Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Reduce the difficulty of stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

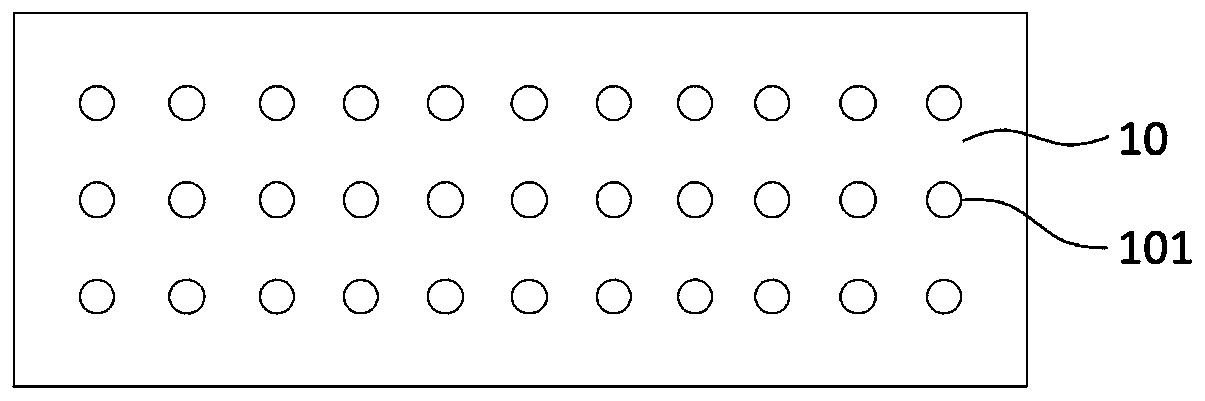

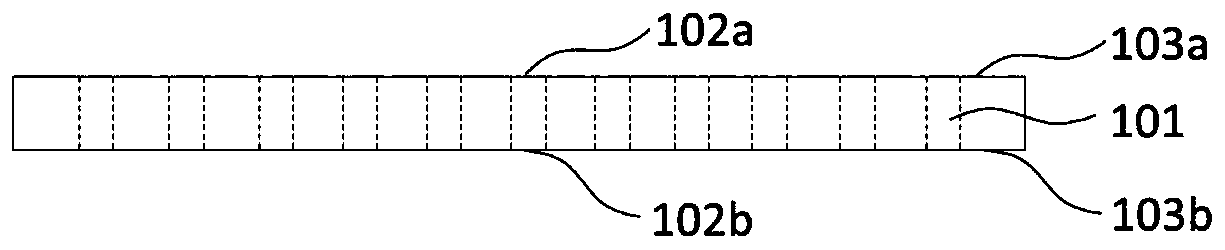

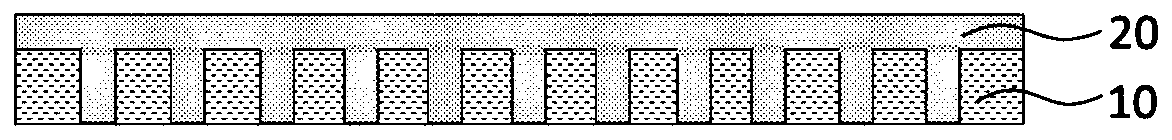

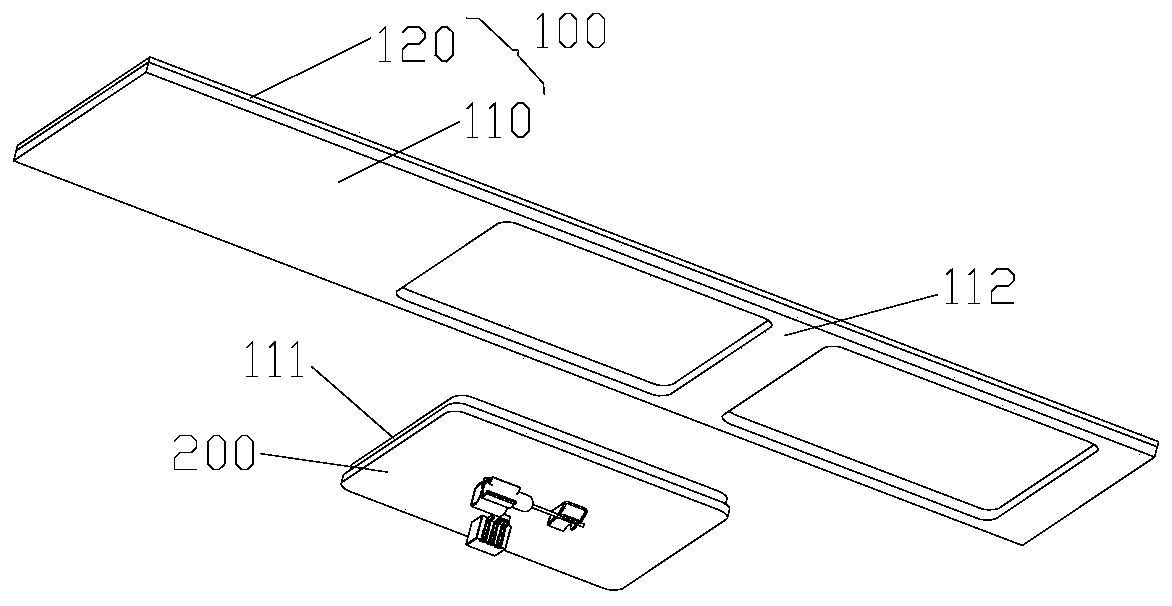

Flexible substrate, production method thereof and display device

ActiveCN104880846AReduce the difficulty of strippingEasy to peelNon-linear opticsProduction lineDisplay device

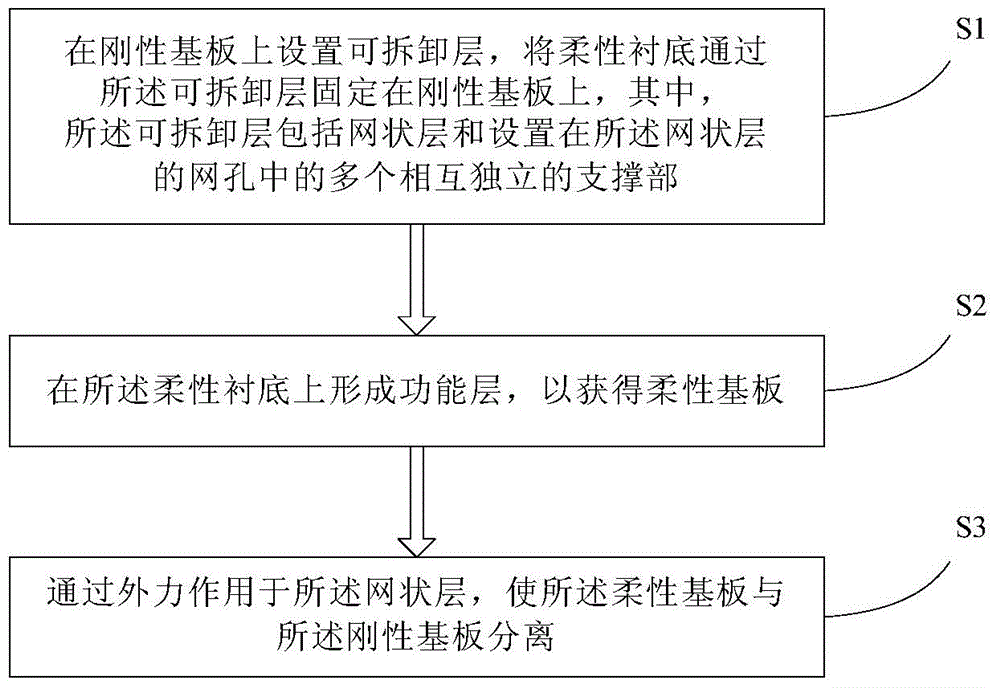

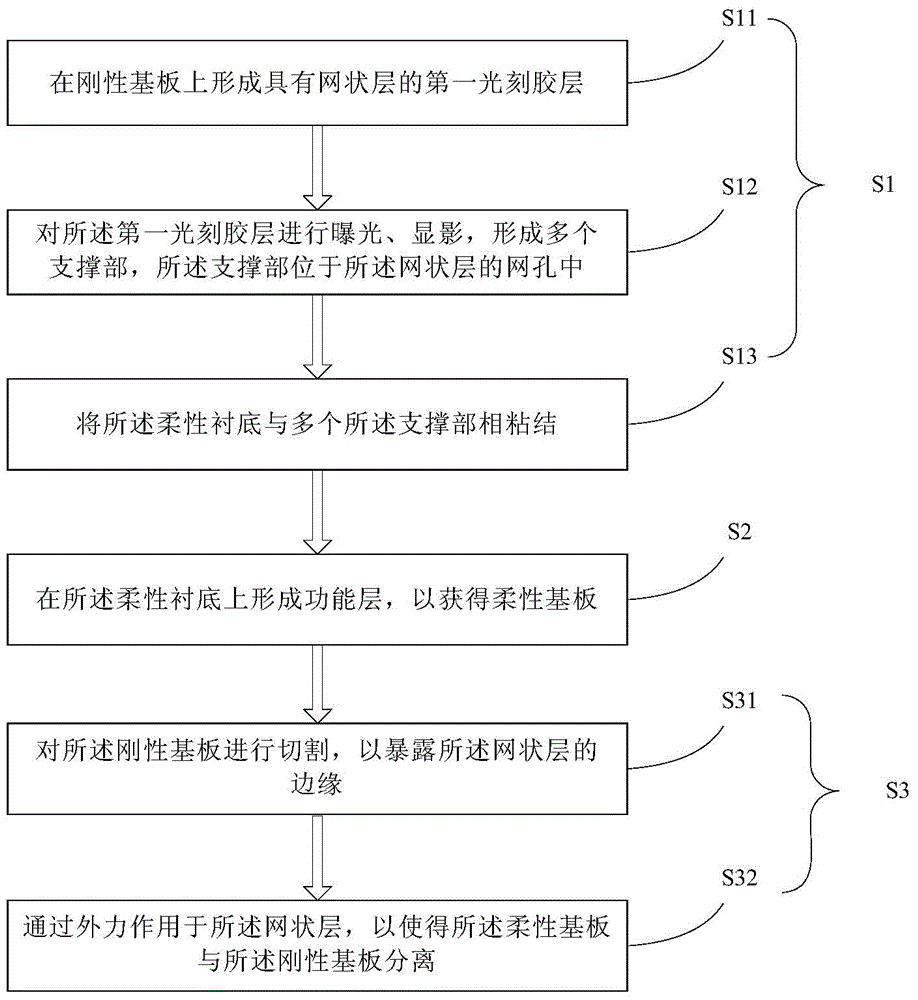

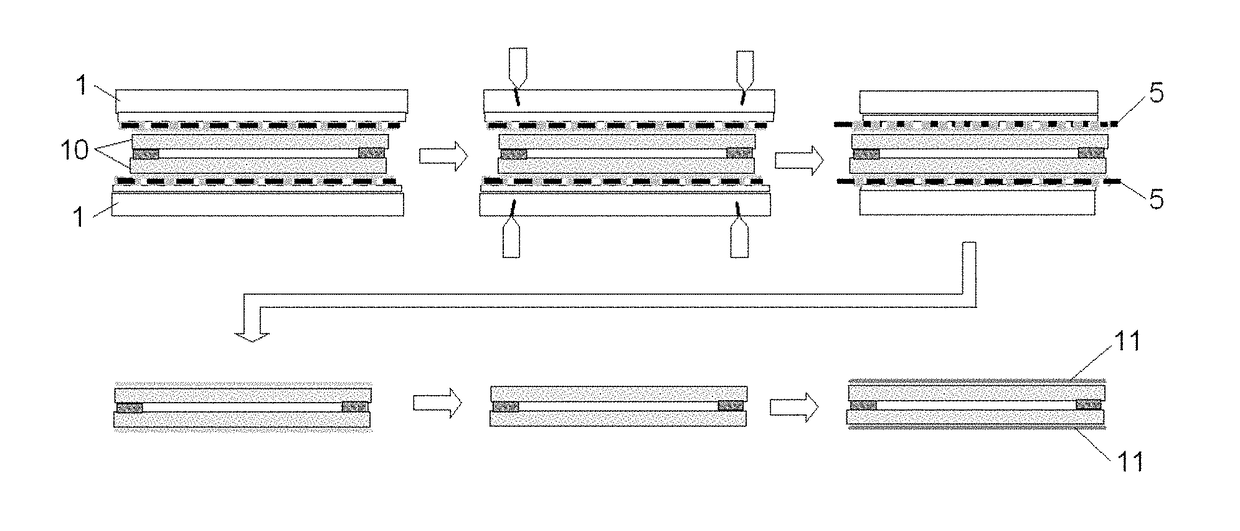

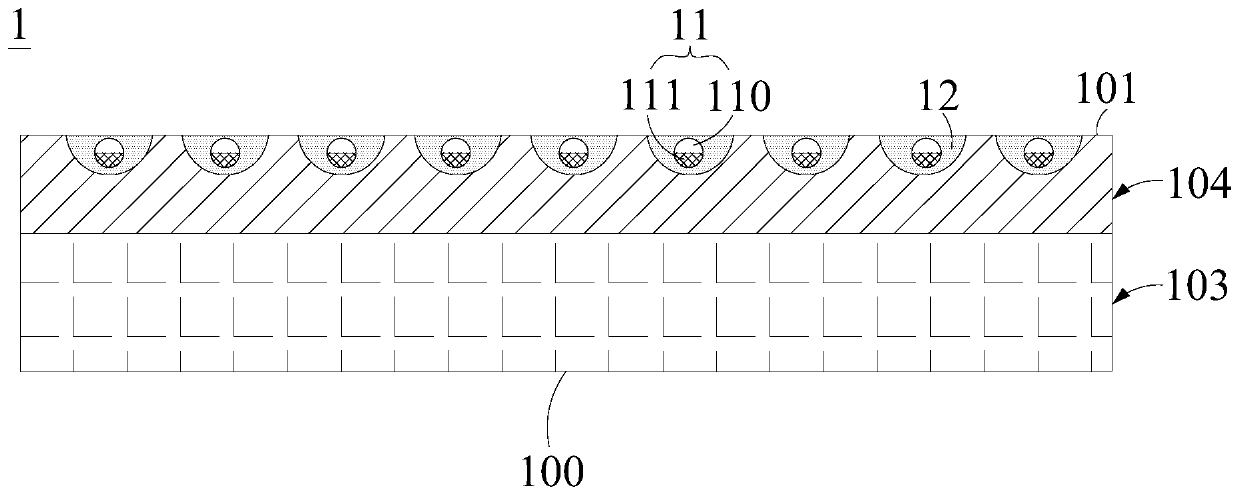

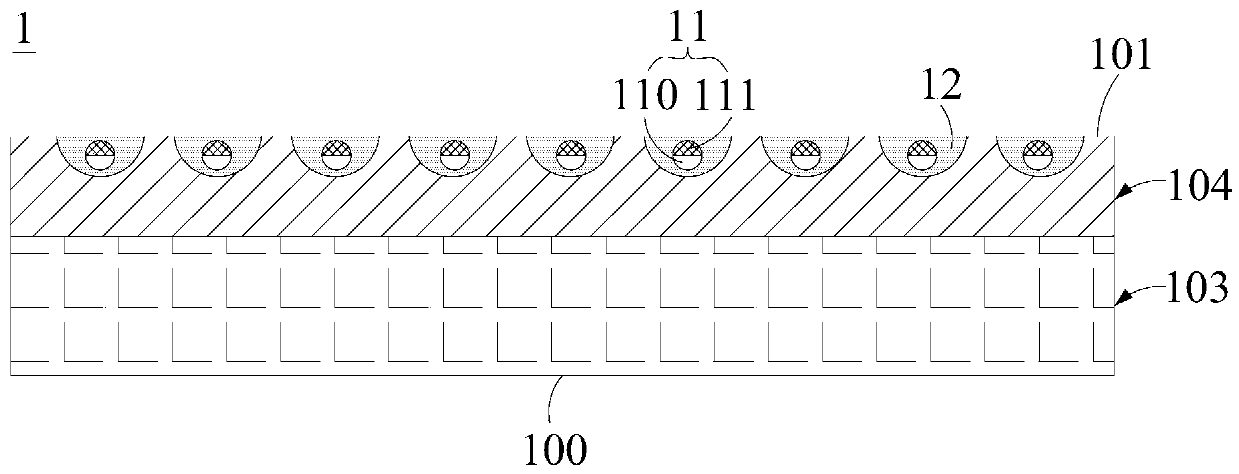

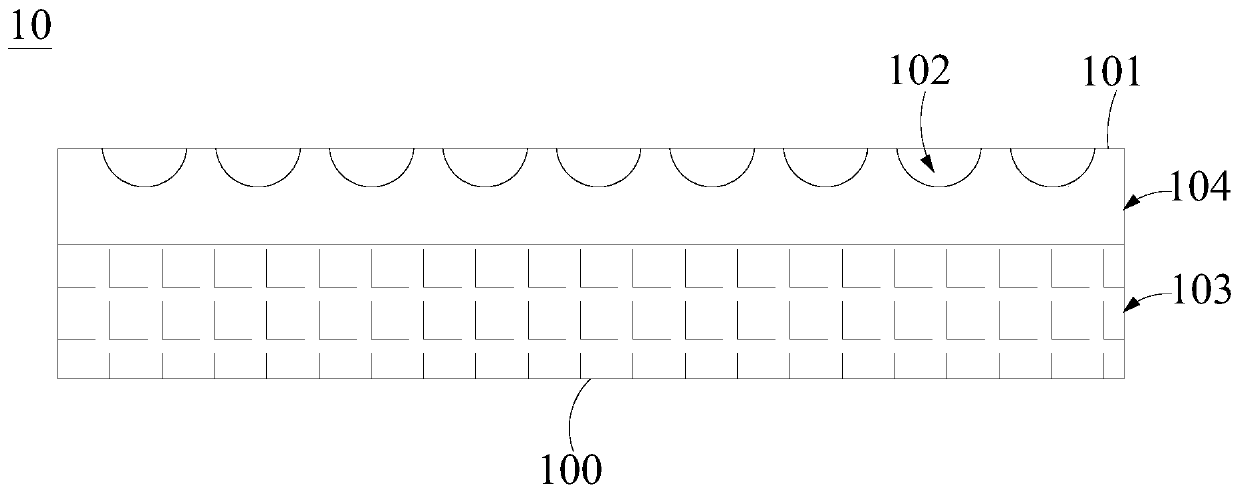

The invention discloses a flexible substrate, a production method thereof and a display device. The production method comprises the following steps: a detachable layer is arranged on a rigid substrate; a flexible underlayer is fixed on the rigid substrate through the detachable layer, wherein the detachable layer comprises a reticular layer and multiple mutually independent support parts arranged in meshes of the reticular layer; a functional layer is formed on the flexible underlayer to obtain the flexible substrate; external force acts on the reticular layer to enable the flexible substrate to be separated from the rigid substrate. The flexible substrate is easier to strip after production, the production yield is improved, the processing compatibility with a common production line is provided, and the cost is saved.

Owner:BOE TECH GRP CO LTD +1

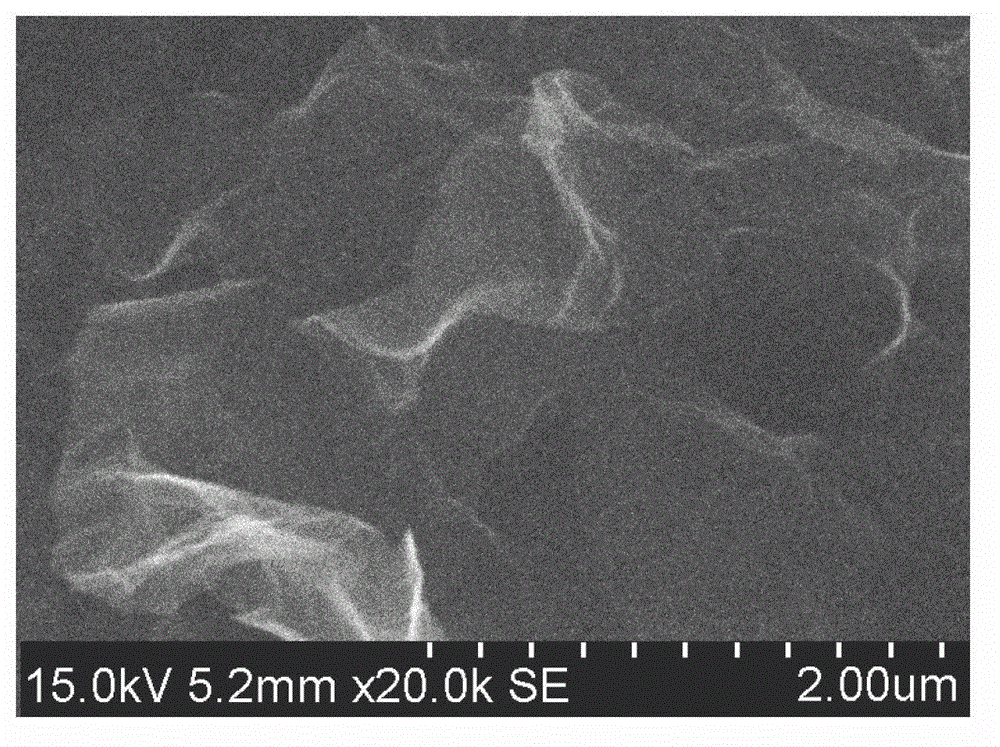

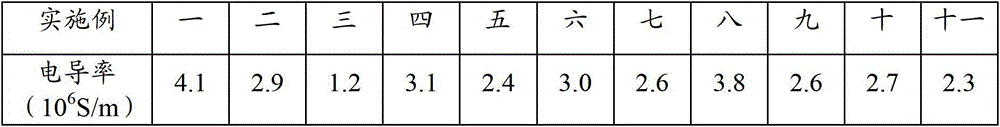

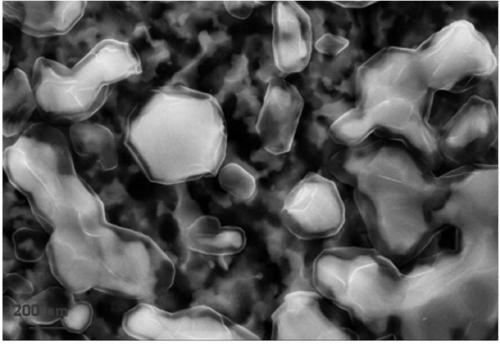

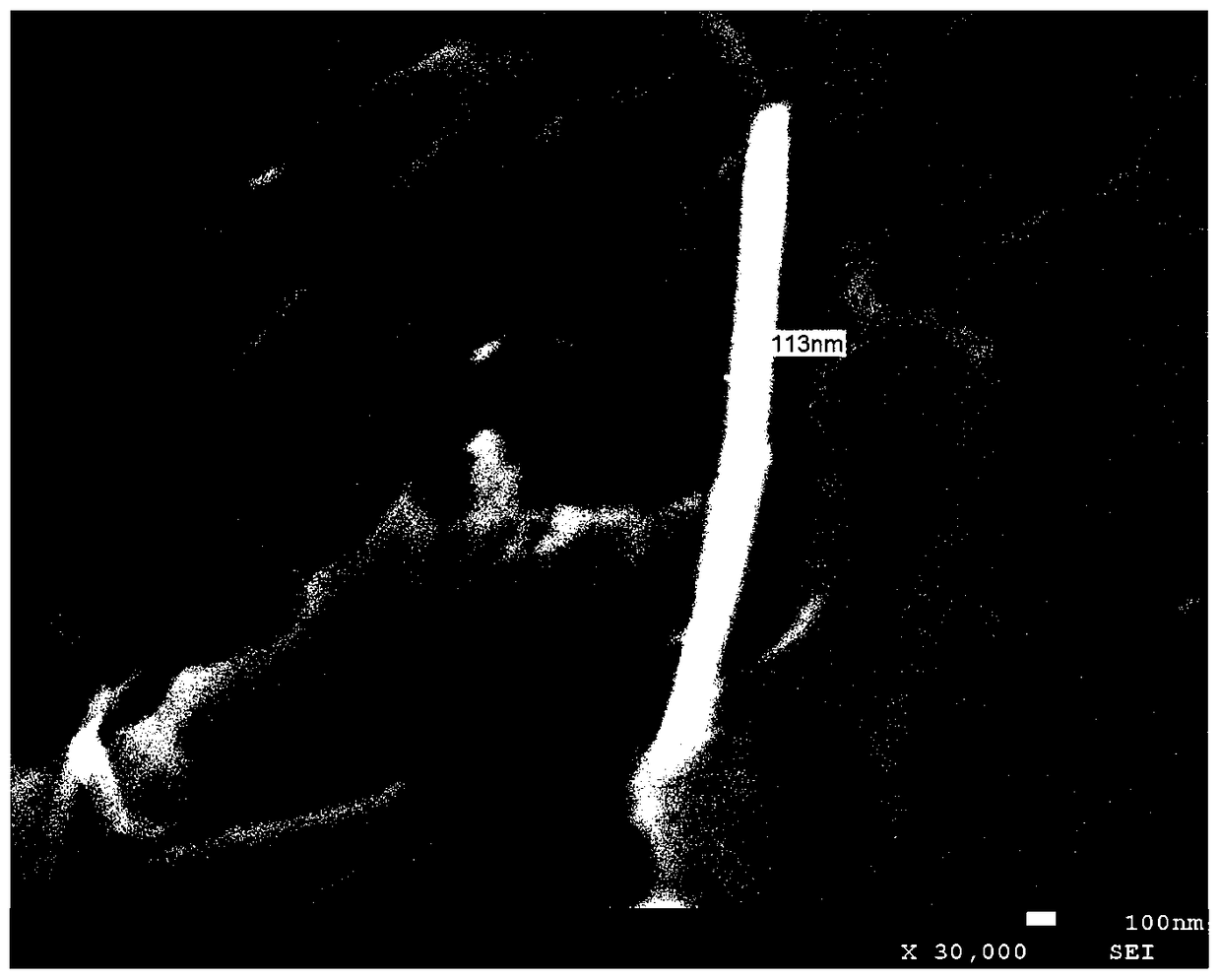

Graphene material and preparation method thereof

The invention discloses a preparation method of a graphene material. The preparation method includes the following steps that (1) after graphite and alkali metal are evenly mixed, vacuumizing and heat treatment are carried out, so that alkali metal intercalation graphite is obtained; (2) the alkali metal intercalation graphite is collected to be added into molten ionic liquid, after even stirring is conducted, the mixture is placed into an ultrasonic pulverizer, ultrasonic treatment is performed, and accordingly graphene suspension liquid is obtained; (3) the graphene suspension liquid is filtered, organic solvent for filtering residues is collected for washing and filtering, then, deionized water is used for conducting repeated washing and filtering until an eluate is neutral, filter objects are dried, and hence the graphene material is obtained. The invention further discloses the graphene material obtained through the preparation method. According to the graphene material and the preparation method thereof, the graphite and the alkali metal are mixed to be subjected to heat treatment first, the alkali metal intercalation graphite is obtained and then is dispersed into the ionic liquid, and after ultrasonic treatment is completed, the graphene material which is complete in laminated structure, high in monolayer rate and good in dispersity can be obtained; the method is simple, cost is low, efficiency is high, and the graphene material and the preparation method thereof are suitable for industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

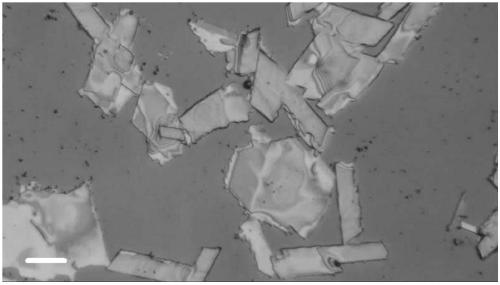

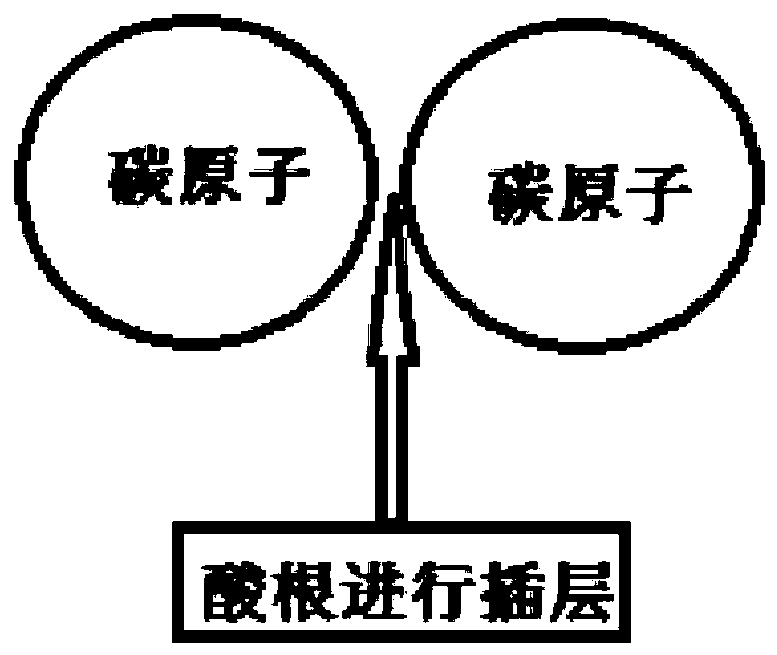

Preparation method for preparing graphene dispersion liquid by electrochemical swelling

InactiveCN109553093AGood dispersionImprove production efficiencyGrapheneElectrolysisQuaternary ammonium cation

The invention belongs to the field of material preparation, and relates to a preparation method for preparing a graphene dispersion liquid by electrochemical swelling. The method comprises the following steps: (1) taking graphite sheets as a cathode and taking a graphite substrate as a cathode to carry out electrolysis on the electrodes in an electrolytic tank, wherein the electrolyte is an acetonitrile solution dissolved with a quaternary ammonium salt, and the concentration of the quaternary ammonium salt is 5-10 mg / mL; (2) rinsing the cathode by using a rinsing solution containing a dispersing agent, carrying out ultrasonic stripping on the solution subjected to rinsing to form a dispersion, then centrifuging the dispersion, washing the dispersion by using isopropyl alcohol to remove the excess dispersing agent; and (3) separating solid impurities to obtain the graphene dispersion liquid. According to the method, the graphene nanosheets are swelled and dispersed through an electrochemical method, quaternary ammonium salt cations are inserted into interlayers of the graphene, and then interlayer expansion is achieved, and preparation efficiency of the graphene dispersion liquid is improved.

Owner:厦门十一维科技有限公司

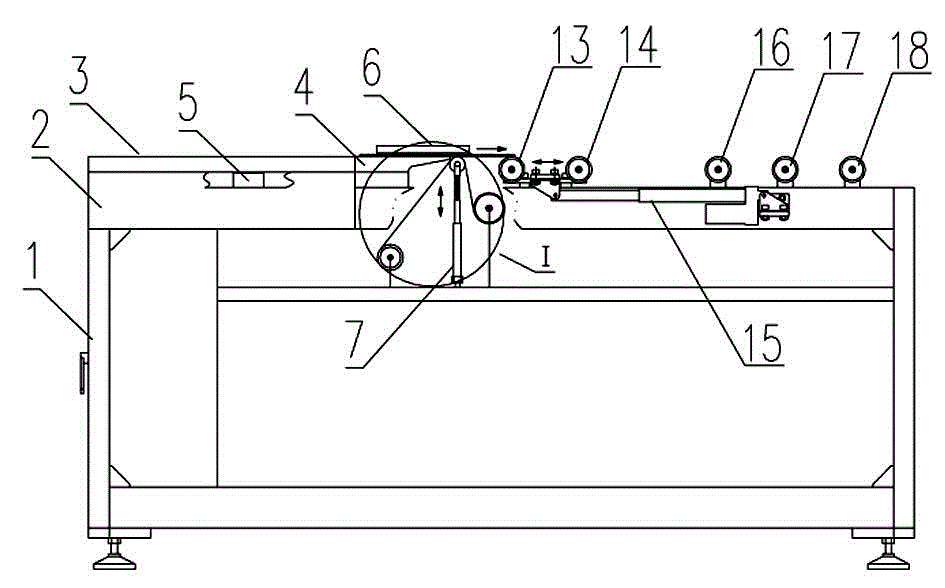

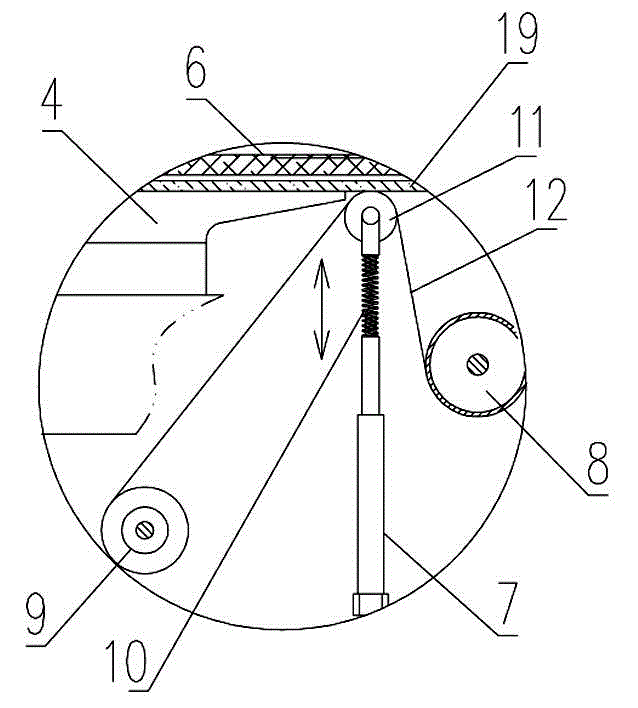

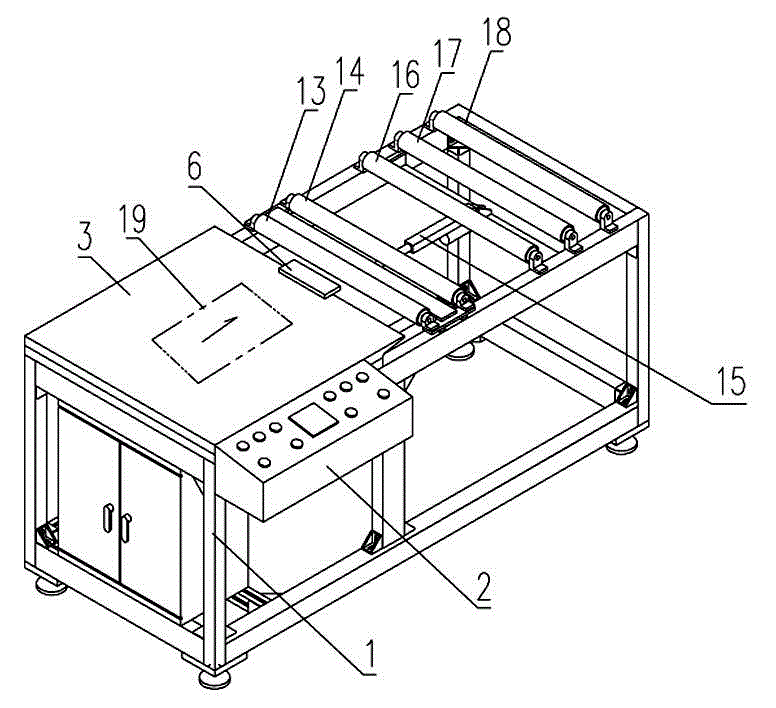

Device for disassembling liquid crystal display polarizer

ActiveCN104865718AAvoid damageReduce the difficulty of strippingNon-linear opticsLiquid-crystal displayAgricultural engineering

The invention discloses a device for disassembling a liquid crystal display polarizer. The device comprises a frame and a temperature controller arranged on the frame, a liquid crystal display input platform is arranged on the left side of the frame, a glass substrate output supporting roller group is arranged on the right side of the frame, a polarizer separating mechanism is arranged below an open space between the liquid crystal display input platform and the glass substrate output supporting roller group on the frame, an electric heating aluminum plate and a temperature sensor are embedded into the surface of the liquid crystal display input platform, the polarizer separating mechanism comprises a vertical electric push rod, a power roller and a rubber belt roller, the vertical electric push rod is arranged on the frame upwards, the power roller is arranged on the right side of the vertical electric push rod, the rubber belt roller is arranged on the left side of the vertical electric push rod, a pressure spring is vertically fixed upwards at the top end of the vertical electric push rod, a rubber belt pressing wheel is arranged at the top end of the pressure spring, and a rubber belt on the rubber belt roller bypasses the rubber belt pressing wheel and is connected with the power roller in a winding manner. The device has the advantages that disassembly efficiency is improved, the device is simple to operate, and a liquid crystal display is less damaged.

Owner:SIPPR ENG GROUP

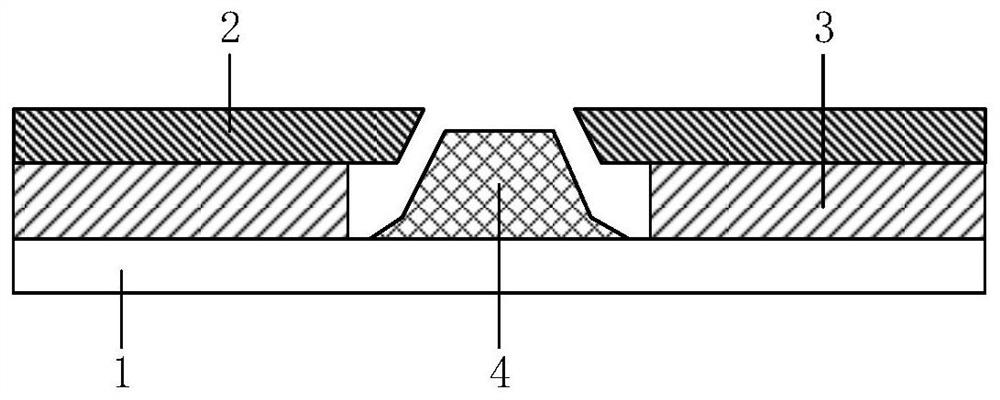

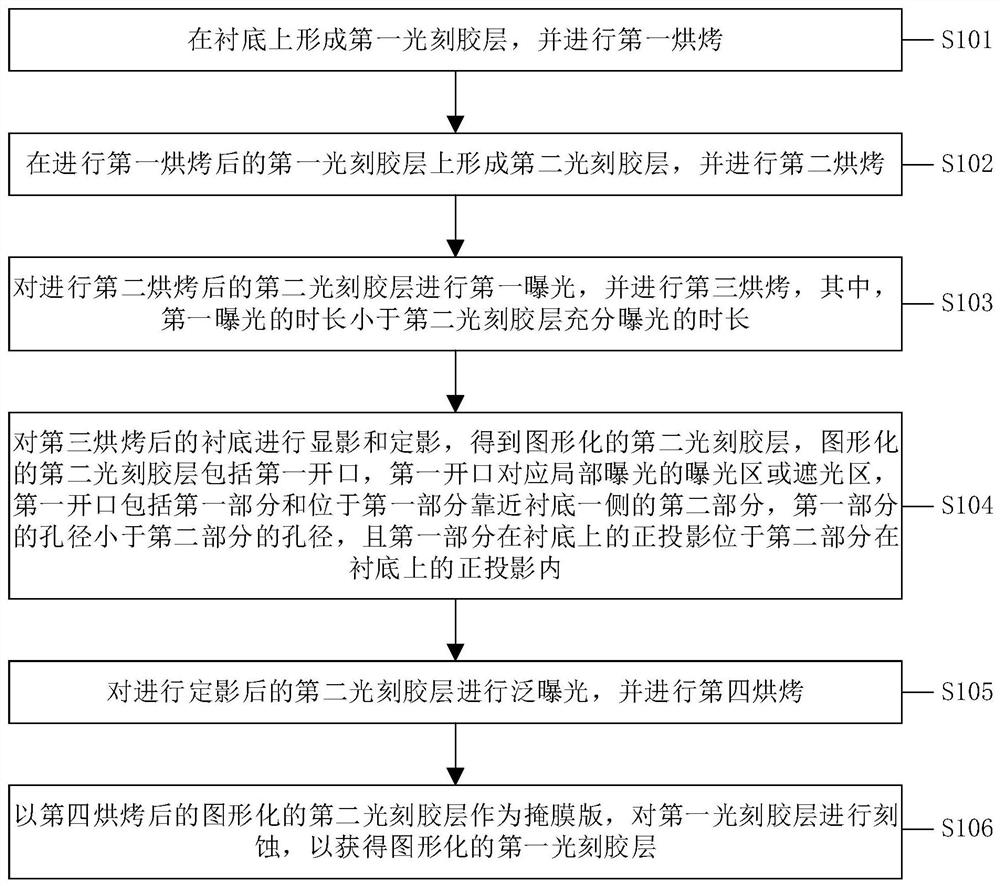

Photoresist structure, graphical deposition layer, semiconductor chip, and manufacturing methodd of photoresist structure, graphical deposition layer and semiconductor chip

ActiveCN112652522AGood lookingAvoid corrosion damageSemiconductor/solid-state device manufacturingPhotosensitive material processingSemiconductor chipEngineering

The embodiment of the invention provides a photoresist structure, a graphical deposition layer, a semiconductor chip, and manufacturing methods of the photoresist structure, the graphical deposition layer and the semiconductor chip. According to the manufacturing method of the photoresist structure, a single photoresist is utilized, the second photoresist layer containing the undercut can be obtained only by using a single developing solution for one-time development, and the size of the undercut can be controlled through the development time, so the problems of stripping difficulty and the like caused by adhesion of a deposition material and the side wall of the photoresist structure in a traditional stripping process are avoided; the first photoresist layer is used as a protective adhesive layer, so that corrosion damage of a developing solution to a substrate material during development can be avoided; and the first photoresist layer is etched, so that the first photoresist layer serving as a protective adhesive layer is converted into a pattern limiting adhesive layer, lateral diffusion at the bottom of a deposition material can be effectively prevented in the material deposition process, and the deposition layer with good morphology is obtained.

Owner:TENCENT TECH (SHENZHEN) CO LTD

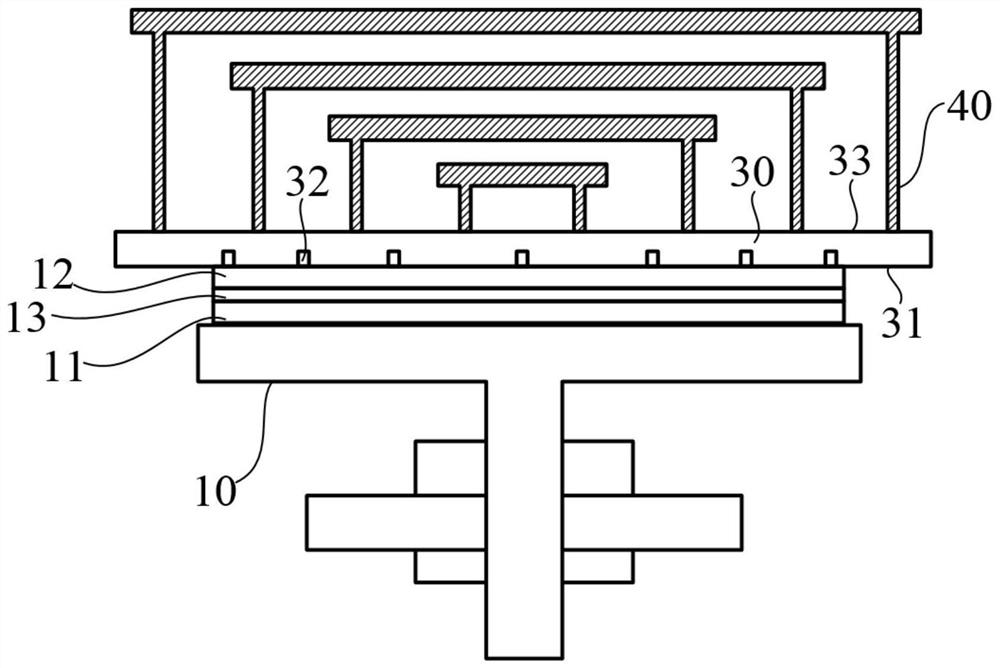

Flexible substrate and manufacturing method thereof and display device

The present invention discloses a flexible substrate and a manufacturing method thereof, and a display device, comprising: disposing a detachable layer on a rigid substrate, and fixing the flexible base on the rigid substrate by the detachable layer, wherein the detachable layer comprises a mesh layer and a plurality of mutually independent supporting parts disposed in meshes of the mesh layer; forming a functional layer on the flexible base to obtain a flexible substrate; separating the flexible substrate from the rigid substrate by applying an external force on the mesh layer. The present invention makes it easier for the flexible substrate to be stripped off after it is manufactured, improves the yield rate; moreover, the present invention has the process compatibility of ordinary production lines, and saves costs.

Owner:BOE TECH GRP CO LTD +1

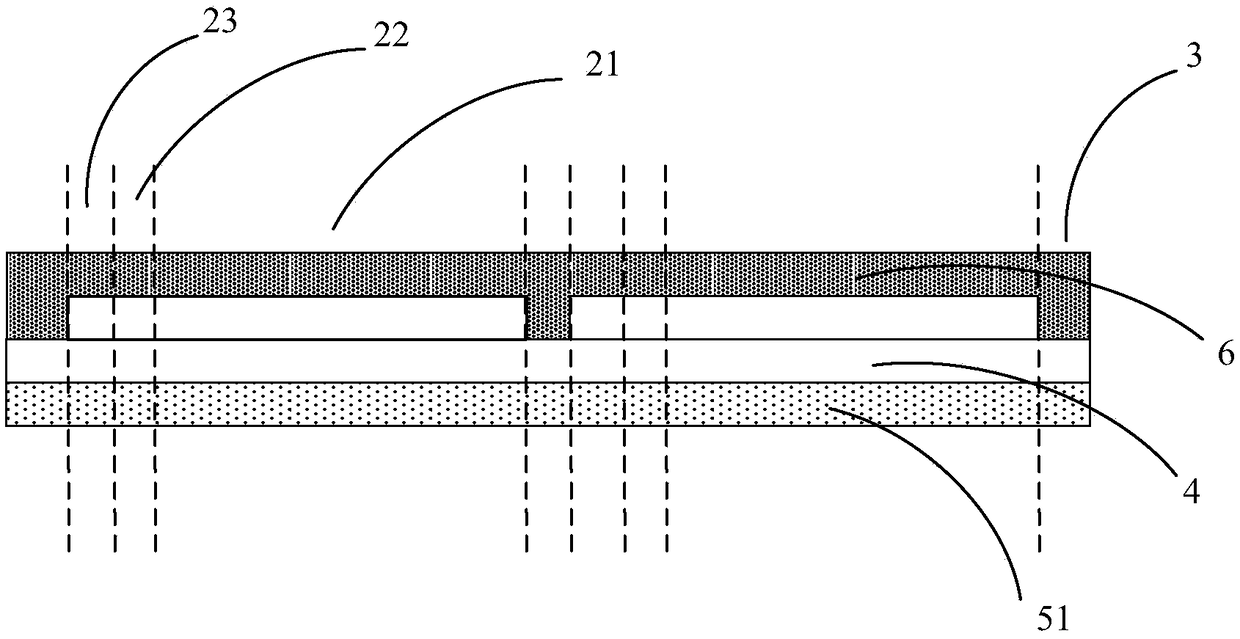

Bearing substrate and manufacturing method thereof, flexible substrate and manufacturing method thereof, and display device

ActiveCN109904352AImprove product qualityChange bindingFinal product manufactureSolid-state devicesDisplay deviceEngineering

The present invention relates to the technical field of display, especially to a bearing substrate and a manufacturing method thereof, a flexible substrate and a manufacturing method thereof, and a display device. The bearing substrate comprises: a substrate comprising a first surface and a second surface opposite to the first surface; a bonding portion arranged at the second surface and comprising magnetic particles, wherein the magnetic particles can rotate under the action of an external magnetic field, the magnetic particles comprise a first portion and a second portion, when the first portion faces one side far away from the first surface, the binding force between the bonding portion and the flexible substrate can be weakened, and when the second portion faces one side far away fromthe first surface, the binding force between the bonding portion and the flexible substrate is enhanced. The bearing substrate and the manufacturing method thereof can reduce the stripping difficultyand the stripping cost of the flexible substrate and the bearing substrate while improving the manufacturing quality of the flexible substrate.

Owner:BOE TECH GRP CO LTD

Substrate and peeling method

ActiveCN110299466AImprove device yieldReduce the difficulty of strippingFinal product manufactureSolid-state devicesSurface energyEngineering

The invention provides a substrate and a preparation method of a flexible light-emitting electroluminescent device. The substrate includes a first surface and a second surface opposite to the first surface. The first surface is provided with a plurality of first openings, the second surface is provided with a plurality of second openings, the first surface is used for carrying a film layer, the plurality of first openings and the plurality of second openings are in one-to-one correspondence and communicate with each other to form a plurality of hole channels, the surface energy of the first surface and the surface energy of the film layer are both smaller than the surface energy of inner surfaces of the hole channels, and the deviation of the surface energy of the film layer from the surface energy of the first surface is within + / -10%. By changing the surface performance of the substrate surfaces and the inner surfaces of the substrate hole channels, the rapid peeling of a flexible device and the substrate is achieved, and the peeling efficiency is improved. At the same time, the device and the substrate can be separated under the condition that the device is not mechanically damaged through the acting force of the etching medium destroying a sacrificial layer material and substrate contact interface, the stripping and preparation of the flexible device are completed, and thepreparation yield of the flexible device is improved.

Owner:NANJING TECH CORP LTD

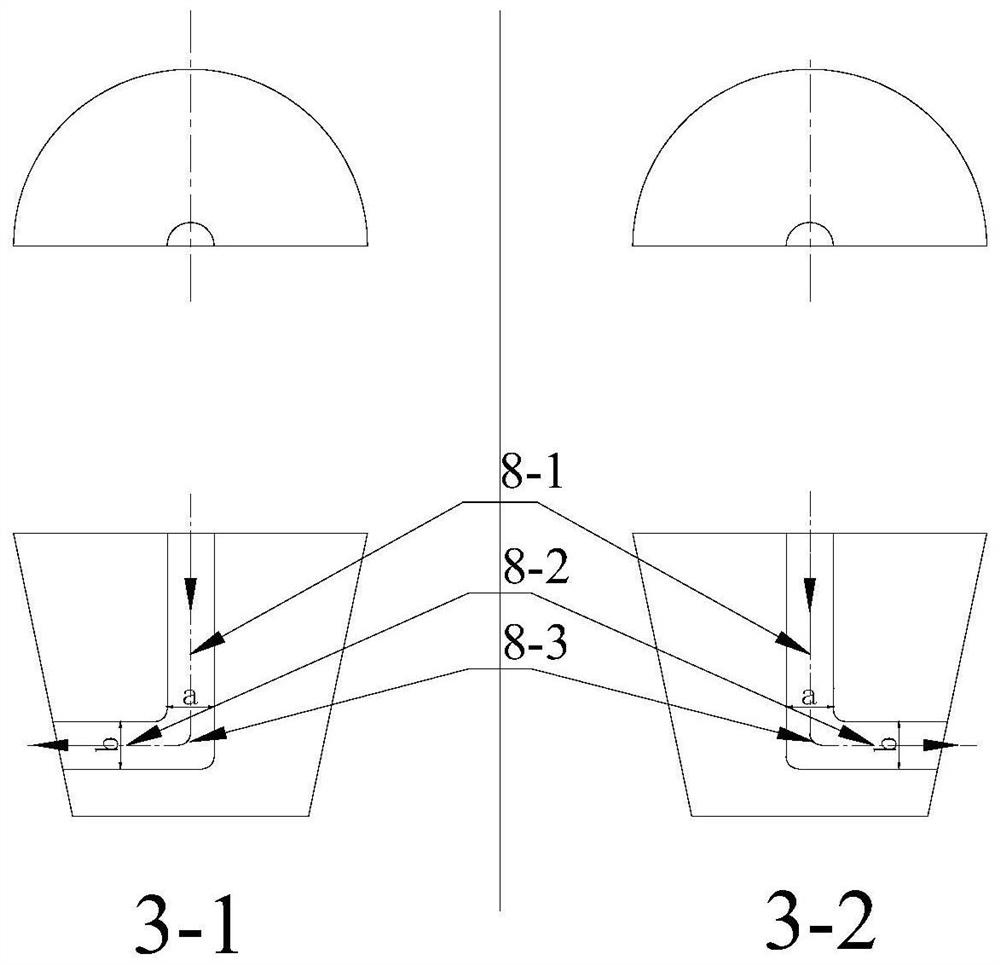

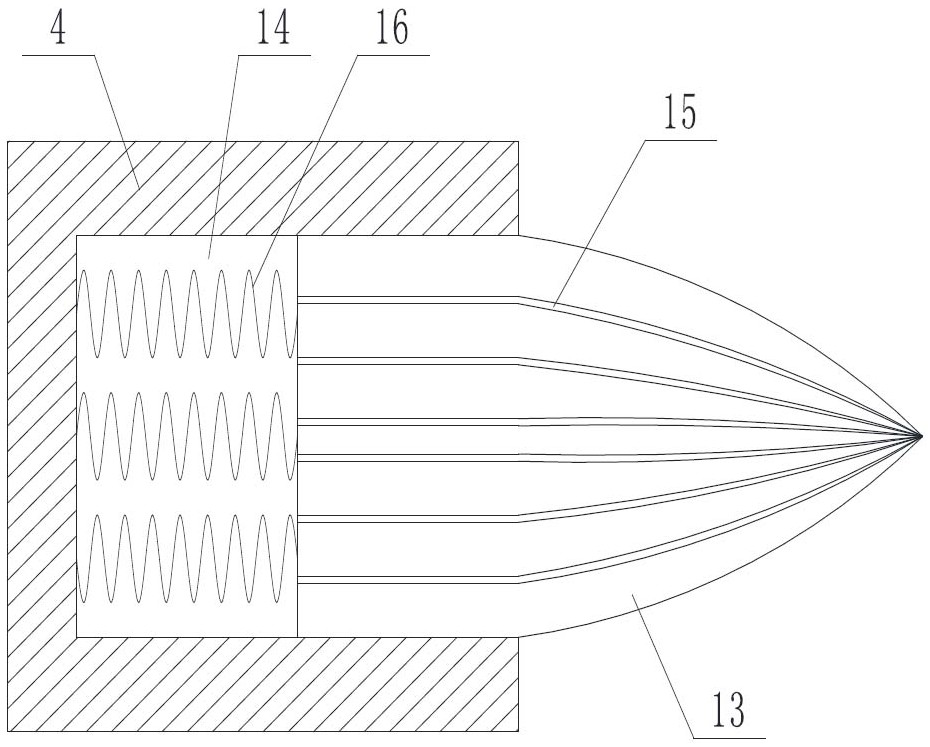

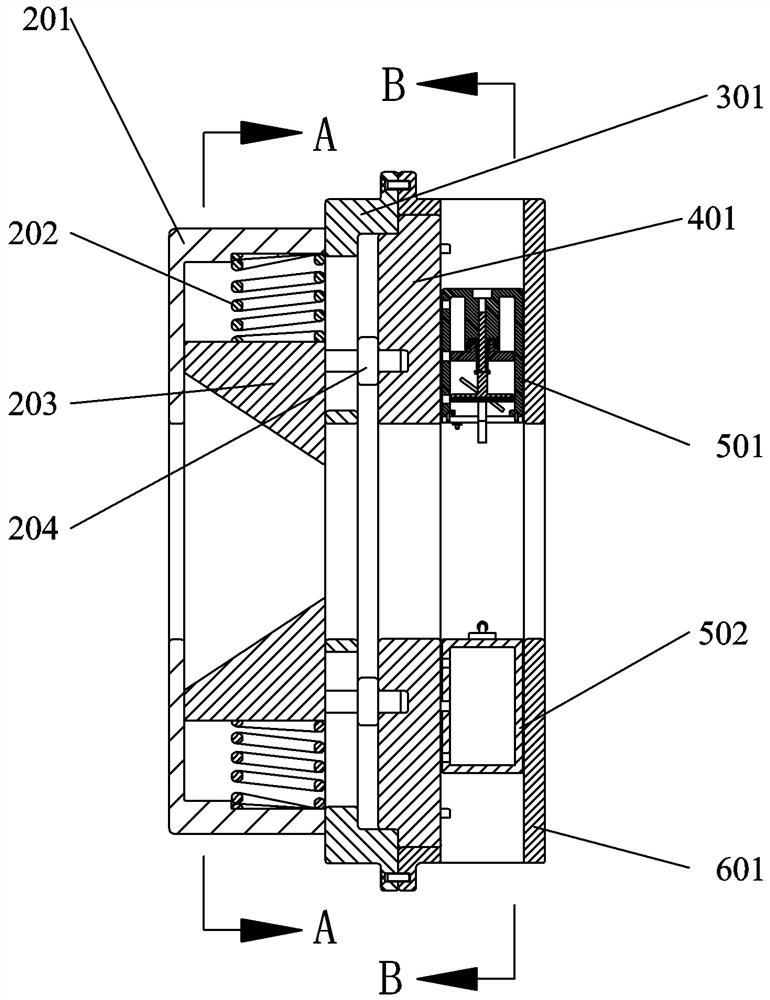

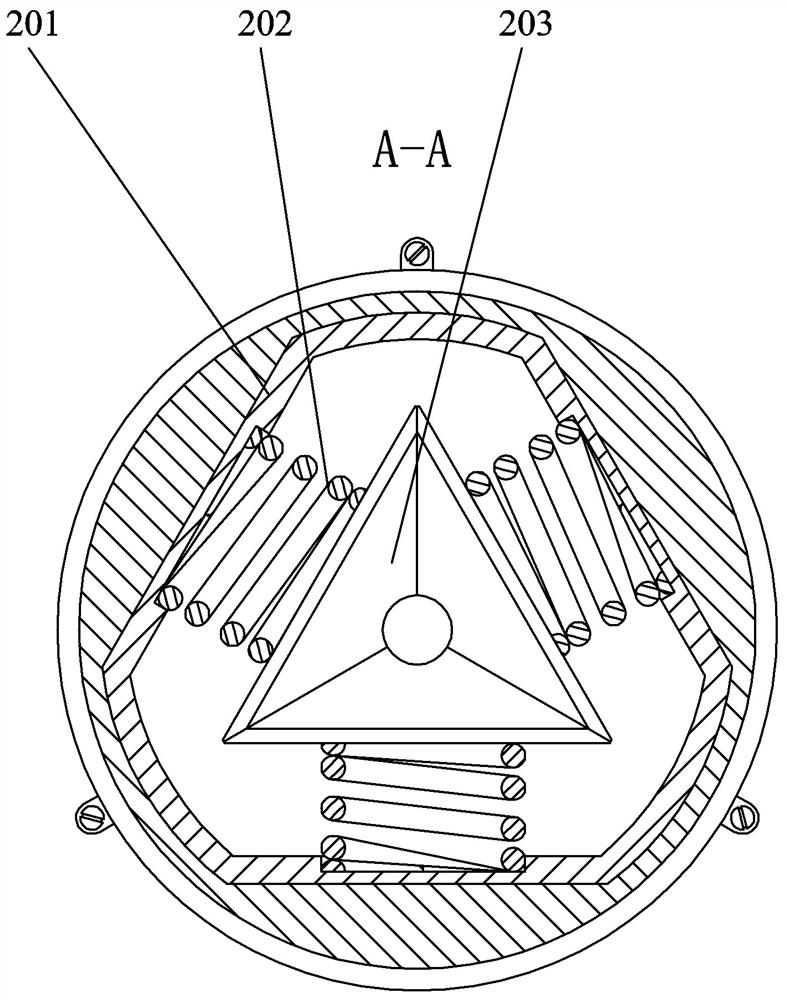

Real-time online heating constant temperature equal channel angular extrusion device and method

ActiveCN112453090AImprove production efficiencyImprove energy utilizationExtrusion diesEqual channel angular extrusionMechanical engineering

The invention discloses a real-time online heating constant temperature equal channel angular extrusion device and method. The device comprises a heating body, an insulating sleeve, an extrusion die,a die sleeve, a die fixing seat and an extrusion rod. The extrusion die is cone-shaped integrally and is mounted in the die sleeve, the die sleeve is fixedly connected to the die fixing seat, an extrusion channel is arranged in the extrusion die, the extrusion bar is matched with the extrusion channel, the extrusion channel is composed of an extrusion-in channel, an extrusion channel and an extrusion corner, the cross section of the extrusion channel is smaller than that of the extrusion-in channel; the extrusion corner is formed in a connecting position of the extrusion-in position and the extrusion channel, and the angle of the extrusion corner is 90-150 degrees; and a duct is arranged around the extrusion channel, the insulating sleeve is placed in the duct, and the heating body is arranged in the insulating sleeve.

Owner:SHANDONG UNIV

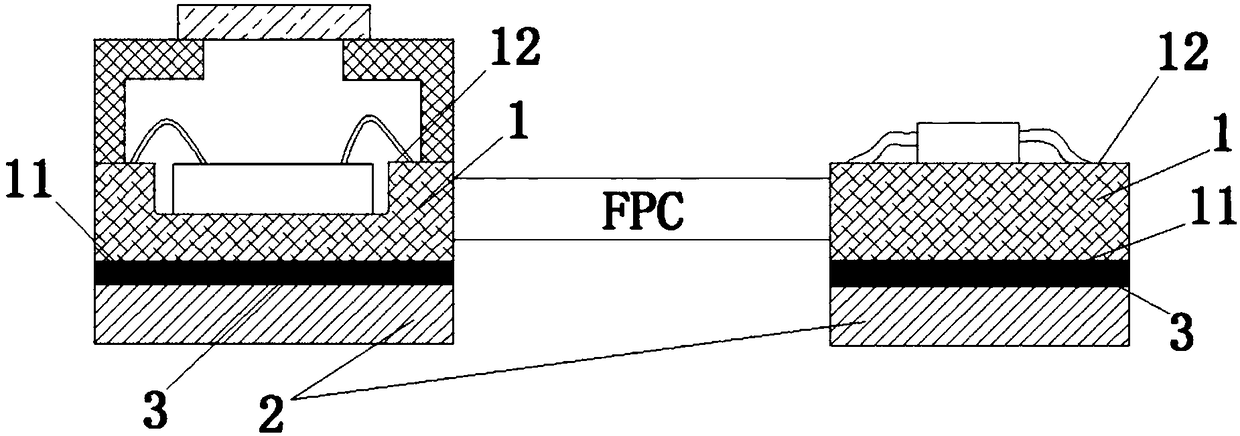

Circuit board procesing method

ActiveCN109041444AReduce the difficulty of strippingReduce workloadPrinted circuit assemblingPrinted circuit aspectsOn boardSurface mounting

The invention relates to a circuit board processing method, comprising: a) bonding a reinforcing plate on a first surface of the circuit board, wherein the area of the reinforcing plate is at least 85% of the area of the first surface of the circuit board, and in the range of 80 to 170 DEG C, the peeling strength between the first surface and the reinforcement plate is greater than 35.0 gf / mm; b)performing surface mounting (SMT) on the second surface of the circuit board; c) performing chip-on-board (COB) packaging on the second surface of the circuit board; and d) peeling the reinforcementplate from the first surface of the circuit board. According to the method of the invention, the deformation of the circuit board in the processing process can be effectively controlled. By effectively controlling the area ratio of the reinforcing board to the circuit board to be processed, the deformation of the circuit board can be avoided in the reflow soldering process, the area of the reinforcing board can be reduced, and the peeling workload and the peeling difficulty of the reinforcing board can be simplified and reduced.

Owner:NINGBO SUNNY OPOTECH CO LTD

Thermosetting resin micro-fluidic chip and preparation method thereof

PendingCN113731519AMolding temperature is adjustableMolding time is adjustableLaboratory glasswaresPolymer sciencePrepolymer

The invention relates to a thermosetting resin micro-fluidic chip and a preparation method thereof, and the preparation method comprises the following steps: preparing a prepolymer: injecting liquid resin into a mold with a microstructure on the inner surface, heating, keeping the constant temperature for preset time, and taking out to obtain a resin prepolymer with a microstructure on the surface as a cover plate; injecting liquid resin into a mold with a smooth inner surface, heating, keeping constant temperature for preset time, and taking out to obtain a resin prepolymer with a smooth surface as a substrate; attaching the surface, with the microstructure, of the cover plate to the substrate, heating and keeping constant temperature for preset time, so that the substrate and the cover plate react and are bonded to obtain a micro-fluidic chip crude product; and carrying out finish machining on the micro-fluidic chip crude product to obtain a micro-fluidic chip finished product. Compared with the prior art, the method has the advantages that the thermosetting engineering resin is used as a raw material, a thermal bonding process with a simple process is developed by controlling a curing process of the resin, and batch production of the thermosetting micro-fluidic chip with high dimensional precision is realized.

Owner:SHANGHAI RES INST OF CHEM IND

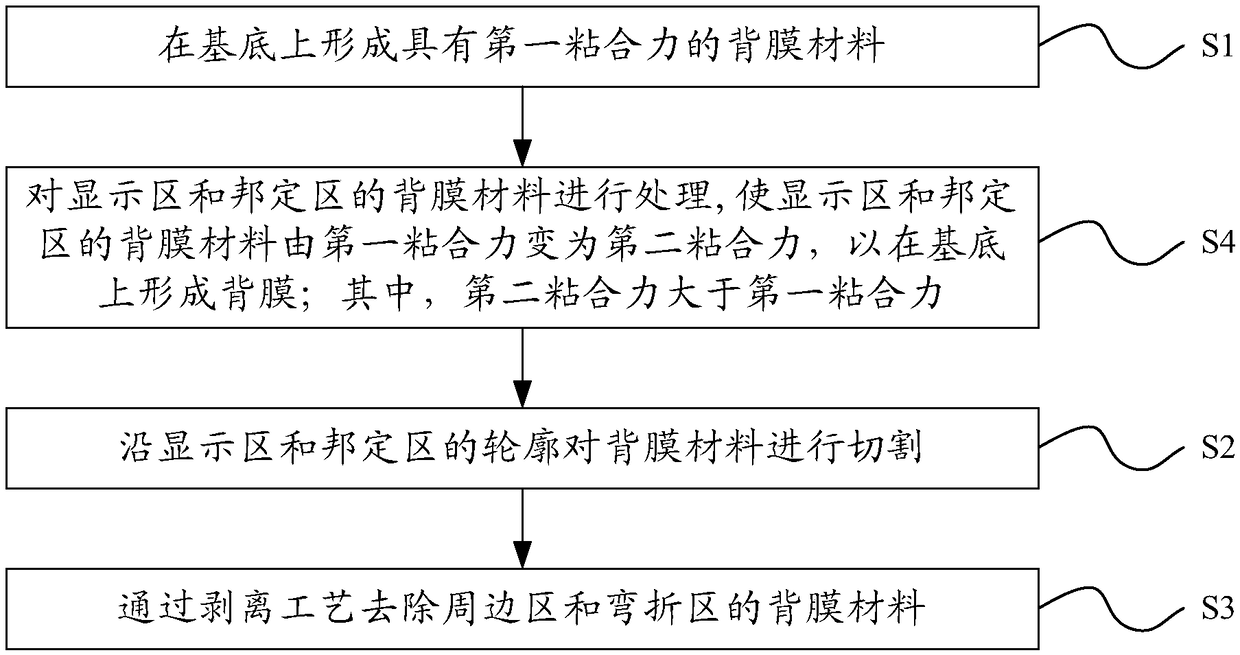

Manufacture method of display substrate

InactiveCN109148337AReduce the difficulty of strippingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFilm material

The invention provides a preparation method of a display substrate, belonging to the technical field of display, which can solve the problems of complicated removing process and bad effect of the existing display substrate back film. A method for preparing a display substrate includes forming a back film material having a first adhesive force on a substrate; The substrate includes a substrate region and a peripheral region surrounding the substrate region. The substrate region comprises a display region, a bent region and a bonding region arranged in sequence along the column direction; Cutting the backing film material along the contours of the display area and the bonding area, removing the backing film material of the peripheral area and the bending area by a peeling process, and treating the backing film material of the display area and the bonding area to change the backing film material of the display area and the bonding area from a first adhesive force to a second adhesive force to form a backing film on the substrate; Wherein the second adhesive force is greater than the first adhesive force.

Owner:BOE TECH GRP CO LTD

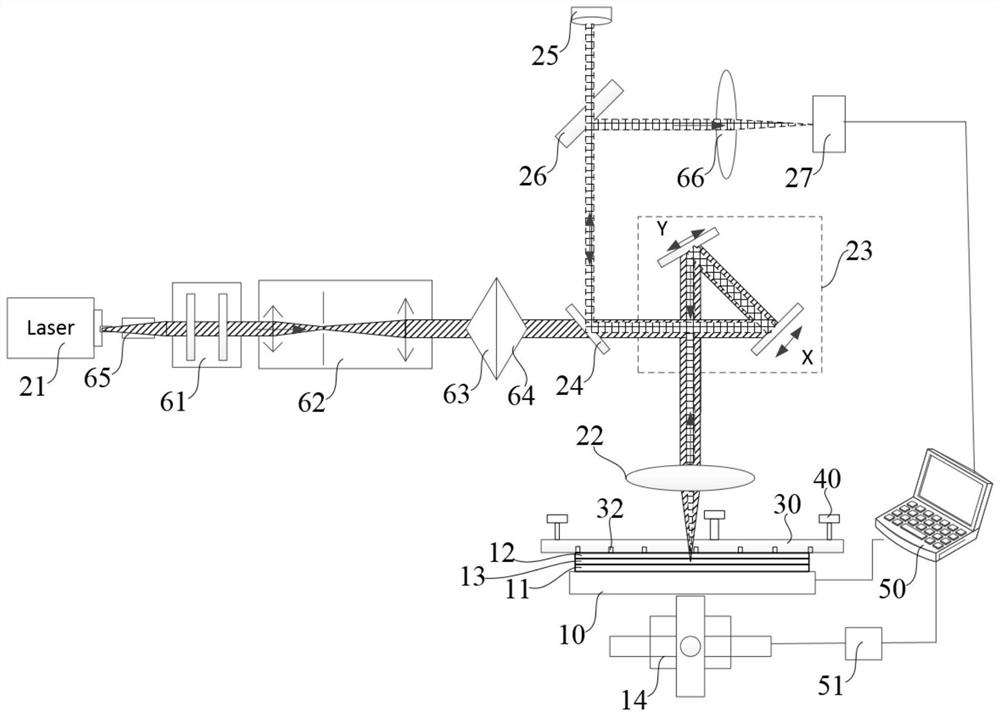

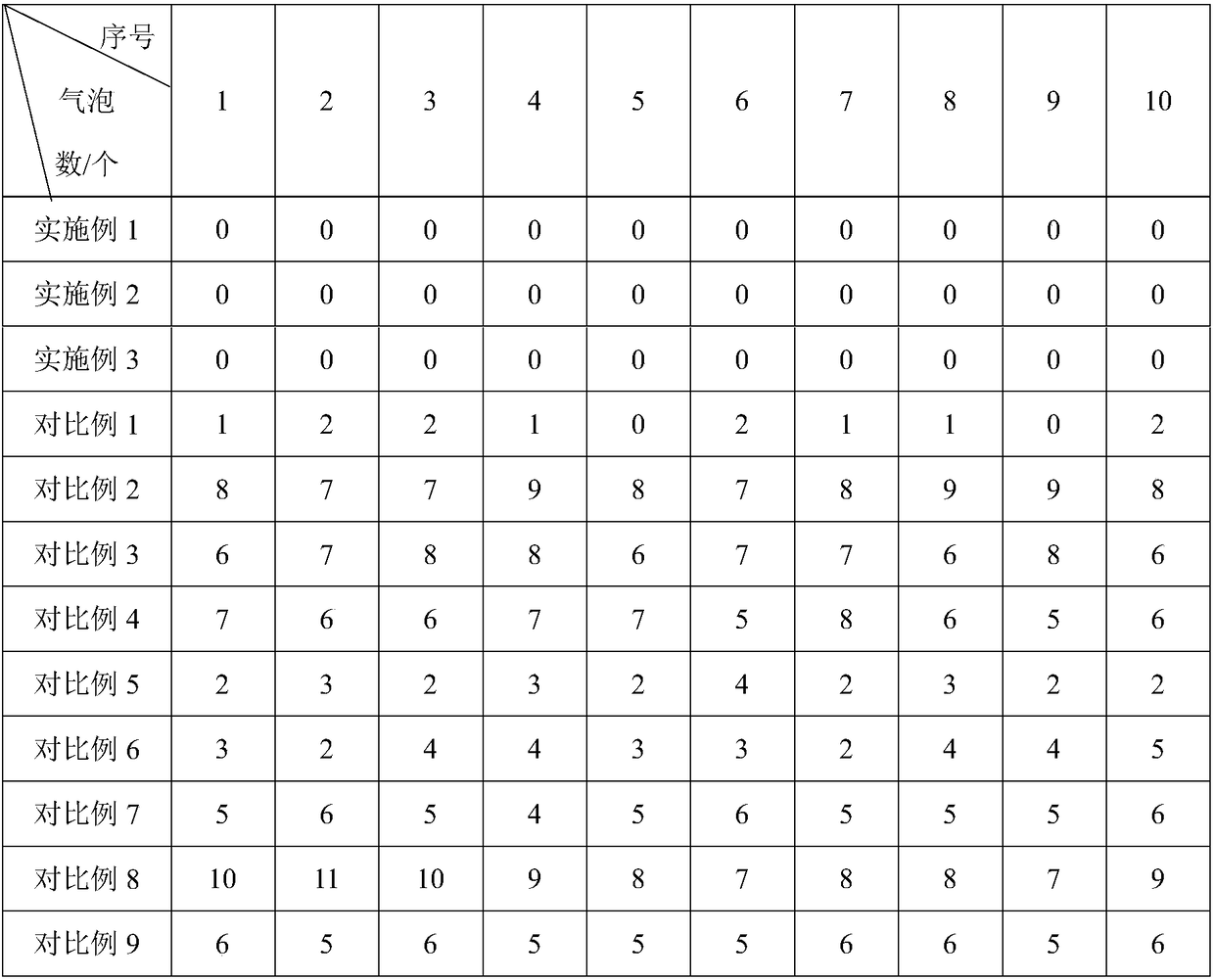

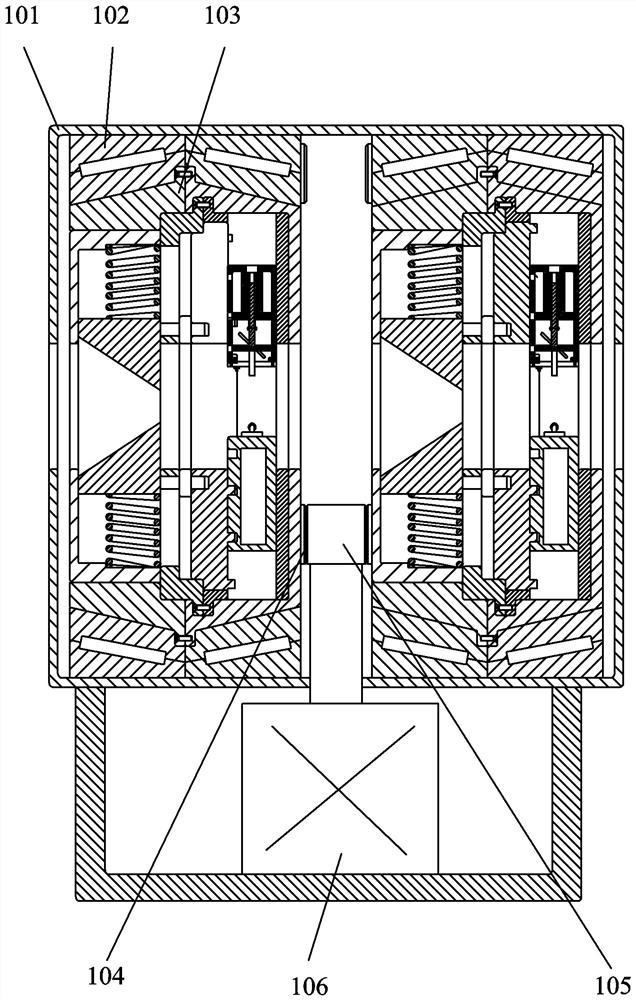

Detection control system for laser de-bonding

ActiveCN113838777APrevent re-adhesionReduce the difficulty of strippingSemiconductor/solid-state device manufacturingBeam splittingLight spot

The invention provides a detection control system for laser de-bonding. In a laser de-bonding process, a suction cup is adsorbed on the surface of a substrate, a laser beam sequentially penetrates through the suction cup and the substrate and then is focused on a bonding layer, and after the focus of the laser beam is controlled to be behind a unit area of a scanning part of the bonding layer, a lifting assembly pulls a suction cup upwards, so that the substrate and the wafer are separated at the position of the unit area, the stripping mode that laser de-bonding and suction cup pulling are carried out at the same time is adopted, the substrate and the wafer are prevented from being adhered again due to the fact that a bonding material in a molten state is cooled and solidified again, and therefore the stripping difficulty is reduced. And a semi-reflecting and semi-transmitting mirror, a detection light source, a beam splitting prism, a light spot detection assembly and an upper computer are arranged, so that laser spot position information and bonding layer heated condition information of a local area can be observed in real time, the upper computer can control a galvanometer system to adjust a scanning track and scanning time of a laser beam, and the laser de-bonding efficiency and effect are improved.

Owner:北京中科镭特电子有限公司

Photosensitive resin composition and preparation method thereof

ActiveCN109491205AImprove adsorption capacityImprove plasticityPhotosensitive materials for photomechanical apparatusPrepolymerOrganic chemistry

The invention provides a photosensitive resin composition. The composition is prepared from the following components in parts by weight: 20-25 parts of epoxy acrylate prepolymer, 50-60 parts of modified styrene-acrylate copolymer, 13.5-24.5 parts of alkali-soluble resin, 0.6-2.5 parts of photo-initiator and 1-1.5 parts of dye.

Owner:湖南五江高科技材料有限公司

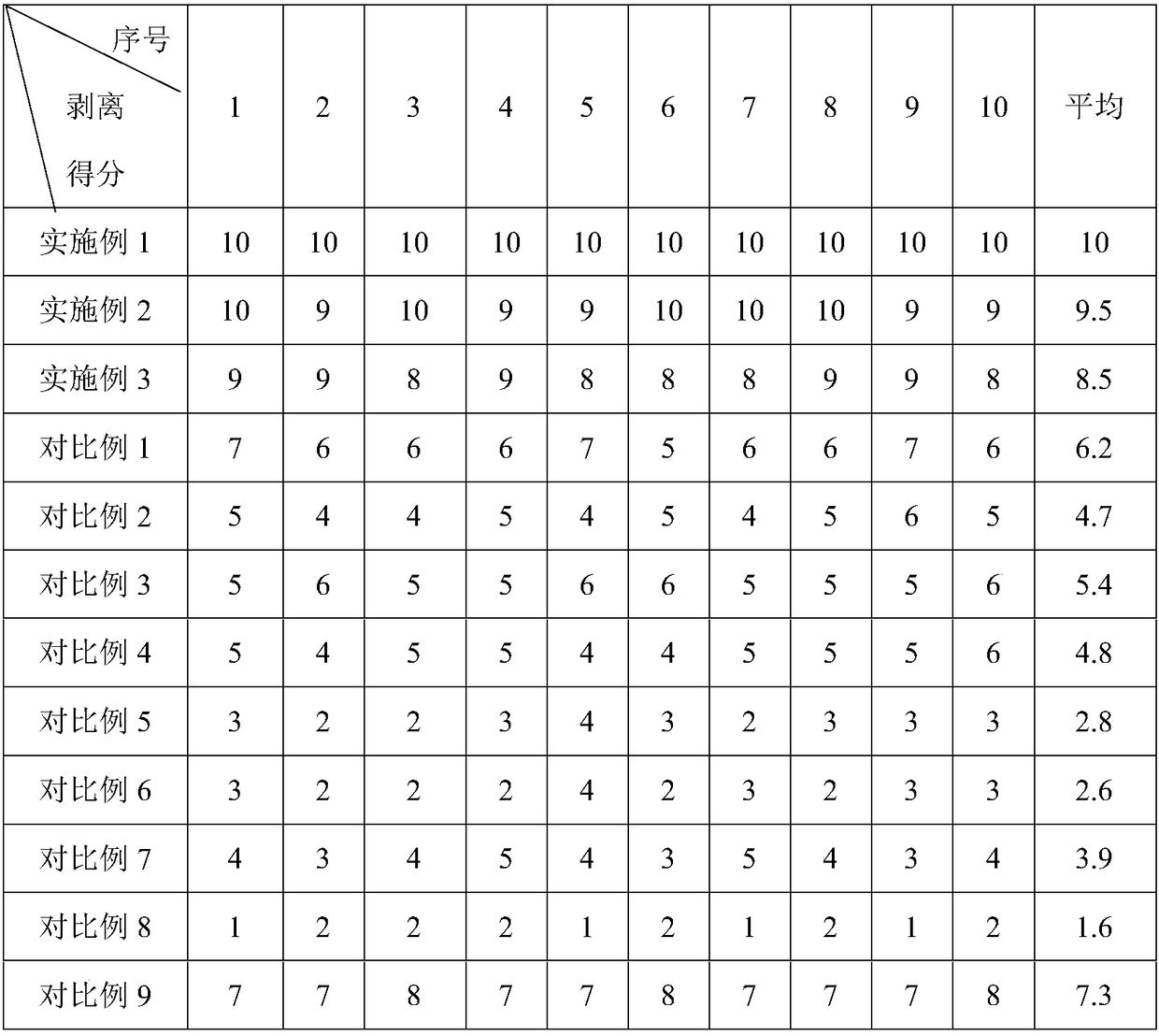

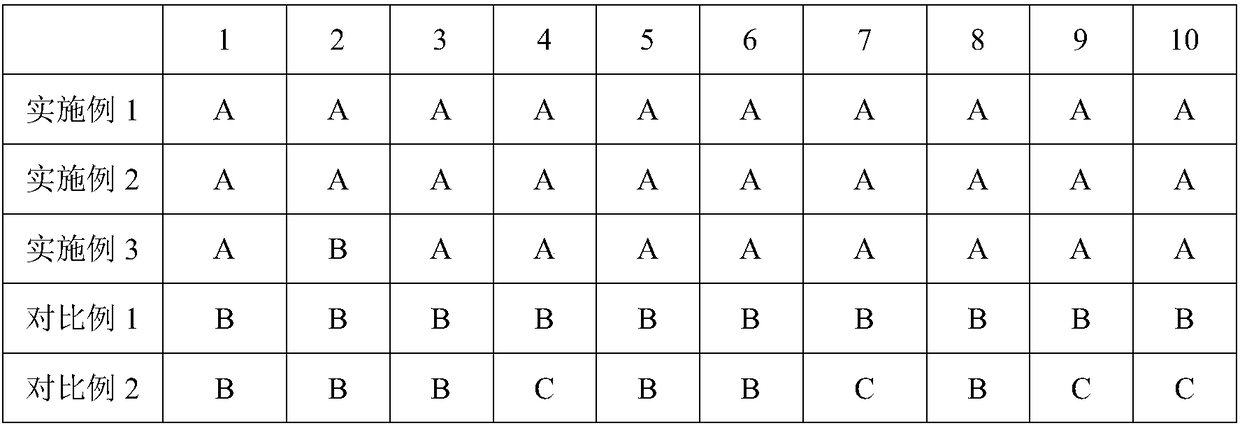

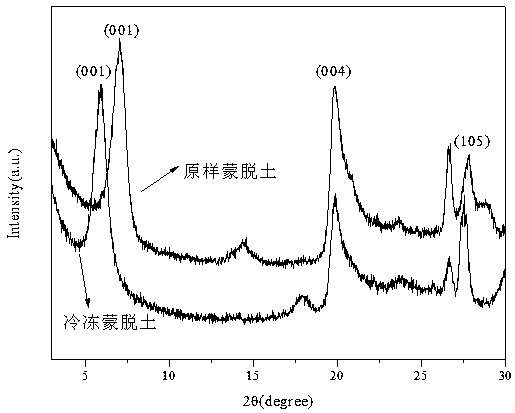

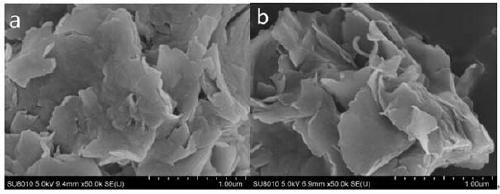

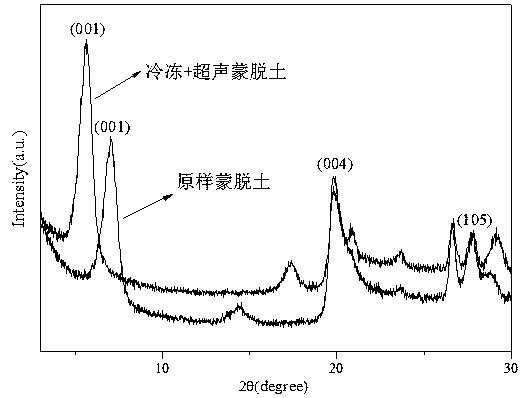

Method for preparing montmorillonite nano-sheets through gas phase stripping

ActiveCN110240172AImprove stripping efficiencyReduce the difficulty of strippingMaterial nanotechnologySilicon compoundsHigh energyLamellar structure

The invention relates to a method for gas phase stripping of montmorillonite nano-sheets. The method comprises: (1) placing montmorillonite into an air blasting drying box, and drying for 6-8 h at a temperature of 60-80 DEG C; (2) placing the montmorillonite obtained in the step (1) in a reaction bottle filled with 50-100 mL liquid nitrogen until the liquid nitrogen is completely vaporized; (3) standing the montmorillonite obtained in the step (2), and taking out so as to be spare after the temperature of the montmorillonite is restored to a room temperature; and (4) repeatedly performing the steps (2)-(3) 1-10 times. According to the present invention, the method solves the problems of consumption of a large amount of mediums, high energy consumption, long process flow, environmental pollution, easy destruction on the lamellar structure and the like in the stripping process of the montmorillonite, and has advantages of simple process, low cost, environment protection, montmorillonite stripping difficulty reducing and stripping efficiency improving.

Owner:SHENYANG POLYTECHNIC UNIV

Hood heat shield forming tool for returnable spacecraft

ActiveCN109955503AReduced thermal protectionPlay a supporting roleDomestic articlesScrew positionClosed chamber

The invention relates to a hood heat shield forming tool for a returnable spacecraft. The hood heat shield forming tool is characterized by comprising a lower die, a middle die, an upper die, an observation window, a vacuum meter, a space occupying lining, a vacuum pipeline, a glue injection pipeline, a tray, a hoisting ring, a compression plate and a compression frame. Along the height direction,the tool is divided into three layers, namely the upper die, the middle die and the lower die. The middle die and the lower die are used for containing a hood head shield of the spacecraft, and a mounting surface between the middle die and the lower die is positioned at the middle position of the tray in the height direction. The upper die is used as an upper cover, and the upper die, the middledie and the lower die form a closed chamber body together after being assembled. The space occupying lining is in screwed connection with the upper die, and a sealing gasket is arranged at a screw position.

Owner:BEIJING SATELLITE MFG FACTORY

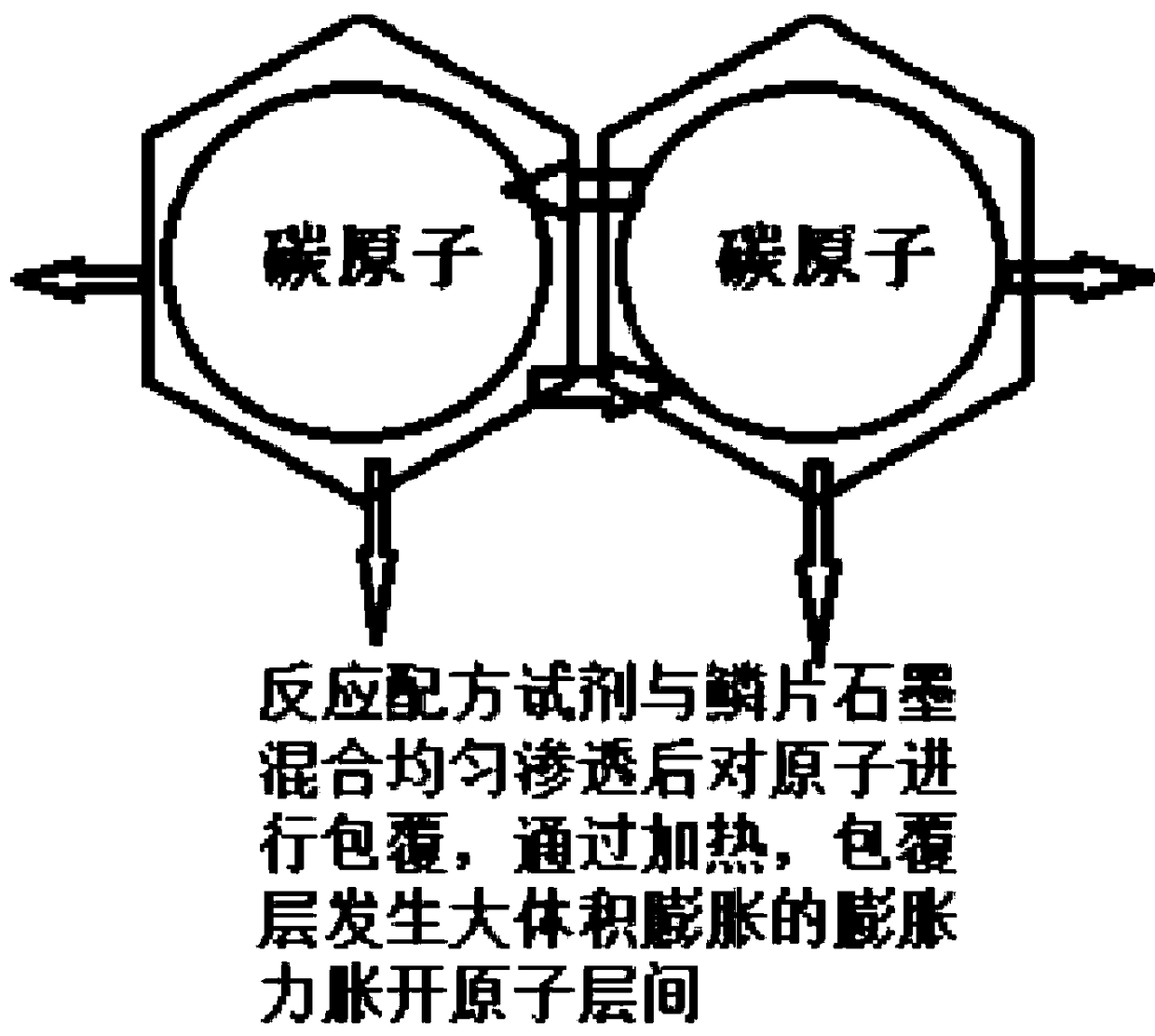

Method for preparing graphene slurry

The invention discloses a method for preparing graphene slurry. The method comprises the following steps: 1) performing high temperature expansion on the expandable graphite, then performing solid-gasseparation to obtain graphite worm, and then spreading the material and finally rolling the material into paper; 2) crushing the graphite paper obtained in step 1) to obtain graphite powder having aparticle size of 200 to 500 [mu]m; 3) crushing the graphite powder obtained in the step 2) to obtain graphite micro powder having the particle size of 5 [mu]m or less; and 4) mixing the graphite finepowder with a solvent, uniformly stirring a mixture, and then using a high-speed shearing machine for processing, and then performing ultrasonic processing to obtain the graphene slurry. The method expands high-rate expandable graphite and then rolls the graphite to paper to increase the unit volume density, and then performs subsequent preparation, and the stripping is more sufficient; by high-temperature expansion and gas separation, the exhaust gas and impurities can be removed, and the quality of the graphene slurry can be improved.

Owner:YICHANG XINCHENG GRAPHITE

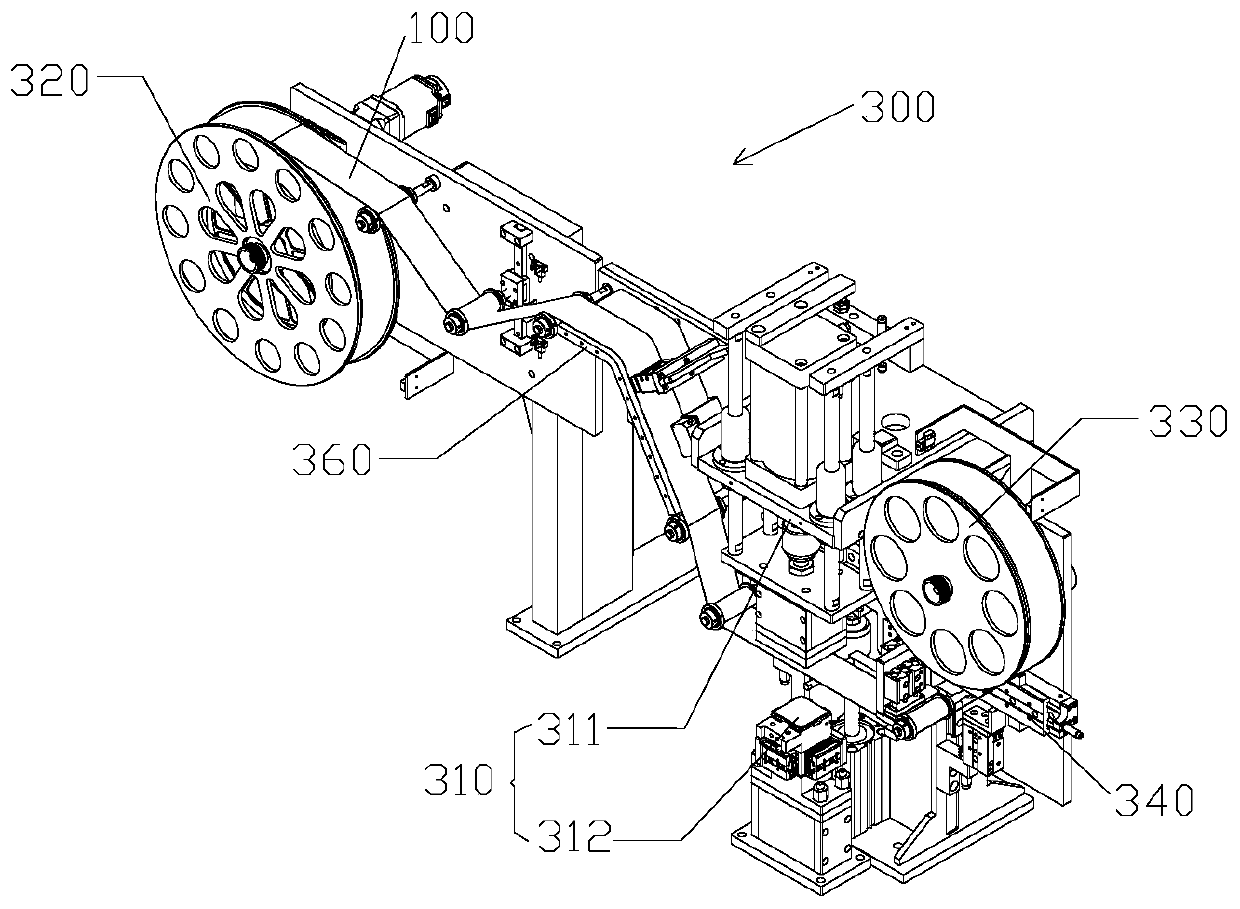

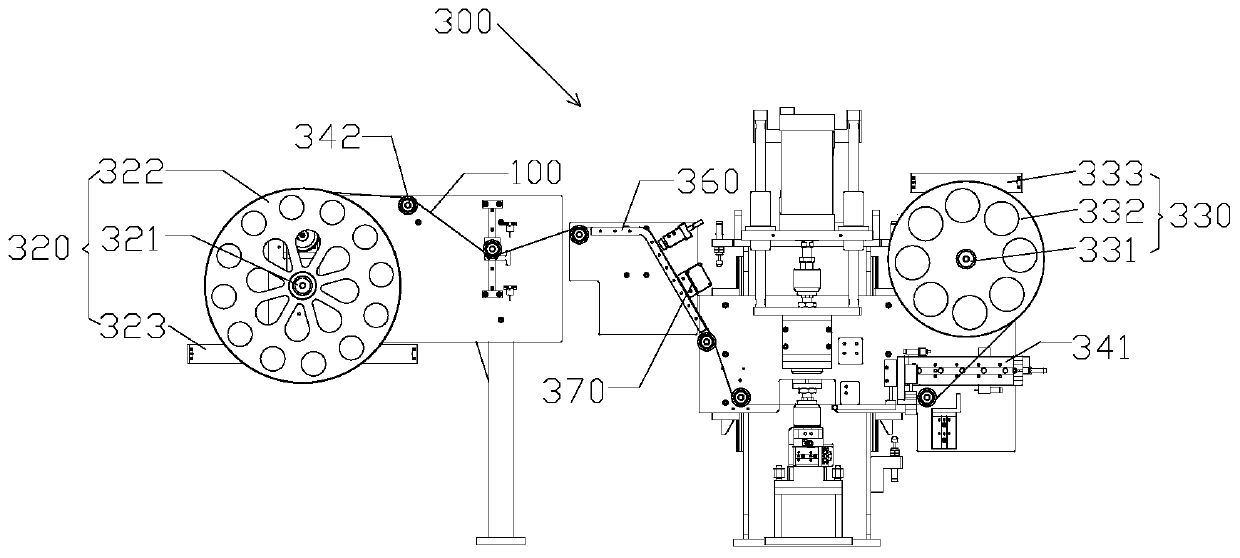

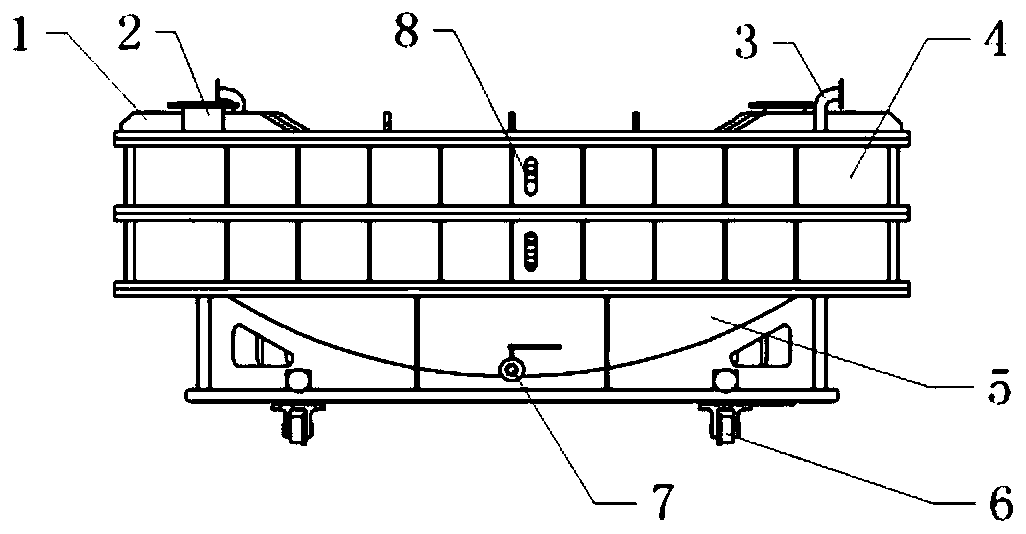

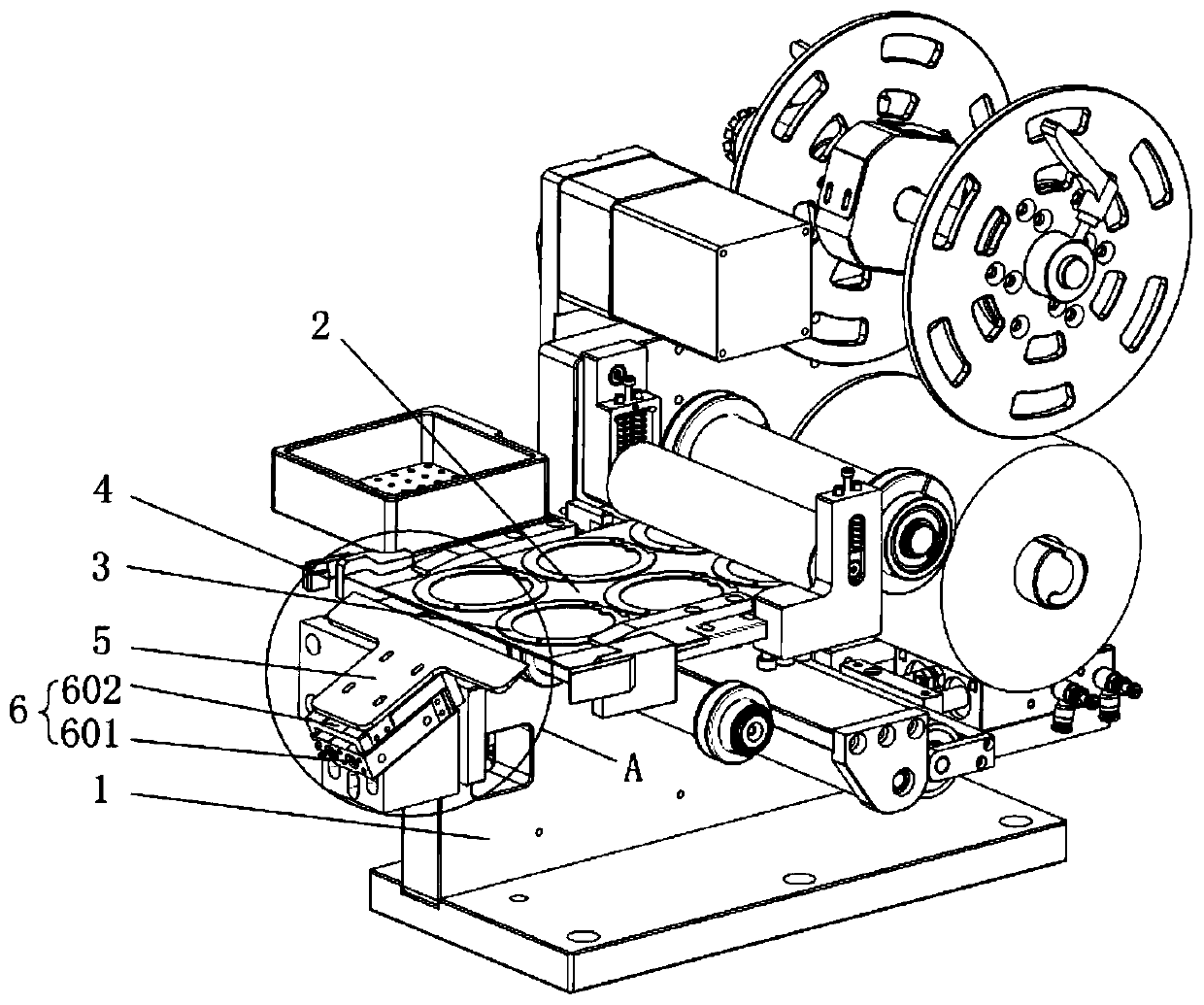

Gel assembling system and assembling method

PendingCN111421836AReduce product defect rateReduce the difficulty of strippingLayered productsLaminationProcess engineeringStructural engineering

The invention provides a gel assembling system. The system is used for cutting gel from a raw material layer of a gel strip and assembling the gel on a part. The system involves a cutting and assembling mechanism, a feeding mechanism, a recycling mechanism, a conveying mechanism and a stripping mechanism; the cutting and assembling mechanism is provided with a feeding end and a recycling end and is used for cutting the raw material layer from one side and assembling the cut gel on the part to be assembled; the feeding mechanism is used for feeding the gel strip for the feeding end of the cutting and assembling mechanism; the recycling mechanism is used for recycling release films and raw material layer waste which are stripped after cutting from the recycling end of the cutting and assembling mechanism; the conveying mechanism is used for providing power to continuously convey the gel strip from the feeding mechanism to the cutting and assembling mechanism and conveying the release films and raw material layer waste which are stripped after cutting to the recycling mechanism; and the stripping mechanism is used for stripping the release films and the raw material layer waste from the gel from one end to the opposite end in the gel strip conveying direction. The invention further provides a gel assembling method. According to the system and method, the problem that the gel and the raw material layer waste cannot be easily separated is solved, and the reject ratio of products is reduced.

Owner:SHENZHEN MEIHAO CHUANGYI MEDICAL TECH

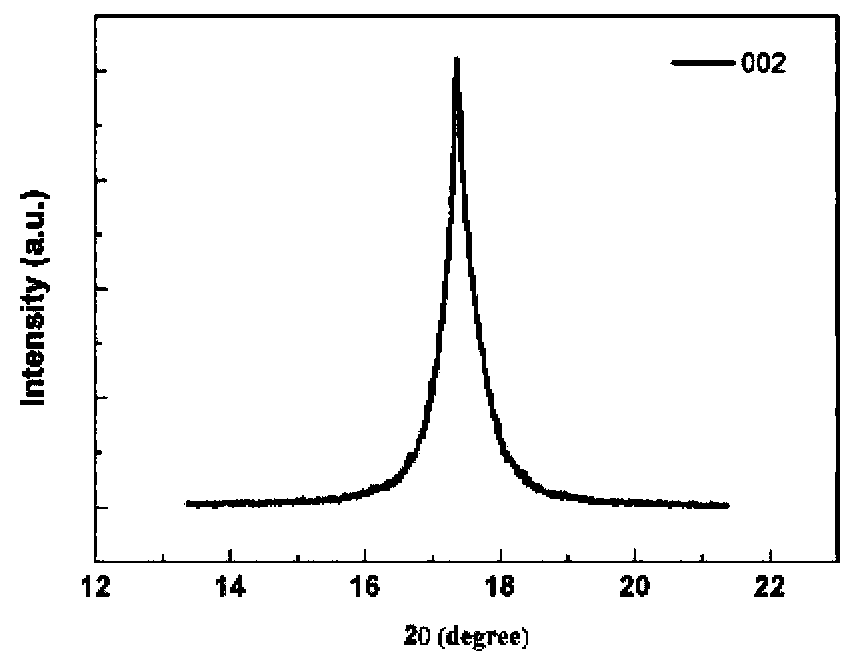

LED epitaxial growth method taking graphene as buffer layer

InactiveCN110993752AAvoid dependenceQuality assuranceSemiconductor devicesComposite substratePhysical chemistry

The invention provides an LED epitaxial growth method taking graphene as a buffer layer. The LED epitaxial growth method comprises the following steps: 1, growing a graphene buffer layer on a substrate; 2, growing an aluminum nitride layer on the graphene buffer layer; 3, processing the composite substrate; 4, growing an aluminum gallium nitride layer; 5, growing an undoped gallium nitride layer;6, growing a silicon-doped N-type gallium nitride layer; 7, growing a light-emitting layer; 8, growing a P-type aluminum gallium nitride layer doped with aluminum and magnesium; 9, growing a P-type gallium nitride layer doped with magnesium; and 10, carrying out heat preservation for 20-30 minutes at the temperature of 650-680 DEG C, closing the heating system and the gas supply system, and carrying out furnace cooling. The epitaxial growth method provided by the invention can effectively solve the problems of preparation of a large-area gallium nitride epitaxial layer and high stripping difficulty between the epitaxial layer and the substrate.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

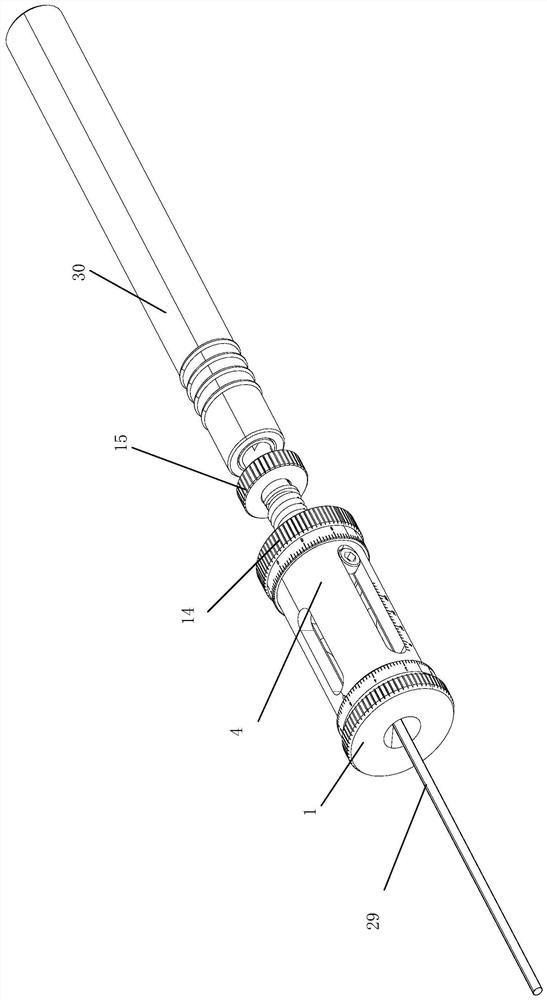

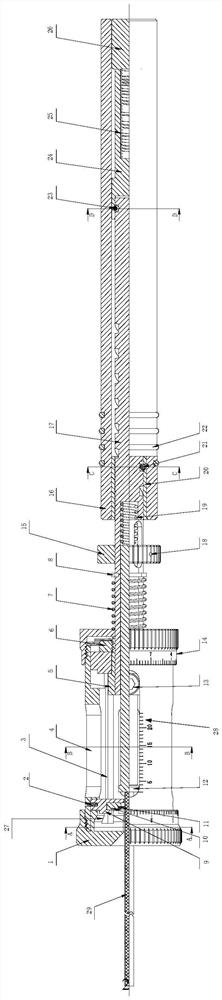

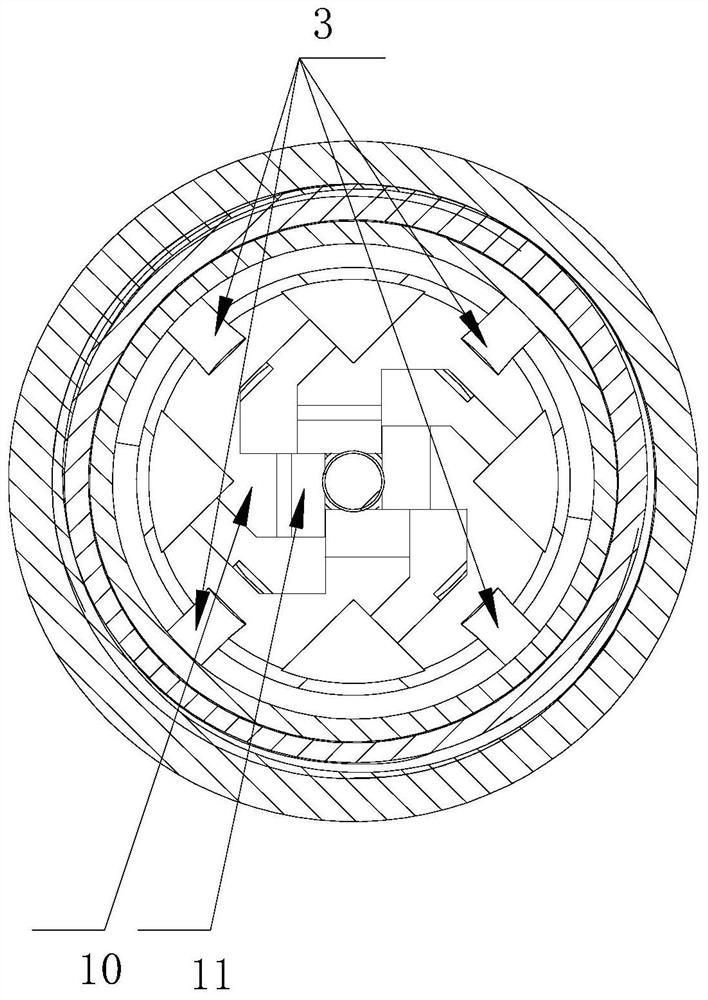

Portable flexible cable stripping device

PendingCN113328323AMeet stripping needsSmooth skin separationLine/current collector detailsTool bitPower cable

The invention relates to a portable flexible cable stripping device which comprises a stripping box, wherein a stripping cutter is arranged in the wire inlet end of the stripping box, a positioning rod is arranged at the position, located at the rear end of the stripping cutter, in the stripping box, a reset expansion assembly is arranged in the stripping box, the head end of the reset expansion assembly is connected with a cutter head movement guide rail, a wire stripping cutter is arranged on the cutter head movement guide rail, the head end of the reset expansion assembly is further connected with a wire stripping outer diameter fine-tuning knob, a wire inlet hole is formed in the wire stripping outer diameter fine-tuning knob, the tail end of the reset expansion assembly is provided with a wire stripping length fine-tuning knob, a fine-tuning assembly is connected with a screw rod, a positioning rod is inserted into the screw rod, an auxiliary reset assembly is arranged at the contact end of the positioning rod and the threaded rod, a main elastic reset assembly is arranged on the threaded rod, and the tail section of the threaded rod is connected with a transmission hand pull rod. Therefore, the stripping requirements of various conventional power cables can be met, and smooth sheath separation can be realized. Through cooperation of the fine-tuning knob and a scale bar, high-precision wire stripping control can be realized.

Owner:昆山频谱电子科技有限公司

Treatment equipment for PDC drill bit out of well

ActiveCN113020096AFacilitate automatic strippingGood solubility and dispersibilityCleaning using toolsCleaning using liquidsStructural engineeringMechanical engineering

The invention discloses treatment equipment for a PDC drill bit out of a well. The treatment equipment comprises a box body and a treatment barrel, a rotary table is arranged on the upper surface of the box body, the rotary table is driven by a driving assembly to rotate, the rotary table comprises a square step surface, and the step surface is used for bearing a drill bit loading and unloading device; the treatment barrel is positioned below the rotary table, the treatment barrel and the rotary barrel are in motive seal fit, the treatment barrel and the box body are fixed, and a discharge valve is arranged at the bottom of the treatment barrel; and the treatment barrel is used for accommodating a treatment agent. According to the treatment equipment for the PDC drill bit out of the well, the problem that in the prior art, a large amount of manpower is consumed in stripping of balling rock debris wrapping the drill bit is solved, and the purposes of reducing the stripping difficulty of the balling rock debris of the PDC drill bit and reducing manpower consumption are achieved.

Owner:SOUTHWEST PETROLEUM UNIV +1

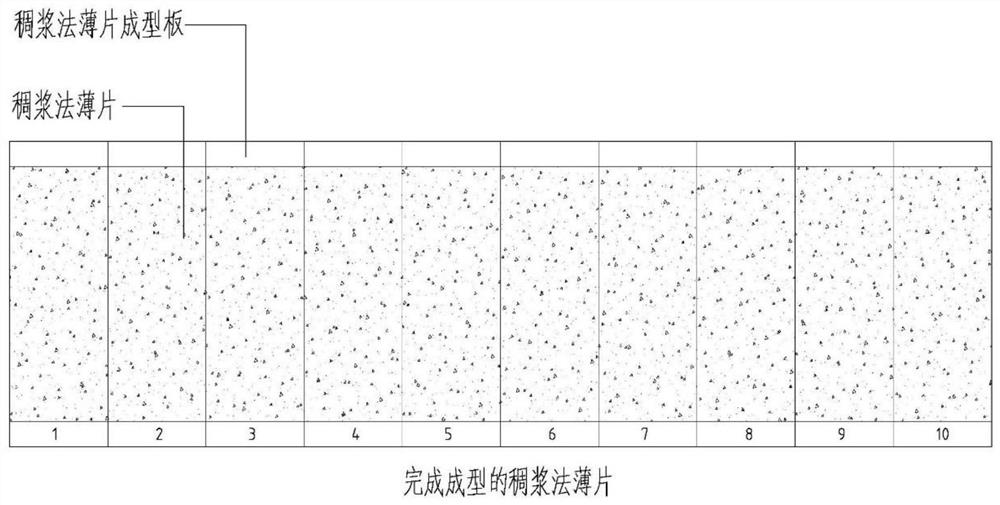

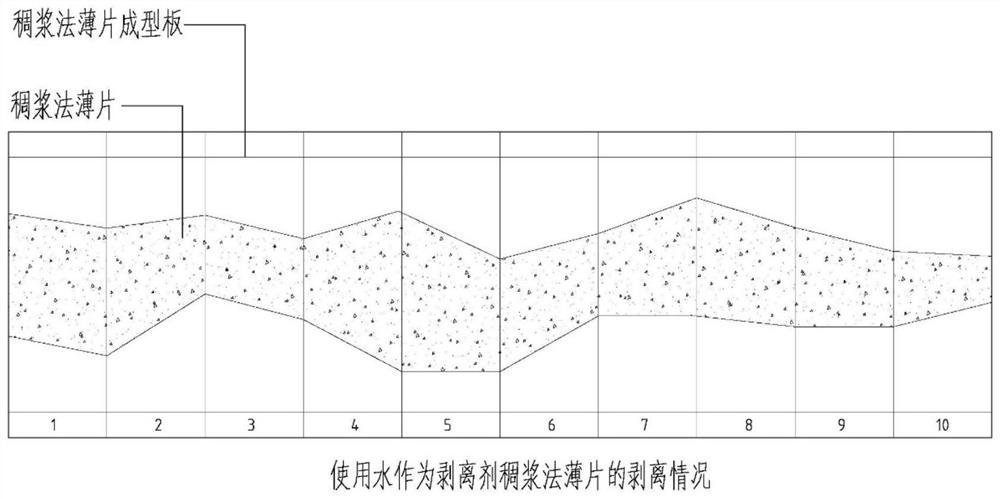

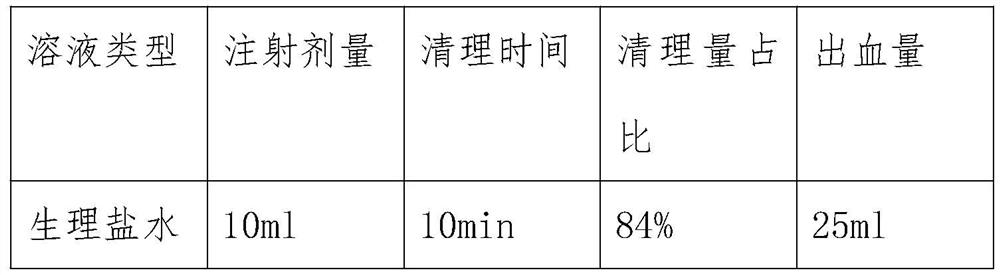

Stripping composition, stripping reagent, application preparation method of stripping reagent, and method for stripping reconstituted tobacco

ActiveCN111838747AImprove integrityImprove qualityTobacco preparationTobacco treatmentSodium phosphatesLinseed oil

The invention relates to the technical field of reconstituted tobacco preparation, and especially relates to a stripping composition, a stripping reagent, application and a preparation method of the stripping reagent, and a method for stripping reconstituted tobacco. The mass of linolenic acid, linseed oil, palmitic acid, behenic acid, stearic acid and lauric acid in the stripping composition accounts for 1-20% of the mass of the stripping composition, and the mass of each of gelatin, starch, sodium alginate, sodium dodecyl phosphate and vitamin E accounts for 1-10% of the mass of the stripping composition. The stripping composition can be beneficial to stripping of the reconstituted tobacco, the integrity of the horizontal scroll of the stripped reconstituted tobacco is improved, the situation that powder falls off from the baking surface of the reconstituted tobacco is reduced, the quality of the reconstituted tobacco is improved, and meanwhile, the smoking quality of the reconstituted tobacco cannot be affected by using the stripping composition.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

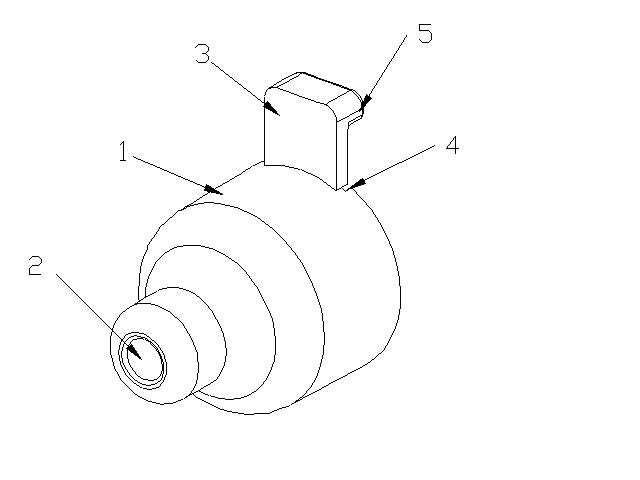

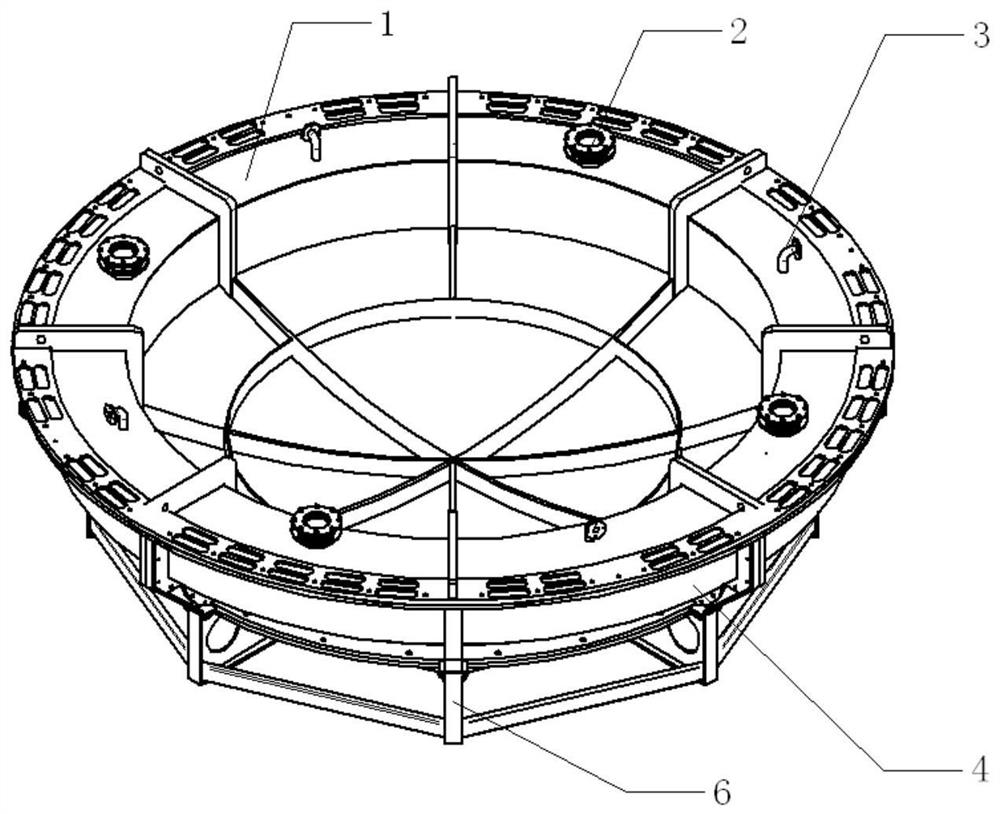

Returning type airship side wall heat shielding layer forming tool

ActiveCN109955500AImprove thermal protection performanceReduce the number of chunksDomestic articlesFiberEngineering

The invention discloses a returning type airship side wall heat shielding layer forming tool. The returning type airship side wall heat shielding layer forming tool comprises an upper mold, a middle mold, a lower mold, a tray, a lifting ring, an upper mold observing window, a temperature sensor, a glue injection pipeline, a vacuum pipeline, a pressing frame, a supporting base, a pressing plate anda heat shielding layer. In the height direction, the upper mold, the middle mold and the lower mold are arranged; the middle mold and the lower mold are used for containing the airship side wall heatshielding layer, the mounting face between the middle mold and the lower mold is arranged in the middle position in the height direction of an inner tray, the upper mold serves as an upper cover, andafter assembling, a closed cavity is jointly formed by the upper mold, the middle mold and the lower mold. The problem that a fiber enhanced low-density protection material is prone to deforming is solved, material lifting, transferring and turnover in the preparing process can be achieved, it is ensured that after the material is formed, the conical shape of the returning type airship heat proofside wall is directly formed, and multiple pieces are prepared through one time.

Owner:BEIJING SATELLITE MFG FACTORY

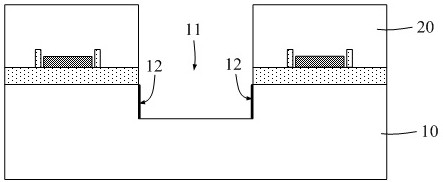

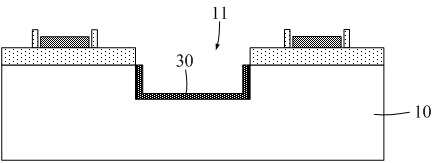

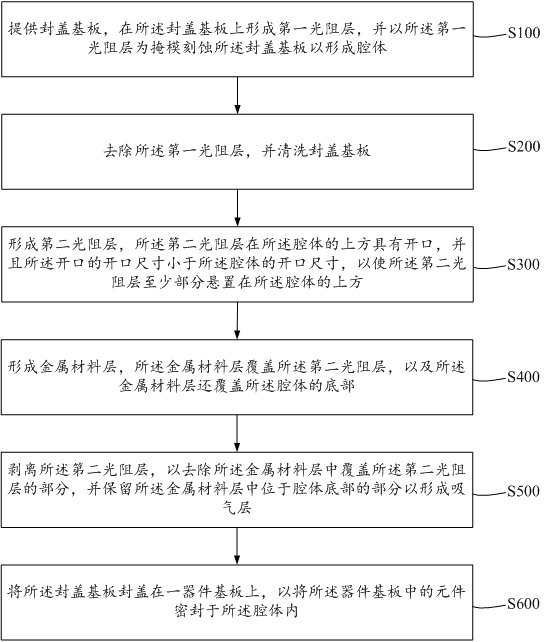

Electronic device and its manufacturing method

ActiveCN112978675BAdjust topographical propertiesReduce the difficulty of strippingDecorative surface effectsSolid-state devicesPhotoresistMaterials science

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

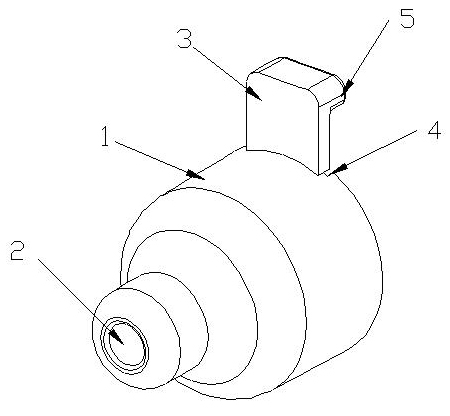

Water nozzle

InactiveCN102028981AReduce difficultyReplace hygieneEnemata/irrigatorsNozzleArchitectural engineering

The invention discloses a water nozzle, which comprises a water nozzle body, wherein the water nozzle body is provided with a sharp nose and is a hollow body, the top of the water nozzle body is provided with a water introducing hole, an outer side wall at the bottom of the water nozzle body is provided with a handheld part protruding out of the side wall, and a connection part between the handheld part and an end edge of the water nozzle body is provided with a tearing port. In the invention, by arranging the handheld part on the side wall of the water nozzle body and arranging the tearing port on the connection part between the handheld part and the end edge of the water nozzle body, the purpose of better sanitation can be achieved during the replacement of the water nozzle, and the water nozzle can be stripped from a handle more easily. In the invention, a tearing groove is further arranged on the inner wall of the water nozzle body along the extending direction of the tearing port so that the difficulty in stripping the water nozzle from a spray nozzle is further reduced.

Owner:DONGGUAN YISHEN ELECTRONICS S&T

Tape stripping device and tape stripping machine

ActiveCN106865324BReduce the difficulty of strippingGood peeling effectArticle deliveryEngineeringMechanical engineering

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

Preparation method of amazingel removal stripping solution in holographic six-dimensional delamination amazingel removal operation

The invention discloses a preparation method of an amazingel removal stripping solution in a holographic six-dimensional delamination amazingel removal operation. The amazingel removal stripping solution comprises a pretreatment solution and a stripping solution, wherein the pretreatment solution is composed of the following components in parts by weight of 5-10 parts of blue tansy essential oil, 3-5 parts of amino acid, 5-10 parts of vitamin B, 1-5 parts of carbonated water and the balance of normal saline, and the total amount is 100 parts; and the stripping solution is composed of the following components in parts by weight of 20-25 parts of acidified water, 2-5 parts of a povidone-iodine solution, 3-5 parts of vitamin C and the balance of normal saline, and the total amount is 100 parts. The amazingel removal stripping solution comprises the pretreatment solution for soaking and the stripping solution; firstly the pretreatment solution with the relatively low temperature is used for soaking an affected part, human tissue and amazingel shrink, then the stripping solution is used for flow flushing, cold contraction and thermal expansion are generated, and the distance between the amazingel and the human tissue is increased; and meanwhile, the blue tansy essential oil has a lubricating effect, so that the amazingel can conveniently flow out along with the stripping solution, and the stripping difficulty of the amazingel is reduced.

Owner:广州市荔湾区人民医院

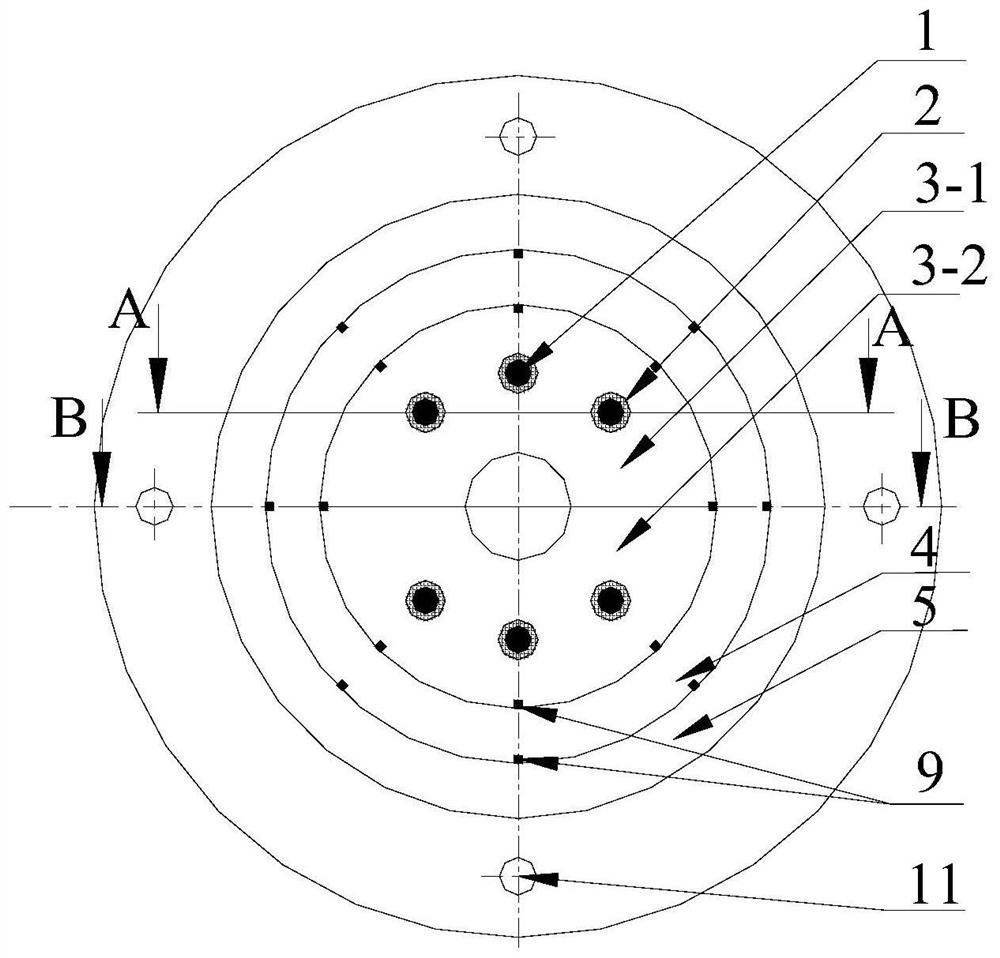

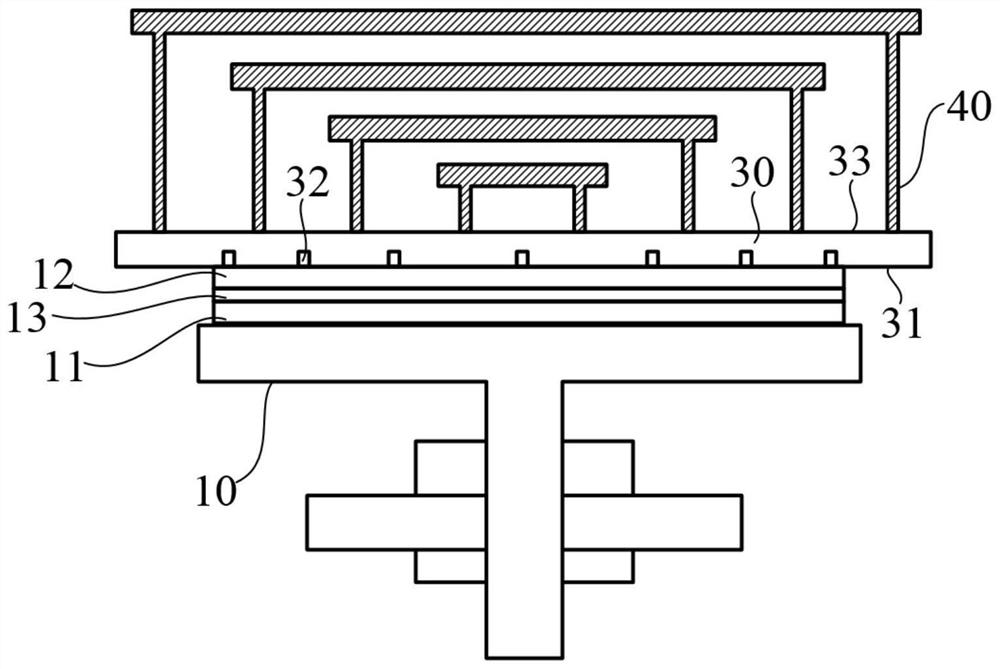

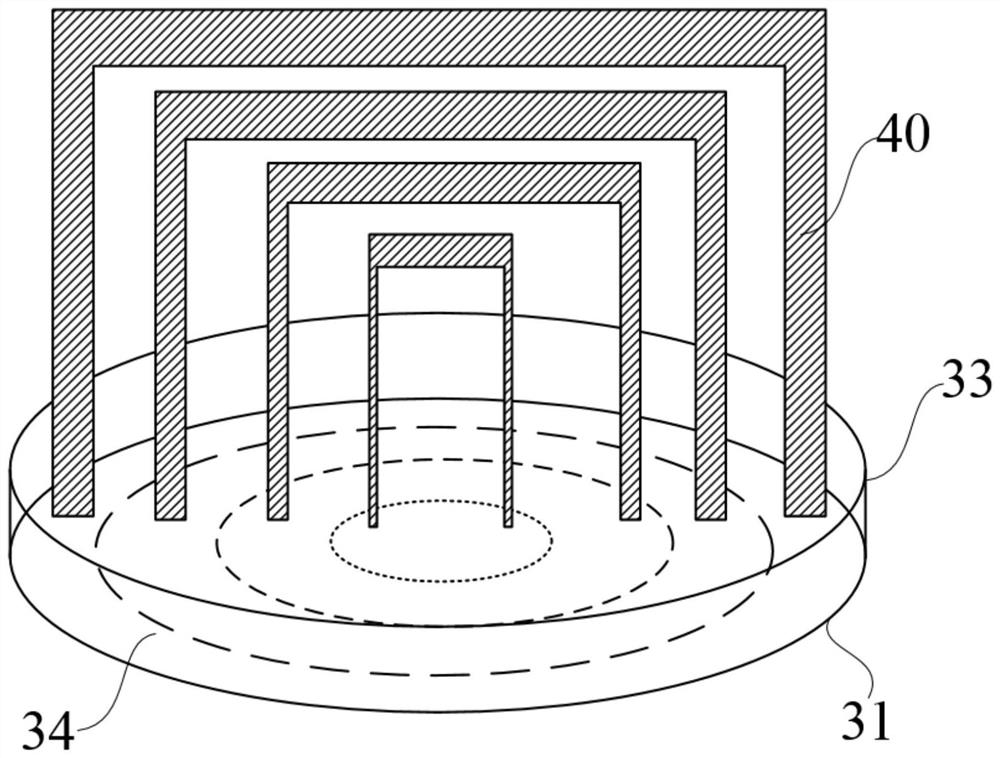

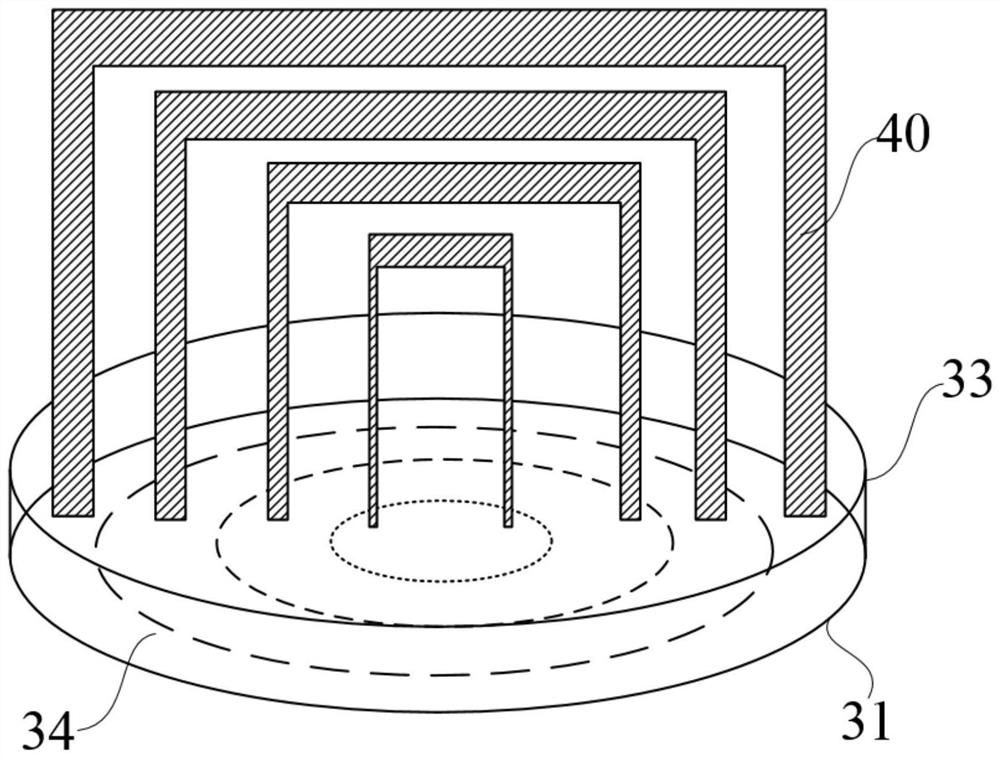

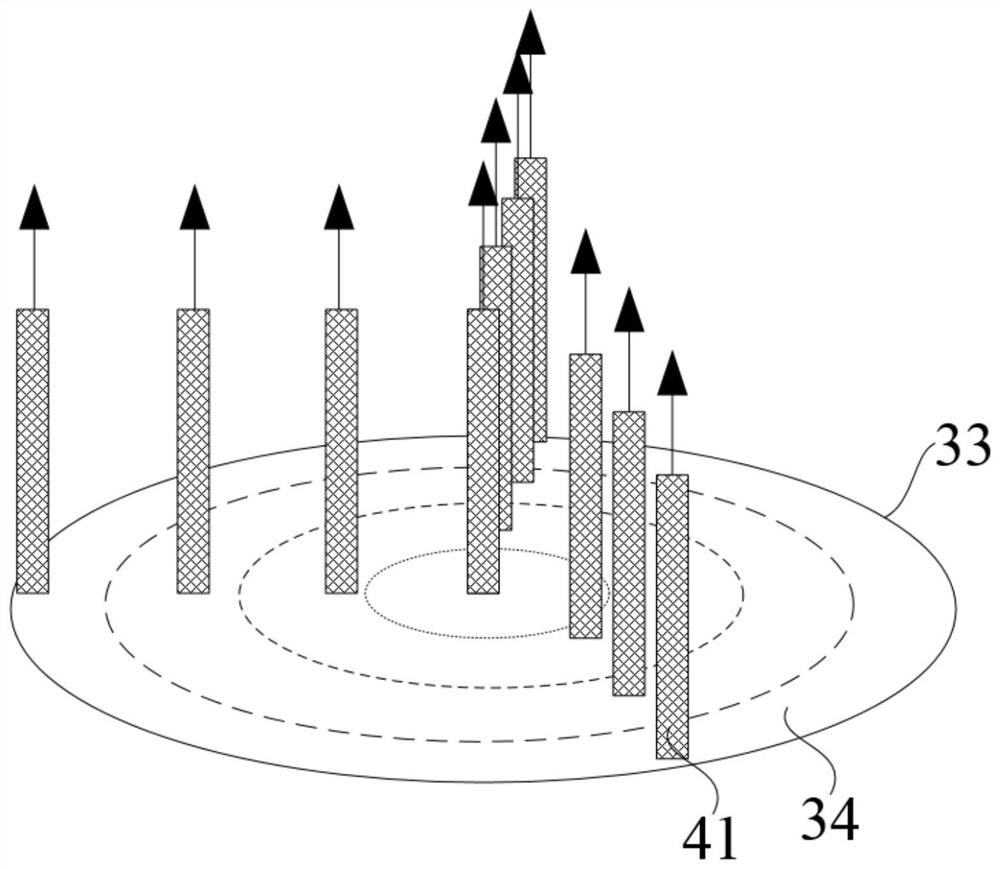

Objective table assembly and laser de-bonding device

PendingCN113851396APrevent re-condensation bondingShorten the timeSolid-state devicesSemiconductor/solid-state device manufacturingLaser scanningEngineering

The invention provides an objective table assembly and a laser de-bonding device. The objective table assembly comprises an objective table, a suction cup and lifting assemblies. The first layer structure is fixed on the objective table. The suction cup is provided with an adsorption end face and a connecting end face, the adsorption end face is divided into at least three adsorption areas, and the adsorption areas comprise a circular adsorption area located in the center of the suction cup and at least two annular adsorption areas sequentially arranged from the circular adsorption area to the outside. The number of the lifting assemblies is at least three, and each lifting assembly is used for upwards pulling up the corresponding adsorption area after the bonding layer at the corresponding adsorption area position is heated by laser and subjected to phase change, so that the first layer structure and the second layer structure are separated at the corresponding adsorption area position. After part of the bonding layer area is scanned by laser, the corresponding adsorption area of the suction cup can be immediately lifted, so that the two layer structures at the adsorption area are separated, the situation that the bonding layer in the molten state is condensed and bonded again due to the fact that the part of the bonding layer area is heated by the laser is prevented, the stripping difficulty is reduced, the stripping time is shortened, and the stripping efficiency is improved.

Owner:北京中科镭特电子有限公司

A flame-retardant PVC high-voltage wire harness recovery processing equipment and processing technology

ActiveCN112259302BReduce the difficulty of strippingConducive to guiding throughBasic electric elementsElectronic waste recyclingEngineeringHigh tension line

The invention relates to the technical field of cable recycling, in particular to a flame-retardant PVC high-voltage wire harness recycling and processing equipment and processing technology. It includes a cage and two crushing devices with opposite directions installed inside the cage. The crushing device includes a threading assembly. The right side of the threading assembly is connected to a turntable. The right side of the turntable is installed with a cutting The part includes a support frame and a support wheel, and the cutting part includes a knife holder and a knife. The invention self-adapts the telescopic amount of the telescopic block in the threading assembly through the diameter of the high-voltage wire harness, and further drives the turntable to rotate through the telescopic movement of the telescopic block, and the rotation of the turntable drives the knife holder and the supporting frame to move synchronously to support and cut the high-voltage wire harness. At the same time, the depth of cut and the distance between the cutters are adjusted synchronously through the rotation of the turntable, so as to cut and break the high-voltage wire harness casings with different diameters to different degrees, and reduce the difficulty of stripping the high-voltage wire harness casings.

Owner:JIANGSU PUCAO TECH CO LTD

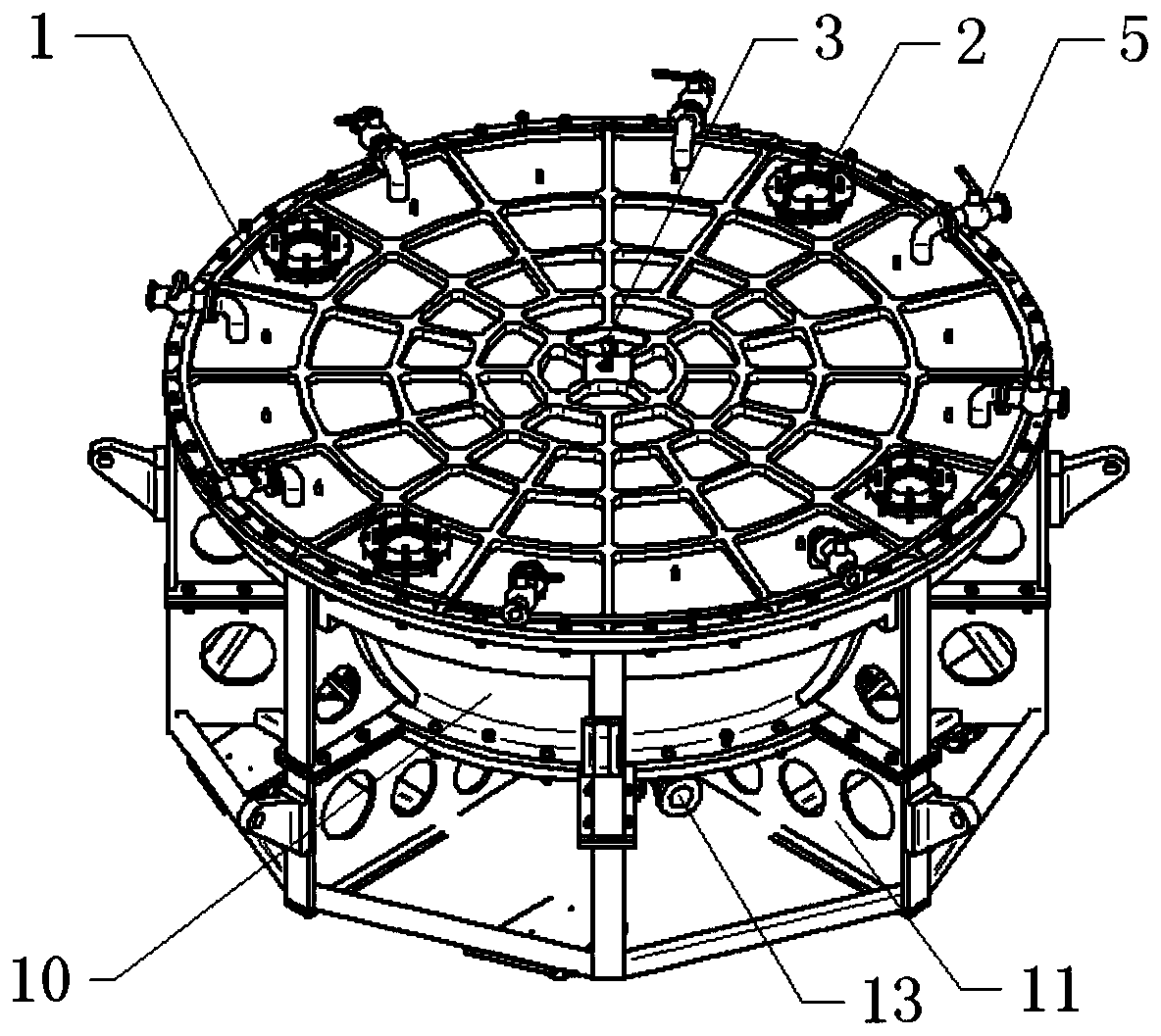

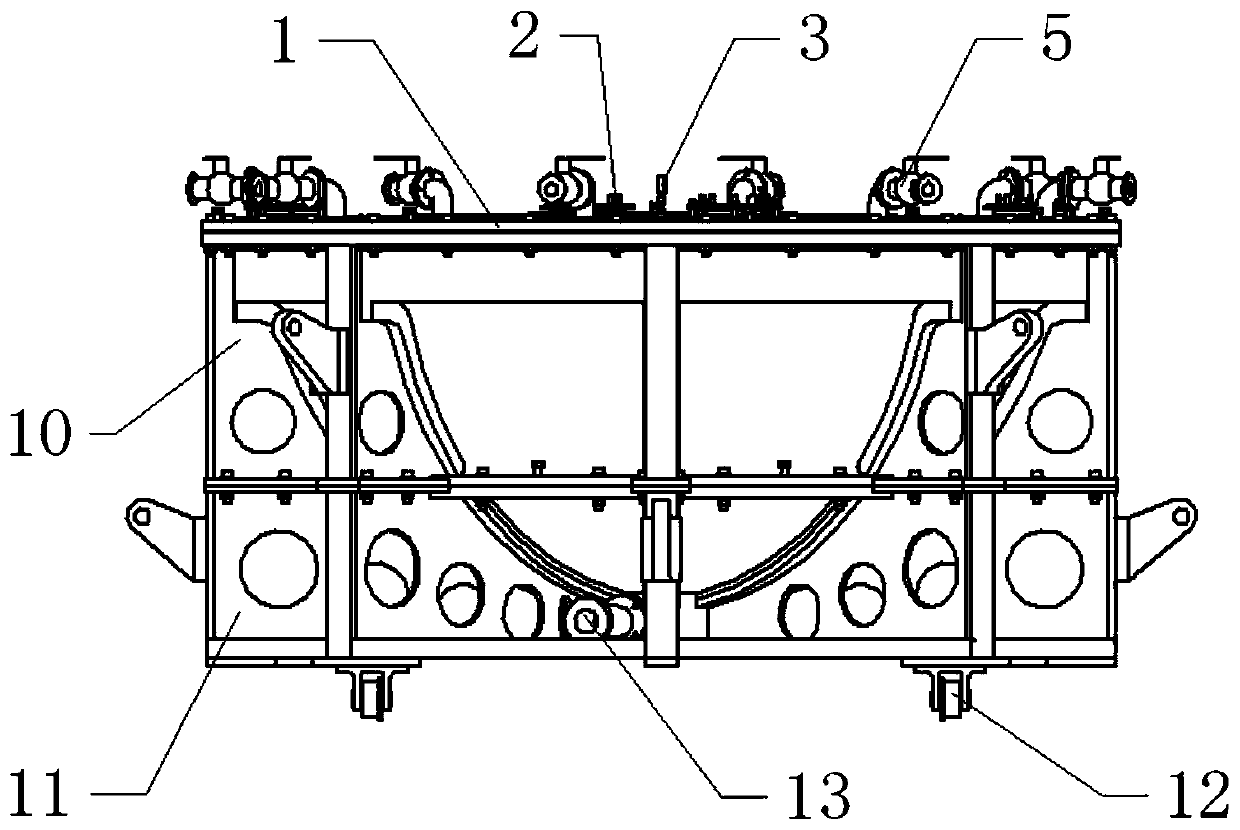

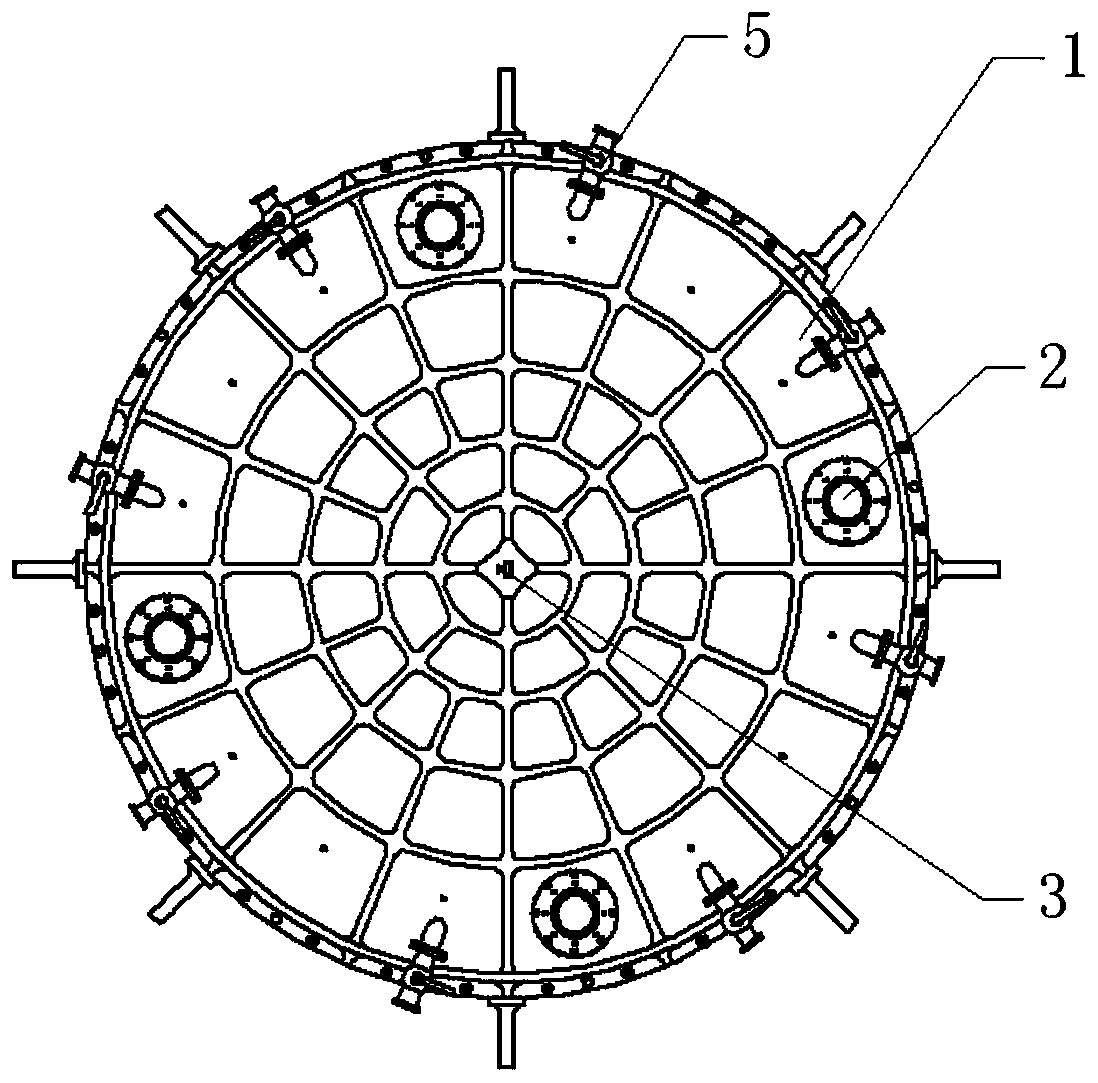

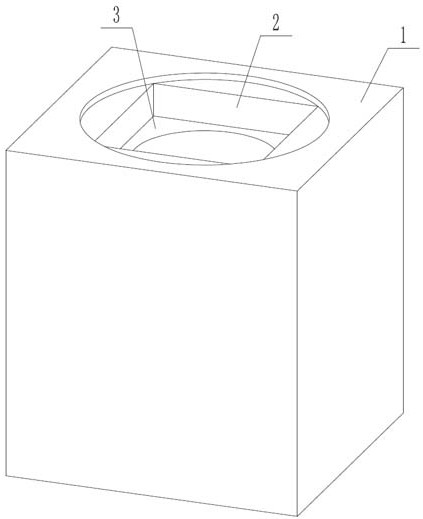

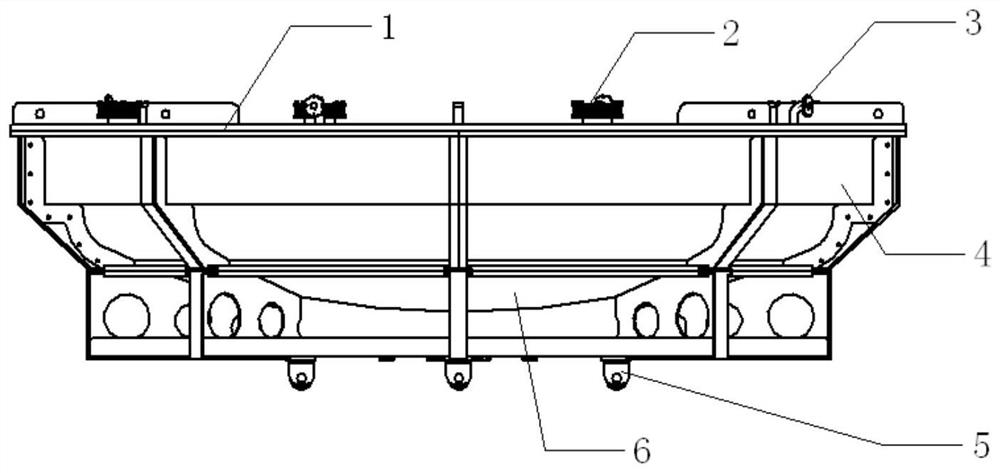

A heat-proof layer forming tool for the outsole of a returnable spaceship

ActiveCN109955499BReduced thermal protectionPlay a supporting roleDomestic articlesClosed cavityPhysics

A heat-proof layer molding tool for the outsole of a returnable spaceship, including a lower mold (6), a middle mold (4), an upper mold (1), an observation window (2), a vacuum pipeline (3), and a glue injection pipeline (7) , pallet (10), lifting ring (9), compression plate (8), compression frame (12); along the height direction, the tooling is divided into three layers, upper mold (1), middle mold (4), lower mold (6); the middle mold (4), the lower mold (6) are used to hold the spaceship outsole heat-proof layer (11); the mounting surface between the middle mold (4) and the lower mold (6) is in the inner tray (10) ) in the middle of the height direction; the upper mold (1) is used as an upper cover, and after assembly, forms a closed cavity together with the middle mold (4) and the lower mold (6). The invention overcomes the difficult problem that the heat-proof large bottom layer of the returnable airship cannot directly implement the processes of vacuum impregnation, drying and curing.

Owner:BEIJING SATELLITE MFG FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com