Superhard material electroplating grinding wheel abrasive rearrangement uniform distribution sanding device and method

A technology of superhard materials and superabrasives, applied in grinding devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problem of large fluctuations in abrasive density, abrasive agglomeration in the abrasive layer of the grinding wheel, uncontrollable buried sand volume, etc. problems, to reduce the probability of abrasive agglomeration, improve the consistency of abrasive density, and achieve the effect of a single sanding requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

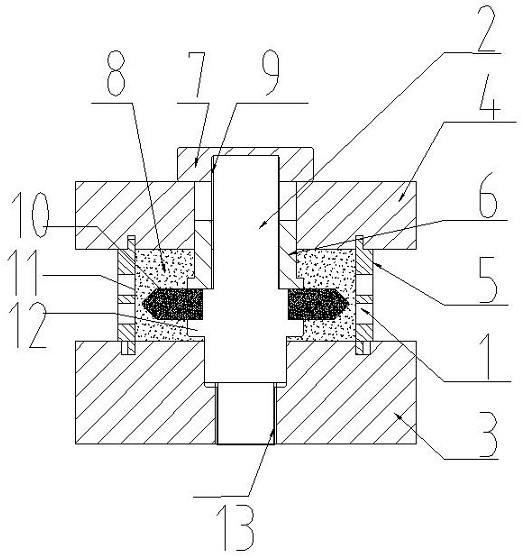

Image

Examples

Embodiment 1

[0037] Electroplating a parallel grinding wheel

[0038] Grinding wheel parameters: diameter 35mm, electroplating surface is cylindrical.

[0039] Base Material: Steel

[0040] (1) Electroplating

[0041] The electroplating solution is configured according to the conventional nickel sulfate electroplating solution formula, and the method is used to bury the sand. After the substrate has undergone pre-treatment, pre-plating and other processes, it is clamped into the patented fixture, filled with abrasive CBN 120 / 140, the volume is 40.5ml, the operation time is 6 minutes, and the sand is placed for 40 minutes. After the electroplating is finished, take out the unloaded sand from the electroplating tank, unscrew the shaft with the grinding wheel, transfer the thickening tank for thickening, and get the finished product after 6 hours of thickening.

[0042] (2) Post-plating detection

[0043] The runout detected by the projector is less than 0.01mm, and the number of abrasive...

Embodiment 2

[0045] Electroplating a Double-end Butterfly Grinding Wheel

[0046] Grinding wheel parameters: diameter 185mm, electroplating surface is single tooth surface.

[0047] Base Material: Steel

[0048] (1) Electroplating

[0049] The electroplating solution is configured according to the formula of the sulfamic acid nickel electroplating solution, and the method is used to bury the sand. After the substrate has undergone pretreatment, pre-plating and other processes, it is clamped into the patented fixture, filled with abrasive CBN 50 / 60, with a volume of 331ml, the operation time is 7 minutes, and the sand is placed for 90 minutes. After the electroplating is finished, take out the unloaded sand from the electroplating tank, unscrew the shaft with the grinding wheel, transfer the thickening tank for thickening, and get the finished product after 17 hours of thickening.

[0050] (2) Post-plating detection

[0051] The runout detected by the projector is less than 0.02mm. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com