Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Solder connection is firm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

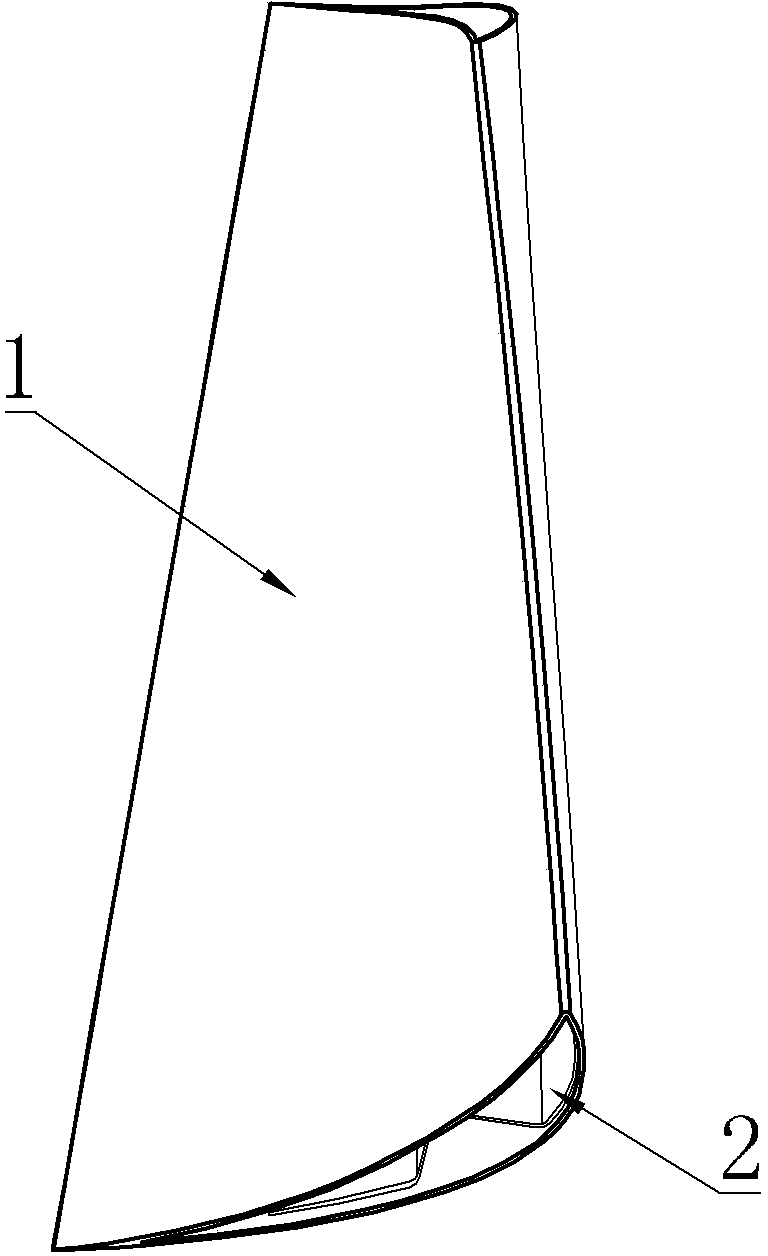

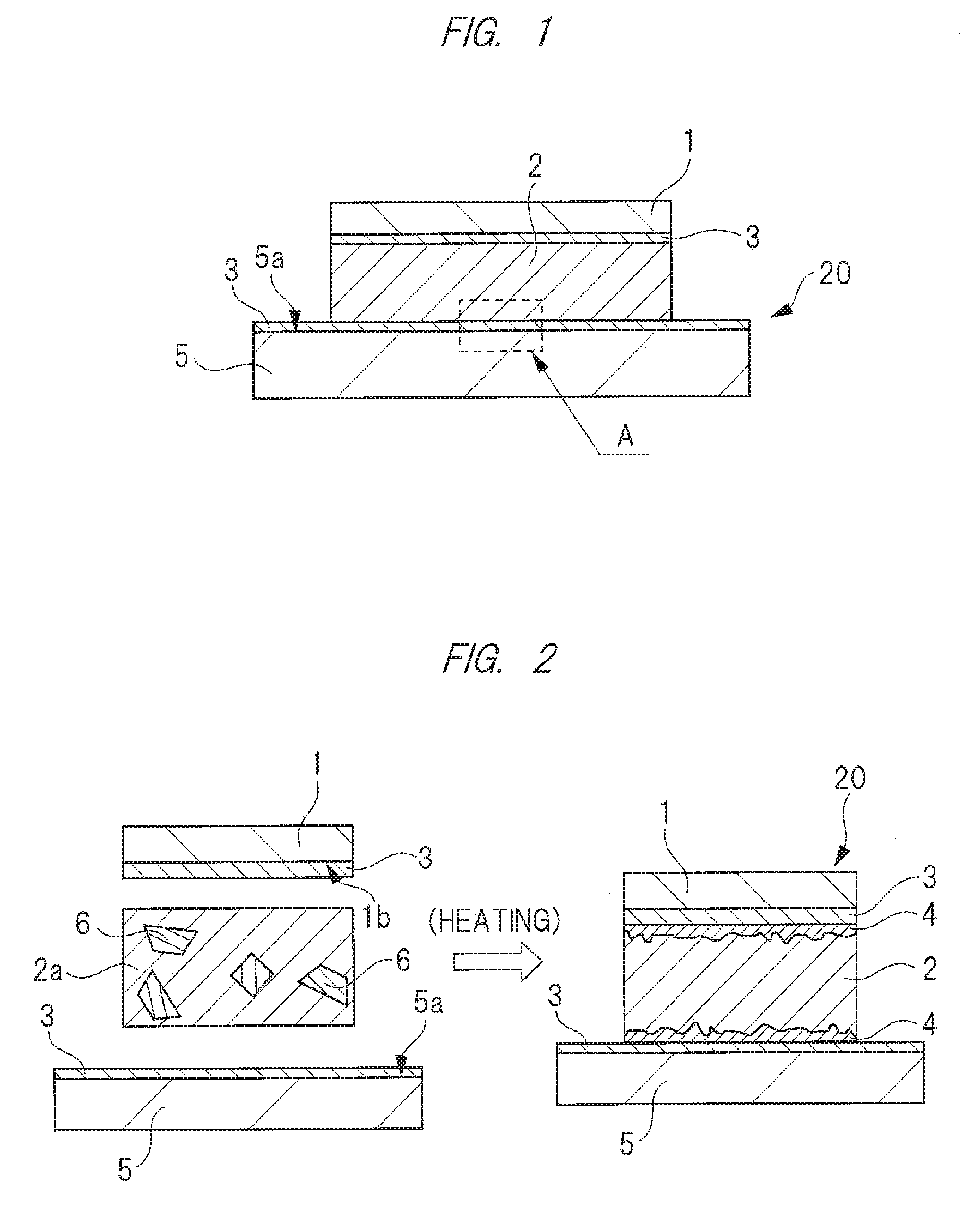

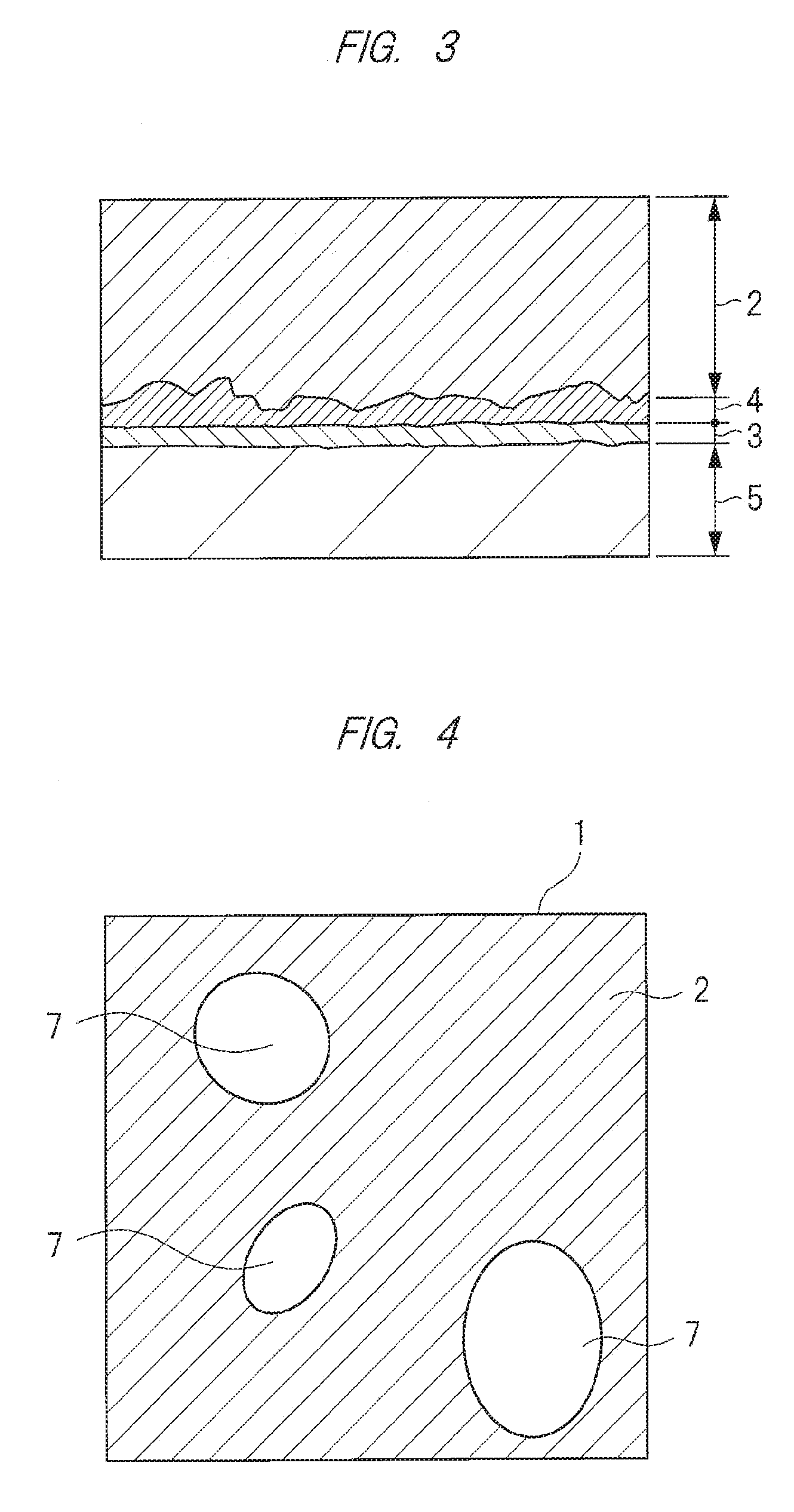

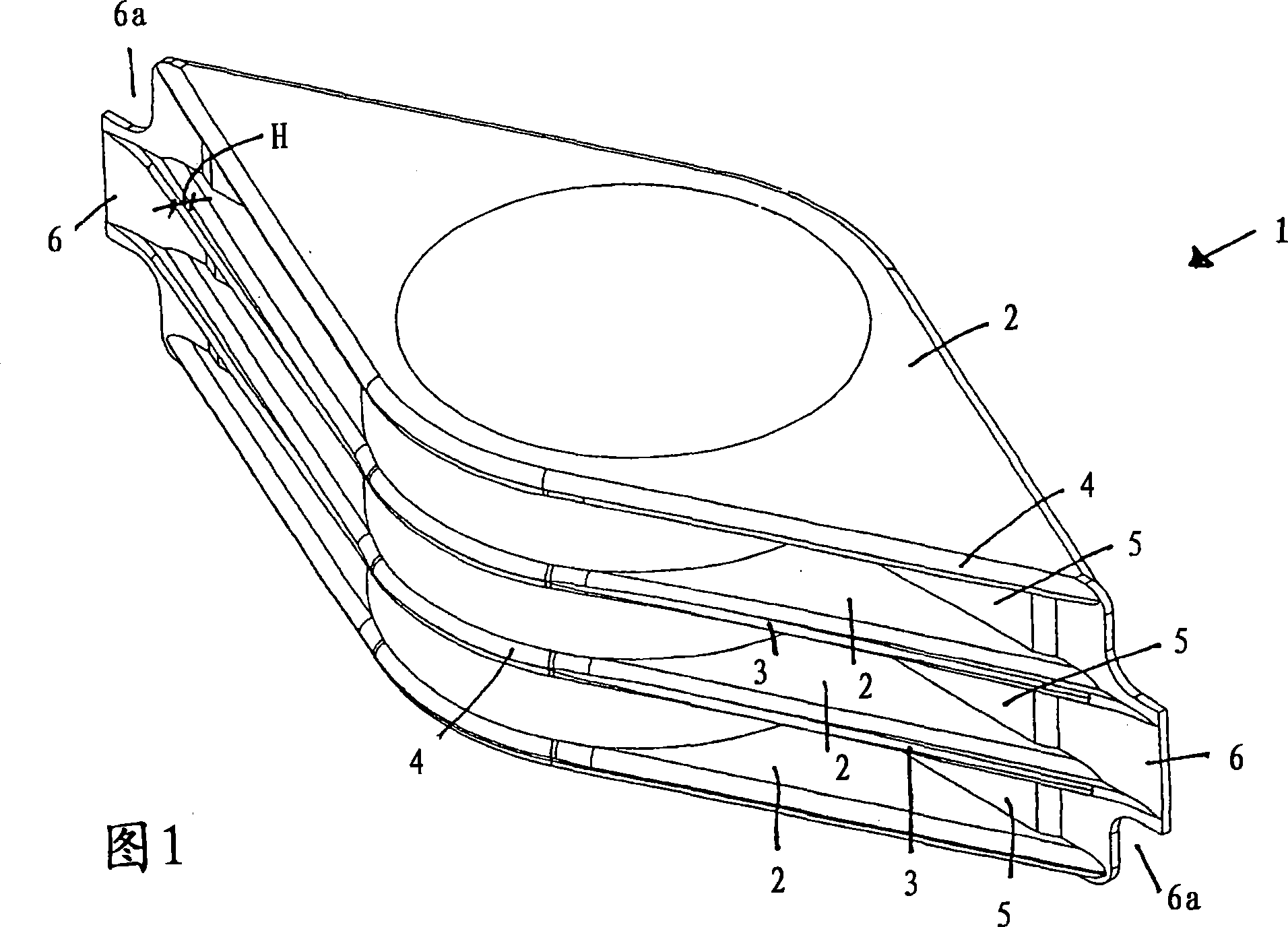

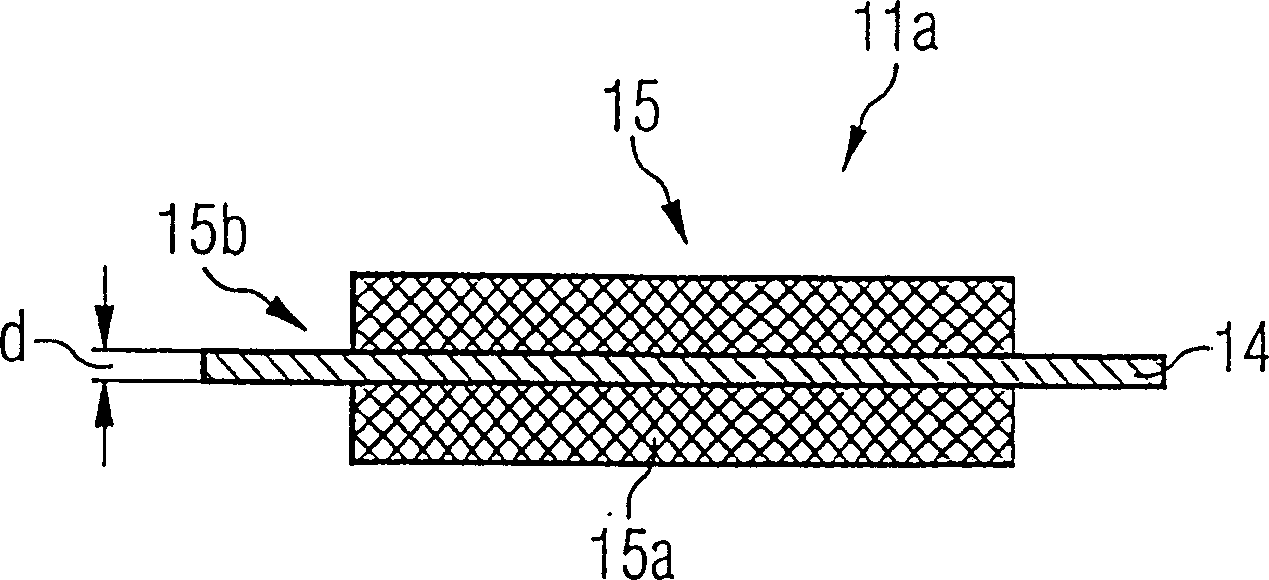

Electrically conductive textile

ActiveUS20060027552A1Improve robustnessProcess stabilityPrinted circuit assemblingVehicle seatsConductive textileConductive coating

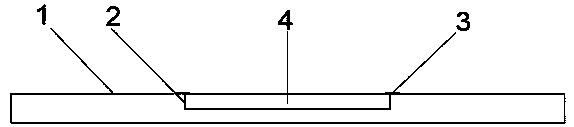

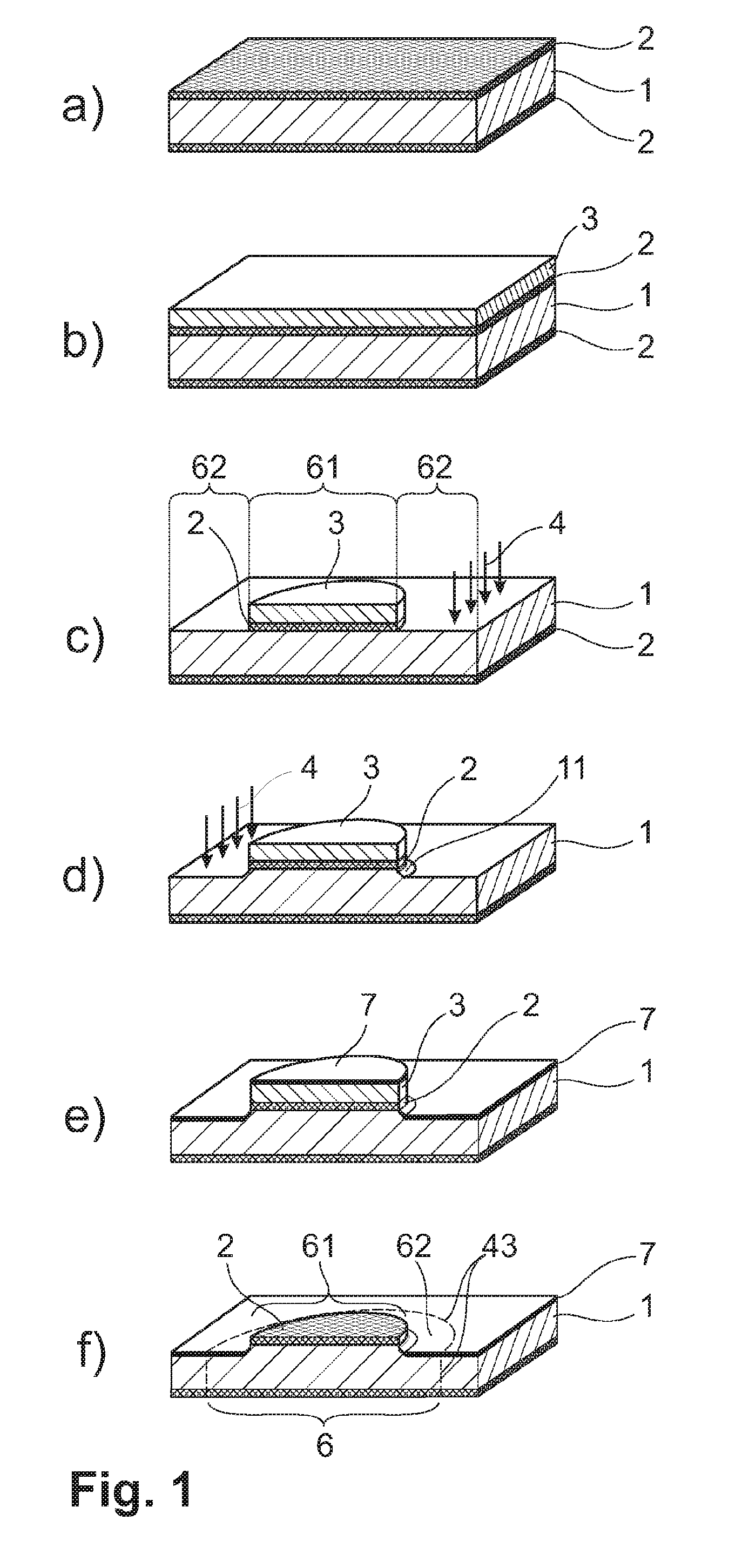

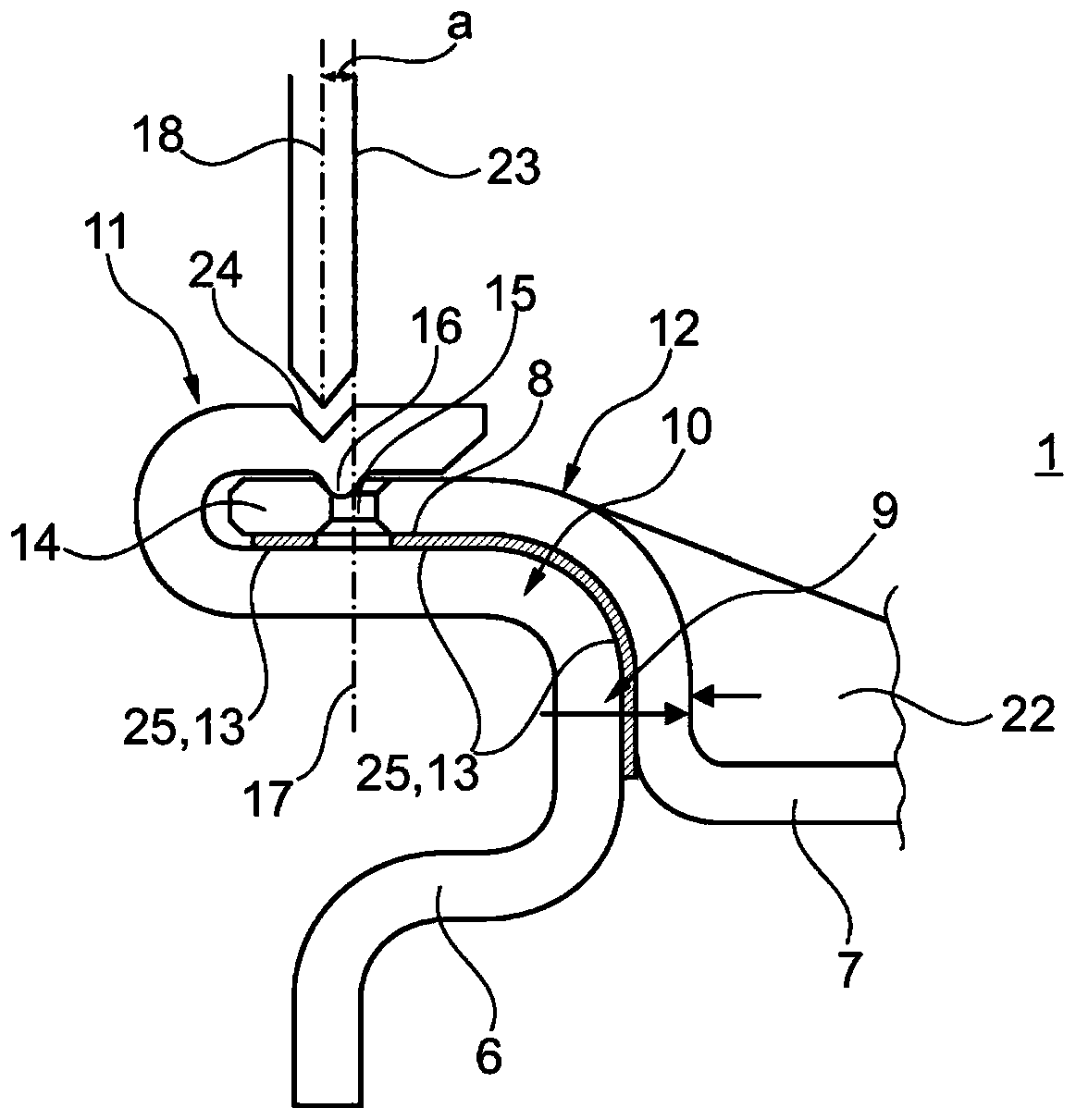

A surface structure (1) that is at least partially electrically conductively coated by a conductor coating (11), and which can be connected to an electric power source by at least one electric connecting conductor (2). The connecting conductor (2) electrically contacts the conductor coating (11) at at least one solder point (3), and the conductive coating (11) is thickened at least at one contact zone (4) in the area of the solder point (3) as opposed to other areas (7) of the surface structure (1).

Owner:GENTHERM GMBH

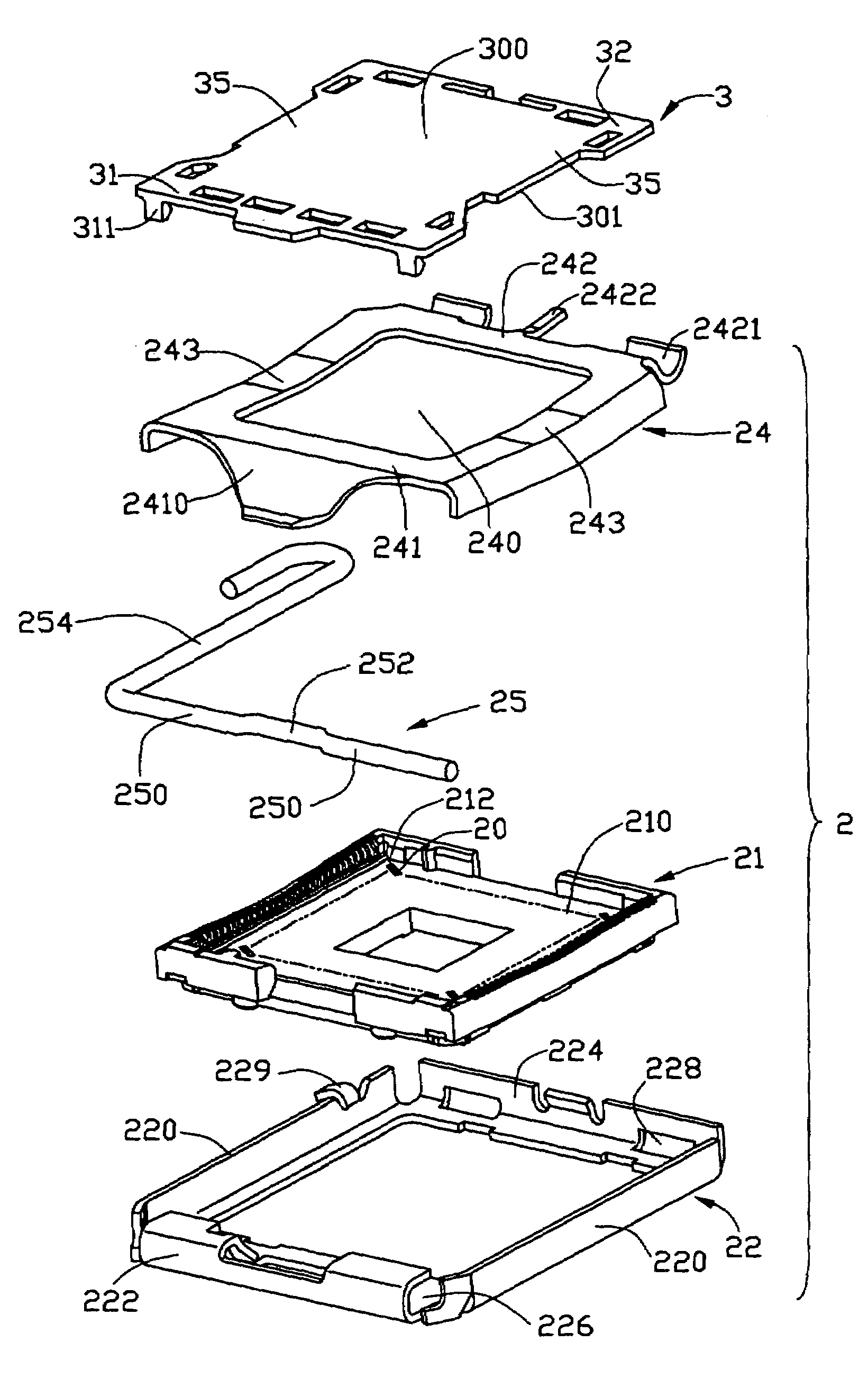

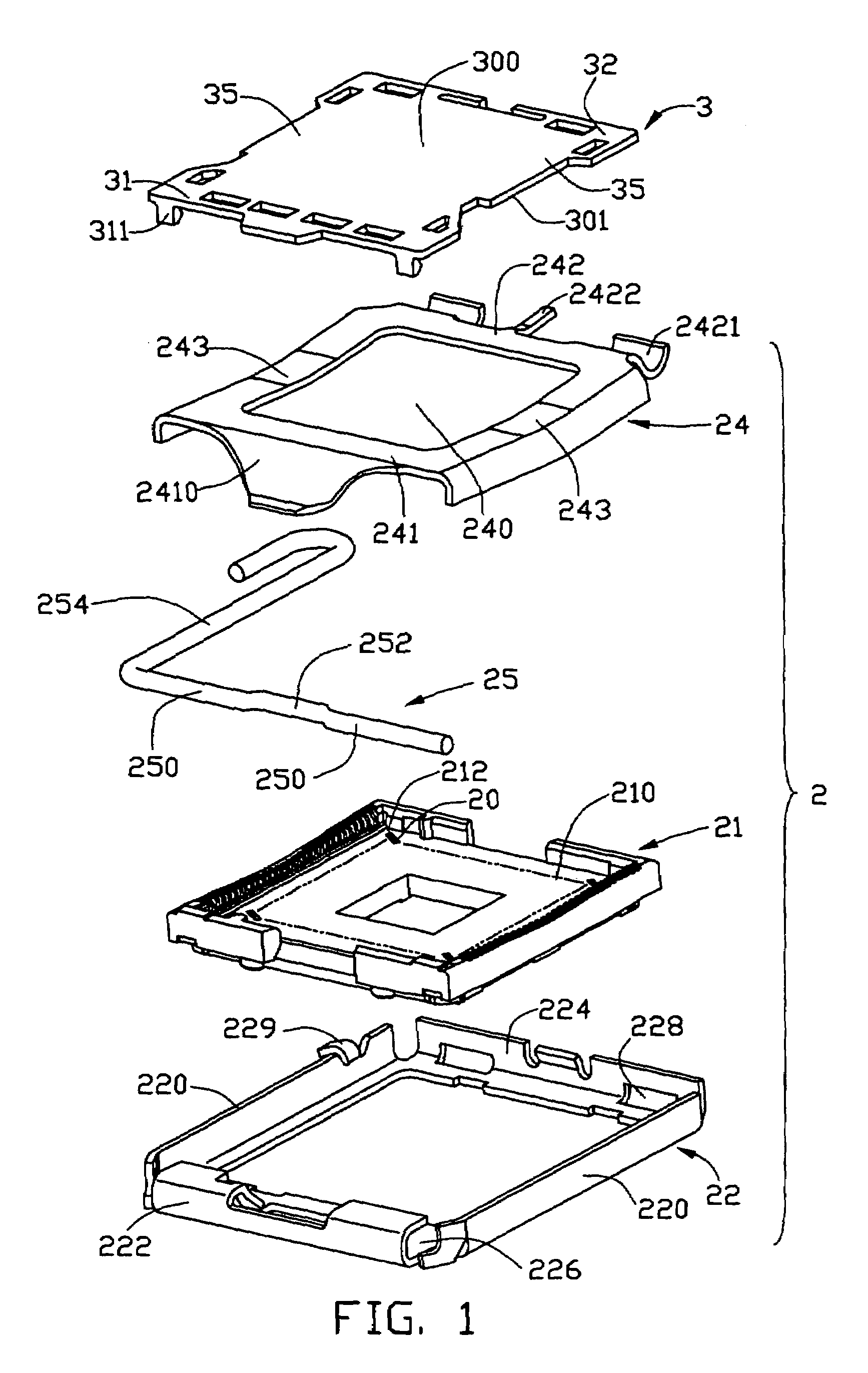

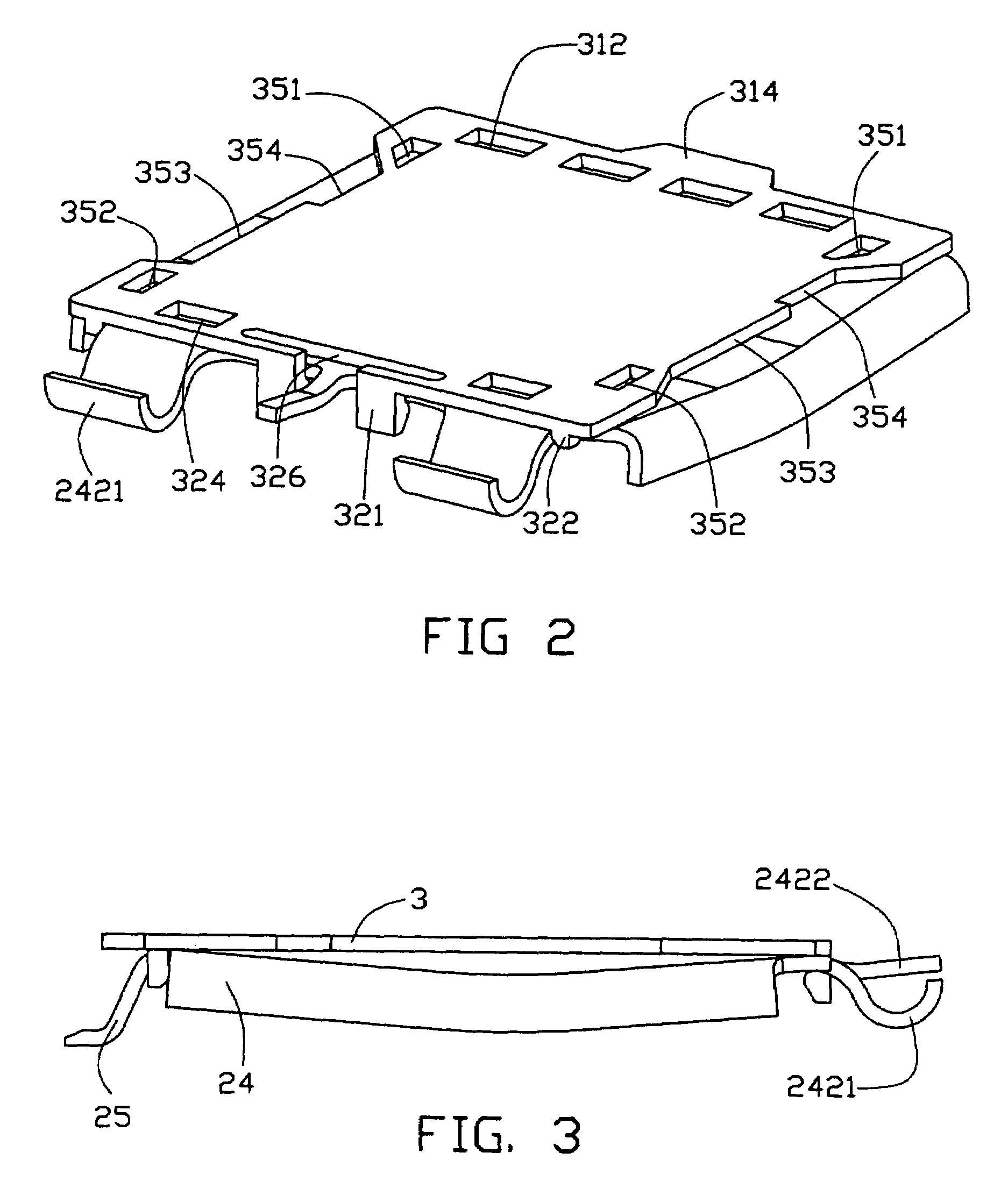

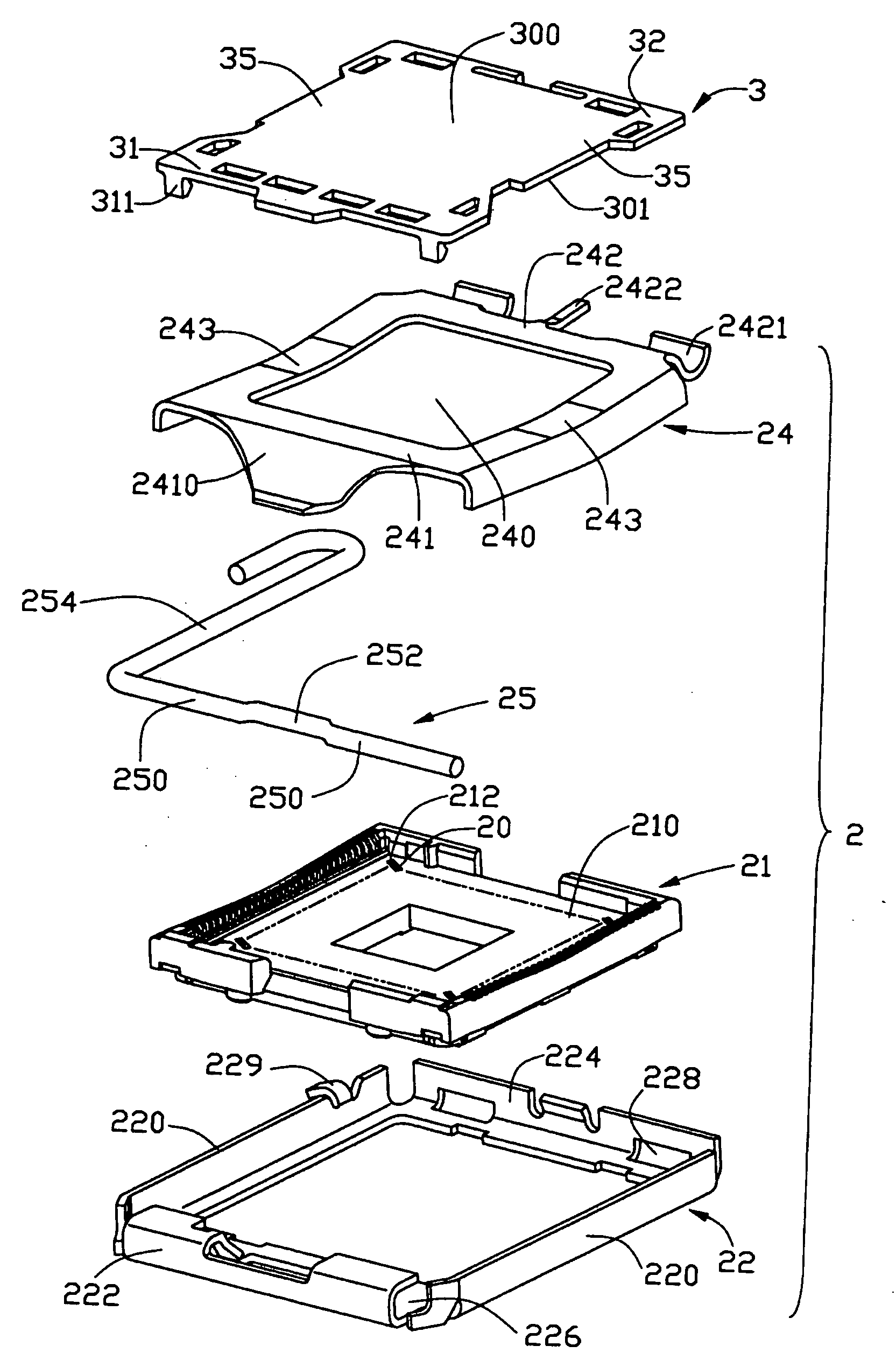

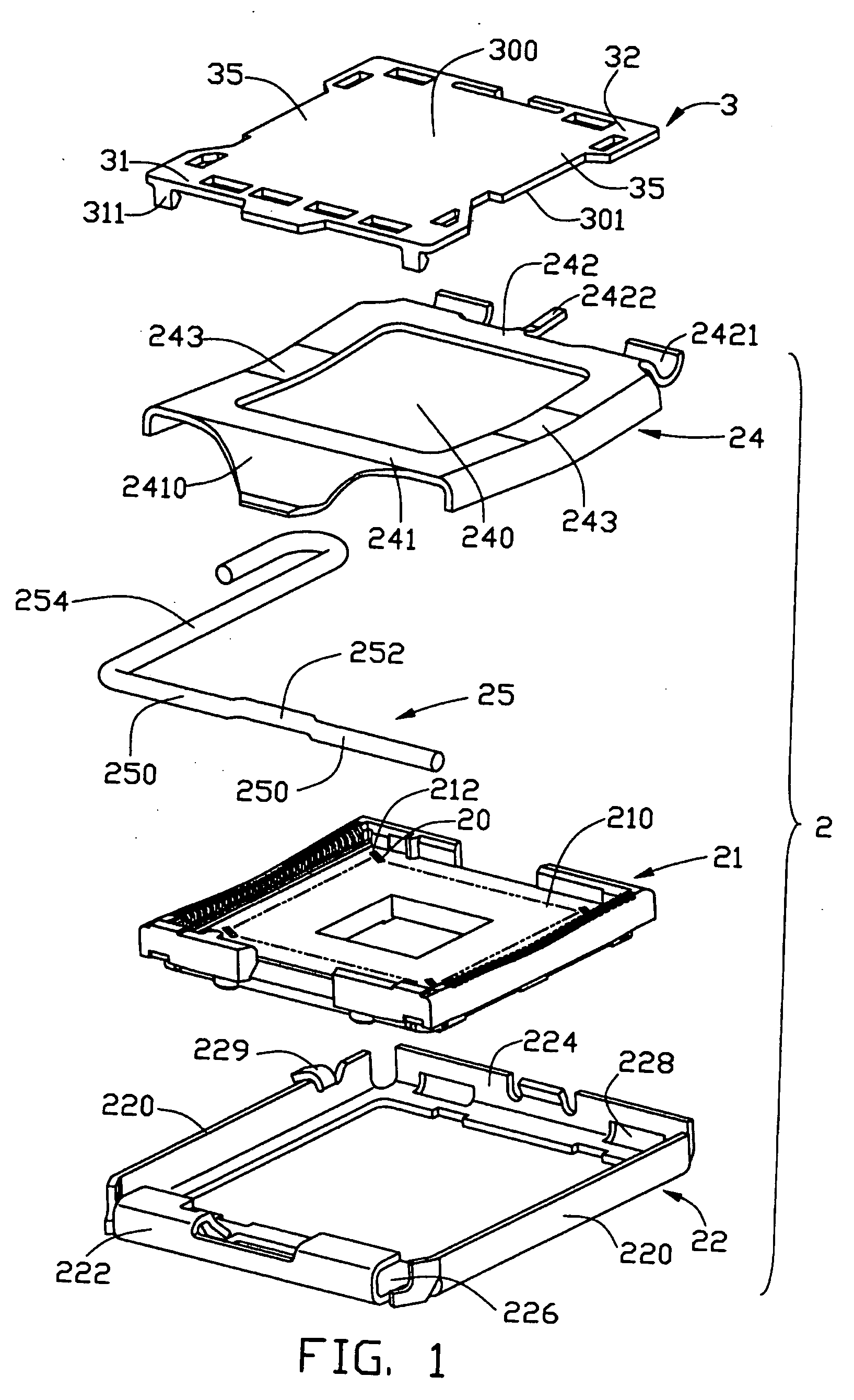

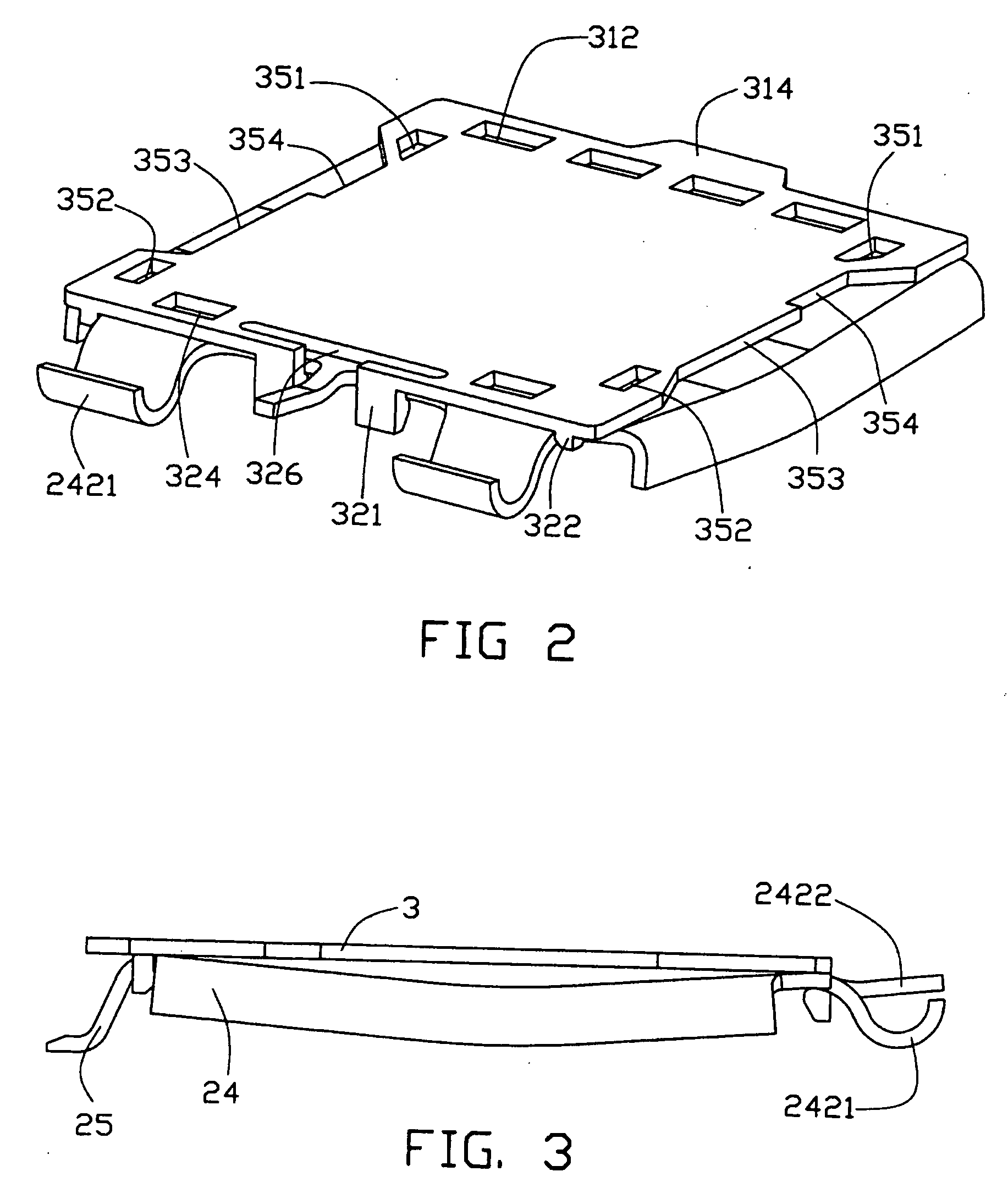

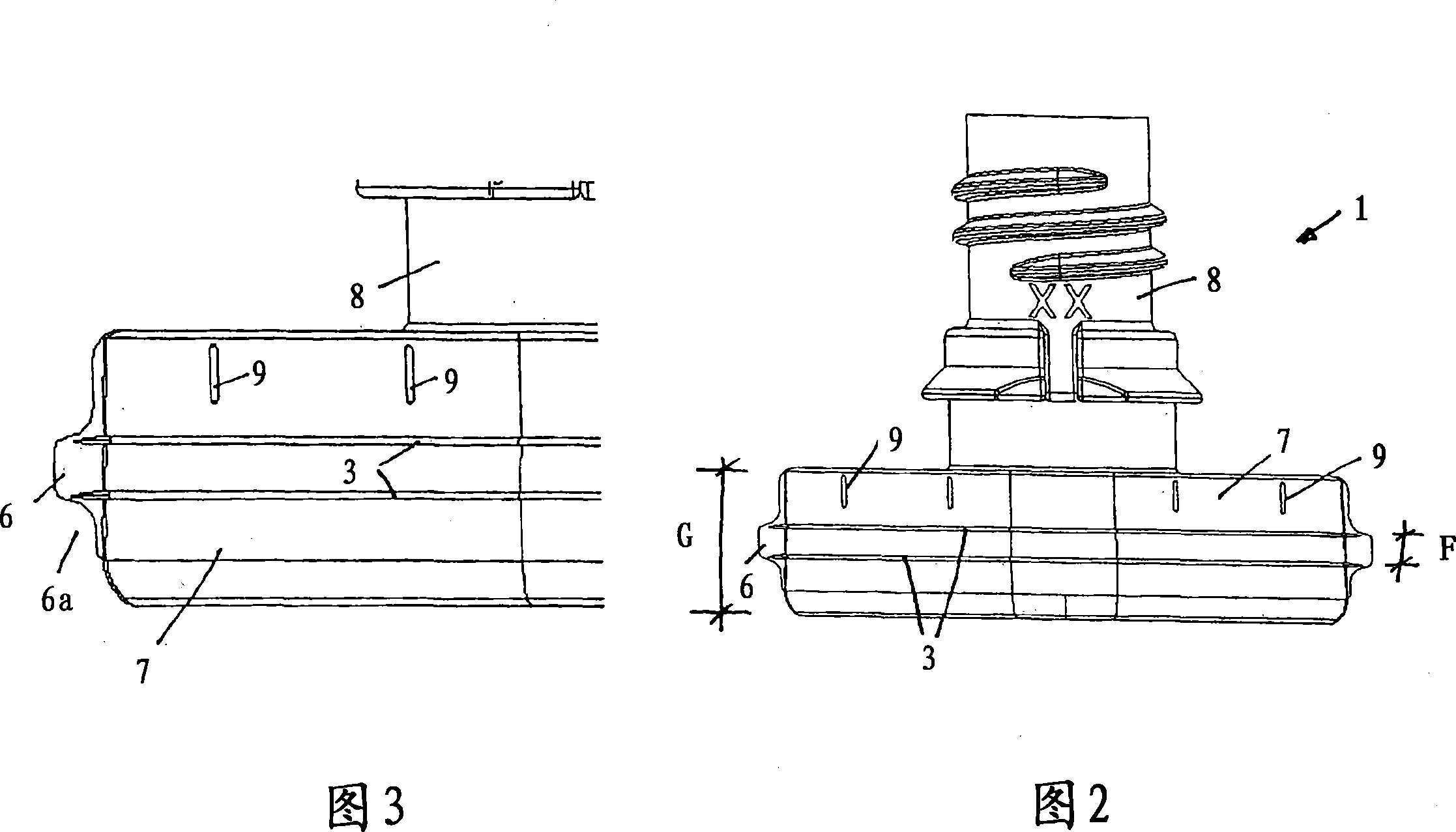

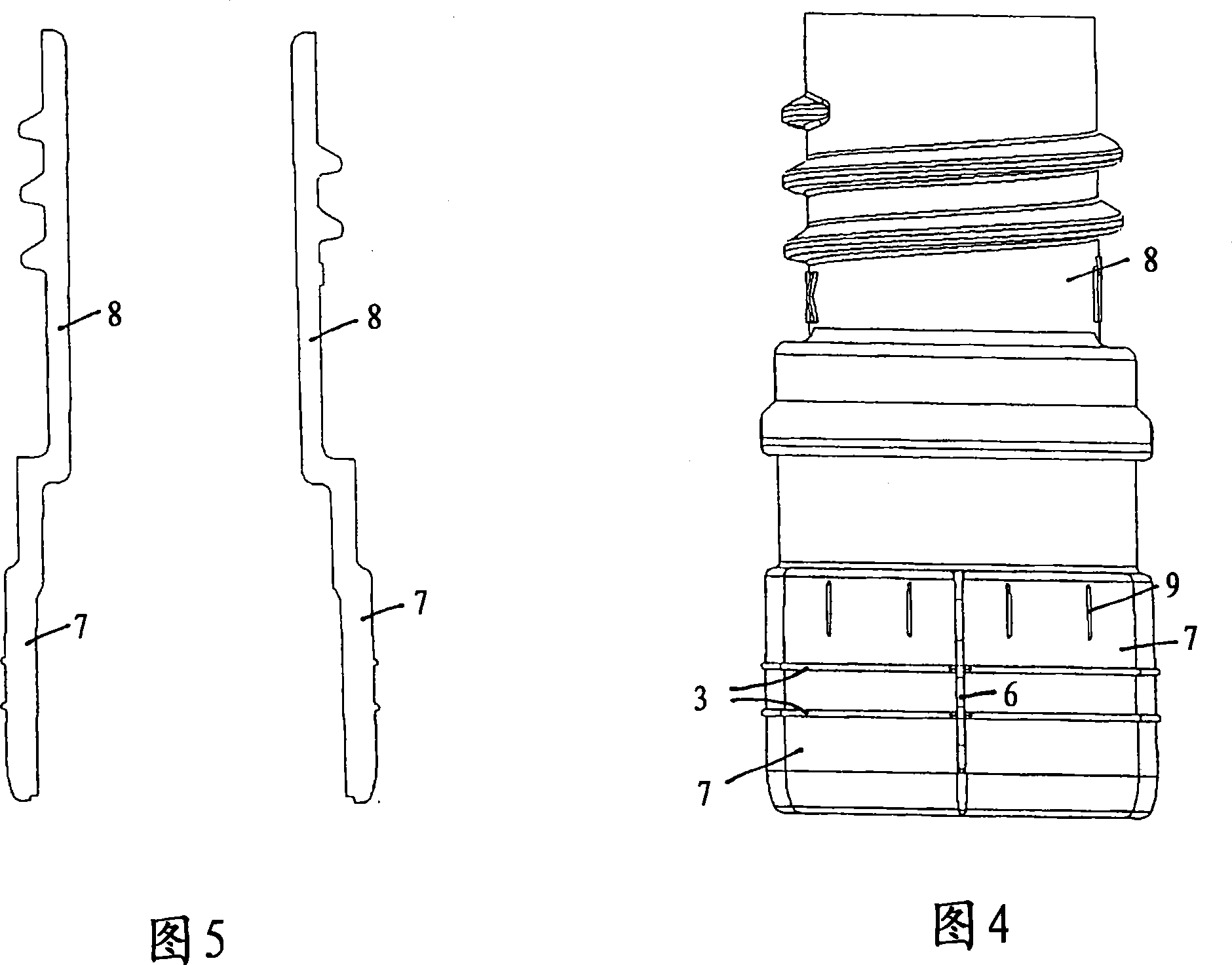

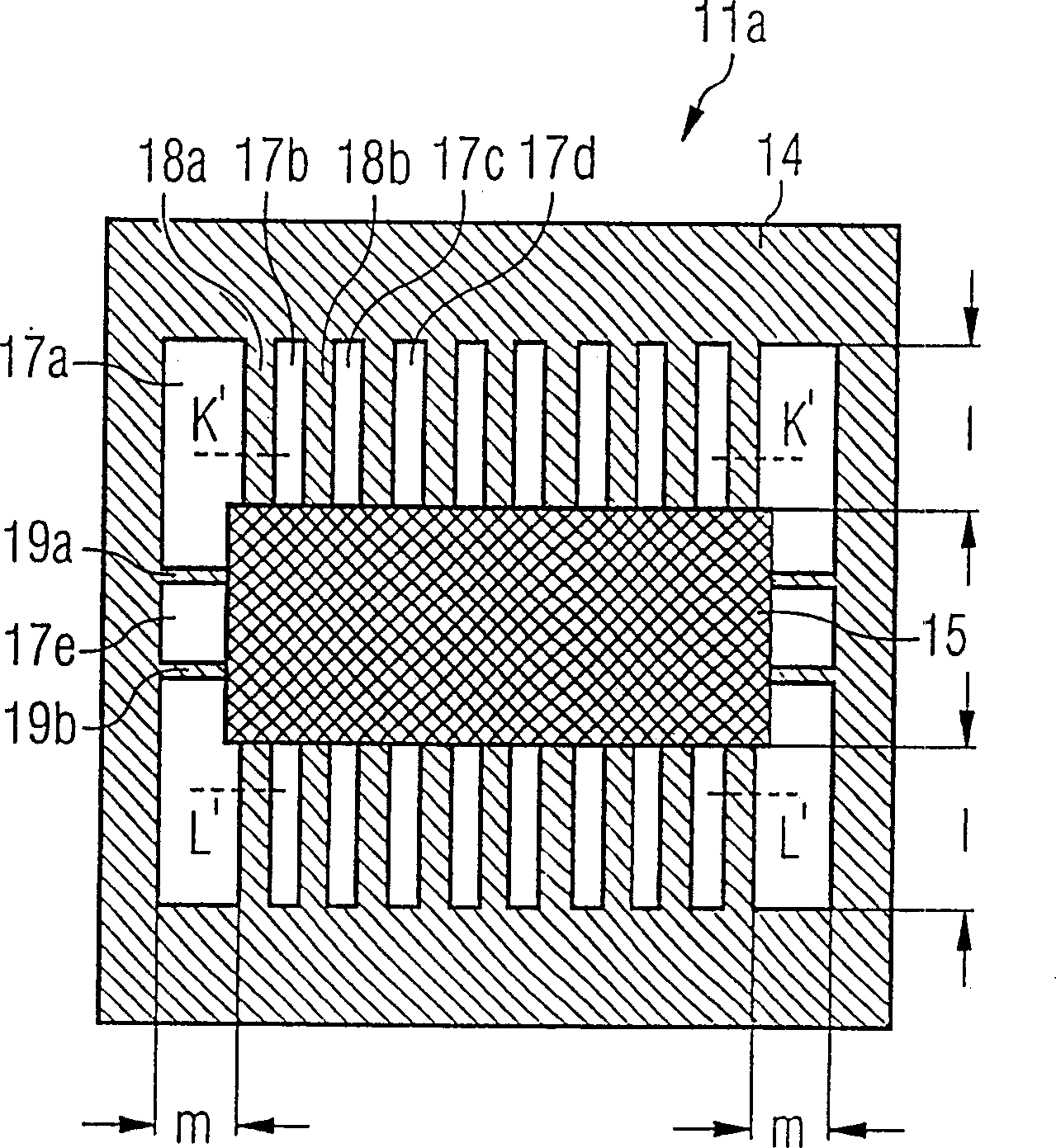

Pick up cap for LGA connector assembly

InactiveUS7165988B2Evenly heatedSolder connection is firmEngagement/disengagement of coupling partsLine/current collector detailsEngineeringMechanical engineering

A pick up cap for an LGA connector, the connector has a housing which defines a multiplicity of passageways, a plurality of electrical contacts received in the passageways, a metal clip and a pick up cap. The clip defines a rectangular window in the middle thereof. Around the window there are two opposite sidepieces and two opposite urging sides. The pick up cap is detachably mounted on the clip. The pick up cap has a rectangular planar body which defines two opposite end portions and two opposite side portions. Each of the two side portions has a waist. When the pick up cap is mounted on the clip, two end portions engage with two opposite sidepieces, two opposite sidepieces and two opposite end portions cooperatively define two rifts therebetween.

Owner:HON HAI PRECISION IND CO LTD

Aluminium alloy free from si primary particles

InactiveUS20130302643A1Simple structureGood welding performanceWelding/cutting media/materialsThin material handlingIngotSoldering process

The invention relates to an aluminium alloy, and aluminium alloy product consisting at least in part of an aluminium alloy, an ingot formed from an aluminium alloy, and also a method for producing an aluminium alloy. An improved soldering process is achieved by an AlSi aluminium alloy that has the following proportions of alloy components in percentage by weight:4.5%≦Si ≦12%,P≦10 ppm,B≦10 ppm,30 ppm≦Ti≦240 ppm, Fe ≦0.8%,Cu ≦0.3%,Mn≦0.10%,Mg ≦2.0%,Zn≦0.20%,Cr≦0.05%,the remainder being Al and unavoidable impurities, individually at most 0.05% by weight and in total at most 0.15% by weight, wherein the aluminium alloy is free from Si primary particles with a size of more than 10 μm.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

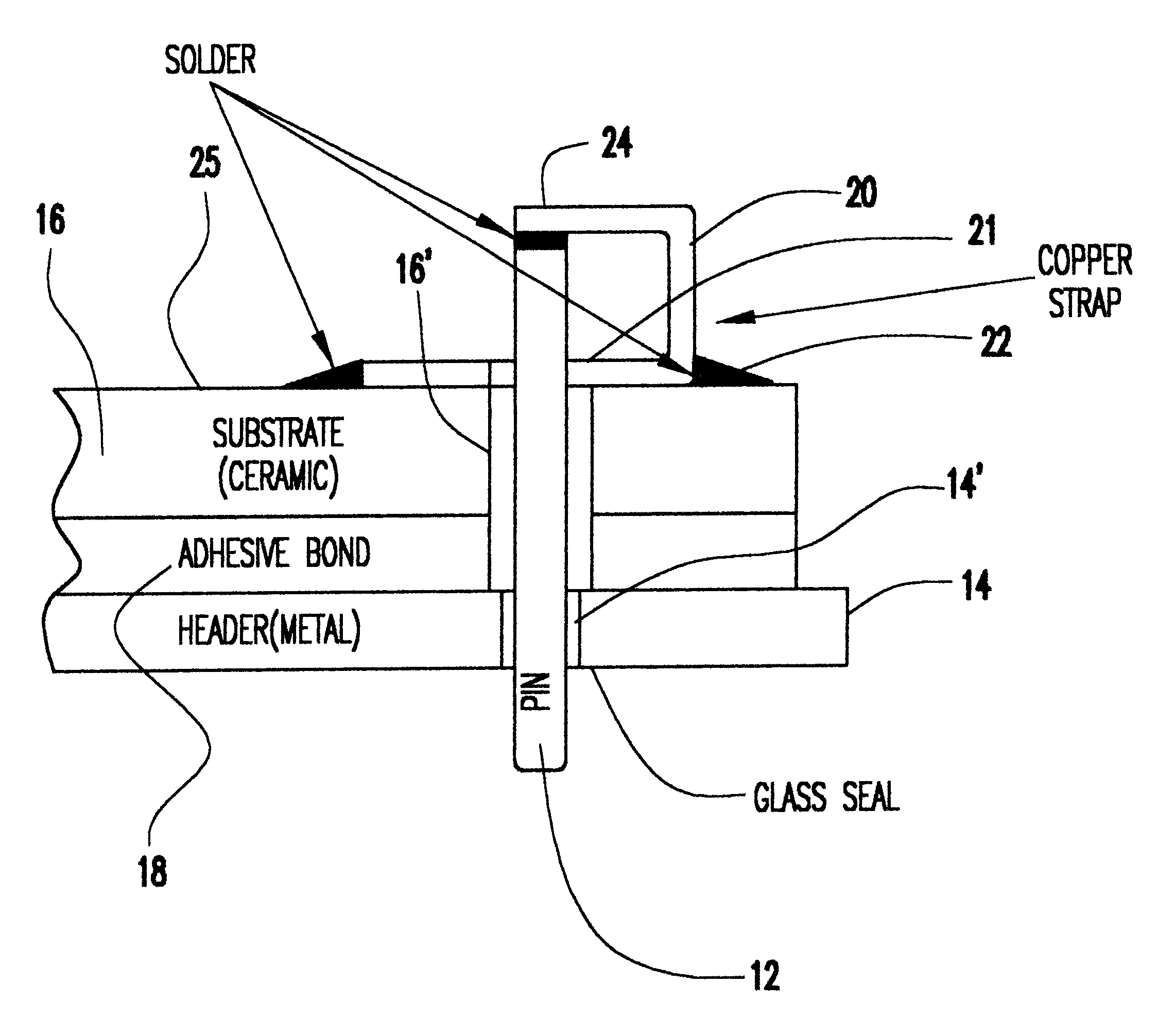

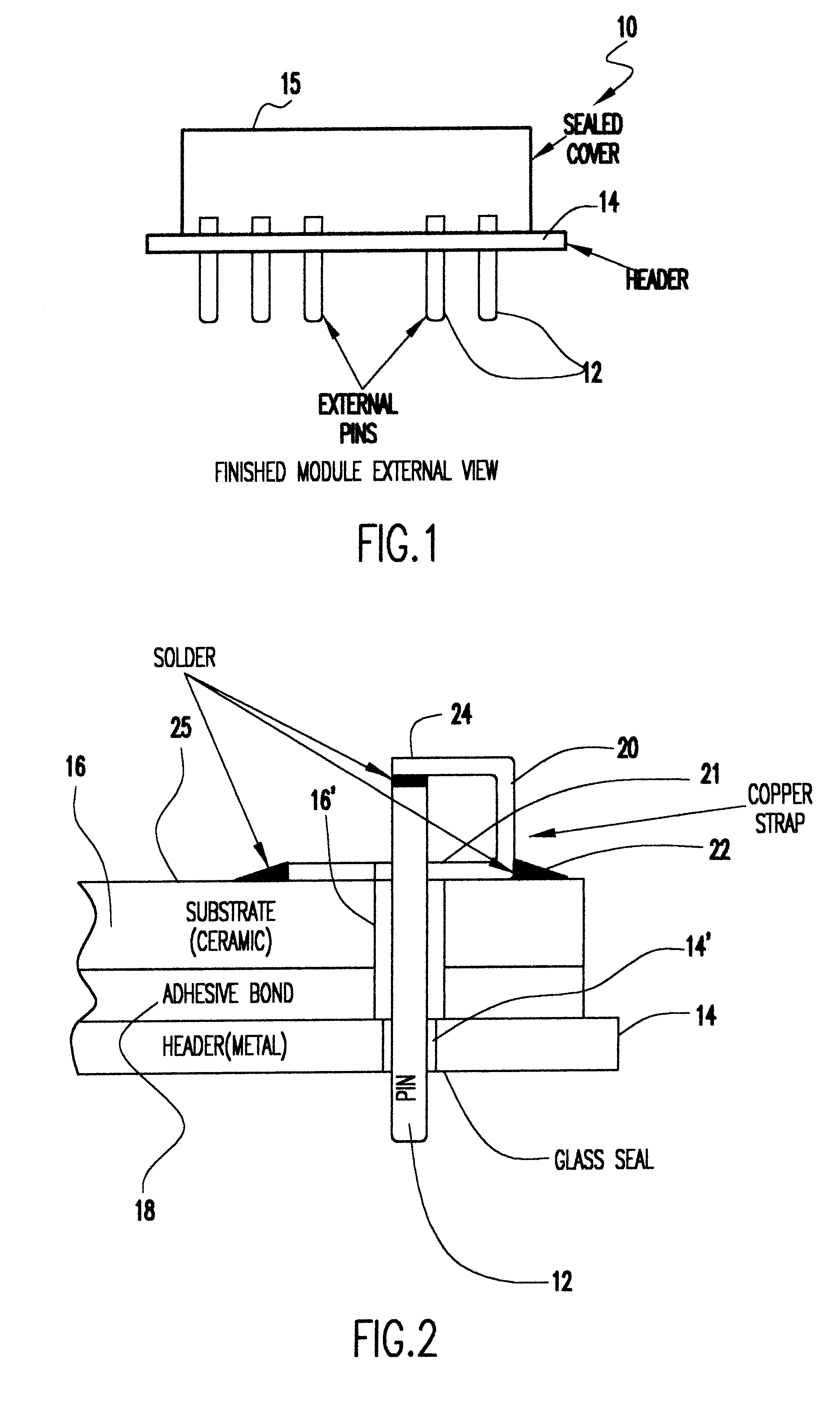

Solder cracking resistant I/O pin connections

InactiveUS6172306B1Solder connection is firmSimple and inexpensivePrinted circuit assemblingSoldered/welded conductive connectionsContact padCopper

A robust connection is made from contact pad metallization on a substrate of a modular circuit to a connection pin by solder bonding. The connection includes a flexible copper strap with an aperture at one end which is sized to fit over the connection pin. The opposite end of the strap is solder bonded to an end of the connection pin. The connection thus made avoids application of stress from pin flexure to the solder bonds to avoid cracking while providing a connection having a low profile and minimal protrusion above the modular circuit substrate.

Owner:LOCKHEED MARTIN CORP

Repair method of cylinder body

InactiveCN104959774AAvoid economic lossGuaranteed installation qualityWelding apparatusVacuum pumpingPolystyrene

The invention discloses a repair method of a cylinder body. The repair method comprises following steps: A, adopting polystyrene to produce an internal lost foam casting mould and an external lost foam casting mould of a load-reducing valve body in the same shape of the load-reducing valve body for standby-by application; B, filling dry sand into the interior of the internal lost foam casting mould and carrying out vibration ramming operation and vacuum pumping operation from a reserved opening thereof, adopting resin-bonded sand to seal the reserved opening of the internal lost foam casting mould such that a reinforcing block is formed by the internal lost foam casting mould; C, combining the internal lost foam casting mould formed with the reinforcing block to the external lost foam casting mould of the load-reducing valve body in order to form an overall mould of the load-reducing valve body; D, disposing the overall mould of the load-reducing valve body into a sand box (3); filling dry sand into the sand box (3), carrying out vibration ramming operation and vacuumizing the interior of the sand box (3); E, casting the sand box (3) from a pouring channel so that lost foam casting of the load-reducing valve body is finished. Compared with the prior art, the repair method of the cylinder body helps to solve problems including poor casting quality of the load-reducing valve body and high cost.

Owner:LIUZHOU BAITIAN MACHINERY

Process method for producing tool through caulking groove substrate

The invention discloses a process method for producing a tool through a caulking groove substrate. The process method comprises the following steps of (1) substrate preparing, (2) substrate cleaning,(3) high-speed steel bar embedding, (4) vacuum welding, (5) tempering, (6) straightening, (7) accurate grinding, (8) blade planing, (9) long blank cutting, (10) blade accurate grinding, (11) tool cutting, (12), perforating, (13), straightening and (14) cleaning, rust prevention and finished product packaging. By means of the process, the machining steps and process are shortened, the machining difficulty is reduced, the machining efficiency is improved, the machining cost is saved, and the machining yield and the stability of quality and performance are improved.

Owner:DONGE LIYUAN MACHINERY KNIFE

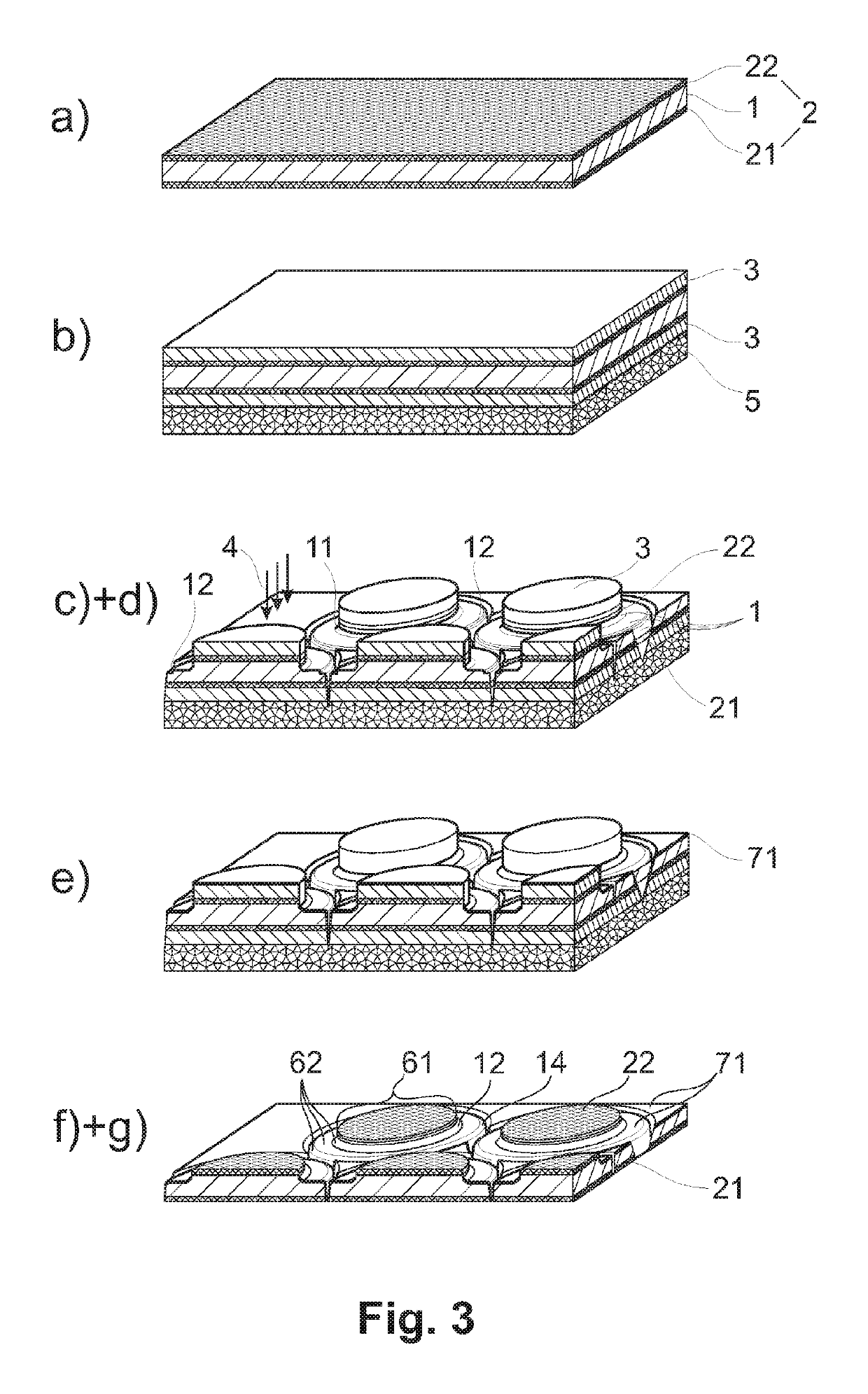

Method for Producing Window Elements that Can Be Soldered into a Housing in a Hermetically Sealed Manner and Free-Form Window Elements Produced in Accordance with Said Method

ActiveUS20160062127A1Improve reliabilityMinimize unwanted extraneous radiationRadiation pyrometryPhotometryHigh energyOptical coating

A method for production of window elements which can be soldered into a housing in a hermetically tight manner with optical coating and free-form window elements are disclosed. After application of optical coatings, a protective layer is applied to the optical coating, the two layer systems are selectively removed by means of a machining beam of high-energy radiation for the purpose of ablation of a desired optically active free-form surface for window elements with any geometric shape through a localized machining beam in edge regions of the optically active free-form surface such that the protective layer remains on the optical coating as lift-off mask which is lifted off after applying a metallization for a solder layer by an etching process that acts selectively only on the protective layer but not on the optical coating, and the metallization remains only on the peripheral edge regions circumscribing the free-form surfaces.

Owner:JENOPTIK OPTICAL SYST +1

Method for welding hollow static blade body and inner cavity supporting board of turbine

ActiveCN103658939AReliable penetrationImprove comfortTurbinesArc welding apparatusSurface oxidationSpot welding

The invention provides a method for welding a hollow static blade body and an inner cavity supporting board of a turbine. The method can solve the problem that the hollow static blade body and a folded supporting board can not be reliably welded through an existing resistance spot welding method. The method for welding the hollow static blade body and the inner cavity supporting board of the turbine is characterized in that a hollow static blade and the inner cavity supporting board are assembled in the finished product positions, the hollow static blade body and the inner cavity supporting board of the turbine are welded through a plug welding connecting method, and the method comprises the following steps of (1) before-welding preparation, (2) plug welding, (3) after-welding inspection and (4) repair welding, wherein in the before-welding preparation step, plug welding grooves are formed in position where an inner arc board of the hollow static blade is welded to the inner cavity supporting board, the grooves are then cleaned, and an oxide layer or a re-melting layer, oil dirt and dirt on the surface of each groove are removed; in the plug welding step, argon tungsten-arc welding is used for backing welding, root penetration is guaranteed, the portions, above the backing welding positions, of the grooves are filled until the grooves are full.

Owner:WUXI TURBINE BLADE

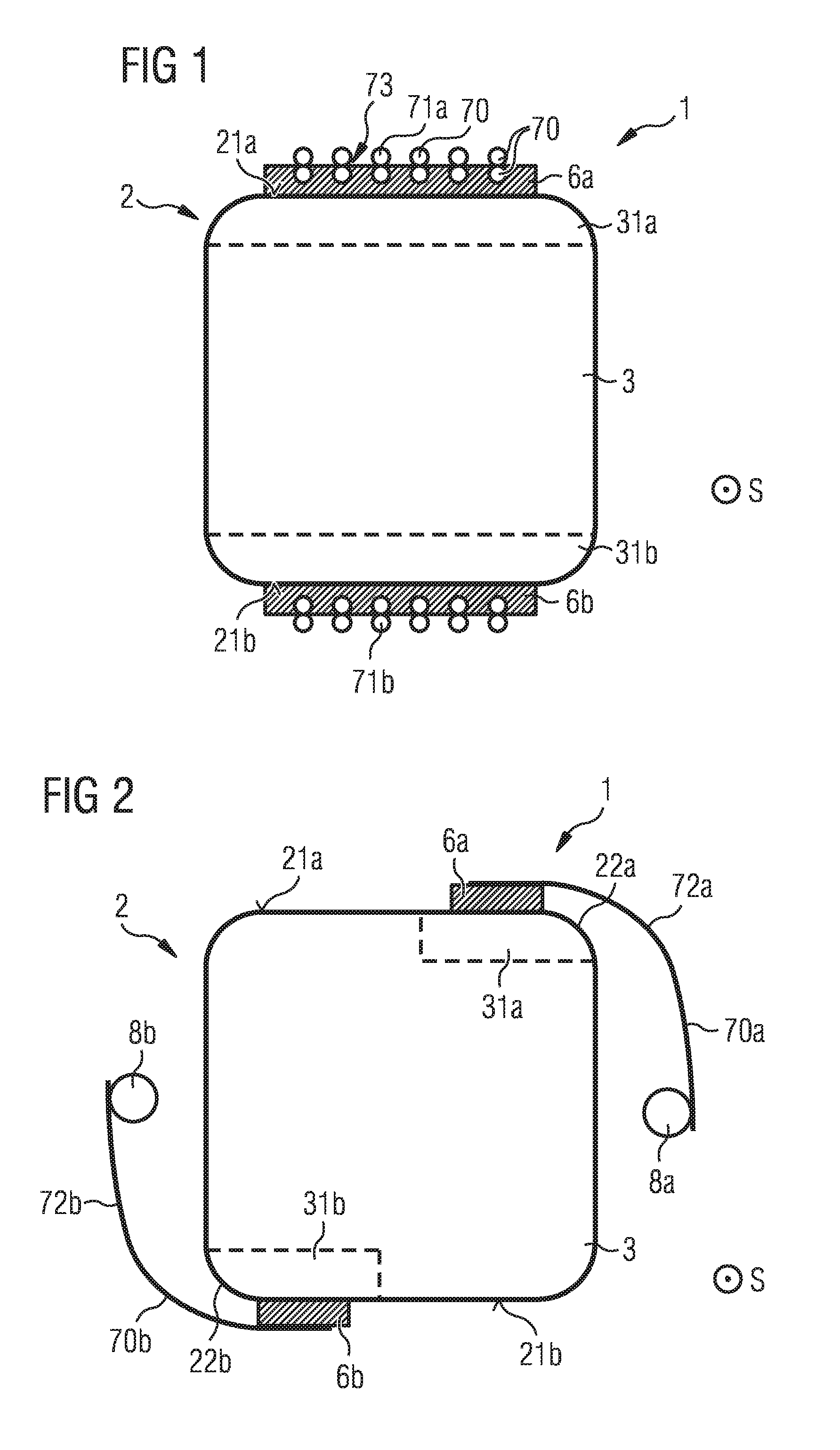

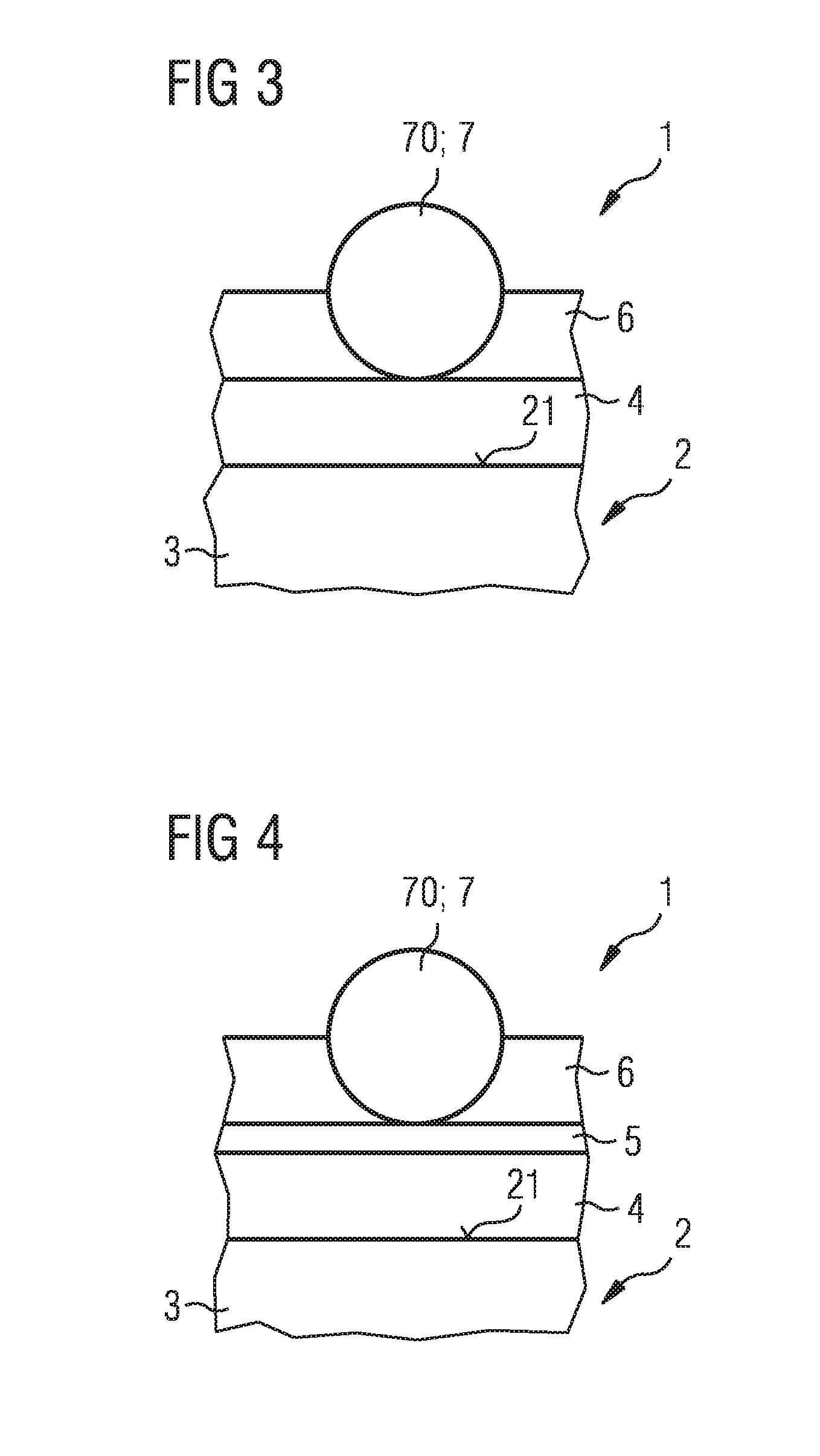

Electrically conductive textile

ActiveUS8198569B2Improve robustnessSolder connection is firmPrinted circuit assemblingVehicle seatsConductive textileConductive coating

A surface structure (1) that is at least partially electrically conductively coated by a conductor coating (11), and which can be connected to an electric power source by at least one electric connecting conductor (2). The connecting conductor (2) electrically contacts the conductor coating (11) at at least one solder point (3), and the conductive coating (11) is thickened at least at one contact zone (4) in the area of the solder point (3) as opposed to other areas (7) of the surface structure (1).

Owner:GENTHERM GMBH

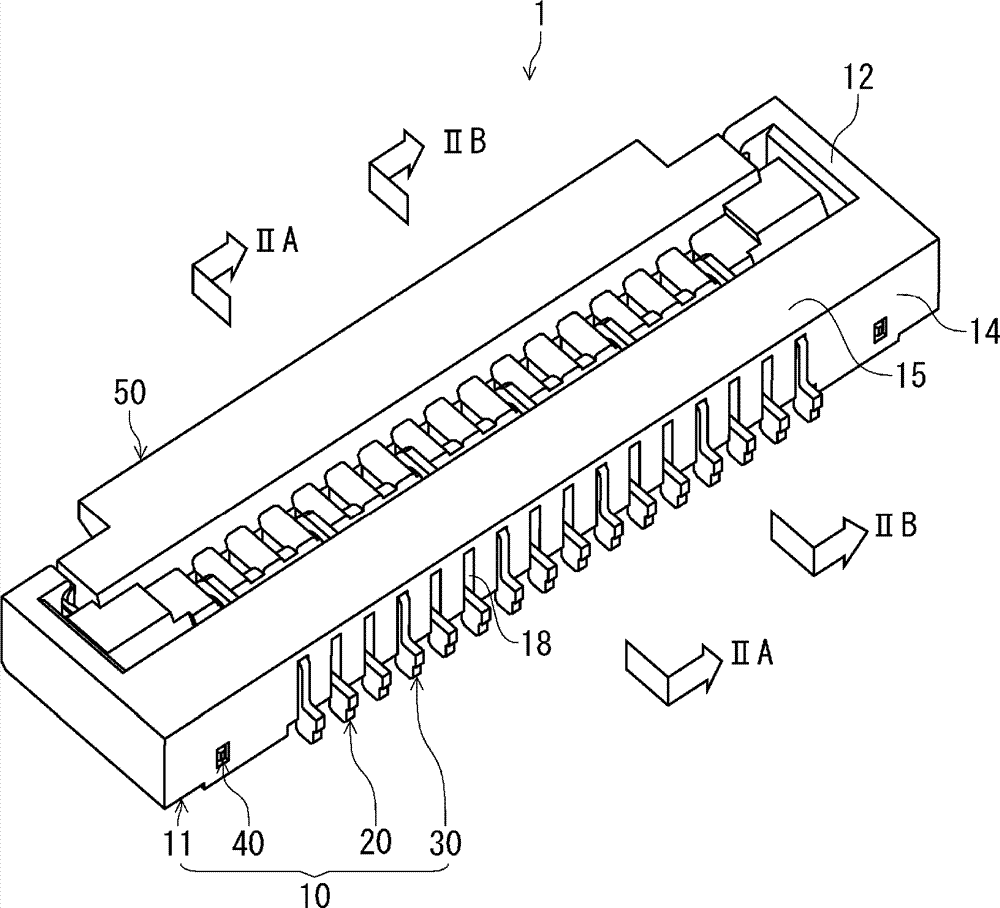

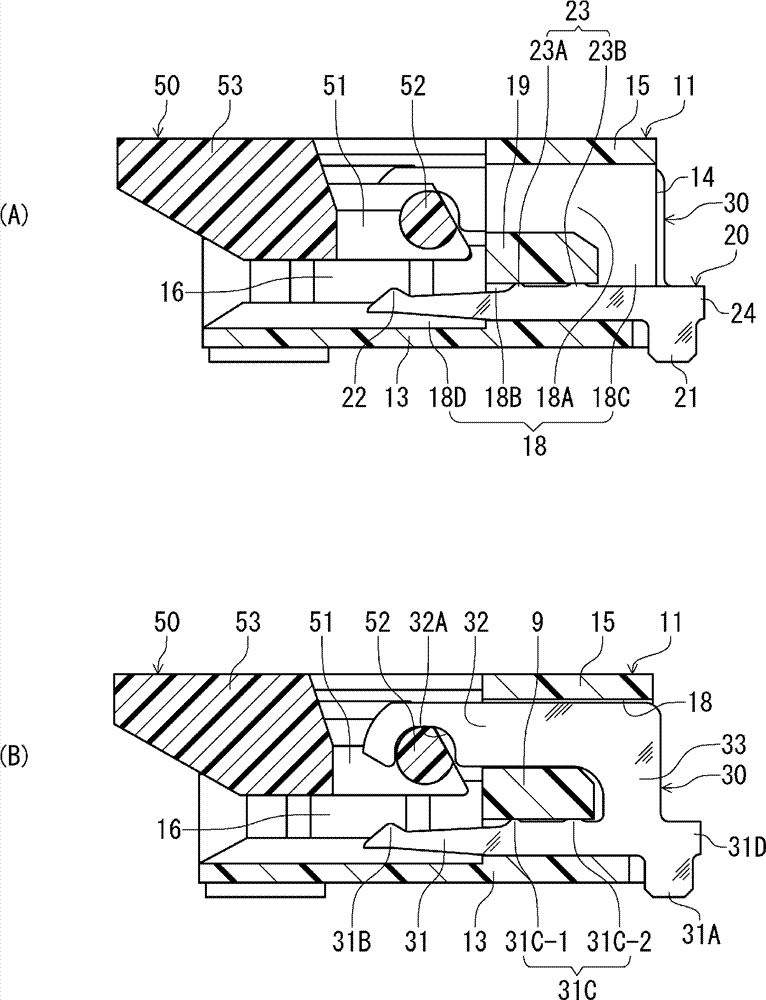

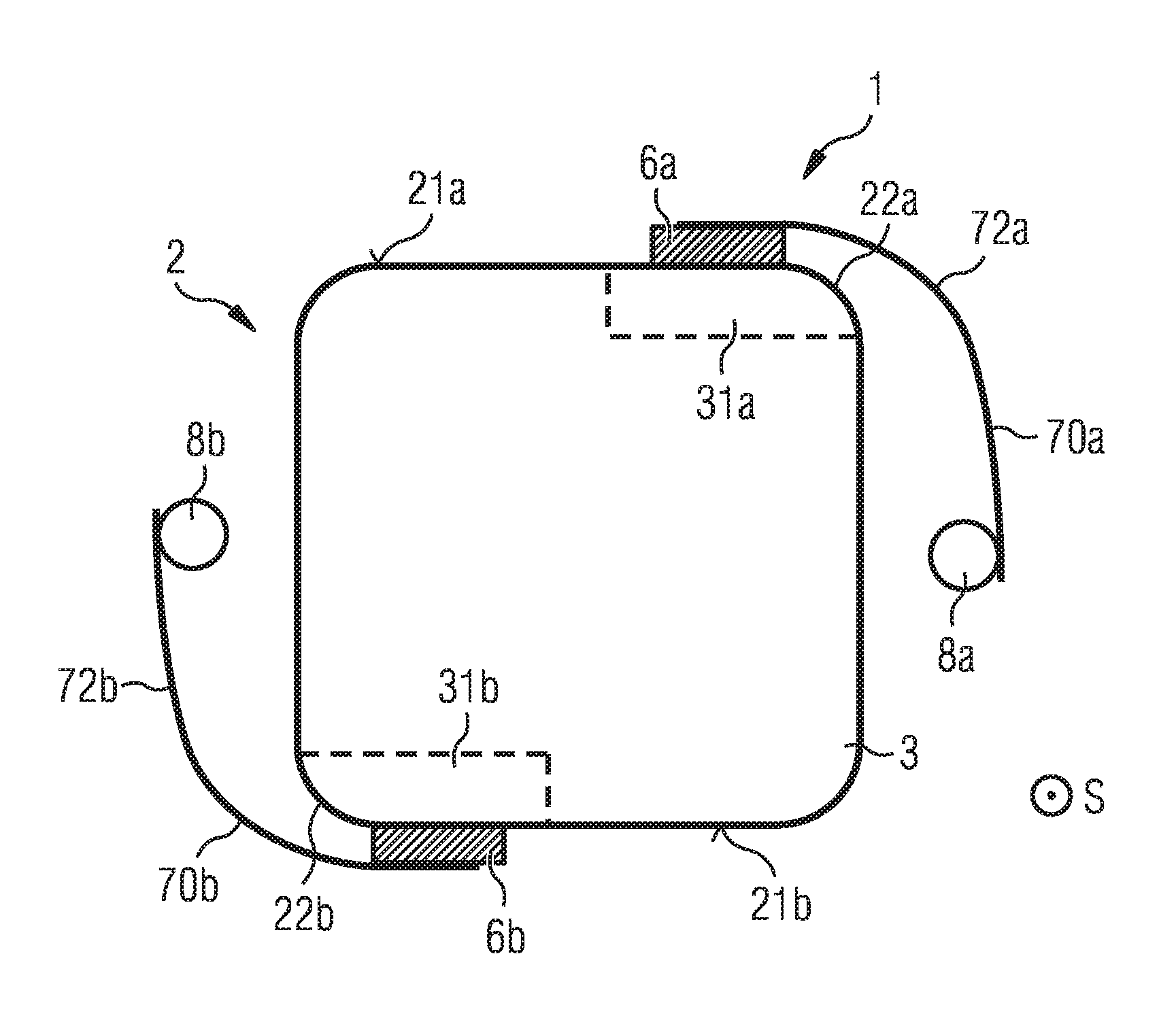

Pick up cap for LGA connector assembly

InactiveUS20050153581A1Evenly heatedSolder connection is firmEngagement/disengagement of coupling partsLine/current collector detailsEngineeringMechanical engineering

A pick up cap for an LGA connector, the connector has a housing which defines a multiplicity of passageways, a plurality of electrical contacts received in the passageways, a metal clip and a pick up cap. The clip defines a rectangular window in the middle thereof. Around the window there are two opposite sidepieces and two opposite urging sides. The pick up cap is detachably mounted on the clip. The pick up cap has a rectangular planar body which defines two opposite end portions and two opposite side portions. Each of the two side portions has a waist. When the pick up cap is mounted on the clip, two end portions engage with two opposite sidepieces, two opposite sidepieces and two opposite end portions cooperatively define two rifts therebetween.

Owner:HON HAI PRECISION IND CO LTD

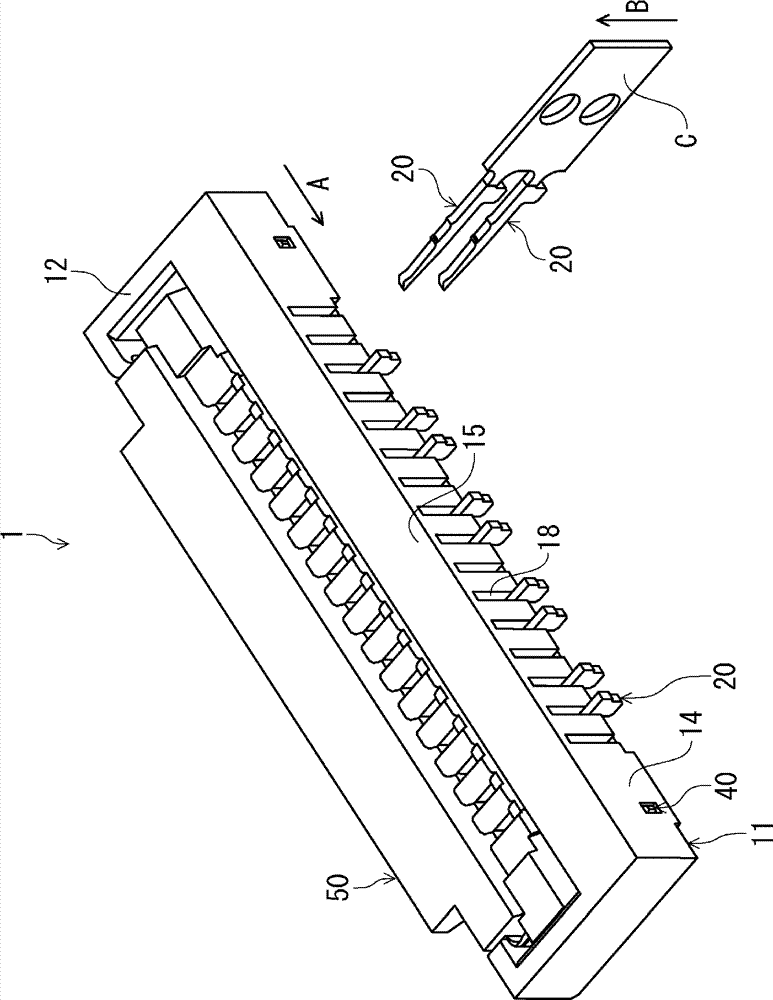

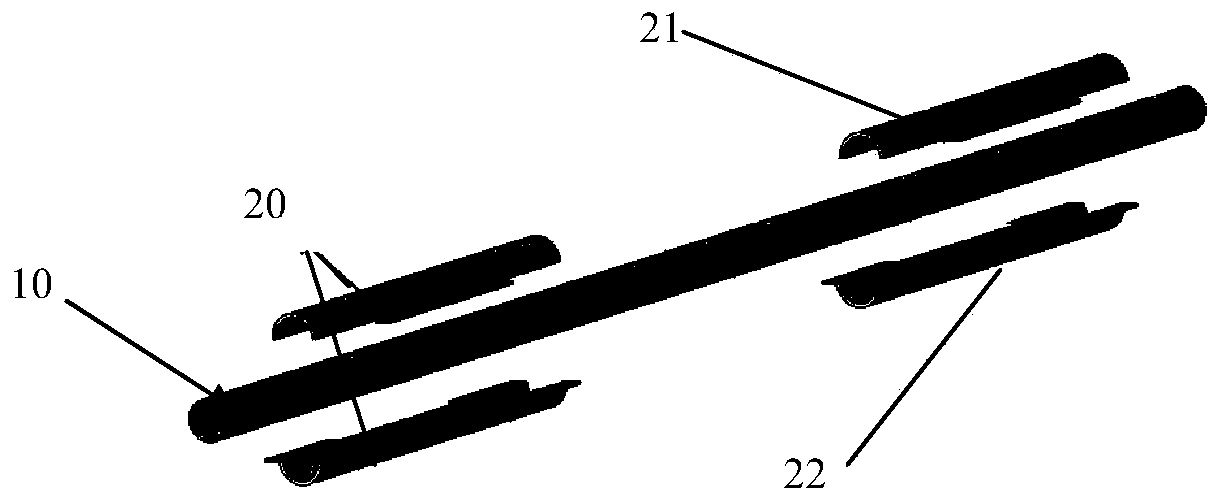

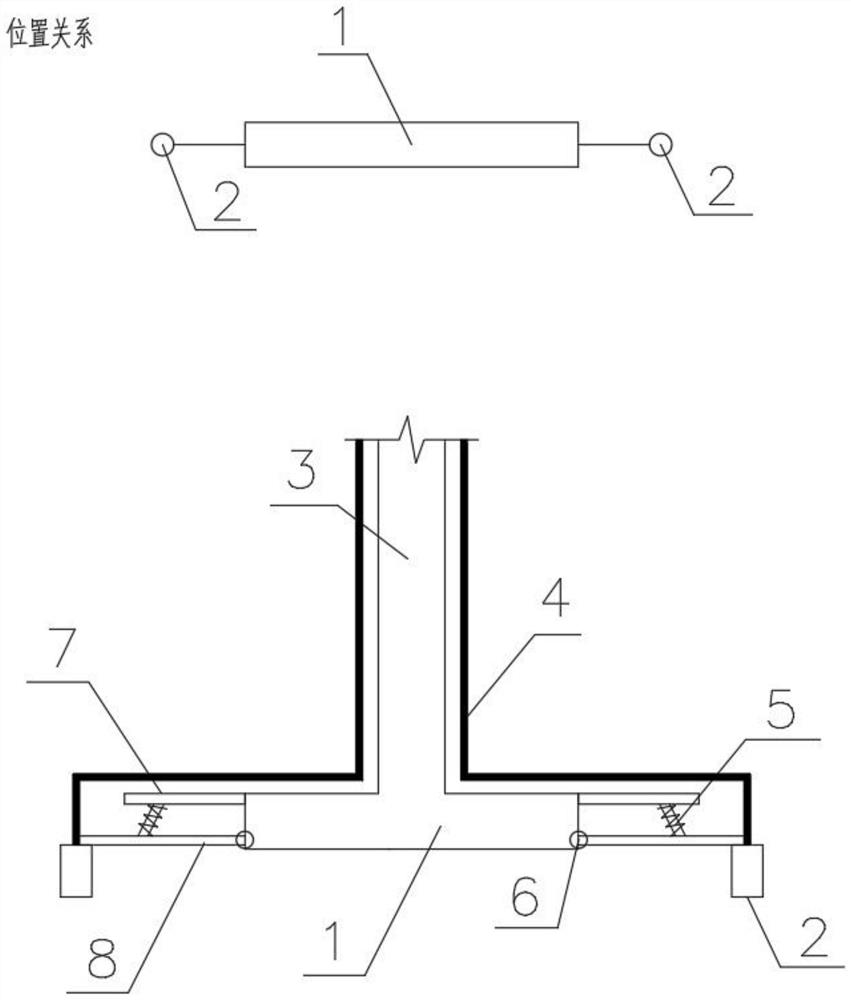

Electric connector for circuit substrate

ActiveCN102738622AEasy to operateEnsure high-speed transmission characteristicsSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

The invention provides an electric connector for a circuit substrate. A terminal can be pressed in a stable posture without enlargement of the size of the terminal in an up-down direction. A first terminal (20) is separated from a supporting plate after maintenance of blanking of a plate surface upon a metal plate in a state of connecting the supporting plate, a linear shape extending along the front-back direction is formed, a contact portion (22) is disposed at the back end, a connecting portion (21) and a supporting plate separating portion (24) above the connecting portion (21) and cut and separated from the supporting plate are disposed at the front end, a pressing protruding portion (23) protruding from the upper edge of the first terminal (20) and clamped on the inner surface of a terminal maintaining groove (18) is formed in the middle position in a front-back direction, after the first terminal (20) is separated from the supporting plate at the supporting plate separating portion (24), in a connector (1) pressed from the front part to the terminal maintaining groove (18), the cutting end surface of the supporting plate separating portion (24) and the supporting plate in an up-down direction is in the range of the upper edge of the middle position.

Owner:HIROSE ELECTRIC GROUP

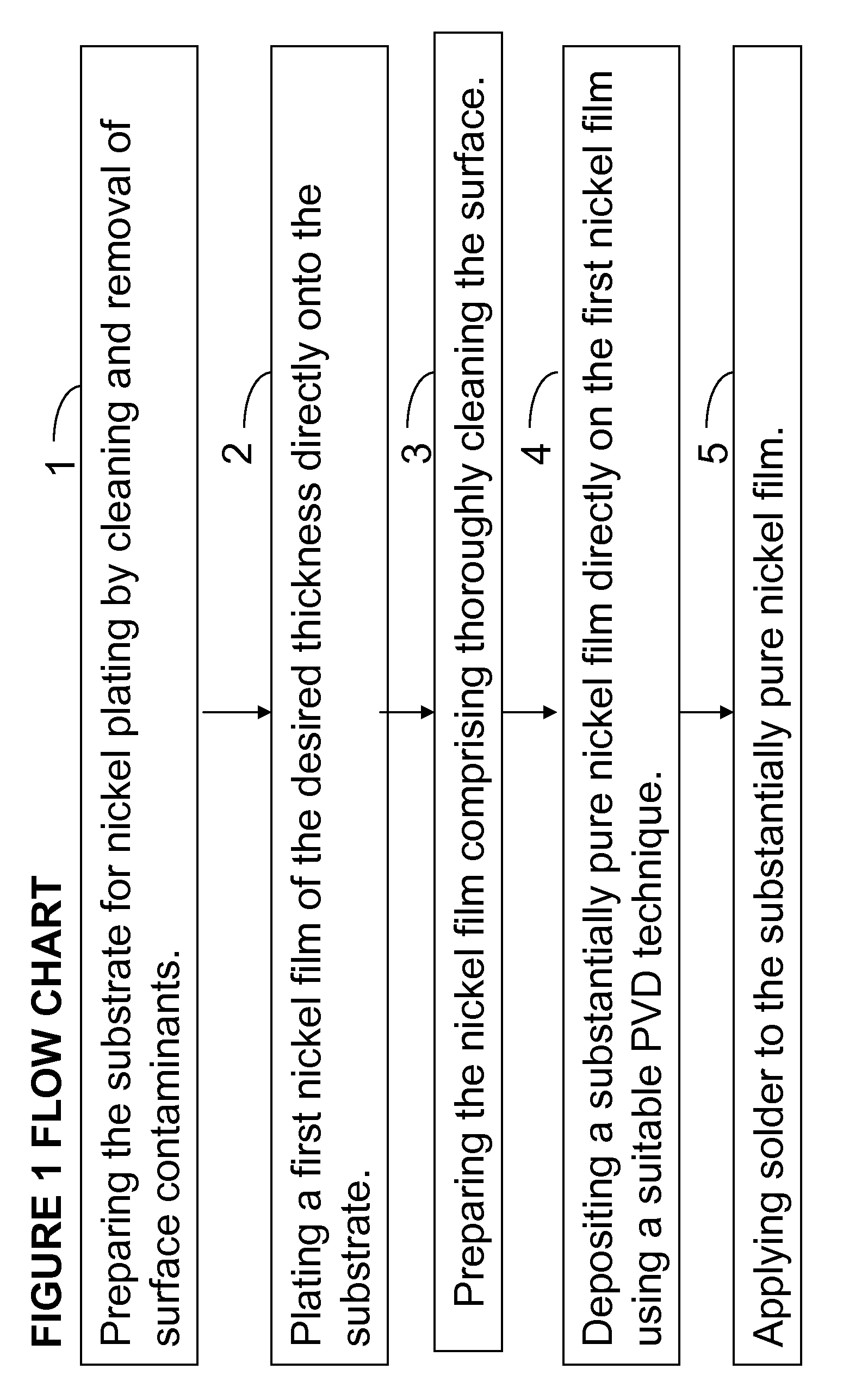

Enhanced solderability using a substantially pure nickel layer deposited by physical vapor deposition

InactiveUS20110048954A1Reliable and reliablePoor solderabilityVacuum evaporation coatingSoldering apparatusElectrolysisGas phase

A first preferred method for increasing the solderability of a substrate comprising: preparing the substrate for nickel plating by cleaning and removal of surface contaminants; plating a first nickel film of the desired thickness directly onto the substrate; preparing the nickel film comprising thoroughly cleaning the surface; depositing a substantially pure nickel film directly on the first nickel film using a suitable PVD technique; and applying solder to the substantially pure nickel film. Another preferred method for increasing the solderability of a substrate comprising plating a first nickel layer directly onto the substrate by using an electrolytic or electroless nickel plating process; depositing a substantially pure nickel film directly on the first nickel film using physical vapor deposition; and applying solder to the substantially pure nickel film.

Owner:ARMY US SEC THE

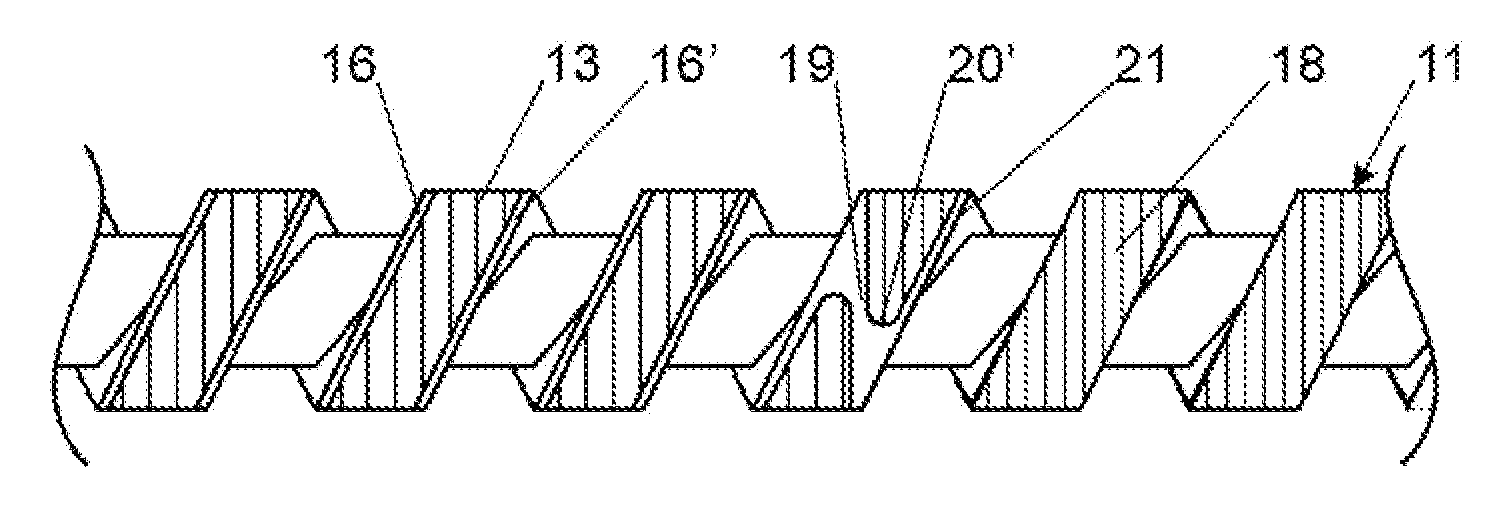

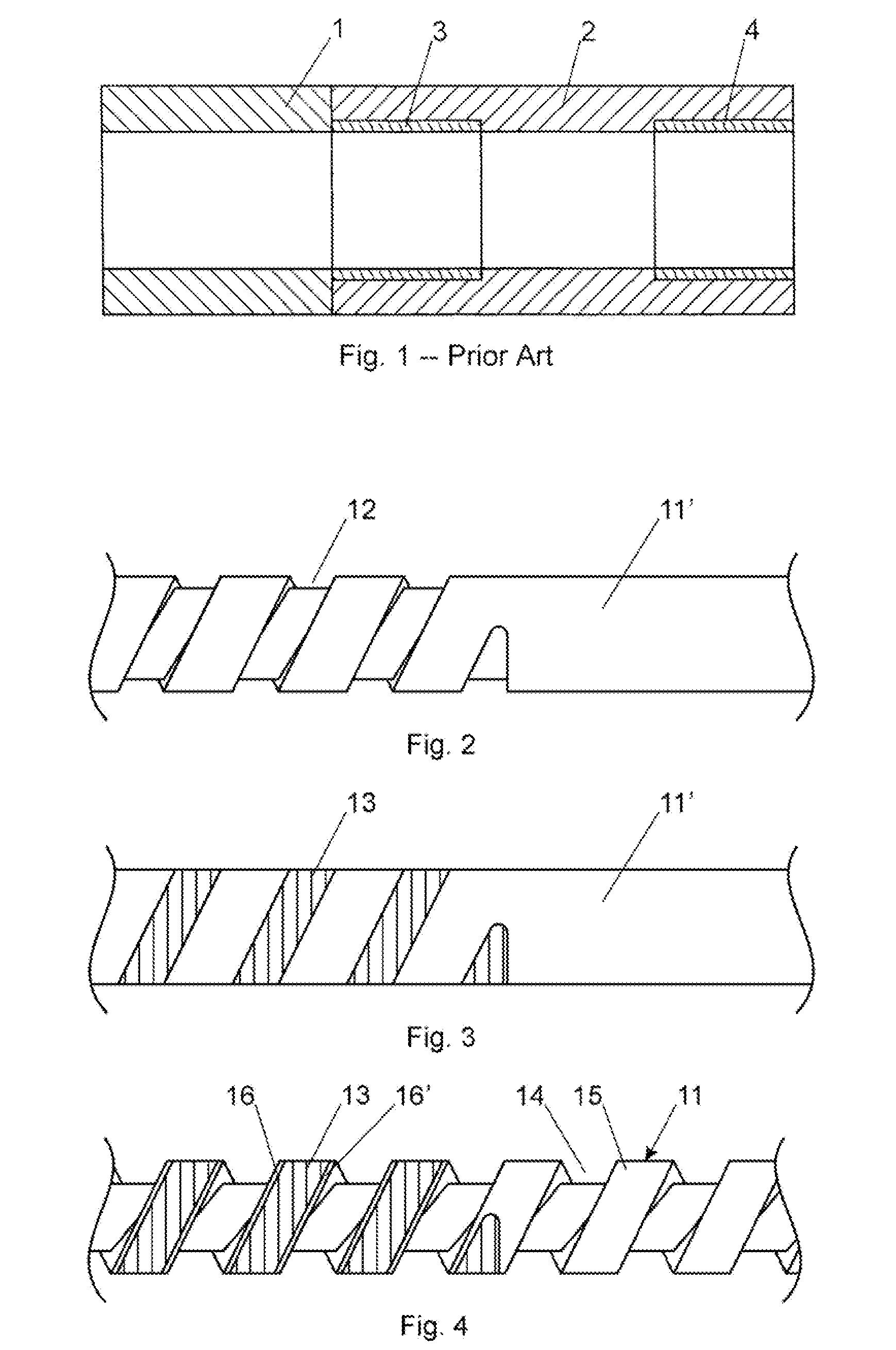

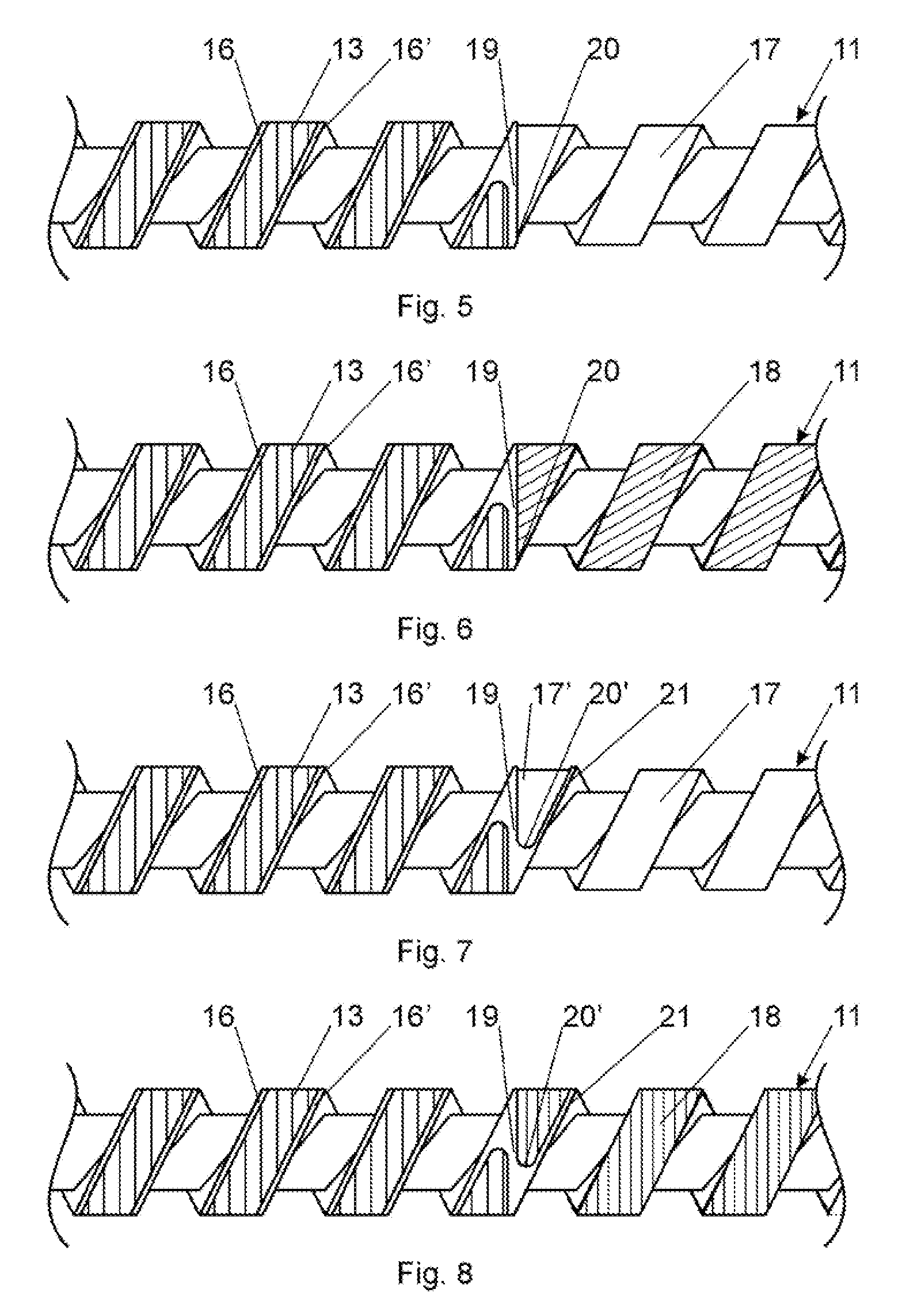

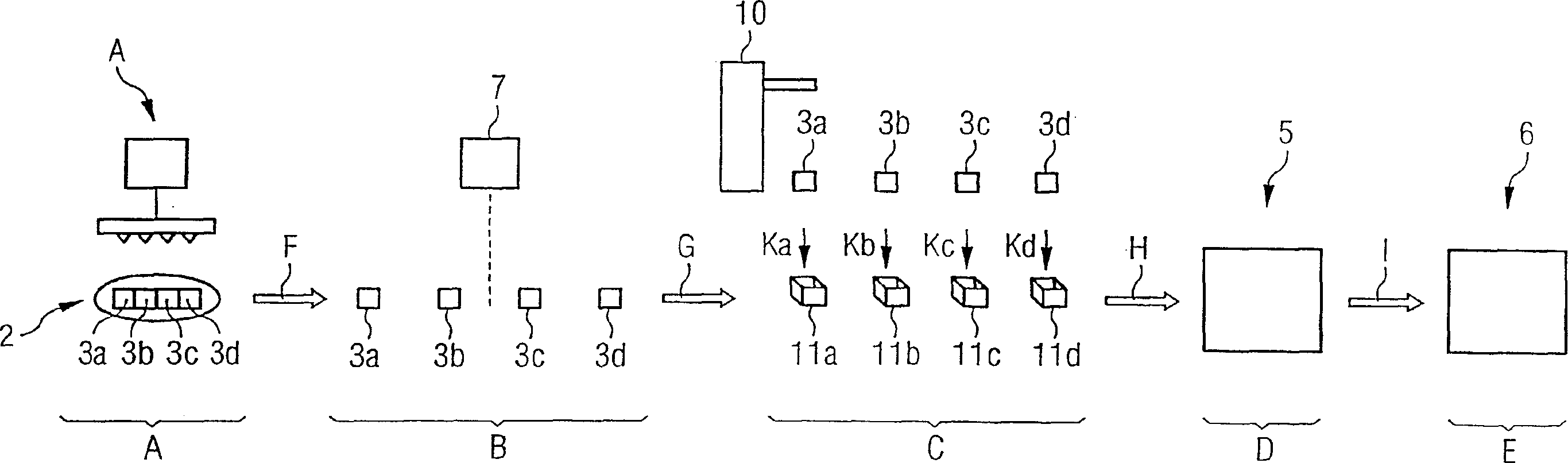

Process for production of a screw for an extruder, and screw

InactiveUS20090162470A1Reduce riskSolder connection is firmExhaust apparatusFrozen sweetsEngineeringProtection layer

At least one section of the screw (11) has a wear-protection layer (13) and at least one other section of the screw preferably has an anti-friction layer (18). In a solid rod (11′), abed (12) for the wear-protection layer (13) is first formed, and in this the wear-protection layer (13) is then applied, and finally the interstices (14) between the screw flights (15) are formed. According to the invention, the wear-protection layer (13), for example composed of tungsten carbide, is applied by build-up welding, and the interstices (14) are formed with lateral separation (16, 16′) with respect to the wear-protection layer (13). For production of the anti-friction layer, the dimension of that / those section(s) of the screw (11) where the anti-friction layer, e.g. composed of molybdenum, is to be applied is reduced below specification, while providing lateral separation (19) with respect to the wear-protection layer. The anti-friction layer is then applied in the under-dimensioned region (17). Finally, the screw (11) is brought to the specified dimension.

Owner:THEYSOHN EXTRUSIONSTECHNIK GMBH

Lead-Free Solder Alloy and Semiconductor Device

InactiveUS20160300809A1Solder connection is firmSemiconductor/solid-state device detailsSolid-state devicesMetallurgySemiconductor chip

A semiconductor device 20 has: a semiconductor chip 1; a connected member 5 connected to the semiconductor chip 1 via a solder alloy (lead-free solder alloy) 2; and an external terminal electrically connected to the semiconductor chip 1. The above-described solder alloy 2 of the semiconductor device 20 is composed of: Cu of 5 to 10 weight %; any one, two, or more of Bi of 1 weight % or more and 4 weight % or less, Sb of 1 weight % or more and less than 10 weight %, and In of 1 weight % or more and 4 weight % or less; and Sn as a residual.

Owner:HITACHI LTD

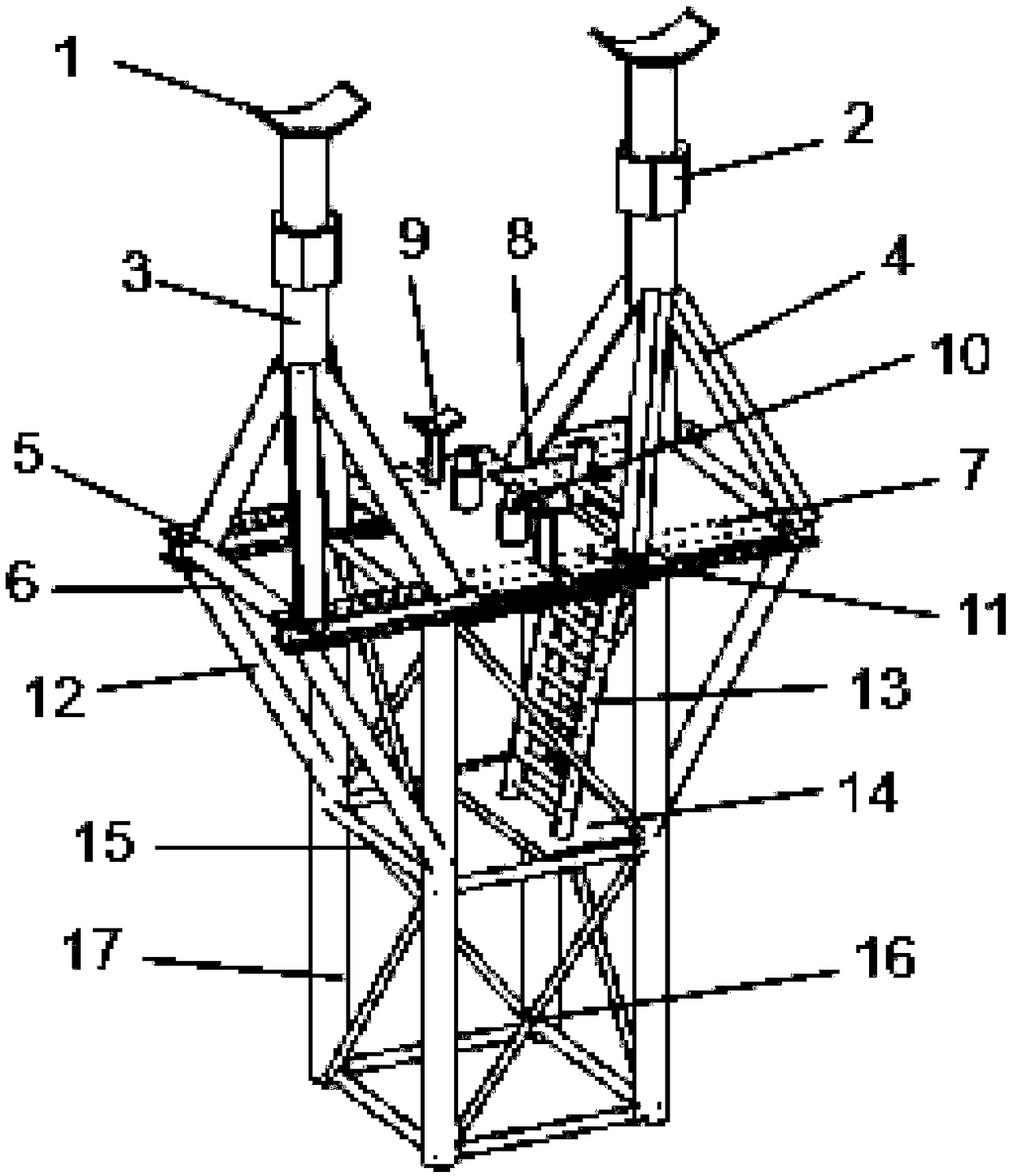

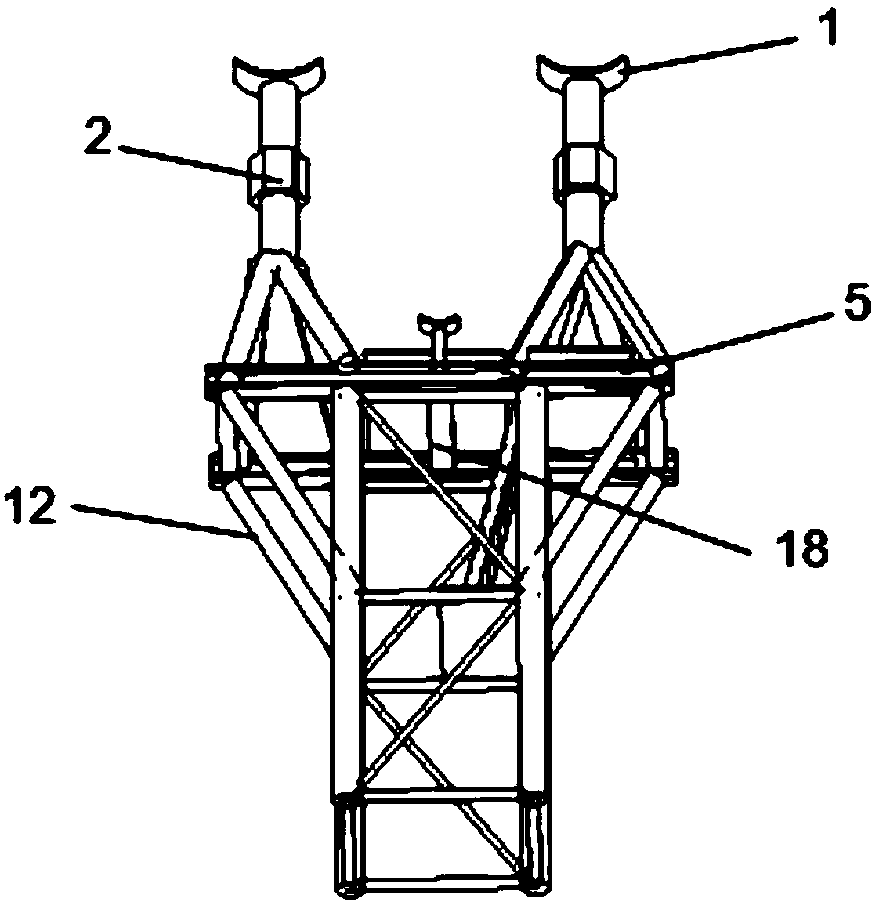

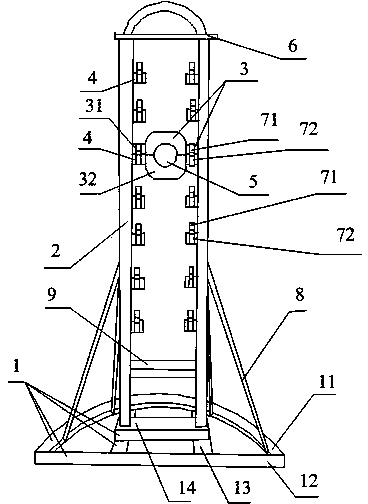

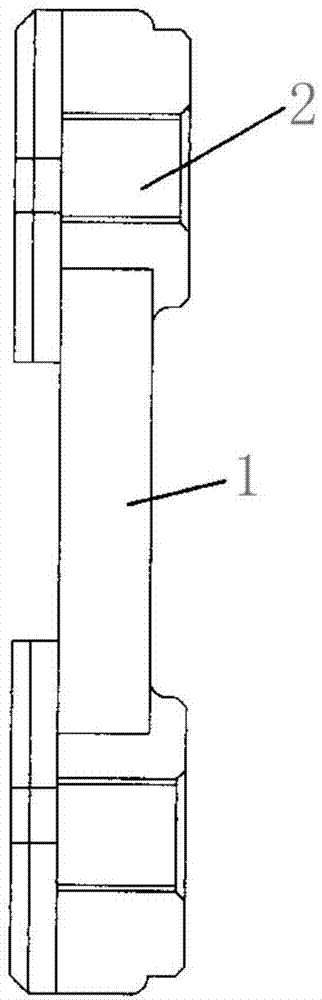

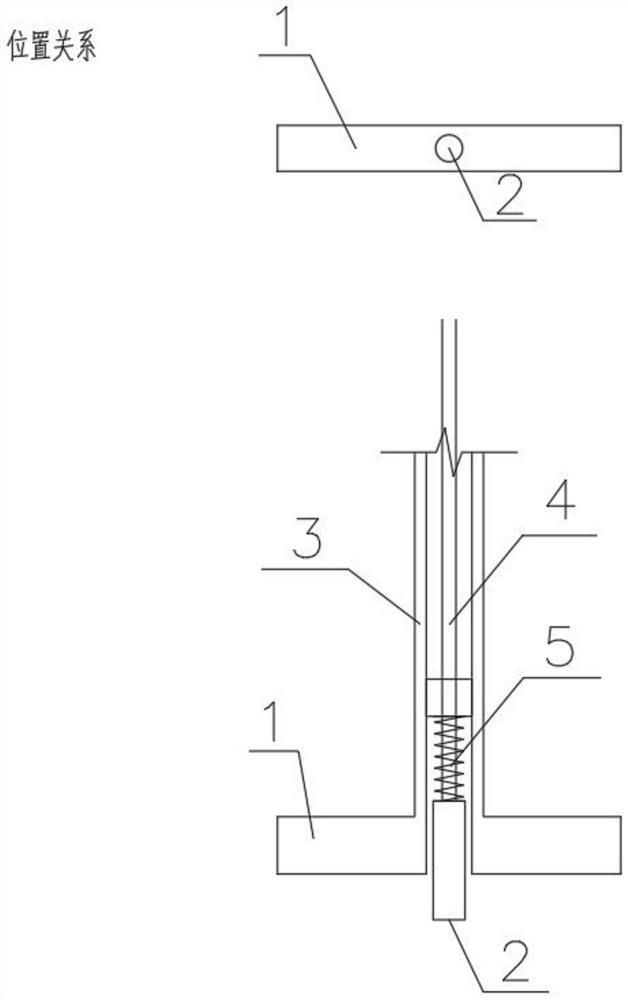

Novel precisely adjustable large-span steel pipe truss unloading bracket and using method thereof

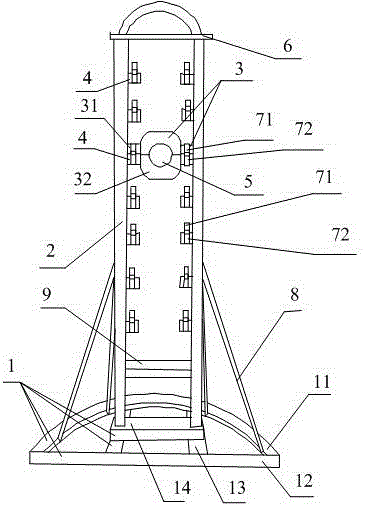

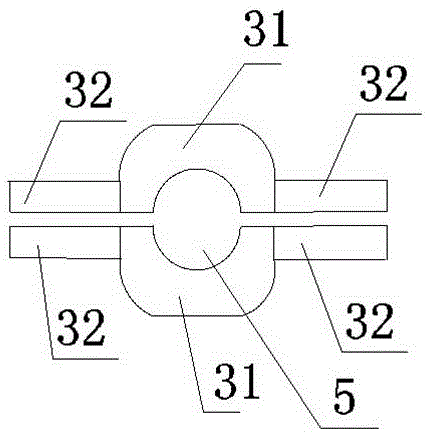

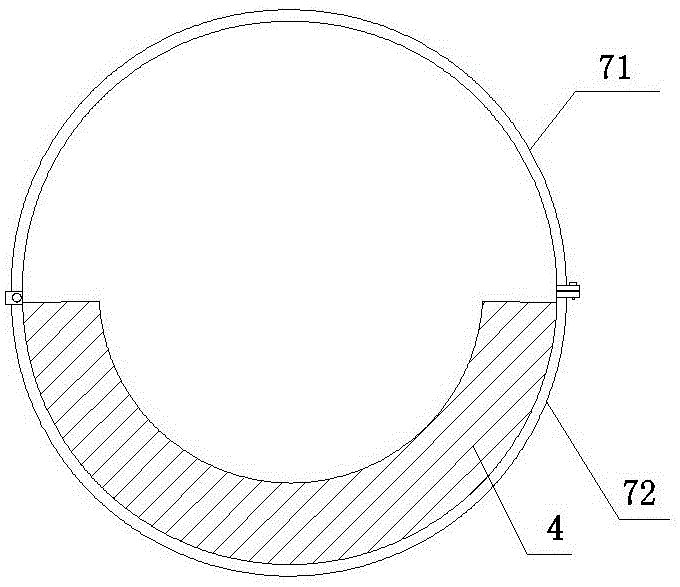

ActiveCN109505424AEasy to makePrecise constructionBuilding material handlingWelding apparatusSteel tubeLong span

The invention provides a novel precisely adjustable long-span steel pipe truss unloading bracket and a using method thereof. The unloading bracket includes an upper structure, a middle platform structure and a lower structure. The upper structure includes two bolt support columns, two short support columns and two jacks. The lower structure is tower crane standard sections. During working, a trussis placed on a tile support. The cylinder head of each jack abuts against the lower surface of the truss. The truss rises, the bolt support columns are controlled to enable the truss to deviate fromthe tile support, and then the jacks fall back to complete unloading. The bracket is simple to make, mostly welded, and can be produced at a construction site. The construction is fast and accurate. The number of the standard sections is determined according to the truss height to avoid idle resources. The resources are saved, and the cost is reduced.

Owner:CHONGQING UNIV

Solder material for fastening an outer electrode on a piezoelectric component and piezoelectric component comprising a solder material

ActiveUS8823245B2Bonded firmlySolder connection is firmPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRare earthTitanium

A solder material can be used for fastening an outer electrode on a piezoelectric component. The solder material contains tin as the main constituent and at least one addition from the group of cobalt, tungsten, osmium, titanium, vanadium, iron and rare earth metals. A piezoelectric component includes such a solder material. The solder material is applied by means of a base metallization.

Owner:EPCOS AG

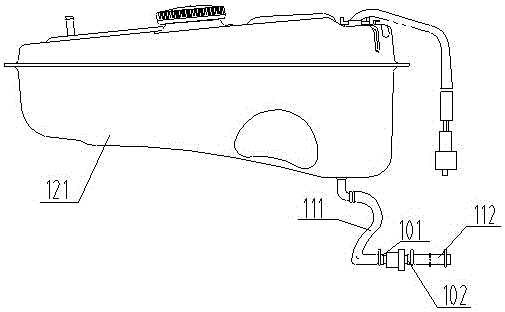

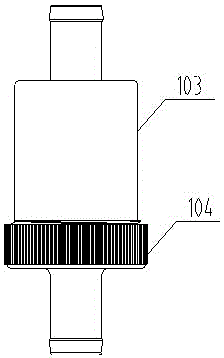

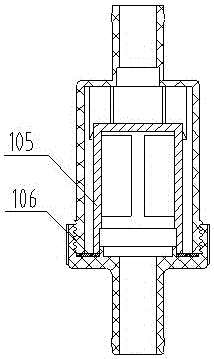

Motorcycle fuel filtering device

InactiveCN105134437AImprove securitySolder connection is firmMachines/enginesLiquid fuel feedersUltrasonic weldingEngineering

The invention discloses a motorcycle fuel filtering device. The motorcycle fuel filtering device comprises a shell, a cover and a filtering cover, wherein the cover covers the shell, and the filtering cover is located in space inside the shell. The shell and the cover are formed through welding. Because the shell and the cover are connected through welding, for example, ultrasonic welding or heat seal welding is adopted, no relative movement is generated when a motorcycle shakes or vibrates, fuel leakage is eradicated, and then the integral safety of the motorcycle is improved; threads do not need to be machined, and therefore the machining technology is simple; seal rings are omitted, and then the manufacturing cost is lowered further.

Owner:力帆科技(集团)股份有限公司

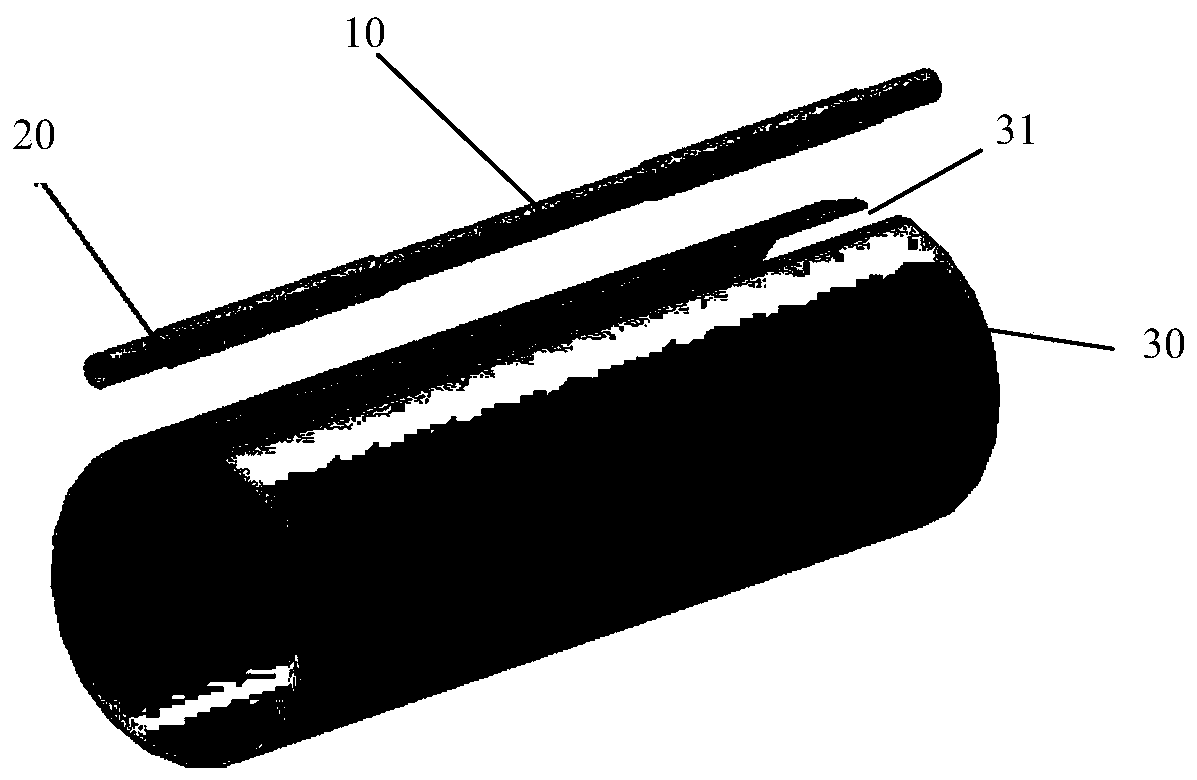

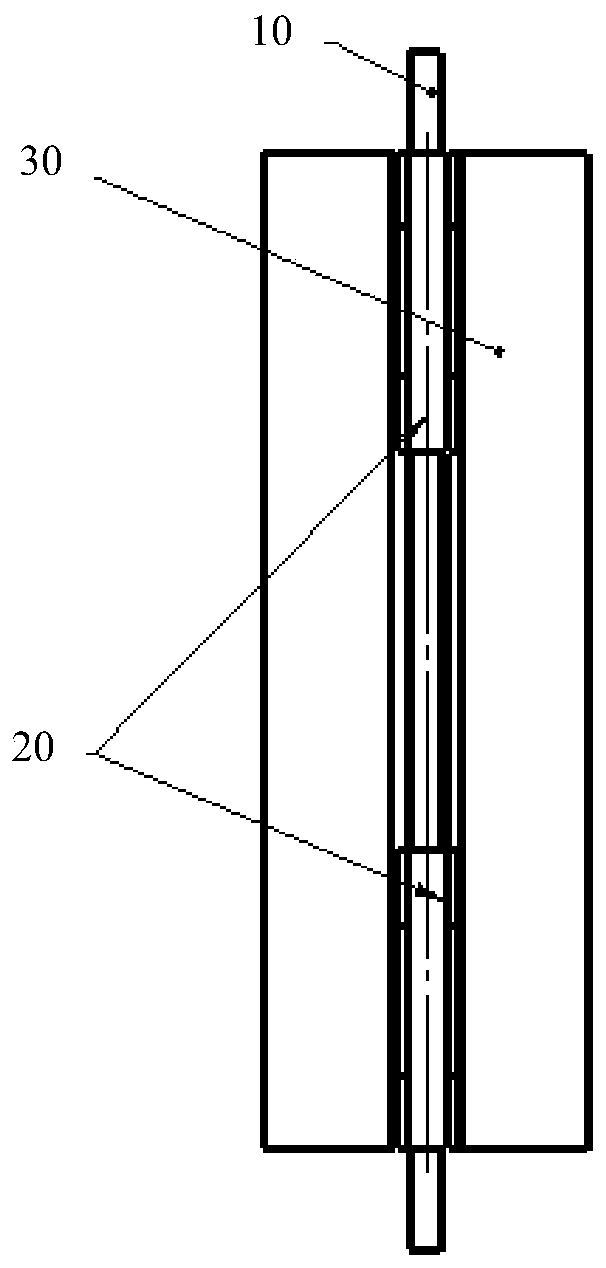

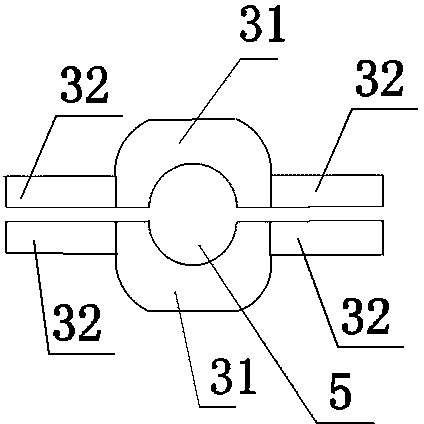

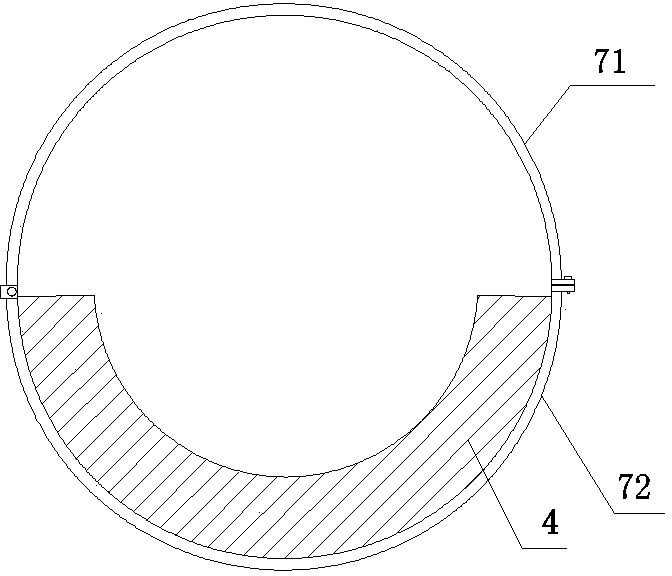

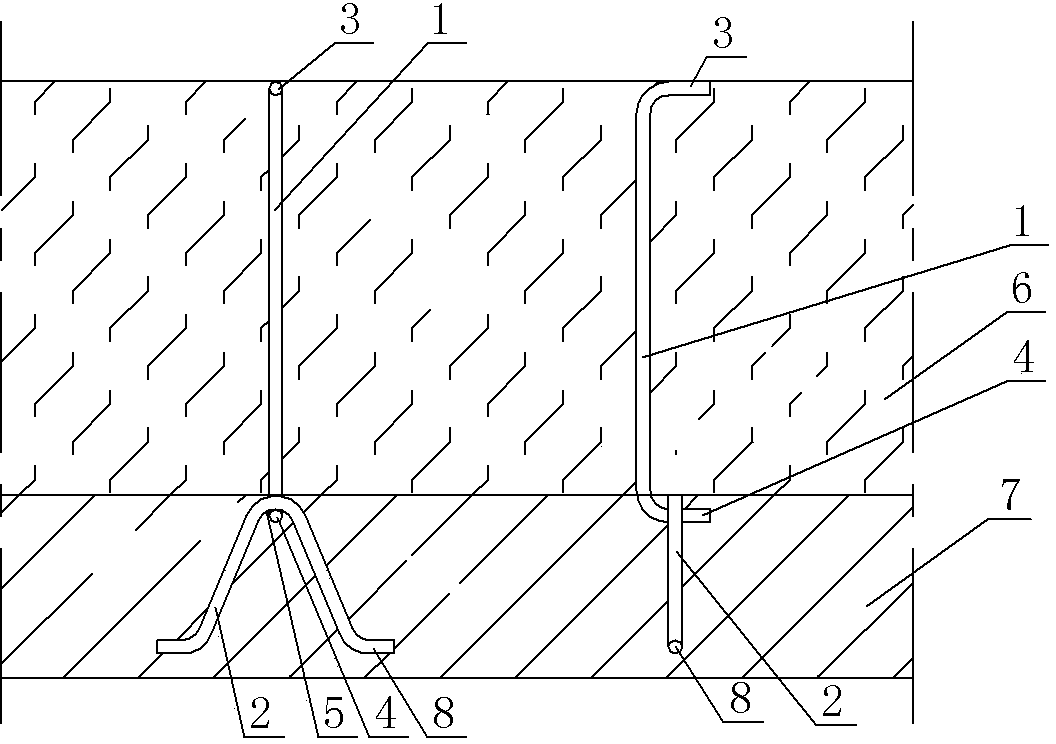

Cold shield structure for low-temperature transportation pipeline

InactiveCN111120781AReduce difficultyReliable thermal connectionThermal insulationPipe protection by thermal insulationThermodynamicsStructural engineering

The invention discloses a cold shield structure for a low-temperature transportation pipeline. The cold shield structure comprises a cold shield and a cooling pipe, and further comprises at least onetransition sleeve which is arranged on the outer surface of the cooling pipe in a sleeving manner, and each transition sleeve is formed through the butt connection of a pair of semicircular cylinderswith opposite openings. Welding plates radially extending outwards are arranged on the outer walls of the transition sleeves; the cold shield is of a cylindrical structure, an axial joint for containing the cooling pipe and the transition sleeves is formed in the cylinder wall of the cold shield, the welding plates are in welding connection with the portions, on the two sides in the circumferential direction of the axial joint, of the cylinder wall in the cold shield, and the cold shield and the transition sleeves are made from a same material. The cold shield structure is easy to weld, high in reliability and wide in application range.

Owner:VACREE TECH

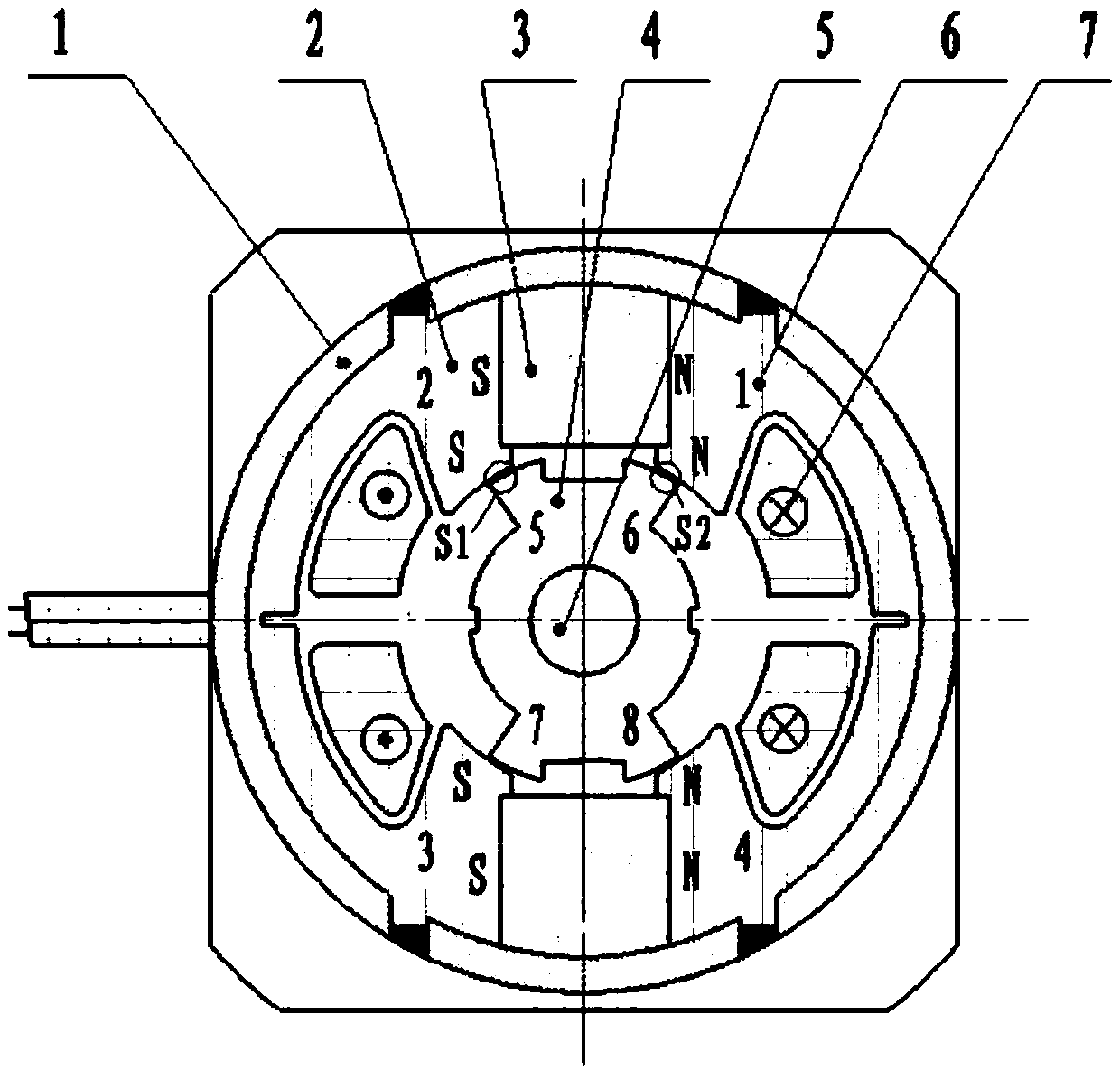

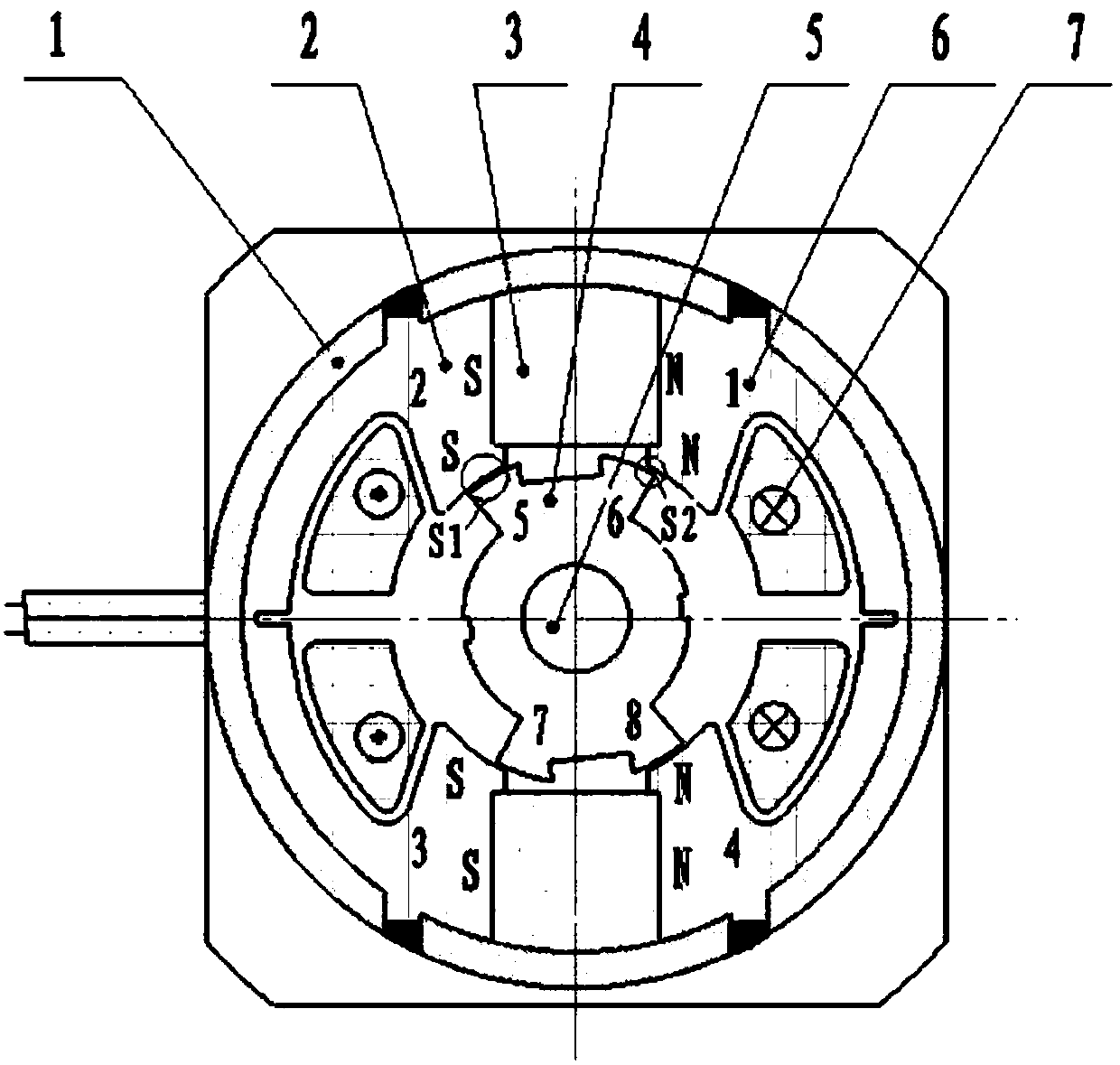

Stator dual-excitation limited angle moment motor

InactiveCN108039807APrecise control of angular positionSimple structureDynamo-electric machinesConductor CoilLimited angle

The invention belongs to the field of a limited turning corner, and concretely discloses a stator dual-excitation limited angle moment motor. The stator dual-excitation limited angle moment motor comprises a stator iron core, a rotor, a magnet and a winding, wherein the stator iron core comprises a first split stator iron core and a second split stator iron core in symmetrical arrangement; two magnets are arranged between the first split stator iron core and the second split iron core; the two magnets are arranged on the center surface passing through the rotor axial line and are symmetrical by using the rotor as a symmetry center; four pole shoes are arranged on the stator iron cores; two completely identical armature windings are symmetrically sleeved on each pole shoes. The two magnetsare arranged between the first split stator iron core and the second split stator iron core of the motor; the two magnets enables the rotor to have a stable position; when the winding on the stator iron core is electrified, under the effect of the winding, the stable position of the rotor changes a certain angle relative to the stable position given to the rotor by the two magnets, so that the limited rotating angle regulation is realized; the angle position is precisely controlled.

Owner:XIAN MICROMOTOR RES INST

Welded in plastic spout part

InactiveCN101018714AWelding for reliable and continuousFaster and more reliable weldingBagsSacksPlastic materialsEngineering

The invention relates to a welded-in plastic spout part that is to be joined to a plastic receptacle part, especially a receptacle part made of film-type plastic material such as a pouch. The inventive spout part comprises parallel planar weld-on ribs which extend along the circumference of a neck area (spout) that defines a pouring passage. A rib-shaped welding burr that is less thick than the weld-on ribs is provided at the outer circumference of said weld-on ribs. The welding burr is molded onto an outer rounded peripheral edge of the weld-on ribs. A partition which protrudes radially on both sides of the neck area is arranged perpendicular to the weld-on ribs. Both ends of said partition extend beyond the ends of the rib base area so as to form lateral flaps. The welding burrs extend past both sides of the flaps while the lateral flaps are provided with one respective recess instead of a top and bottom outer corner.

Owner:GEORG MENSKHEN GMBKH & KO KG

Treatment process for reducing burr production in electric resistance welding process of steel component

ActiveCN113714937AReduce roughnessReduce generationElectrical resistance and conductanceCopper oxide

The invention discloses a treatment process for reducing burr production in the electric resistance welding process of a steel component, and relates to the technical field of steel welding. The method is provided for the to-be-welded steel component, and the technical key point is that a middle layer is formed at the to-be-welded part of the steel component through shot blasting, so that the roughness of a contact surface is reduced, contact resistance is reduced accordingly, and therefore generation of burrs in the electric resistance welding process is reduced; and according to the specific treatment process, silver is loaded on a spherical micron copper oxide surface through electro-deposition, composite powder is formed, and a composite powder layer is formed on the to-be-welded part of the steel component through shot blasting treatment. According to the treatment process, the shot blasting treatment method is adopted, the composite powder layer is formed on the surface of the steel component, the composite powder layer serves as the middle layer of the to-be-welded steel component, the roughness of the contact surface can be effectively reduced when the steel component is welded, the contact resistance is reduced, accordingly, the burrs are reduced, and the attractiveness of a weld joint after the steel component is welded is improved.

Owner:安徽军明机械制造有限公司

Vertical cable paying-off device

ActiveCN104009439AImprove connection stabilityIncrease contact areaCable arrangements between relatively-moving partsEngineering

Owner:STATE GRID SICHUAN ELECTRIC POWER

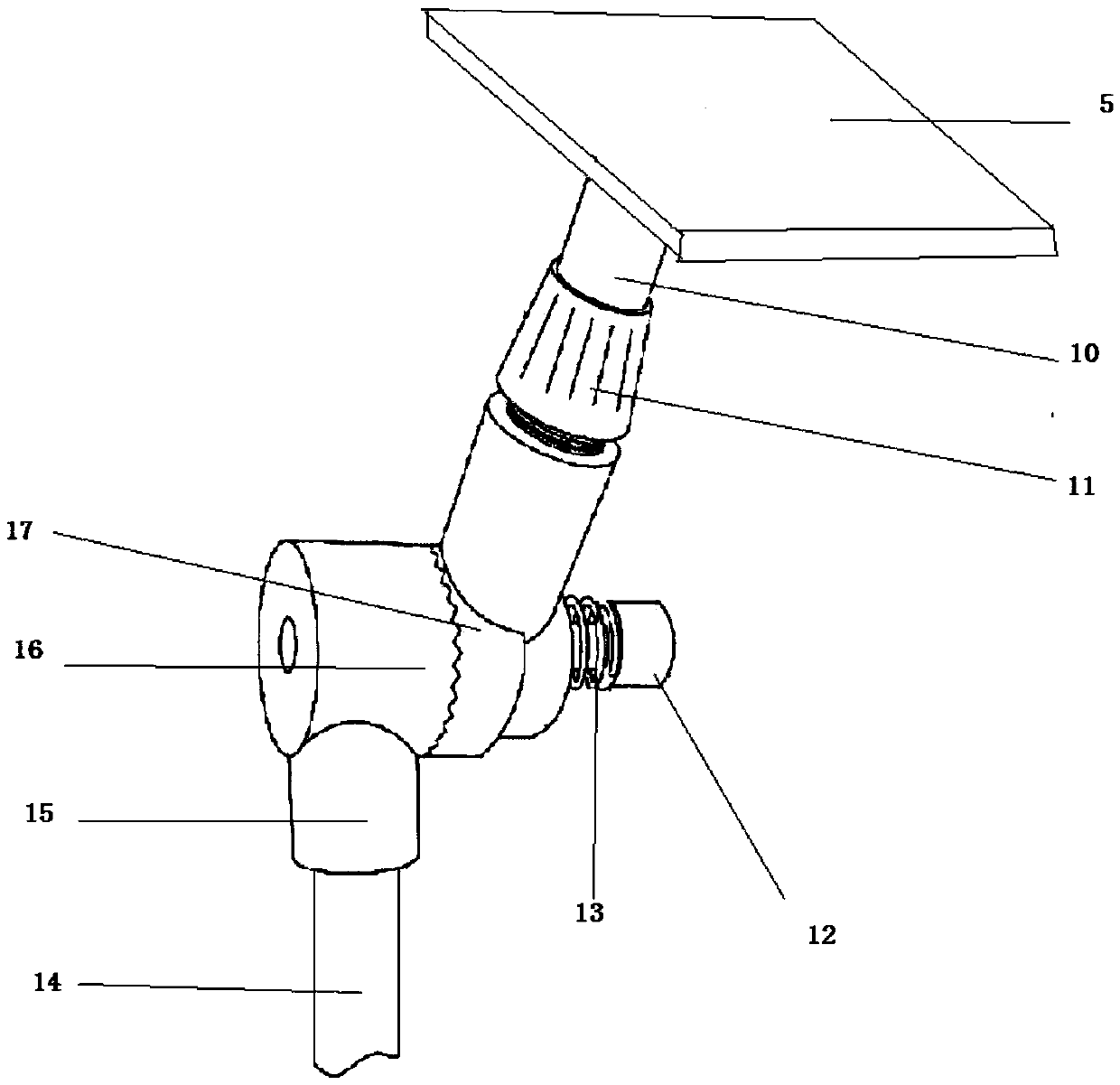

Novel camera device

InactiveCN107725997AWide range of rotationSolder connection is firmTelevision system detailsColor television detailsElectric machineryEngineering

The invention discloses a novel camera device. The novel camera device comprises a bottom board; a camera is arranged above the bottom board; the lower portion of the bottom board is sequentially connected with a first connection rod, a second connection rod, a rotary movement and a movement sleeve; the second connection rod is fixedly connected with the rotary movement; the rotary movement can rotate in the movement sleeve; the lower end of the movement sleeve is welded with a rotary block; the rotary block is a cylinder with the axis parallel with the ground; the movement sleeve is welded tothe side face; the upper bottom face of the rotary block is connected with a housing through connection between a fixing nut and a limiting thread; the limiting thread is arranged on a rotary shaft;the rotary shaft penetrates through the housing and the rotary block; the rotary shaft is controlled by a motor; and the motor is arranged inside the housing. A wireless receiving module is arranged inside the housing and controls the motor and the rotary movement. The bottom board is welded with the first connection rod. Transverse rotation and vertical rotation are adopted to achieve 360-degreerotation.

Owner:成都一拍即合科技有限公司

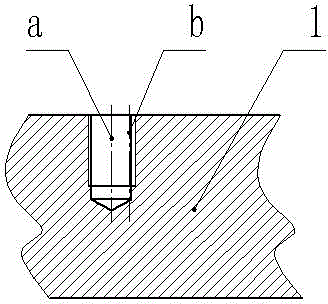

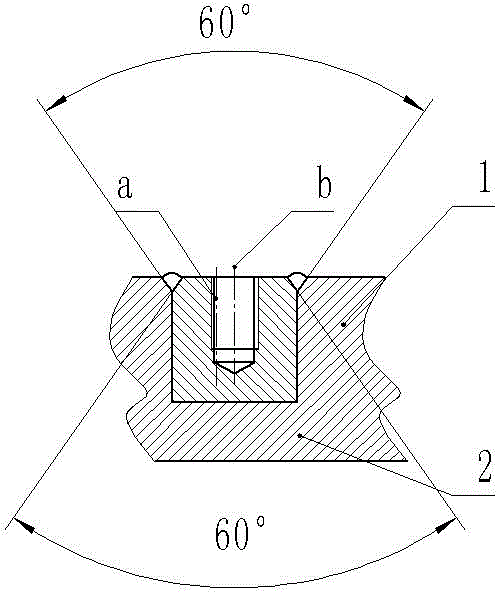

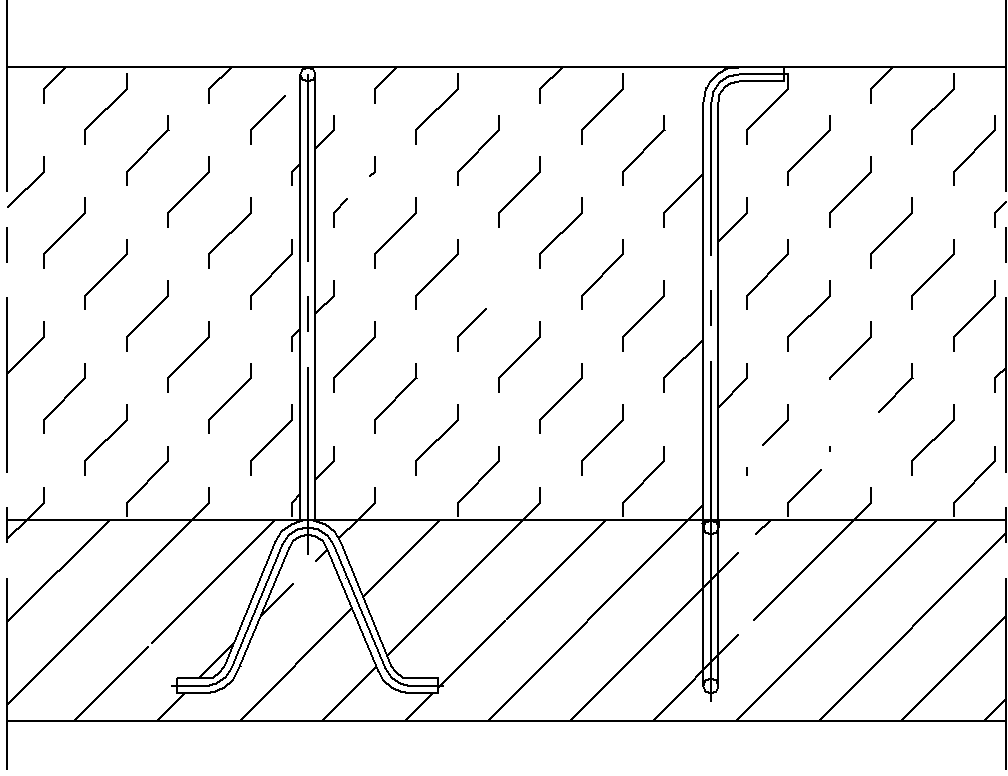

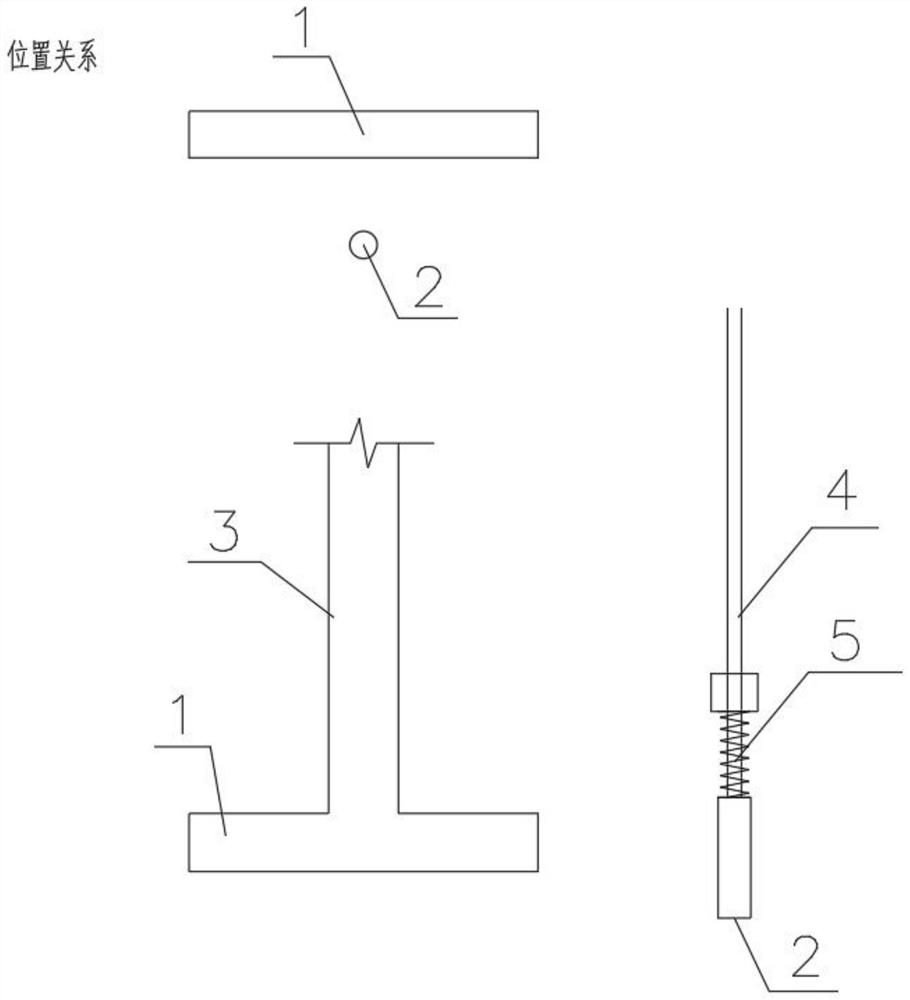

Scratch nail structure for fixing fire resistant materials for boiler

The invention provides a scratch nail structure for fixing fire resistant materials for a boiler. The connection between the head part and the tail part of the scratch nail is reliable, the desoldering is avoided, the connection of the head part and the tail part is still reliable even when a soldering seam is disengaged, the fire resistant materials cannot fall off, and the operation safety and the operation reliability of the boiler are improved. The scratch nail structure comprises a head part structure and a tail part structure, wherein the upper part of the tail part structure is outwards projected, and the head part structure is an outward opening expansion structure with an angle. The scratch nail structure is characterized in that the lower part of the tail part structure is provided with an outward projection hook, and the outward projection hook is welded and connected after hooking the center lower bending position of the outward opening expansion structure with the angle.

Owner:WUXI HUAGUANG BOILER

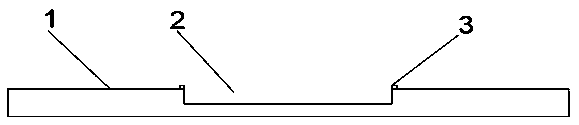

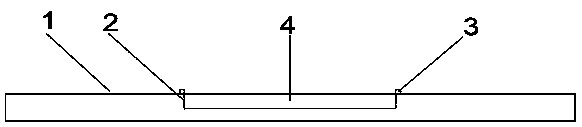

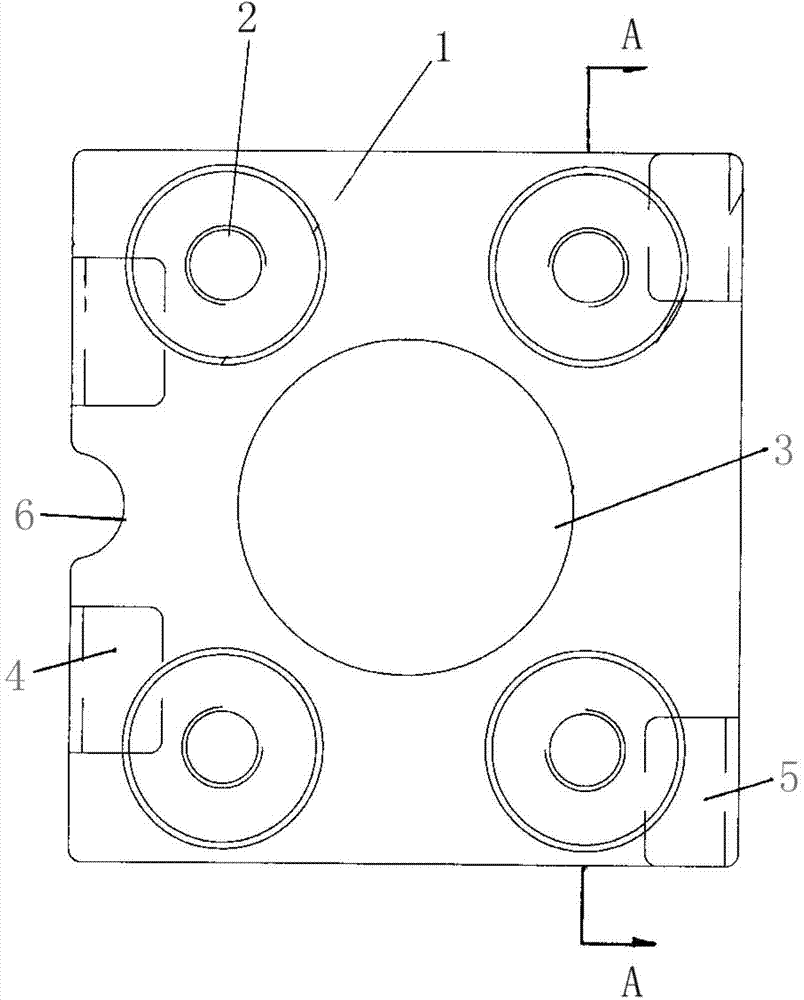

Novel air chamber base plate

The invention discloses a novel air chamber base plate. The novel air chamber base plate is characterized in that support threaded holes are formed in the four corners of a square base plate body, a weld reinforcement process round hole is formed in the middle of the square base plate body, the two sides of the square base plate body are each provided with a front end welding claw and a rear end welding claw, and a preserved welding opening is formed in the middle of one side of the square base plate body. Through the arrangement, the novel air chamber base plate is welded to the upper plane of a car rear axle shell, the front end welding claws and the rear end welding claws are added, so that the novel air chamber base plate is connected with the car rear axle shell more firmly, and practice shows that the defect that an air chamber base plate is unsmooth and inconvenient to weld is overcome.

Owner:ZHUCHENG CITY FURI MACHINERY

Welding forming machine as well as production line and production method of cement floor support plate

PendingCN113245682AReduce manufacturing costIncrease productivityResistance welding apparatusProduction lineMolding machine

The invention provides a welding forming machine as well as an automatic production line and a production method of a cement floor support plate. The welding forming machine comprises a positive electrode and a negative electrode which are arranged on the upper portion of a workpiece, and the negative electrode is arranged on one side of the positive electrode and / or arranged in the positive electrode and / or arranged on the two sides of the positive electrode. According to the welding forming machine as well as the automatic production line and the production method of the cement floor support plate, the design that the negative electrode is arranged on the upper portion is adopted, the positive electrode and the negative electrode which are needed during welding are arranged on the upper portion of the workpiece, the welding strength is guaranteed, the production technology requirement is met, the production technology process that a bottom formwork is arranged on the lower portion and a steel bar framework is arranged on the upper portion is successfully achieved, later plate overturning is not needed, the production efficiency is improved, the production and equipment cost is reduced, the production line is shortened, and the production space is saved.

Owner:李世捷

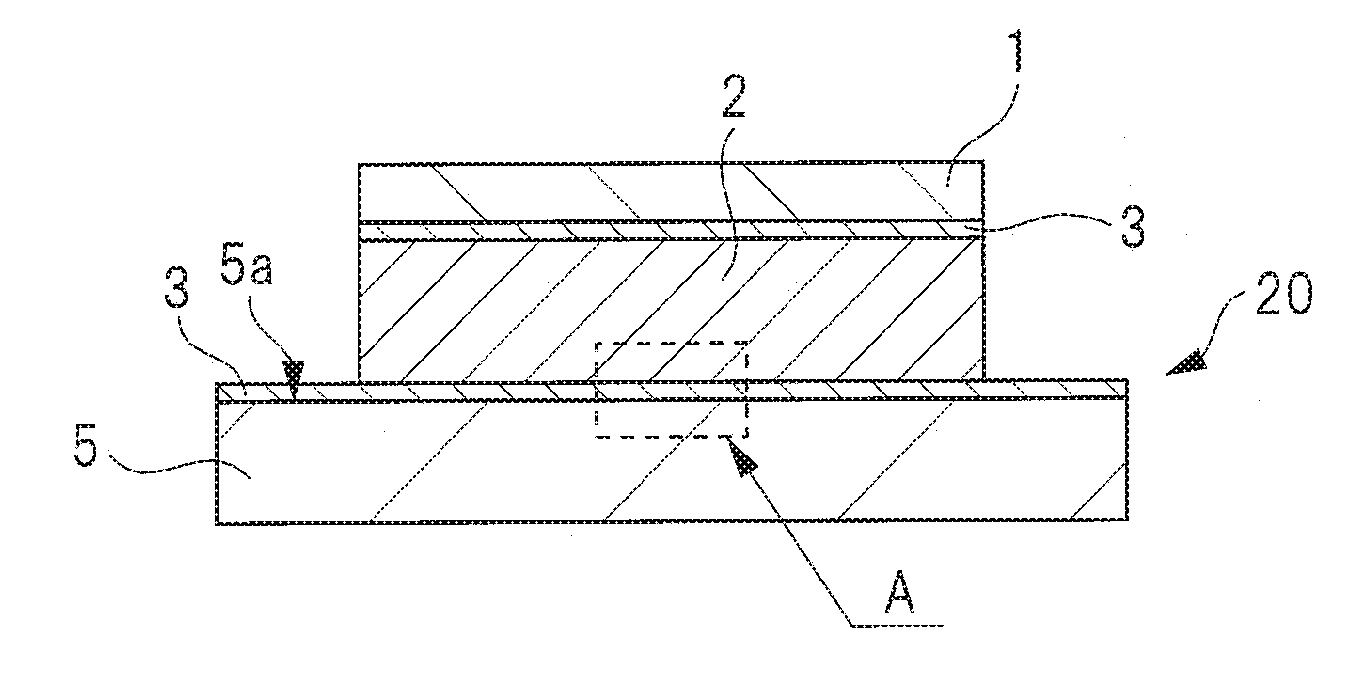

Method for producing window elements that can be soldered into a housing in a hermetically sealed manner and free-form window elements produced in accordance with said method

ActiveUS10330941B2Minimizing penetrationSolder connection is firmRadiation pyrometryPhotometryHigh energyOptical coating

A method for production of window elements which can be soldered into a housing in a hermetically tight manner with optical coating and free-form window elements are disclosed. After application of optical coatings, a protective layer is applied to the optical coating, the two layer systems are selectively removed by means of a machining beam of high-energy radiation for the purpose of ablation of a desired optically active free-form surface for window elements with any geometric shape through a localized machining beam in edge regions of the optically active free-form surface such that the protective layer remains on the optical coating as lift-off mask which is lifted off after applying a metallization for a solder layer by an etching process that acts selectively only on the protective layer but not on the optical coating, and the metallization remains only on the peripheral edge regions circumscribing the free-form surfaces.

Owner:JENOPTIK OPTICAL SYST +1

Casing. esp. for semiconductor device, foot of such semiconductor device and mfg. method of such foot

InactiveCN1519904ASolder connection is firmAvoid mechanical propertiesPrinted circuit assemblingFinal product manufactureMetal coatingElectrical conductor

The method involves one or more stamping process steps in which at least one pin is stamped out of a base body, especially a lead frame. The pin or a section of the pin is coated with a separate metal coating only after final stamping out of the pin. The end face of the outer end section of the pin is also coated with the metal coating. Independent claims are also included for the following: (a) a housing, especially for semiconducting components (b) and a semiconducting component pin.

Owner:INFINEON TECH AG

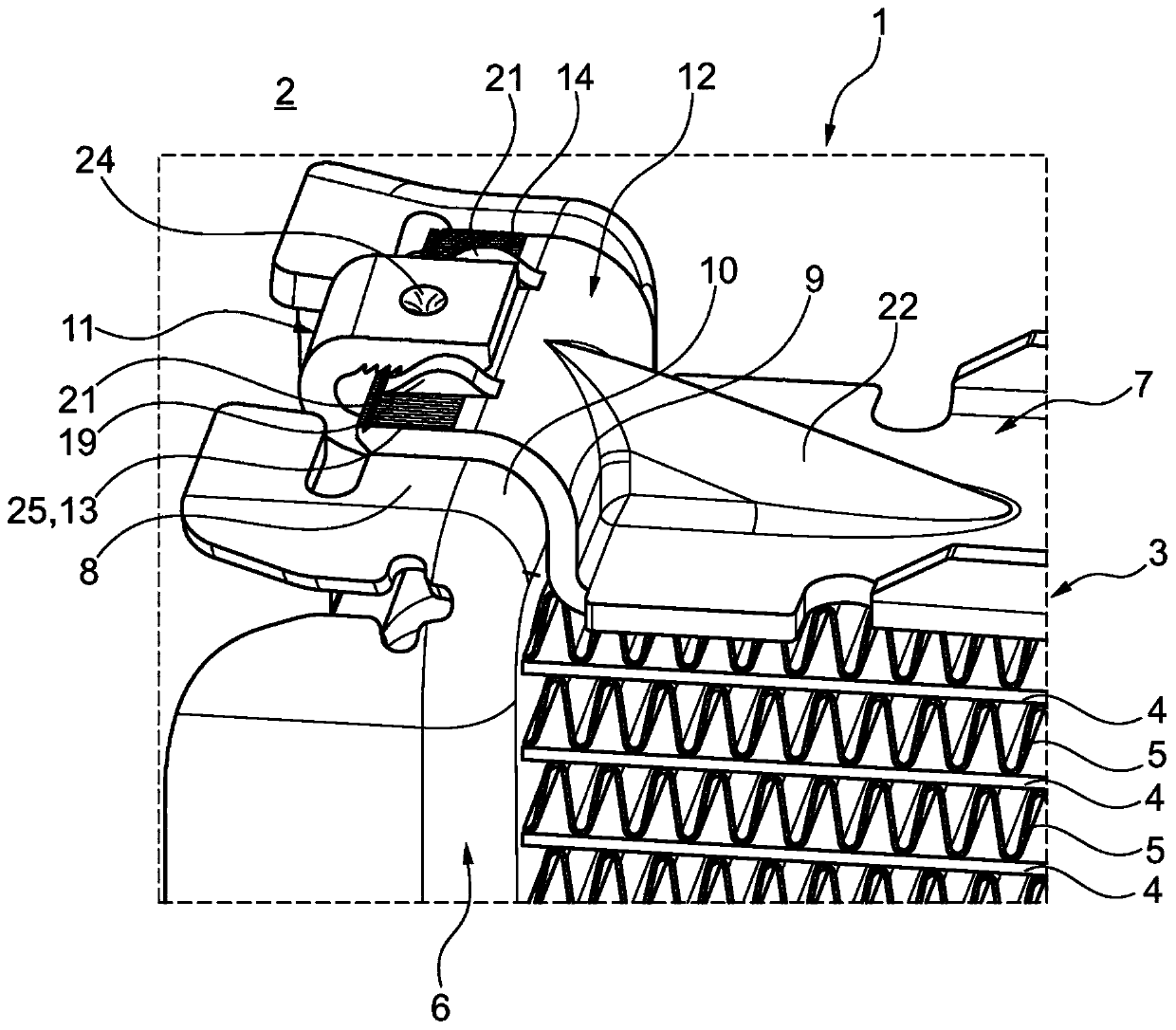

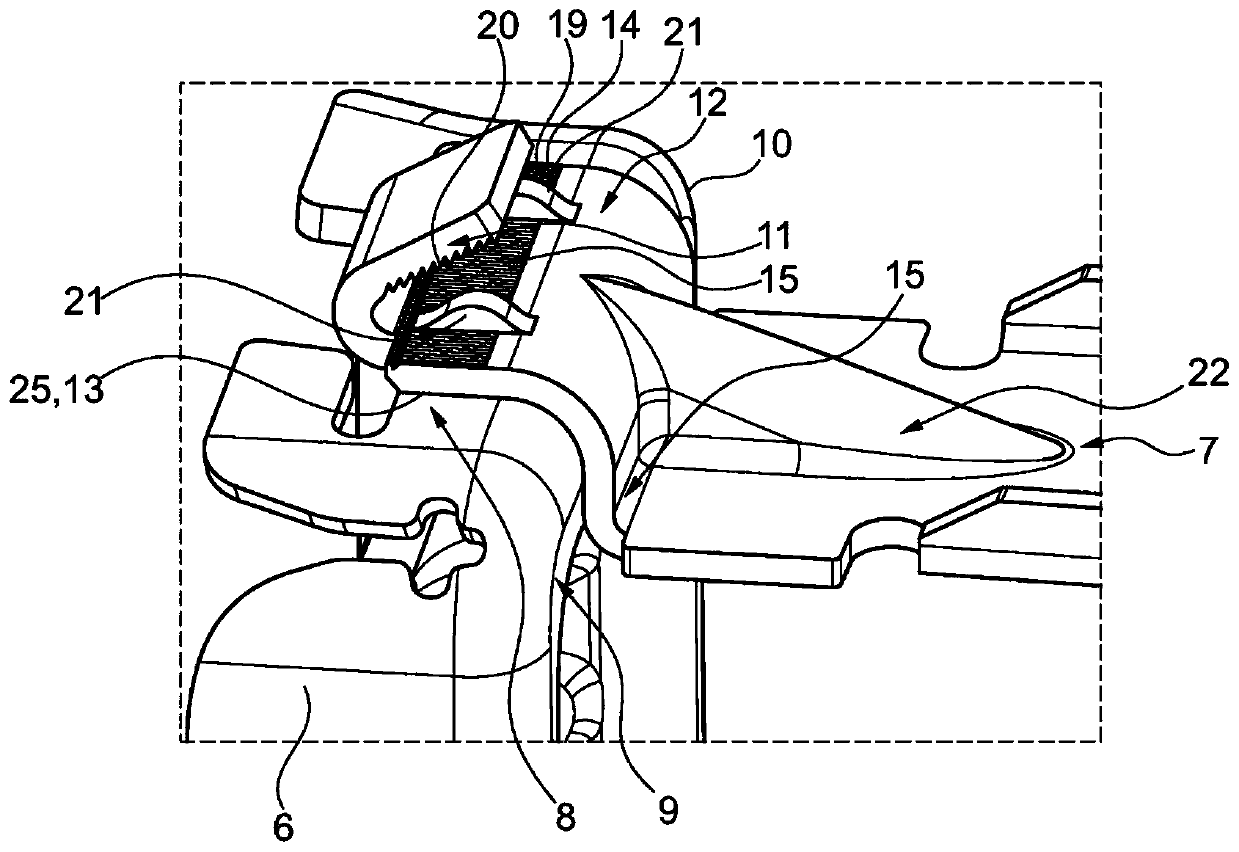

Heat exchanger for motor vehicle and corresponding production method

ActiveCN111306974AQuality improvementHigh strengthVehicle heating/cooling devicesStationary conduit assembliesMotorized vehicleMechanical engineering

The invention relates to a heat exchanger for a method vehicle. The heat exchanger includes a heat exchanger block closed by a side part. Each side is mechanically and cohesively connected to the tubebottom via a welded connection. It is essential that the tube bottom has a front side and a bottom side that converge with each other via a circular corner region. A deformable hook is arranged on the front side of the tube bottom; the side part is provided with a connecting sheet on the longitudinal end side; the tabs are designed complementarily to the circular corner regions of the tube base,have sections abutting against the front side of the tube base and comprising through-holes or recesses, into which through-holes or recesses the material portions of the hooks are displaced by meansof punch holes, the axes of which are arranged offset parallel to each other, in the event that the heat exchanger has been assembled.

Owner:MAHLE INT GMBH

Vertical cable pay-off device

ActiveCN104009439BImprove connection stabilityIncrease contact areaCable arrangements between relatively-moving partsEngineeringConductor Coil

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com