Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce the probability of reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

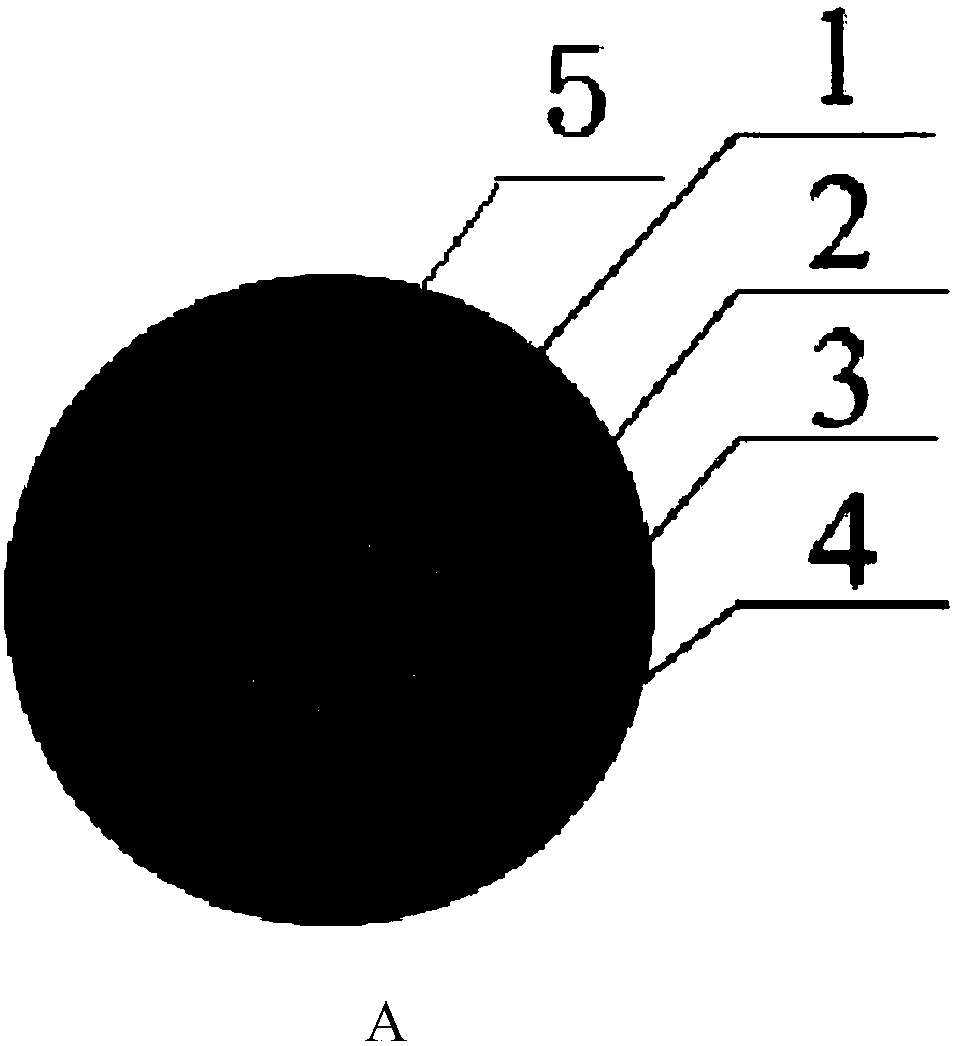

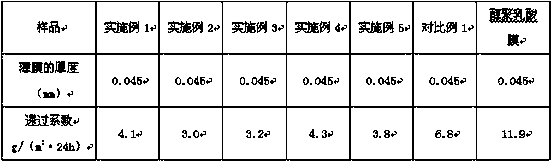

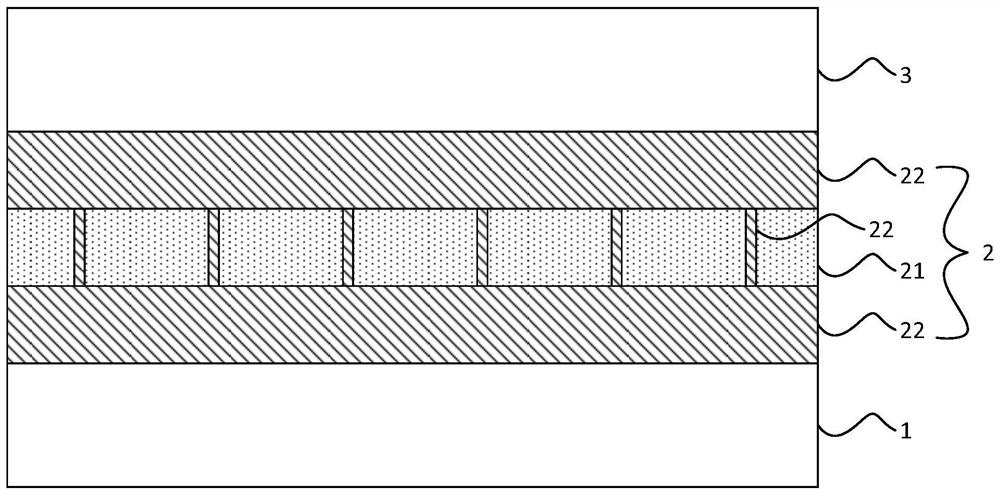

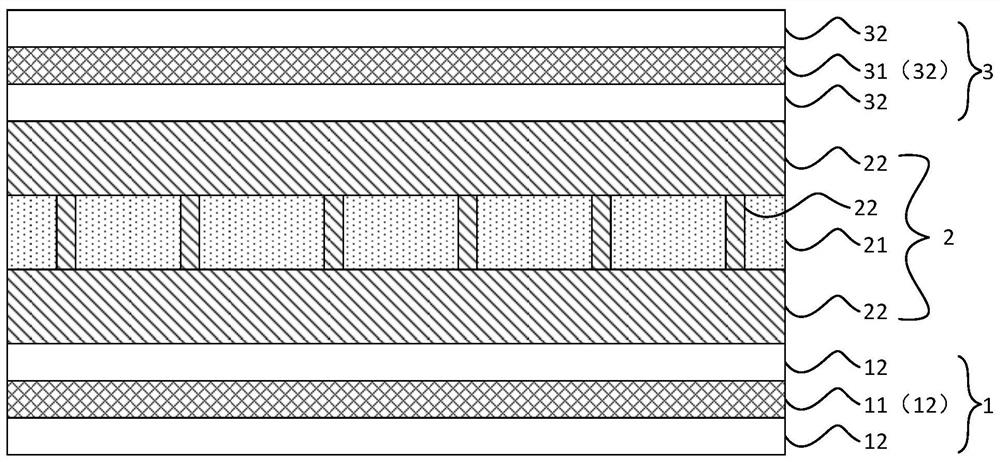

All-solid-state electrolyte and preparation method thereof, and lithium ion battery

ActiveCN111180788AHigh mechanical strengthImprove interface compatibilitySolid electrolytesSecondary cellsSolid state electrolyteComposite electrolyte

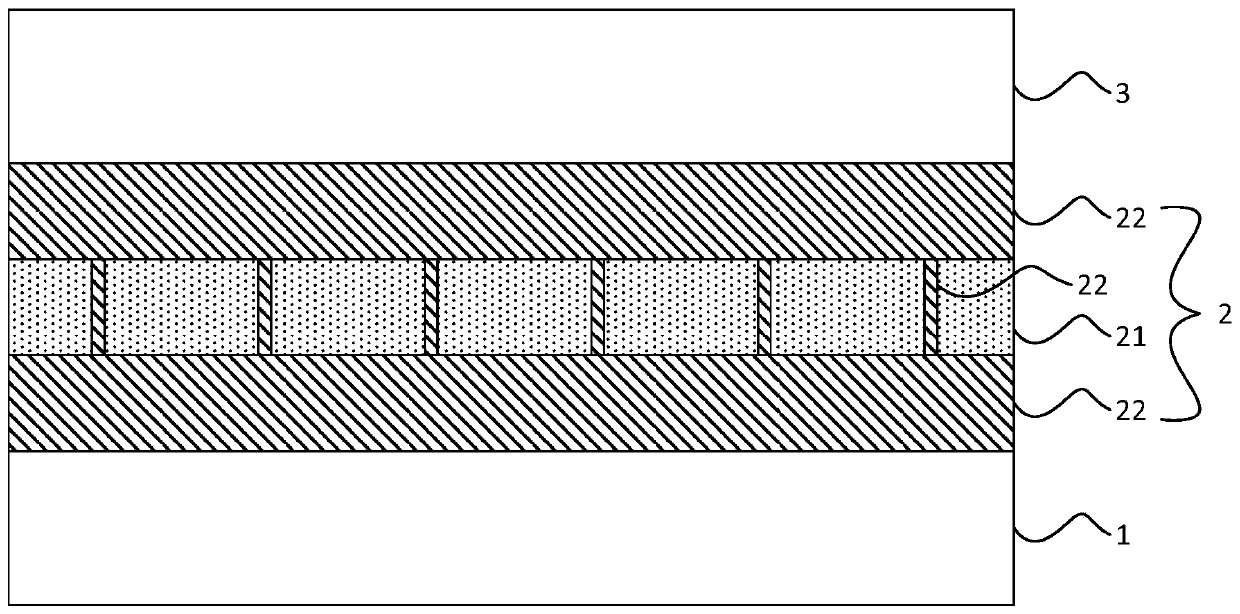

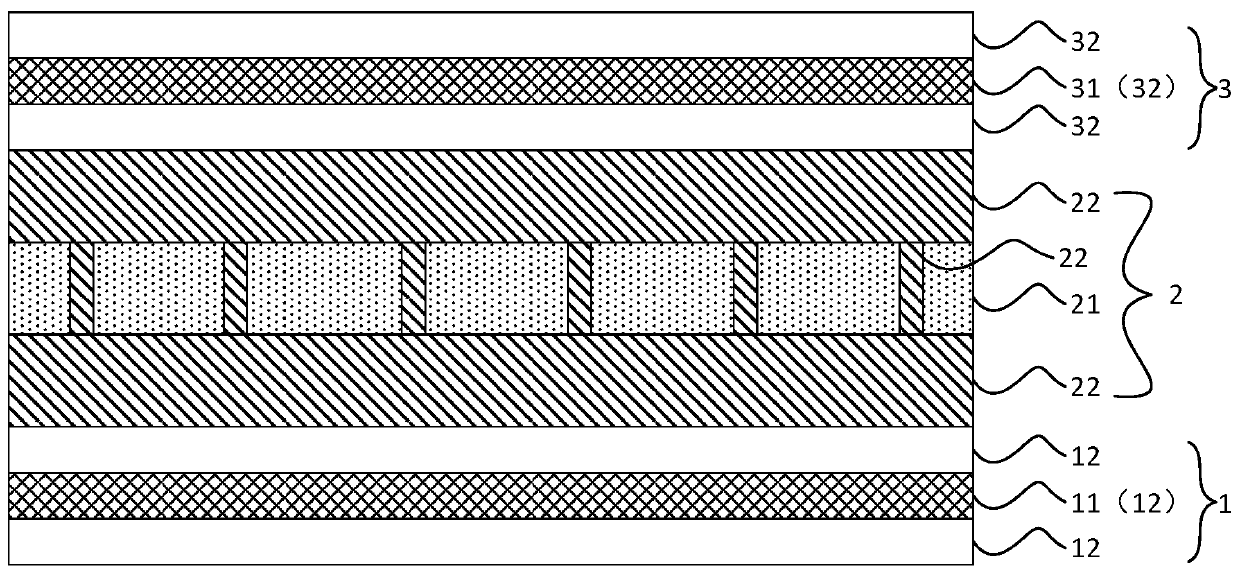

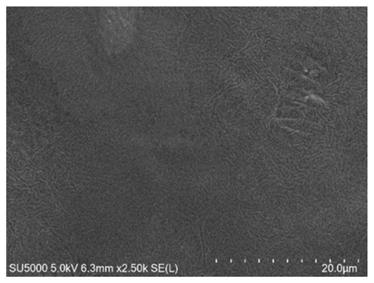

The invention provides an all-solid-state electrolyte and a preparation method thereof, and a lithium ion battery. The all-solid-state electrolyte comprises a first functional layer, an intermediate functional layer and a second functional layer, the first functional layer is arranged on a lower surface of the intermediate functional layer, and the second functional layer is arranged on an upper surface of the intermediate functional layer; the intermediate functional layer comprises a composite electrolyte layer and modified layers, the composite electrolyte layer is filled with the modifiedlayers, the modified layers cover a whole upper surface and a whole lower surface of the composite electrolyte layer, and the composite electrolyte layer comprises an inorganic electrolyte, a polymerand lithium salt; and the first functional layer and the second functional layer include the polymer and the lithium salt. The all-solid-state electrolyte is good in interface stability and interfacecompatibility, high in mechanical strength and capable of well coping with a volume strain, a risk of short circuit in battery manufacturing is reduced, meanwhile, a lithium dendrite inhibiting capacity of the electrolyte is enhanced, and therefore cycle performance and a charging and discharging capacity of the lithium ion battery can be effectively improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

LED coating for encapsulating quantum dots by multiple layers and preparation method thereof

PendingCN108511582ADense high barrier particlesControl glow qualityLuminescent paintsSemiconductor devicesQuantum dotHigh surface

The invention relates to an LED coating for encapsulating quantum dots by multiple layers. The LED coating comprises a traditional encapsulation material layer and a plurality of encapsulation particles of quantum dots and scattered particles, which are scattered in the traditional encapsulation material layer, wherein from inside to outside, the encapsulation particle of the quantum dot and the scattered particle comprises a quantum dot, a compatible polymer layer and a water and oxygen barrier film layer in sequence, and a plurality of inorganic nano scattered particles are scattered in thecompatible polymer layer. The compatible polymer and the quantum dot are highly compatible, so that the high surface energy property of the quantum dot is prevented from damaging colloid crosslinking,and the quantum dot is more stable. According to the LED coating, the quantum dot is wrapped in the compatible polymer and then is crushed into particles, the surface of the particle is encapsulatedby the water and oxygen barrier film layer, and finally, the obtained particles are scattered in another colloid, so as to prepare the quantum dot coating, therefore, the quantum dots are less likelyto gather so as to maintain the luminescence performance; and the multilayer encapsulation structure improves the water and oxygen blocking performance of the quantum dot coating.

Owner:SOUTH CHINA UNIV OF TECH

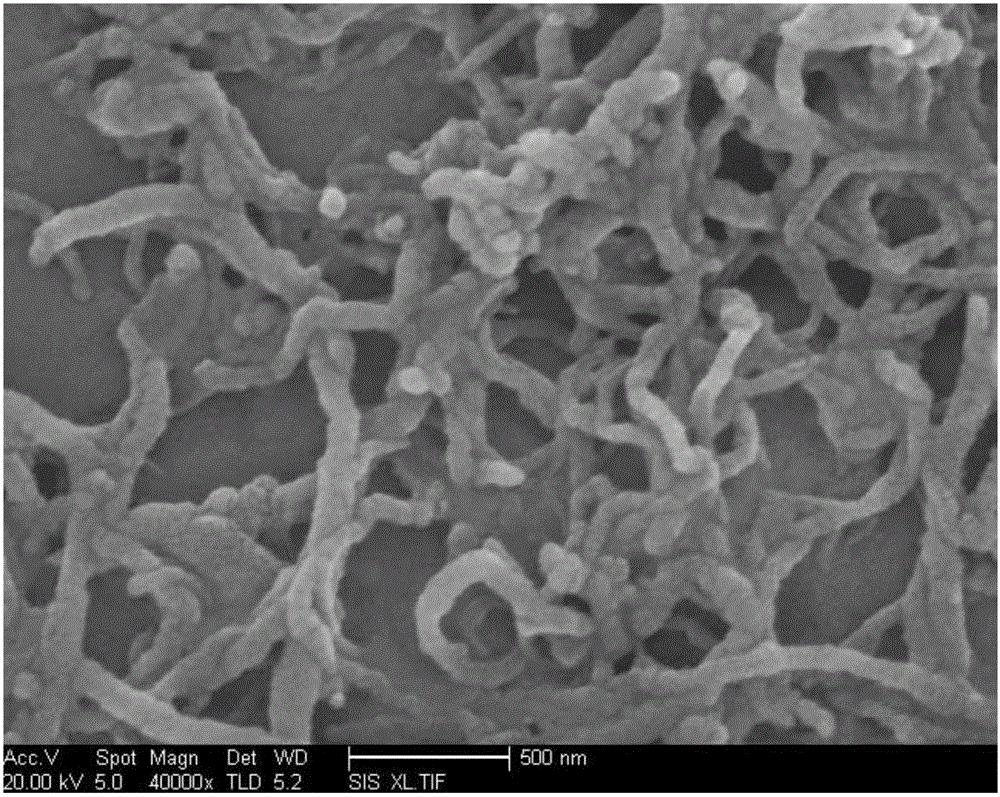

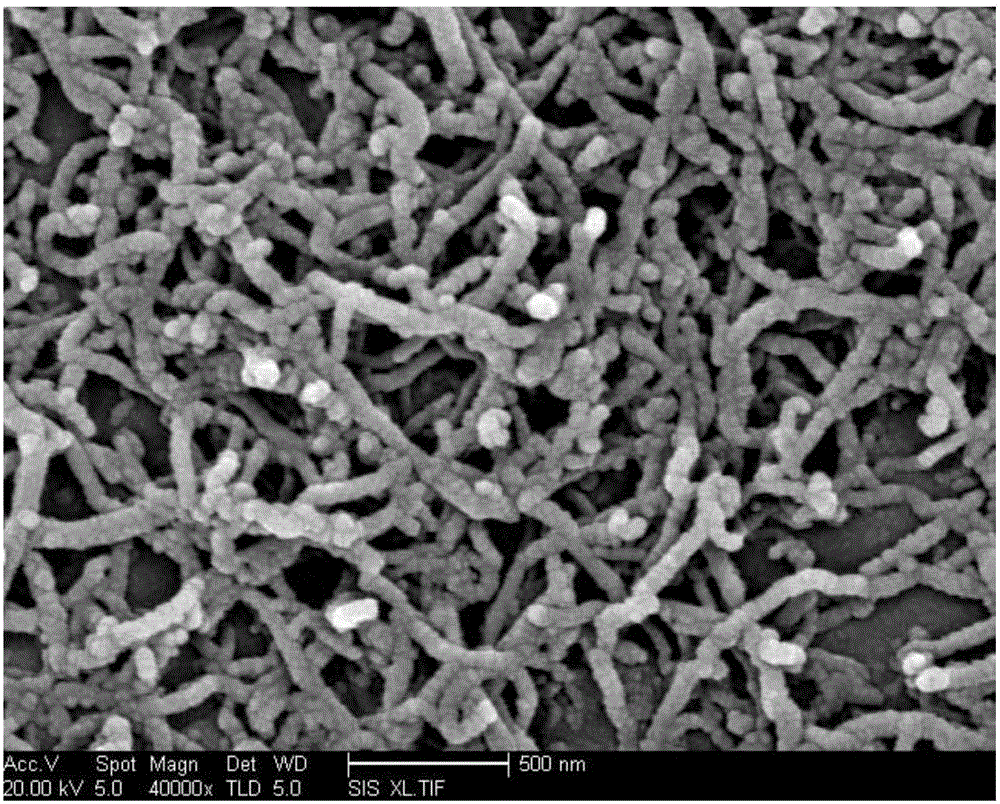

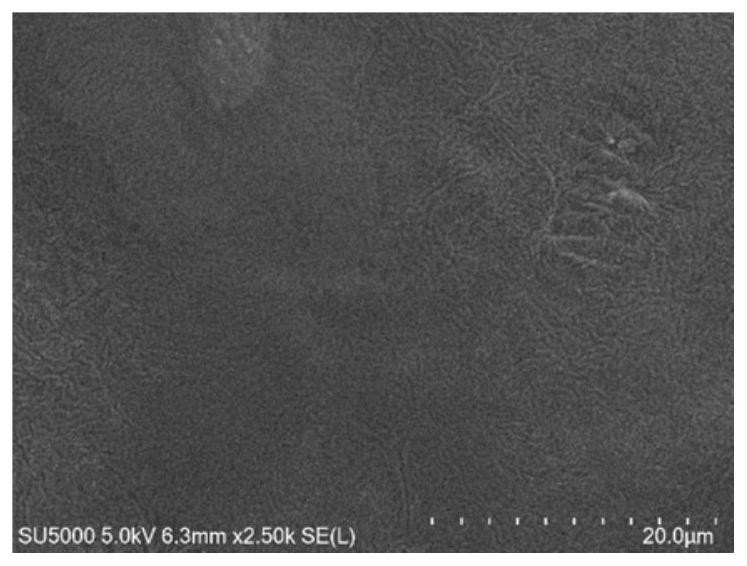

Preparation method of functionalized carbon nanotube powder

InactiveCN105733317AStrong interface bindingSignificant performance enhancementPigment physical treatmentPigment treatment with non-polymer organic compoundsTube furnaceCarbon nanotube

The invention discloses a preparation method of functionalized carbon nanotube powder, relating to a preparation method of carbon nanotube powder. The purpose of the method is to solve the problems that the existing method for preparing functionalized carbon nanotubes has a high risk of reaction and is difficult to control, the grafting rate of surface functional groups is difficult to control, and the combination of the product and the composite material is weak. Method: 1. Heat the carbon nanotubes in a tube furnace and cool down to obtain purified carbon nanotubes; 2. Prepare FeSO 4 Solution, adjust the pH; 3. Place the purified carbon nanotubes in FeSO 4 solution, forming a suspension, oil bath, H 2 o 2 Adding to the suspension, standing still after the reaction, to obtain the product; 4. Washing, replacing with an organic solvent, centrifuging to obtain a muddy product, and freeze-drying to obtain the functionalized carbon nanotube powder. The reaction of the method is controllable, and the prepared powder can be dispersed in some organic solvents to form a uniform and stable system, and has a certain orientation ability under a specific field strength. The invention is used for preparing functionalized carbon nanotubes.

Owner:HEILONGJIANG HEIKE TECH CO LTD

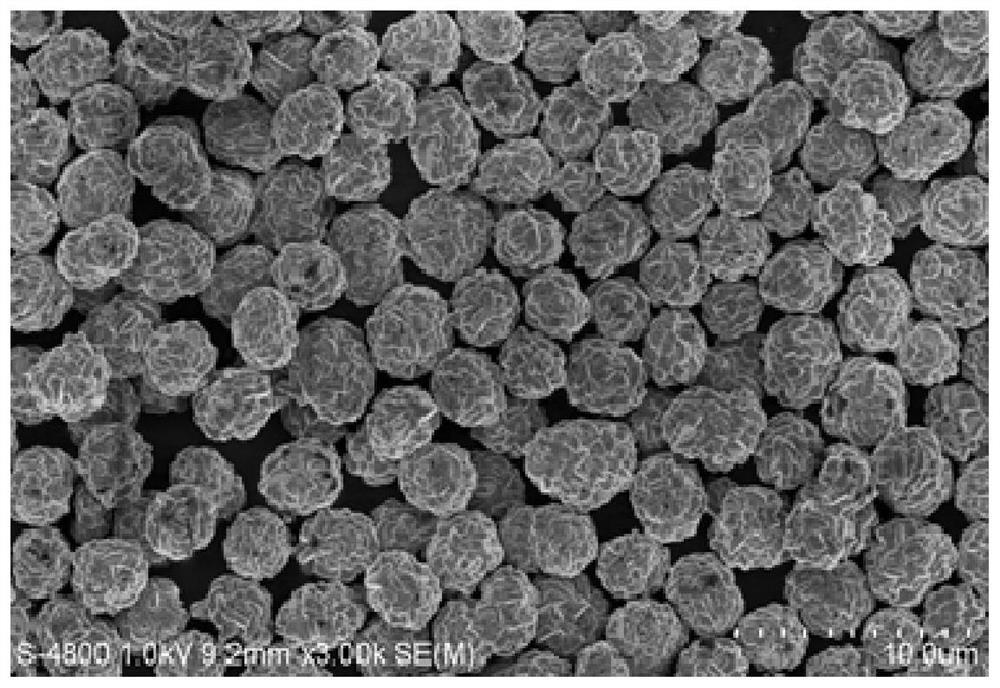

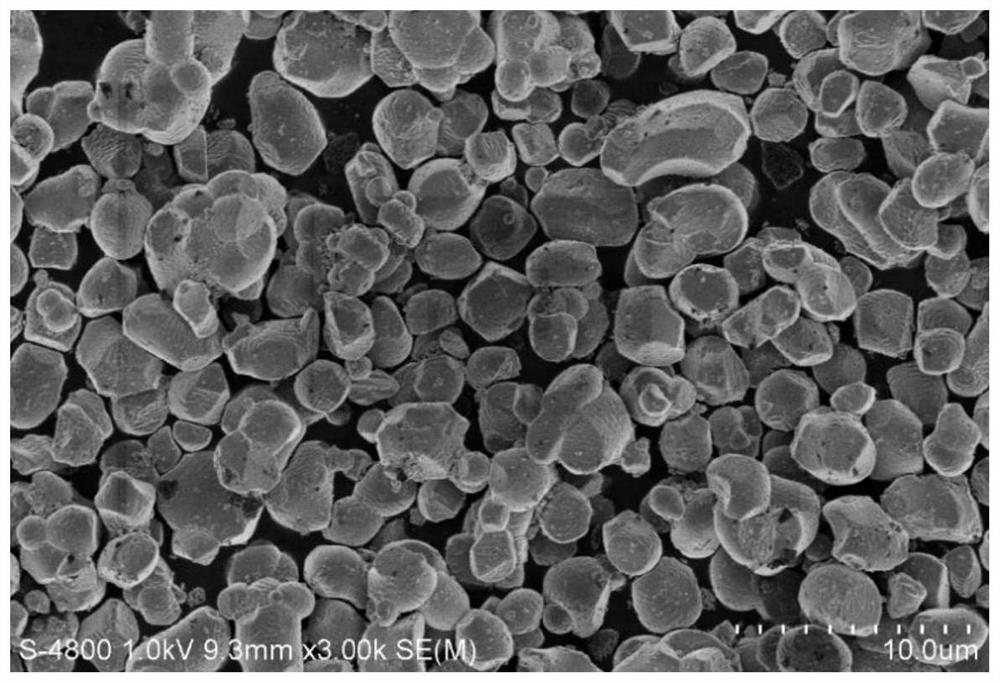

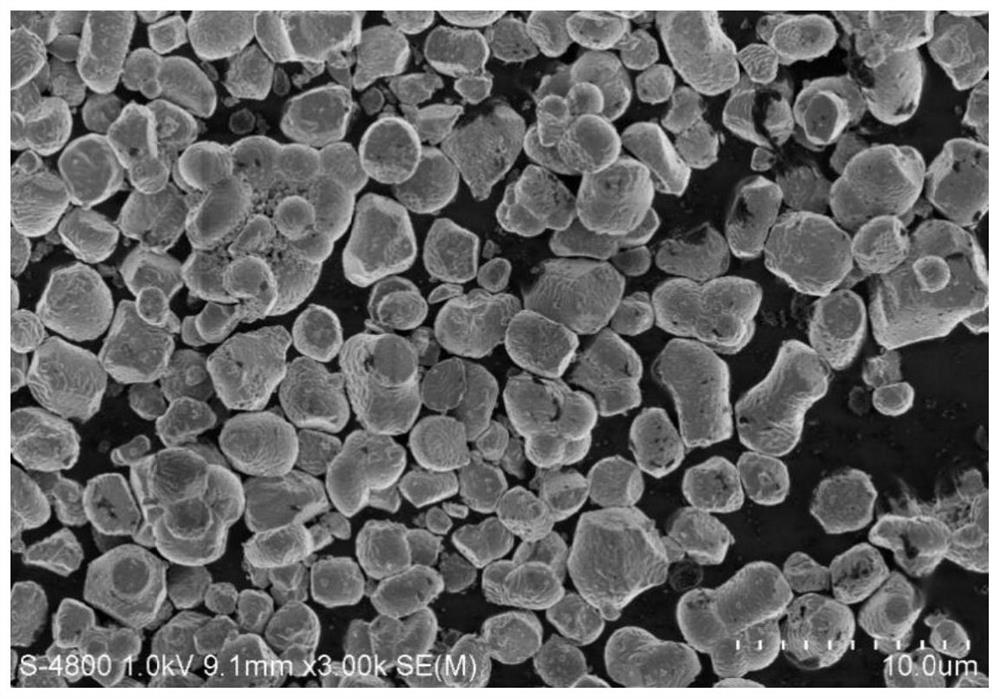

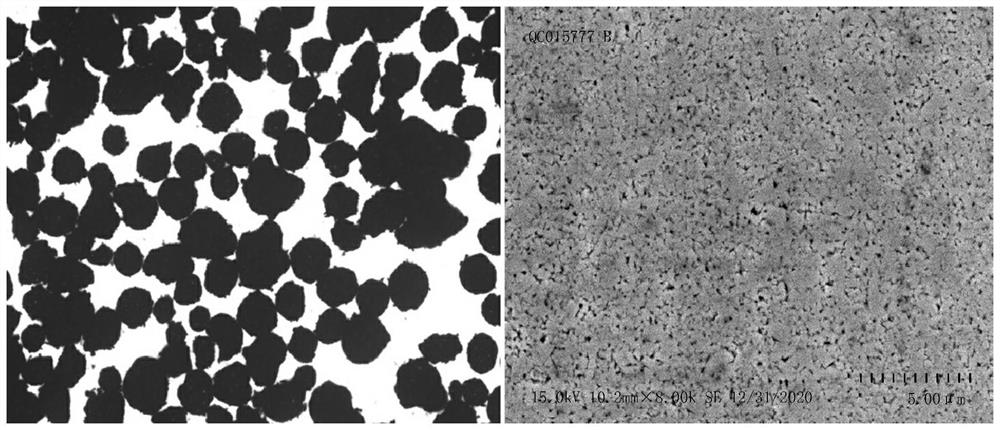

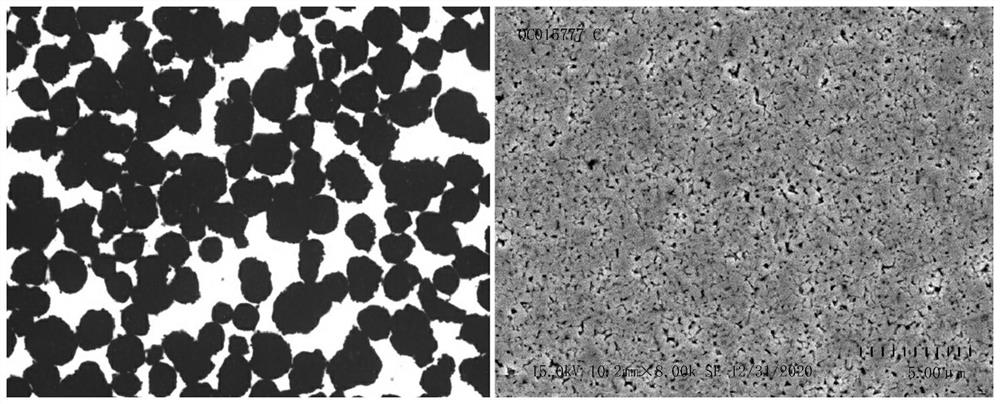

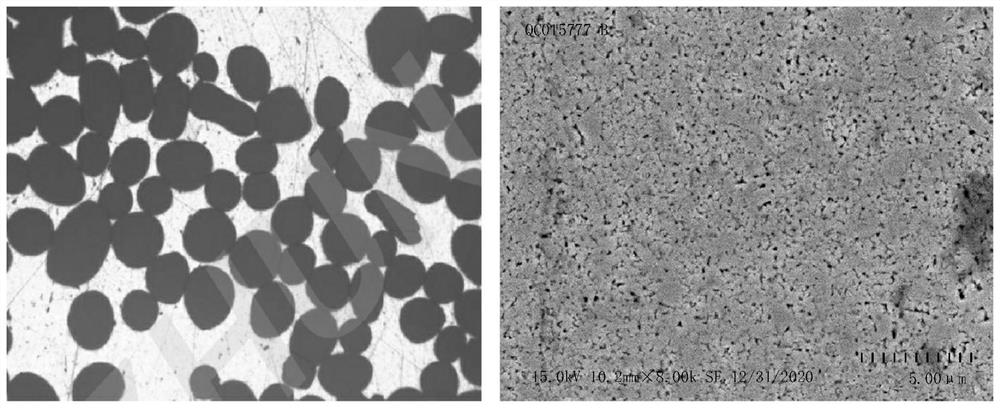

Single-crystal type multi-element positive electrode material as well as preparation method and application thereof

ActiveCN114703544ARound shapeUniform particle sizePolycrystalline material growthElectrode thermal treatmentPhysical chemistrySingle crystal

The invention relates to the technical field of lithium ion batteries, and discloses a single crystal type multi-element positive electrode material and a preparation method and application thereof. The positive electrode material meets the following conditions: the single crystal sizes DPS90, DPS10 and DPS50 of the positive electrode material measured by SEM meet the following relation: 0.1 < = B90 = (DPS90-DPS10) / DPS50 < = 1.5; the agglomeration rate of the positive electrode material is less than or equal to 20%; wherein 90% of the single crystal size of the DPS90 positive electrode material is smaller than that of DPS90; the single crystal size of the DPS50 positive electrode material is 50% smaller than that of DPS50; the single crystal size of the DPS10 positive electrode material is 10% smaller than that of DPS10. The single crystal type multi-element positive electrode material is round and full in morphology, uniform in particle size, less in agglomeration, less in adhesion, high in compaction density and good in structural stability, and when the single crystal type multi-element positive electrode material is applied to the lithium ion battery, the energy density, the rate capability, the cycling stability and the safety of the lithium ion battery can be improved.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

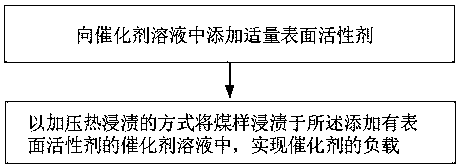

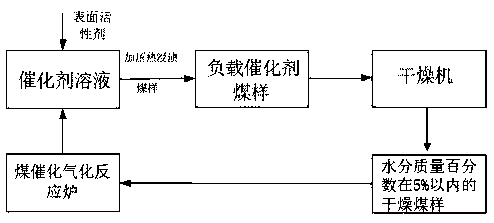

Coal gasification catalyst loading method

InactiveCN110075931AReduced chance of reunionAvoid coal sample sticking to the wall and clogging equipmentCatalyst activation/preparationChemistrySURFACTANT BLEND

The invention provides a coal gasification catalyst loading method which comprises the following steps: putting a proper amount of a surfactant into a catalyst solution; soaking a coal sample into thecatalyst solution with the surfactant in a pressurized hot soaking mode, thereby achieving loading of a catalyst. By adopting the catalyst loading method provided by the invention, the surfactant isput into the catalyst solution, so that sufficient infiltration of the catalyst solution with the coal sample can be promoted; by using a pressurized hot soaking method, the catalyst solution with thesurfactant is loaded in the coal sample, so that a small amount of the catalyst solution is retained on the surface of the coal sample, a small amount of a catalyst crystal is evaporated and separated, the aggregation probability of coal powder granules is greatly reduced, and the problem that the coal sample is adhered to walls and equipment is blocked can be effectively avoided.

Owner:ENN SCI & TECH DEV

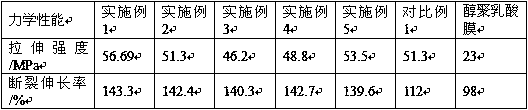

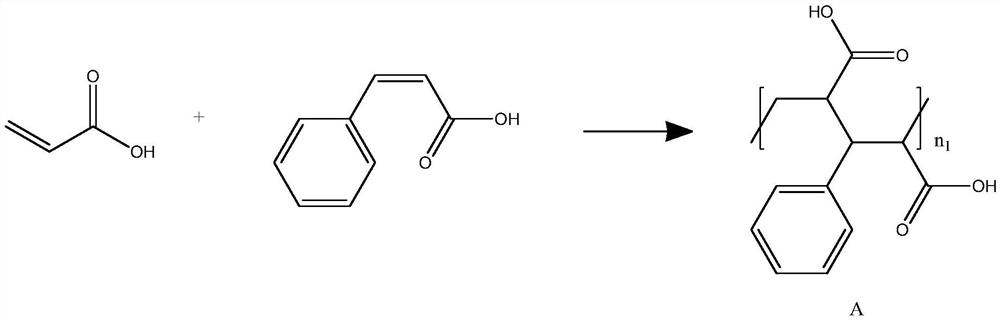

High-barrier graphene masterbatch for degradable packaging plastic and preparation method thereof

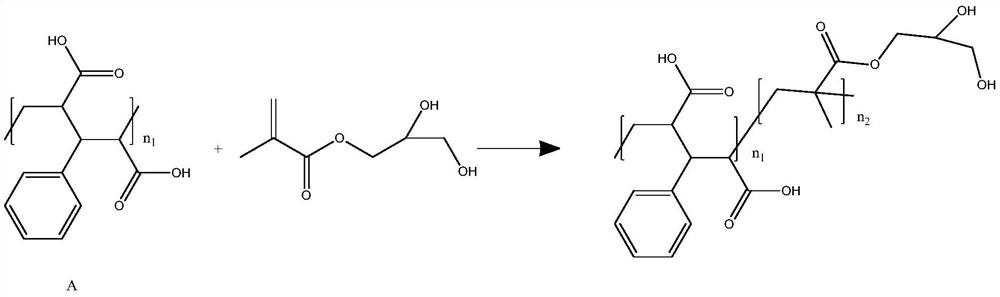

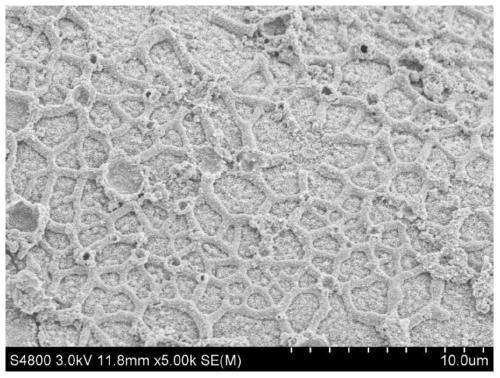

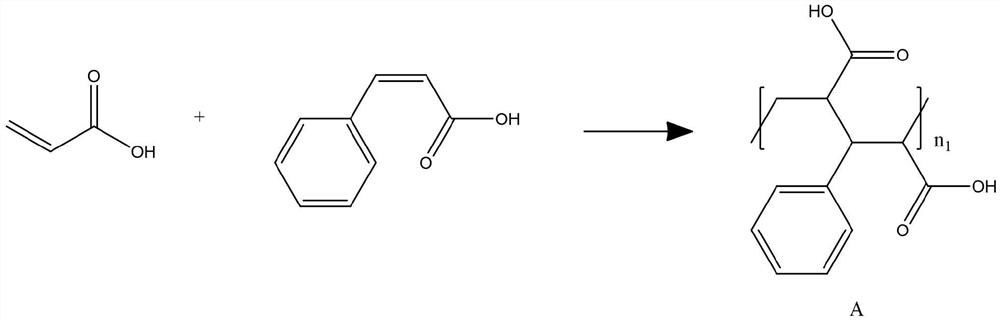

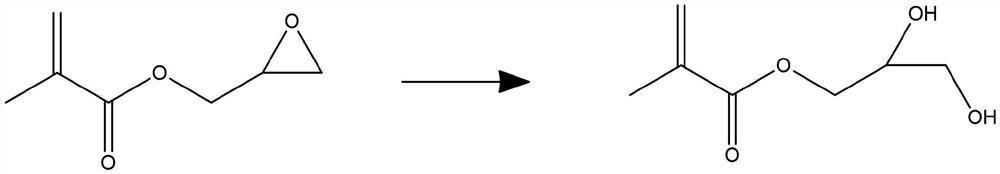

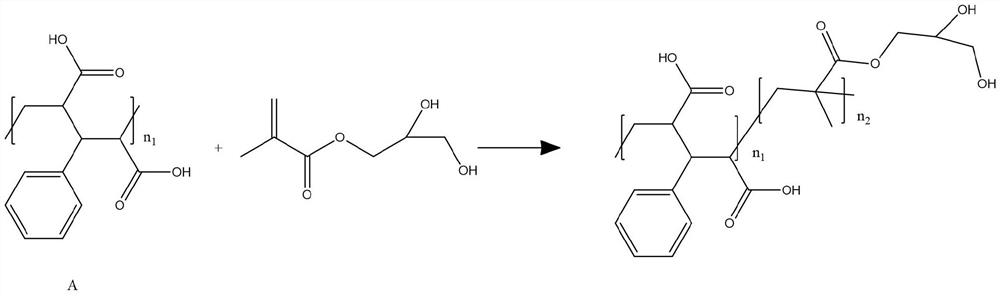

The invention belongs to the technical field of a degraded plastic, and concretely provides a high-barrier graphene masterbatch for a degradable packaging plastic and a preparation method thereof. Thenegatively charged polyacrylic acid modified graphene is prepared, then is combined with hydrotalcite, the PAA-graphene is uniformly laminated with the hydrotalcite, the combination is tight, shedding is not easy, the probability of secondary agglomeration of graphene is reduced, graphene with a layered structure and hydrotalcite are uniformly dispersed in a film matrix, and the barrier properties of the degradable packaging plastic can be significantly improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Industrial production method of N-ethyl pyrrolidone

ActiveCN110183370AHigh puritySolve temperature problemsOrganic chemistryHeterogenous catalyst chemical elementsComing outReaction temperature

The invention provides an industrial production method of N-ethyl pyrrolidone, and belongs to the technical field of preparation of fine chemical engineering products. The method comprises the following steps: step 1, gamma-butyrolactone is added into a stirring vessel, row tubes are welded on a stirrer, the row tubes are filled with catalysts, and solvent flows out of holes on the row tubes to befully mixed with gamma-butyrolactone; step 2, materials flowing out of the stirring vessel are fully mixed with monoethyl amine and are then fed into a tubular reactor, a feeder is provided with atomizing nozzles, the solvent is fully mixed with the materials coming out of an upper reaction section after being atomized, and a mixture is collected and uniformly enter the row tubes of a lower reaction section after passing through a distributor; step 3, products flowing out of the tubular reactor are fed into the jacket of the stirring vessel, heat transfer is carried out on the products and materials in the step 1, and then the products flow out from the outlet of the jacket and enter a refining stage. The industrial production method provided by the invention overcomes the deficiencies, such as high reaction temperature, high reaction pressure, high requirements on equipment and low environmental protection benefit, existing in existing production of N-ethyl pyrrolidone.

Owner:MAIQI CHEM CO LTD

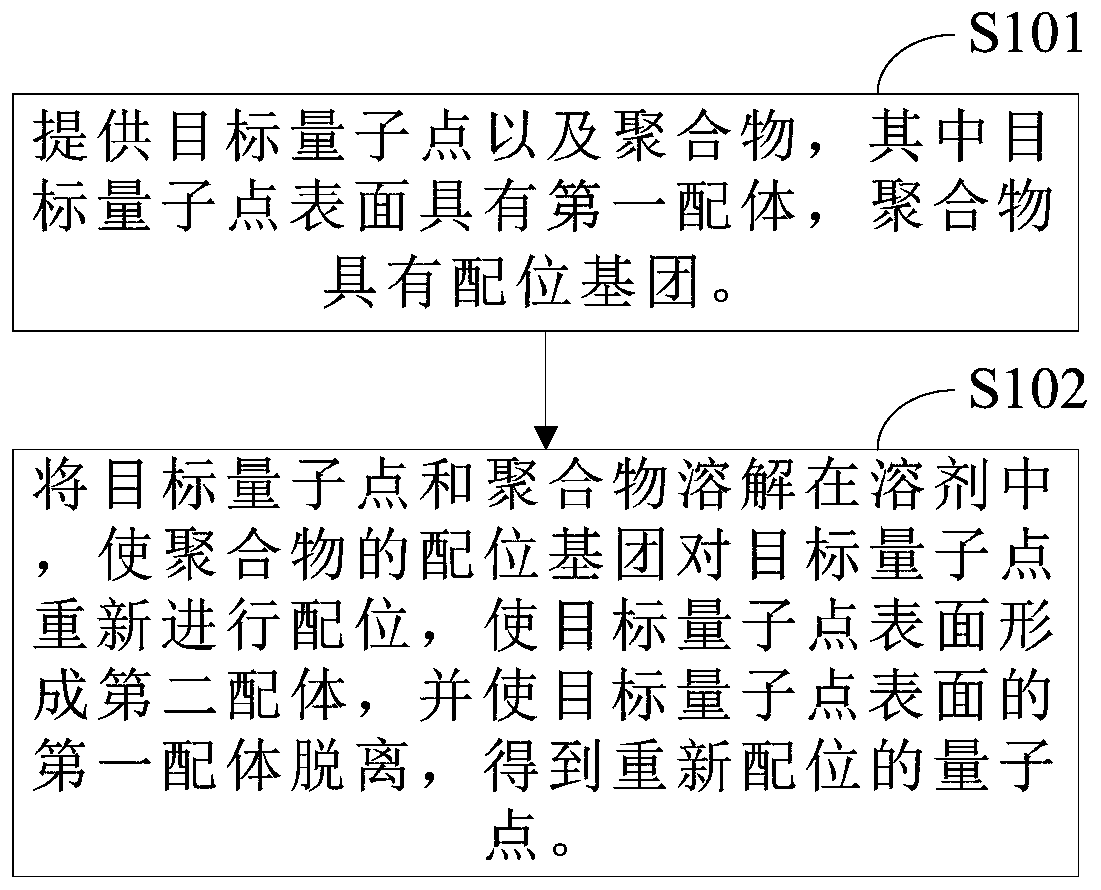

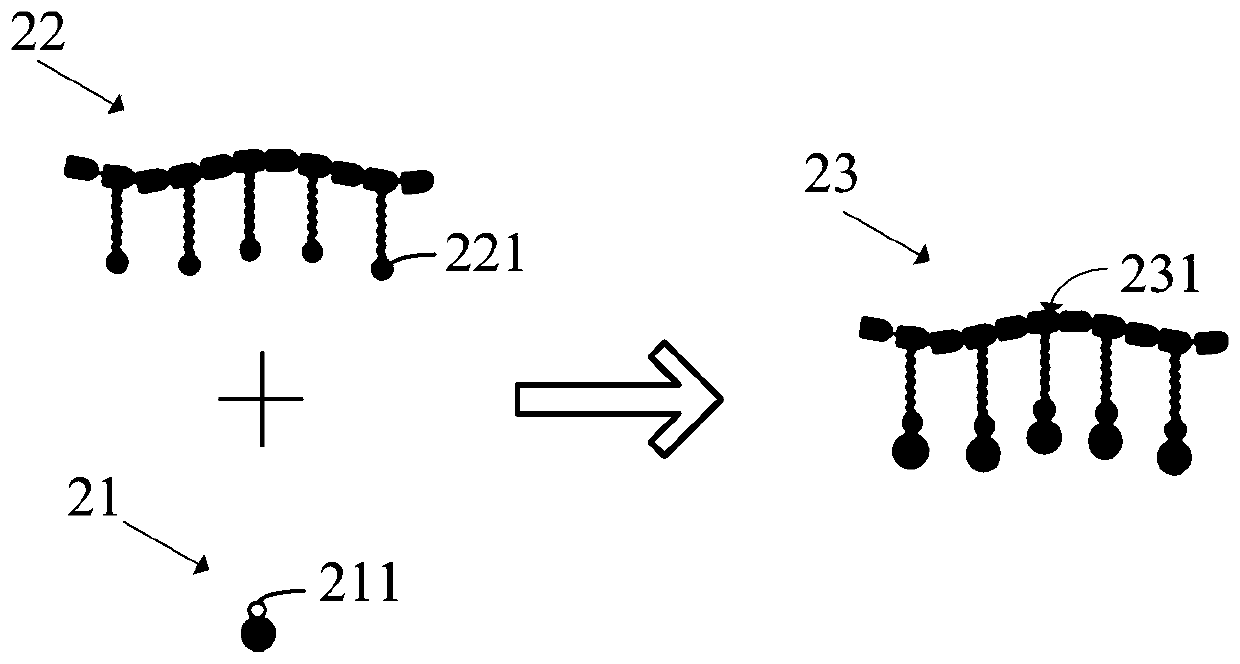

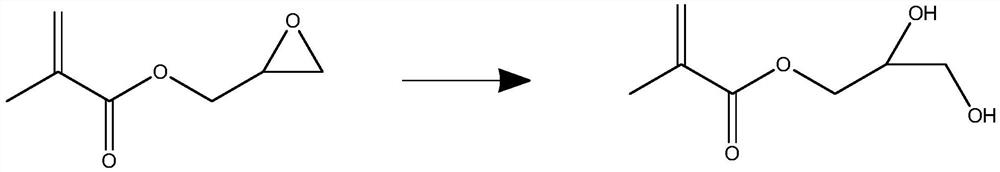

Coordination method of quantum dots, quantum dots and display device

InactiveCN110643346AReduce the probability of reunionSolid-state devicesSemiconductor/solid-state device manufacturingPolymer dissolutionChemical physics

The invention provides a coordination method of quantum dots, the quantum dots and a display device. The coordination method of the quantum dots includes the steps: providing quantum dots and a polymer, wherein a first ligand is arranged on the surface of the quantum dots, and the polymer is provided with coordination groups; and dissolving the quantum dots and the polymer in a solvent so as to achieve re-coordination of the coordination groups of the polymer with the quantum dots and form a second ligand on the surface of the quantum dots, and achieving separation of the first ligand from thesurface of the quantum dots so as to obtain the re-coordinated quantum dots. According to the technical scheme, the agglomeration rate of the quantum dots is reduced through re-coordination of the quantum dots with the polymer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

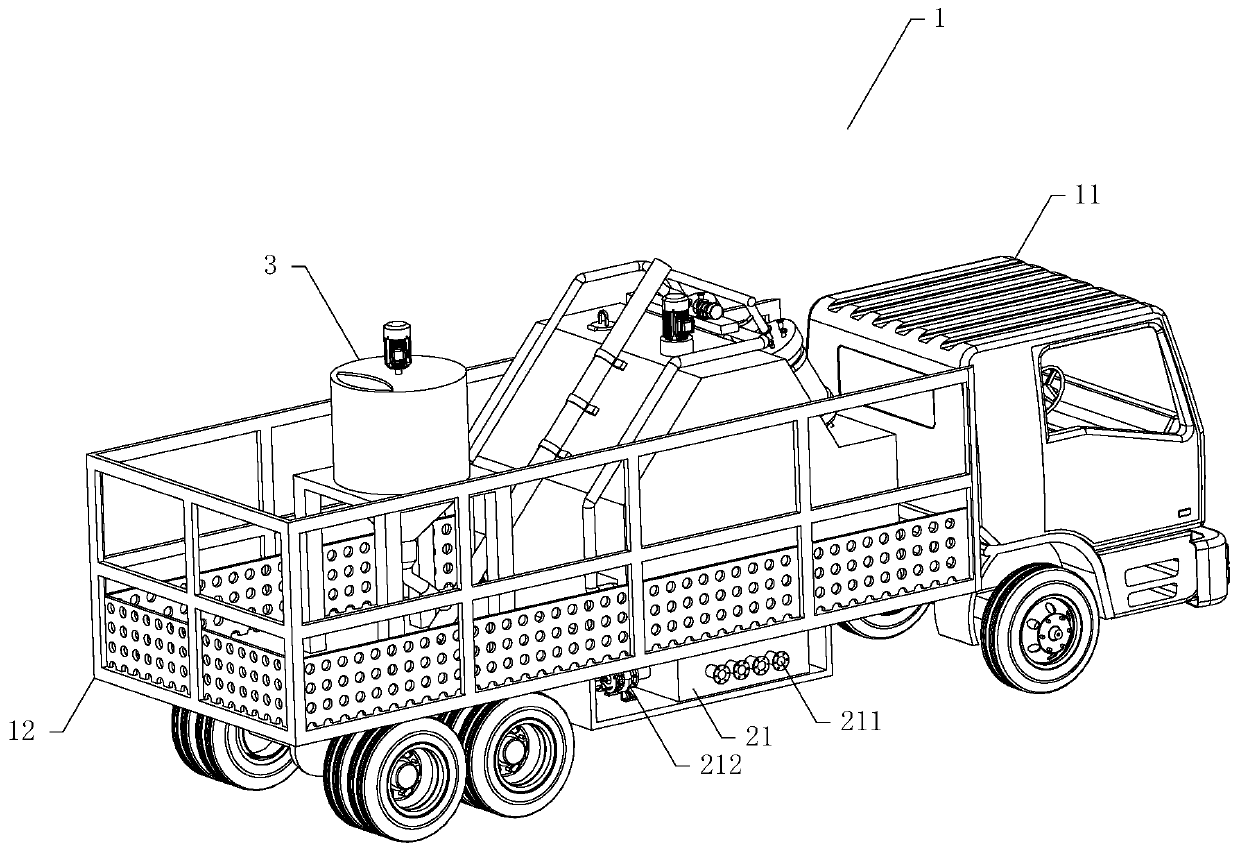

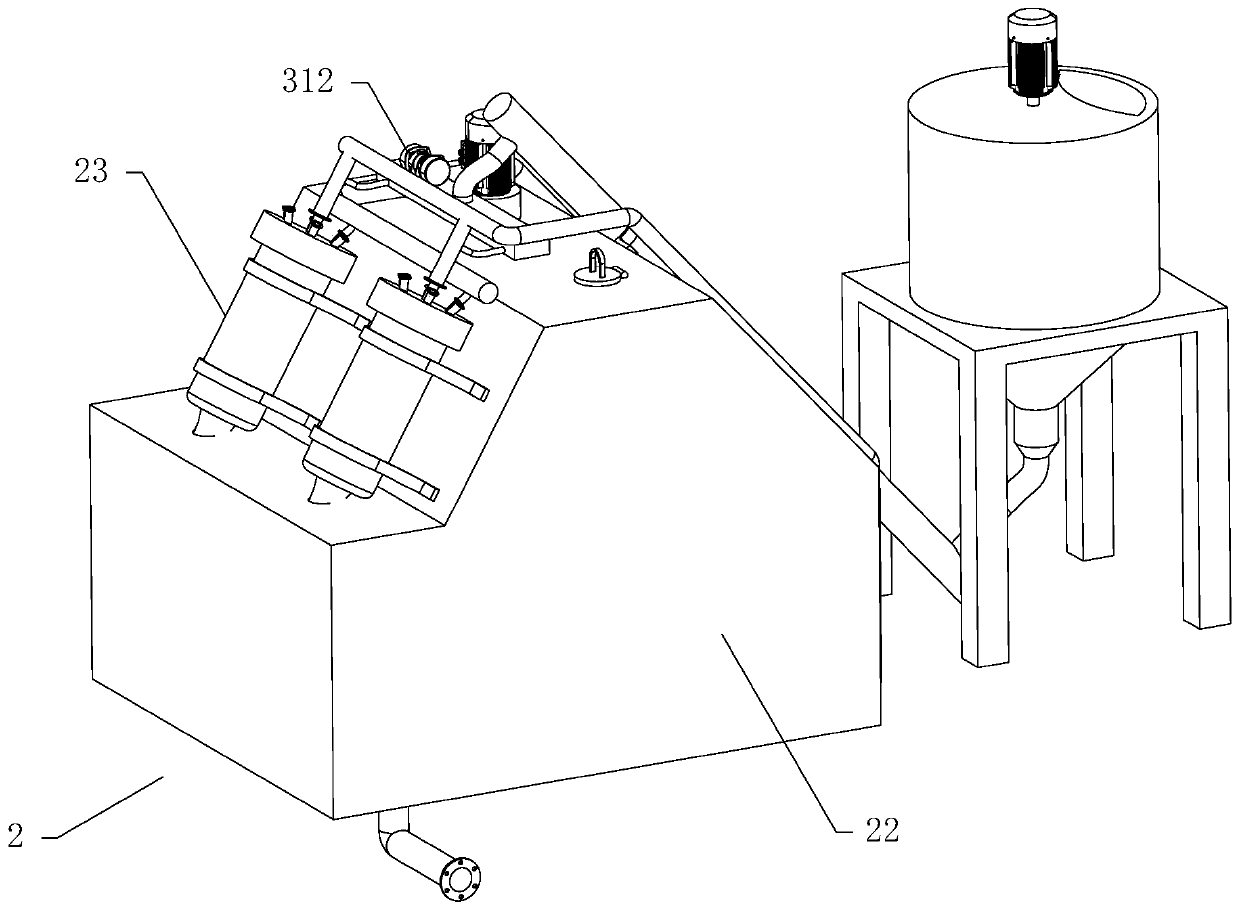

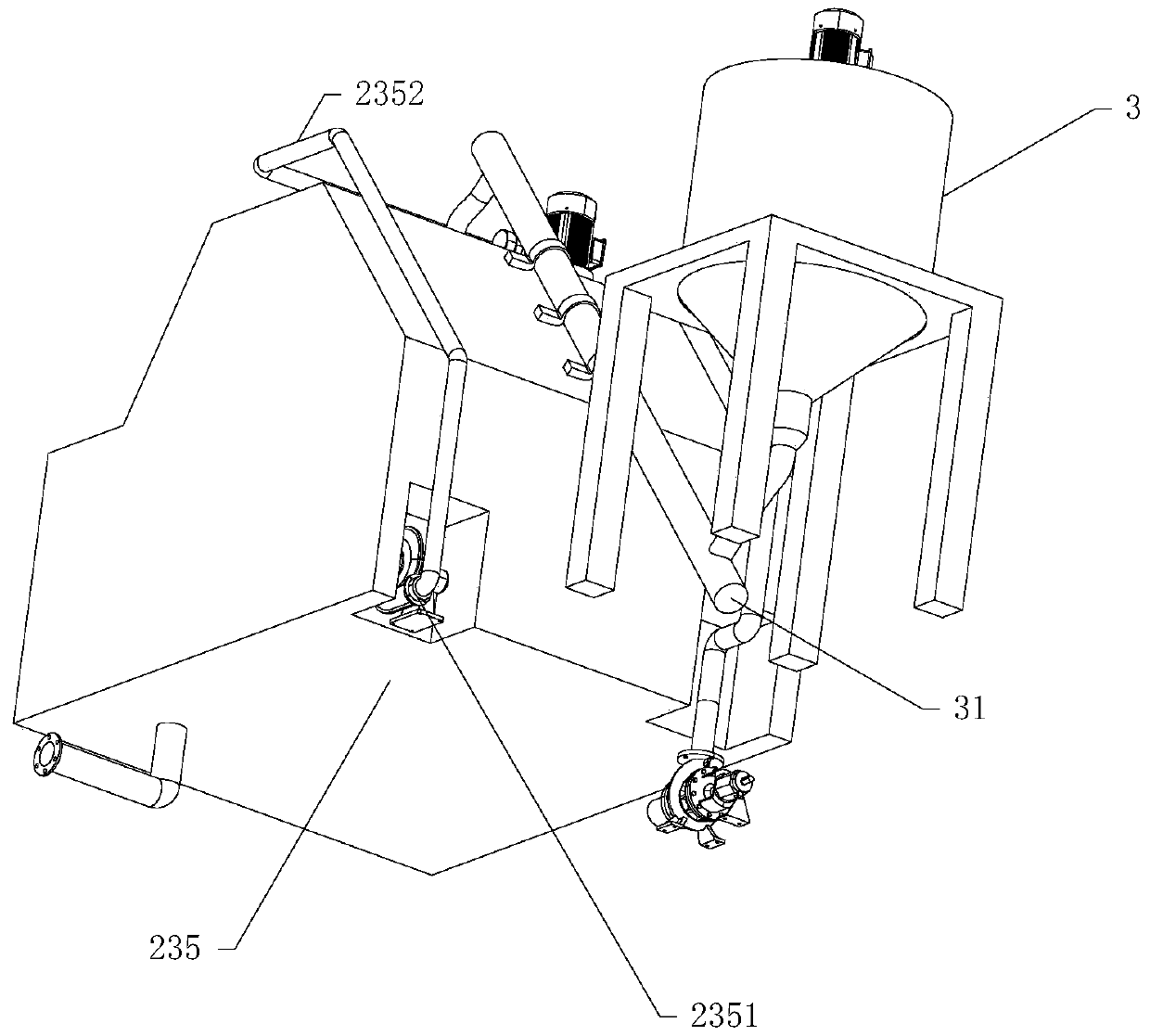

Efficient environment-friendly mixing vehicle

ActiveCN110947309AReduce the probability of reunionReduce energy consumptionRotating receptacle mixersTransportation and packagingDissolutionDelivery system

The invention relates to the field of oil exploitation. The invention discloses an efficient environment-friendly mixing vehicle. The vehicle comprises a vehicle body, a mixing chamber and a bin, thevehicle body is divided into a vehicle head and a carrying seat arranged behind the vehicle head, the mixing chamber is arranged on the carrying seat, the bin is arranged at the other end of the carrying seat, the mixing chamber comprises a water tank arranged at the bottom of the carrying seat, a storage bin arranged on the carrying seat and a plurality of mixing rollers arranged on the storage bin, and a metering powder conveying system is arranged at the bottom of the bin. The invention has the following advantages and effect that: by arranging the mixing roller, the conventional shearing and stirring are changed into mutual dissolution of powder and water drops, so that the probability of powder agglomeration is greatly reduced, the speed required by stirring is reduced, the dissolvingspeed and the production efficiency are improved, the energy consumption is reduced, and multiple purposes are achieved.

Owner:HUBEI PETROKH MACHINE MFG

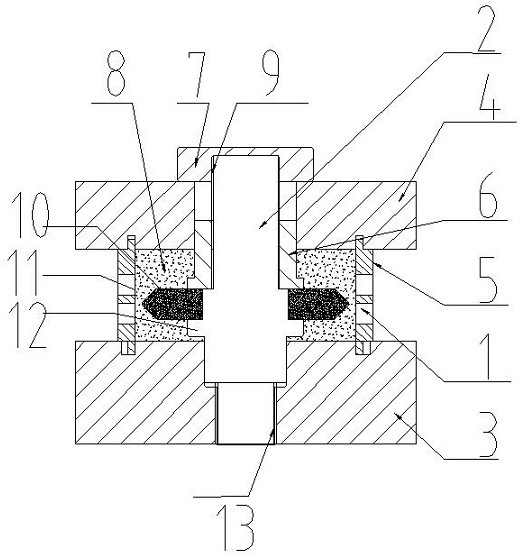

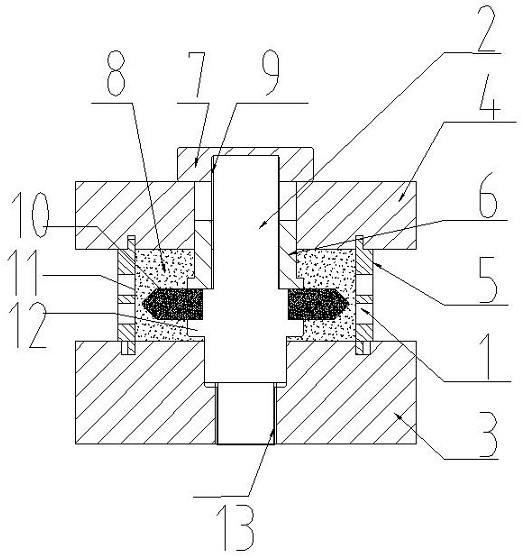

Superhard material electroplated grinding wheel abrasive rearrangement and uniform distribution sanding device and method

The invention provides a superhard material electroplated grinding wheel abrasive rearrangement and uniform distribution sanding device and method. The superhard material electroplated grinding wheelabrasive rearrangement and uniform distribution sanding device comprises supporting plates and cover plates which are correspondingly arranged up and down, a sanding shaft is arranged between the supporting plates, a grinding wheel base body is fixedly arranged on the sanding shaft, sand covers are arranged between the supporting plates and the cover plates, superhard abrasives are arranged between the sand covers, and the grinding wheel base body is arranged in the superhard abrasives. According to the device, the abrasive density consistency can be improved, quantitative addition of the abrasives is achieved by stipulating the amount of the abrasives, the consistency of pressure in a jig during each time of sanding is guaranteed, a grinding wheel rotates and moves downwards through the characteristic of screw-thread fit, the abrasives attached to the surface of the grinding wheel base body are rearranged, the distribution uniformity of the abrasives is guaranteed, and on the premiseof keeping the total electric quantity unchanged, the consistency of the abrasive density of each grinding wheel is controlled. Meanwhile, the method can achieve one-time sand feeding success, meet the requirement for one-time sand feeding of the electroplated grinding wheel profile, completely eradicate the influence of sand supplementation on the size of the plated grinding wheel and effectivelyreduce the jerk value of the profile of the plated grinding wheel.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Sulfur-containing slow-release compound fertilizer and preparation method thereof

InactiveCN105272577AGood sustained release effectPrevents agglomeration and cakingFertilizer mixturesFertilizerChemistry

The invention relates to the technical field of slow release fertilizers, in particular to a sulfur-containing slow-release compound fertilizer and a preparation method thereof. A sulfur-containing ammonium phosphate mixed and coated slow-release fertilizer is designed to comprise a core layer and a coating layer, the coating layer is subjected to spraying coating treatment through sulfur coating slurry, the raw material ratio of the core layer and the granularity are combined for limitation, the thickness relation between the coating layer and the core layer is combined, accordingly, the prepared sulfur-containing ammonium phosphate mixed and coated fertilizer has a better slow release effect, agglomeration and caking phenomena caused due to the action of the slow-release fertilizer and water in the air are prevented, the quality of the slow-release fertilizer is improved, and the guarantee period is prolonged.

Owner:GUIZHOU KAILIN GRP CO LTD

Building sunscreen heat insulation coating and preparation method thereof

ActiveCN113372776AImprove dispersion stabilityPromote the development of high-grade green buildingsEpoxy resin coatingsEpoxyNonlinear optical crystal

The invention discloses a building sunscreen heat insulation coating and a preparation method thereof. The preparation method comprises the following steps: mixing waterborne acrylic resin, modified silicon dioxide sol, zinc phosphate, organic fluorine epoxy resin and organic silicon resin to obtain a blended material, adding the blended material into a stirring tank, uniformly stirring, and filtering. Boric acid microparticles and an inorganic filler are doped into a SiO2 sol precursor, so defects in the nonlinear optical crystal are filled, the infrared radiation performance is further regulated and controlled, and the function of enhancing the infrared radiation performance of the atmospheric window wave band is achieved; and a dispersing agent is added the molecular chain of the dispersing agent can be completely expanded in an aqueous solution, and forms a surface adsorption layer with a certain thickness on the surfaces of SiO2 aerogel particles, and a steric hindrance effect is generated, so that the aims of promoting the development of high-grade green buildings and improving the dispersion stability of a SiO2 aerogel system are fulfilled.

Owner:JIANGSU MIRAFUL NANO MATERIAL CO LTD +1

SiO2-TiO2 composite metamaterial structure photocatalyst and preparation method thereof

ActiveCN111437806AImprove photocatalytic performanceImprove liquidityCatalyst activation/preparationEnergy based wastewater treatmentPhoto catalysisPhotochemistry

The invention discloses a SiO2-TiO2 composite metamaterial structure photocatalyst and a preparation method thereof. The preparation method comprises the following steps: preparing a SiO2 inverse opalstructure by taking PS colloidal crystals as a template, and growing TiO2 in the SiO2 inverse opal structure by adopting a hydrothermal method to prepare the SiO2-TiO2 composite metamaterial structure photocatalyst. The method is simple in process, short in period, simple in equipment and low in cost, and the obtained composite material shows high photocatalytic performance due to the change of curved surface composite morphology.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of building sun-proof and heat-insulating coating and preparation method thereof

ActiveCN113372776BImprove dispersion stabilityPromote the development of high-grade green buildingsEpoxy resin coatingsEpoxyNonlinear optical crystal

Owner:JIANGSU MIRAFUL NANO MATERIAL CO LTD +1

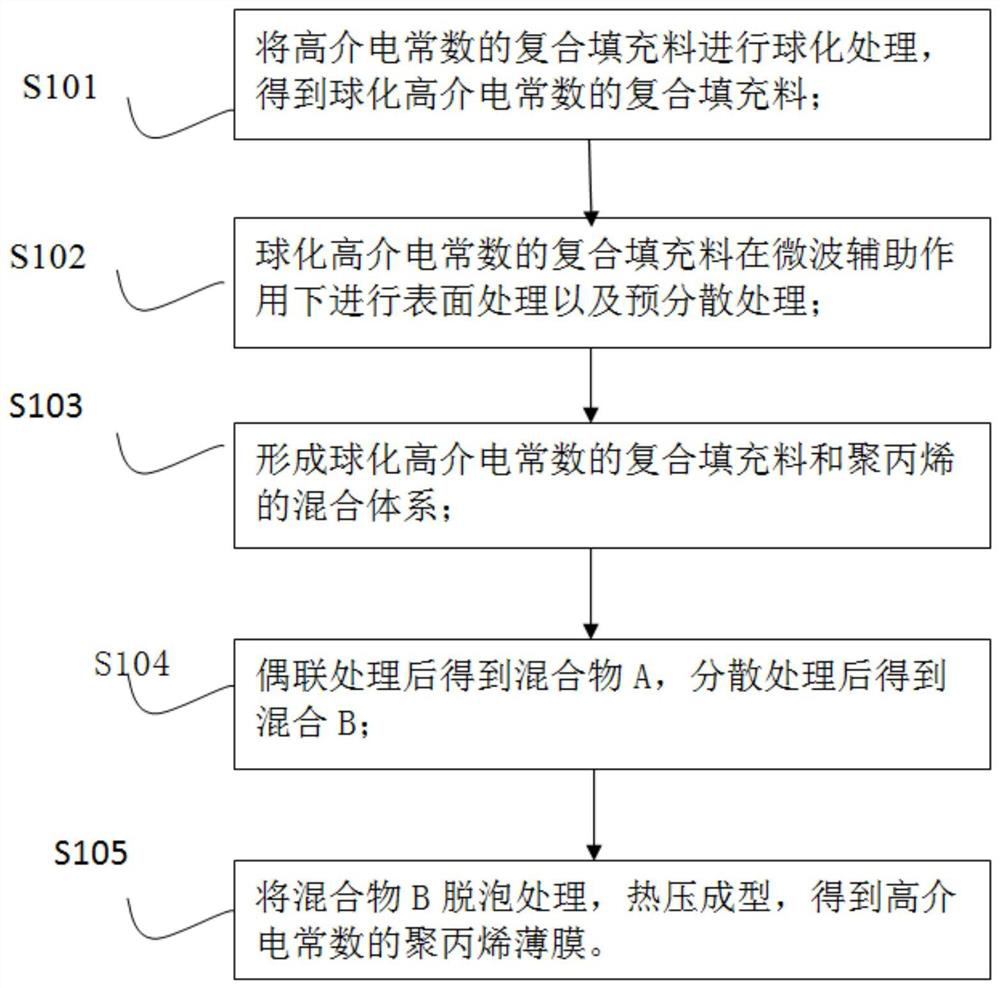

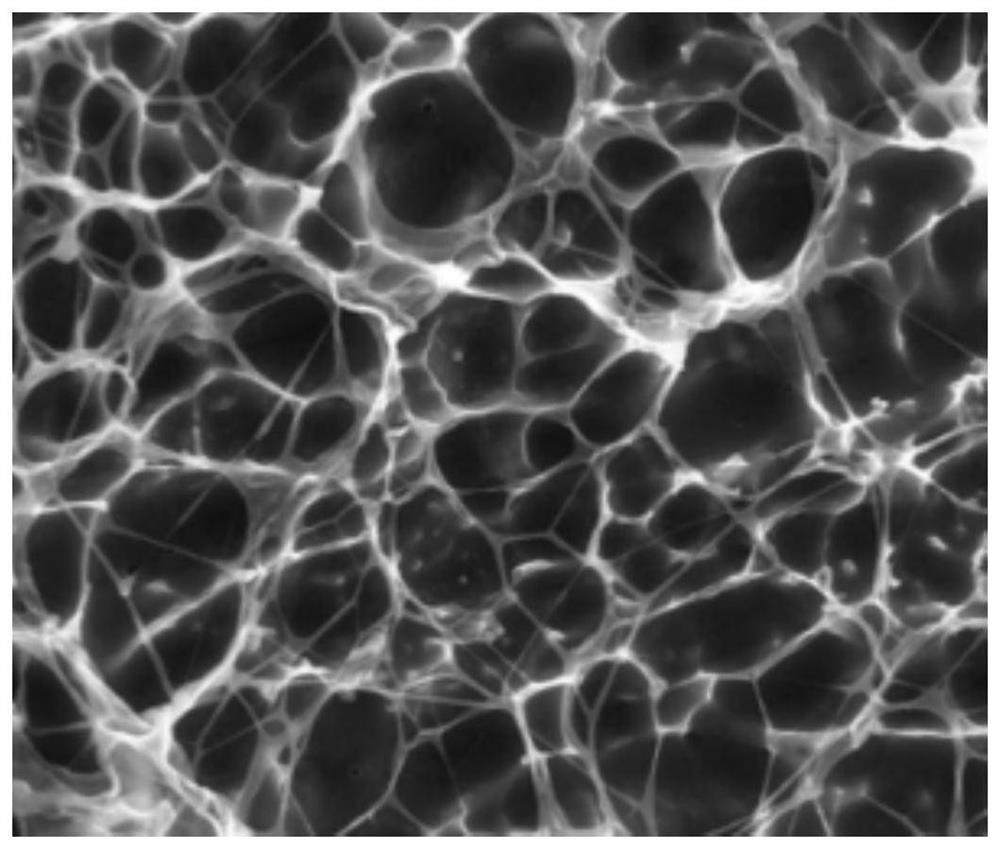

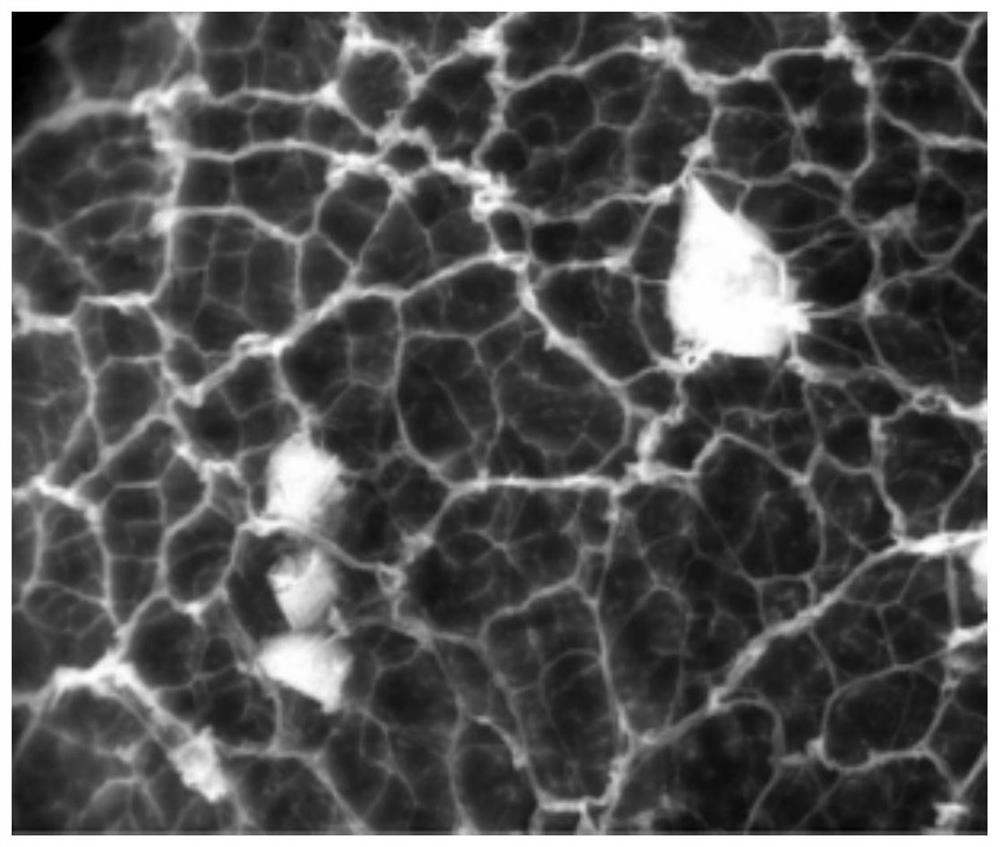

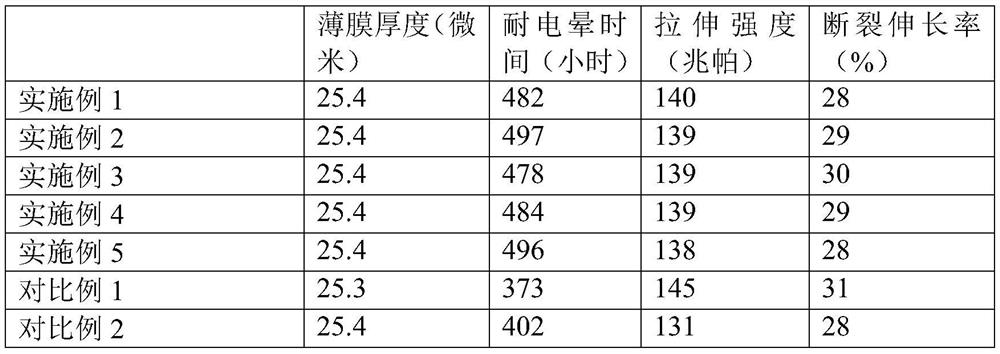

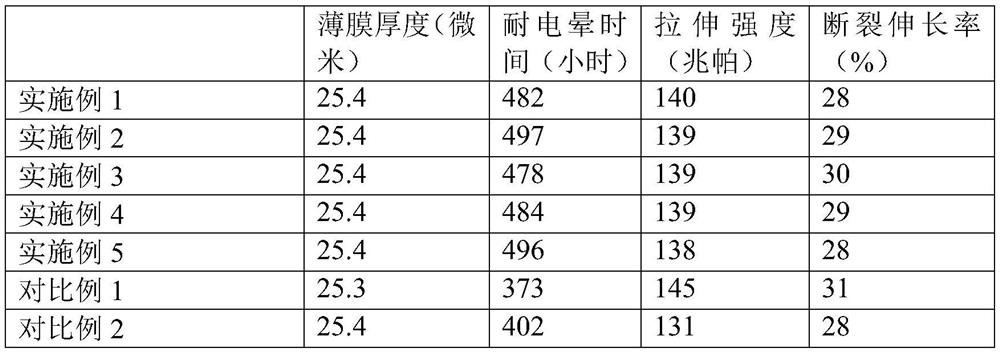

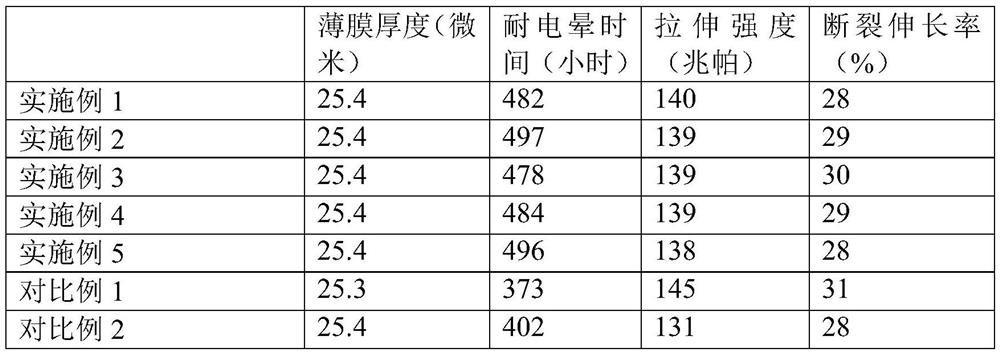

Method for improving dielectric constant of polypropylene film

ActiveCN111607125AImprove interface compatibilityGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentThin membraneDielectric loss

The invention provides a method for improving the dielectric constant of a polypropylene film. The method comprises the following steps of: putting a composite filler with a high dielectric constant into a spheroidizing device into which a direct-current arc plasma flame flow is introduced, and spheroidizing under the action of surface tension to obtain a spheroidized high-dielectric-constant composite filler with the average particle size of 95-270nm and the average pore size of 350-650nm; and carrying out surface treatment and pre-dispersion treatment on the spheroidized high-dielectric-constant composite filler under the assistance of microwaves, and adding the filler to the polypropylene film preparation process. The problem of easy agglomeration of the filler can be solved on the premise of the guaranteeing of the mechanical property of the polypropylene film, the dielectric constant of the polypropylene film can be improved, the dielectric loss is low, the breakdown field intensity is more than 430 KV / mm, and better application reliability can be obtained in the actual application.

Owner:STATE GRID CORP OF CHINA +1

A kind of polyimide composite material, composite film and preparation method thereof

The invention relates to a polyimide composite material, a composite film and a preparation method thereof. Polyimide composite materials include polyimide, noble metal Au, Ag or Pt nanoparticles and TiO 2 nanotubes, noble metal nanoparticles grown in situ on the TiO 2 on the inner and outer walls of the nanotubes. Photoreduction process on TiO 2 In-situ growth of noble metal nanoparticles on the inner and outer walls of nanotubes, and then adding them to dianhydride and diamine precursors for in-situ polymerization to obtain polyimide precursor composite materials, and then imidization to obtain the described Polyimide composite material. On the upper and lower surfaces of the ordinary polyimide intermediate layer, the polyimide precursor composite material is coated at the same time, and then imidized to obtain a polyimide composite film. The polyimide composite film of the invention has obviously improved corona resistance while maintaining excellent mechanical properties.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

Method for recovering organic tin acetate from waste floccules in sucralose production

PendingCN113717215AReduce concentrationGood dispersionEsterified saccharide compoundsTin organic compoundsPtru catalystSucrose

The invention relates to a method for recovering organic tin acetate from waste floccules in sucralose production, which comprises the steps of distillation, neutralization, centrifugation, water separation, acylation and extraction, and is characterized in that between the distillation step and the neutralization step, a black brown floccule obtained by distillation is mixed with and dissolved in a protonic solvent according to a volume ratio of 10: (1-5); and crude dibutyltin oxide obtained through centrifugation in the neutralization step is dried at 40-100 DEG C to obtain dried crude dibutyltin oxide. The method has the advantages that the black brown floccule is dissolved with the protic solvent, the dispersion effect of the dibutyltin oxide in water can be promoted, the treated dibutyltin oxide powder is uniform in particle, the appearance of the product is similar to that of a pure product in color, the impurity content is low, and the production efficiency can reach the standard of a normal catalyst and is relatively stable; and the method is easy to operate, the reaction efficiency and the material utilization rate of the whole production process are optimized, and the economic benefits of enterprises are obviously increased.

Owner:ANHUI JINGHE IND

Preparation method of nano hard alloy

ActiveCN114855018AHall flow rate is fastIncreased transverse fracture toughnessTransportation and packagingMetal-working apparatusAlcoholAlloy

The invention provides a preparation method of a nano hard alloy, which comprises the following steps: providing a ball mill, adding powdered tungsten carbide, powdered cobalt, a nucleation inhibitor, absolute ethyl alcohol, a dispersing agent and paraffin into the ball mill, dissolving the dispersing agent in the absolute ethyl alcohol, adding the mixture into the ball mill, and uniformly stirring; the dispersing agent comprises fatty alcohol-polyoxyethylene ether, polyglycerol-6 laurate and stearic acid, and continuously ball-milling to obtain a first nano hard alloy mixture; the first nano hard alloy mixture is dried to remove absolute ethyl alcohol, and a second nano hard alloy mixture is obtained; and the second nano hard alloy mixture is placed in a mold, dewaxing is conducted on the second nano hard alloy mixture to remove the paraffin and the dispersing agent, and then sintering is conducted to obtain the nano hard alloy.

Owner:晋城鸿智纳米光机电研究院有限公司 +1

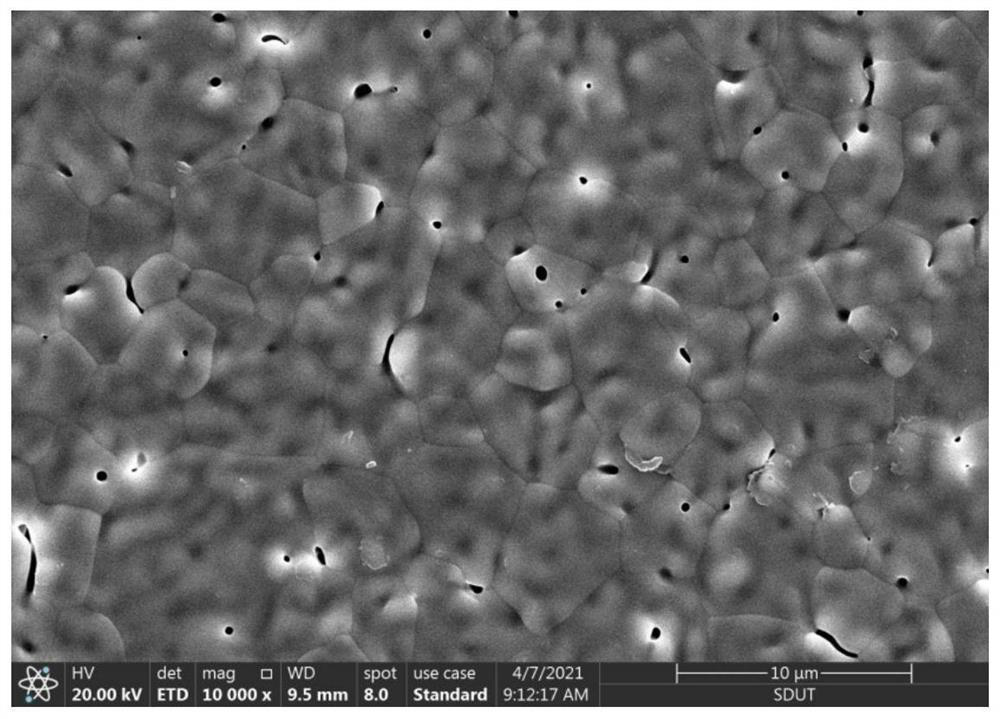

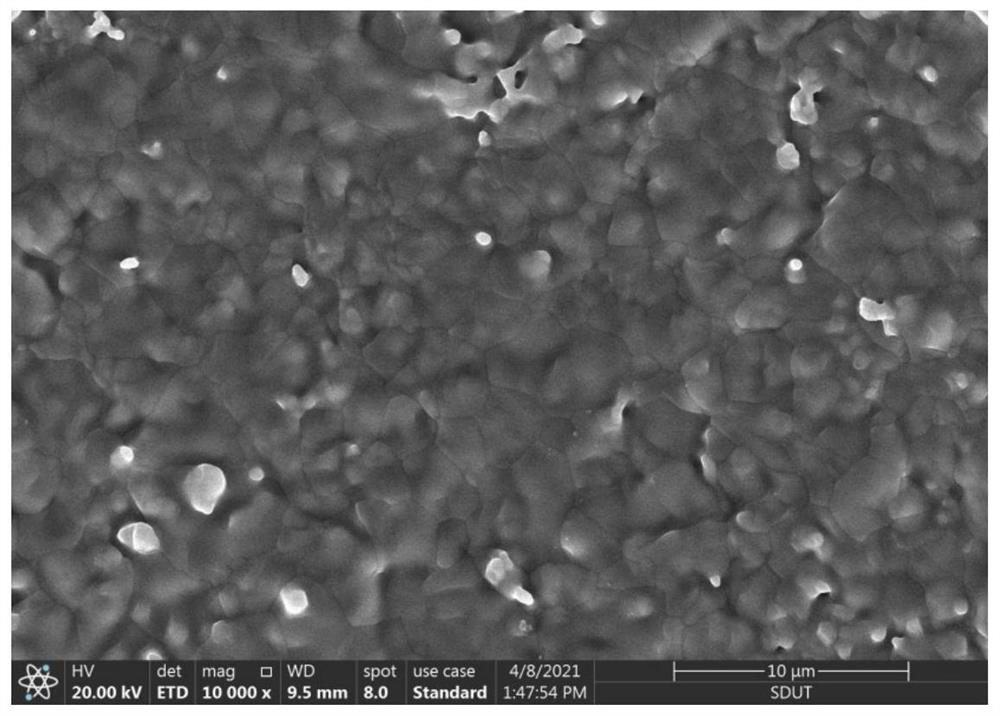

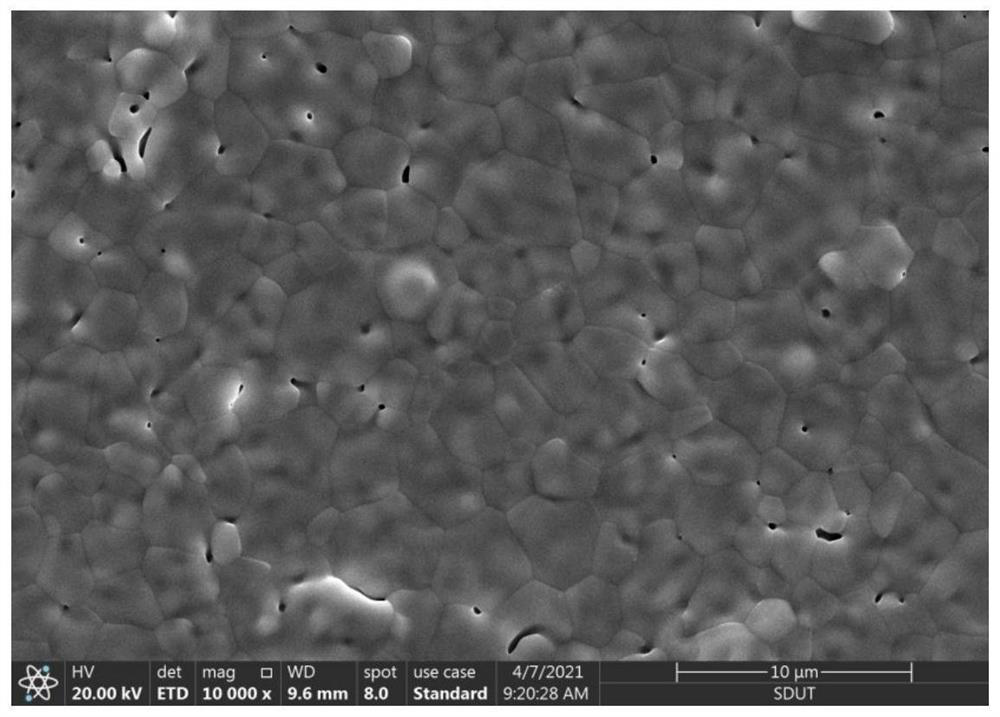

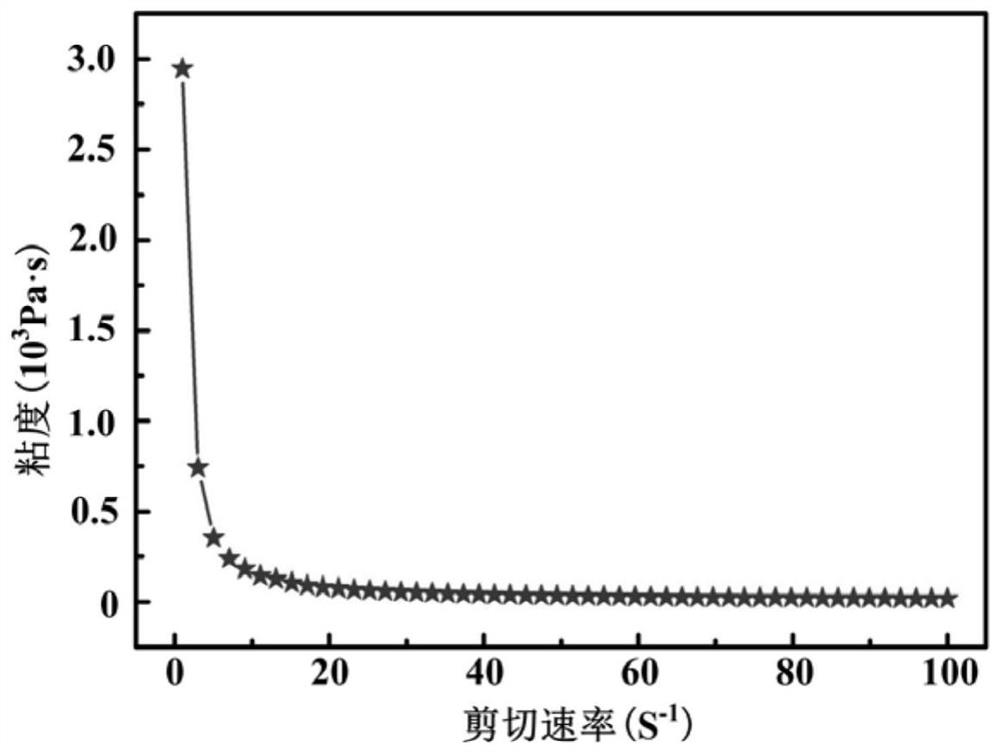

YSZ electrolyte slurry and preparation method thereof

The invention provides YSZ electrolyte slurry, which comprises YSZ powder, a binder and a dispersing agent, and the YSZ powder comprises nano-scale YSZ powder, submicron-scale YSZ powder and micron-scale YSZ powder; the particle size D50 of the nano-scale YSZ powder is 0.05-0.07 [mu] m, the particle size D50 of the submicron-scale YSZ powder is 0.1-0.5 [mu] m, and the particle size D50 of the micron-scale YSZ powder is 1-1.2 [mu] m. According to the invention, the nanoscale, submicron and micron YSZ powder with the particle size range is adopted for grain grading, the large-size powder inhibits abnormal growth of crystal grains when an electrolyte membrane layer is prepared, sintering shrinkage of the membrane layer is inhibited, and defects are reduced; and the small-size powder is filled into the pores, is preferentially sintered at a high temperature and is in contact with the large-size powder to generate mass transfer, so that grain growth rearrangement is promoted, and the densification of the electrolyte membrane layer is further promoted. On the premise of reducing defects of the electrolyte membrane layer and ensuring compactness through grain composition, the sintering temperature required for compactness of the electrolyte membrane layer is reduced. In addition, the dispersing agent inhibits powder agglomeration and improves the dispersity, so that the slurry is uniformly dispersed.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Preparation method of negative electrode slurry for 3D printing

InactiveCN112382744AGuaranteed molding effectSmall particle sizeCell electrodesSecondary cellsSlurryUltrasonic oscillation

The invention discloses a preparation method of negative electrode slurry for 3D printing in the field of chemical energy storage batteries, which comprises the following steps: weighing carboxymethylcellulose (CMC), putting the CMC into water, carrying out ultrasonic oscillation dissolution, adding a silicon-carbon material, a conductive agent and SBR, and uniformly mixing by using a planetary dispersion machine to obtain 3D printing slurry. The negative electrode slurry provided by the invention can be directly used for direct-writing 3D printing, manufacturing a preformed pole piece and then drying to obtain the pole piece, and the preparation method is simple, and due to short preparation time, agglomeration and mixing can be reduced, so that the negative electrode slurry is more uniform, the printing fluency is improved, and the performance of the pole piece is more excellent.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD +1

Polyimide composite material, composite film and preparation methods of polyimide composite material, composite film

The invention relates to a polyimide composite material, a composite film and preparation methods of thepolyimide composite material and the composite film. The polyimide composite material comprises polyimide, noble metal Au, Ag or Pt nanoparticles and a TiO2 nanotube, wherein the noble metal nanoparticles grow on the inner wall and the outer wall of the TiO2 nanotube in situ. The preparation method of the polyimide composite material comprises the following steps of: performing in-situ growth of noble metal nanoparticles on the inner wall and the outer wall of a TiO2 nanotube through a photoreduction process; adding the TiO2 nanotube with the noble metal nanoparticles into dianhydride and diamine precursors for in-situ polymerization to obtain a polyimide precursor composite material; and performing imidization to obtain the polyimide composite material. The upper and lower surfaces of a common polyimide intermediate layer are coated with the polyimide precursor composite material on at the same time, and then imidization is performed to obtain the polyimide composite film. The polyimide composite film disclosed by the invention has obviously improved corona resistance under the condition of keeping excellent mechanical properties.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

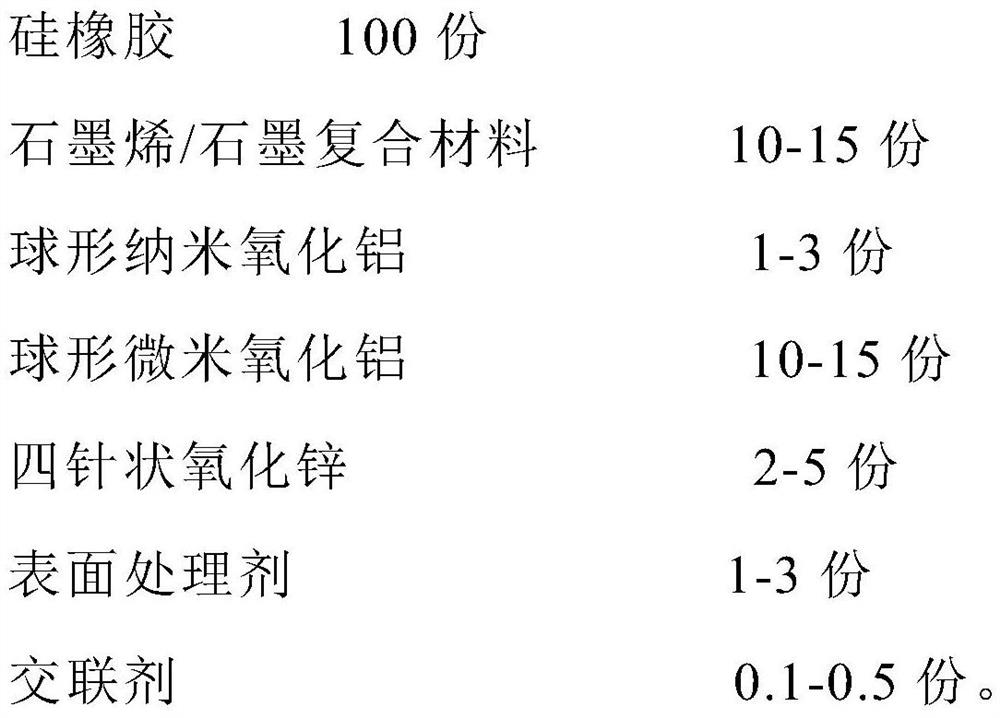

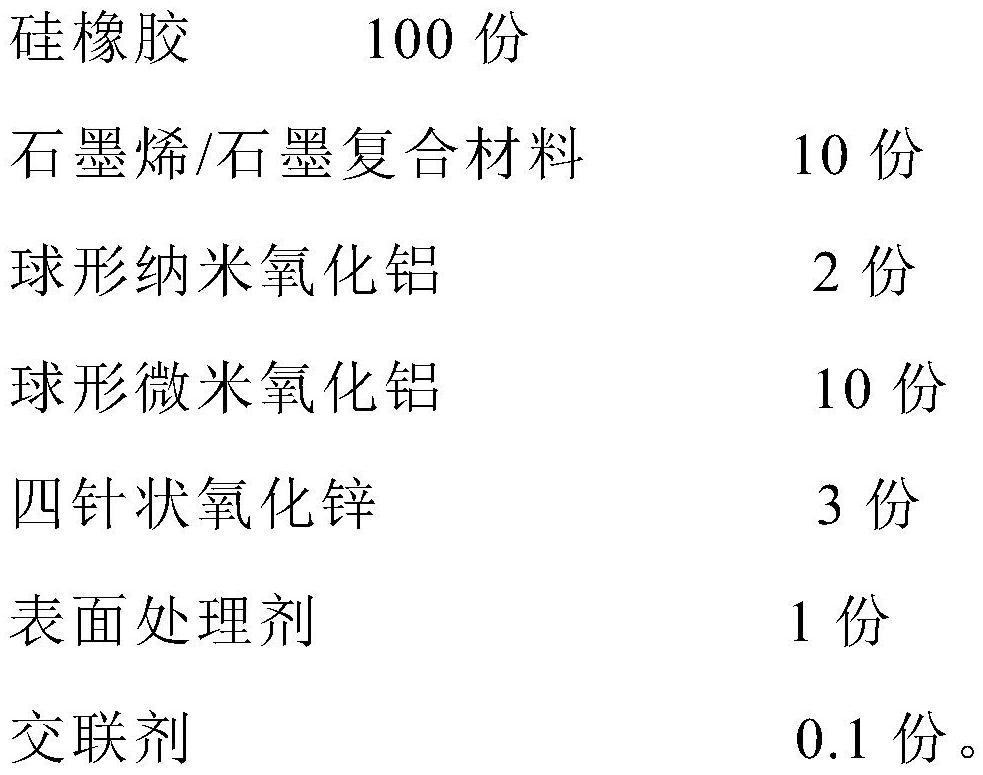

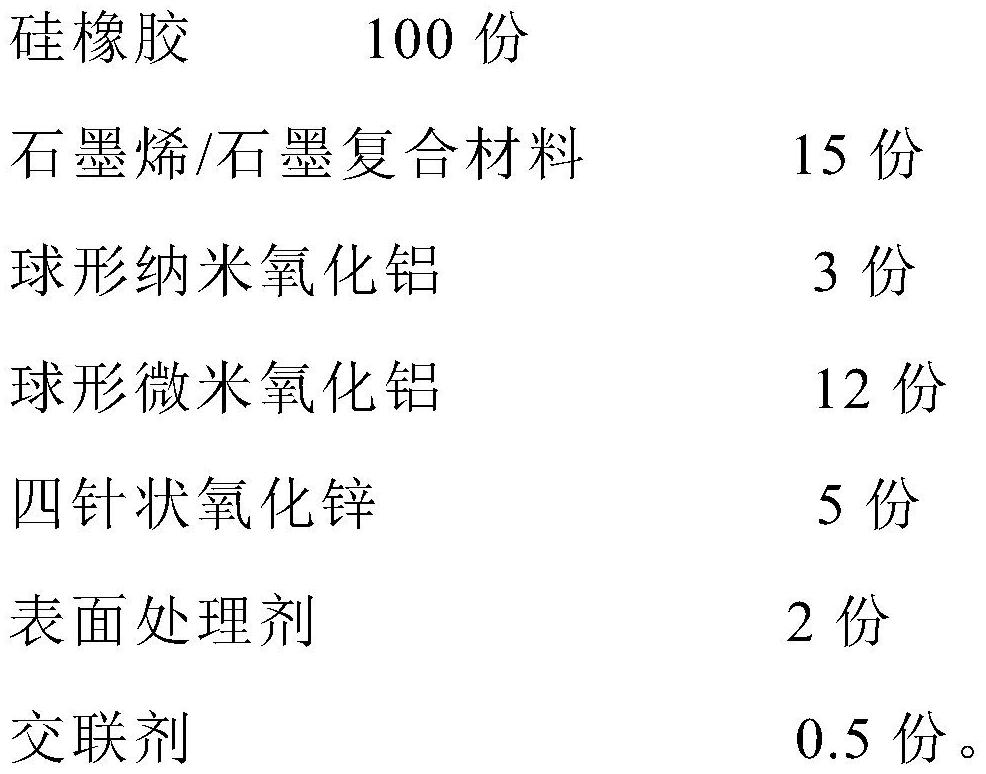

A silicone rubber high thermal conductivity material

ActiveCN112080149BGood compatibilityImprove thermal conductivityHeat-exchange elementsPolymer scienceGraphite particle

The invention relates to the technical field of thermally conductive silicone rubber, in particular to a silicone rubber material with high thermal conductivity. The thermal conductivity of silicone rubber is the same as that of most polymers. The thermal conductivity is poor, and the thermal conductivity is only 0.2w / m·k. Graphene is simply dispersed into the silicone rubber material system. The compatibility of graphene and silicone rubber is not Too good, and the graphene particles are easy to agglomerate, which is very unfavorable for improving the thermal conductivity of silicone rubber. Based on the above problems, the present invention provides a silicone rubber material with high thermal conductivity, which uses a special titanate coupling agent to connect graphene and graphite to form a larger heat conduction network, and adds graphene or graphite and silicone rubber material The compatibility between them reduces the probability of agglomeration of graphene or graphite particles themselves. In the present invention, spherical alumina and tetrapod zinc oxide with different particle sizes are added to the silicone rubber system, and the thermally conductive fillers work synergistically. Greatly improved the thermal conductivity of the silicone rubber material.

Owner:惠州市帕克威乐新材料有限公司

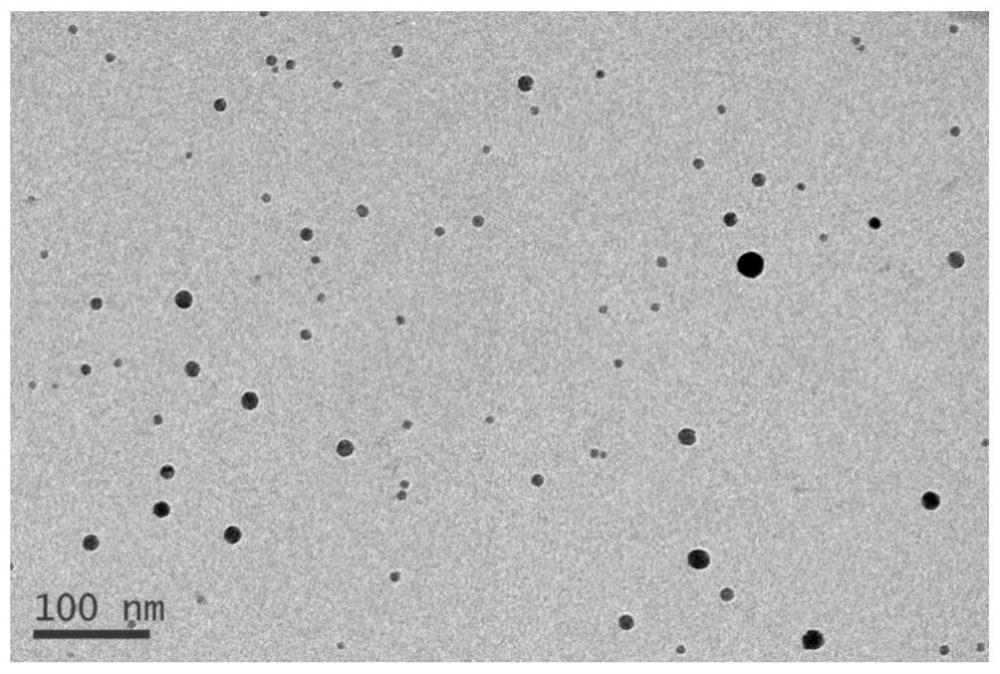

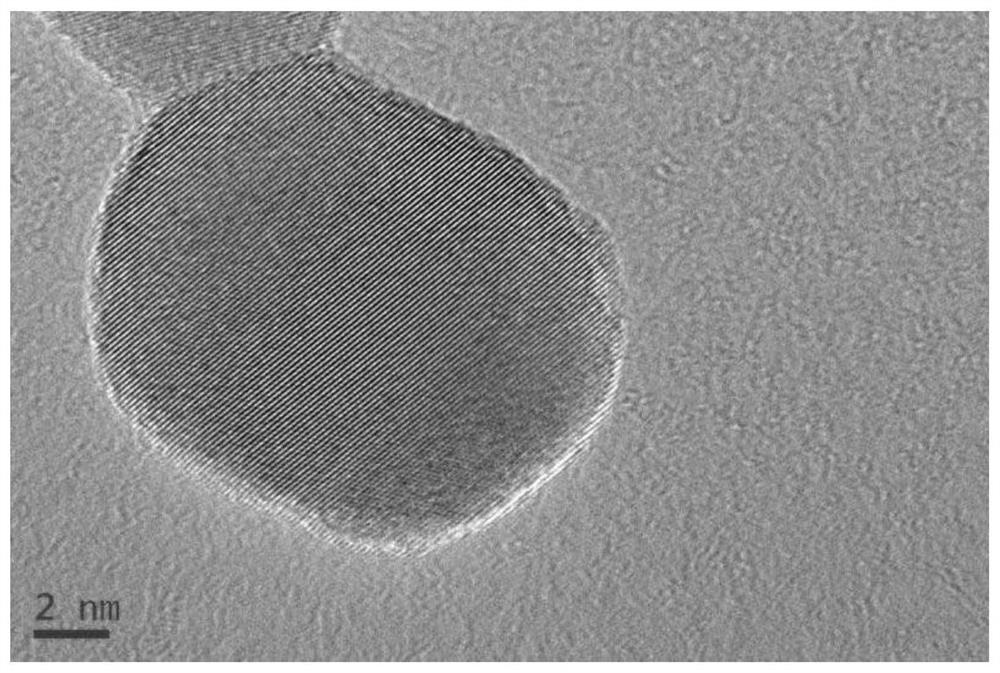

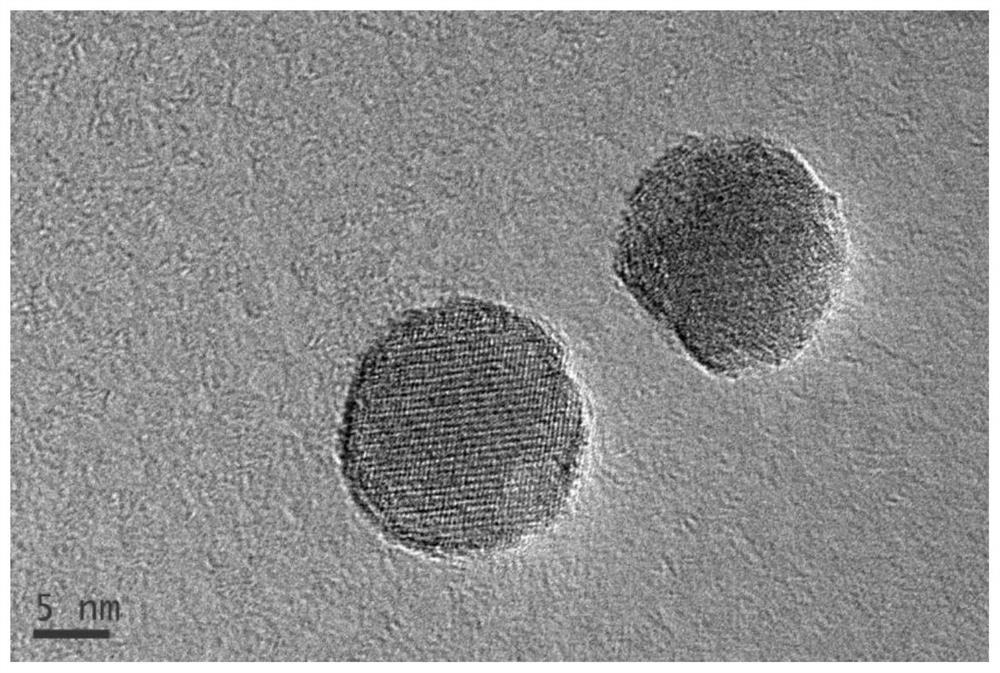

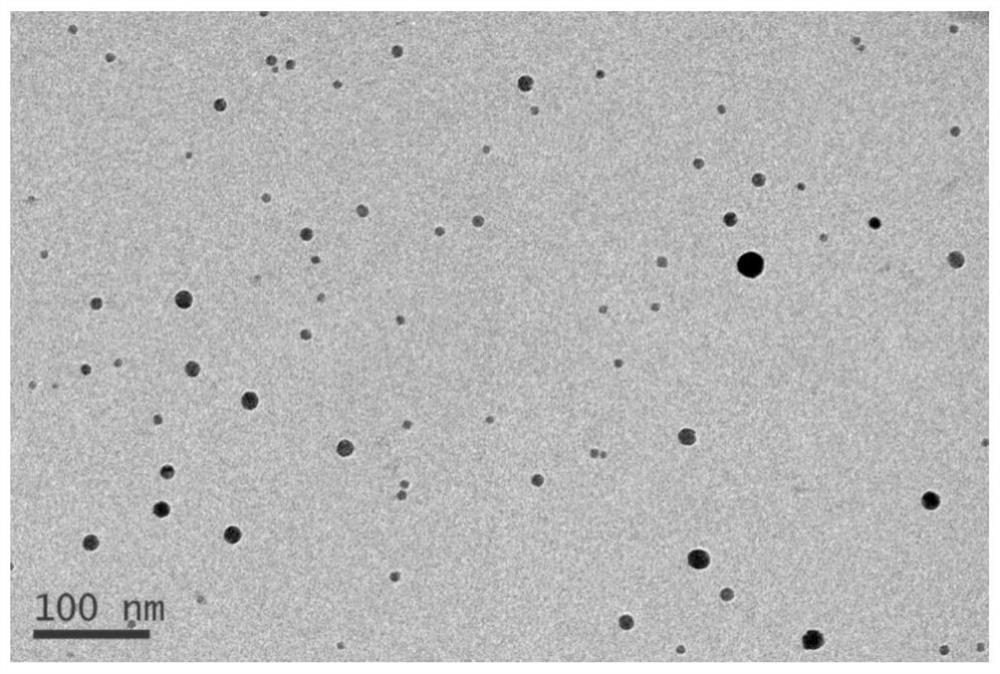

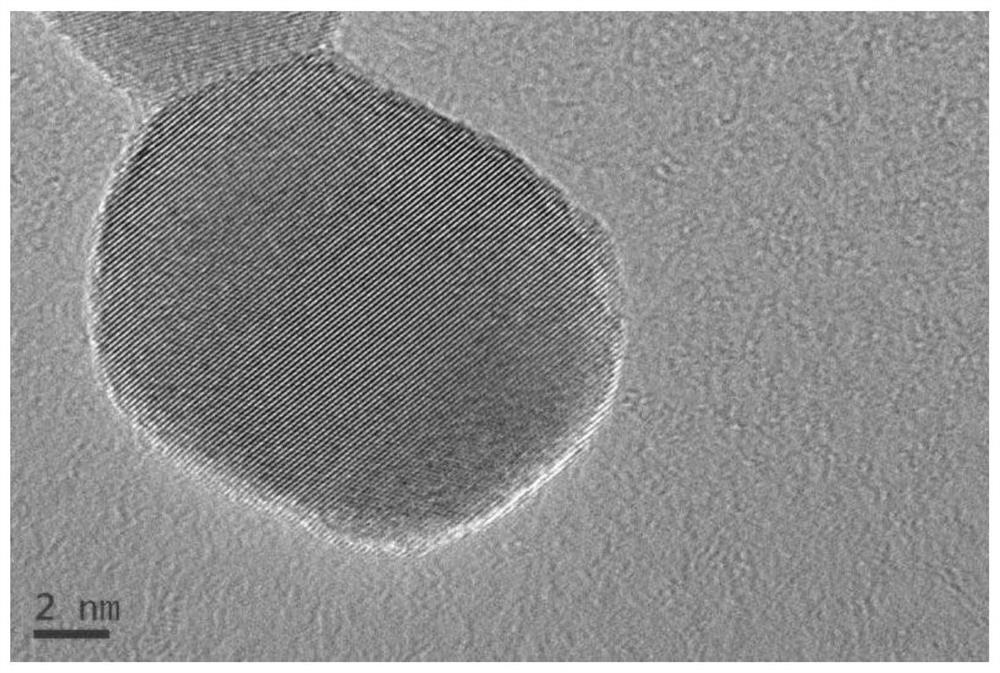

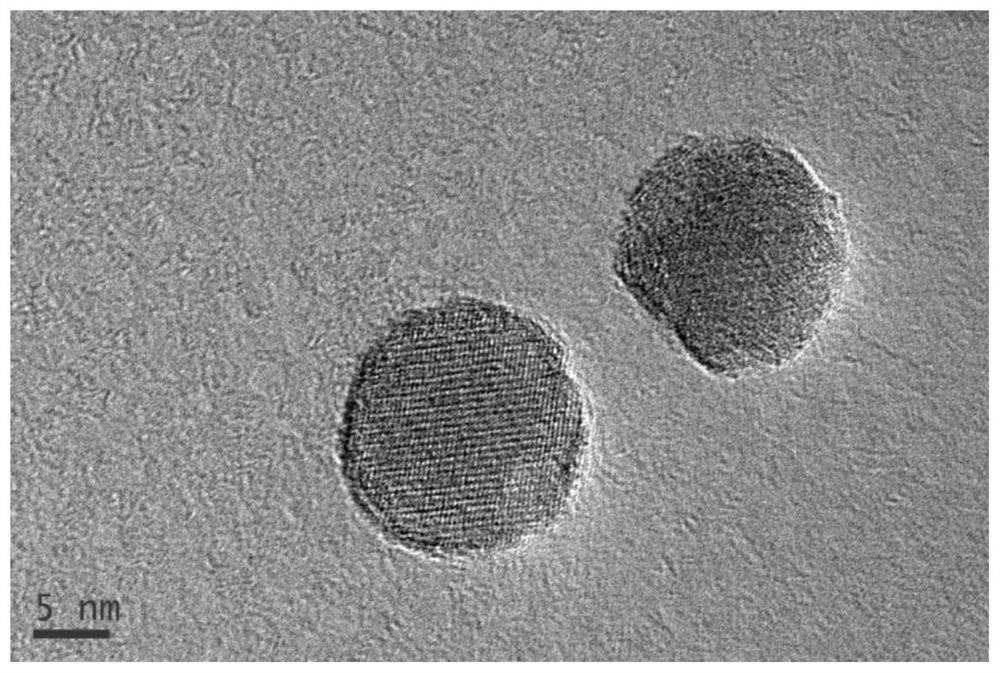

Method for extracting nano second phase by using non-aqueous solution electrolysis system

ActiveCN112255252AQuick extractionSimple methodMaterial analysis by transmitting radiationElectrolytic agentAqueous solution

The invention relates to a method for extracting a nano second phase by using a non-aqueous solution electrolysis system and application thereof. Through the unique design of the electrolysis system,an electrolyte solution forms overflow and eddy current in the electrolysis process, the overflow and eddy current electrolyte solution continuously scours an electrode and an electrolytic cell, and the adsorption of the nano second phase on the surfaces of the electrode and the electrolytic cell and the agglomeration of the nano second phase can be effectively prevented. Through electrolyte solution component design, especially cooperative use of an electrolyte, a thickening agent and a complexing agent, selective electrolytic reaction of the ferromagnetic alloy can be realized, effective separation of a matrix and a second phase in the ferromagnetic alloy is realized, and sedimentation and coating of Fe<3+> on the surface of the second phase are inhibited; the sedimentation resistance ofthe second phase is effectively increased and the sedimentation of the second phase is inhibited. By using the electrolyte solution and the electrolysis system, the electrolytic reaction efficiency can be improved, the collection rate of the second phase with a size smaller than 20nm, especially the collection rate of the second phase with a size smaller than 15nm is increased, and extraction andcharacterization of the nano second phase in the ferromagnetic alloy are achieved.

Owner:CENT SOUTH UNIV

A kind of industrial production method of n-ethylpyrrolidone

ActiveCN110183370BHigh purityHigh yieldOrganic chemistryHeterogenous catalyst chemical elementsPtru catalystPyrrolidinones

The invention provides an industrial production method of N-ethylpyrrolidone, which belongs to the technical field of preparation of fine chemical products, and comprises the following steps: Step 1, adding γ-butyrolactone into a stirred tank, and a tube is welded on the stirrer, The catalyst is filled in the tube, and the solvent flows out through the holes on the tube and fully mixed with γ-butyrolactone; step 2, the material flowing out of the stirred tank is fully mixed with monoethylamine and then sent to the tube reactor, and the feeder has Atomizing nozzle, after the solvent is atomized, it is fully mixed with the material from the upper reaction section, collected, and evenly enters the tubes of the lower reaction section after passing through the distributor; step 3, the product flowing out of the tube-and-tube reactor is sent to the stirring In the jacket of the kettle, after exchanging heat with the material in step 1, it flows out from the outlet of the jacket and enters the refining stage. The invention solves the shortcomings of high reaction temperature, high reaction pressure, high equipment requirements and low environmental protection benefit existing in the existing N-ethylpyrrolidone production.

Owner:MAIQI CHEM CO LTD

A method for extracting nanometer second phase by using non-aqueous solution electrolysis system

ActiveCN112255252BQuick extractionSimple methodMaterial analysis by transmitting radiationElectrolytic agentElectrolyte composition

The invention relates to a method for extracting a nanometer second phase by using a non-aqueous solution electrolysis system and its application. The invention uses a unique design of the electrolysis system to make the electrolyte form overflow and eddy current during the electrolysis process, and the overflow and eddy current electrolyte continuously washes the electrodes and the electrolytic cell, which can effectively prevent the second nano-phase from forming in the electrode and the electrolytic cell. Surface adsorption and agglomeration of nanosecond phases. Through the design of electrolyte composition, especially the combined use of electrolyte, thickener and complexing agent, the selective electrolysis reaction of ferromagnetic alloy can be realized, the effective separation of matrix and second phase in ferromagnetic alloy can be realized, and the Fe 3+ Settling and covering on the surface of the second phase; effectively increasing the second phase settling resistance and inhibiting the second phase settling. The use of the electrolyte solution and electrolysis system is beneficial to improving the efficiency of the electrolysis reaction, improving the collection rate of the second phase with a size smaller than 20nm, especially smaller than 15nm, and realizing the extraction and characterization of the nanometer second phase in the ferromagnetic alloy.

Owner:CENT SOUTH UNIV

A method for preparing non-metallurgical grade alumina by electrolysis

ActiveCN109652813BFine granularityReduce the probability of reunionAluminium compoundsElectrolysis componentsElectrolysisMetallurgy

The invention relates to the technical field of aluminum hydroxide manufacturing, and especially relates to a method for preparing non-metallurgical alumina by an electrolysis process. Reasonable control of the caustic-to-alumna molar ratio of a sodium aluminate solution and electrolysis, washing and microwave radiation treatments make the sodium oxide content of the prepared alumina greatly reduced to 0.1% or less, so the method has the advantages of low cost and high yield; the alumina product has a high purity and a high yield, and a byproduct sodium hydroxide is obtained, so the recyclingof the sodium hydroxide is achieved.

Owner:贵州博汇联润铝业有限公司 +1

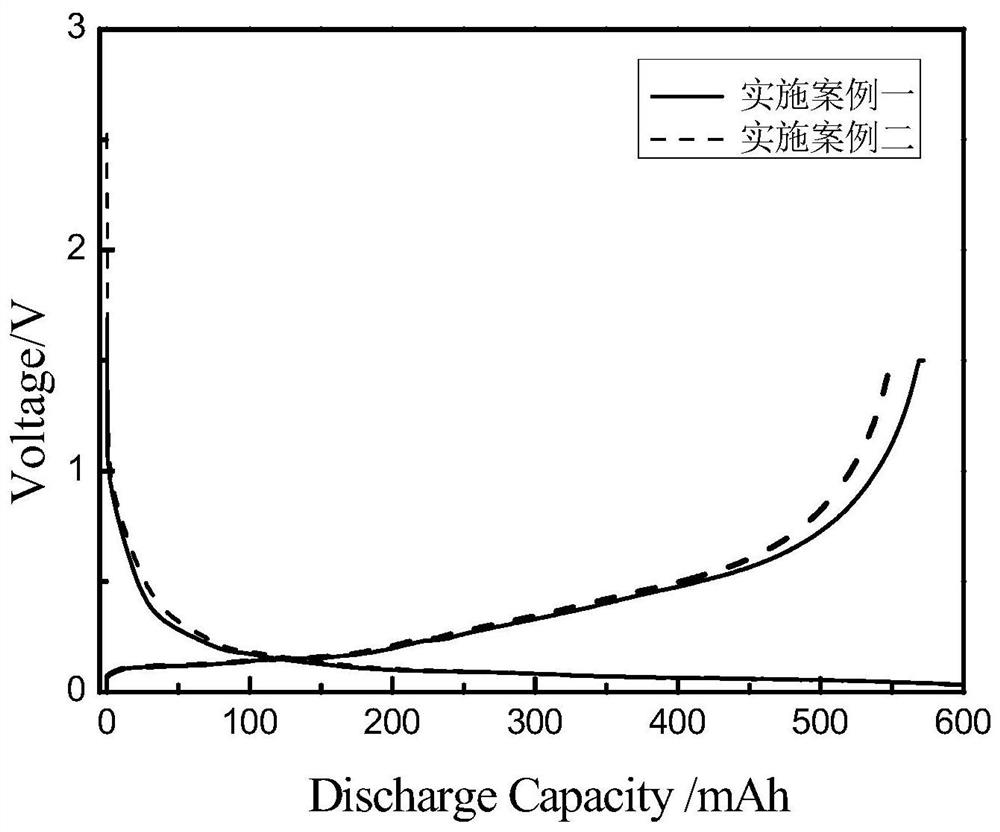

An all-solid-state electrolyte, preparation method thereof, and lithium ion battery

ActiveCN111180788BHigh mechanical strengthImprove interface compatibilitySolid electrolytesSecondary cellsSolid state electrolyteComposite electrolyte

The invention provides an all-solid electrolyte, a preparation method thereof, and a lithium-ion battery. The all-solid electrolyte includes: a first functional layer, an intermediate functional layer, and a second functional layer. The first functional layer is arranged on the lower surface of the intermediate functional layer. The second functional layer is arranged on the upper surface of the intermediate functional layer; wherein, the intermediate functional layer includes a composite electrolyte layer and a modified layer filled inside the composite electrolyte layer and covers the entire upper and lower surfaces of the composite electrolyte layer. The composite electrolyte layer includes an inorganic electrolyte, a polymer substance, lithium salt; the first functional layer and the second functional layer include polymer and lithium salt. The all-solid electrolyte not only has good interfacial stability and interfacial compatibility, but also has high mechanical strength, can well cope with volume strain, reduces the risk of short circuit in battery preparation, and enhances the ability of the electrolyte to suppress lithium dendrites, so it can Effectively improve the cycle performance and charge and discharge capacity of lithium-ion batteries.

Owner:ZHUHAI COSMX BATTERY CO LTD

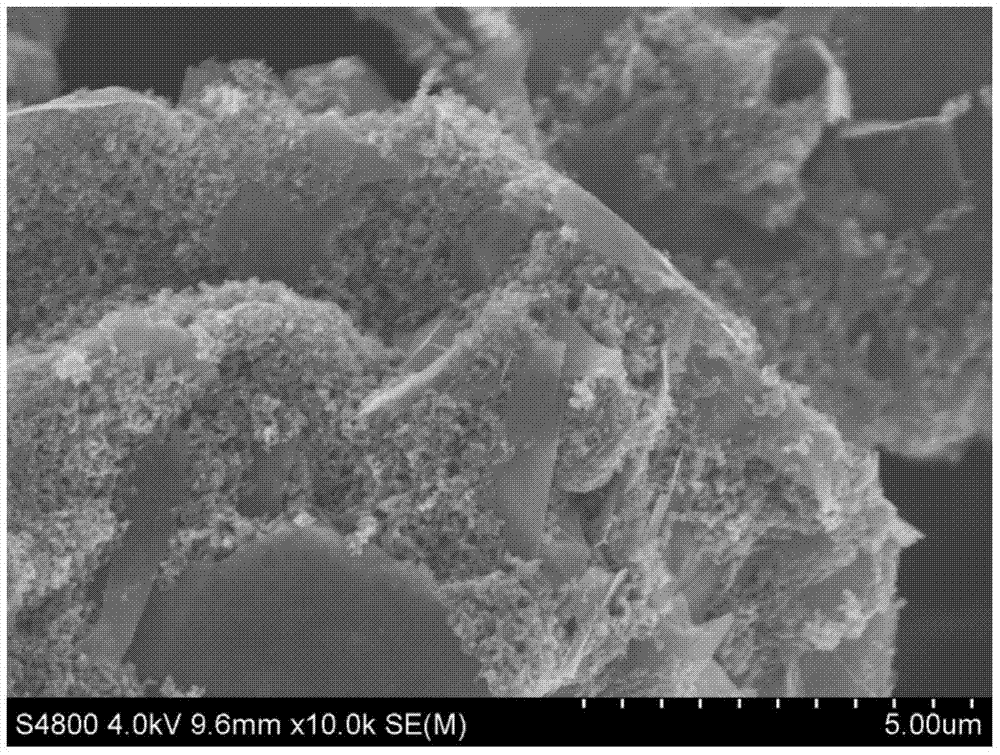

Graphene composite powder material and preparation method thereof

The invention relates to a graphene composite powder material, which comprises a graphene material and a micro-nano structure material attached to the surface of the graphene material. The micro-nano structure material is uniformly dispersed in the graphene material and composited with the graphene material through chemical bonds or physical effects. The graphene composite powder material has the advantages of better dispersibility and less agglomeration. The invention also relates to a preparation method of the graphene composite powder material.

Owner:NINGBO MORSH TECH +1

Superhard material electroplating grinding wheel abrasive rearrangement uniform distribution sanding device and method

ActiveCN112536737BImprove consistencyEnsure consistencyGrinding devicesSuperhard materialGrinding wheel

The invention provides a device and method for rearranging and evenly distributing sand on super-hard material electroplated grinding wheel abrasives, which includes support plates and cover plates correspondingly arranged up and down, upper sand shafts are arranged between the support plates, and the upper sand shafts are fixed A grinding wheel base is provided, a sand cover is provided between the supporting plate and the cover plate, superhard abrasives are arranged between the sand covers, and the grinding wheel base is placed in the superhard abrasives. The invention can improve the consistency of the abrasive density, realize the quantitative addition of abrasives by specifying the amount of abrasives, ensure the consistency of the pressure in the jig each time the sand is applied, and realize the rotation and downward movement of the grinding wheel through the characteristics of thread matching, so that it will be close to the surface of the grinding wheel base The abrasives are rearranged to ensure the uniformity of abrasive distribution, and the consistency of the abrasive density of each grinding wheel is controlled under the premise that the total power remains unchanged. At the same time, the method can realize the success of one-time sanding, realize the single-time sanding requirement of the electroplated grinding wheel profile, eliminate the impact of sand filling on the plated size of the grinding wheel, and can effectively reduce the runout of the plated profile of the grinding wheel.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Polyimide composite material, composite film and preparation method thereof

The invention relates to a polyimide composite material, a composite film and a preparation method thereof. The polyimide composite material comprises polyimide, noble metal Au, Ag or Pt nanoparticles and a TiO2 nanotube, wherein the noble metal nanoparticles grow on the inner wall and the outer wall of the TiO2 nanotube in situ. The preparation method comprises the following steps: performing in-situ growth of noble metal nanoparticles on the inner wall and the outer wall of a TiO2 nanotube through a photoreduction process, adding the noble metal nanoparticles into dianhydride and diamine precursors for in-situ polymerization to obtain a polyimide precursor composite material, and performing imidization to obtain the polyimide composite material. And coating the polyimide precursor composite material on the upper and lower surfaces of the common polyimide intermediate layer at the same time, and then performing imidization to obtain the polyimide composite film. The polyimide composite film disclosed by the invention has obviously improved corona resistance under the condition of keeping excellent mechanical properties.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com