Method for manufacturing toner, toner and image forming method

A manufacturing method and technology of toner, applied in the direction of electric recording process using charge pattern, equipment and developer of electric recording process using charge pattern, etc., capable of solving the problems of particle collapse, insufficient mechanical strength, waste of carrier, etc. , to achieve the effect of suppressing the amount of toner adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

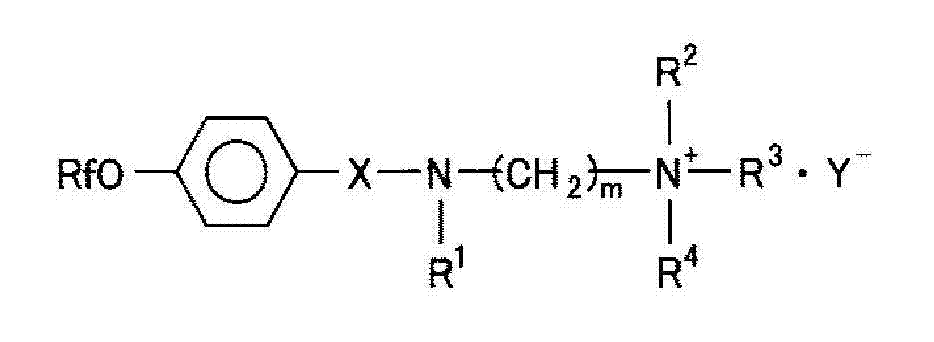

Method used

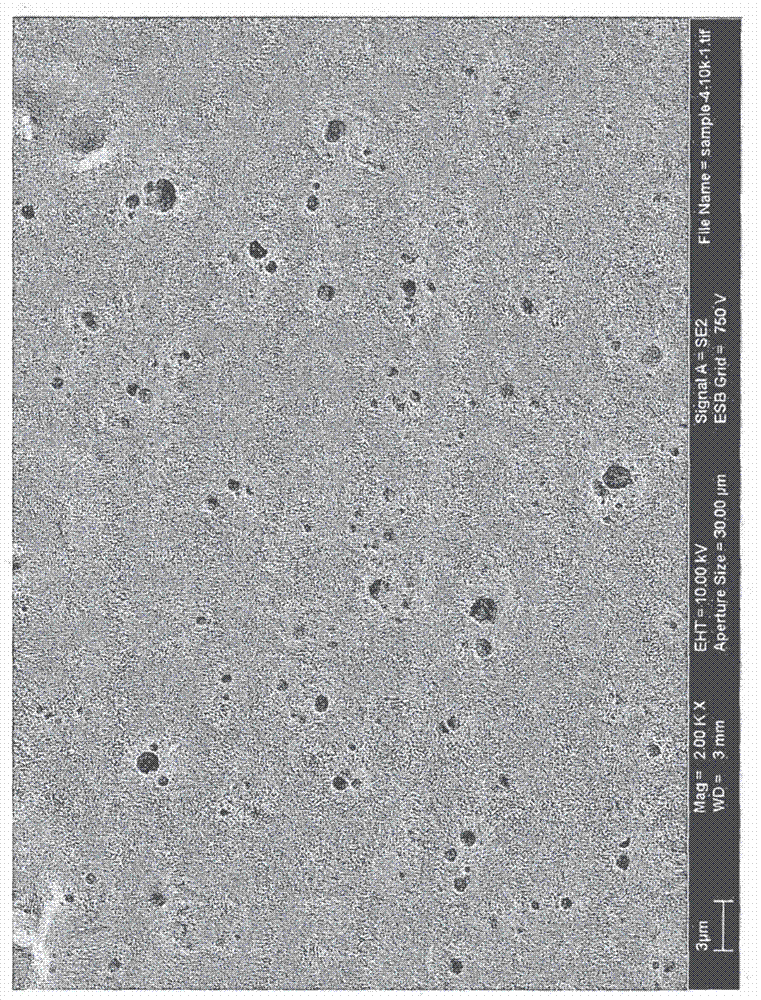

Image

Examples

Embodiment

[0217] Hereinafter, the present invention will be further described in detail with reference to examples, but the examples should not be construed as limiting the scope of the present invention. Note that the unit "part" in the examples means "part by mass".

[0218] [Preparation of the first liquid]

manufacture example 1

[0219] Production Example 1: First Liquid (a1)

[0220] In a tank were placed 170 parts of a 35% by mass dispersion of carnauba wax in ethyl acetate, 120 parts of styrene-methyl acrylate copolymer, 20 parts of yellow pigment PY155 (manufactured by Clariant (Japan) K.K.), 70 parts Ethyl acetate and 2 parts of isophoronediamine and mixed with stirring for 2 hours. It was then circulated and mixed for 1 hour using a high-efficiency dispersing device EBARA MILDER (manufactured by Ebara Corporation) to obtain a first solution (a1). The styrene-methyl acrylate copolymer as the binder resin had an acid value of 15 KOHmg / g.

manufacture example 2

[0221] Production Example 2: First Solution (a2)

[0222] The first solution (a2) of Production Example 2 was obtained in the same manner as the first solution (a1), except that a polyester resin was used instead of the styrene-methyl acrylate copolymer in Production Example 1. This polyester resin as a binder resin had an acid value of 15 KOHmg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com