Battery separator

A battery and diaphragm technology, applied in the field of battery diaphragms, can solve the problems of increased battery resistance and reduced battery cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

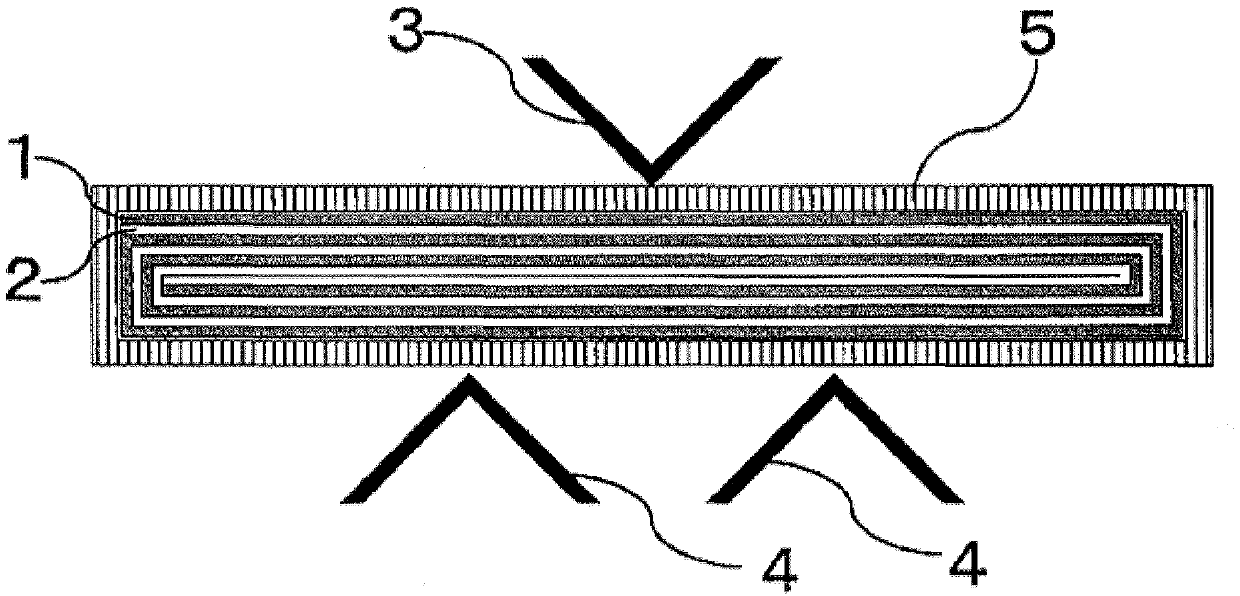

Image

Examples

preparation example Construction

[0064] (1) Preparation process of polyolefin solution

[0065] After adding respective suitable film-forming solvents to polyolefin resins, melt-kneading is carried out to prepare polyolefin solutions. As the melt-kneading method, for example, the method using a twin-screw extruder described in Japanese Patent No. 2132327 and Japanese Patent No. 3347835 can be used. Since the melt-kneading method is known, description is omitted.

[0066] In the polyolefin solution, the mixing ratio of the polyolefin resin and the film-forming solvent is not particularly limited, but the film-forming solvent is preferably 70-80 parts by mass relative to 20-30 parts by mass of the polyolefin resin. If the ratio of the polyolefin resin is within the above range, when the polyolefin solution is extruded, expansion and shrinkage at the outlet of the die can be prevented, and the moldability of the extruded molded product (gel-like molded product) can be improved. And self-supporting is good.

...

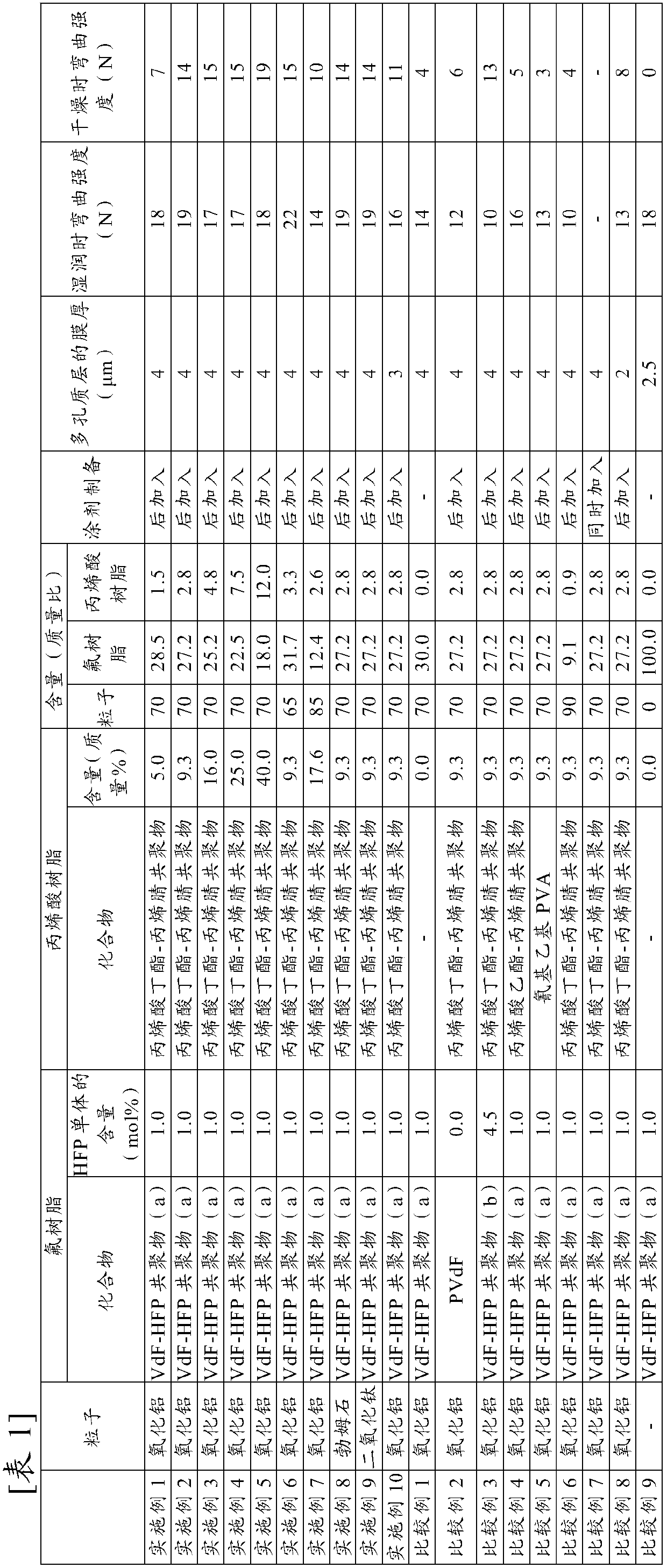

Embodiment 1

[0170] [Vinylidene fluoride-hexafluoropropylene (VdF-HFP) copolymer]

[0171] Using vinylidene fluoride, hexafluoropropylene and monomethyl maleate as starting materials, the vinylidene fluoride-hexafluoropropylene copolymer (a) was synthesized by suspension polymerization. By NMR measurement, it was confirmed that the weight average molecular weight of the obtained vinylidene fluoride-hexafluoropropylene copolymer was 1.5 million, and the moles of vinylidene fluoride monomer unit / hexafluoropropylene monomer unit / monomethyl maleate monomer unit The ratio is 98.5 / 1.0 / 0.5.

[0172] [Acrylic]

[0173] Using acrylonitrile and n-butyl acrylate as starting materials, a butyl acrylate-acrylonitrile copolymer was synthesized as an acrylic resin by emulsion polymerization, and then water was replaced with N-methyl-2-pyrrolidone (NMP) to obtain a solid component Acrylic resin solution with a concentration of 5% by mass. It was confirmed by NMR measurement that the Tg of the obtained ...

Embodiment 2

[0177] A coating solution prepared such that the solid content concentration was 13% by mass and the mass ratio of alumina particles: vinylidene fluoride-hexafluoropropylene copolymer (a): acrylic resin was 70:27.2:2.8 was used, except that A battery separator was obtained in the same manner as in Example 1. The obtained battery separator was evaluated for powder fall and was favorable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com