blue film fixing structure 2 , a crystal block adsorption structure 3 , a silver paste sprinkling structure 4 , and a body 5 . The blue film fixing structure 2 is installed above the thimble structure 1 , the crystal block adsorption structure 3 is installed on the top of the body 5 , and the silver paste sprinkling structure 4 is installed in front of the thimble structure 1 .

[0018] The elastic thimble 102 of the thimble structure 1 is fixedly installed on the sliding thimble base 103 , and the sliding thimble base 103 is slidably connected with the transverse sliding platform 106 . One end of the pressure spring 101 is in contact with the bottom baffle of the transverse sliding table 106 , and the other end of the pressure spring 101 is in contact with the baffle of the sliding thimble ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com