Preparation method of functionalized carbon nanotube powder

A carbon nanotube and functionalization technology, which is applied in the field of carbon nanotube powder preparation, can solve the problem of weak binding force between products and composite materials, high risk of functionalized carbon nanotube reaction, difficult to control, and grafting of surface functionalized groups The efficiency is difficult to control and other problems, and the preparation process is simple and easy, the interface binding force is strong, and the external conditions are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

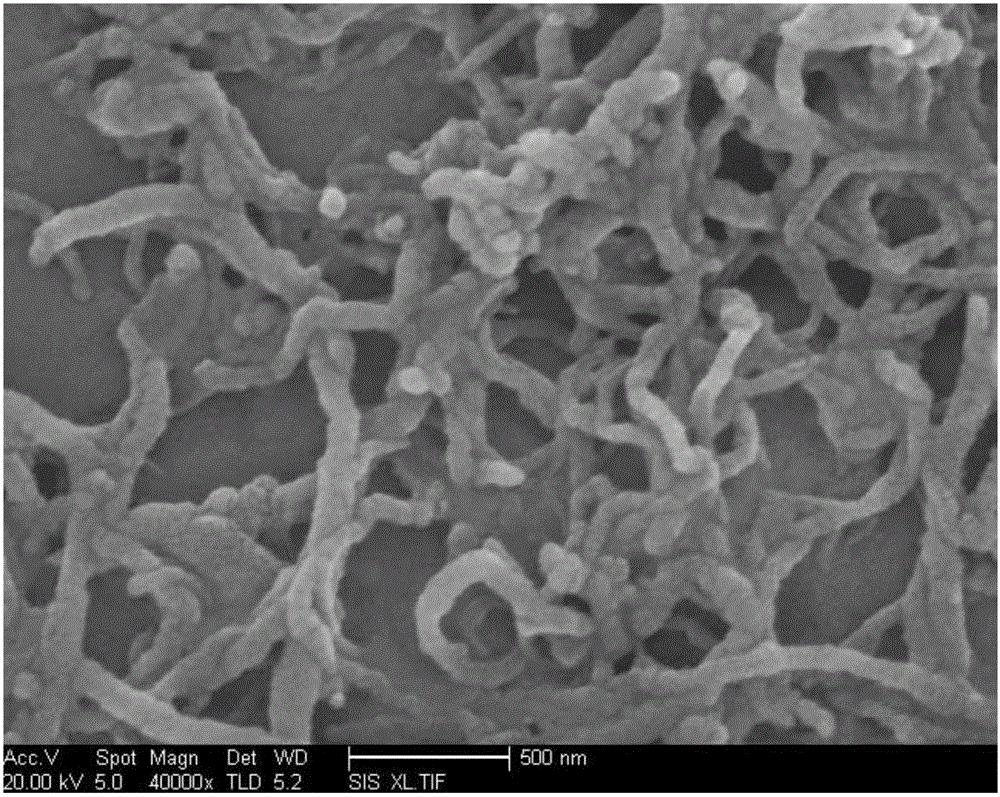

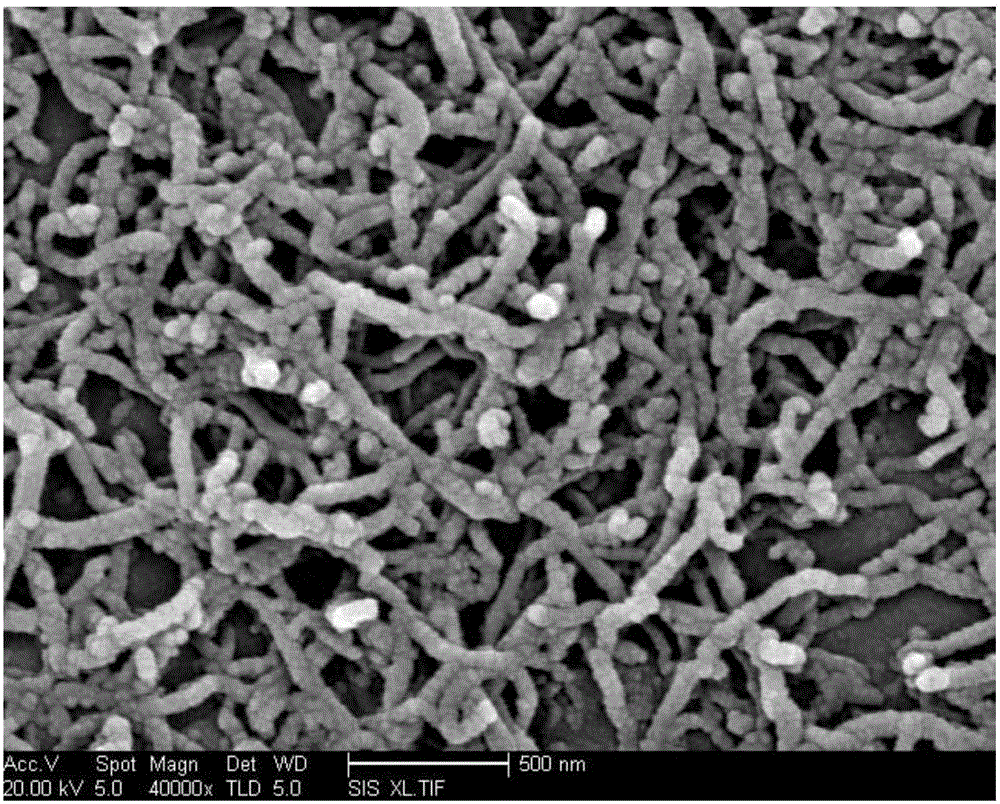

[0036] Specific embodiment one: the preparation method of the functionalized carbon nanotube powder of this embodiment is carried out according to the following steps:

[0037] 1. Place the carbon nanotubes in a tube furnace, heat them at 350-500°C for 1-1.5 hours under a protective atmosphere, and cool down to room temperature after treatment to obtain purified carbon nanotubes;

[0038] 2. With deionized water as solvent, FeSO 4 ·7H 2 O was the solute, and FeSO was prepared by ultrasonic oscillation method 4 solution, and then adjust the pH of the solution;

[0039] 3. Place the carbon nanotubes purified in step 1 in FeSO 4 solution, ultrasonically oscillated to form a stable suspension of carbon nanotubes, and then in a constant temperature oil bath at 15°C, H 2 o 2 Add dropwise into the suspension of carbon nanotubes, carry out mechanical stirring reaction under the irradiation of ultraviolet lamp, stand still after the reaction, and obtain the product;

[0040] 4. W...

specific Embodiment approach 2

[0046] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the carbon nanotubes described in step 1 are multi-walled carbon nanotubes, and the diameter specifications are 10-20, 20-40 or 40-60 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the protective atmosphere in step 1 is a nitrogen atmosphere. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com