0.022 mm temperature-tolerance decoration foil and preparation method thereof

A technology with high temperature resistance and mass fraction, which is applied in the field of aluminum foil processing, can solve the problems of heat softening of materials, deformation and wrinkling of aluminum foil, and instability of mechanical properties of aluminum foil, so as to improve metal temperature resistance, increase recrystallization temperature, and increase alloy strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for preparing a 0.022mm heat-resistant decorative foil, the mass fraction of alloy elements in the 0.022mm thick decorative foil is mainly composed of the content in Table 2, and the process is as follows:

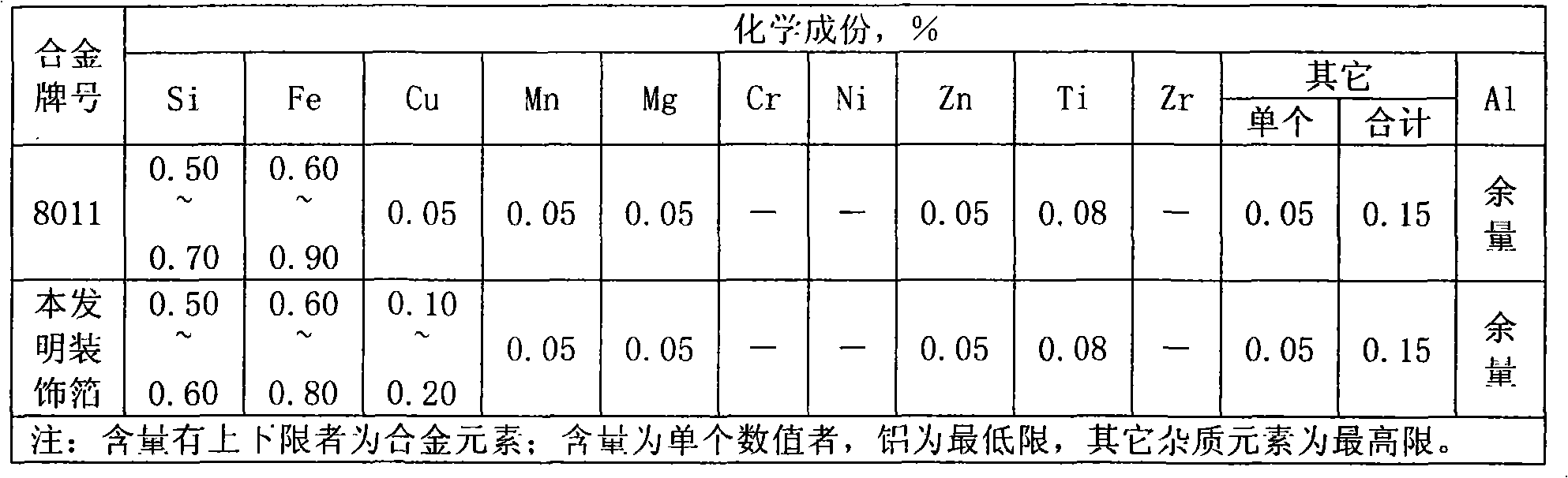

[0023] 1. The chemical composition is described in Table 2:

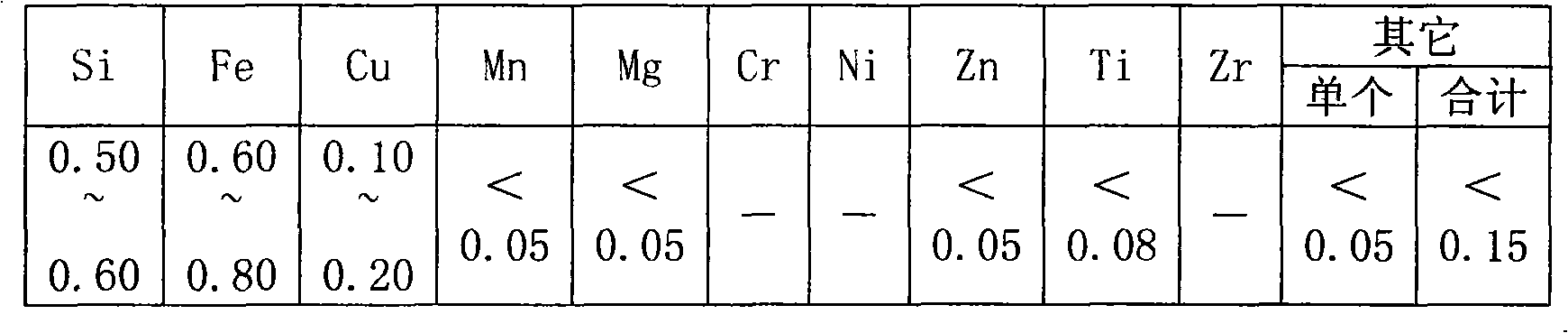

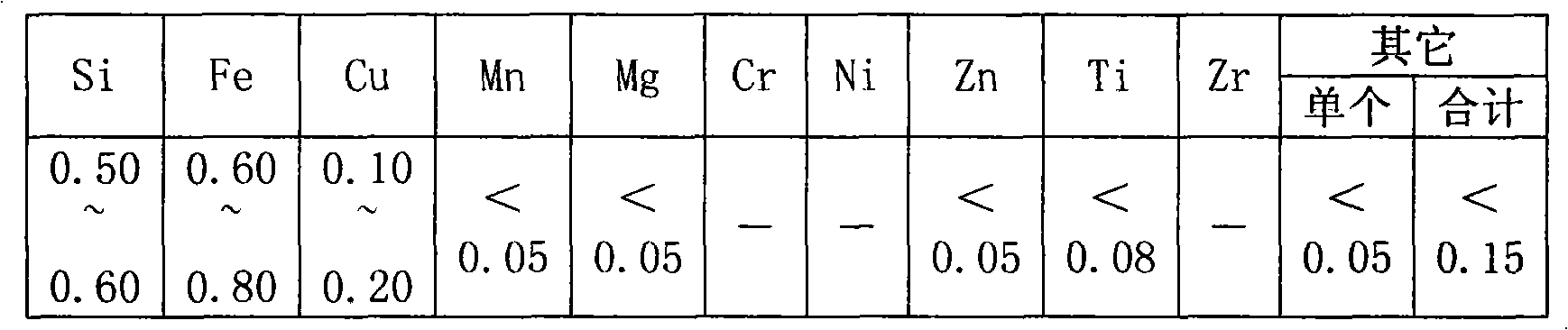

[0024] Table 2 chemical composition

[0025]

[0026] 2. Other quality indicators of cast-rolled coils meet the requirements of YS / T90-2002 aluminum and aluminum alloy cast-rolled strip standards;

[0027] 3. Production process: 6.0~10.0mm (cast rolling plate)→cold rolling to 0.44~0.85mm→intermediate annealing (H22 state)→cold rolling to 0.28~0.60mm→foil rolling to finished product thickness (0.022mm) → Slitting.

[0028] 4. Intermediate annealing process system

[0029] Furnace gas temperature control method is used for annealing, that is, furnace is installed at ≤100°C, heated for 1.5 hours to 350-450°C, and kept for 5-15 hours; cooled for 0.5 hours to 320-380°C, kept for 5-15 hours, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com