Novel fuel cell stack with inlet gas multistage self-preheating function and control method

A fuel cell stack and self-preheating technology, which is applied in the direction of fuel cells, fuel cell additives, and fuel cell heat exchange, can solve the problems of chemical energy loss, the difference between the actual efficiency of the battery and the theoretical efficiency, and achieve dynamic regulation , avoid heat loss, improve the overall efficiency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

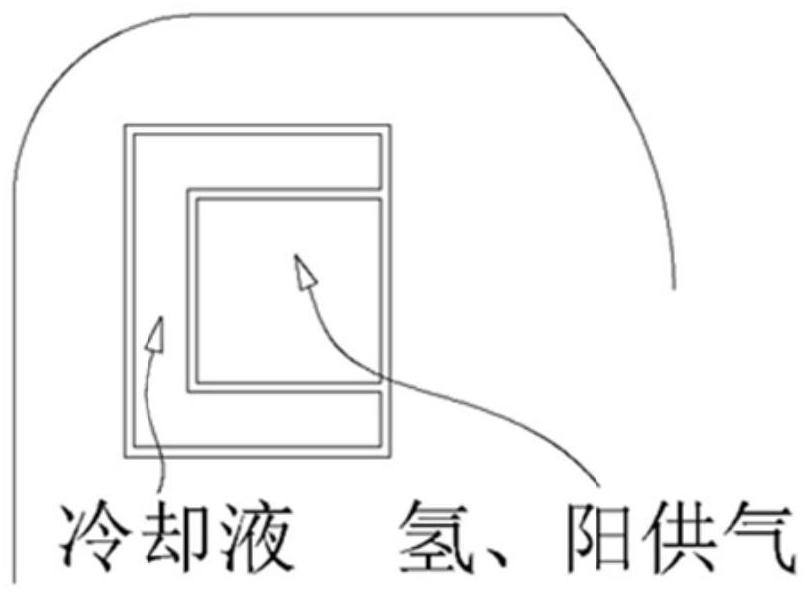

[0035] In one or more embodiments, a new type of fuel cell stack with intake air multi-stage self-preheating is disclosed. The hydrogen and oxygen gas supply in the stack includes three preheating stages. The first preheating method is to The outlet of the coolant flow channel in the stack is surrounded by the periphery of the intake manifold to form a sleeve-type intake manifold, and the coolant flows in the opposite direction to the intake fluid to form a counter-current convection heat exchange; the second stage preheating method is through dual The flow of coolant in the polar plate provides heat, and the coolant in the bipolar plate flows from the middle area of the bipolar plate to the intake area on both sides, so that the hotter coolant flows in the intake area; the third stage preheating method is A resistance wire is installed in the intake manifold to realize the temperature regulation of the hydrogen and oxygen gas supply, forming a complete preheating process of ...

Embodiment 2

[0045] In one or more embodiments, a control method of a new type of fuel cell stack with intake air multi-stage self-preheating is disclosed. The method is based on the stack structure in Example 1; for specific methods, refer to Figure 8 , including the following process:

[0046] (1) First, calculate the preheated intake air temperature required for the required hydrogen and oxygen supply according to the existing working conditions of the fuel cell;

[0047] (2) Through the sleeve-type intake manifold, the residual heat of the coolant can convectively exchange heat with the fluid in the intake manifold;

[0048] (3) The intake area is heated by circulating coolant in the bipolar plate;

[0049] (4) Judging whether the gas temperature is lower than the required preheating intake temperature at this time, if it is lower, turn on the resistance wire heating; otherwise, turn it off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com