Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1322results about "Cable arrangements between relatively-moving parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

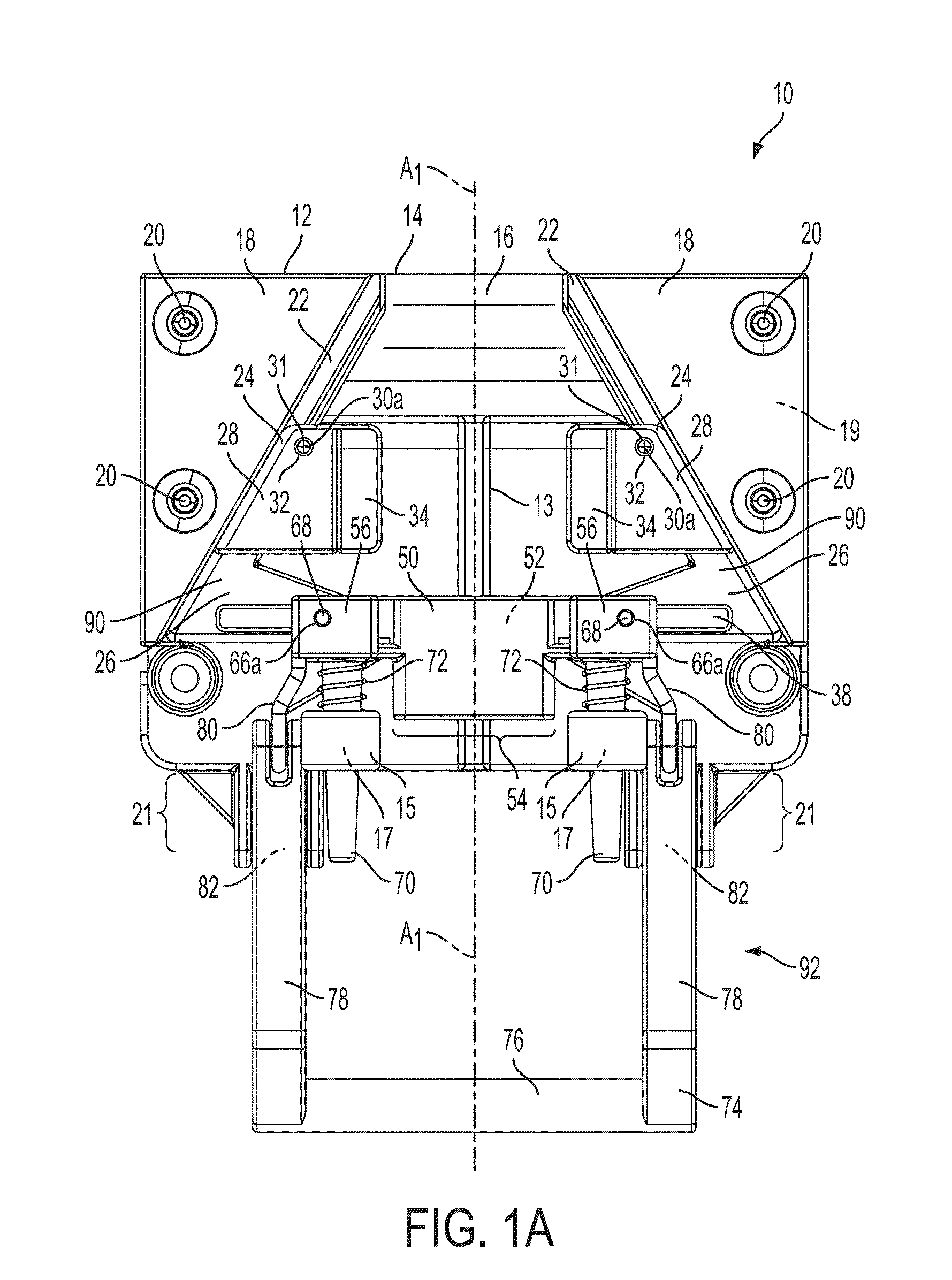

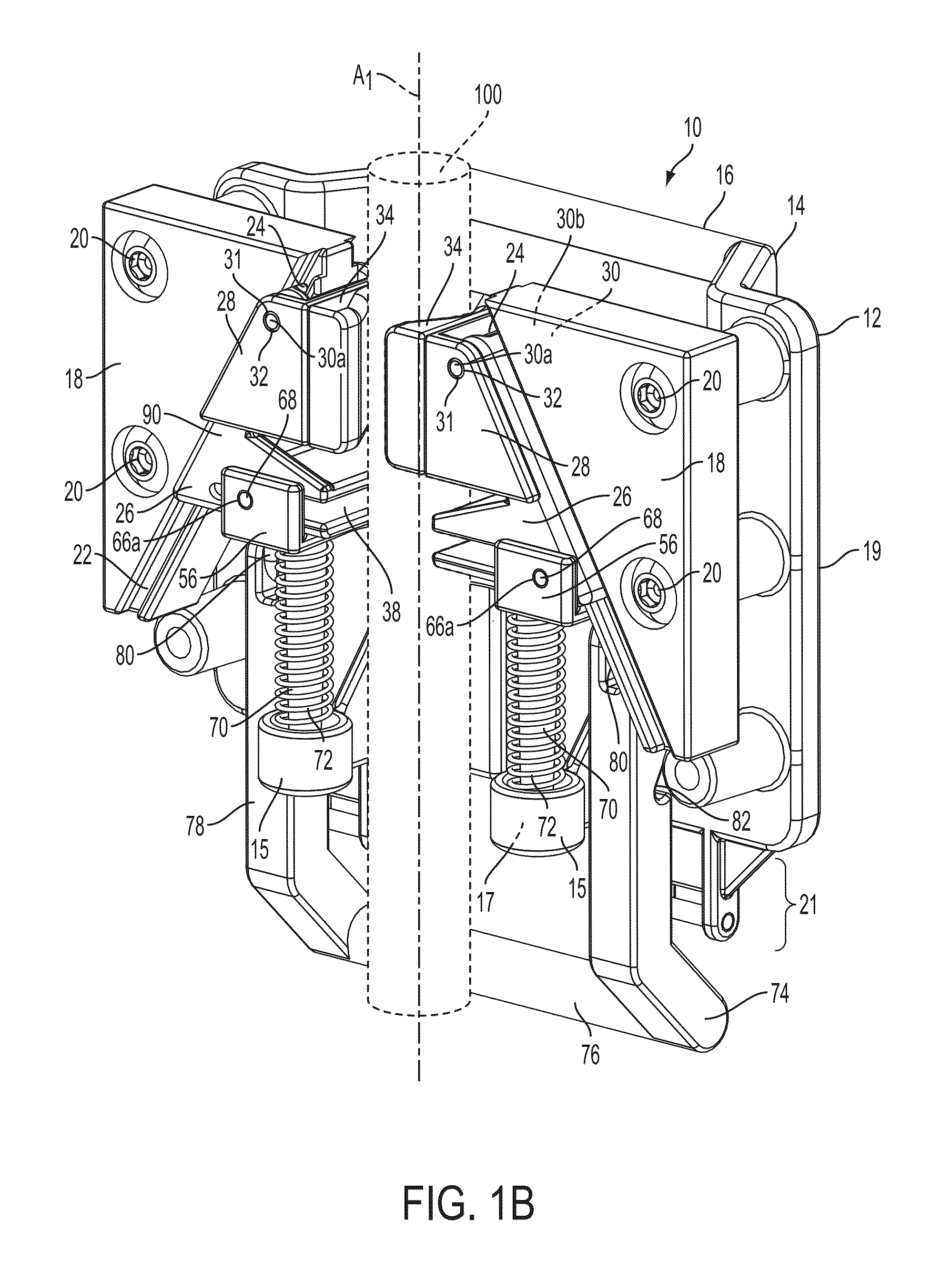

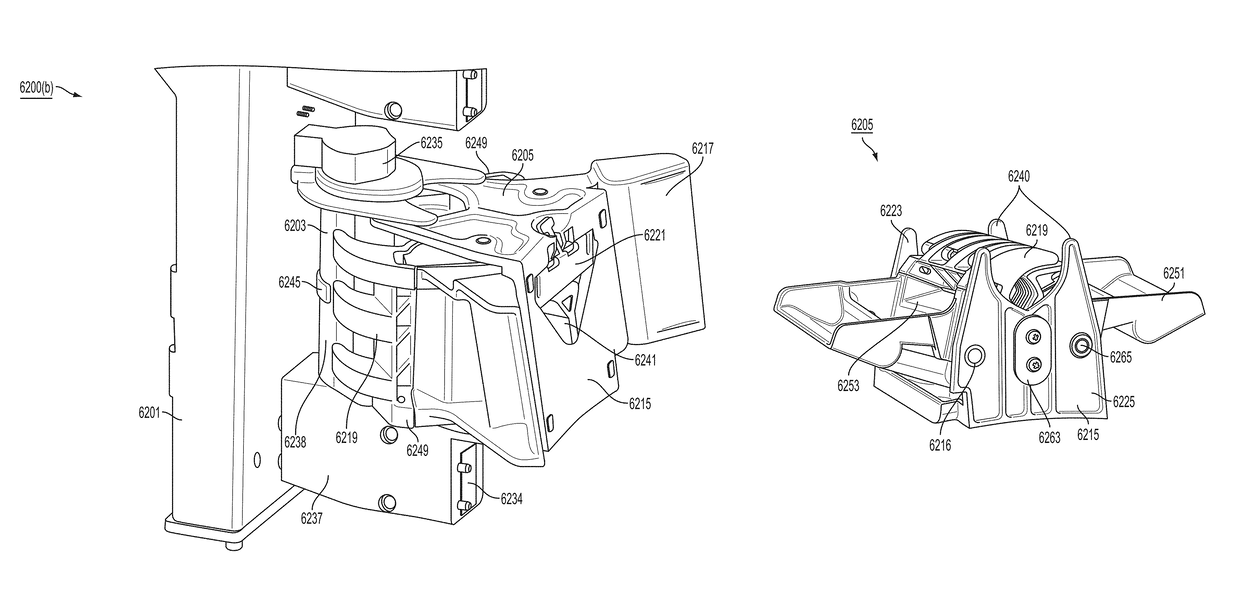

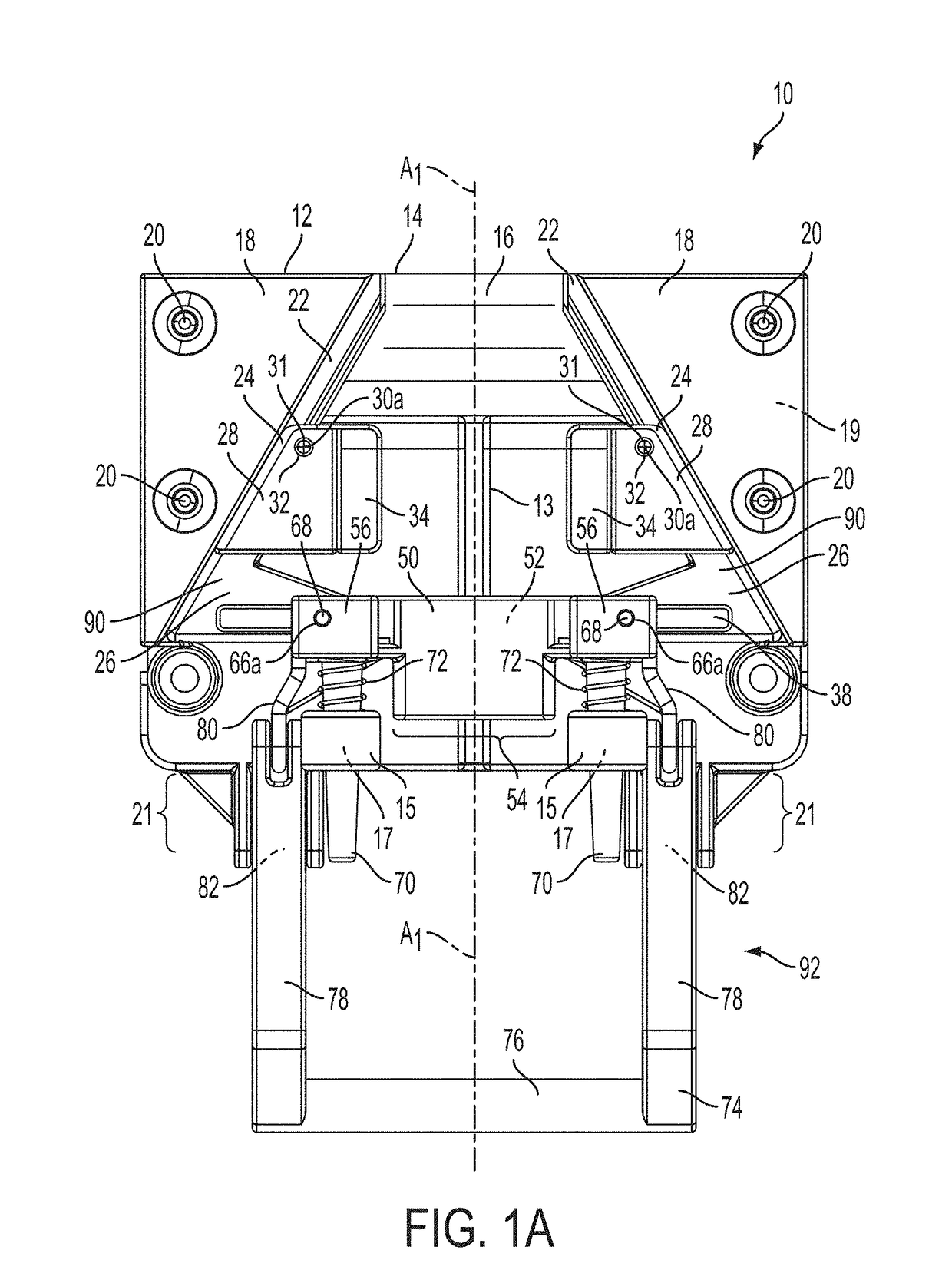

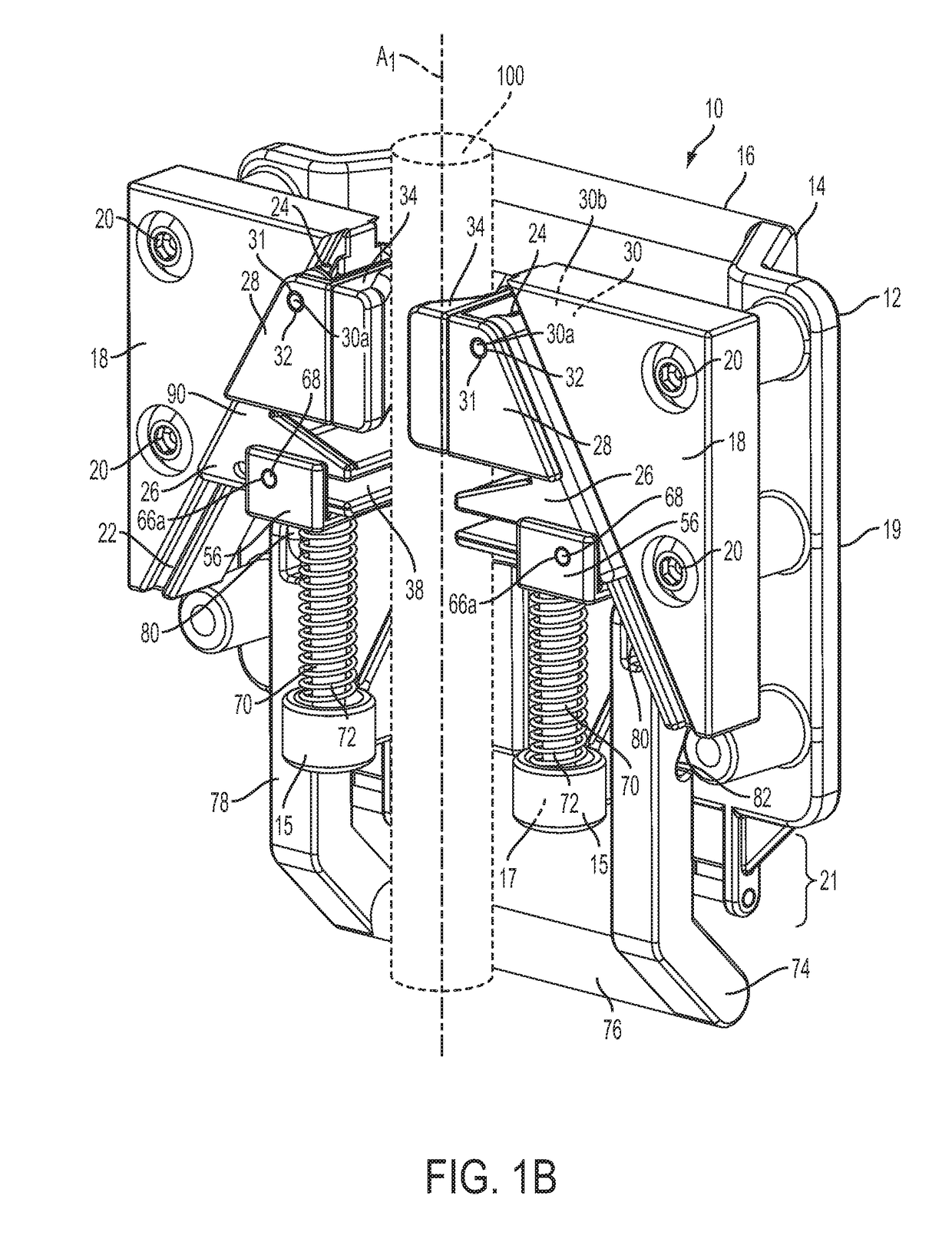

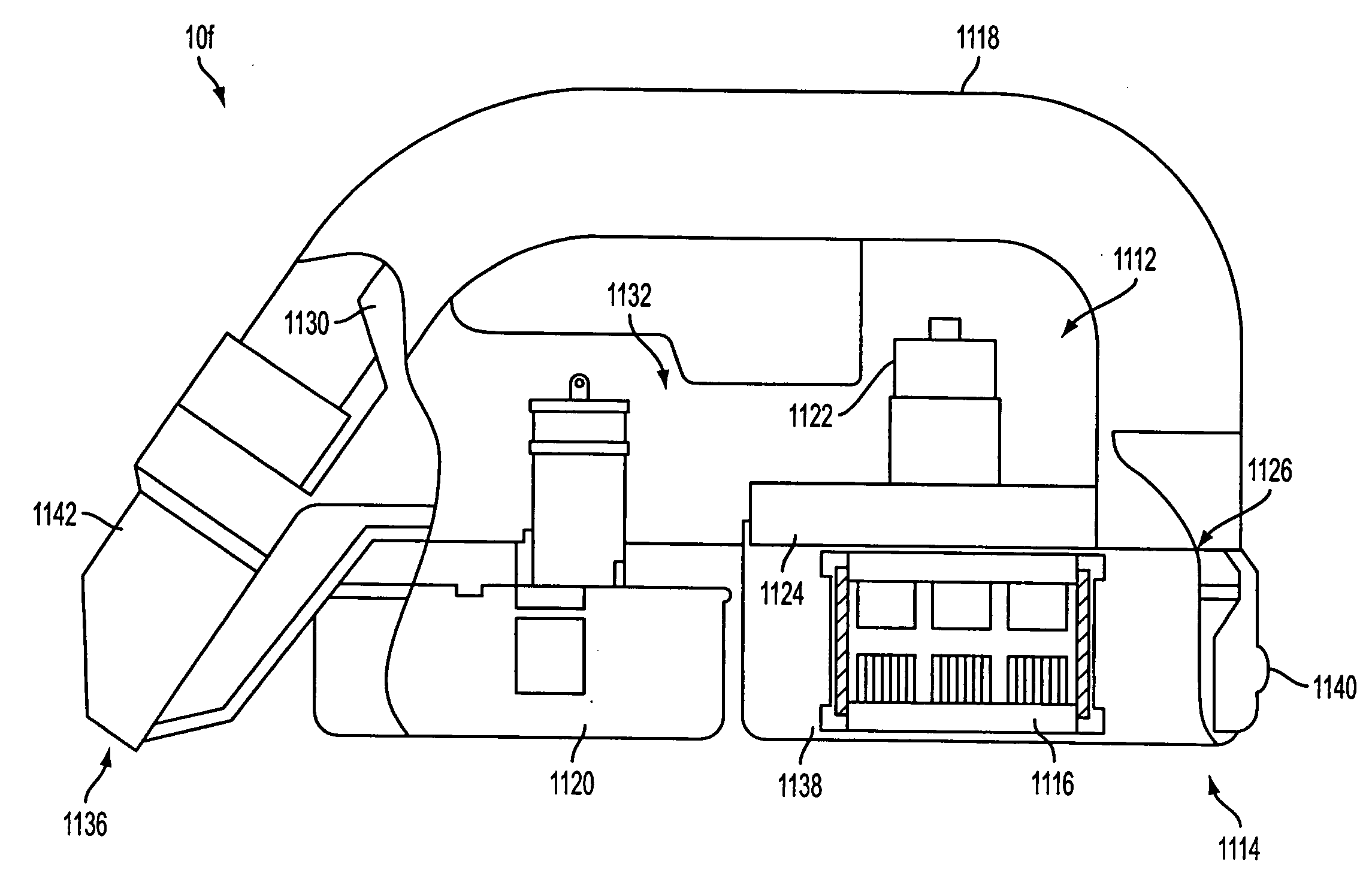

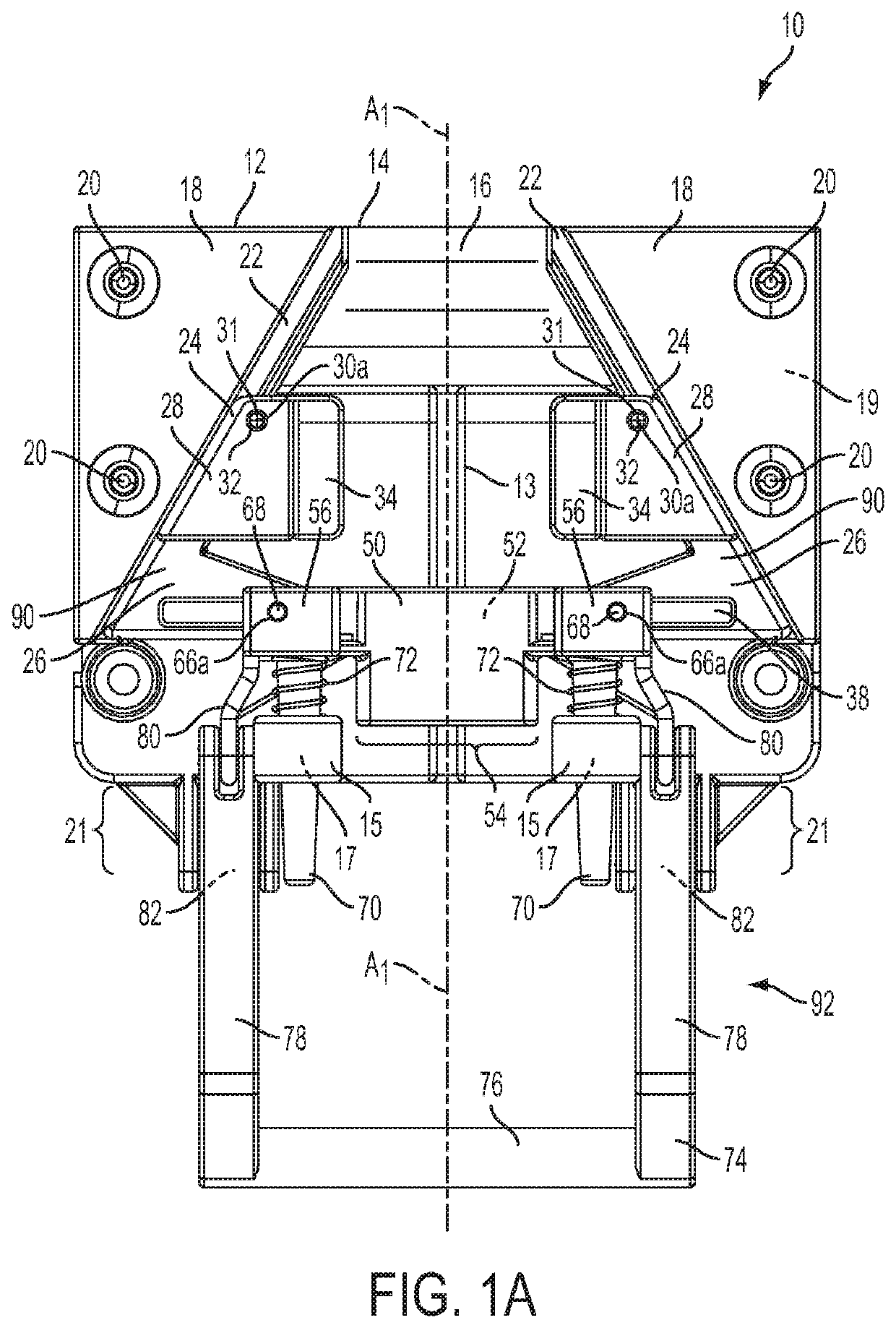

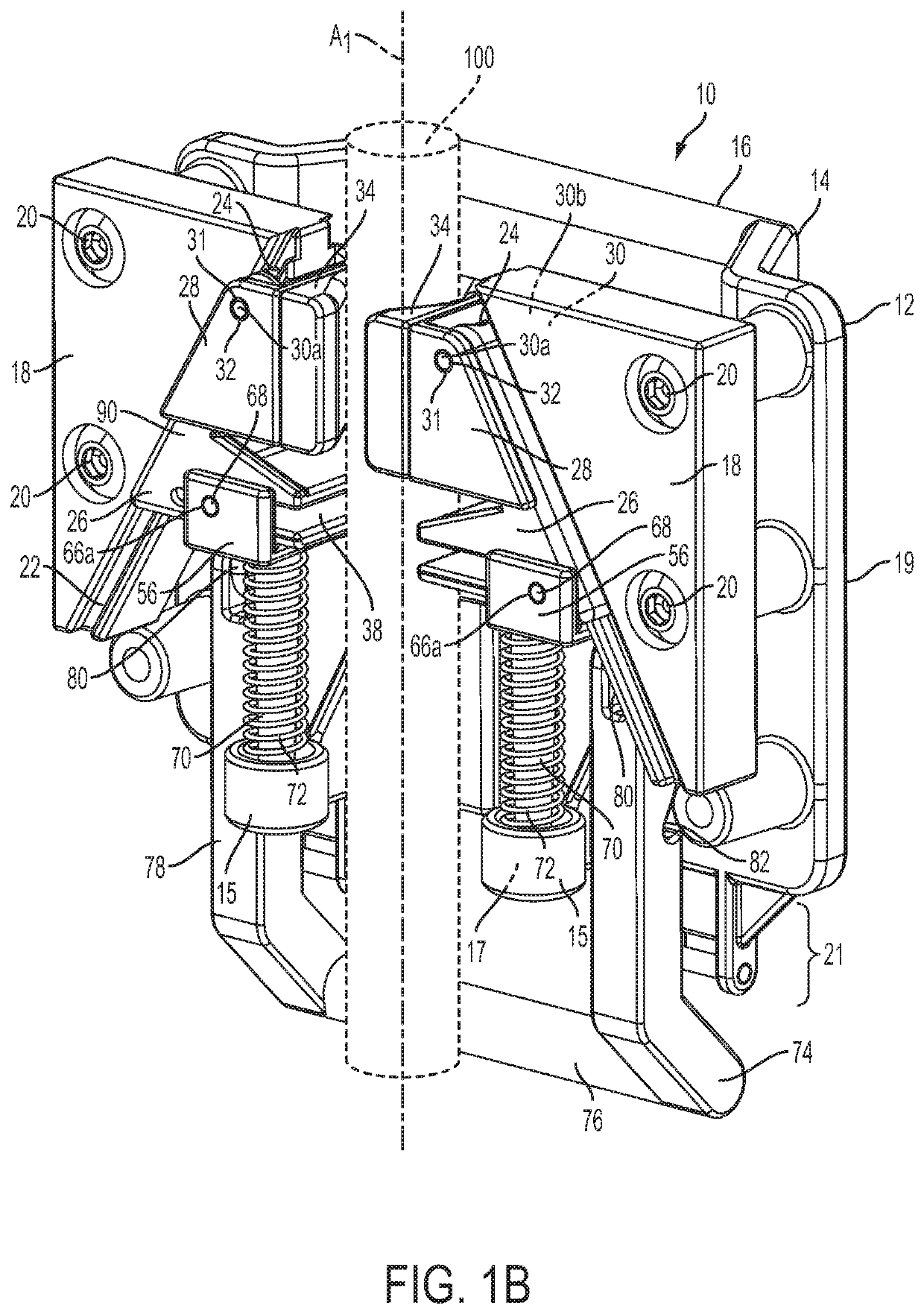

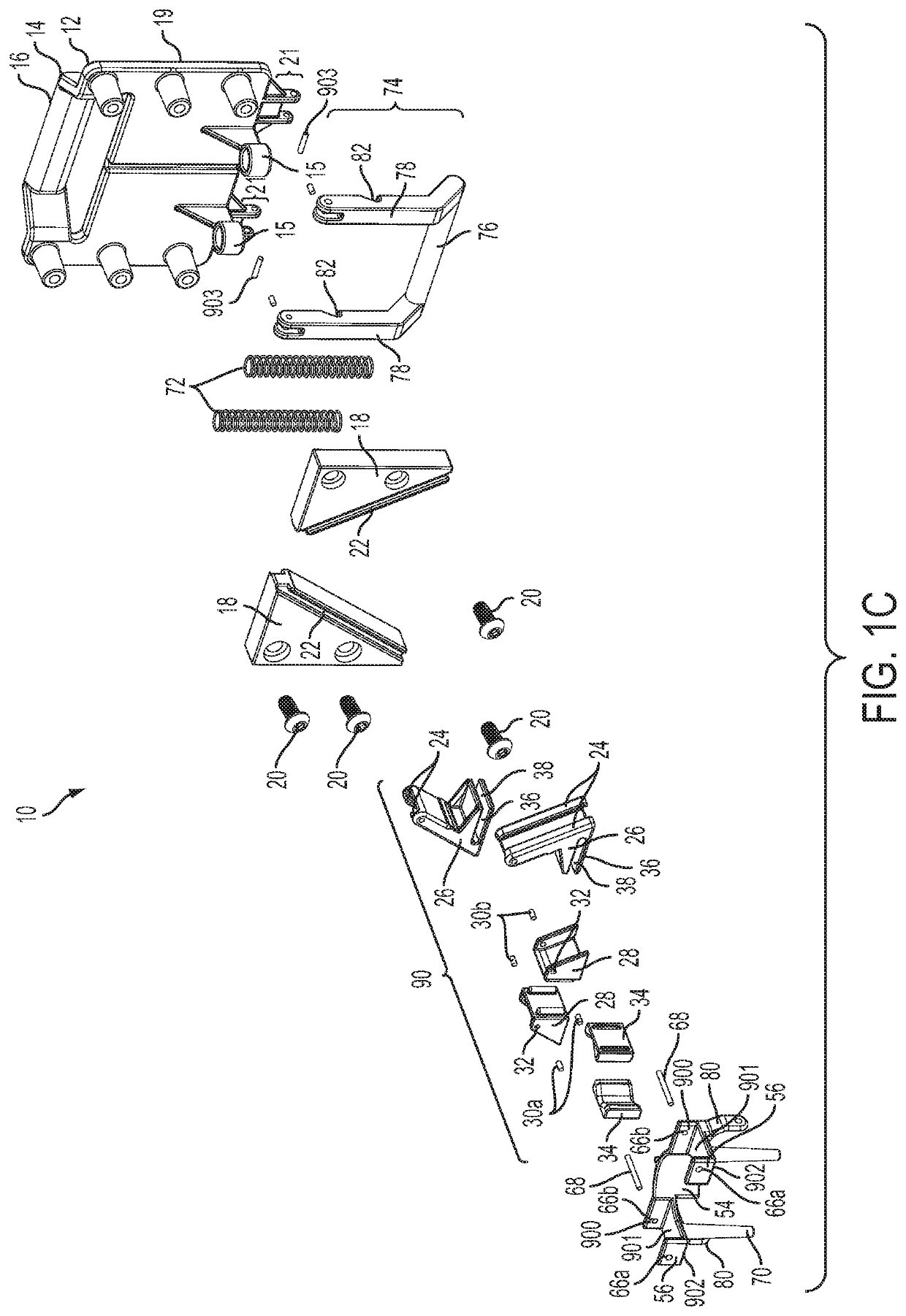

System, Method, and Apparatus for Clamping

ActiveUS20160084434A1Freedom of movementSubstation/switching arrangement detailsMachine supportsNetwork connectionEngineering

A number of racks which are configured to allow a number of devices to couple thereto are provided. In some embodiments, the racks are for use with a number of medical devices. Devices may be coupled to a rack by clamps. The racks may include a number of connectors which provide power and / or a network connection to devices coupled thereto. The racks may include a clamp which allows the racks to couple to a supporting structure such as a pole.

Owner:DEKA PROD LLP

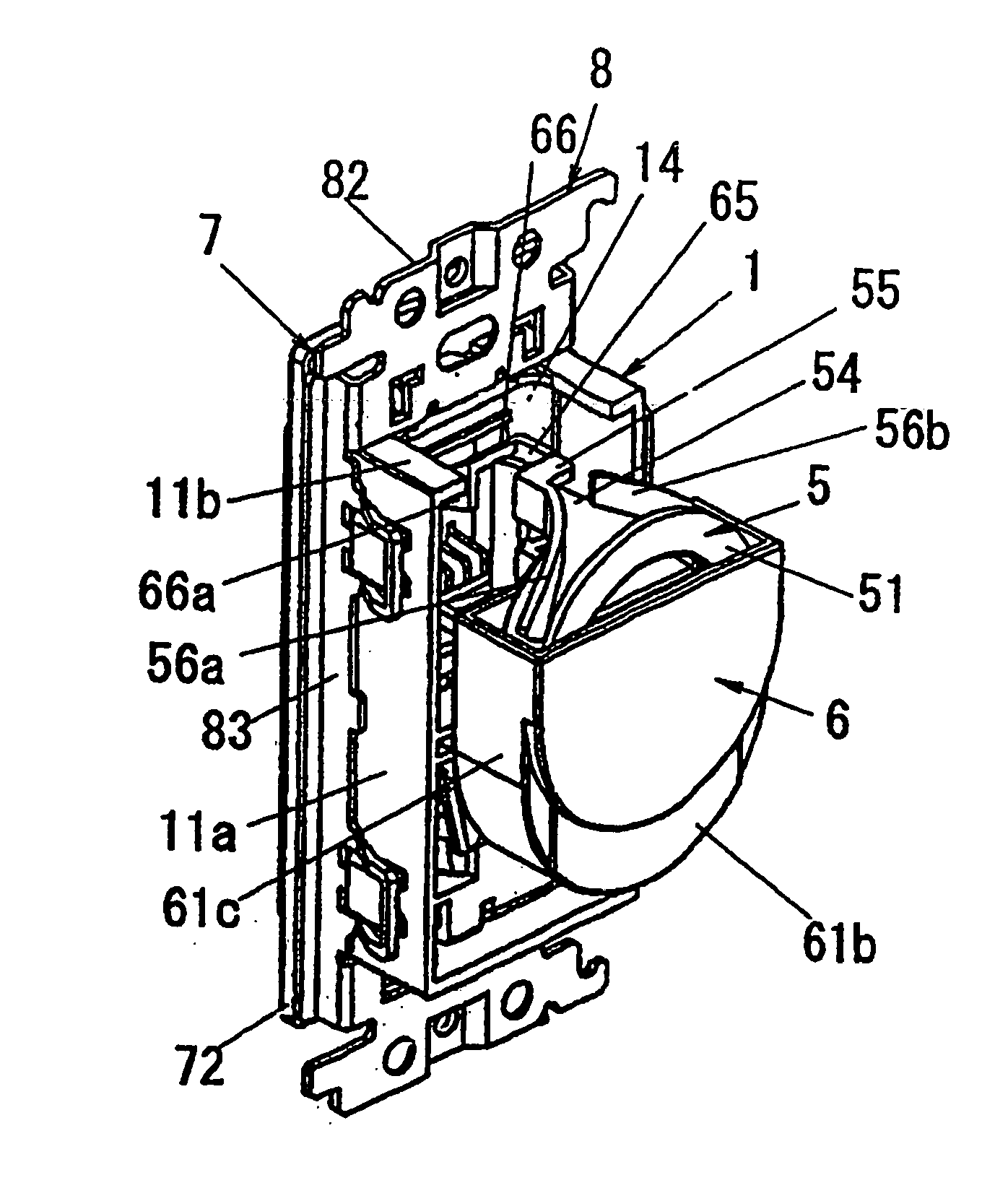

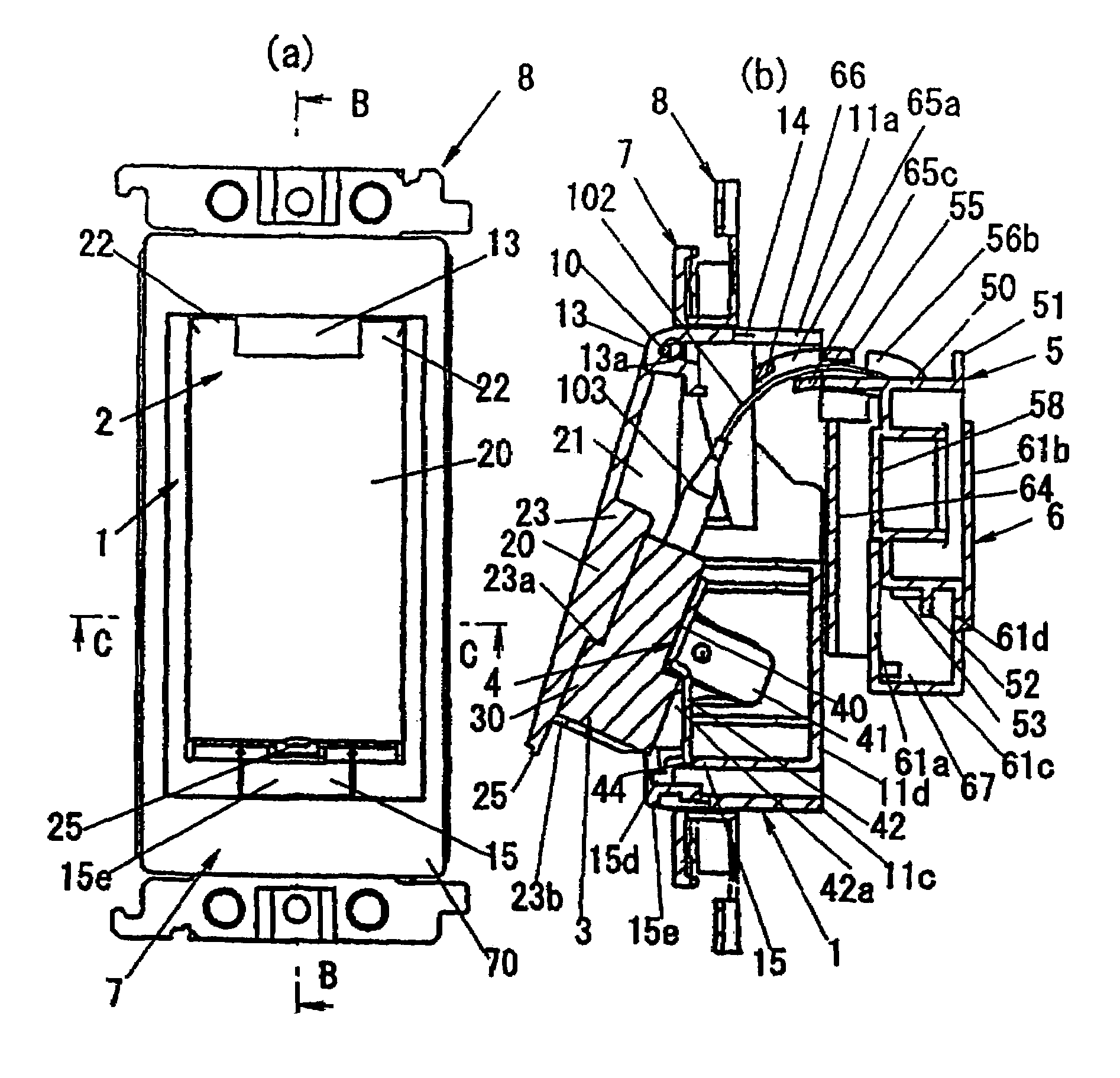

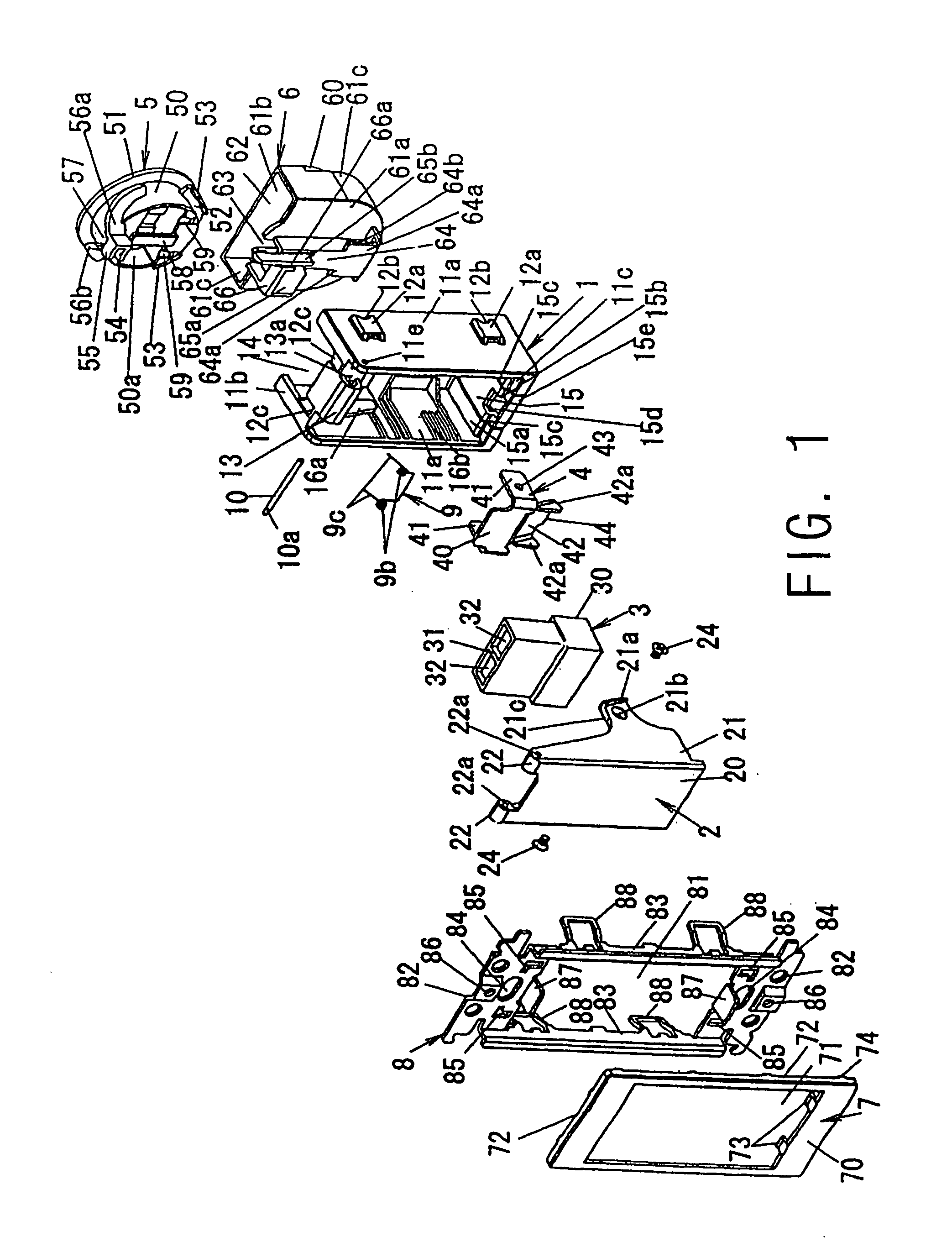

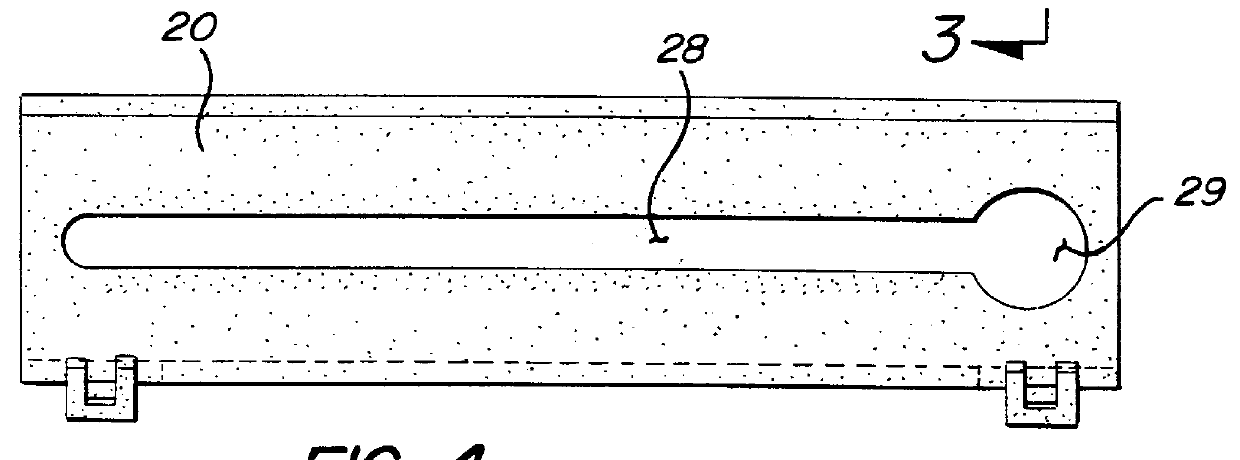

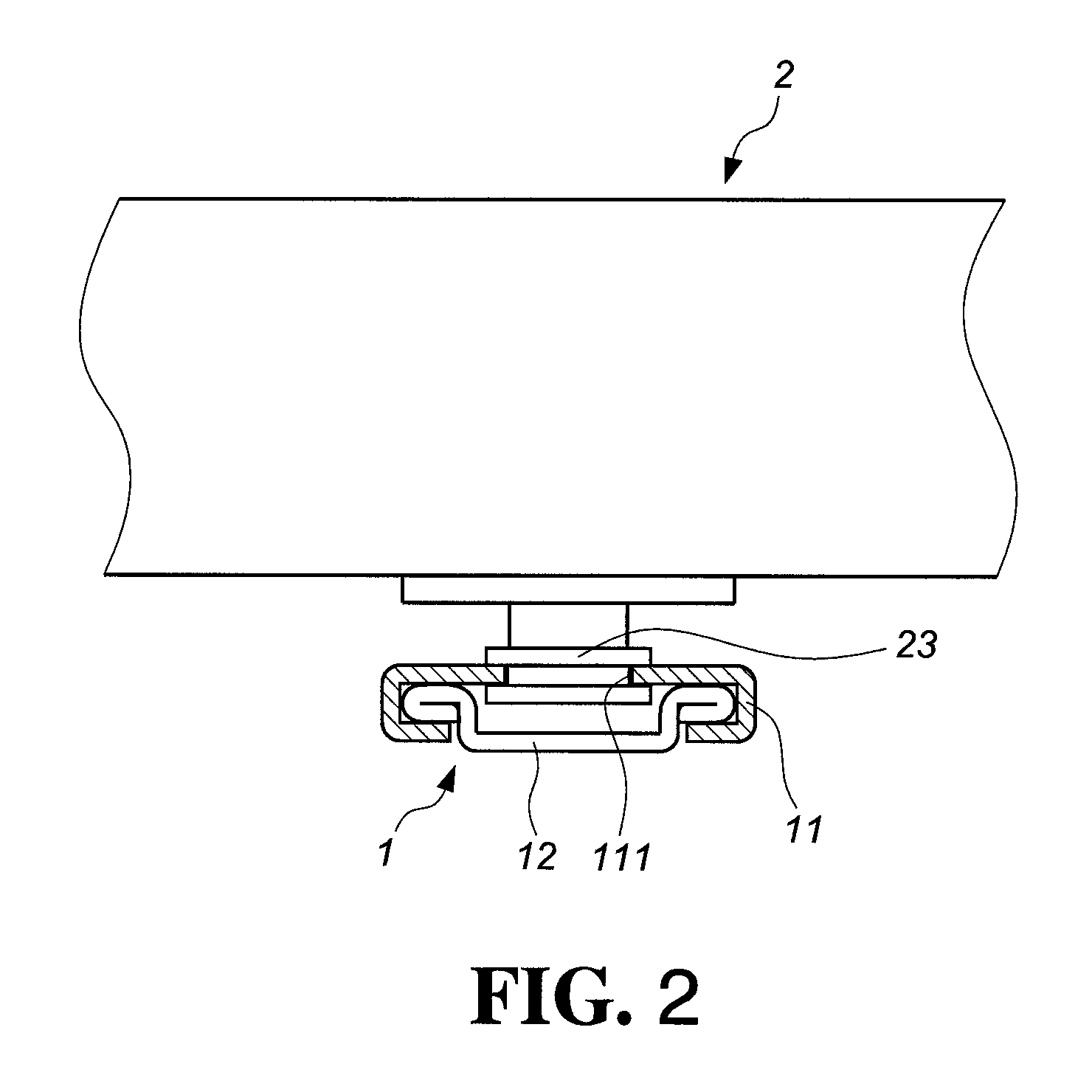

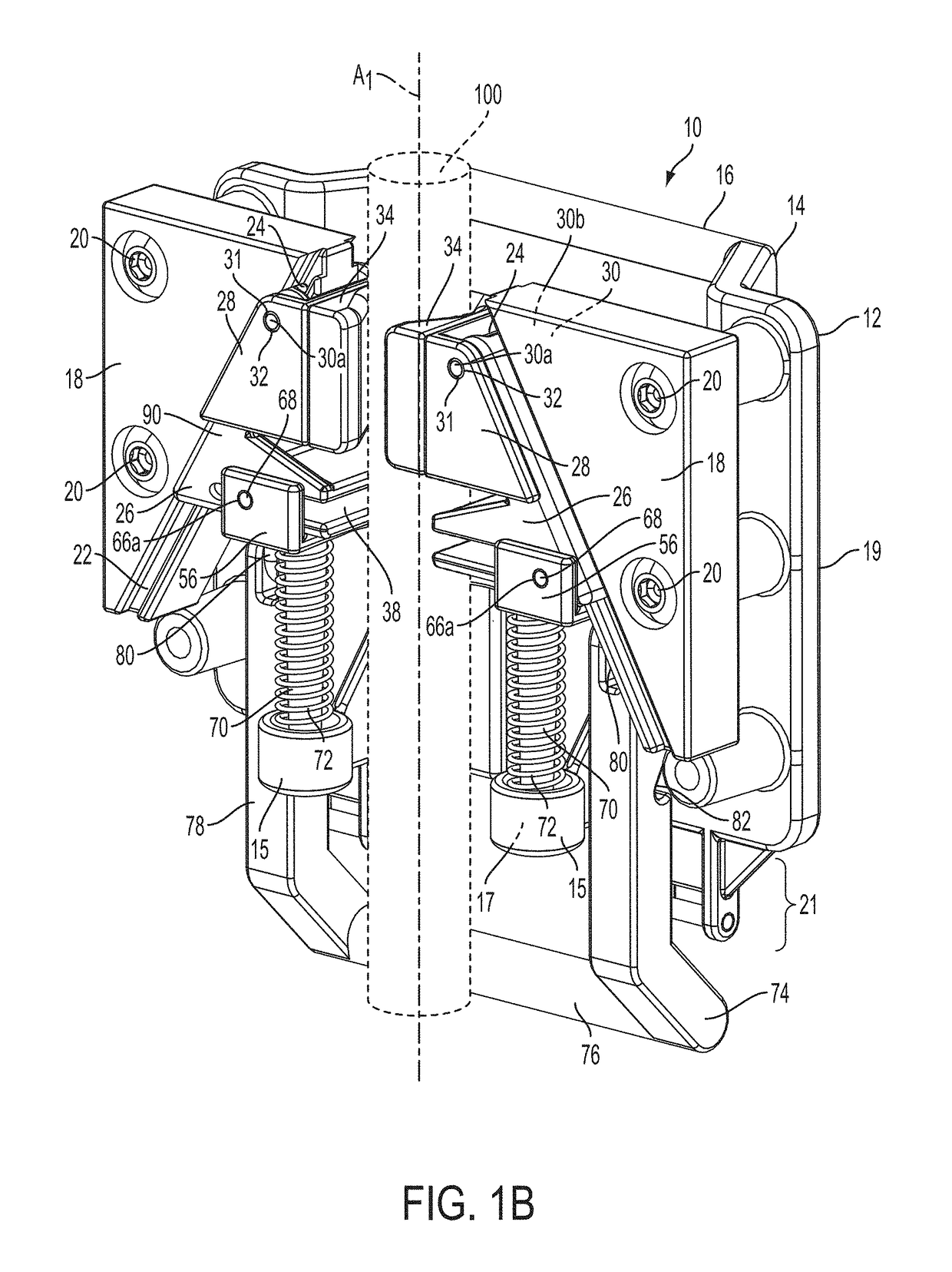

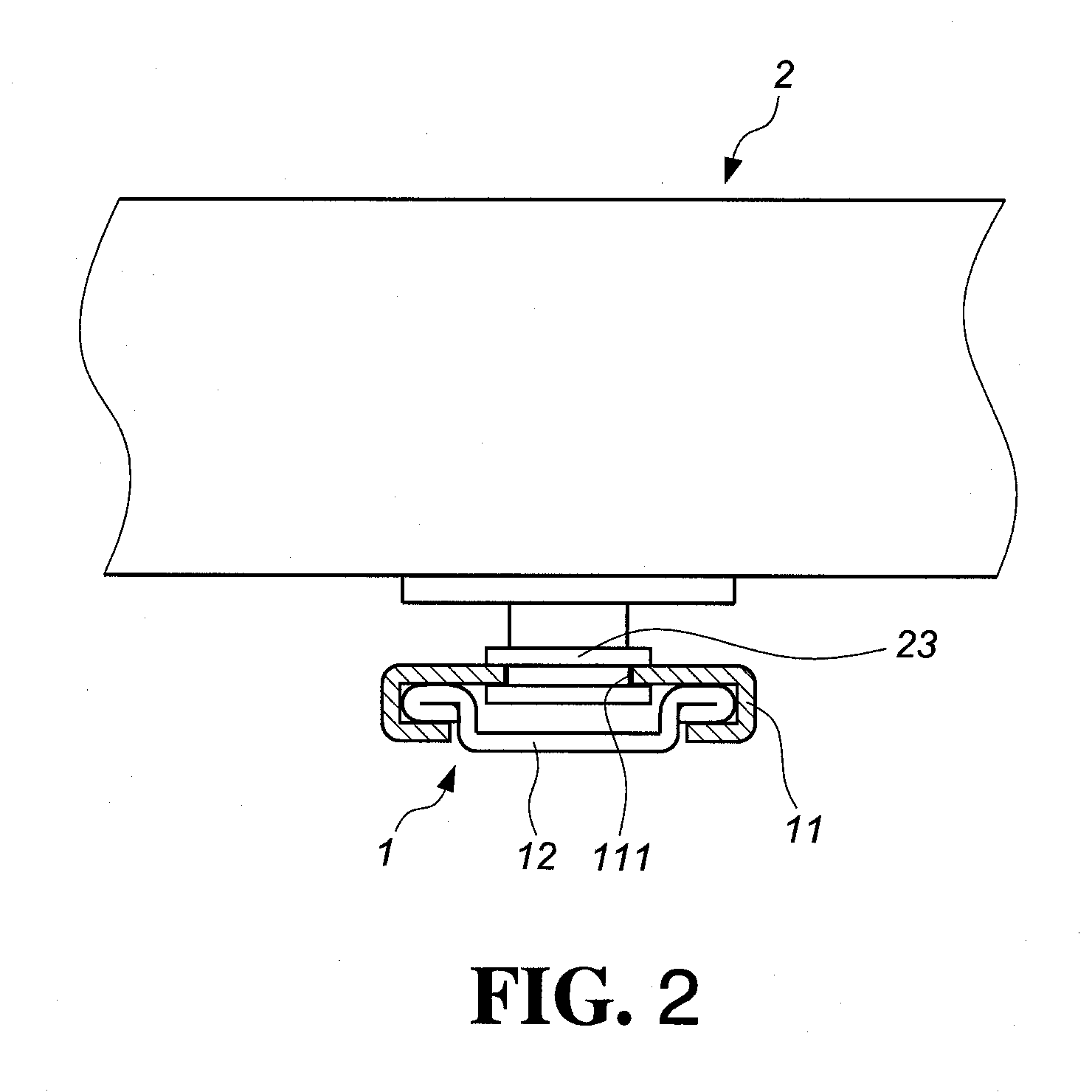

Wiring device for optical fiber

InactiveUS20050213920A1Improve performanceWithout deteriorationCable arrangements between relatively-moving partsCoupling light guidesEngineeringElectric cables

There is provided wiring device for optical fiber capable of increasing the performance of connection work of an optical fiber cable without deteriorating a signal transmitting properties of the optical fiber cable. The wiring device comprise a plug receptacle main body which is mounted on a mounting opening opened in the outer surface of a building, a receptacle being provided to the plug receptacle main body and having a plug connection hole facing an outside of the plug receptacle main body, a winder including a winding body which has an outer circumferential surface of radius of curvature larger than the permitted minimum radius of curvature of an optical fiber cable wired to the inside of a building and connected to the receptacle and on which a core wire of the optical fiber cable is wound, and a retainer being provided on the plug receptacle main body to maintain the winder inner side of a building, in which the receptacle for optical fiber and the winder are arranged in parallel with each other in the front-back direction, and pressing pieces are formed integrally with the winder and the retainer for contacting the bent portion of the core wires to prevent the bent portion from being expanded.

Owner:MATSUSHITA ELECTRIC WORKS LTD

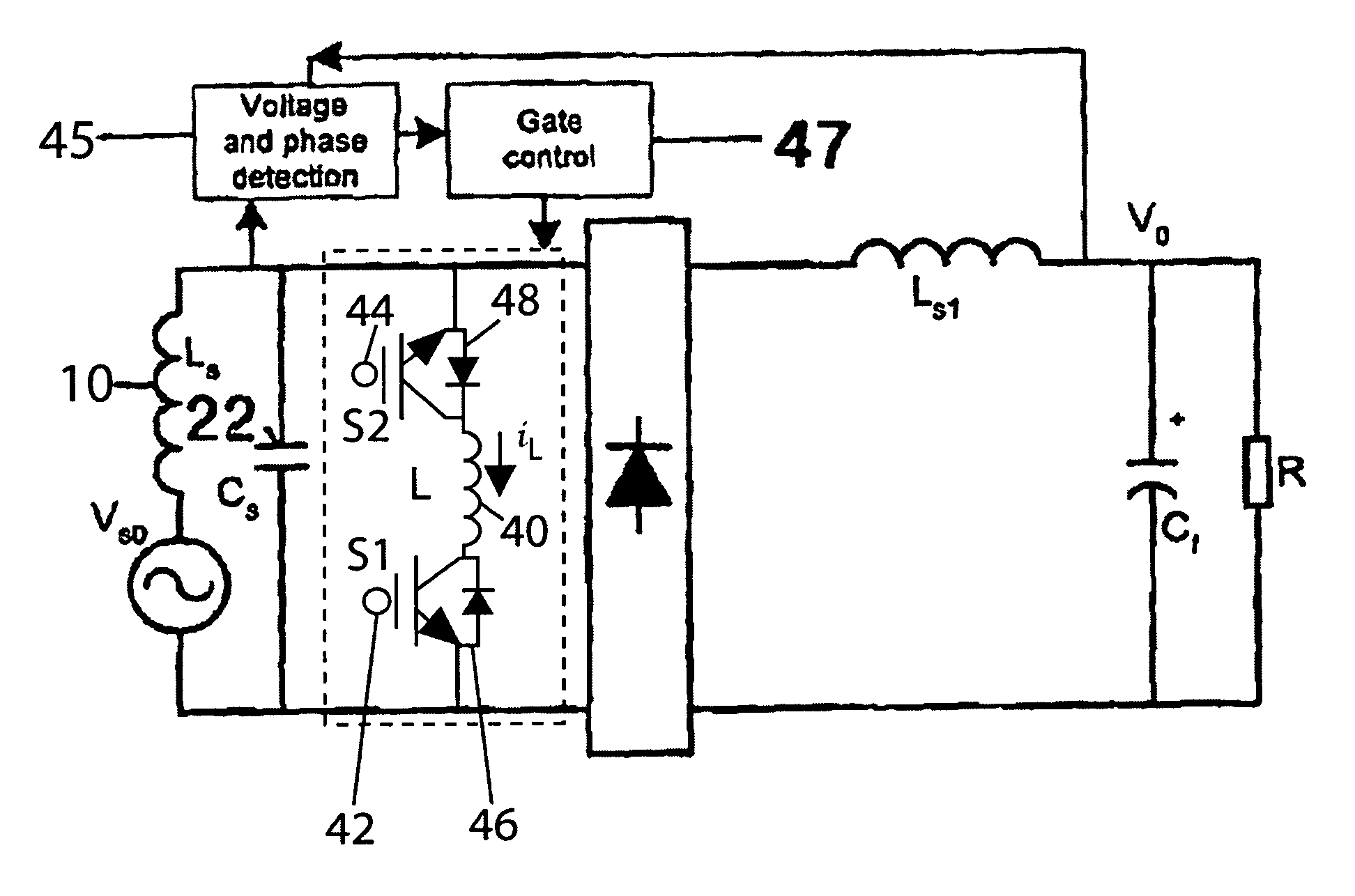

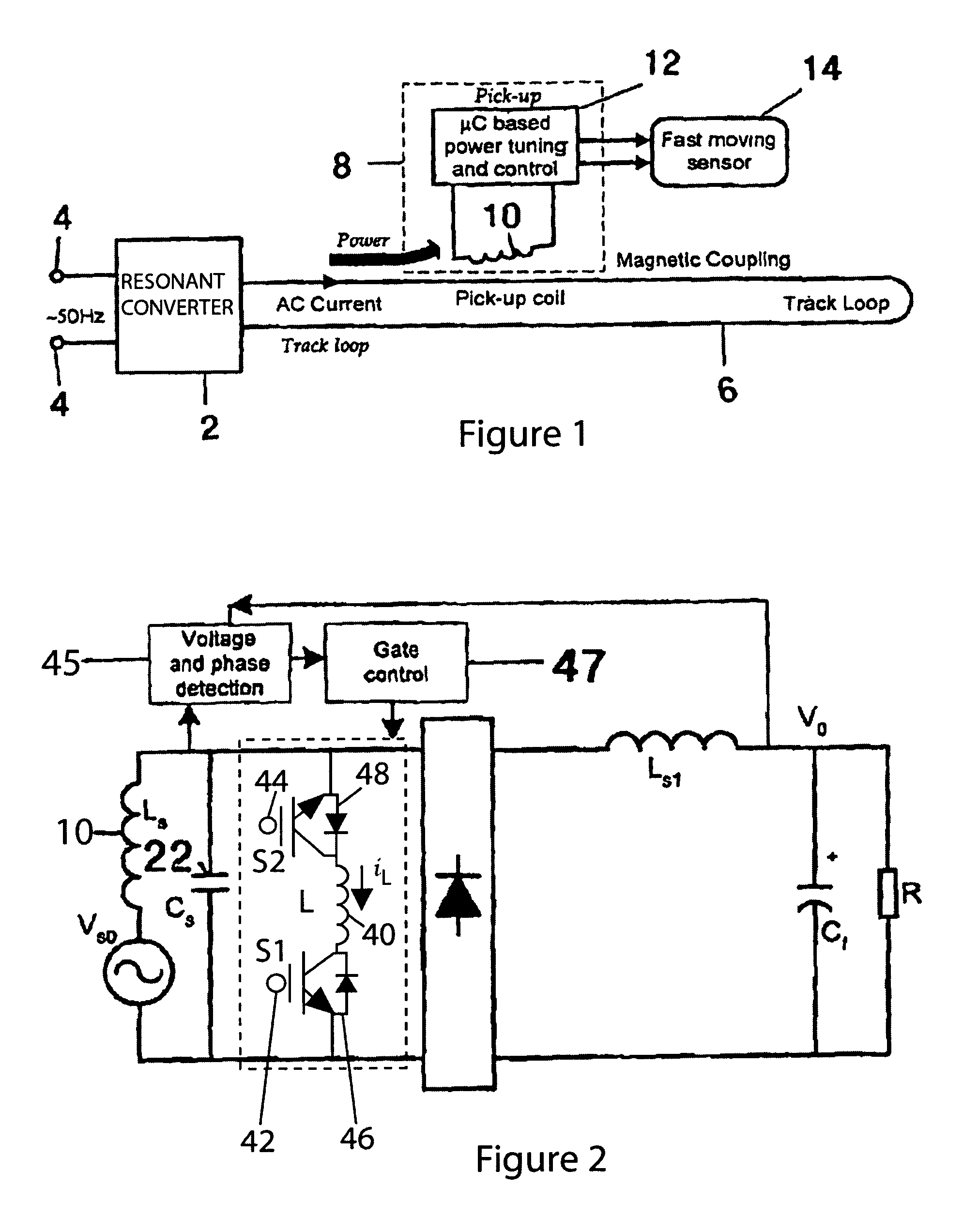

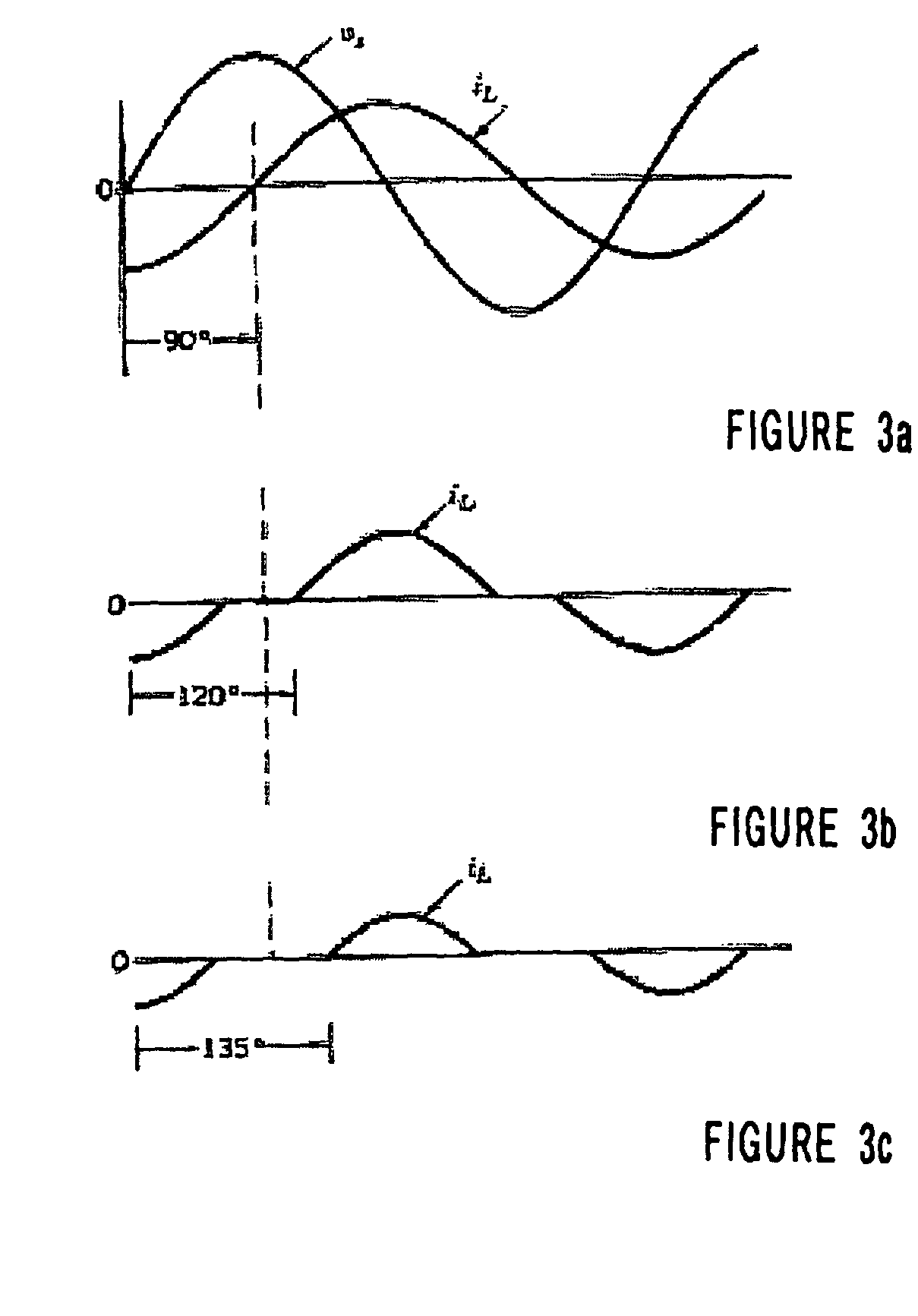

Method and apparatus for control of inductively coupled power transfer systems

ActiveUS8093758B2Improve disadvantagesBatteries circuit arrangementsAc-dc conversionCapacitancePower flow

A power pick-up for an Inductively Coupled Power Transfer (ICPT) system is provided having a resonant pick up circuit. The natural frequency of the pick-up circuit may be varied by controlling the conductance or capacitance of a variable reactive in the resonant circuit. The load being supplied by the pick-up circuit is sensed, and the effective capacitance or inductance of the variable reactive component is controlled to vary the natural resonant frequency of the pick-up circuit to thereby control the power flow into the pick-up to satisfy the power required by the load.

Owner:AUCKLAND UNISERVICES LTD

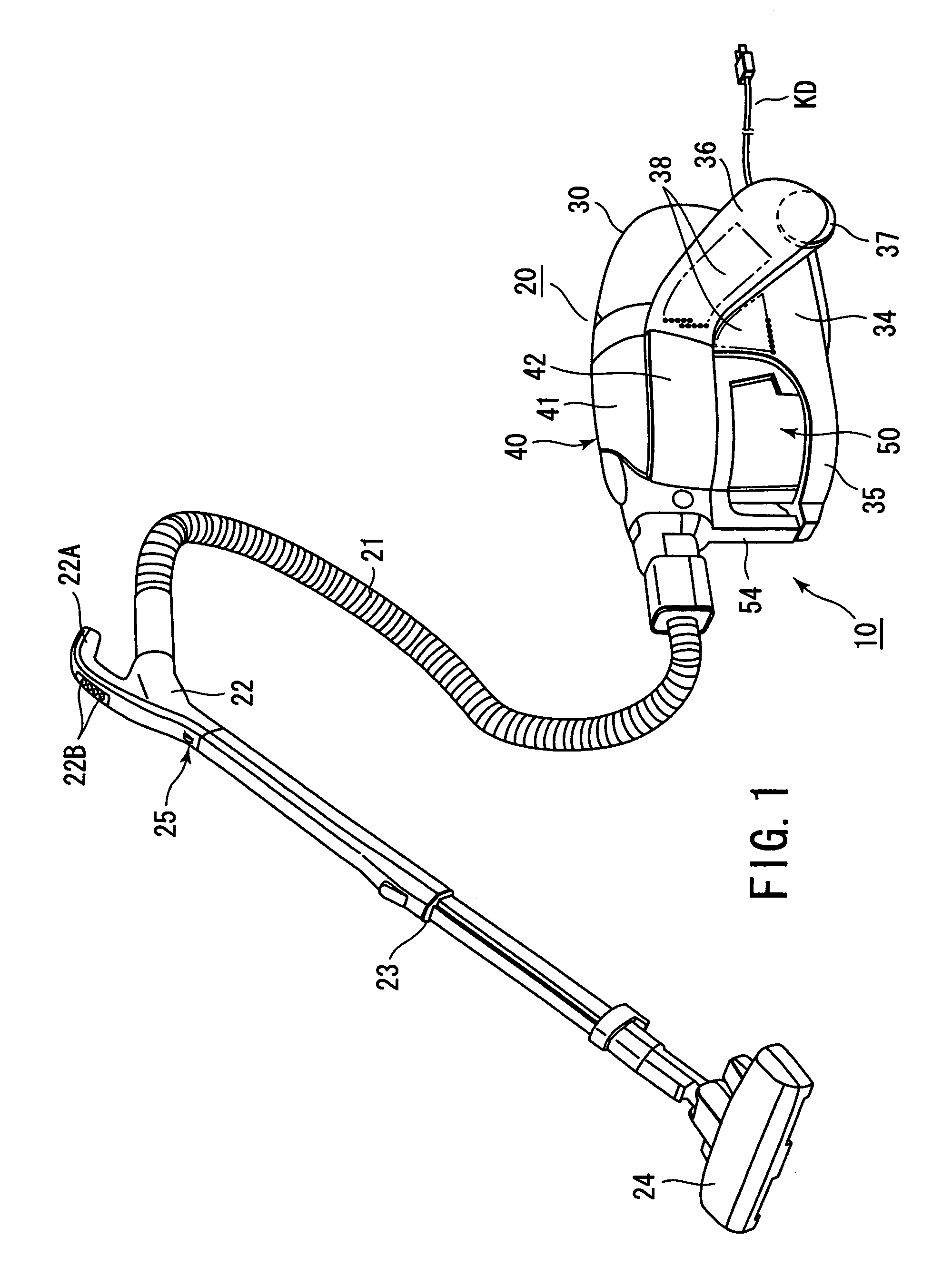

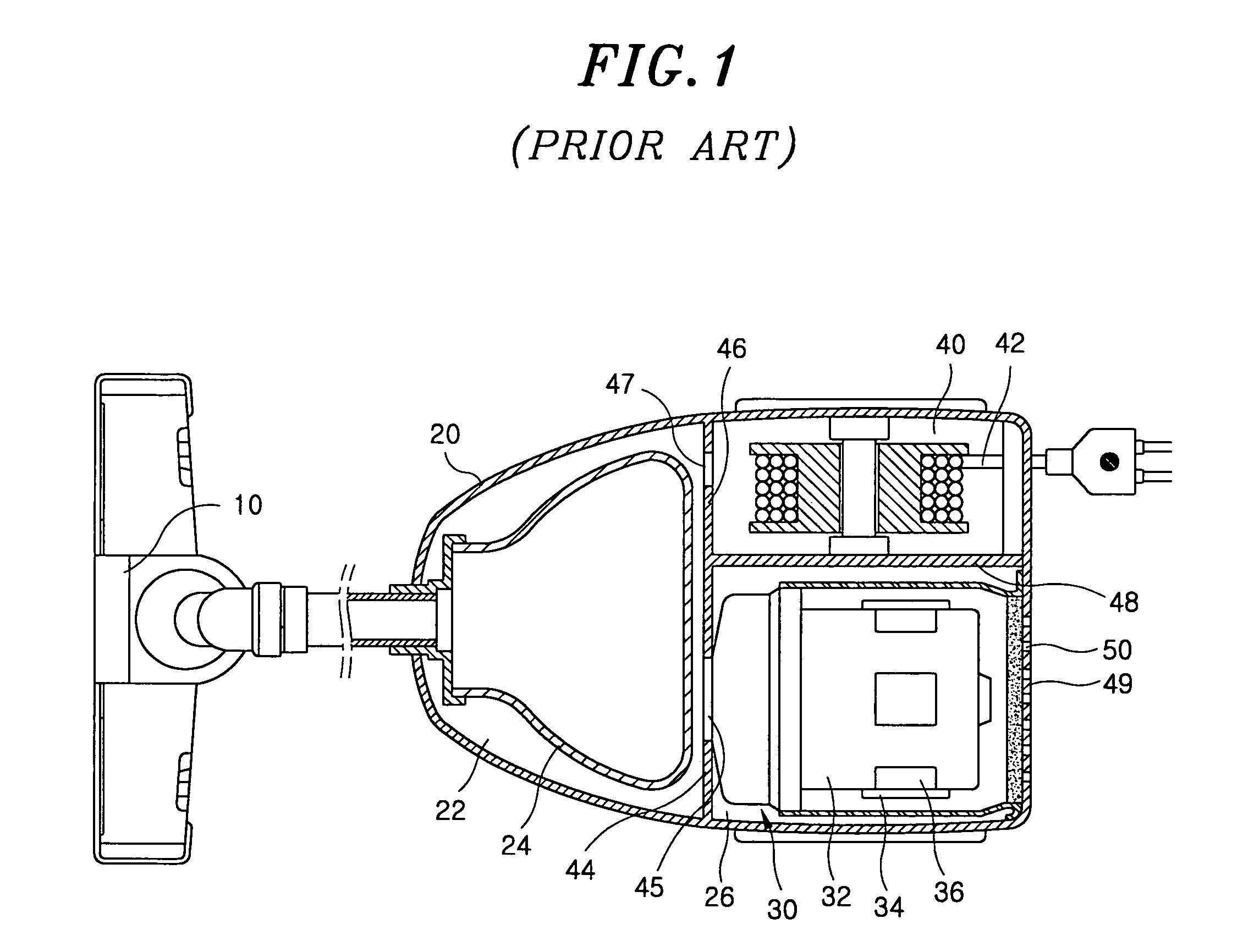

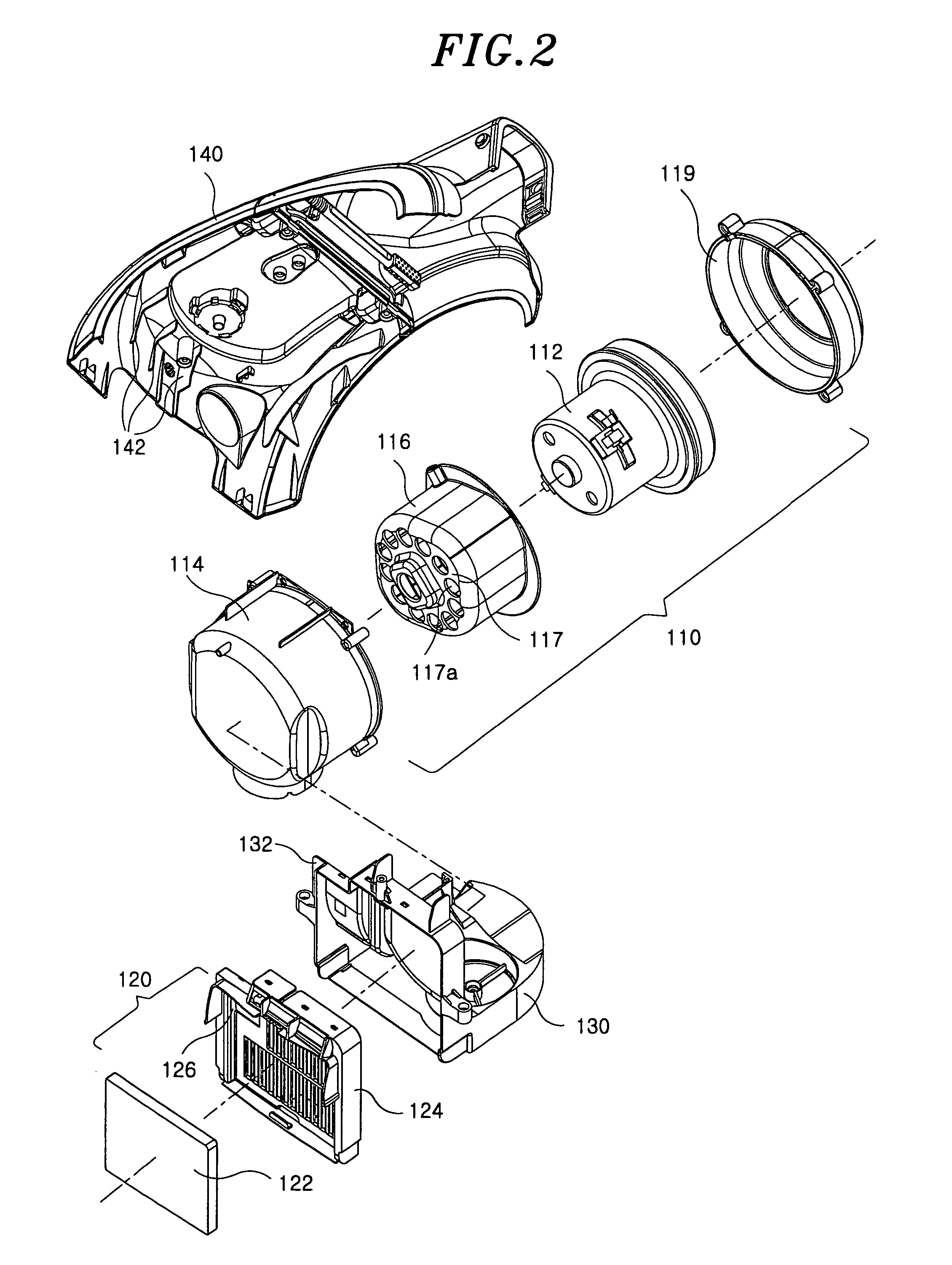

Vacuum cleaner

InactiveUS7198656B2Windage is smallEasy to cleanCleaning filter meansCombination devicesVacuum cleanerElectrical and Electronics engineering

There is disclosed a vacuum cleaner including a dust separation section which separates air and dust flowing toward an intake port of a motor blower through a connection port of a cleaner main body. The dust separation section includes an air path forming member which performs a separation function. The forming member includes an introductory port, a derivative port, and an opening disposed between these. In the separation function, while dust-containing air flows toward the derivative port from the introductory port, a part of the air is sucked by the motor blower through the opening. Accordingly, the air is separated from the dust which goes straight in the air path forming member with inertia.

Owner:TOSHIBA TEC KK

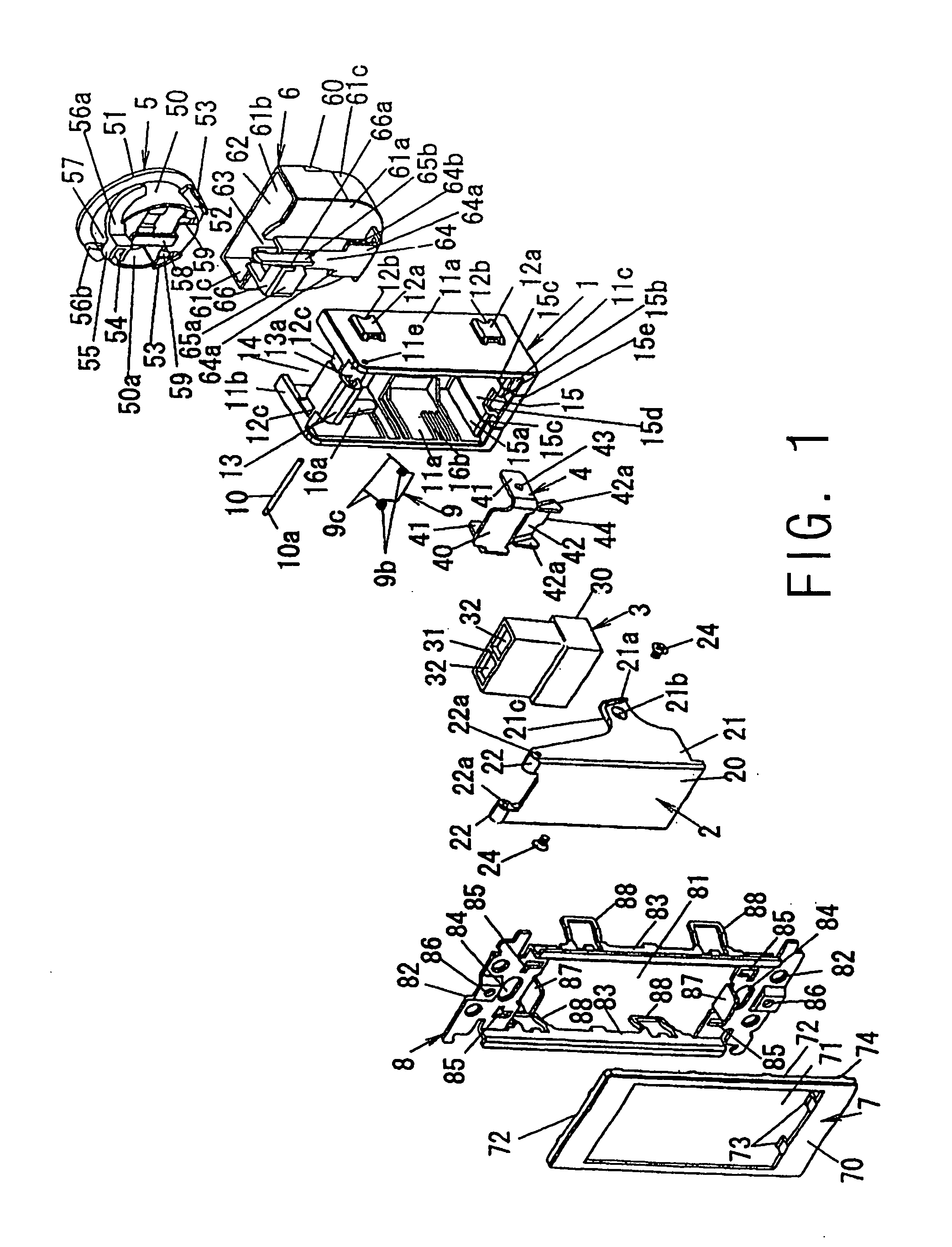

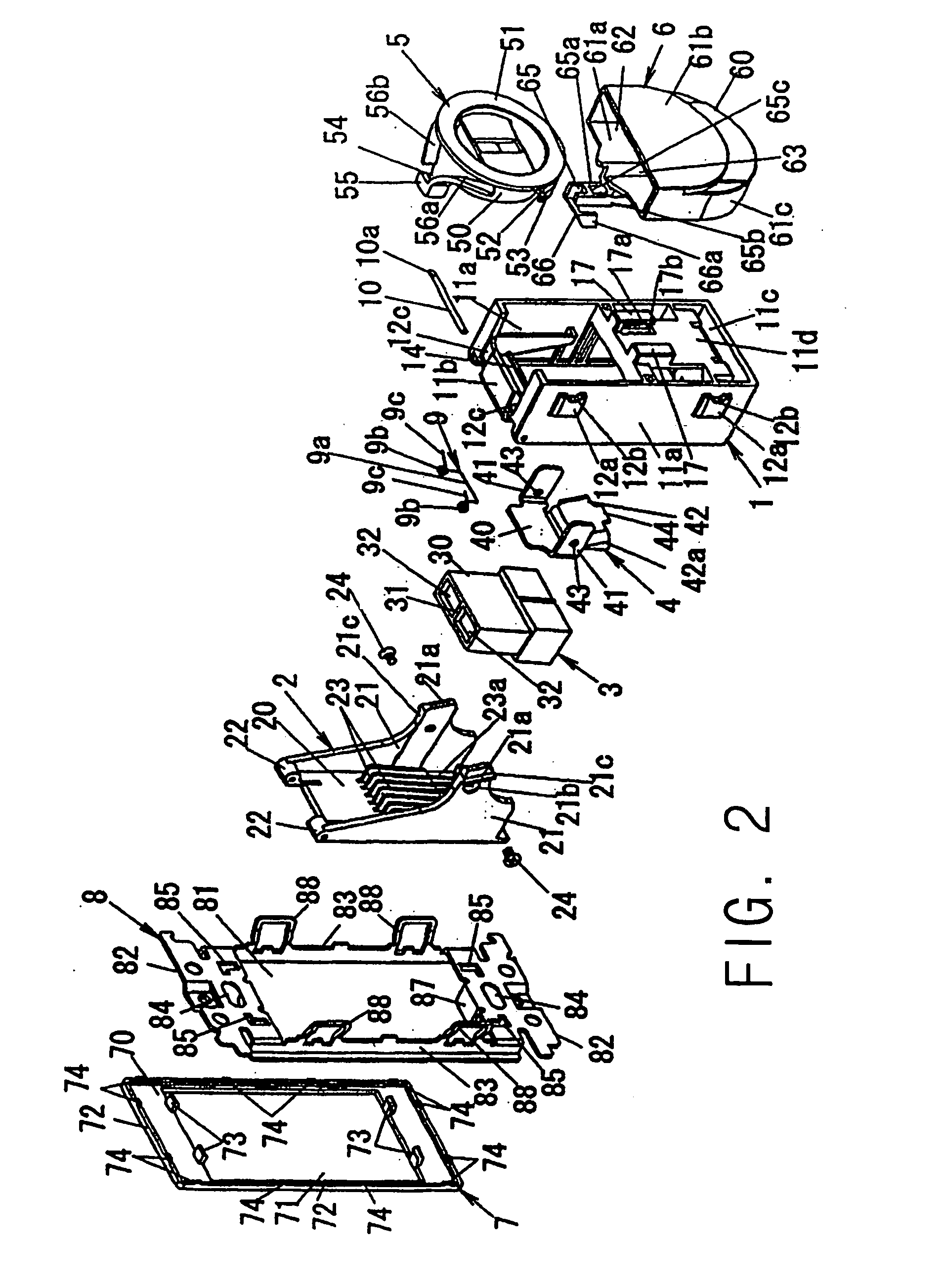

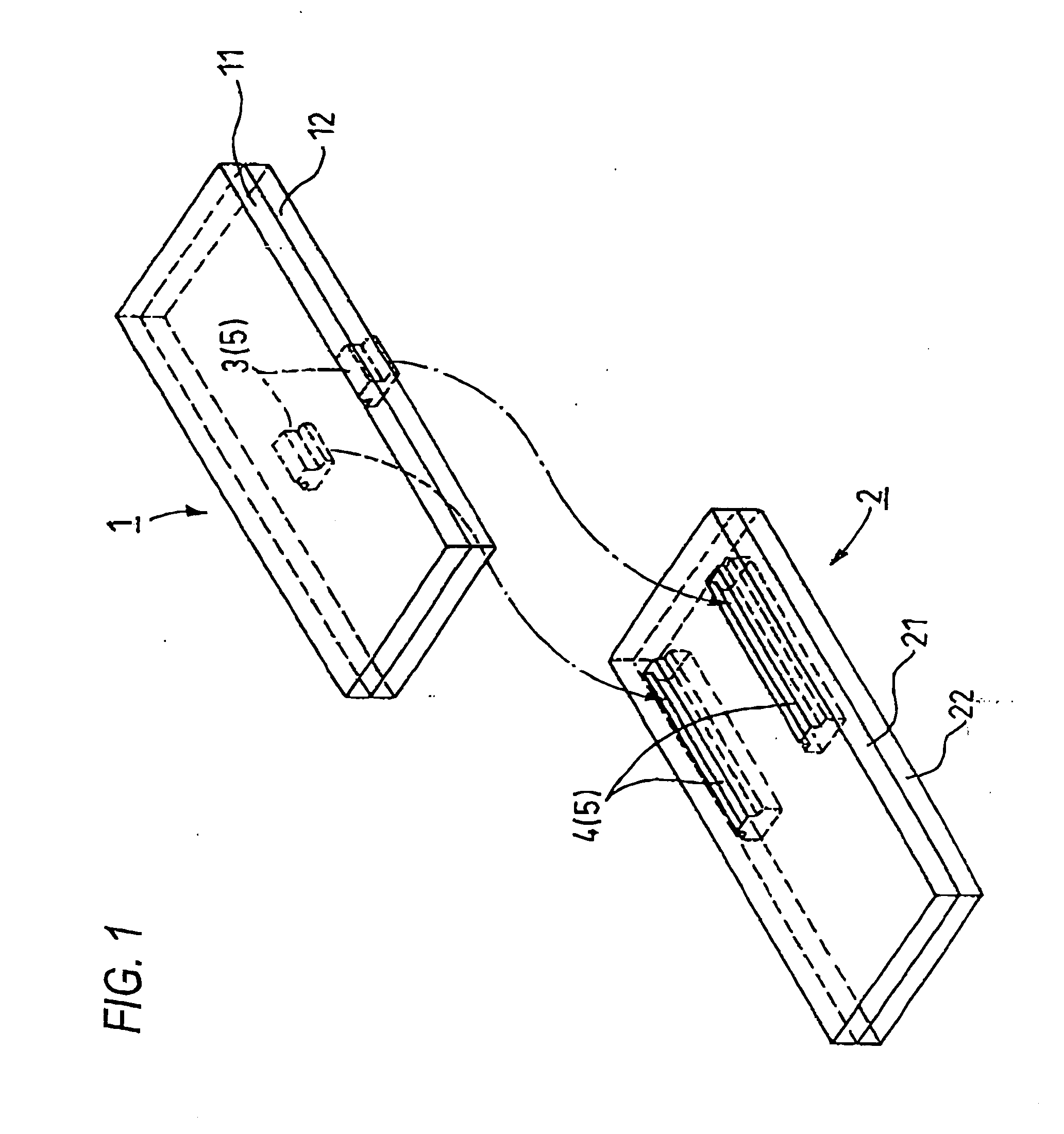

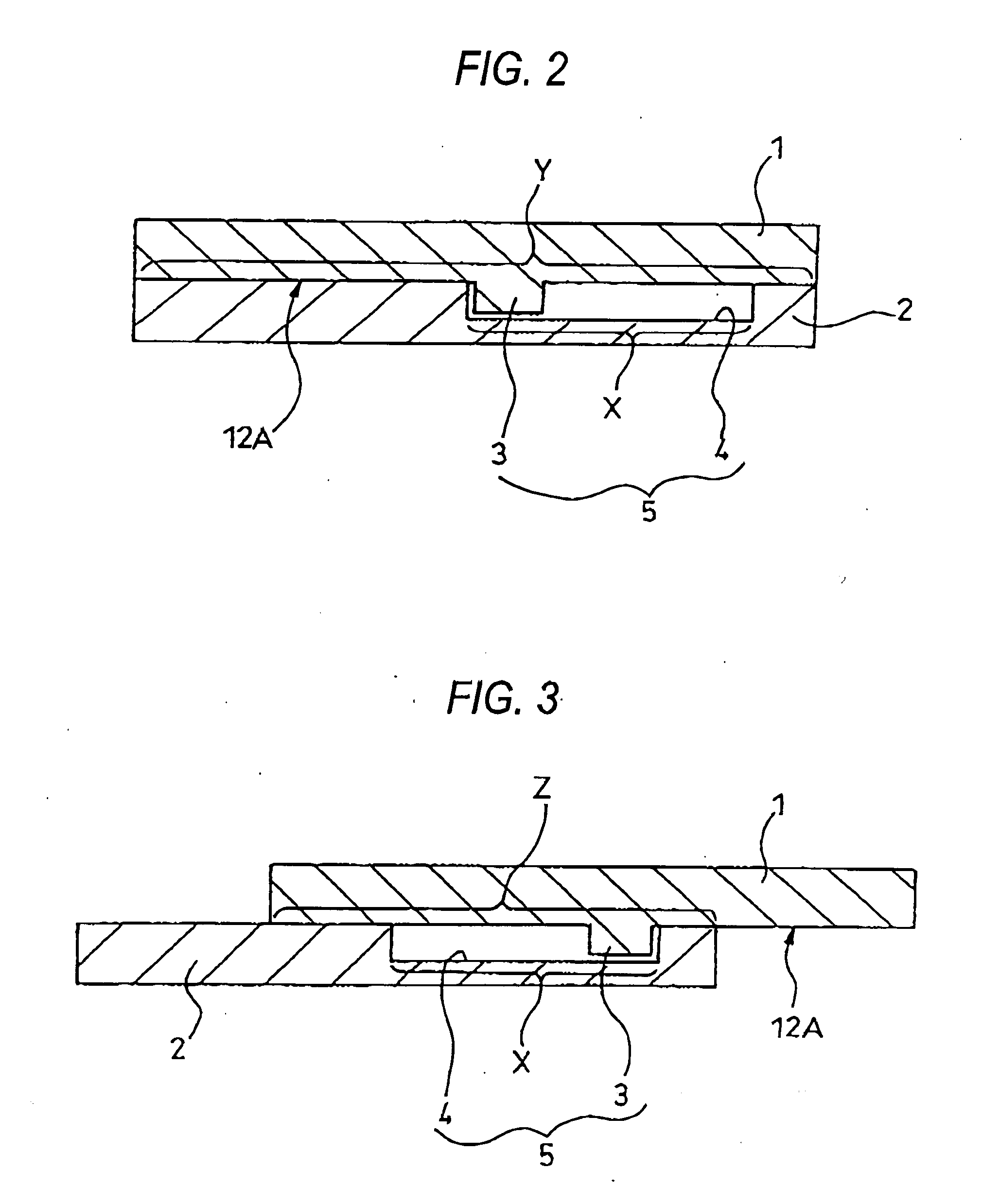

Wiring device for optical fiber

InactiveUS7016590B2Improve performanceWithout deteriorationCable arrangements between relatively-moving partsCoupling light guidesElectric cablesOptical fiber cable

There is provided wiring device for optical fiber capable of increasing the performance of connection work of an optical fiber cable without deteriorating a signal transmitting properties of the optical fiber cable. The wiring device comprise a plug receptacle main body which is mounted on a mounting opening opened in the outer surface of a building, a receptacle being provided to the plug receptacle main body and having a plug connection hole facing an outside of the plug receptacle main body, a winder including a winding body which has an outer circumferential surface of radius of curvature larger than the permitted minimum radius of curvature of an optical fiber cable wired to the inside of a building and connected to the receptacle and on which a core wire of the optical fiber cable is wound, and a retainer being provided on the plug receptacle main body to maintain the winder inner side of a building, in which the receptacle for optical fiber and the winder are arranged in parallel with each other in the front-back direction, and pressing pieces are formed integrally with the winder and the retainer for contacting the bent portion of the core wires to prevent the bent portion from being expanded.

Owner:MATSUSHITA ELECTRIC WORKS LTD

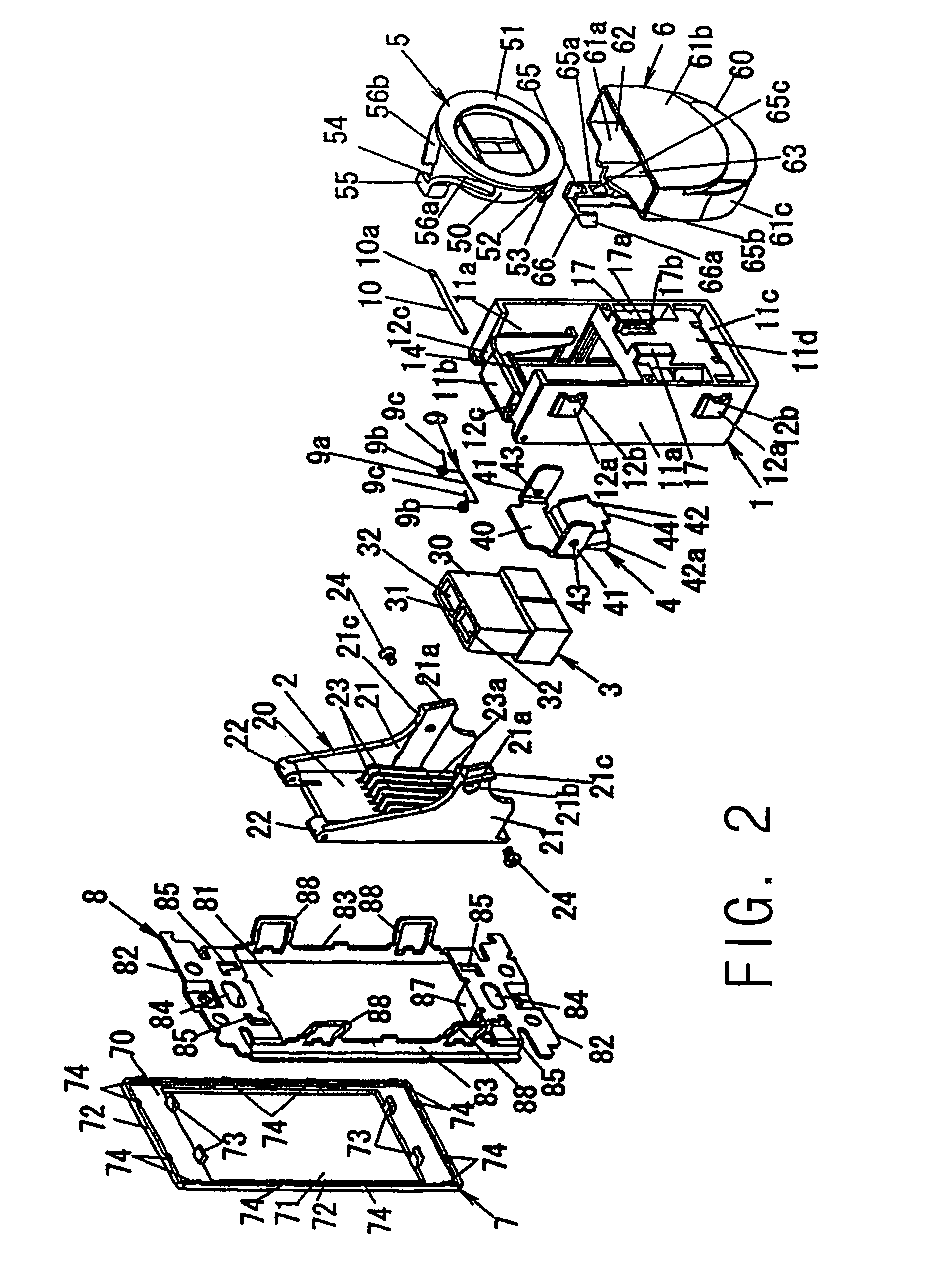

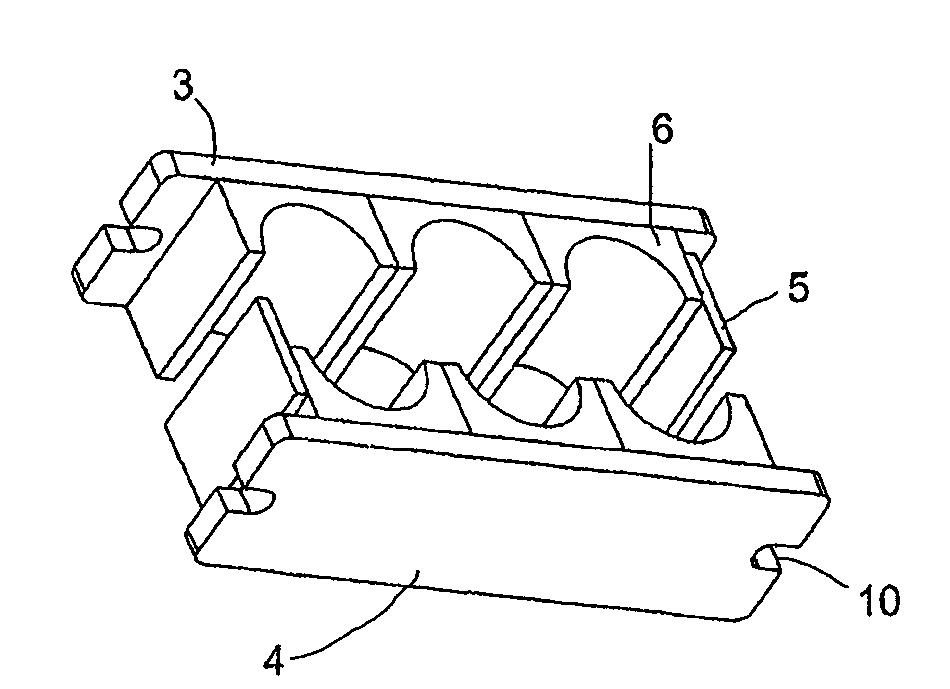

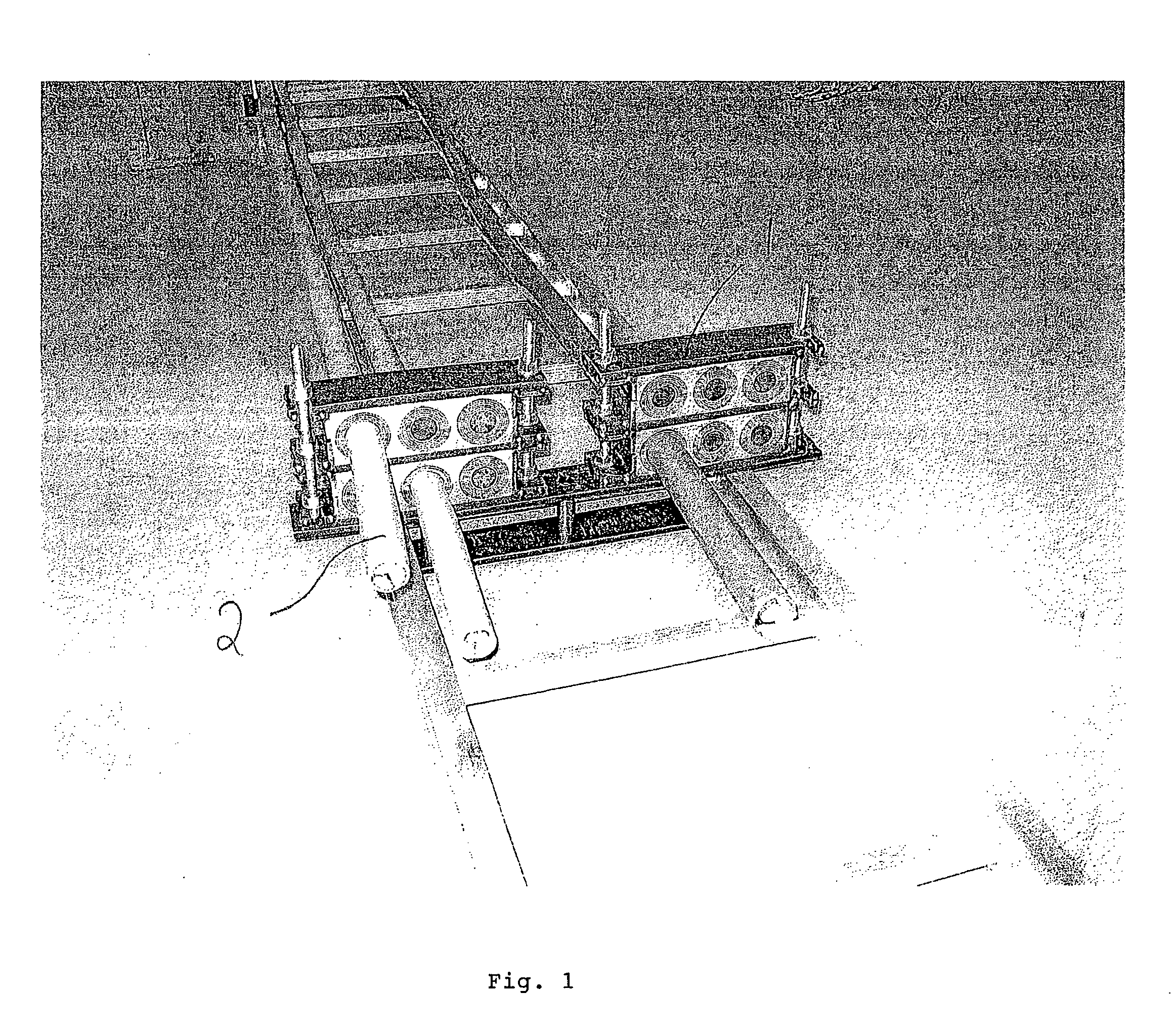

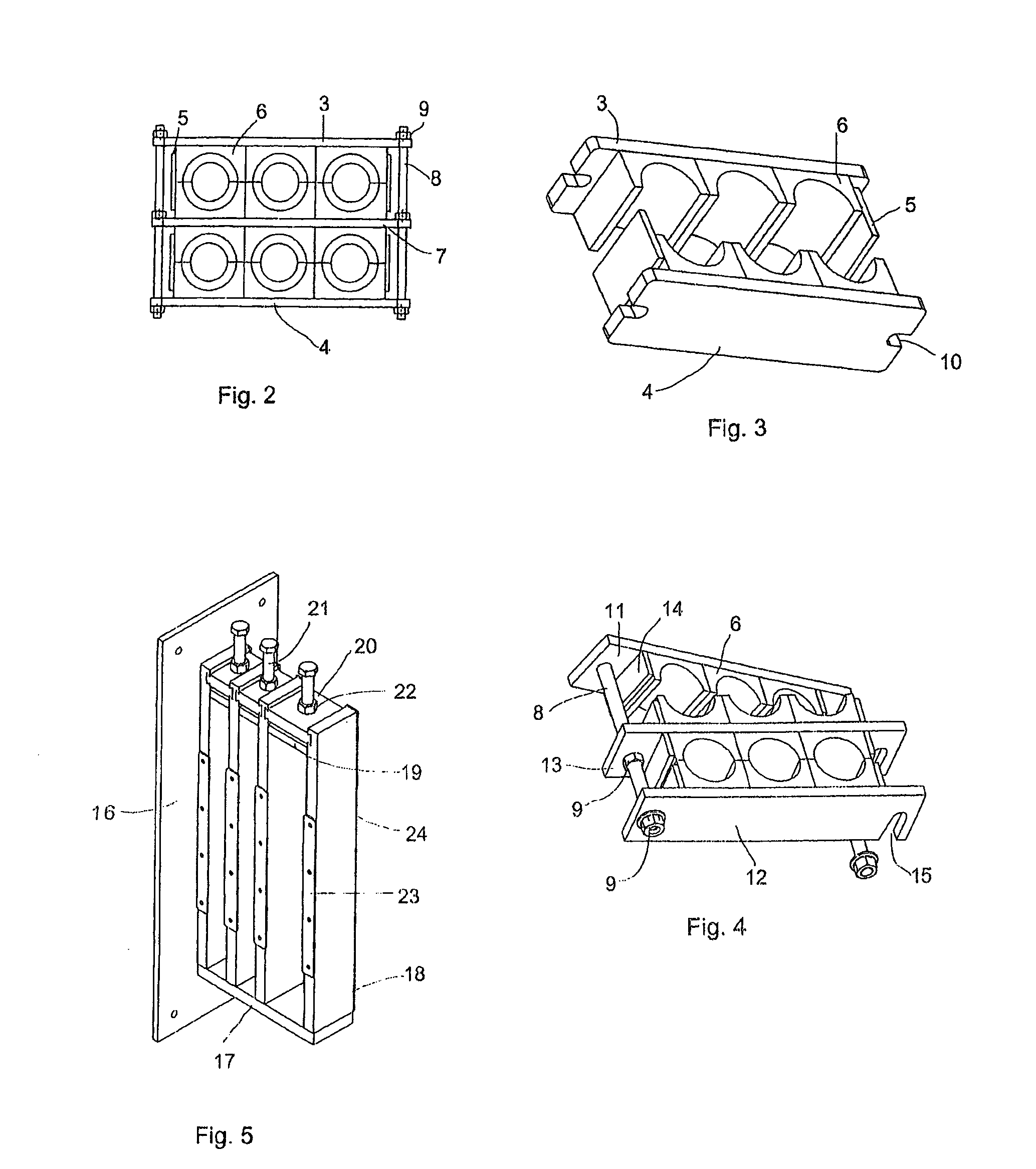

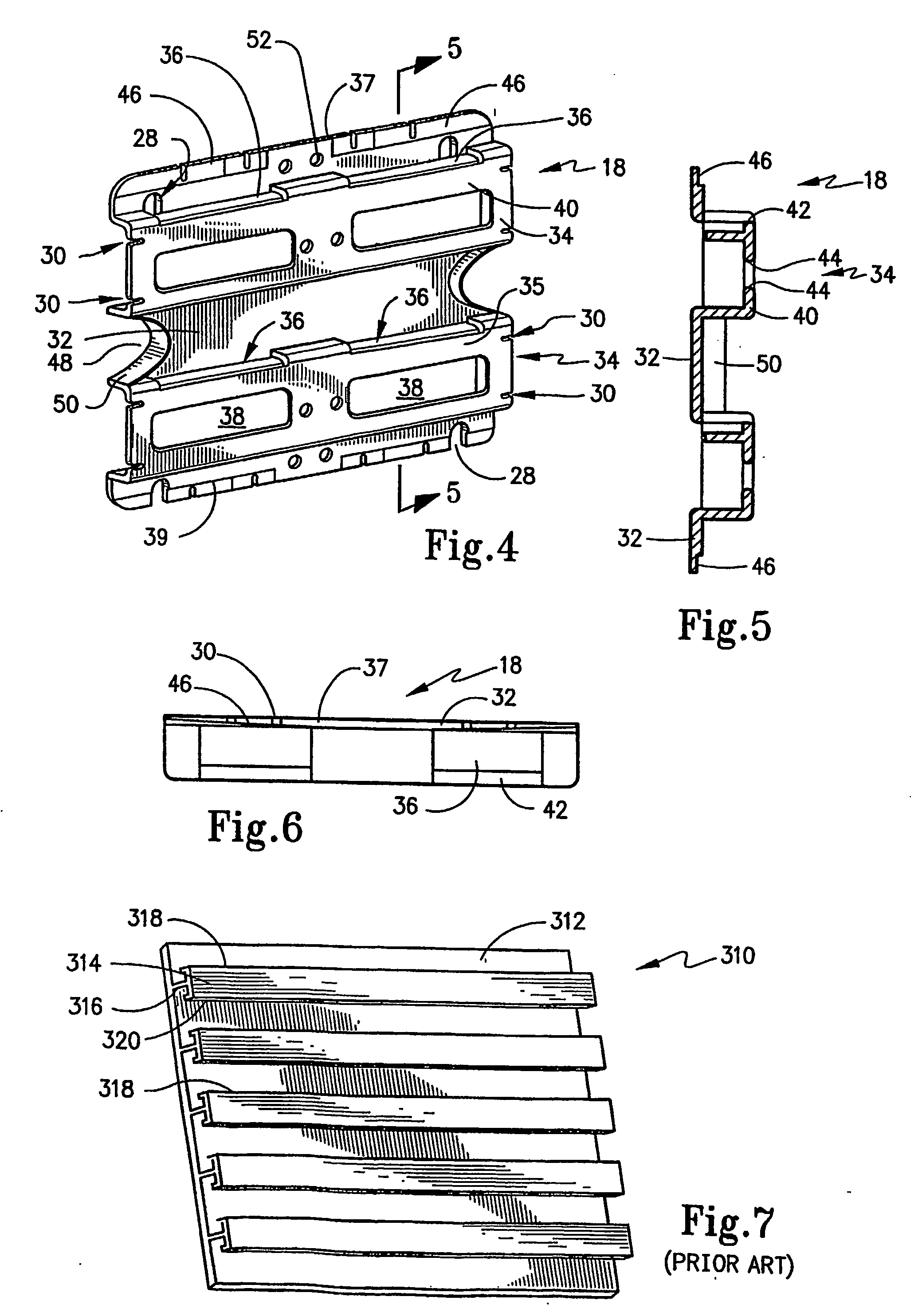

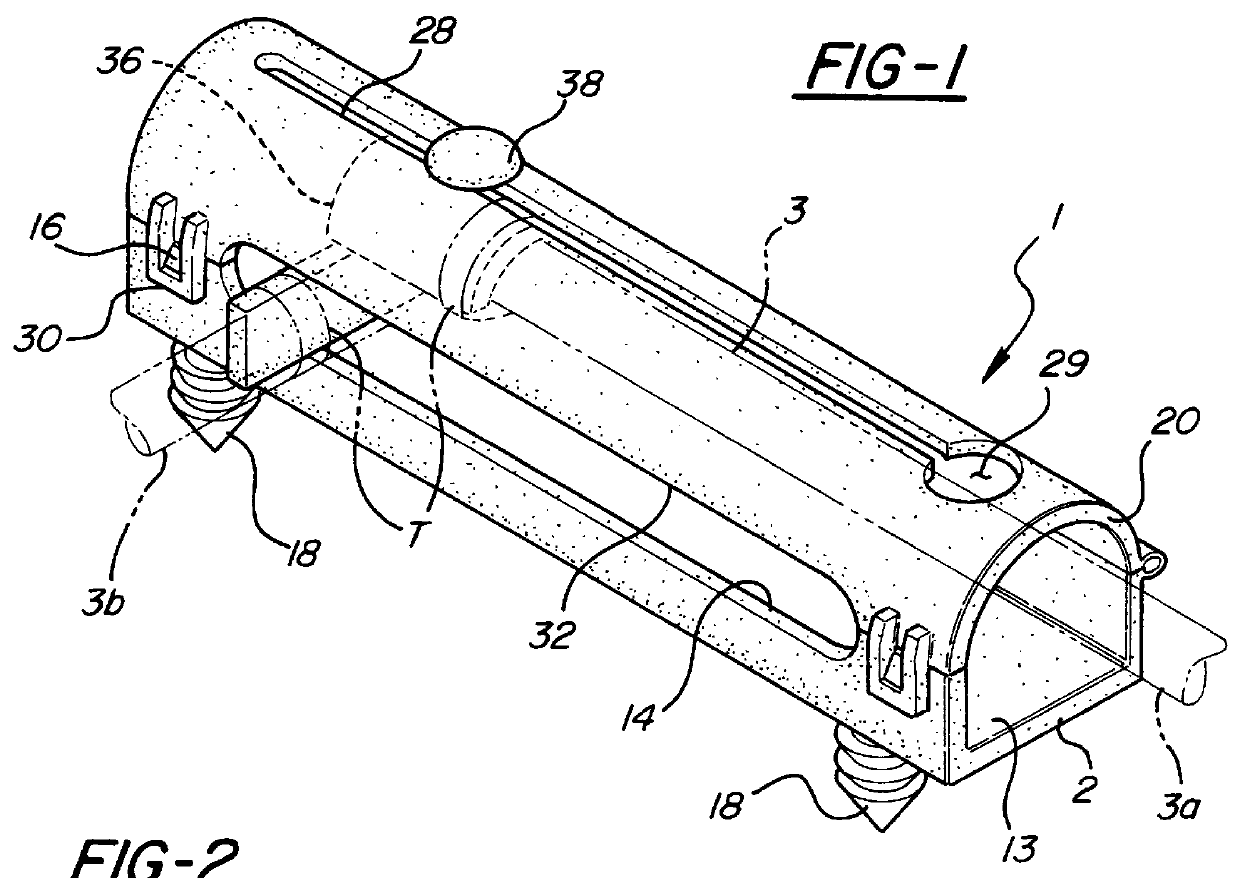

Cable Retention Device

The present invention concerns a cable retention device, which also may be used for pipes or wires, to take up forces actuated by or on a cable (2) etc. Each cable (2) is received in a module, formed of two module halves (6, 55, 58, 62). The modules are received inside a rigid frame construction. The modules inside the frame construction are to be compressed. The compression is accomplished by means of a compression unit (36, 41) inside the frame construction and / or by assembly of the cable retention device.

Owner:ROXTEC AB

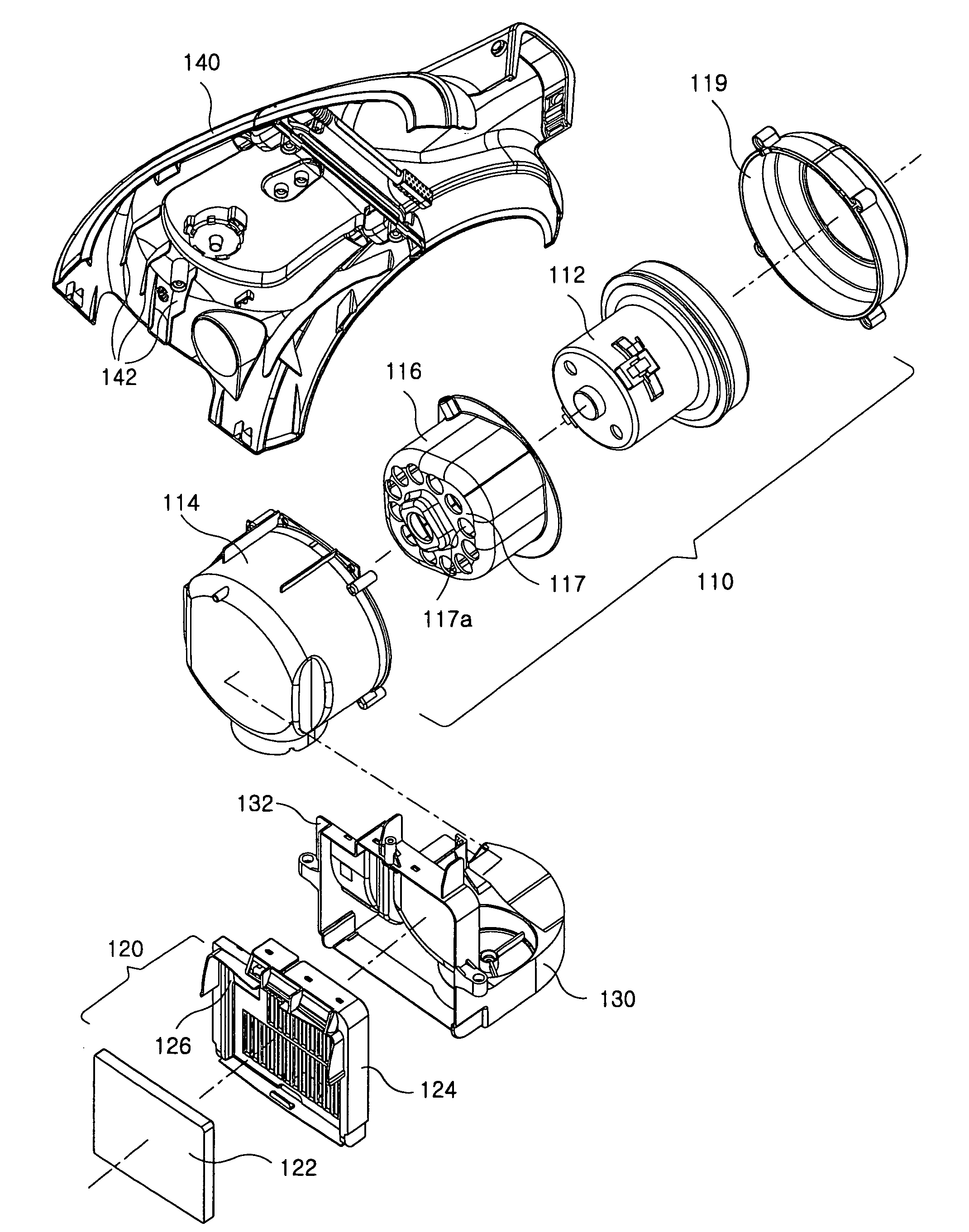

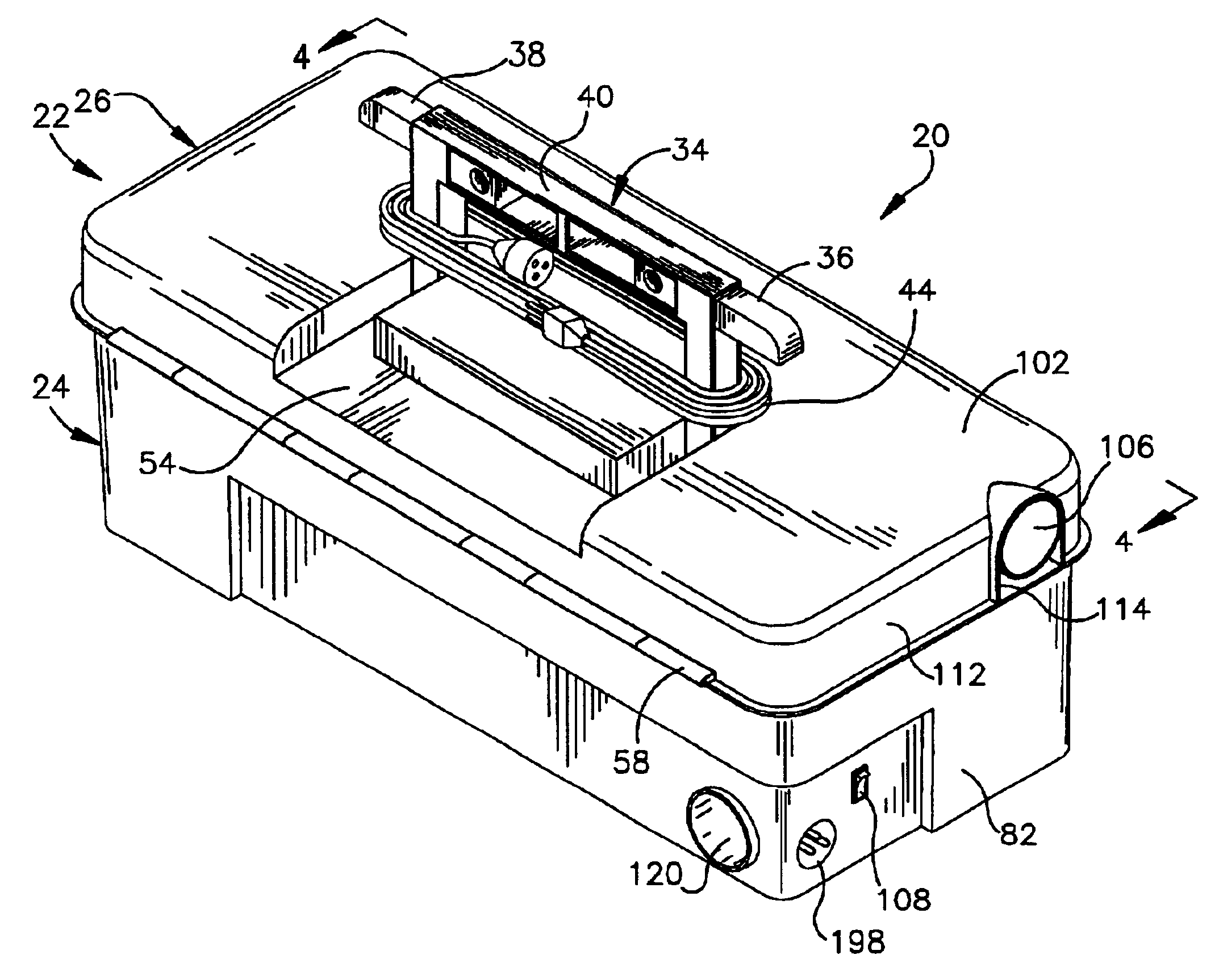

AC/DC hand portable wet/dry vacuum having improved portability and convenience

A wet / dry utility vacuum with a canister, a powerhead assembly with a fan, a shut-off device that prevents the fan from drawing liquids into the fan inlet when a volume of the liquid in the canister exceeds a predetermined volume. The powerhead assembly includes a controller that permits the utility vacuum to be operated in a desired power mode so that the user may employ either an AC power source or a DC power source, such as a battery pack, for example. In some applications, the battery pack may be interchangeable with the battery packs of various cordless tools, including drill / drivers and saws. A tool set and a method for operating a battery-powered tool set are also provided.

Owner:BLACK & DECKER INC

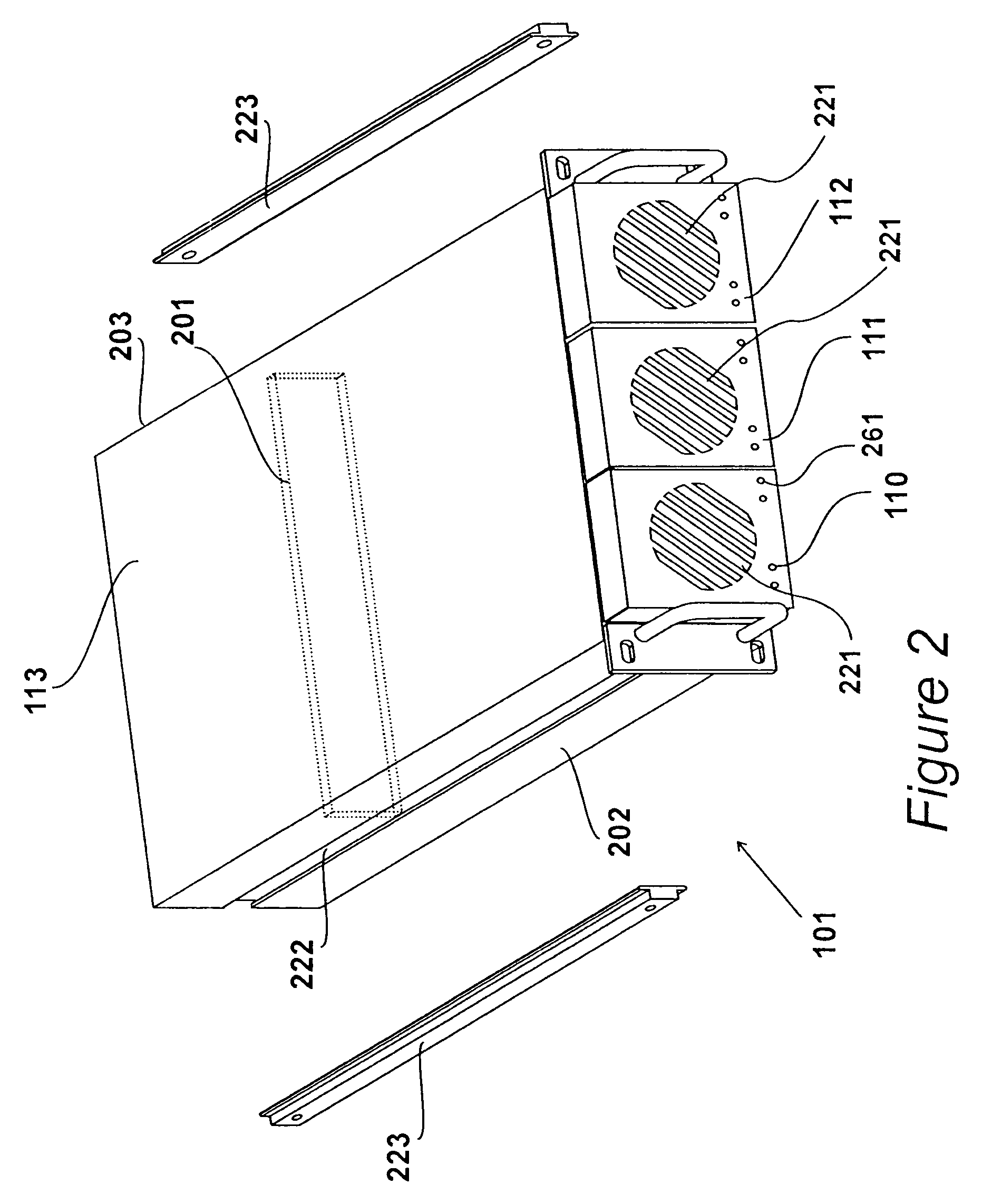

Cable organization and hardware shelving system

InactiveUS20050236544A1Reduce tanglingReduce clutterServersCable arrangements between relatively-moving partsEngineeringElectric wire

A mounting bracket is used in a system for supporting electrical components to a support structure. The mounting bracket includes a base with an elongate beam that having a planar web and at least one transverse flange and a hook structure that may be an elongate arm. The mounting bracket has various structures to secure wires, auxiliary suspension members, cable ties and the like. The system utilizes two brackets that together form a shelf to support electronic equipment. The brackets may mount on a slotwall-type upright support member or,

Owner:DEVICE WORKS

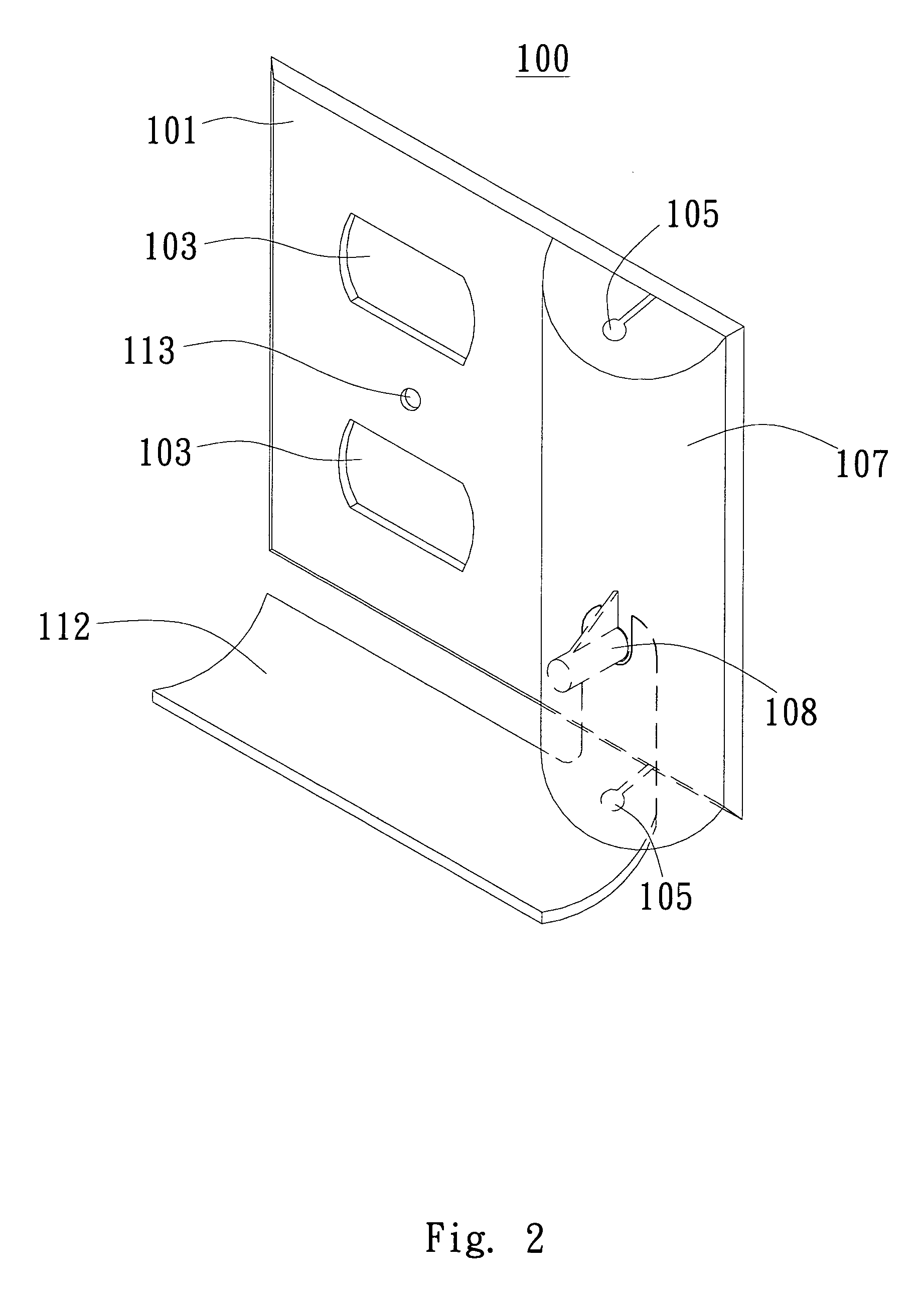

Power supply cover box

InactiveUS7528323B2Easy to storeReduce confusionCasings/cabinets/drawers detailsCable arrangements between relatively-moving partsEngineeringMechanical engineering

An outlet cover includes an outlet surface and a cord container for convenient cord storage is provided. The outlet surface has at least one outlet opening, and the cord container is disposed corresponding to the outlet opening. The above cord container has a plurality of cord entry / exit holes and at least one passage connecting the plurality of cord entry / exit holes. A power supply cover box includes a body and at least a cord container is also provided. The body includes a first end having at least one outlet opening. The cord container of the power supply cover box has a plurality of cord entry / exit holes and passages connecting the plurality of cord entry / exit holes. The passages have a predetermined width, which is preferably slightly smaller than the diameter of a regular electric cord, to retain the cord within the cord container. The cord container only allows the cord to enter or exit through the cord entry / exit holes.

Owner:WU HSINHAN +1

Wire harness protector with anti-rotation and sliding features

A wire harness protector having an open slide trough closed by a removable cover, and containing an internal wire harness carrier attached to the harness, for example by taping, and connected to the cover to slide in the trough when the cover is closed. The carrier is generally L-shaped, and the trough has a wire slot formed in a sidewall thereof generally parallel to the guide slot in the cover, such that the wire harness is redirected laterally within the trough by the carrier, with an incoming end sliding longitudinally in the trough, and an outgoing end sliding laterally through the wire slot in the side wall. The wire harness protector according to the invention is especially useful for protecting and controlling wire harness slack found between hinged and sliding surfaces in a vehicle, for example doors, hoods and trunk lids.

Owner:YAZAKI CORP

Portable terminal device

InactiveUS20050221873A1Improve practicalityImprove sealingCasings/cabinets/drawers detailsCable arrangements between relatively-moving partsTerminal equipmentComputer terminal

Owner:PANASONIC CORP

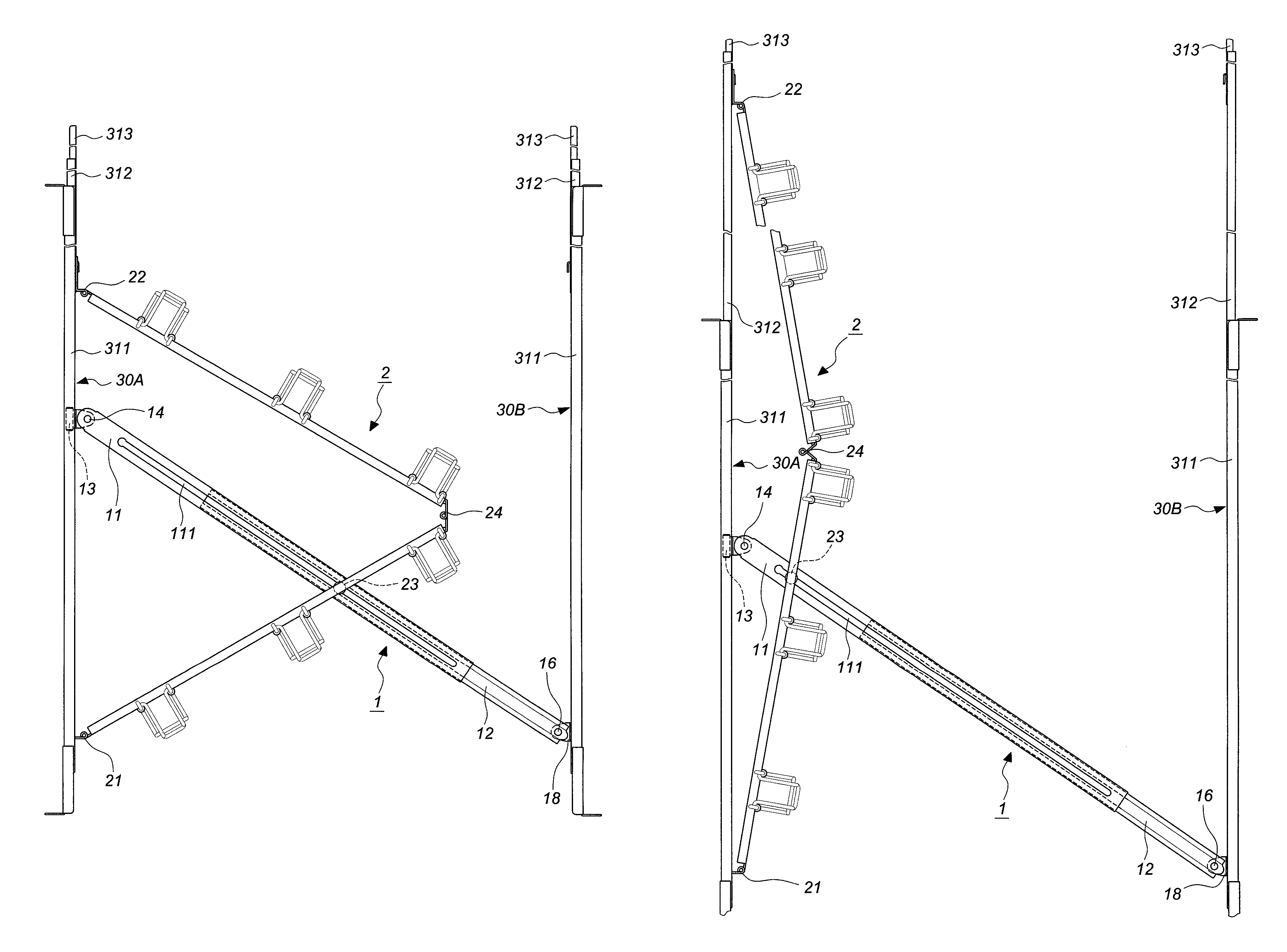

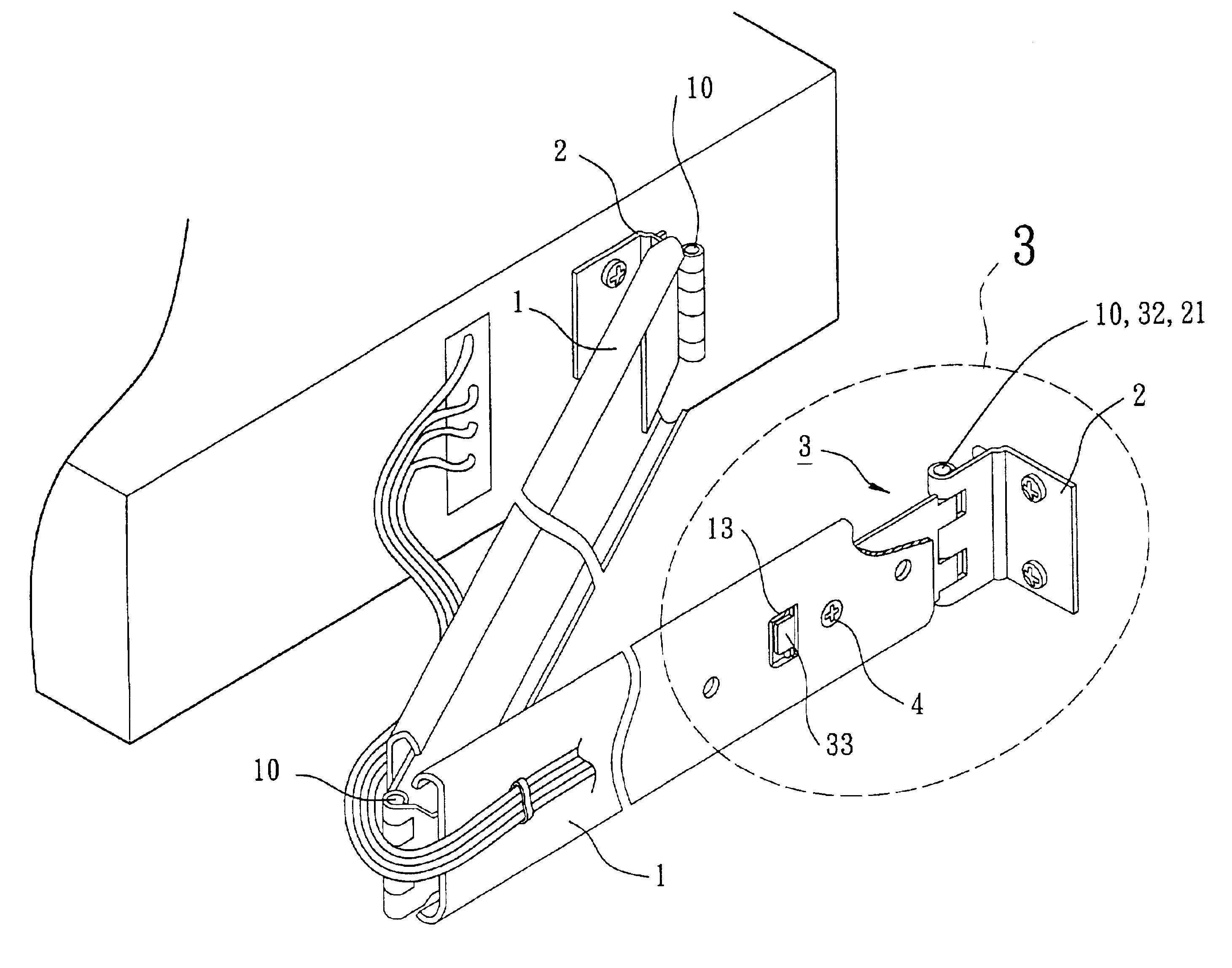

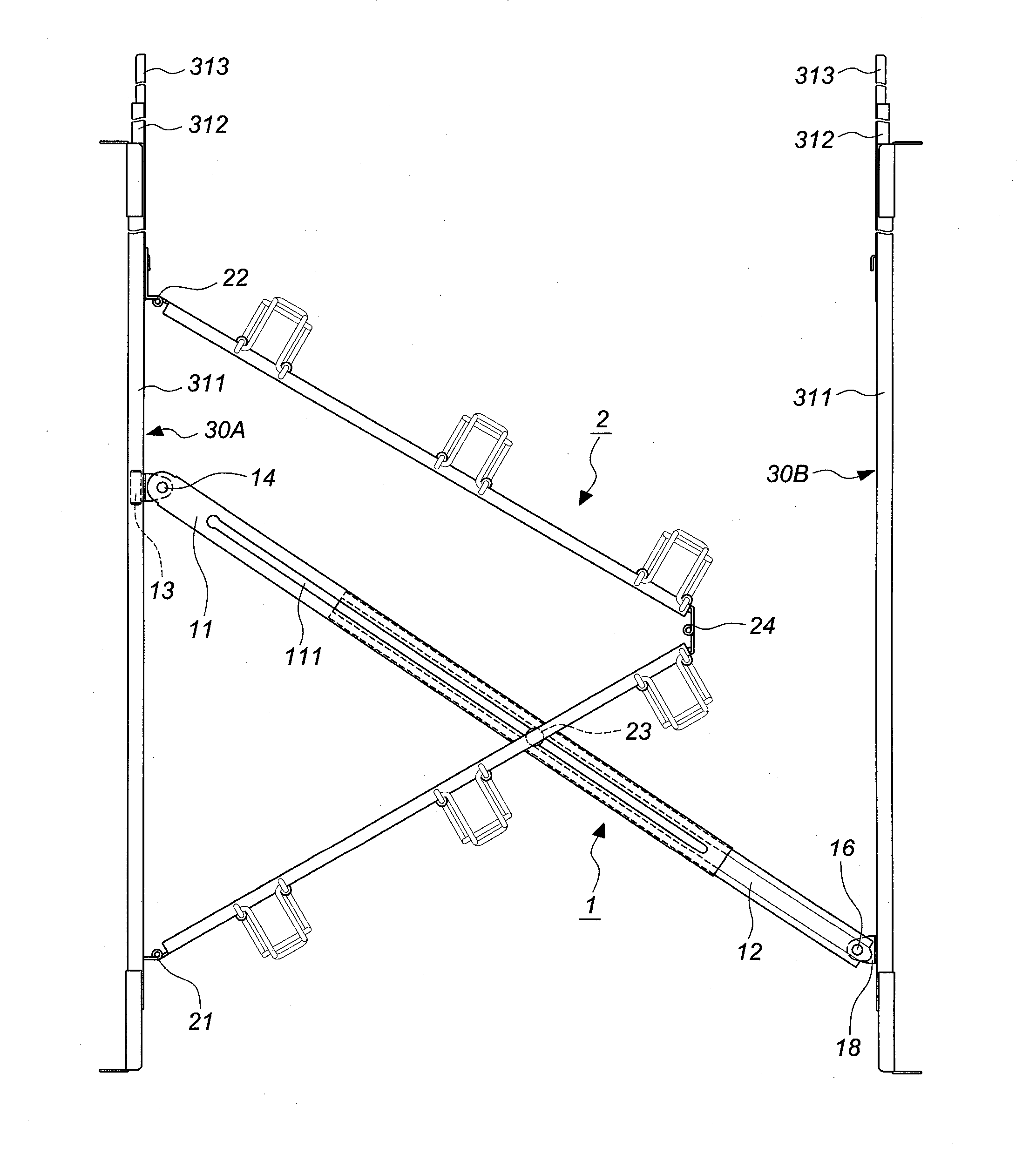

Support slide assembly for a cable management arm

A support slide assembly for a cable management arm includes first and second slide assemblies. The cable management arm is connected between the two slide rails of the first slide assembly. A third pivot member and a sliding member are located between first and second pivot members on two ends of the cable management arm. Two ends of a support slide rail are connected to the first and second slide assemblies respectively. The support rail is retractable by the slidable first and second rods. The first rod has one end pivotably connected to a sliding block which is slidably connected to the first slide assembly. The second rod has one end pivotably connected to the second slide assembly. The sliding member is slidably connected to the support slide rail. When the first slide assembly pulls the cable management arm out, the first and second rods extend relative to each other and form an angle relative to the first and second slide assemblies.

Owner:KING SLIDE WORKS CO LTD

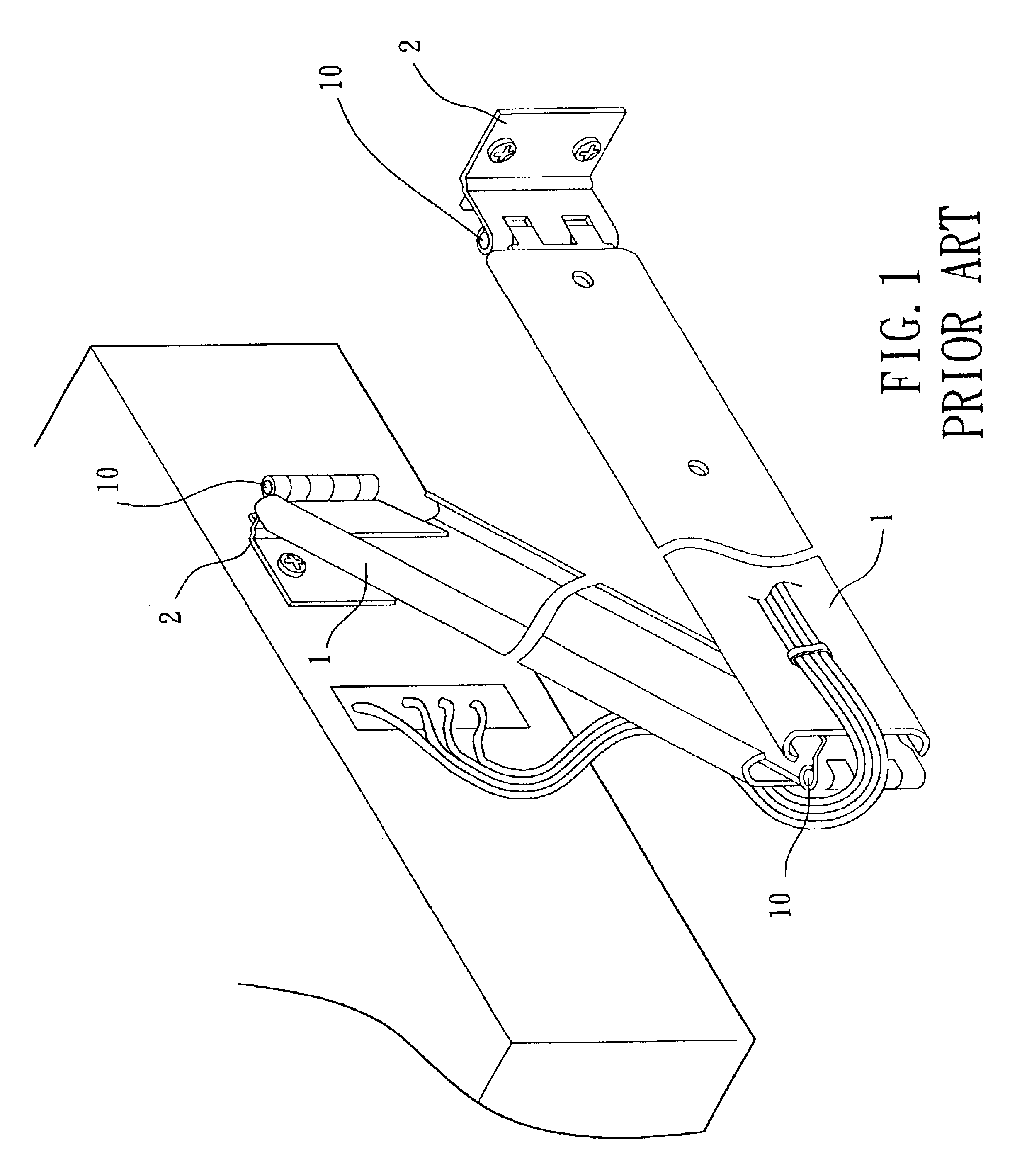

Adjustable cable management arm for furniture

An adjustable cable management arm devise. The device includes a pair of cable arms, pivotal pins, an adjustable arm, and an adjusting member. A first end of a first cable arm is connected to an end of a second cable arm, which is capable of folding each other, so as to form a combination of cable arms. The adjustable arm is inserted into an end of the combination of the cable arms and adapted to receive the pivotal pin. The adjustable arm is adapted to adjust a horizontal angle of a cable arm with respect to a wall bracket, so as to allowing the pivotal pin being smoothly rotated between the adjustable arm and the wall bracket.

Owner:KING SLIDE WORKS CO LTD

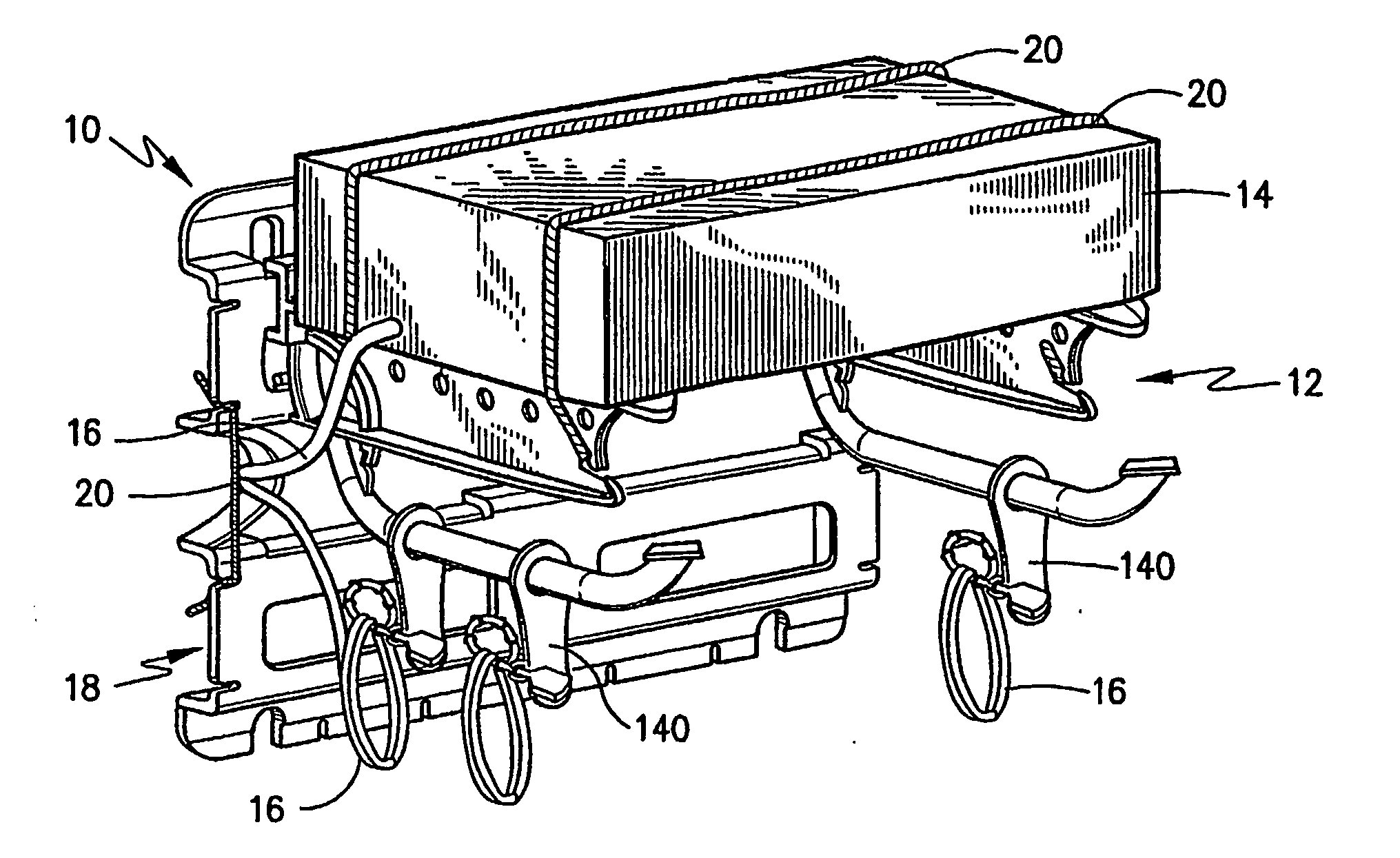

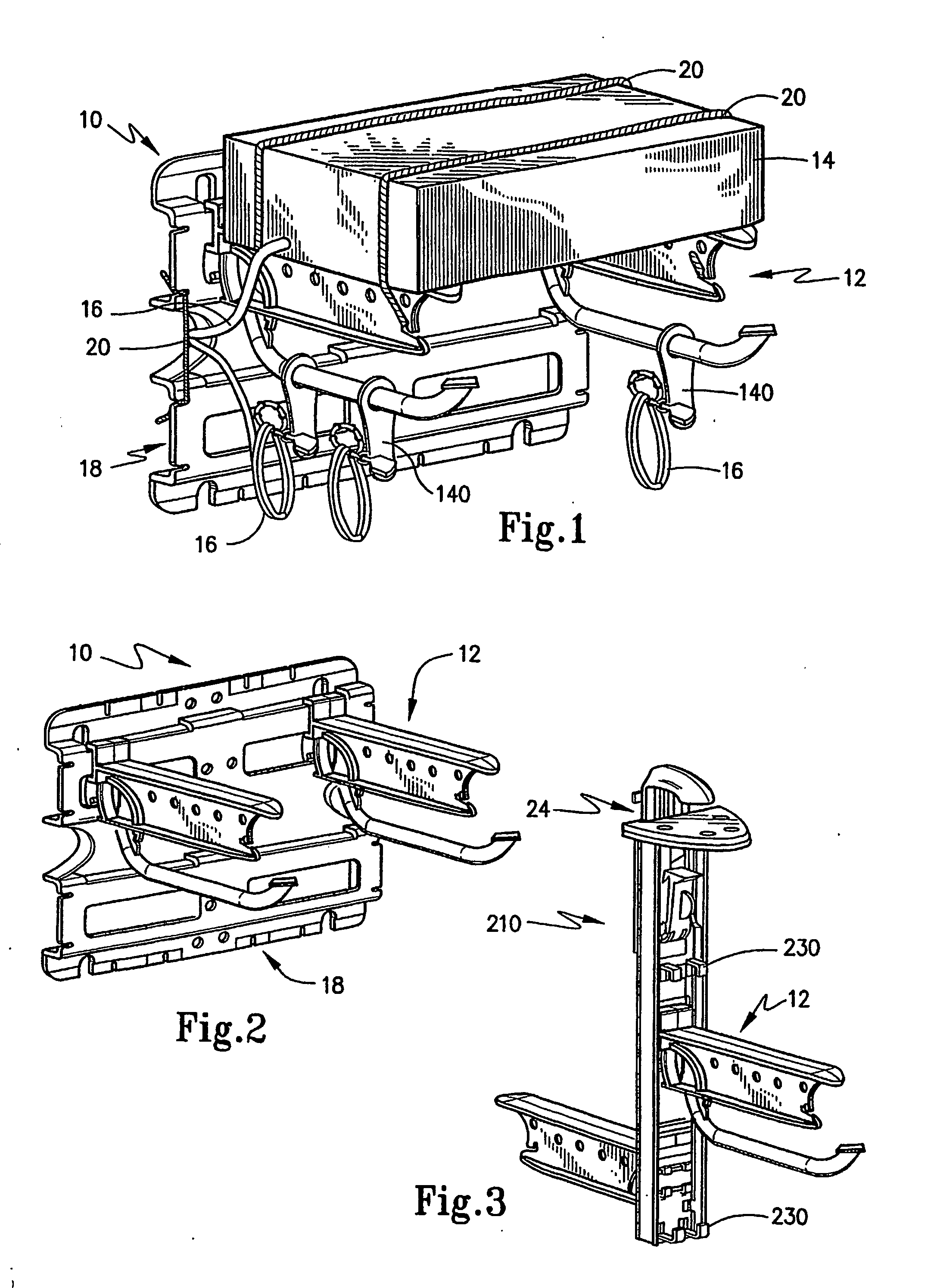

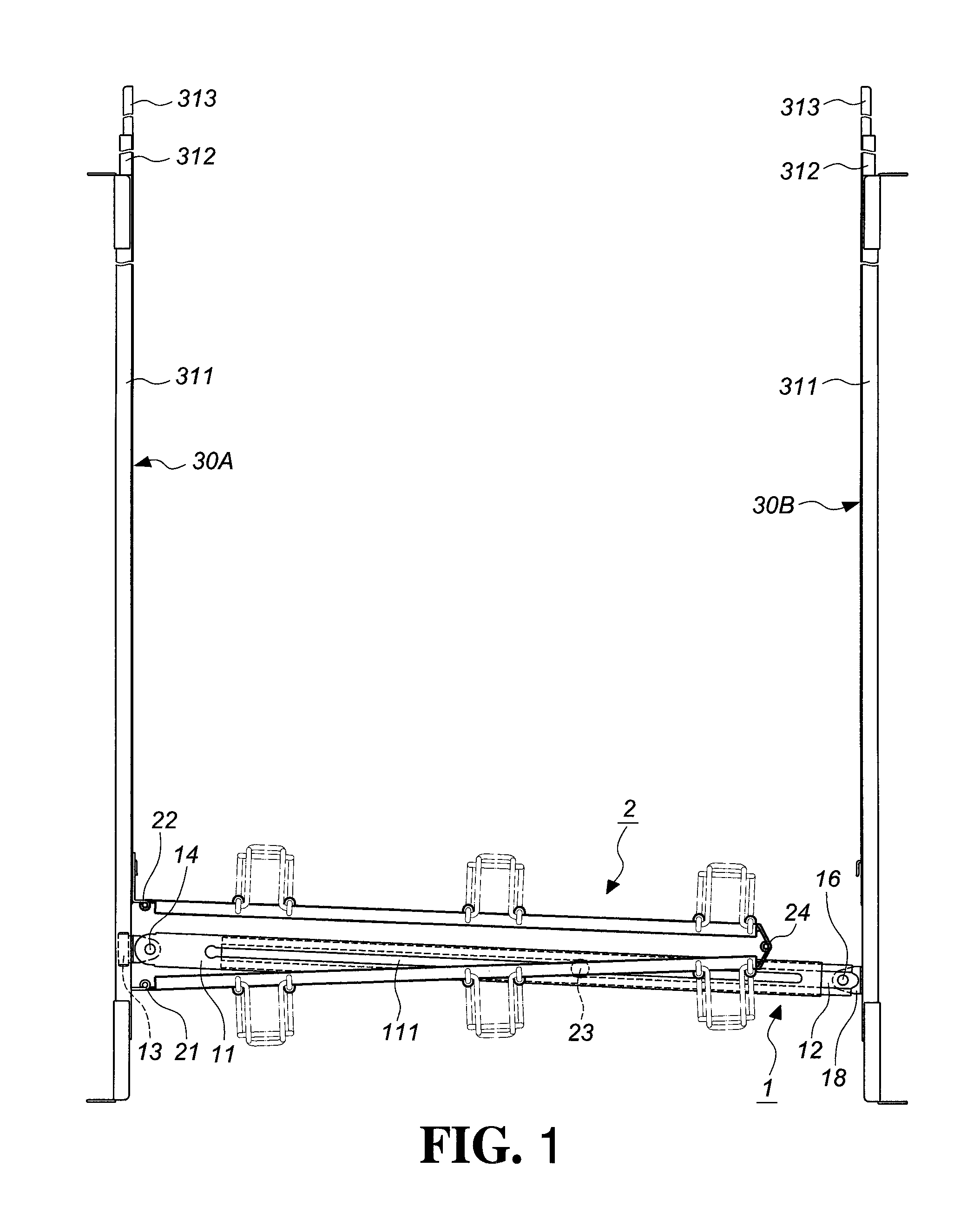

System, method, and apparatus for clamping

A number of racks which are configured to allow a number of devices to couple thereto are provided. In some embodiments, the racks are for use with a number of medical devices. Devices may be coupled to a rack by clamps. The racks may include a number of connectors which provide power and / or a network connection to devices coupled thereto. The racks may include a clamp which allows the racks to couple to a supporting structure such as a pole.

Owner:DEKA PROD LLP

Vacuum cleaner

A vacuum cleaner includes a main body, a motor assembly installed at the main body, the motor assembly including a motor for generating a suction force, an exhaust filter for filtering fine foreign substances from air passing through the motor assembly, and a guide member for guide a portion of air going via the exhaust filter to the inside of the main body. The guide member has a horizontal guide member and a vertical guide member for guiding portions of air passing through the exhaust filter to the side and the top of the main body respectively.

Owner:DAEWOO ELECTRONICS CO LTD

Cord retainer for vacuum cleaner

InactiveUS6510583B2Easy to disassembleCleaning filter meansSuction filtersVacuum cleanerElectrical and Electronics engineering

A vacuum cleaner has a cord retainer for holding looped cord in a horizontal position against the housing of the vacuum cleaner. The cord retainer includes two cord locks that are pivotally mounted to the vacuum cleaner housing. The cord locks are limited in their pivotal movement from a horizontal or near horizontal position to a vertical or near vertical position. The cord locks are mounted onto shafts which, in turn, are either integrally molded with the vacuum cleaner housing or connected to the vacuum cleaner housing in a suitable fashion.

Owner:SHOP VAC

Data storage apparatus

Owner:STORCENTRIC DIP LENDER LLC

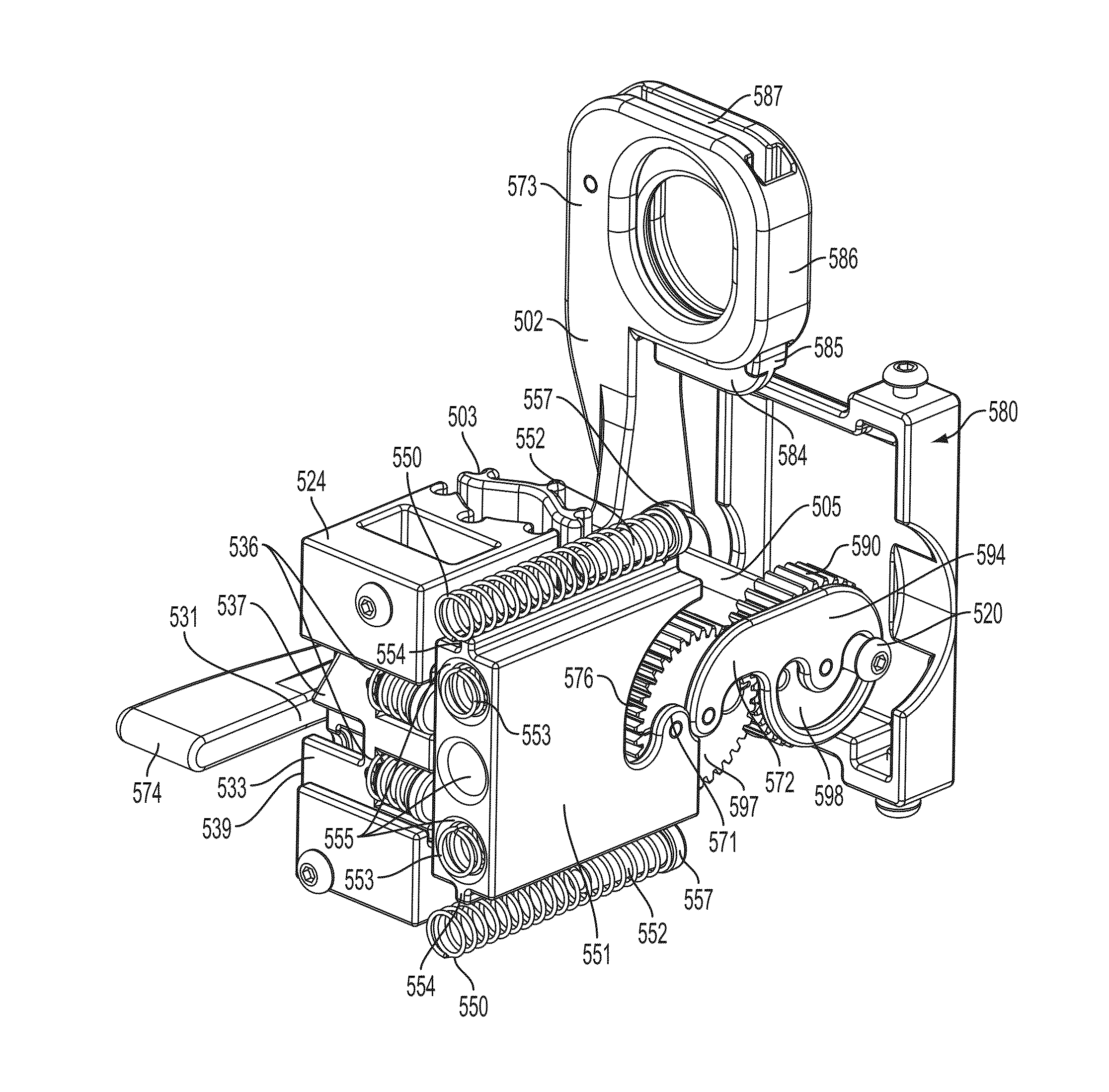

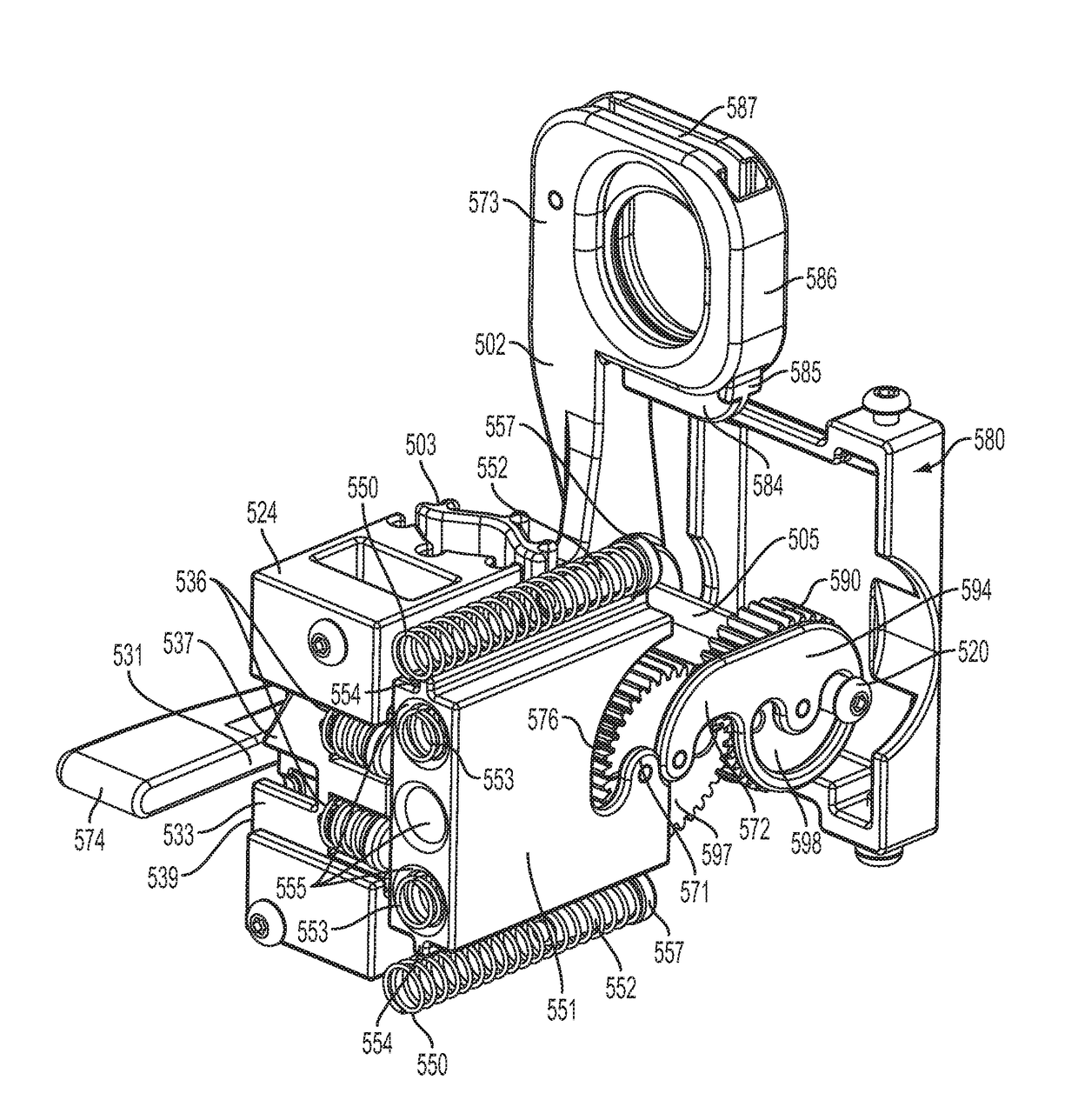

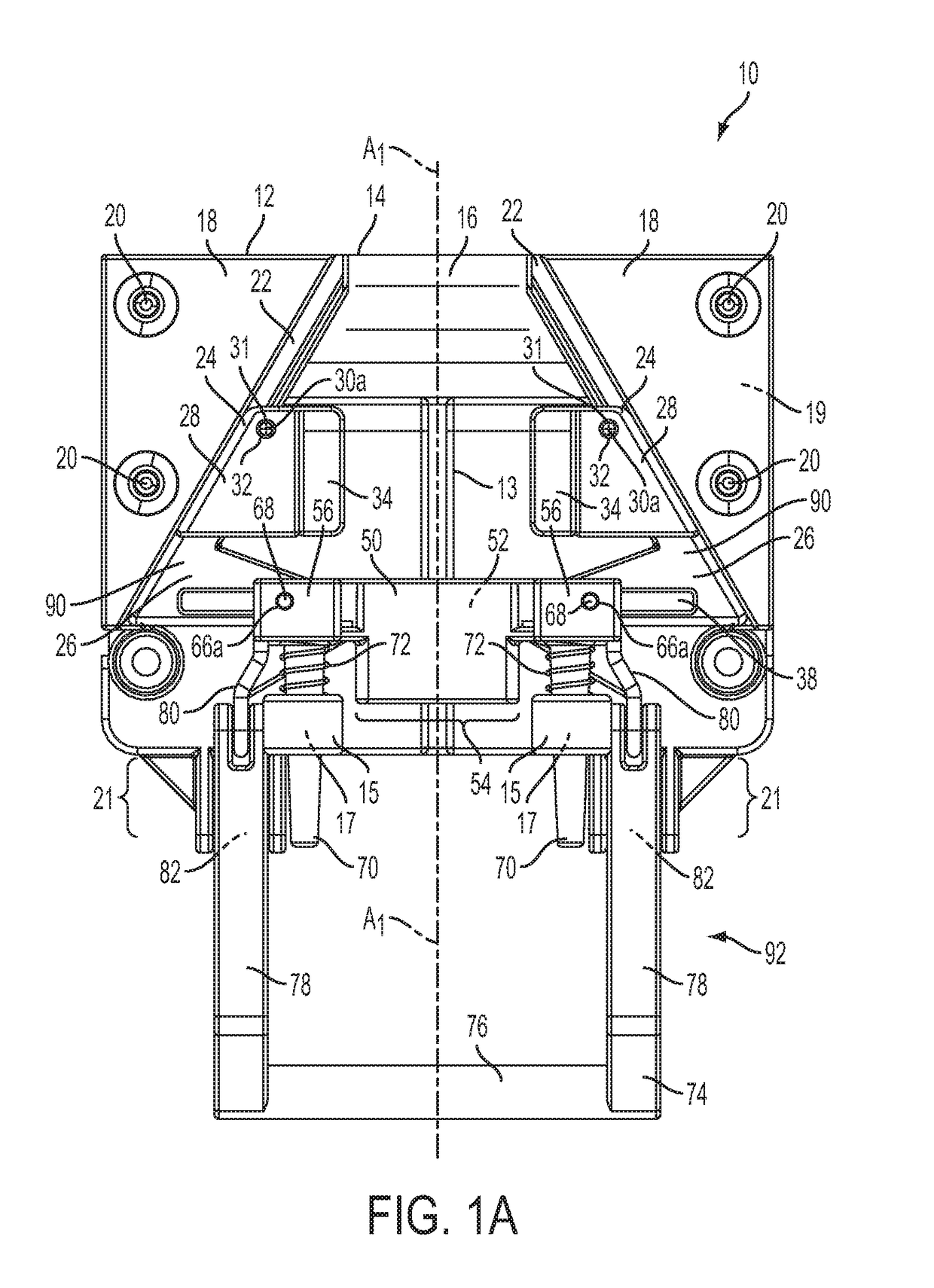

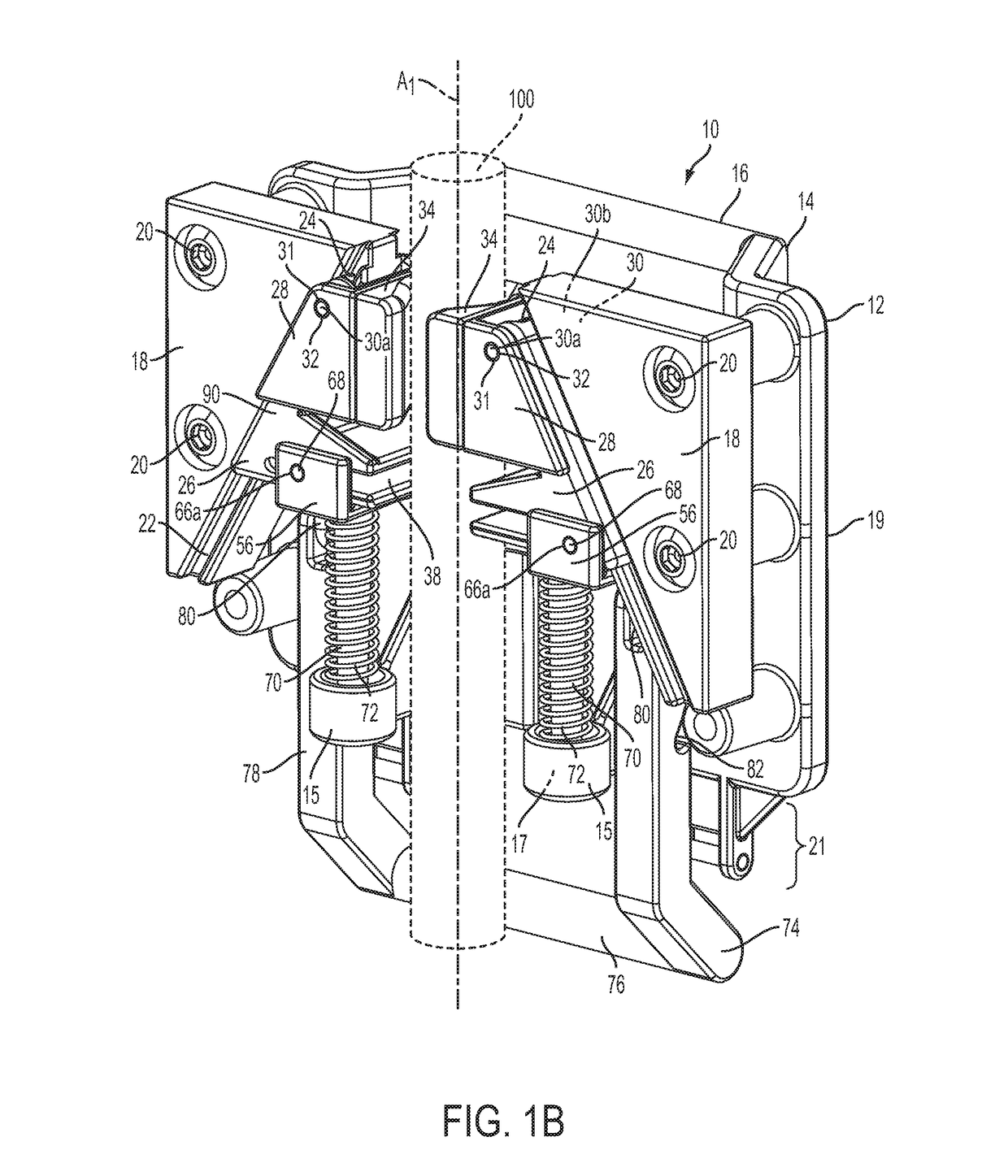

System, Method, and Apparatus for Clamping

A clamp apparatus is disclosed that includes a body, first and second actuators, first, second, third and fourth gear sets, first and second movable grippers, and at least one leaf spring. The first gear set is coupled to the first actuator and the second gear set is coupled to the second actuator. The first gear set engages the second gear set. The first and second movable grippers are each operatively coupled to the body. The third gear set is coupled to the first movable gripper and the fourth gear set is coupled to the second movable gripper. The third gear set operatively engages the fourth gear set. The leaf spring engages with the third gear set and the fourth gear set to urge the first movable gripper and the second movable gripper toward a clamped position.

Owner:DEKA PROD LLP

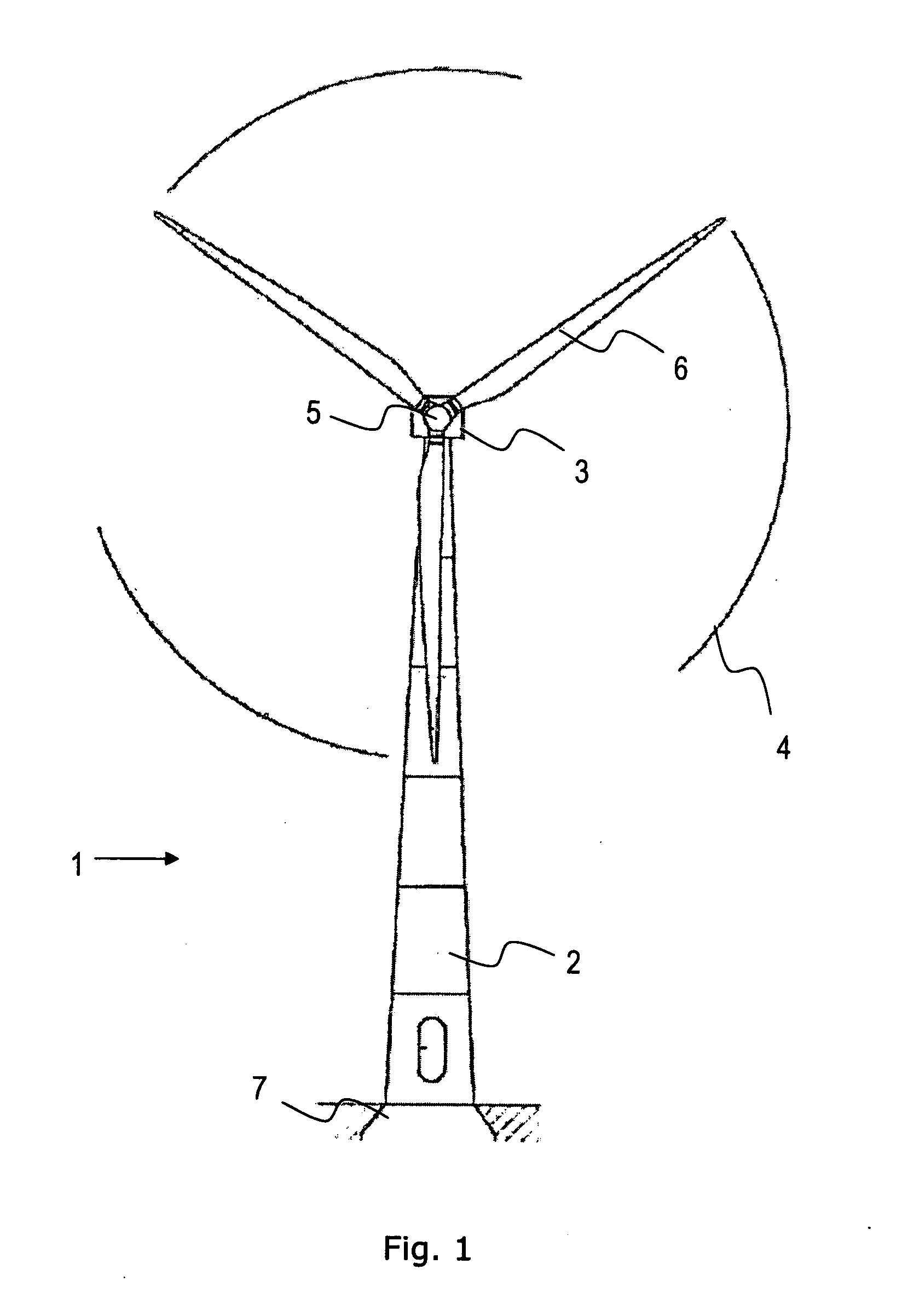

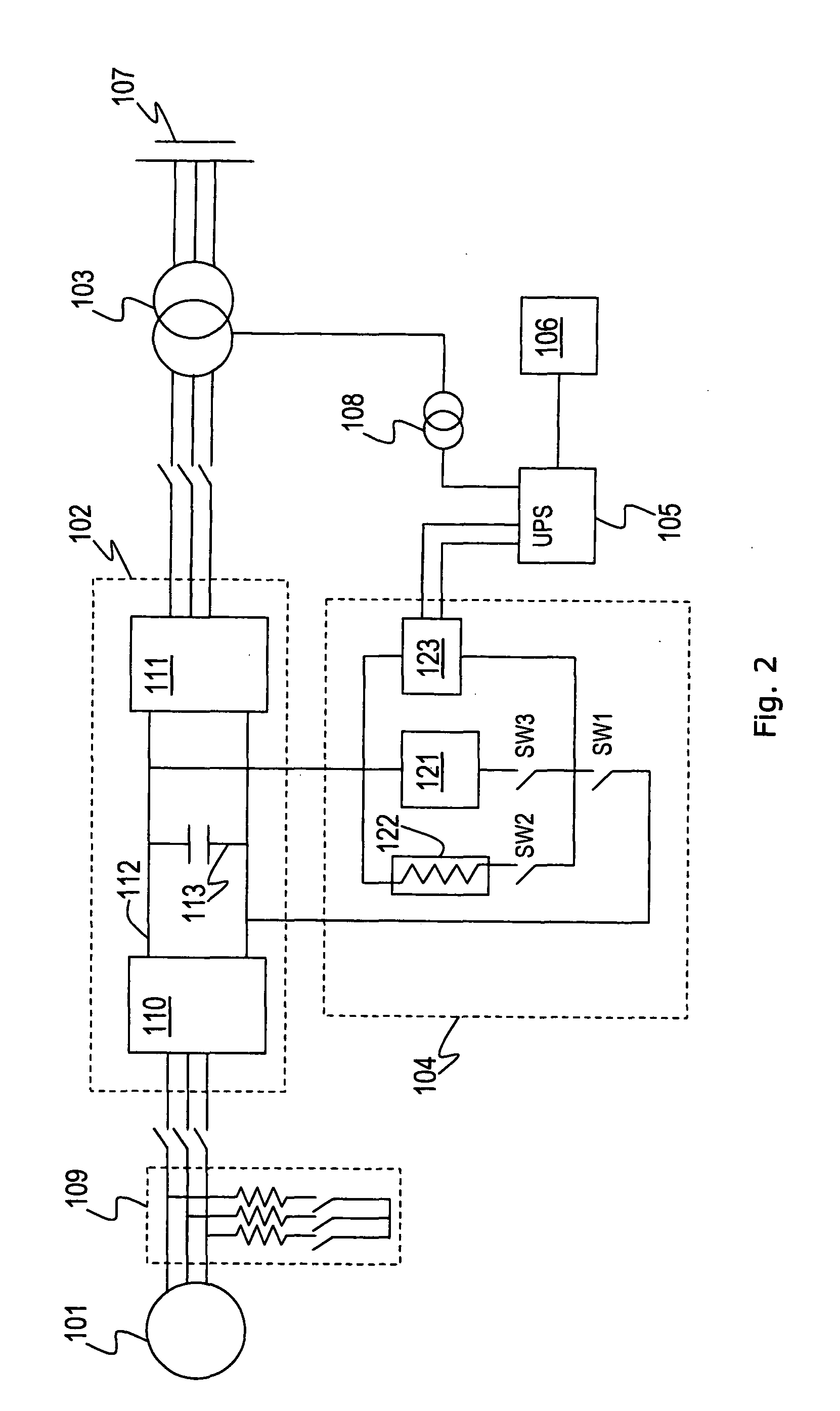

Variable speed wind turbine, and a method for operating the variable speed wind turbine during a power imbalance event

ActiveUS20120217824A1Better energy managementExcess power being dissipatedRotary current collectorWind motor controlVariable speed wind turbineTurbine

A variable speed wind turbine is provided. The wind turbine comprises a generator, a power converter for converting at least a portion of electrical power generated by the generator, an energy management arrangement coupled to the power converter, the energy management arrangement comprises an energy storage unit, and a controller. The controller is adapted to detect a power imbalance event and to transfer at least a portion of excess electrical energy generated by the generator to the energy storage unit to be stored therein when the power imbalance event is detected.

Owner:VESTAS WIND SYST AS

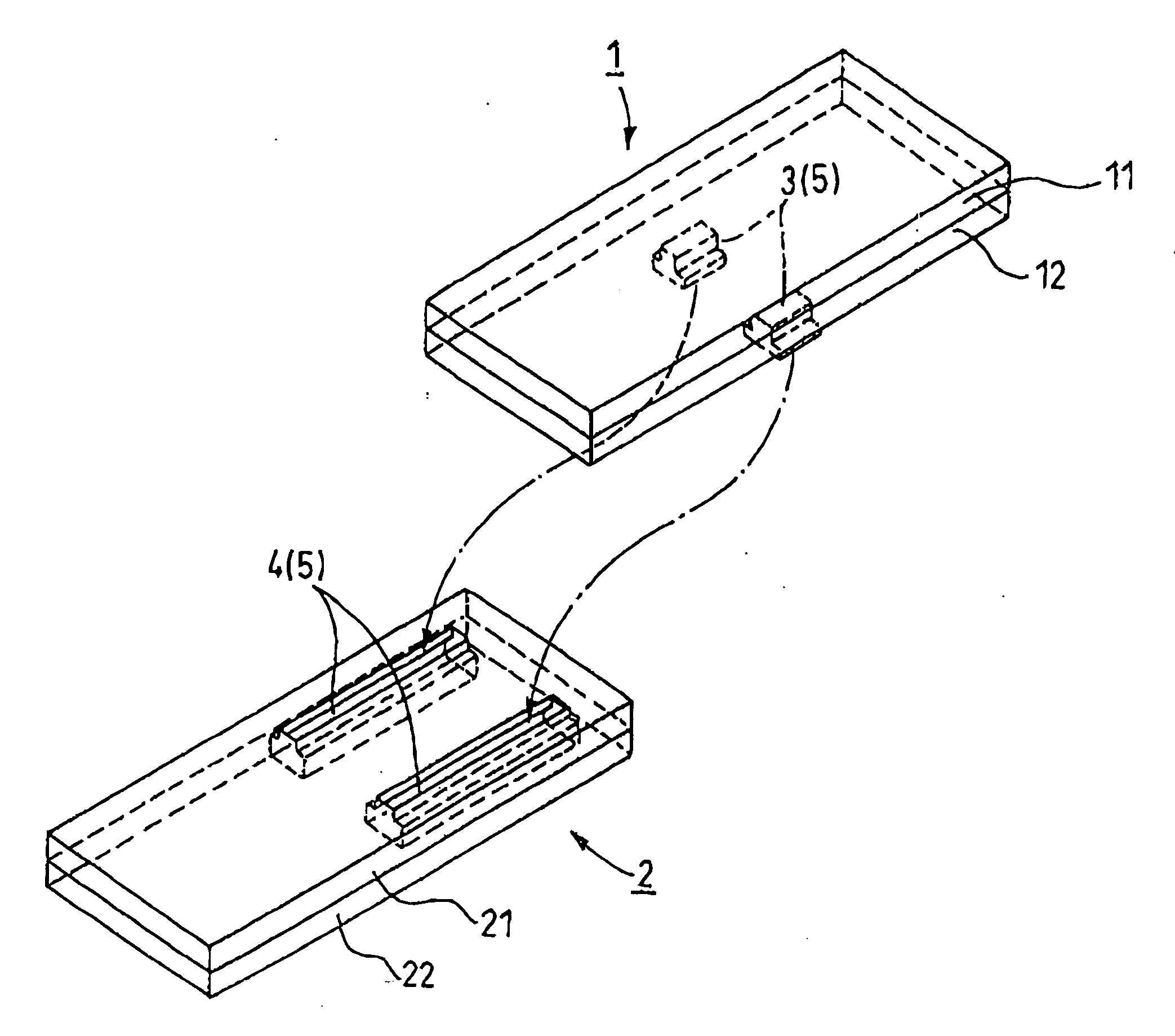

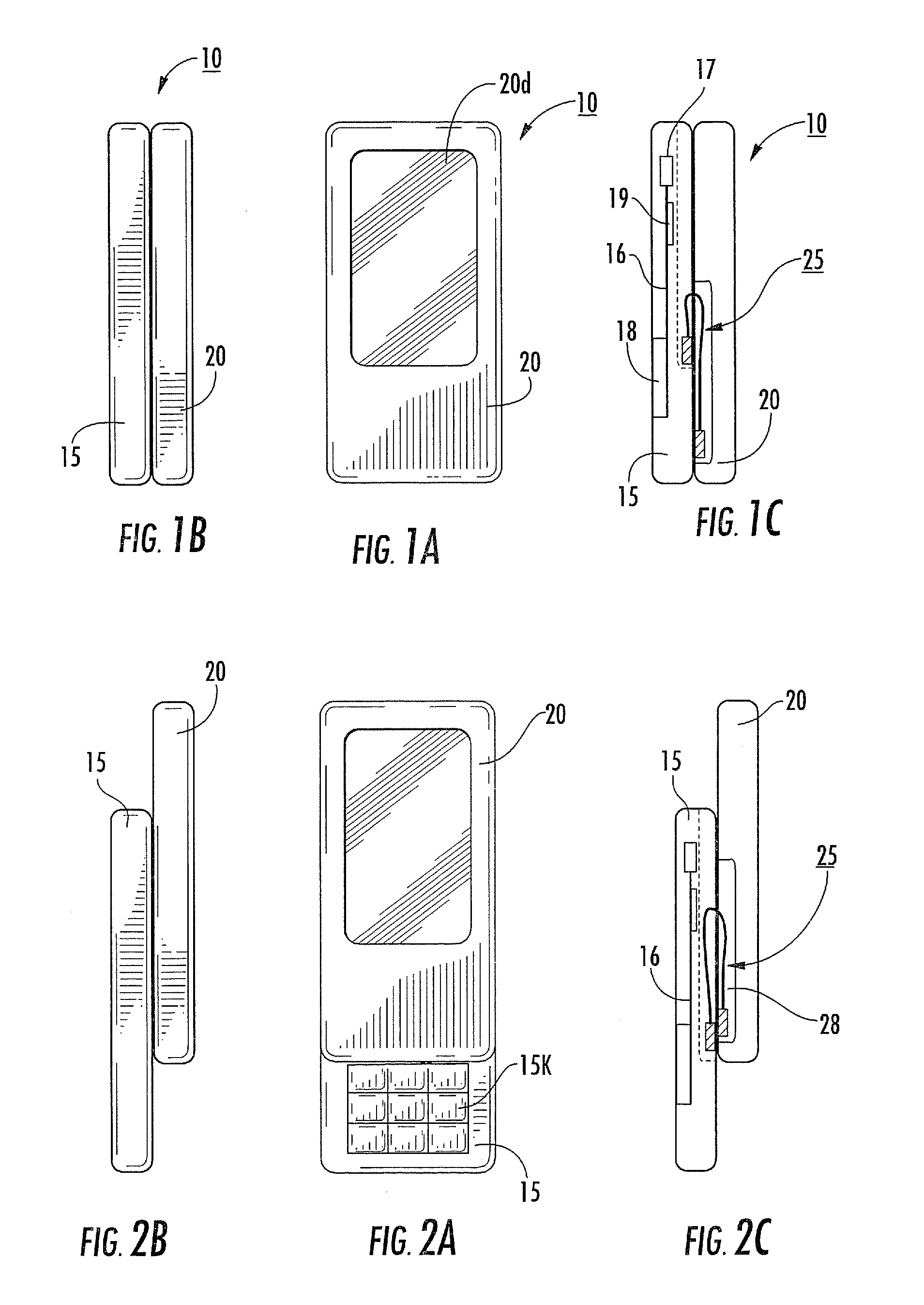

Flexible gaskets for wireless terminals with sliding members

InactiveUS20070275774A1Avoid interior spacesCable arrangements between relatively-moving partsTransmissionInterior spaceElectrical and Electronics engineering

Gaskets and wireless terminals with gaskets for sealing a space between sliding members in wireless terminals. The wireless terminals include: (a) a first member; (b) a second member overlying the first member, wherein at least one of the first and second members is configured to slide between open and closed configurations; and (c) a gasket attached to the first and second members, the gasket having an elongate body portion with opposing first and second end portions affixed to a respective one of the first and second members. The gasket is configured to provide an electrical path between at least one component in the first member to at least one component in the second member. The elongate body portion is configured to snugly abut the first and second members to inhibit dust from entering a target interior space when the wireless terminal is in the open configuration.

Owner:SONY ERICSSON MOBILE COMM AB

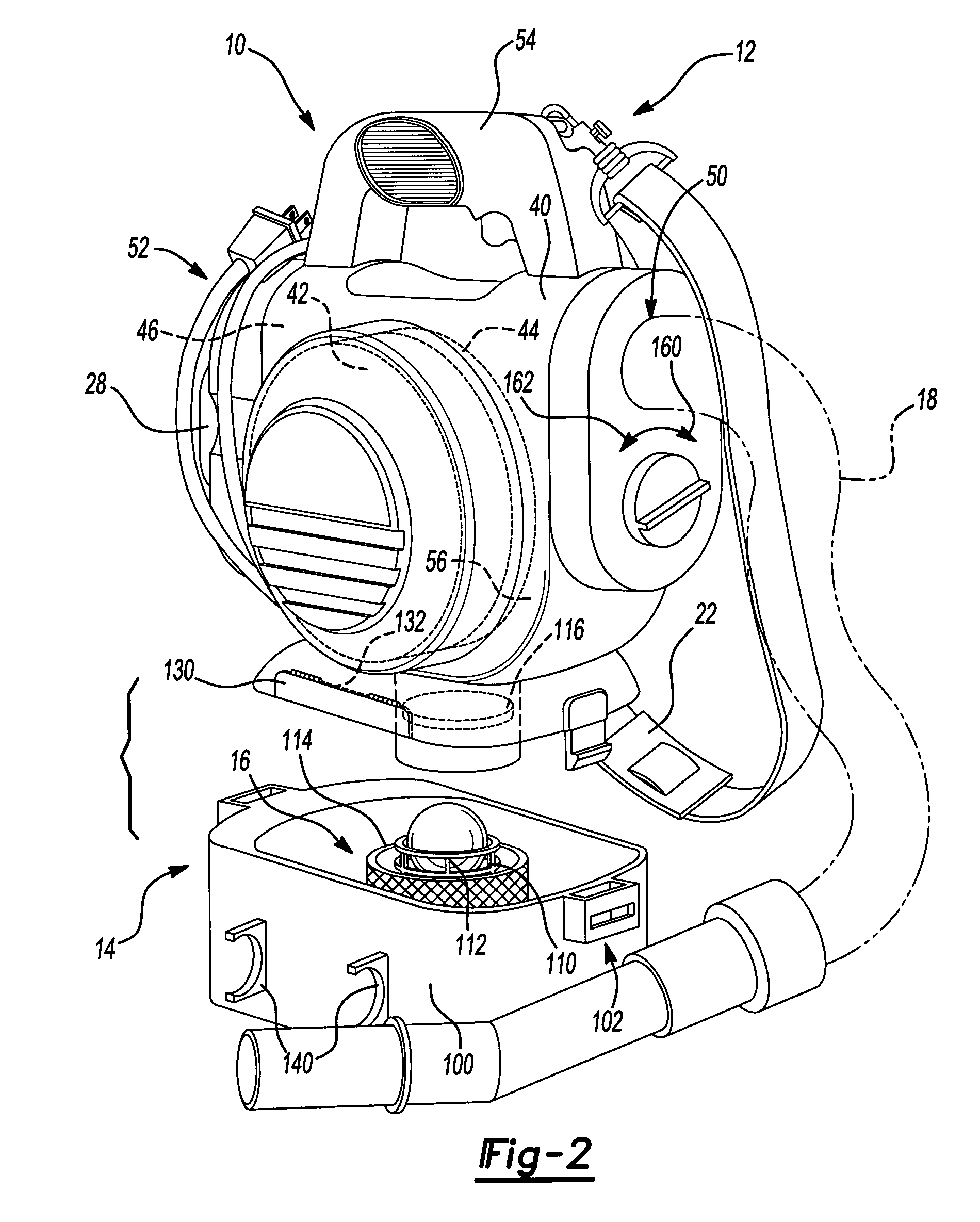

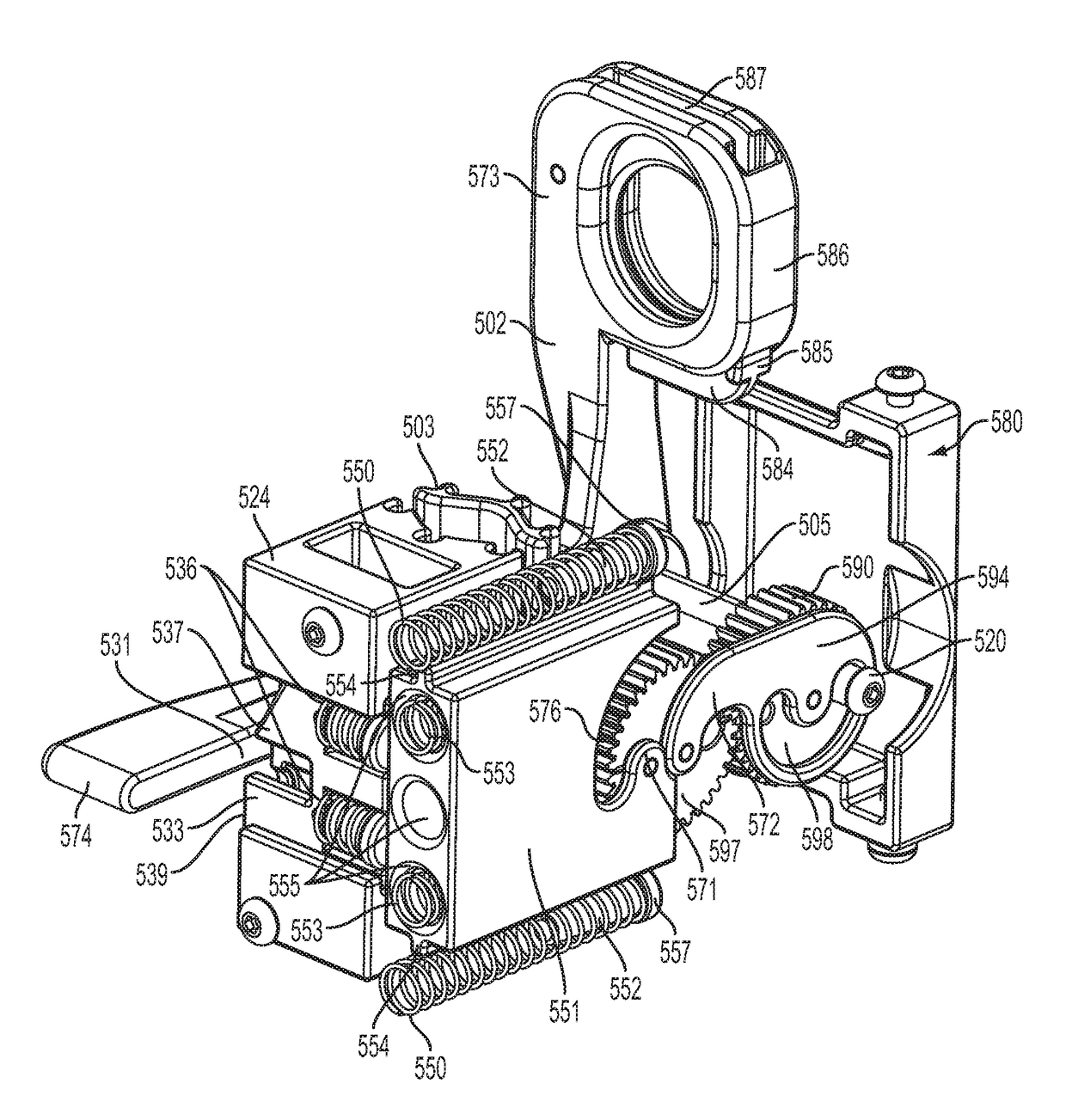

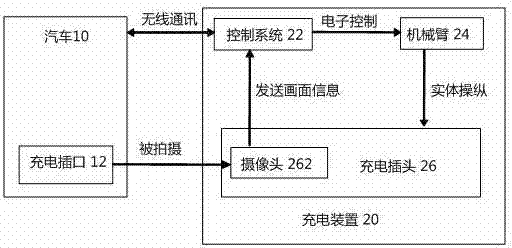

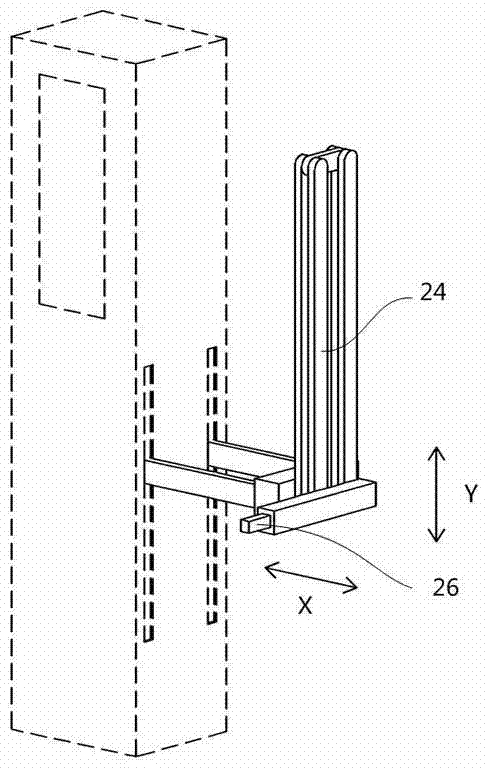

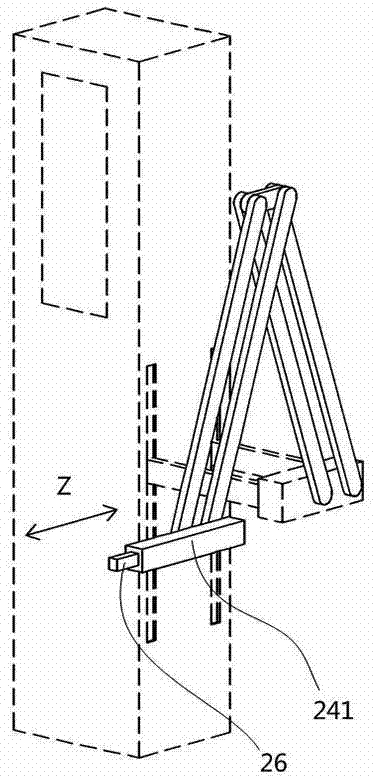

Automatic charging interface connection device

ActiveCN104241948AEasy to operate manuallyCoupling device detailsCable arrangements between relatively-moving partsThree-dimensional spaceControl system

The invention discloses a device capable of being automatically connected to a charging power source and a charging port on an automobile through a mechanical arm. The device does not need to be connected to a plug manually, through wireless communication between the plug and an automobile, the device is connected automatically to charge after the automobile is stopped, the device is automatically cut off before the automobile is started, and operation complexity is simplified. The automatic charging interface connection device is characterized in that the device further comprises a control system, a photographic device and a mechanical arm. The photographic device is arranged on the charging plug, the charging plug is arranged at the front end of the mechanical arm. The control system controls the mechanical arm to move in the three-dimensional space according to image information filmed by the photographic device, and the charging plug is inserted into a charging interface.

Owner:齐向前

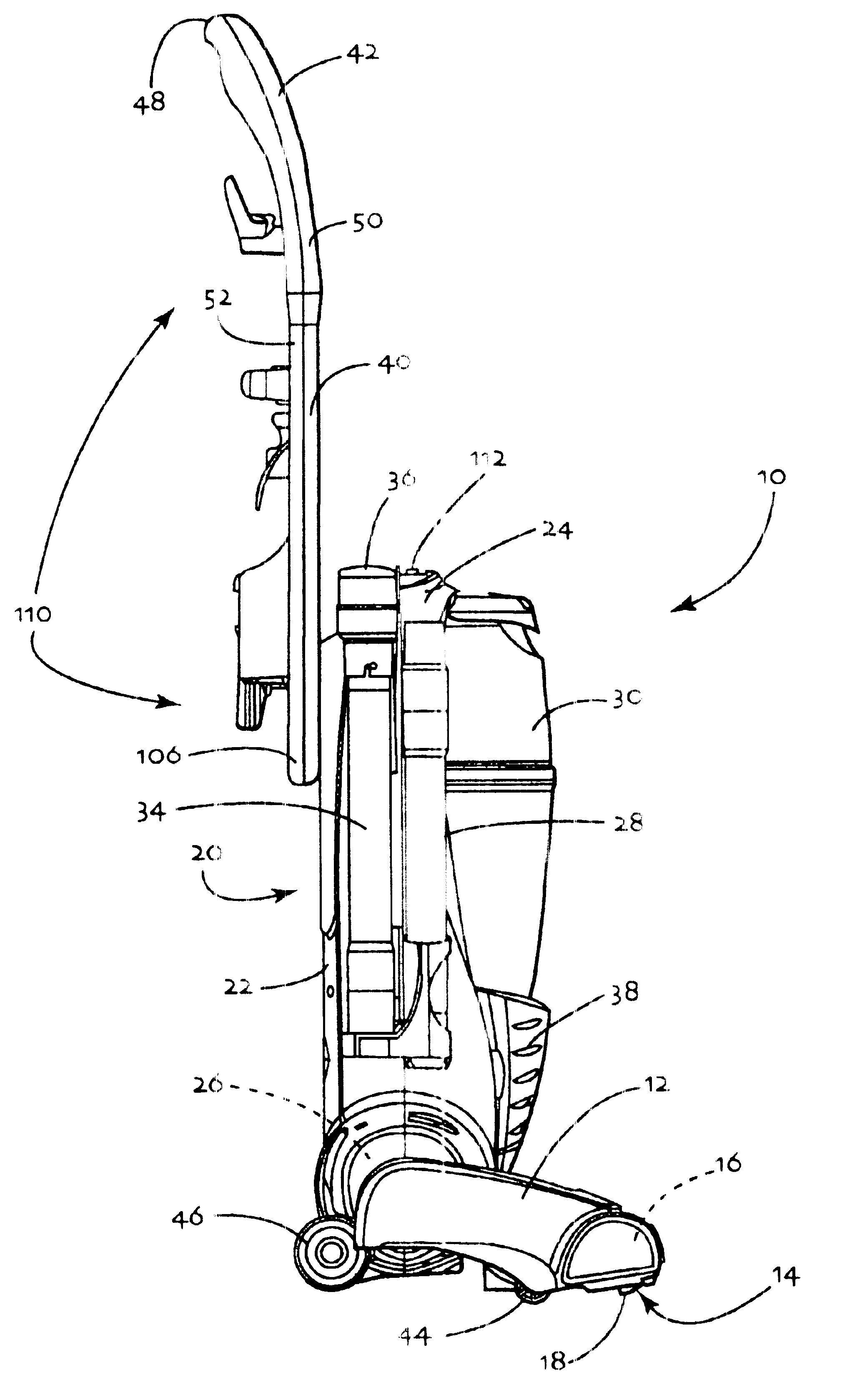

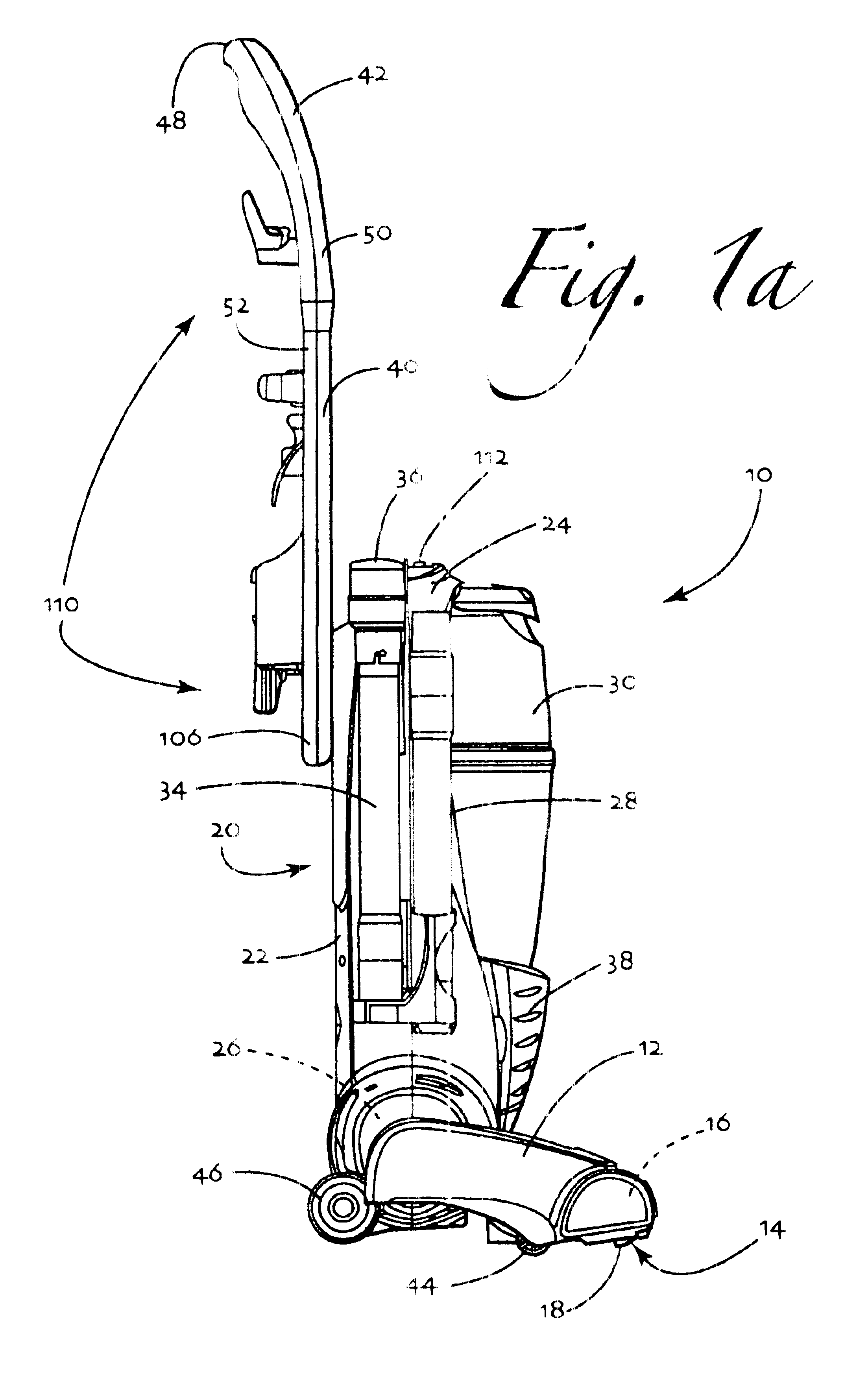

Rotating operating handle for vacuum cleaner

InactiveUS6941615B2Prevent tippingAvoid cleaningCleaning filter meansSuction filtersEngineeringVacuum cleaner

A floor cleaning apparatus includes a nozzle assembly and a canister assembly connected to the nozzle assembly. A suction generator and a dirt collection vessel are carried by the nozzle assembly or the canister assembly. In addition, the vacuum cleaner includes a control handle displaceable between operating and storage positions. A stabilizer on the handle is provided adjacent the floor in the storage position. Engagement of the stabilizer with the floor prevents the vacuum cleaner from inadvertently tipping over rearwardly.

Owner:PANASONIC OF NORTH AMERICA

AC/DC portable wet/dry vacuum having improved portability and convenience

InactiveUS20050273969A1Improve convenienceImprove performanceBatteries circuit arrangementsCarpet cleanersPower modeEngineering

A wet / dry utility vacuum with a canister, a powerhead assembly with a fan, a shut-off device that prevents the fan from drawing liquids into the fan inlet when a volume of the liquid in the canister exceeds a predetermined volume. The powerhead assembly includes a controller that permits the utility vacuum to be operated in a desired power mode so that the user may employ either an AC power source or a DC power source, such as a battery pack, for example. In some applications, the battery pack may be interchangeable with the battery packs of various cordless tools, including drill / drivers and saws. A tool set and a method for operating a battery-powered tool set are also provided.

Owner:BLACK & DECKER INC

System, Method, and Apparatus for Clamping

A clamp apparatus is disclosed that includes a body, first and second actuators, first, second, third and fourth gear sets, first and second movable grippers, and at least one leaf spring. The first gear set is coupled to the first actuator and the second gear set is coupled to the second actuator. The first gear set engages the second gear set. The first and second movable grippers are each operatively coupled to the body. The third gear set is coupled to the first movable gripper and the fourth gear set is coupled to the second movable gripper. The third gear set operatively engages the fourth gear set. The leaf spring engages with the third gear set and the fourth gear set to urge the first movable gripper and the second movable gripper toward a clamped position.

Owner:DEKA PROD LLP

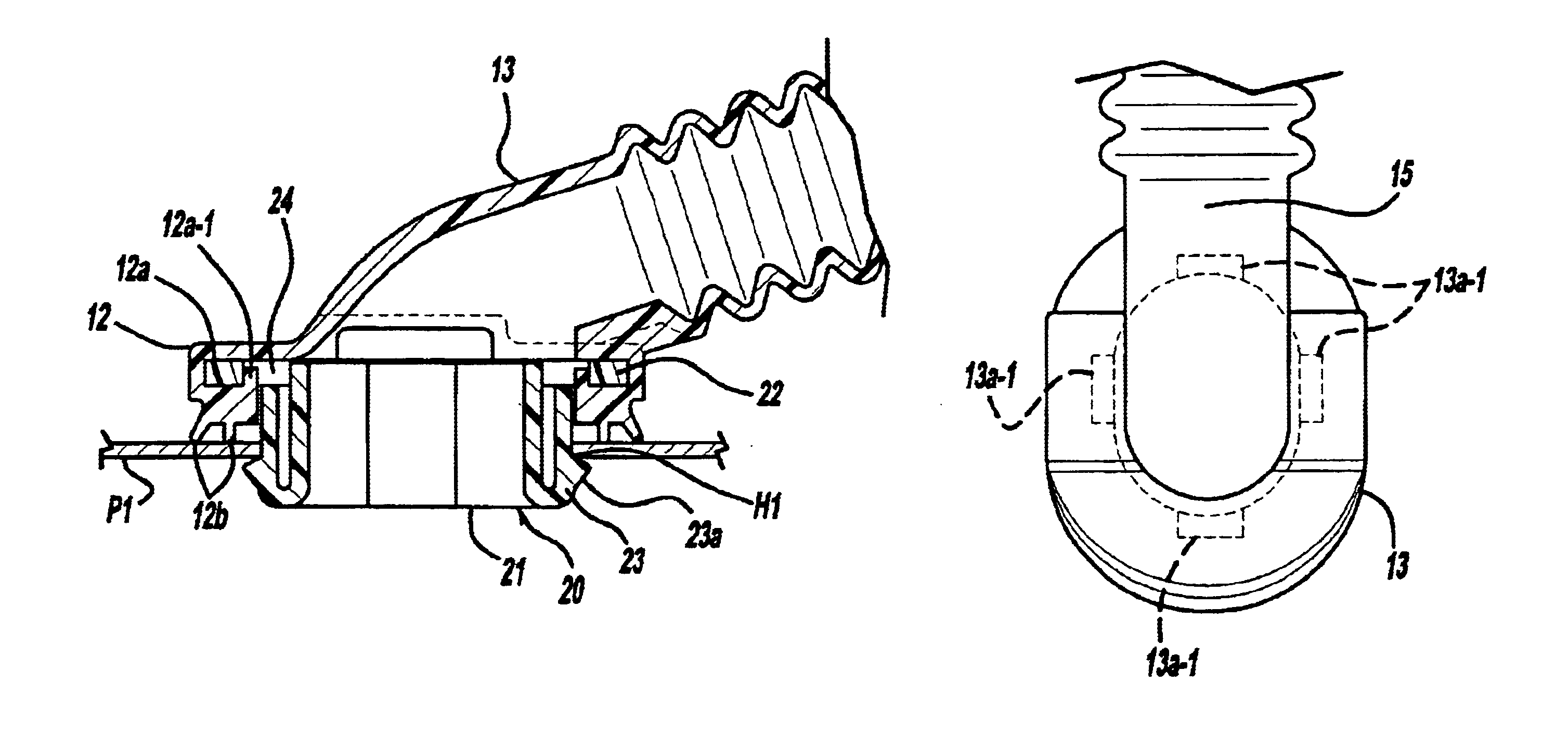

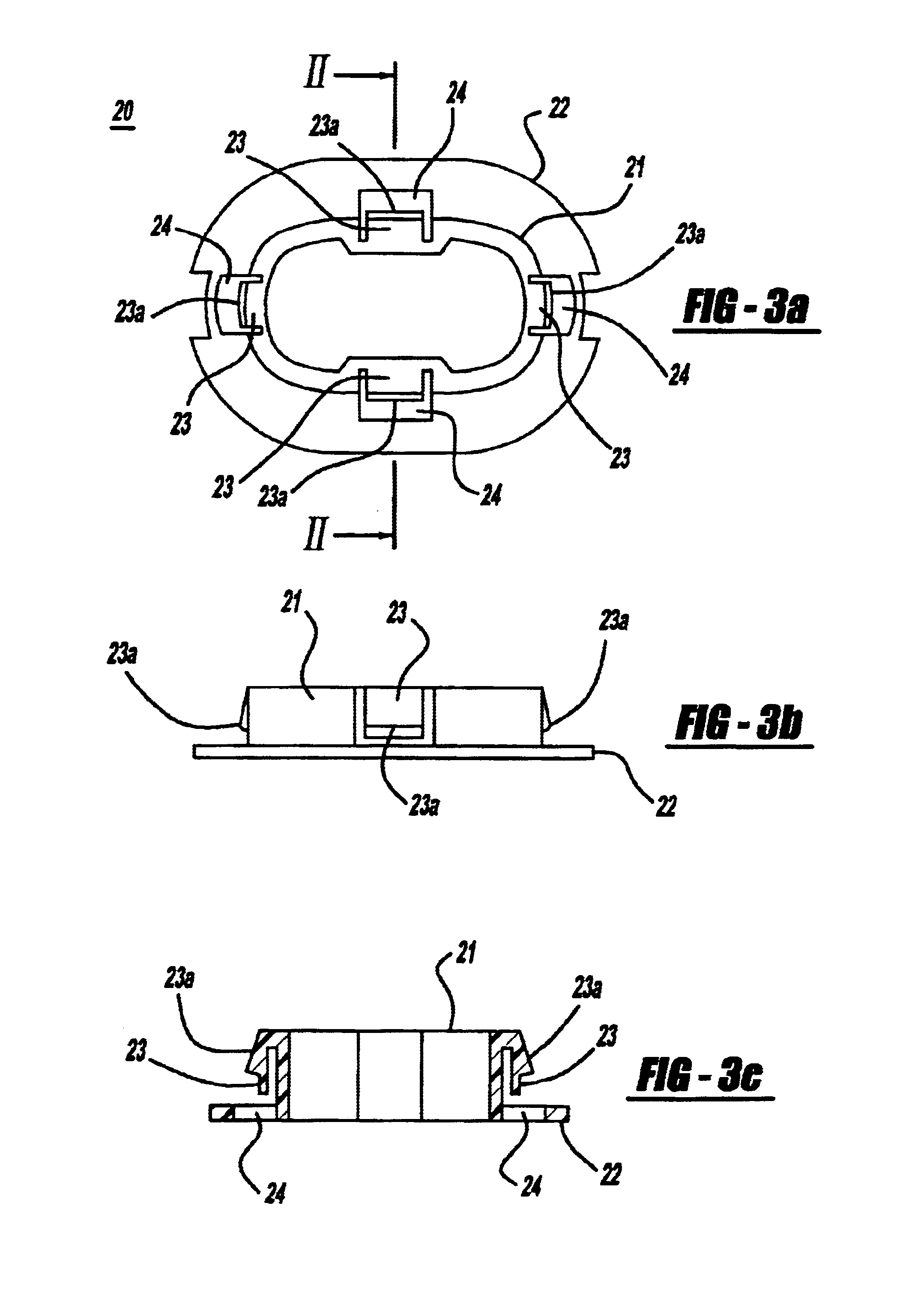

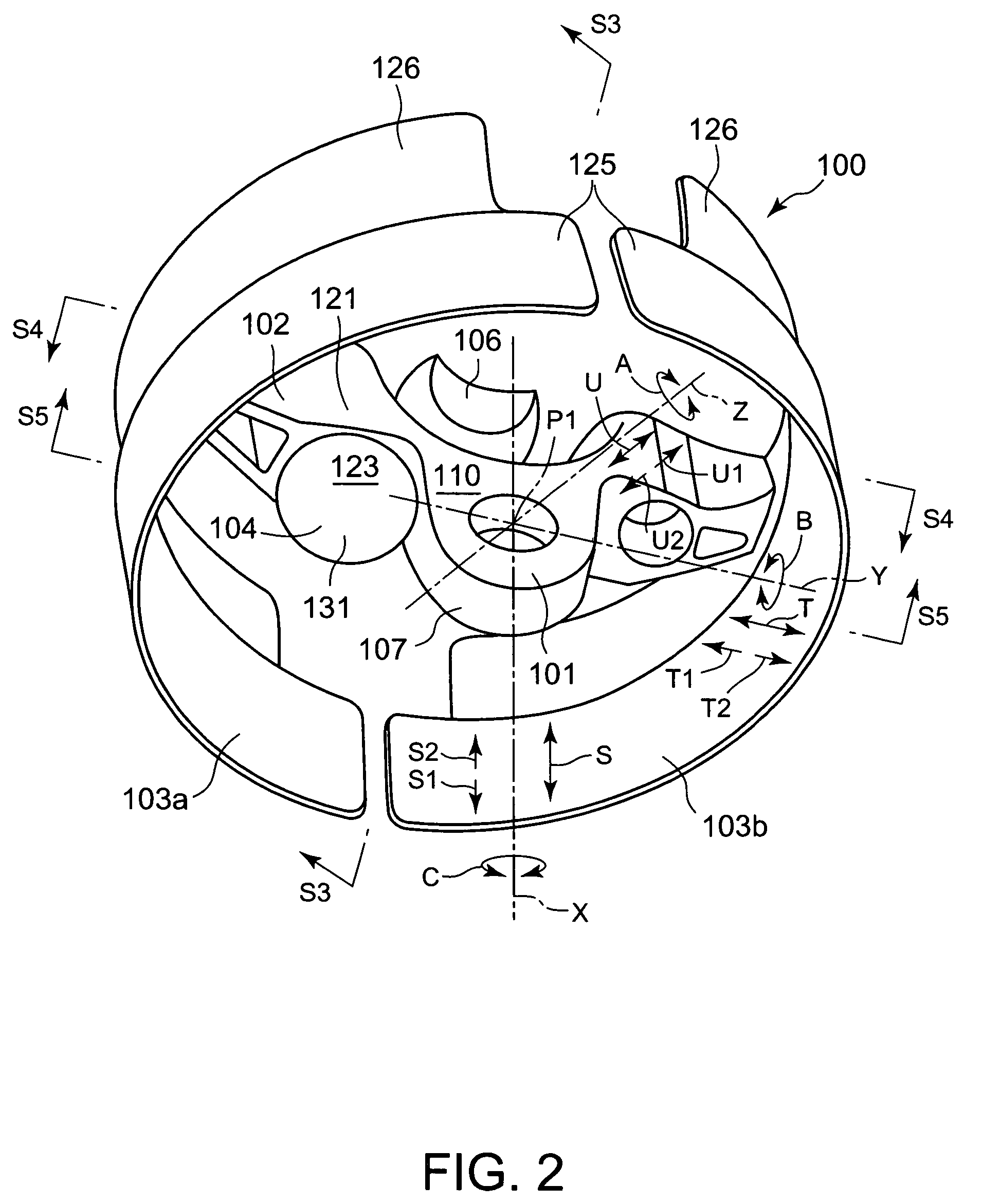

Resin inner member-provided grommet

InactiveUS6901627B2Improve dustproof performanceImprove waterproof performancePipesCable arrangements between relatively-moving partsEngineeringGrommet

A locking claw (23a) to be locked to a through-hole (H) projects outwardly from a peripheral wall (21) of a resinous inner member (20). At least one pair of locking holes (24) is formed on a locking flange part (22) projecting from the peripheral wall (21). An annular concavity (12a) (13a), on which the locking flange part (22) fits, is formed on an inner peripheral surface of a large-diameter cylindrical part (12, 13). Locking projections (12a-1, 13a-1) project from a leading end of a side wall of the annular concavity (12a, 13a). The locking projections (12a-1, 13a-1) are inserted into and locked with the locking holes (24). Locking claws (123a-126a) project from the resinous inner member (120) and are locked to a through-hole (H1) of the body panel (P1). A pair of flexible locking pieces (123-126), to be locked to the body panel (P1), project from each of a shorter side and a longer side of an elliptic peripheral wall (121) of the resinous inner member (120) projecting from an open end of the large-diameter cylindrical part (112, 113). A leading end of the locking pieces (123-126) project outwardly from an intermediate position of an outer surface of the locking pieces (123-126). The locking pieces on the longer side are curved longitudinally to form a circular arc shape.

Owner:SUMITOMO WIRING SYST LTD

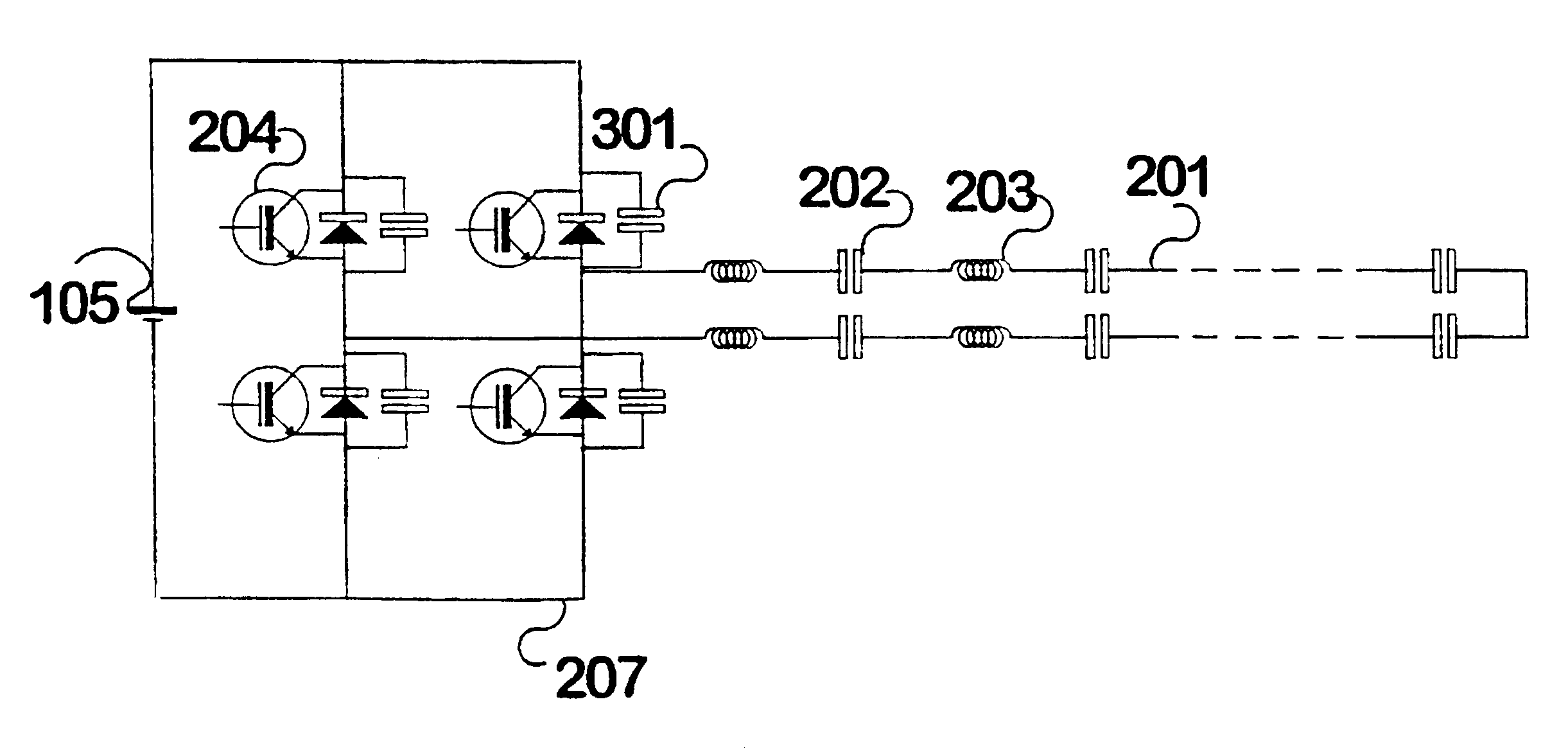

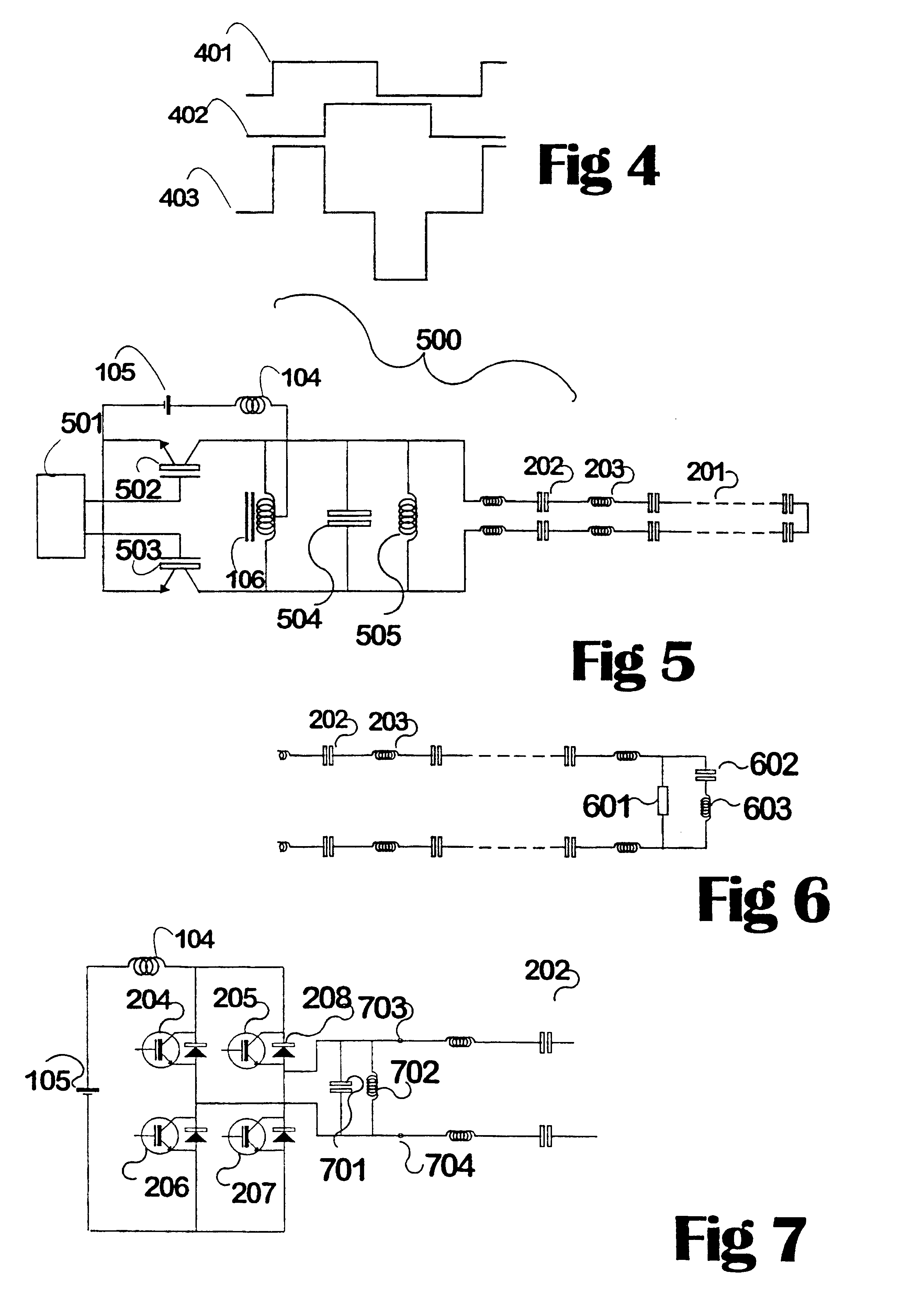

Supply of power to primary conductors

InactiveUS6621183B1Limited amountReduce harmonic contentRail devicesRotary current collectorElectrical conductorFull bridge

Apparatus for providing effective amounts of high-frequency AC power to a long primary trackway (1102), used for inductive power transfer includes transconductance-pi filters (1105) for deliberate mismatching; resulting in independence of current flow and track impedance. These cause the source (1101) to appear as a voltage source and the trackway to appear as a low reactance. Shorting the output (1106) cuts the connected trackway from power without harm. The filter can cause a voltage step-up so driving a longer track. Track termination apparatus is disclosed that acts as a short circuit at only the operating frequency while terminating the track at its characteristic impedance otherwise. Half-bridge and full-bridge power supplies (1101) are described for providing effective amounts of high-frequency AC power to a long primary trackway used for inductive power transfer.

Owner:AUCKLAND UNISERVICES LTD

System, method, and apparatus for clamping

A clamp apparatus is disclosed that includes a body, first and second actuators, first, second, third and fourth gear sets, first and second movable grippers, and at least one leaf spring. The first gear set is coupled to the first actuator and the second gear set is coupled to the second actuator. The first gear set engages the second gear set. The first and second movable grippers are each operatively coupled to the body. The third gear set is coupled to the first movable gripper and the fourth gear set is coupled to the second movable gripper. The third gear set operatively engages the fourth gear set. The leaf spring engages with the third gear set and the fourth gear set to urge the first movable gripper and the second movable gripper toward a clamped position.

Owner:DEKA PROD LLP

Support slide assembly for a cable management arm

A support slide assembly for a cable management arm includes first and second slide assemblies. The cable management arm is connected between the two slide rails of the first slide assembly. A third pivot member and a sliding member are located between first and second pivot members on two ends of the cable management arm. Two ends of a support slide rail are connected to the first and second slide assemblies respectively. The support rail is retractable by the slidable first and second rods. The first rod has one end pivotably connected to a sliding block which is slidably connected to the first slide assembly. The second rod has one end pivotably connected to the second slide assembly. The sliding member is slidably connected to the support slide rail. When the first slide assembly pulls the cable management arm out, the first and second rods extend relative to each other and form an angle relative to the first and second slide assemblies.

Owner:KING SLIDE WORKS CO LTD

Cleaning and tool storage assembly

A cleaning and tool storage assembly includes a housing having a base and a lid which is hingedly connected with the base. A vacuum cleaner assembly is disposed within the housing. A handle on the lid may be utilized to retain an electrical power cord. Articles, such as a hose, which are utilized in association with the vacuum cleaner, may be retained on the lid. A tray for holding items may be provided in the base of the housing. The tray may be removable from the housing to provide access to storage space. A cover for a dust bin of the vacuum cleaner may be opened with the tray in the housing.

Owner:ELECTROLUX HOME CARE PRODS

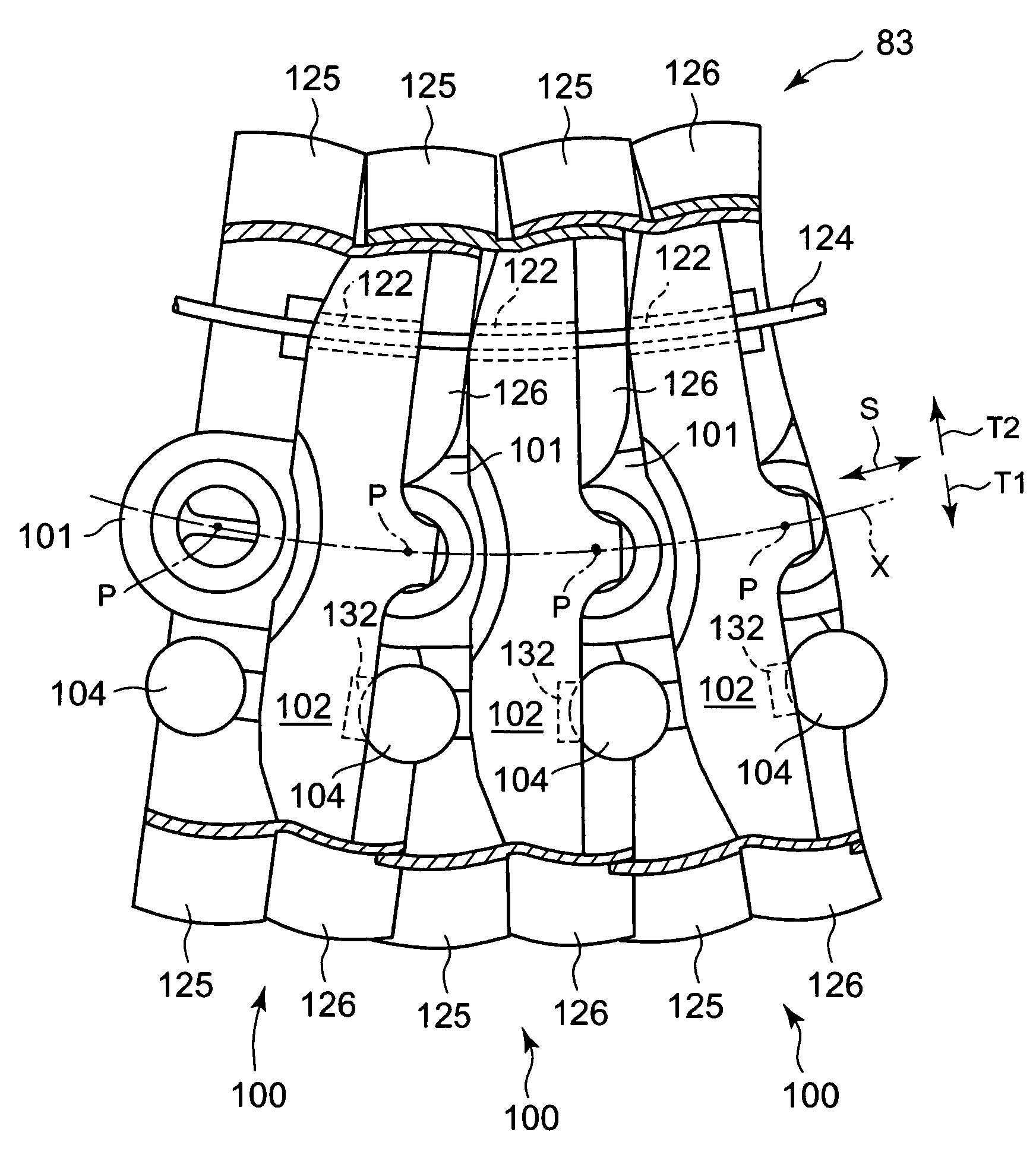

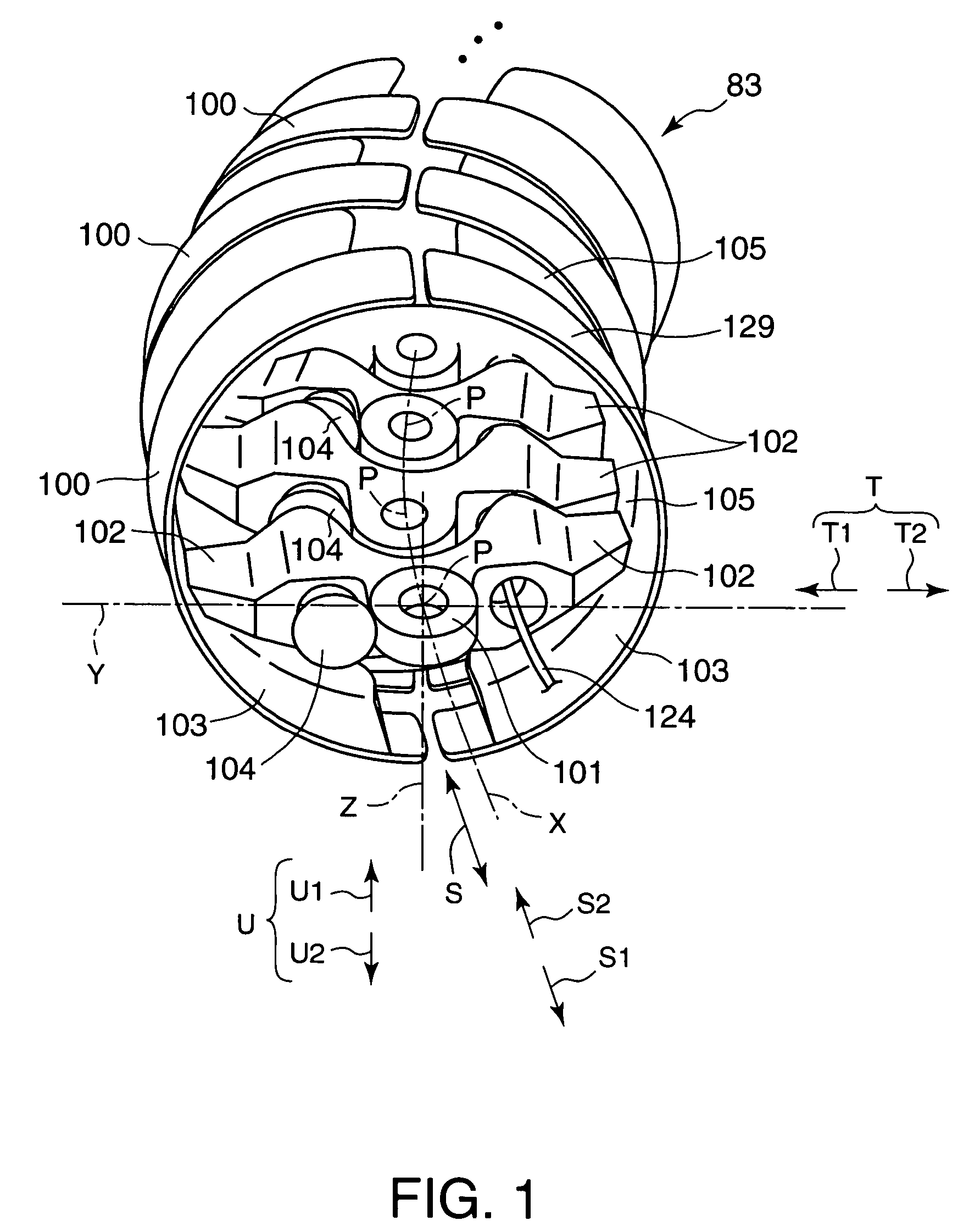

Deformable structure and cable support system

In a deformable structure, connecting parts each of which has a base part are arranged longitudinally so that adjacent connecting parts are connected to each other. Respective first axes of the adjacent connecting parts are inclined to each other in a state that a spacer on one of the two adjacent base parts comes into contact with the other base part. When an external force is exerted on the deformable structure, the spacers restrain the deformable structure from being further curved into a radius of curvature smaller than a predetermined allowable radius of curvature. Most of the external force exerted on the deformable structure is born by the base parts and the spacers so that only a low force acts on the connecting parts. Thus the connecting parts do not break easily so that the deformable structure has a high strength.

Owner:KAWASAKI HEAVY IND LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com