Huge transfer printing head, transfer printing device and transfer method of light emitting diode chip

A technology of light-emitting diodes and transfer heads, which is applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., and can solve the problems of inability to transfer Micro-LED chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

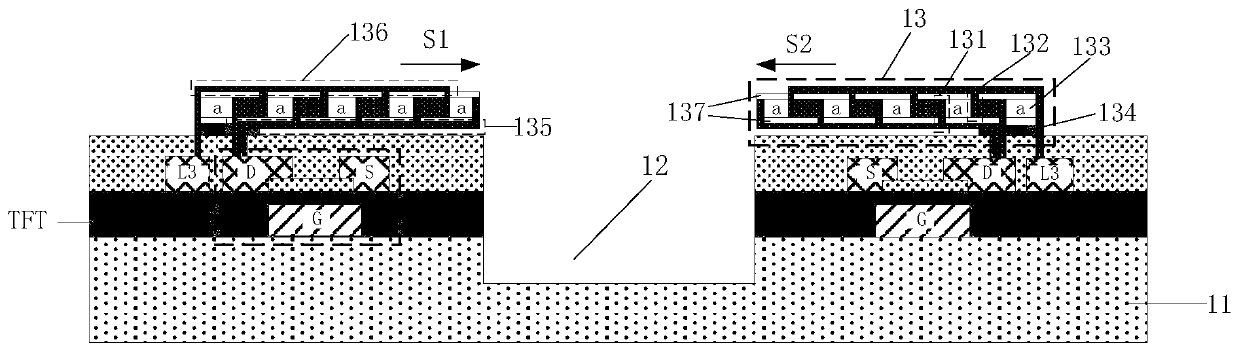

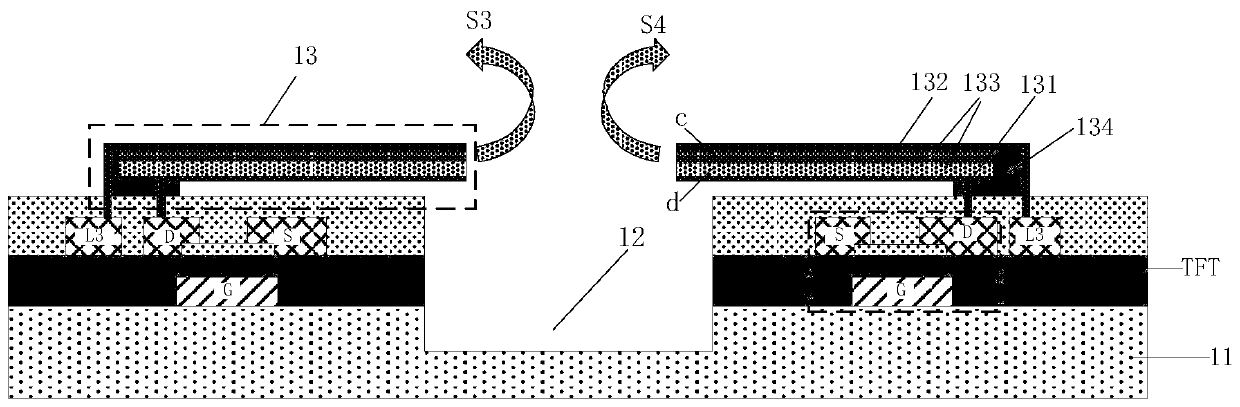

[0059] To solve the problem in the prior art that a large number of micron-sized Micro-LED chips cannot be transferred to the drive backplane, the embodiment of the present invention provides a transfer of a large number of transfer printing heads, transfer equipment and light-emitting diode chips method.

[0060] The specific implementation manners of the mass transfer head, the transfer device and the method for transferring light-emitting diode chips provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The size and shape of each structure in the drawings do not reflect the real scale, but are only intended to schematically illustrate the content of the present invention.

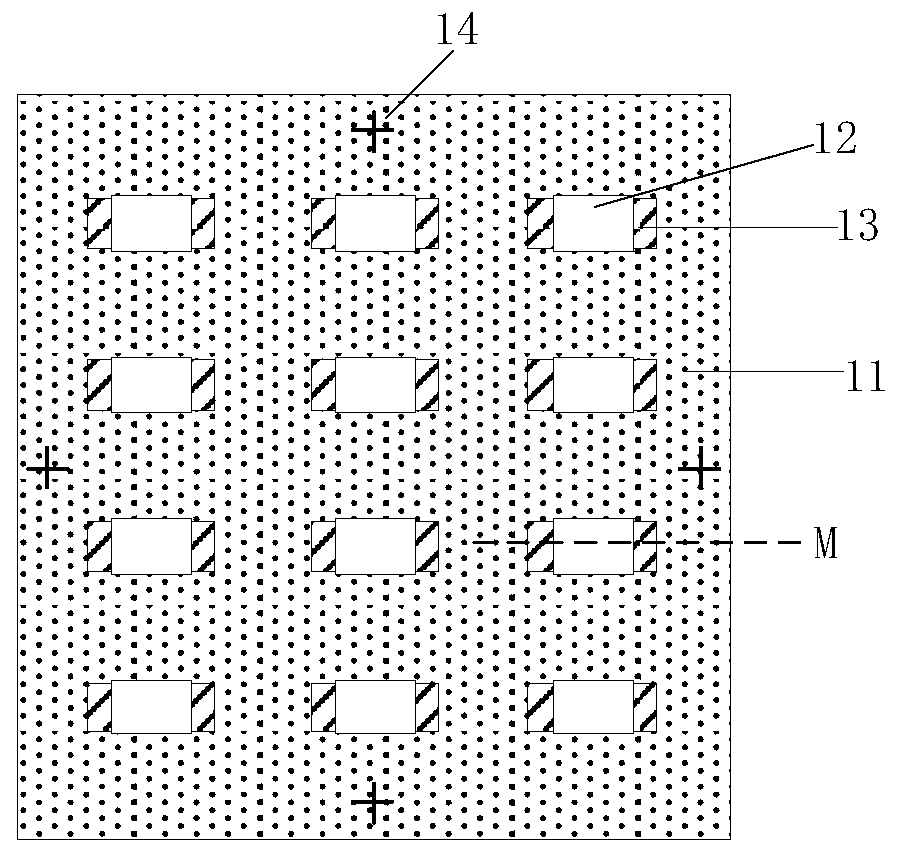

[0061] In the first aspect, the embodiment of the present invention provides a mass transfer head, such as figure 1 As shown, it includes: a transfer substrate 11, a plurality of accommodating grooves 12 for accommodating ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com