Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Save the recycling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

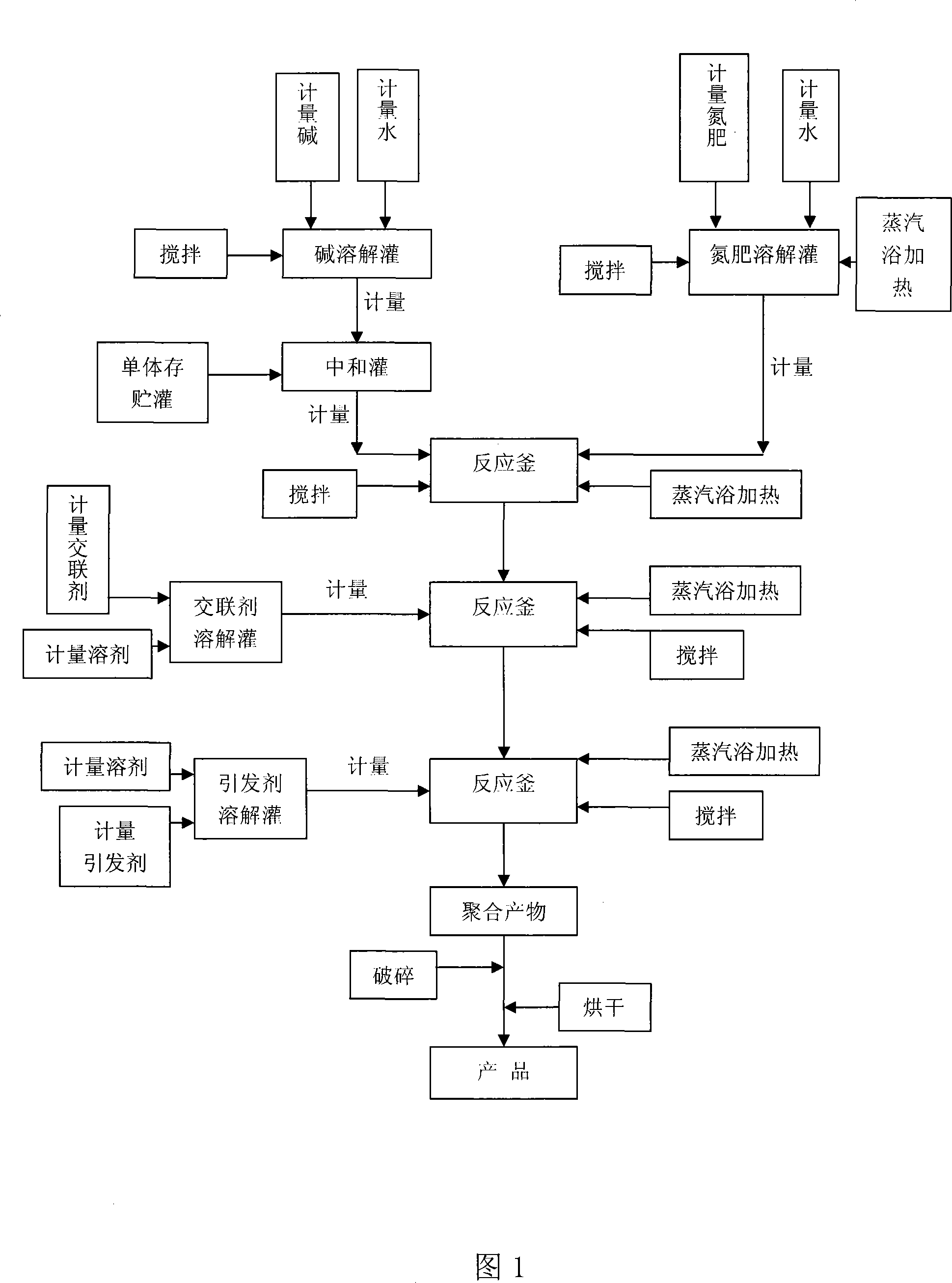

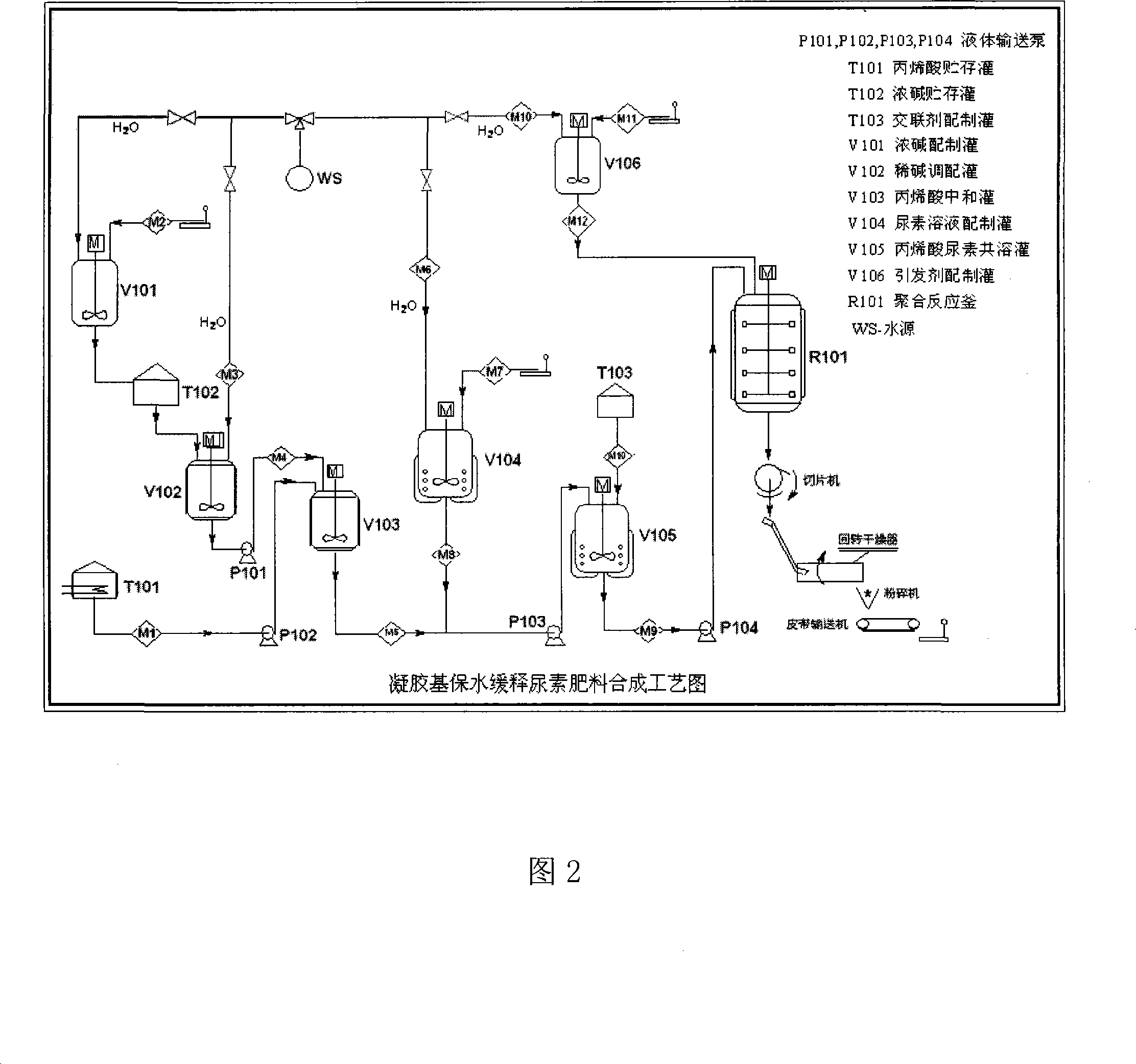

Process for synthesizing gel-based water-holding slow-release carbamide fertilizer and production method

InactiveCN101225009AInnovativeSimple processUrea compound fertilisersFertilizer mixturesGel basedOrganic solvent

The invention discloses a synthetic method for gel-based water-retained slow-release urea fertilizer, mainly comprising the following steps: 1) acrylic monomer is neutralized with 20% potassium hydroxide solution, obtaining a mixed monomer solution with twenty-five percent neutralization degree; 2) the mixed monomer solution is gauged and added into an aqueous urea, forming a polymerization mixed liquid; 3) a cross-bonding agent is added on the condition of heat-preservation stirring, and then a radical initiator is added after agitating the awaiting cross-bonding agent to dissolve; 4) a water gel is generated when the of polymerization is generated on the condition of heat-preservation stirring; 5) the gel-based water-retained slow-release urea fertilizer is crushed, dried, grinded, screened and packed. The synthetic method for gel-based water-retained slow-release urea fertilizer has the advantages of no-use of organic solvent, no solvent recovery problem, simple craft and lower cost.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

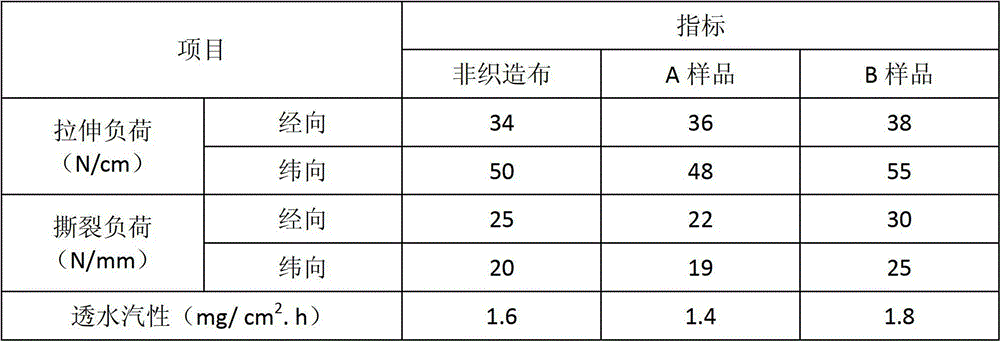

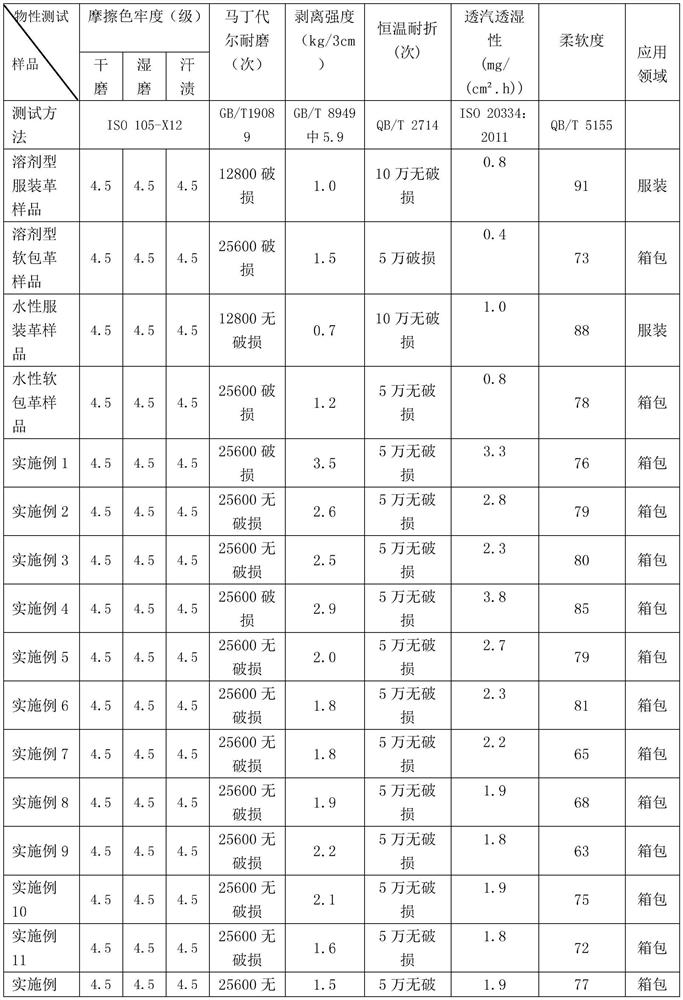

Method for producing aqueous polyurethane synthetic leather for costume by using physically-foamed pore forming coating technology

InactiveCN102425069AImprove hygieneQuality improvementSynthetic resin layered productsTextiles and paperWater vapor permeabilitySolvent based

The invention relates to a method for producing aqueous polyurethane synthetic leather for costume by using a physically-foamed pore forming coating technology. According to the present invention, a physically-foamed polyurethane coating dry film transferring process replaces the original solvent-based polyurethane wet coagulation coating process, such that the problems of pollution and residue of the DMF solvent are solved; with adopting the aqueous polyurethane dry film transferring process to replace the solvent-based polyurethane dry film transferring process, the solvent pollution problem during the production process is eliminated; the synthetic leather for the costume is washed in hot water, the pore forming agent is lixiviated by the hot water, such that the penetrating pores are formed in the aqueous polyurethane coating of the synthetic leather, the water vapor permeability and the air permeability of the synthetic leather for the costume are improved, and the synthetic leather with the good-sanitary property is obtained; with the method, the DMF solvent recovery apparatus and the DMF solvent recovery process are saved, the production cost is reduced, and the technical process is simplified; when the conventional physical properties and the conventional mechanical properties are met, the water vapor permeability of the synthetic leather for the costume is more than or equal to 1.6 mg / cm<2>.h, and the air permeability of the synthetic leather for the costume is more than or equal to 2500 ml / cm<2>.h.

Owner:福建可利得皮革纤维有限公司

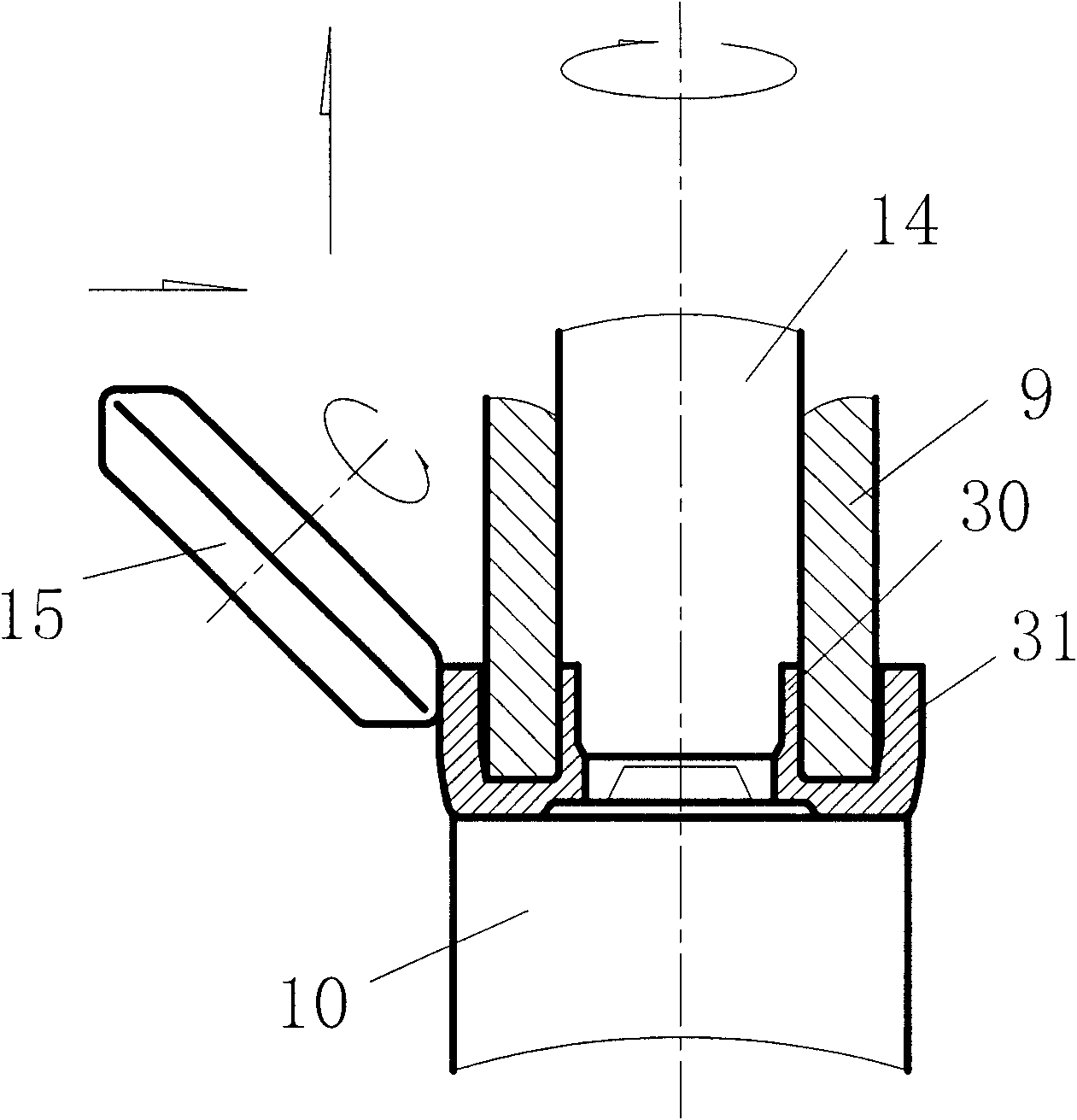

Processing technology of spinning belt pulley with inner and outer lug bosses

The invention relates to a processing technology of a spinning belt pulley with inner and outer lug bosses, which belongs to the field of manufacturing belt pulleys. The processing technology comprises the following steps of: stamping and performing a blank, reprocessing the performed blank and spinning the reprocessed and performed blank, wherein the reprocessing step of the performed blank comprises the following steps of: cold extruding a formed blank A into a performed blank B with a predetermined size; and rolling and forming the performed blank B by a spinning mode to form the performed blank C with inner and outer lug bosses. Compared with the traditional processing technology, the processing technology of the spinning belt pulley with the inner and outer lug bosses has wide source of raw materials, low cost, high production efficiency and low rejection rate, the spinning mode is used for replacing a stamping mode to produce the blank with the inner and outer lug bosses, products are not easy to deform, the dimensions of the product can achieve higher required precision, and an adopted spinning machine has small erosion, low power consumption and convenient maintenance.

Owner:广东港润机电科技有限公司 +1

Production method for waterborne polyurethane synthetic leather wet process impregnated bass

The invention provides a production method for waterborne polyurethane synthetic leather wet process impregnated bass, comprising the following steps of: preparing impregnation liquid by using waterborne polyurethane, filler and water; preparing solidification liquid by mixing a demulsification cross-linking agent with water; saturating a non-woven fabric by the impregnation liquid through an impregnation groove, and extruding some impregnation liquid in the non-woven fabric by a pair of rollers; enabling the non-woven fabric with the impregnation liquid to pass through a solidification groove filled with a coagulating agent to form porous filler by the waterborne polyurethane coagulated by the coagulating agent and the filler, and filling the filler in the non-woven fabric; and washing by water, extruding water and drying to obtain the waterborne polyurethane synthetic leather wet process impregnated bass. The product produced by the invention has the extremely similar microcellular structure, and is better in physical and mechanical properties, water vapor penetration performance, and hand feel characteristic. According to the production method, the solvent pollution problem of DMF (dimethyl formamide) and the product safety problem caused by the residue of the DMF in the production of solvent type polyurethane wet process impregnated bass can be solved.

Owner:FUJIAN KELIDA SYNTHETIC FIBER

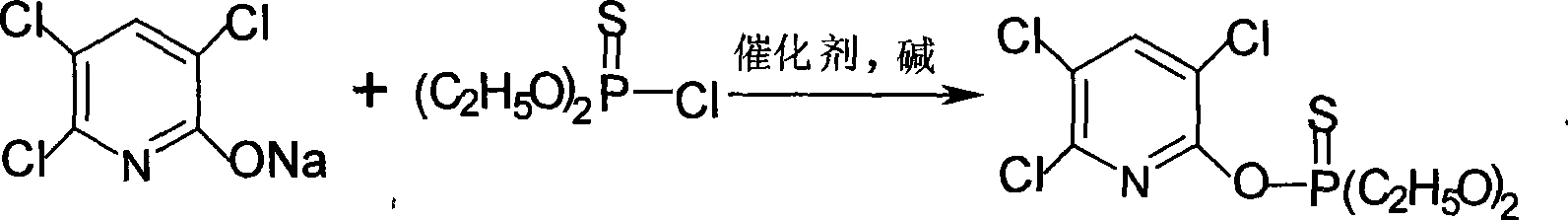

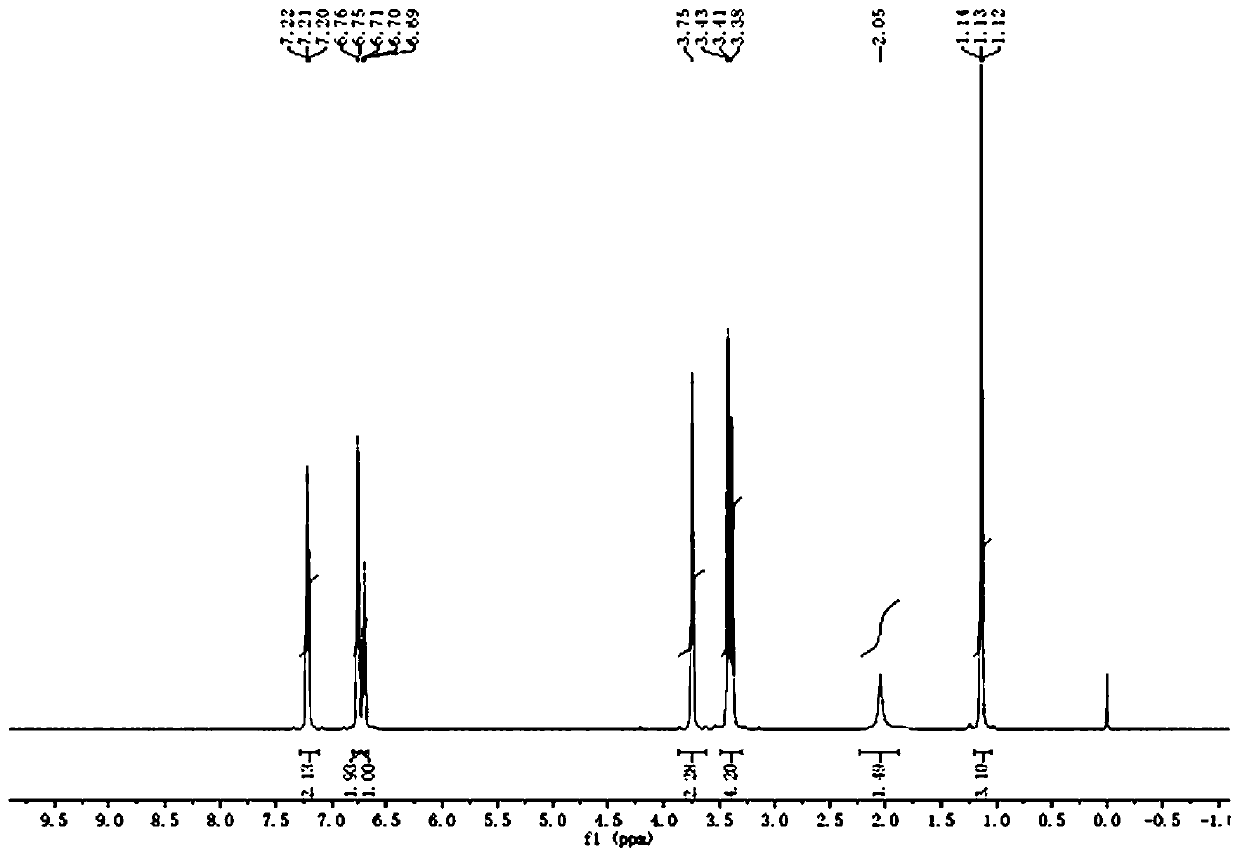

Preparation of O,O-diethyl-O-(3,5,6- trichloro-2-pyridinyl)thiophosphate

InactiveCN101372497ASave the recycling processEasy to operateGroup 5/15 element organic compoundsThiophosphateEthanol

The invention provides a method for preparing O, -O diethyl-O-(3, 5, 6-trichloro-2-pyridyl) thiophosphate, comprising the following steps: O, -O diethyl thiophosphoryl chloride is added into the mixed solution of 3, 5, 6-trichloropyridine-2-ethanol-sodium and water in a dripping way at the temperature of 45-70 DEG C under the condition that a catalytic amount of phase transfer catalyst exists for reaction, and then the target product which is dursban is collected from resultant of reaction; the pH value of a reaction system ranges from 10 to 12, the phase transfer catalyst is a multivariant compound phase transfer catalyst which is formed by 4-dimethylamino naphthyridine and more than one of trialkyl phenmethyl ammonium halide, tetra-allkyl ammonium halide, triethylene diamine or 4-methyl drewamine. The method adopts water as solvent, eliminates the recycling process of organic solvent, is simple and safe to operate, has little waste water, is easy to process and has high yield and product purity.

Owner:SHANGHAI SHENGLIAN CHEM

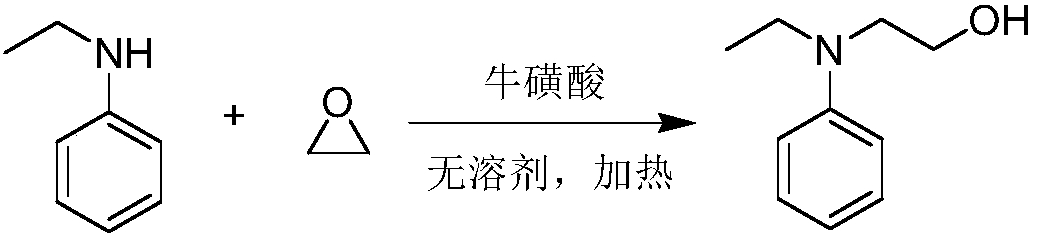

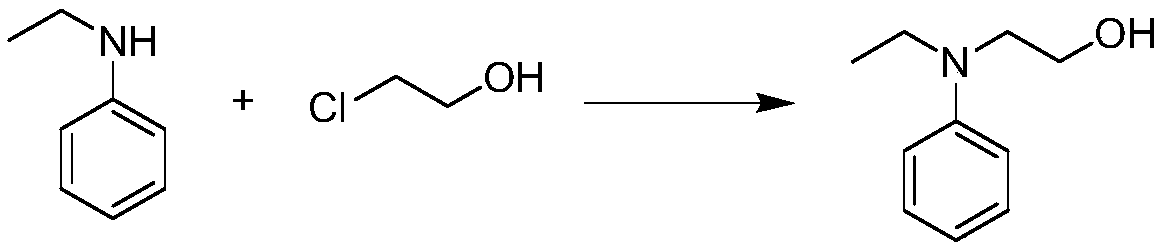

Method for preparing N-ethyl-N-hydroxyethylaniline

InactiveCN108117492AReduce dosageImprove catalytic performanceOrganic compound preparationAmino-hyroxy compound preparationEthylene oxideSolvent

The invention discloses a method for preparing N-ethyl-N-hydroxyethylaniline. The method comprises the following steps: by taking N-ethylaniline and ethylene oxide as raw materials, in the absence ofa solvent, under catalysis of taurine, performing programmed heating, directly synthesizing N-ethyl-N-hydroxyethylaniline, cooling, and discharging, thereby obtaining a finished product. The method iseasy in raw material obtaining, good in atom economy, gentle in reaction condition, green and environment-friendly, simple and efficient and applicable to industrial production.

Owner:JIANGSU YUANDA XIANLE PHARMA

Production method for waterborne polyurethane synthetic leather wet process impregnated bass

The invention provides a production method for waterborne polyurethane synthetic leather wet process impregnated bass, comprising the following steps of: preparing impregnation liquid by using waterborne polyurethane, filler and water; preparing solidification liquid by mixing a demulsification cross-linking agent with water; saturating a non-woven fabric by the impregnation liquid through an impregnation groove, and extruding some impregnation liquid in the non-woven fabric by a pair of rollers; enabling the non-woven fabric with the impregnation liquid to pass through a solidification groove filled with a coagulating agent to form porous filler by the waterborne polyurethane coagulated by the coagulating agent and the filler, and filling the filler in the non-woven fabric; and washing by water, extruding water and drying to obtain the waterborne polyurethane synthetic leather wet process impregnated bass. The product produced by the invention has the extremely similar microcellular structure, and is better in physical and mechanical properties, water vapor penetration performance, and hand feel characteristic. According to the production method, the solvent pollution problem of DMF (dimethyl formamide) and the product safety problem caused by the residue of the DMF in the production of solvent type polyurethane wet process impregnated bass can be solved.

Owner:FUJIAN KELIDA SYNTHETIC FIBER

High-crush-resisting rapid degradation magnesium alloy and preparation method thereof

The invention discloses a high-crush-resisting rapid degradation magnesium alloy and a preparation method thereof. The alloy is prepared from, by mass percent, 5.0-10wt% of Zn, 1.20-6.0wt% of Cu, 1.50-3.0wt% of Ni, 1.50-5.0wt% of Nd, 0.5-1.5wt% of Ca and the balance Mg and the other impurity elements. According to the high-crush-resisting rapid degradation magnesium alloy and the preparation method thereof, Cu, Nd, Ca and other alloy elements are added to improve the crush resistance of a material, and the degradation rate is increased through Cu and Ni. According to the prepared high-crush-resisting rapid degradation magnesium alloy, the corrosion rate in a 3% KC1 solution at the temperature of 25 DEG C can reach 7.4 mg cm<-2>h<-1>, and the corrosion rate in the 3% KC1 solution at the temperature of 93 DEG C can reach 88 mg cm<-2>h<-1>; and high crush resisting strength is achieved, and the high-crush-resisting rapid degradation magnesium alloy and the preparation method thereof are suitable for the field of shale gas extraction with a rapid corrosion requirement.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production method of protein synthetic leather based on salt coagulation and solidification

InactiveCN103015216ASolve pollutionAvoid security issuesTextiles and paperMoisture permeabilityWorking environment

The invention provides a production method of protein synthetic leather based on salt coagulation and solidification. The production method comprises the following steps that (1) an impregnating liquid is prepared, 60-85 parts of water soluble protein and 15-40 parts of anionic stuffing agent by mass are added into a stirring kettle for uniform mixing; (2) a coagulating liquid is prepared, 20-30 parts of coagulation agent, 1-3 parts of cross-linking agent, 3-8 parts of formic acid and 50-66 parts of water by mass are added into the stirring kettle for stirring and mixing; (3) a protein / nonwoven cloth complex is prepared; nonwoven cloth passes through an impregnating groove containing the impregnating liquid; the nonwoven cloth with the impregnating liquid passes through a coagulating groove with the coagulating liquid; and the post-treatment is conducted. According to the production method, a solvent DMF (dimethyl formamide) is not required in the whole production process; a production working environment is safe; the environmental pollution is not caused; and the produced protein synthetic leather has good physical and mechanical properties, breathability, moisture permeability, moisture absorption and removal properties and dyeing property.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing lithium carbonate through thermal reduction of spodumene

InactiveCN113003590AAvoid using effectsReduce usageCement productionLithium carbonates/bicarbonatesMetallic lithiumLithium oxide

The invention relates to the technical field of lithium carbonate production, in particular to a method for preparing lithium carbonate through thermal reduction by taking alpha-type spodumene as a raw material. The method comprises the following steps: mixing alpha-type spodumene concentrate powder with a reducing agent and a flux inhibitor, carrying out reducing in a reduction furnace under vacuum and high-temperature conditions to reduce lithium in spodumene into metal lithium steam, and condensing to obtain metal lithium and reduced spodumene slag containing the metal lithium and lithium oxide; leaching spodumene slag containing metal lithium and lithium oxide with water to obtain leached slag and slurry; and precipitating the leaching residues and the slurry, removing calcium, filtering to obtain a filtrate which is a lithium carbonate raw material solution, and concentrating and precipitating lithium to produce a battery-grade or high-purity lithium carbonate product. The new method is a green and environment-friendly technology, production of high-risk chemical chlorine and use of sulfuric acid in the prior art are avoided, and the environmental load is small; environmental pollution and solid waste emission are avoided, the environmental benefit is high, and the safety is high.

Owner:SICHUAN UNION SHINE NEW ENERGY SCI TECH CO LTD

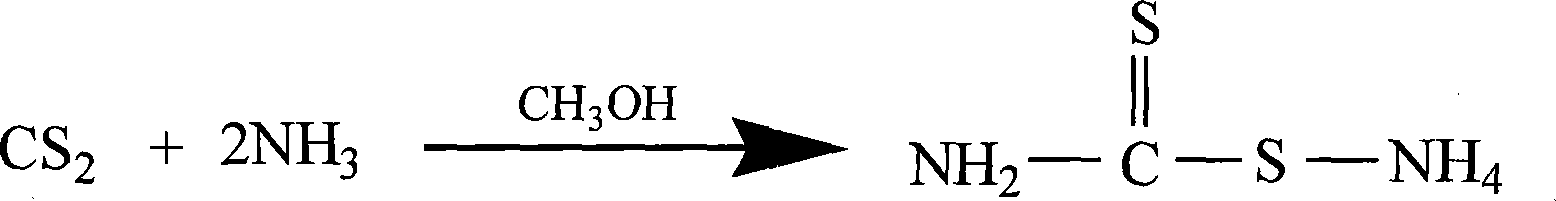

Prepn process of 2-thiothiazolidone

The preparation process of 2-thiothiazoliidone includes the steps of: forming saturated ammonia-alcohol solution, reaction of ammonia and carbon bisulfide to produce ammonium dithiocarbamate, further reaction with chloracetate to obtain clear condensate liquid, mixing with acid solution through stirring to react to produce crystal, separating and purifying to obtain product. The present invention uses ammonia-alcohol solution, rather than ether, as the solvent and pure water, rather than methanol, for purifying coarse product, and has lowered production cost, improved work environment, environment friendship and other advantages.

Owner:XILONG SCI CO LTD

Separation and purification method of dodecanedioic acid

InactiveCN1159280CHigh yieldReduce manufacturing costOrganic compound preparationCarboxylic compound separation/purificationEthylenediamineAcetic acid

The separation and purification method of dodecanedioic acid includes the following steps: decolouring the fermenting liquor in which the organism is fermented with active carbon, filtering, adding chitosan and ethylene diamine tetraacetic acid into the filtrate, making them combine with impurity being in fermenting liquor to form suspended matter, microfiltering to remove the suspended matter, ultrafiltering and further removing impurity to make purification, then adding acid in the filtrate to make dodecanedioic acid precipitate, filtering and drying so as to obtain the dodecanedioic acid product.

Owner:SHANGHAI RES INST OF CHEM IND

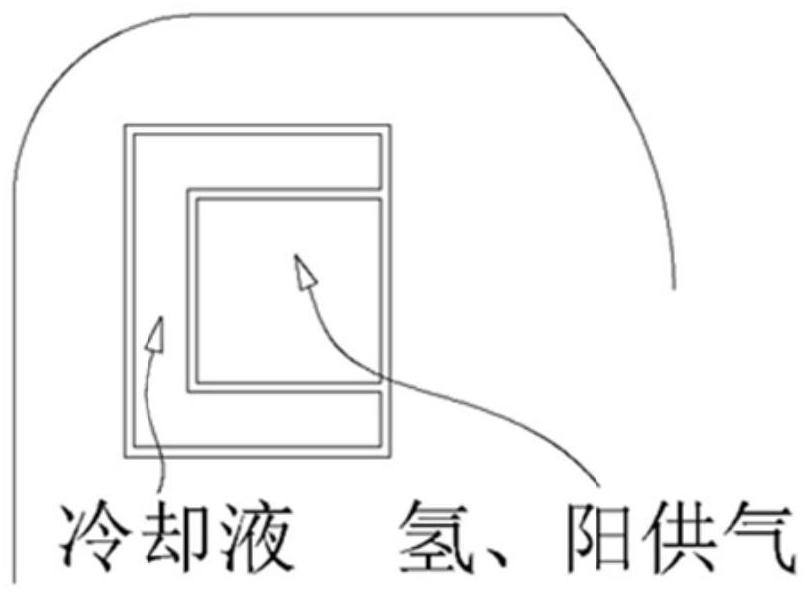

Novel fuel cell stack with inlet gas multistage self-preheating function and control method

The invention discloses a novel fuel cell stack with inlet gas multistage self-preheating and a control method, the novel fuel cell stack comprises an inlet manifold, the inlet manifold comprises an anode gas inlet flow channel and a cathode gas inlet flow channel which are respectively arranged at two sides in the stack; a cooling liquid outlet flow channel is arranged on the periphery of the air inlet manifold in a surrounding mode, and a sleeve type air inlet manifold is formed. And the cooling liquid and the air inlet fluid flow in opposite directions to form counter-flow type convection heat exchange. The hydrogen and oxygen inlet gas is subjected to multi-stage preheating in the galvanic pile, the inlet gas temperature preheating target under different working conditions can be achieved, devices and power consumption required for heating the inlet gas outside the galvanic pile are reduced, a fuel cell system is more portable, and the total efficiency of a fuel cell is improved through step-by-step utilization of waste heat of cooling liquid.

Owner:SHANDONG UNIV

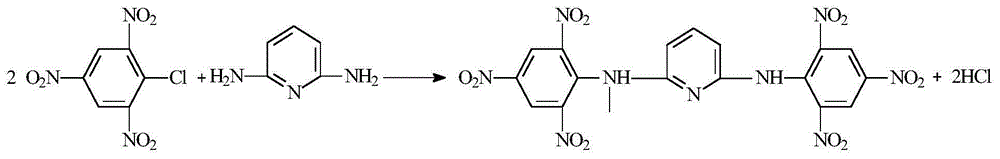

Method for preparing 2, 6-bis-(picrylamino) pyridine

InactiveCN103980190ASave the recycling processReduce pollutionOrganic chemistryOrganic solventPyridine

The invention relates to the technical filed of preparation of organic intermediates, and in particular relates to a method for preparing 2, 6-bis-(picrylamino) pyridine. The method comprises the following steps: with picrylamino and 2, 6-diaminopyridine as raw materials, water as a medium, and NaHCO3 as a reaction promoter, reacting for 2 to 6 hours at the temperature of 83 to 90 DEG C in the presence of a phase transfer catalyst; and filtering, washing by hot water and recrystallizing by methanol to obtain the 2, 6-bis-(picrylamino) pyridine. According to the method, single water is used as the reaction medium to replace an organic solvent adopted by an existing technology, and the phase transfer catalyst is adopted to reduce interfacial tension and improve activity of the reaction; the picrylamino and the 2, 6-diaminopyridine are reacted under the condition being close to a theoretical material ratio so as to reduce consumption and cost of raw materials; the solvent recovery and separation process is simplified, and the pollution to the environment is reduced.

Owner:ZHONGBEI UNIV

Method for producing aqueous polyurethane synthetic leather for costume by using physically-foamed pore forming coating technology

InactiveCN102425069BImprove hygieneQuality improvementSynthetic resin layered productsTextiles and paperWater vapor permeabilitySolvent based

The invention relates to a method for producing aqueous polyurethane synthetic leather for costume by using a physically-foamed pore forming coating technology. According to the present invention, a physically-foamed polyurethane coating dry film transferring process replaces the original solvent-based polyurethane wet coagulation coating process, such that the problems of pollution and residue of the DMF solvent are solved; with adopting the aqueous polyurethane dry film transferring process to replace the solvent-based polyurethane dry film transferring process, the solvent pollution problem during the production process is eliminated; the synthetic leather for the costume is washed in hot water, the pore forming agent is lixiviated by the hot water, such that the penetrating pores are formed in the aqueous polyurethane coating of the synthetic leather, the water vapor permeability and the air permeability of the synthetic leather for the costume are improved, and the synthetic leather with the good-sanitary property is obtained; with the method, the DMF solvent recovery apparatus and the DMF solvent recovery process are saved, the production cost is reduced, and the technical process is simplified; when the conventional physical properties and the conventional mechanical properties are met, the water vapor permeability of the synthetic leather for the costume is more than or equal to 1.6 mg / cm<2>.h, and the air permeability of the synthetic leather for the costume is more than or equal to 2500 ml / cm<2>.h.

Owner:福建可利得皮革纤维有限公司

Environment-friendly water-based synthetic leather and production process thereof

PendingCN114875686AEfficient reuseSave the recycling processTextile/flexible product manufactureTextiles and paperSlurryDomestic waste

The invention discloses environment-friendly water-based synthetic leather which sequentially comprises a surface layer, a middle layer and a base layer from outside to inside, the surface layer is obtained by coating water-based slag surface layer slurry; the middle layer is a one-layer bonding layer or two-layer foaming layers or a one-layer foaming layer and a one-layer bonding layer; the foaming layer is obtained by coating a water-based slag foaming layer; the bonding layer is obtained by coating water-based slag bonding layer slurry; the water-based residue is prepared by grinding coffee residues, dry flower residues and other domestic waste residues through low-temperature liquid nitrogen, adding water-based polyurethane resin and then carrying out high-speed shearing dispersion. One of the purposes of the invention is to provide the environment-friendly water-based synthetic leather which can effectively and repeatedly utilize waste residues in life and has no potential chemical hazard to a user, and the other purpose of the invention is to provide the production process of the environment-friendly water-based synthetic leather.

Owner:浙江嘉柯新材料科技有限公司

A method for comprehensive recovery and utilization of vanadium-titanium series denitrification waste catalyst

ActiveCN107904403BImprove recycling efficiencySimultaneous recycling possibleProcess efficiency improvementSlagTitanium nitride

The invention discloses a method for comprehensively recycling a vanadium-titanium series denitration spent catalyst. The spent catalyst and sodium carbonate are mixed and subjected to high-temperature roasting, then obtained high-temperature melt is subjected to water quenching, and a glass body is manufactured; the glass body is subjected to fine grinding and then water leaching, and filter liquid and filter slag are obtained after filtering; and the filter liquid is used for extracting vanadium oxide, tungsten oxide and molybdenum oxide, and the filter slag is used for preparing titanium dioxide. By means of the method, valuable elements in the spent catalyst are completely recycled, in addition, the obtained product can be directly returned to be used for preparing of the denitration catalyst, various elements can be recycled at the same time, and especially, the titanium element can be recycled. By means of the method, a titanium dioxide product can be directly obtained finally, the purity of the titanium dioxide product can reach 99.0% or above, the process of sulfuric acid method recycling is omitted, and the method has the beneficial effects that the technology is environment-friendly, the comprehensive recycling cost is low, and the product value is high.

Owner:钢研晟华科技股份有限公司

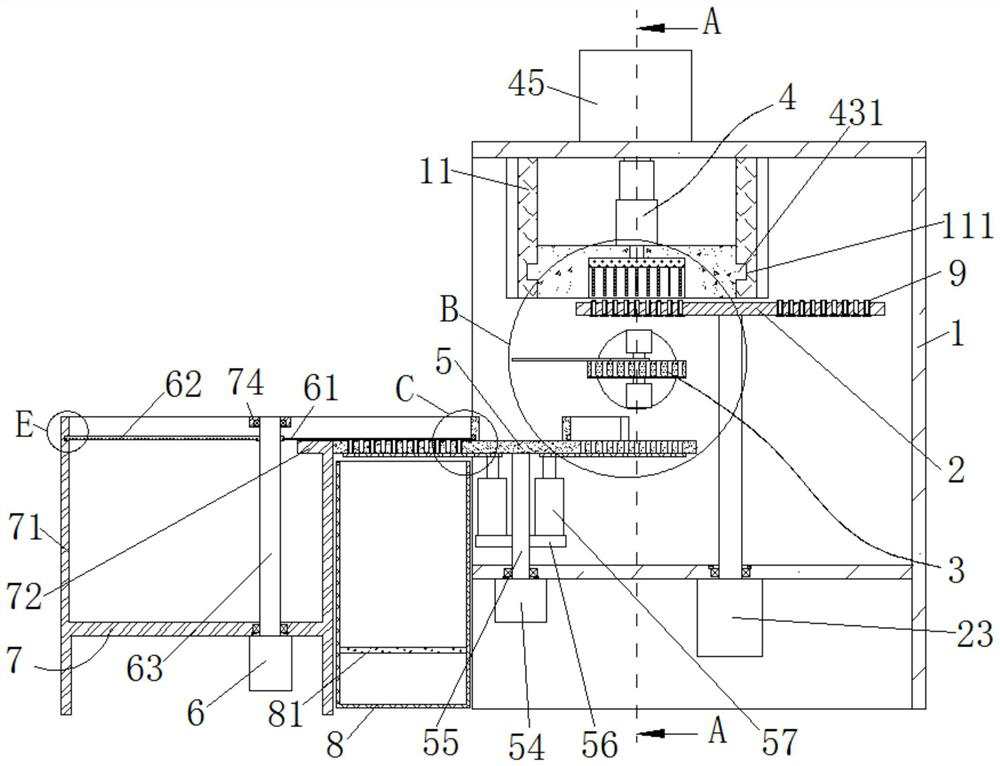

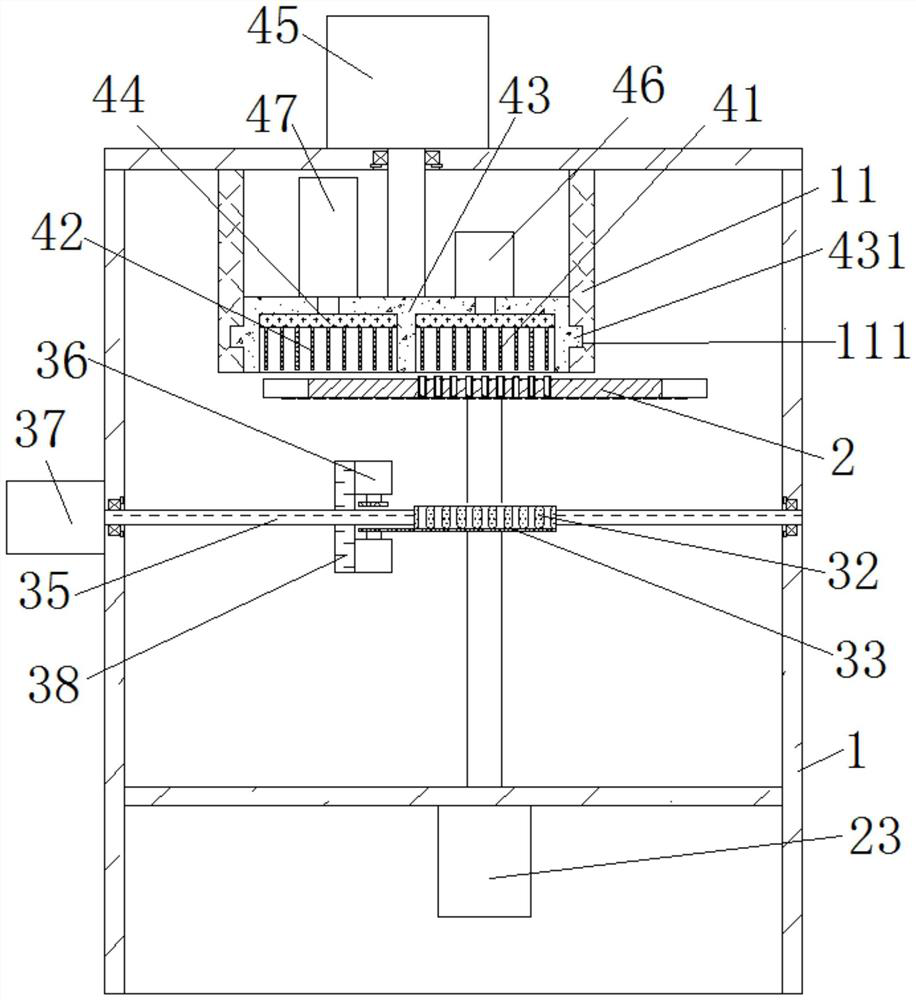

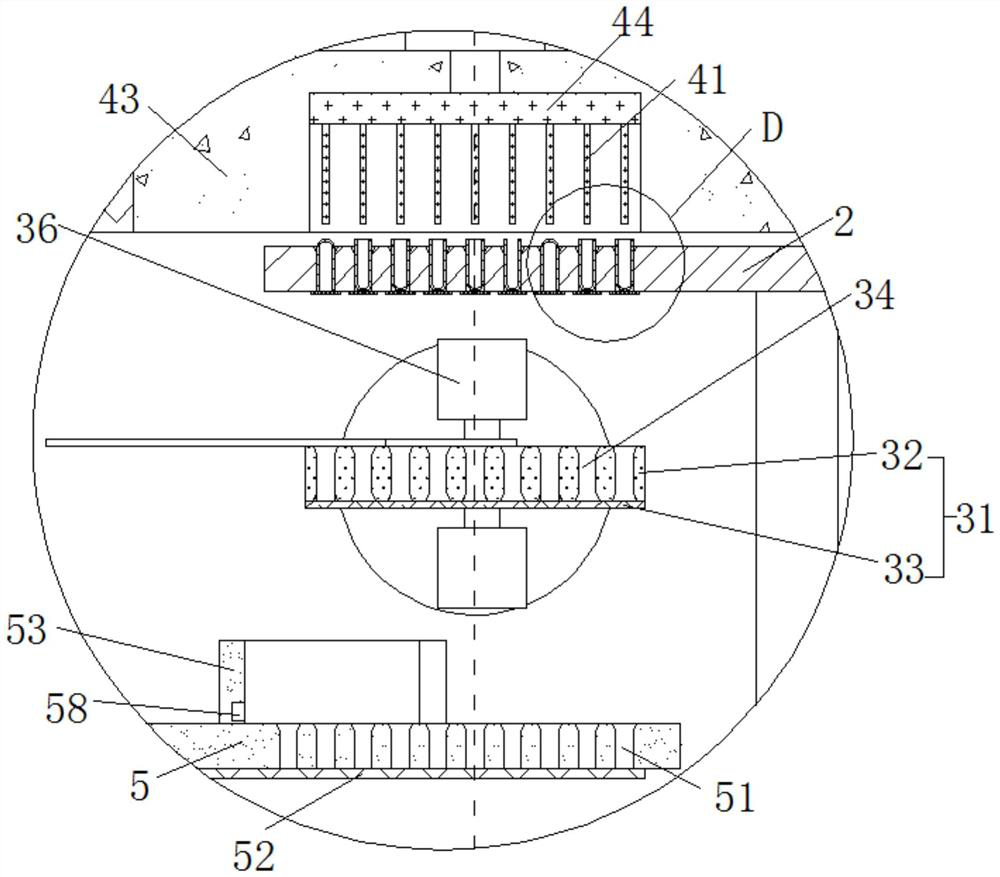

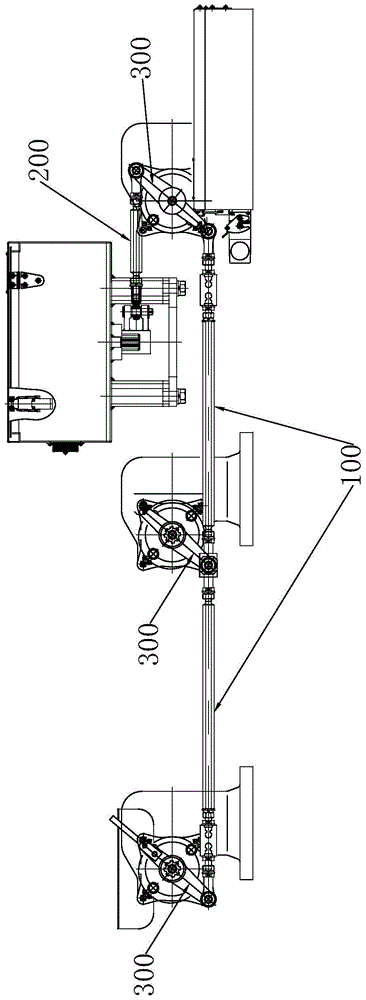

Material cutting system for empty capsule production

ActiveCN114393621ASave the recycling processEnsure blanking full hole rateMetal working apparatusConveyor partsEngineeringMechanical engineering

The invention discloses a material cutting system for empty capsule production, which comprises a rack, a sorting device and a cutting device, the sorting device comprises an index plate capable of gradually and circumferentially rotating, a material turning mechanism and a material ejecting mechanism, and a plurality of groups of material placing holes for placing capsule shells are circumferentially distributed in the index plate; the material ejecting mechanism comprises a first ejector pin set and a second ejector pin set which can synchronously and horizontally rotate by 180 degrees, the cutting device comprises a transferring disc capable of rotating by 180 degrees and a cutting knife capable of rotating in the circumferential direction, the first ejector pin set is used for ejecting inverted capsule shells in the material containing holes to fall to the material overturning mechanism, and the material overturning mechanism is used for overturning the inverted capsule shells to be upright. The second ejector pin group is used for ejecting and conveying the capsule shells which are positively arranged in the material placing hole and the positively arranged capsule shells in the material turning mechanism to fall to the transfer disc; and the transfer disc is used for conveying the capsule shells to a cutting position so as to be cut by the cutting knife. The capsule cutting device is beneficial to improving the cutting yield, simplifying the cutting procedure and greatly improving the capsule production efficiency.

Owner:浙江绿健胶囊有限公司

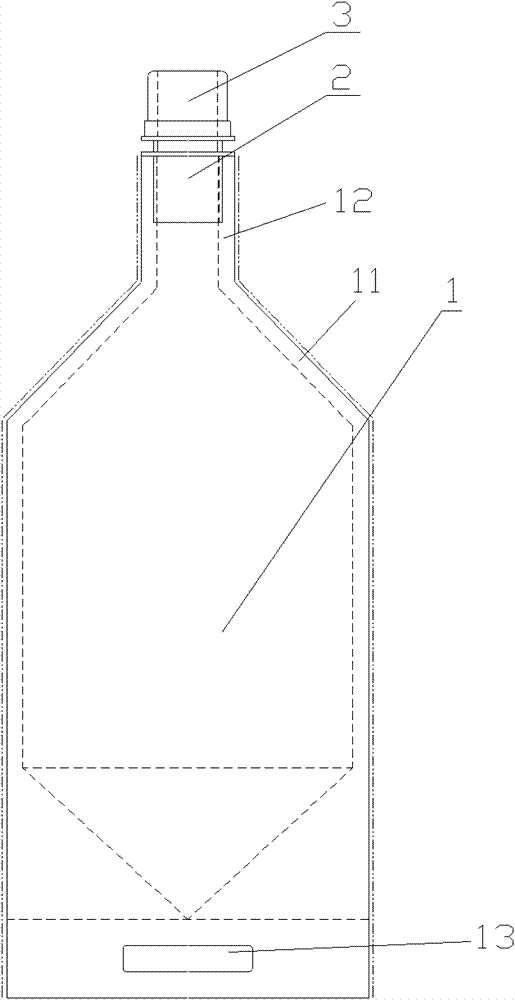

Disposable water bag and processing method thereof

InactiveCN102502055BImprove sealingHigh strengthSynthetic resin layered productsBagsCompound aLeaking water

The invention relates to a water accommodating tool, and provides a disposable water bag, which can prevent a water body in a bucket from being influenced by the outside environment, and a processing method for the disposable water bag. The disposable water bag is provided with a bag body, a bag plug and a plug cap, wherein the bag body is provided with an outer layer, a middle layer and an inner layer. The processing method comprises the following steps of: compounding a polyethylene terephthalate (PET) film and a protactinium (PA) film by glue, and solidifying the compound at constant temperature to obtain a PET and PA compound film; compounding the PET and PA compound film and a polyethylene (PE) film by glue, and solidifying to obtain a PET, PA and PE compound film; making a bag by using the compound film by a bag making machine to form the bag body; performing injection molding to make the bag plug, and performing secondary injection molding on the outer wall at the lower end of the bag plug to form a compound layer; thermally adhering the bottleneck of the bag opening of the bag body to the outer wall at the lower end of the bag plug; filling water, sealing compactly, and detecting whether the water bag leaks water by using a pressure machine; performing injection molding on a threaded body and a movable plug of the plug cap, assembling the threaded body and the movable plug to form a whole, and arranging a sealing gasket; and folding the disposable water bag, putting into a packaging box, and matching the plug cap.

Owner:厦门正兴宏业印刷有限公司

A kind of preparation method of catalyst and method for catalytic preparation of 2,2-bipyridine

ActiveCN105820111BReduce lossesReduce manufacturing difficultyOrganic chemistryMoistureCobalt(II) hydroxide

The invention discloses a preparation method of a catalyst and belongs to the field of preparation and application of catalysts. The preparation method comprises the following steps of: a) in the presence of inert gas, mixing acetylacetone, cobalt hydroxide, benzene and / or benzene derivative, then distilling moisture until the moisture content of reflux is less than 300ppm, so as to obtain a solution A containing cobalt acetylacetonate, and cooling to the temperature below -10 DEG C for later use; b) in the presence of inert gas, mixing cyclopentadiene, 1,5-cyclooctadiene, benzene and / or benzene derivative, cooling to the temperature below -10 DG C, adding triethyl aluminum, and uniformly mixing, so as to obtain a solution B is obtained; and c) slowly adding the solution B into the solution A at the temperature below 0 DEG C, stirring, heating to 25 DEG C, reacting for 3-5 hours, and filtering, wherein the obtained filtrate is the catalyst benzene and / or benzene derivative solution of 1,5-cyclooctadiene cyclopentadienyl cobalt. The invention also discloses a method for preparing 2,2-dipyridyl by utilizing the catalyst.

Owner:HEBI SAIKE CHEM ENG CO LTD

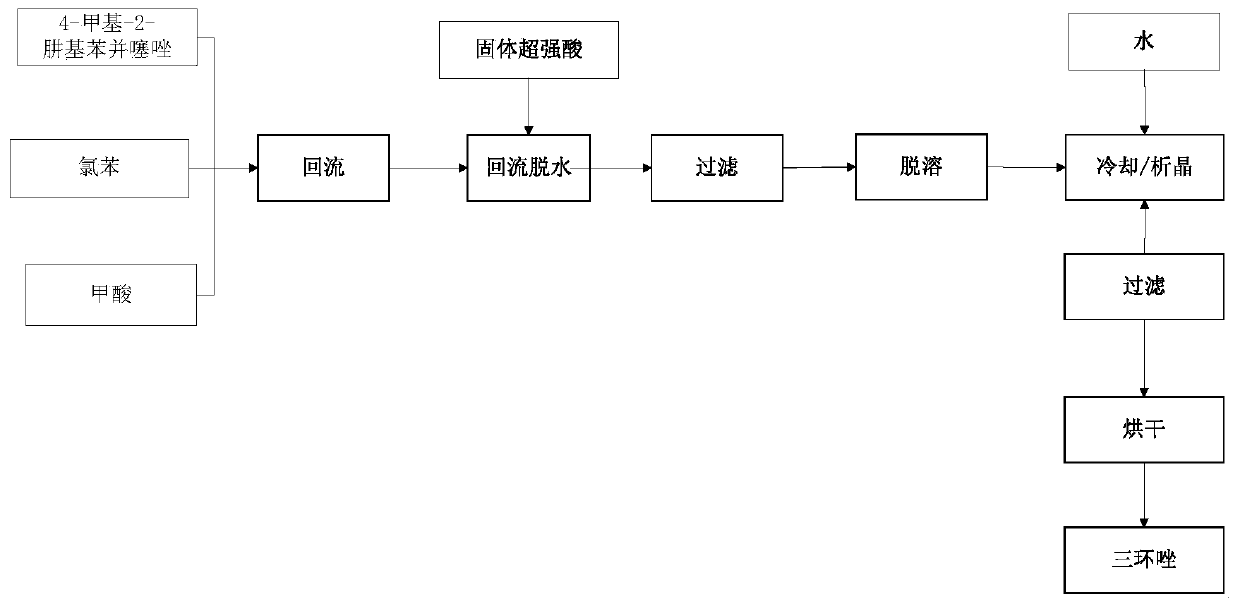

A kind of production technology that uses solid superacid to synthesize tricyclazole

Owner:浙江禾本科技股份有限公司

A method for online adjustment of gas-insulated switch station knife switch

ActiveCN104505755BEasy online adjustment methodOnline adjustment method is reliableSwitchgearThree-phaseSwitchgear

The invention discloses an on-line adjustment method for a switch of a gas insulated switchgear station. The method comprises the following steps of S1, using a multimeter to respectively measure conduction situations of three-phase contacts (A, B and C) in the switch so as to provide display for the on and the off of the switch; S2, inserting a rocker handle into a drive hole in a drive box of the switch, using the rocker handle to switch off the switch by a rocking manner, and manually rocking each linkage rod shaft corresponding to each phase contact outside the switch to a switch-off mechanical limit node; S3, using the rocker handle to switch on the switch by the rocking manner, recording the number of turns of the rocker handle when each linkage rod shaft passes through each node, comparing the recorded number of turns with the preset standard number of turns, if the recorded number of turns meets the requirement of the standard number of turns, finishing the adjustment; if the recorded number of turns does not meet the requirement of the standard number of turns, adjusting according to S4. With the application of the technical scheme, the problems of non-synchronism of the switches with same type, and the matching of electric limit nodes and the mechanical limit nodes are solved.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

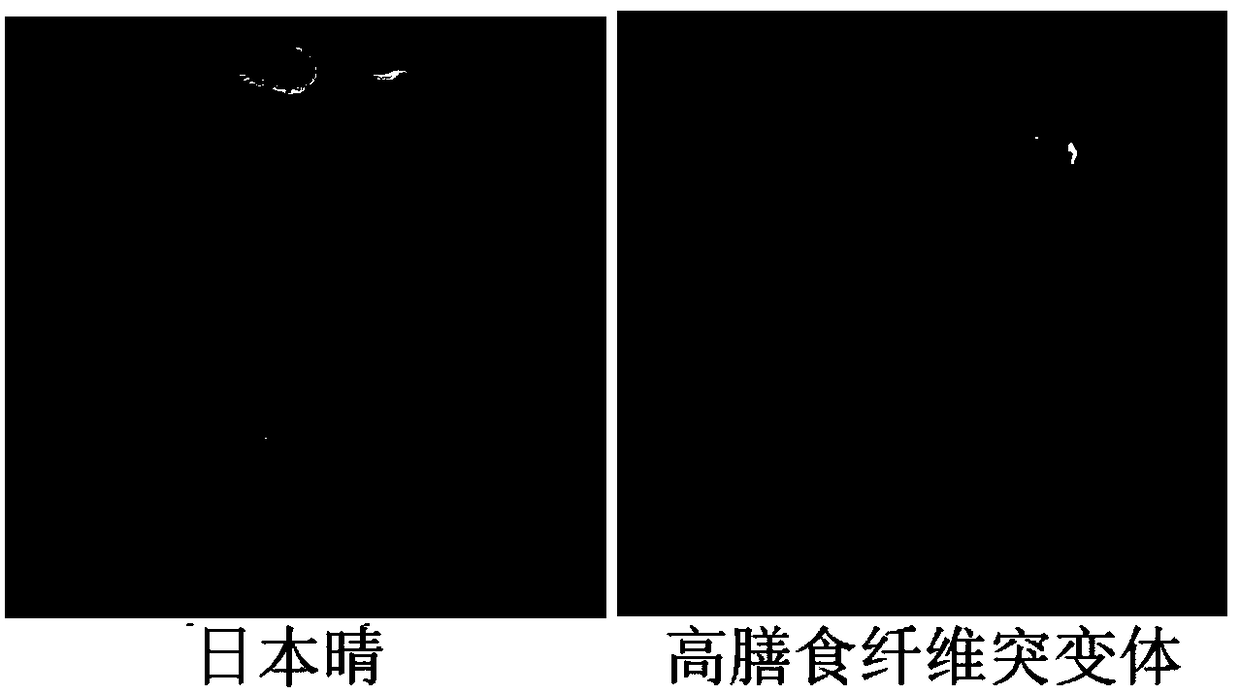

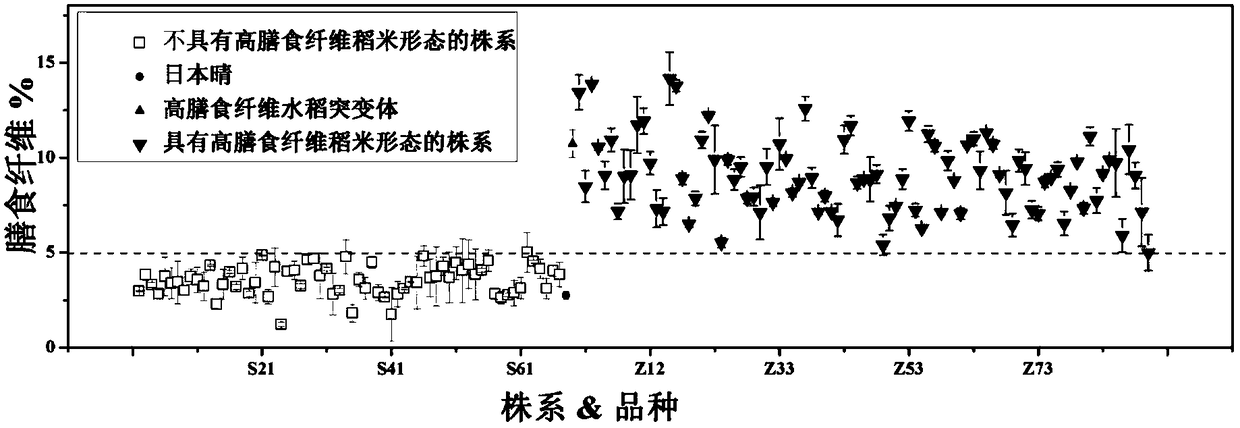

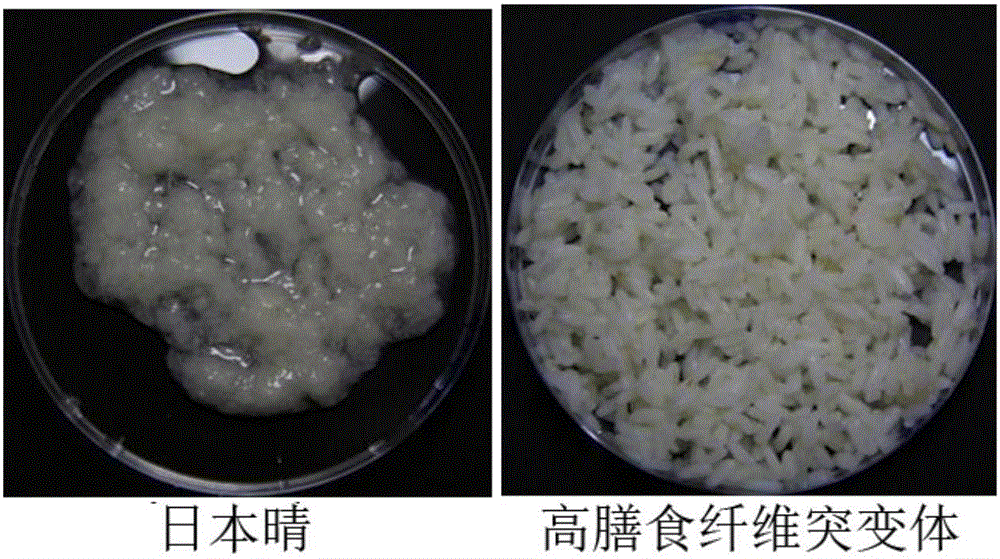

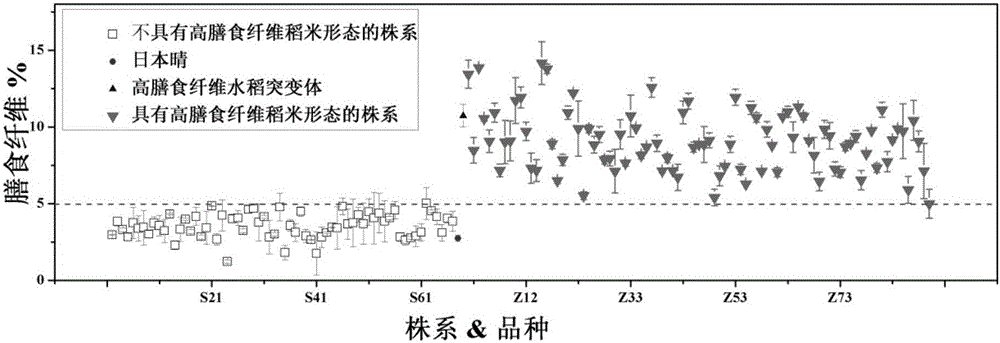

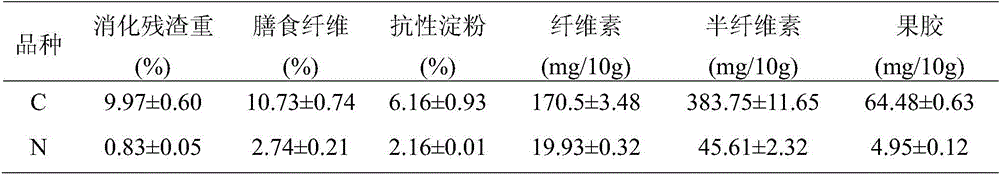

A rapid determination method for rice with high dietary fiber

ActiveCN106198544BSimple methodEfficient methodPreparing sample for investigationMaterial analysis by optical meansFiberAmylase

The invention discloses a method for rapidly determining high dietary fiber rice. The method comprises the following steps: (1) taking polished rice grains and cooking; (2) sequentially removing fat, protein and starch in the cooked rice grains by organic solvent extraction, protease hydrolysis and amylase hydrolysis to obtain residue; (3) by observing the form of the residue with the naked eyes, determining that the residue which can retain the intact grain form is high dietary fiber rice, and the residue which becomes white loose floccules without a grain structure is low dietary fiber rice, wherein the dietary fiber content of the high dietary fiber rice is more than or equal to 5 percent. The cooked polished rice grains are taken as a study object, the fat, the protein and the starch in the rice grains are removed by a relatively mild treatment method, and the content of the dietary fiber in the rice is determined by the appearance form of the rice grains; the method not only is simple and efficient, but also the results are accurate.

Owner:ZHEJIANG UNIV

Production process for synthesizing tricyclazole by using solid super acid

The invention discloses a production process for synthesizing tricyclazole by using a solid super acid. The process takes an intermediate 4-methyl-2-hydrazinobenzothiazole as a raw material, formic acid as a ring-closing agent, chlorobenzene as a solvent, and the solid super acid as a catalyst for synthesizing the tricyclazole, wherein the solid super acid is perfluorosulfonic acid resin. The process comprises the following steps: mixing 4-methyl-2-hydrazinobenzothiazole with chlorobenzene, then adding formic acid, conducting heating for refluxing until the 4-methyl-2-hydrazinobenzothiazole iscompletely converted into an oximido intermediate; then adding the solid super acid, conducting refluxing for dehydrating, when the reaction reaches the end point, filtering out the solid super acidwhile the system is hot, then removing the solvent from the mother liquor, adding water for crystallization, conducting cooling, filtering, water washing and drying to obtain the tricyclazole. The production process disclosed by the invention creatively introduces the solid super acid as the catalyst, and uses a slight excess of formic acid to efficiently synthesize the tricyclazole, thereby increasing the utilization rate of formic acid from 10% to 70% or more, and greatly improving the utilization rate of formic acid.

Owner:浙江禾本科技股份有限公司

Method for rapidly determining high dietary fiber rice

ActiveCN106198544ASimple methodEfficient methodPreparing sample for investigationMaterial analysis by optical meansFiberAmylase

The invention discloses a method for rapidly determining high dietary fiber rice. The method comprises the following steps: (1) taking polished rice grains and cooking; (2) sequentially removing fat, protein and starch in the cooked rice grains by organic solvent extraction, protease hydrolysis and amylase hydrolysis to obtain residue; (3) by observing the form of the residue with the naked eyes, determining that the residue which can retain the intact grain form is high dietary fiber rice, and the residue which becomes white loose floccules without a grain structure is low dietary fiber rice, wherein the dietary fiber content of the high dietary fiber rice is more than or equal to 5 percent. The cooked polished rice grains are taken as a study object, the fat, the protein and the starch in the rice grains are removed by a relatively mild treatment method, and the content of the dietary fiber in the rice is determined by the appearance form of the rice grains; the method not only is simple and efficient, but also the results are accurate.

Owner:ZHEJIANG UNIV

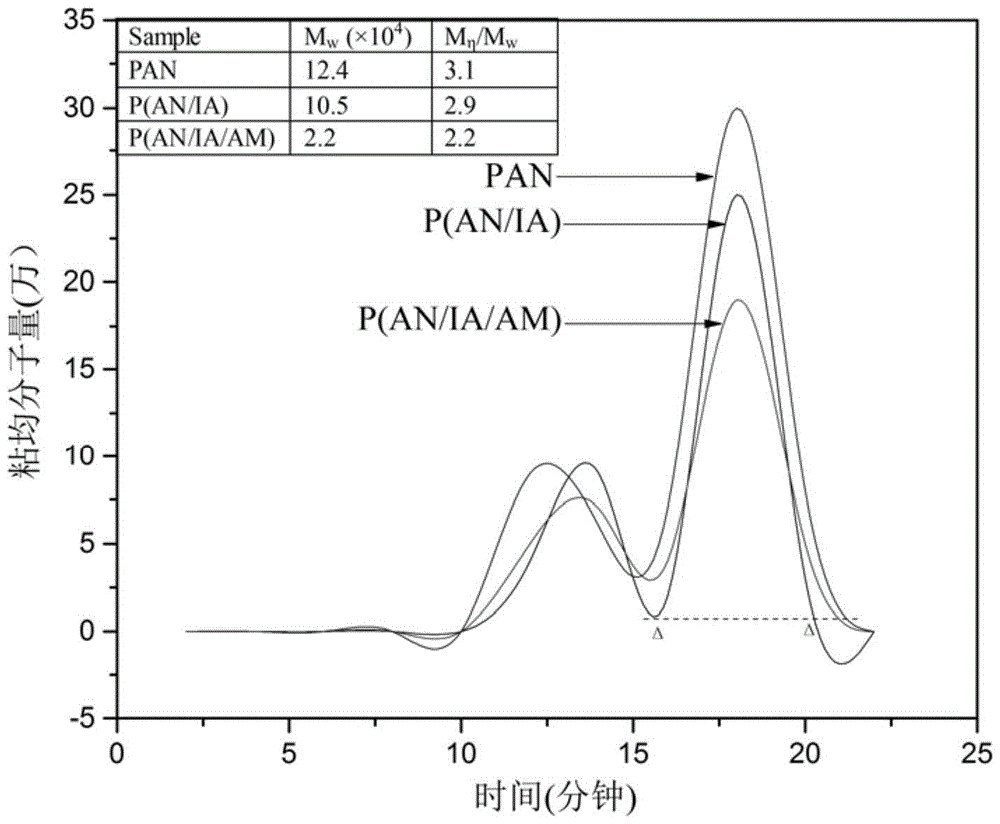

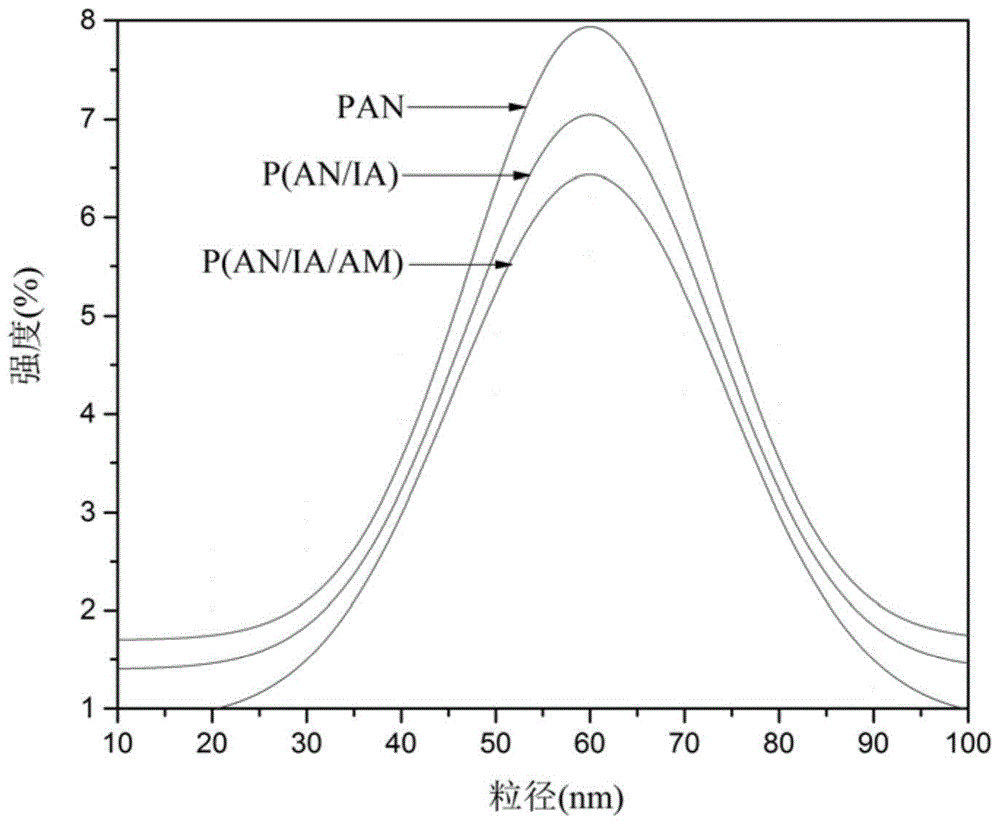

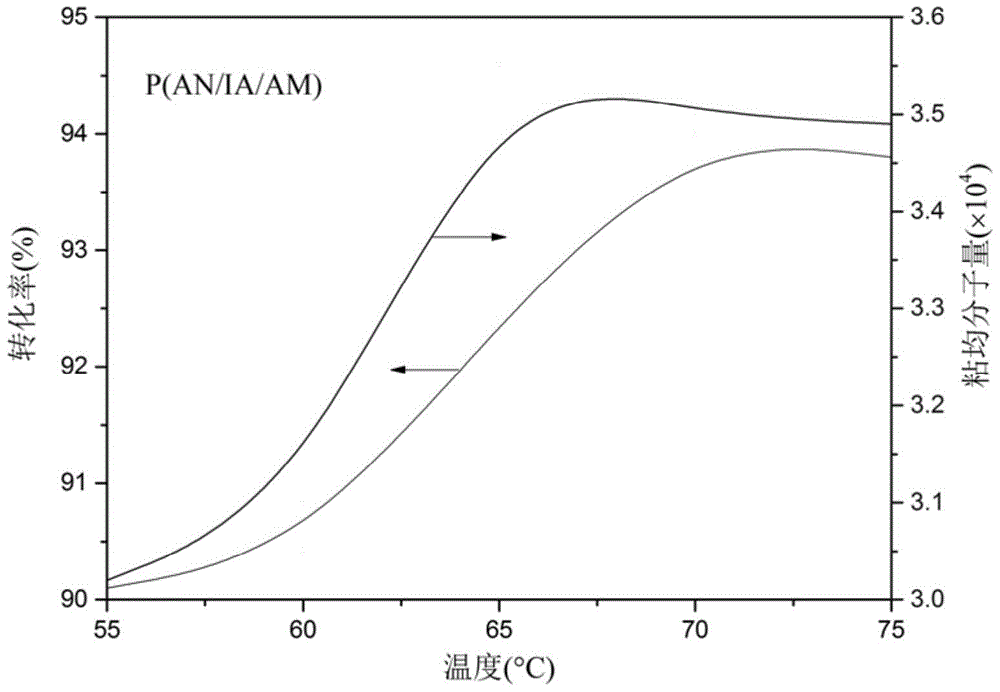

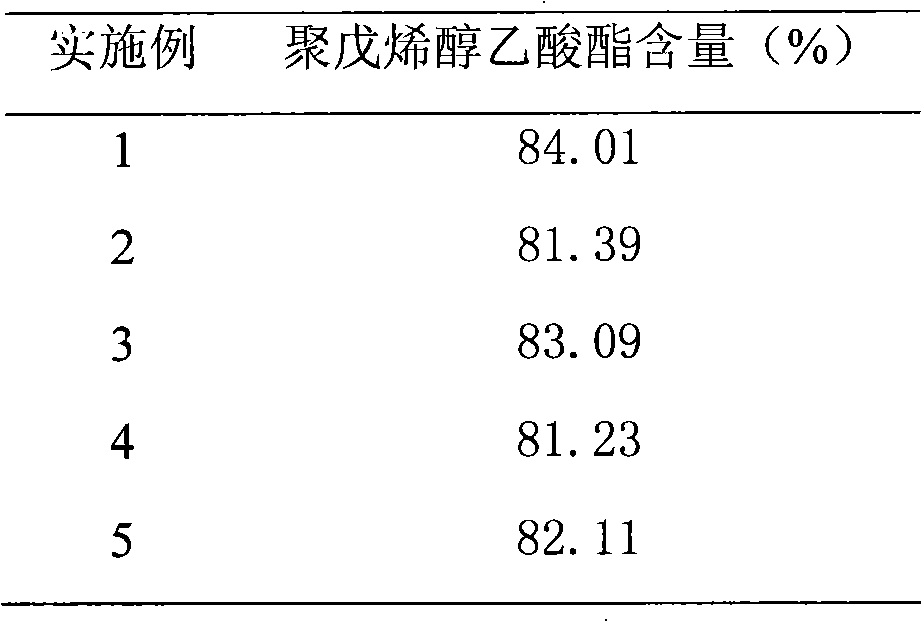

A kind of preparation method of ternary polyacrylonitrile copolymer for carbon fiber precursor

InactiveCN104693348BEasy to rule outPolymerization temperature is easy to controlFibre chemical featuresCarbon fibersPolymer science

The invention relates to a method for preparing a ternary polyacrylonitrile copolymer applicable to a carbon fiber precursor; the method comprises the steps: under the protection of nitrogen gas, mixing acrylonitrile, itaconic acid, dispersant and water and heating to 60-75 DEG C; dropwise adding initiator aqueous solution and acrylamide aqueous solution in sequence; after dropwise adding, timing and reacting for 3-24h, washing, denitrifying, filtering, drying and obtaining the ternary polyacrylonitrile copolymer. A water-phase suspension polymerization process is adopted to polymerization; the polymerization heat is easy to be removed and the polymerization temperature is easily controlled; the average molecular weight of the ternary polyacrylonitrile copolymer is higher and the molecular weight distribution is narrow; the prepared ternary polyacrylonitrile copolymer is capable of effectively improving thermal stability performance at a high-temperature pre-oxidation stage and has certain actual application prospects.

Owner:DONGHUA UNIV

Method for extracting and separating ginkgo leaf polyprenol acetic ester from ginkgo leaf by supercritical carbon oxide

InactiveCN101709030BLow costSave the recycling processCarboxylic acid esters separation/purificationBulk chemical productionOrganic solventGinkgo biloba

Owner:江苏同源堂生物工程有限公司

A preparation method of cofs@hpan nanofiltration composite membrane

ActiveCN111760474BHigh porosityImprove permeabilitySemi-permeable membranesGeneral water supply conservationMasterbatchNanofiltration

The invention discloses a method for preparing a COFs@HPAN nanofiltration composite membrane. COFs and a meltable PAN-based copolymer are fully blended by a high-speed mixing technology to prepare a uniformly distributed COFs-PAN masterbatch, and then the COFs with a uniform distribution are prepared. COFs-PAN blend membrane, and then through three levels of cross-linking in sequence to obtain COFs@HPAN nanofiltration composite membrane. In this method, by adjusting the process parameters of hydrolysis, irradiation and pre-oxidation reaction, the COFs-PAN blend film is processed by hydrolysis-irradiation-pre-oxidation reaction in sequence, and a multi-level adjustable network cross-linked structure can be constructed. According to the needs of different purposes, the network cross-linking structure of the nanofiltration composite membrane can be adjusted to achieve different pore sizes, so as to achieve the functions of efficient decolorization, desalination and virus removal. The prepared asymmetric structure COFs@HPAN nanofiltration composite membrane has excellent permeability and selectivity, high porosity, uniform pore size distribution, excellent thermodynamic stability, chemical resistance, and cycle stability, and can be applied in harsh water environments Separation and purification.

Owner:TIANJIN POLYTECHNIC UNIV

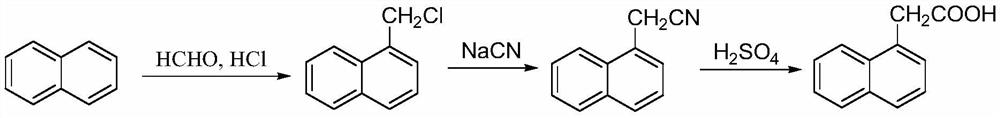

A kind of preparation method of 1-naphthylacetic acid

ActiveCN111153787BReduce generationSave the recycling processMolecular sieve catalystsOrganic compound preparationLiquid stateChloroacetic acids

The invention belongs to the field of pesticide synthesis, and in particular relates to a preparation method of 1-naphthaleneacetic acid. The method specifically comprises: adding naphthalene and chloroacetic acid into a reactor for reaction to obtain a mixture containing 1-naphthaleneacetic acid and excess chloroacetic acid; performing solid-liquid separation on the mixture to obtain 1-naphthaleneacetic acid and a mother liquor; the mother liquor circulation To the above reaction; when the naphthalene is fed, it is in a molten liquid state, and the chloroacetic acid is in a gaseous state. The method for continuously producing 1-naphthaleneacetic acid of the present invention greatly reduces the generation of by-products, solves the problem of excessive chloroacetic acid recovery, is highly efficient and environmentally friendly, saves complicated separation steps, greatly reduces production costs, and is suitable for large-scale continuous production. Production of 1-naphthylacetic acid.

Owner:浙江大鹏药业股份有限公司

Preparation method for ternary polyacrylonitrile copolymer for precursor fibers of carbon fibers

InactiveCN108840974AEasy to rule outEvenly distributedFibre chemical featuresCarbon fibersPolymer science

The invention relates to a preparation method for a ternary polyacrylonitrile copolymer for precursor fibers of carbon fibers. The preparation method comprises the following steps: under a nitrogen protecting condition, mixing a first monomer acrylonitrile, a second monomer acrylamide and a third monomer methacrylic acid with water; raising the temperature to 55-75 DEG C; then successively dropwise adding a chain transfer agent aqueous solution, a reducer aqueous solution and an oxidant aqueous solution; carrying out a timed reaction for 1-6 h after dropwise addition; and carrying out washing,monomer removing, filtration and drying to obtain polymer powder. The copolymer is polymerized by means of a water phase precipitation polymerization method. The polymerization reaction heat is easyto remove, the polymerization temperature is easy to control, and the relative molecular mass and distribution of the polymer are relatively uniform. The ternary polyacrylonitrile copolymer prepared by the method can improve the heat stability of the copolymer in a pre-oxidizing stage and has a certain actual application prospect.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com