Device for disassembling liquid crystal display polarizer

A liquid crystal display and polarizer technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of reducing peeling difficulty, simple operation, and improving disassembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

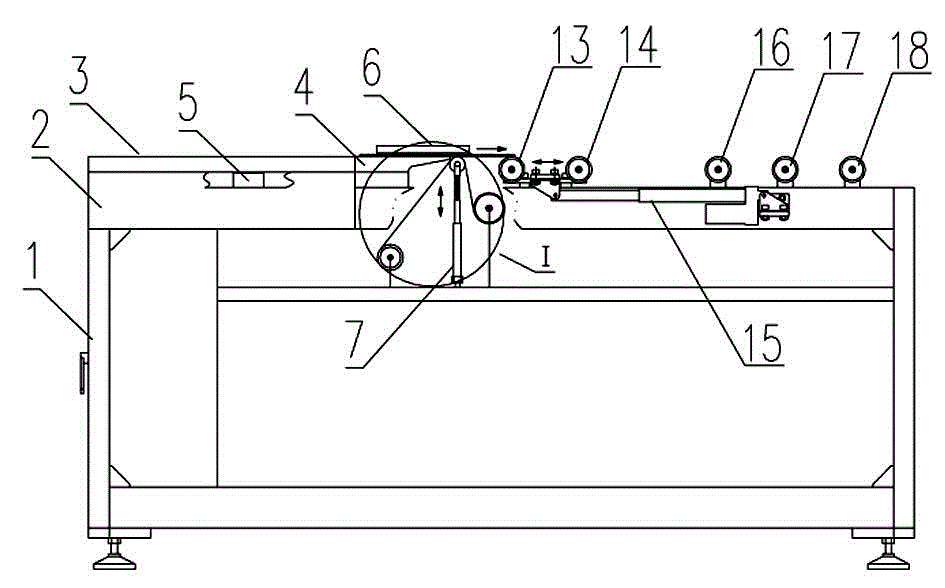

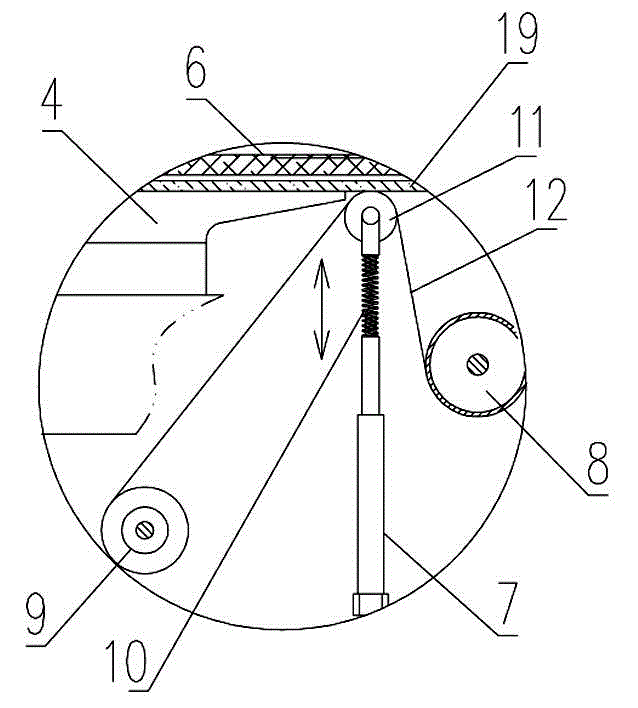

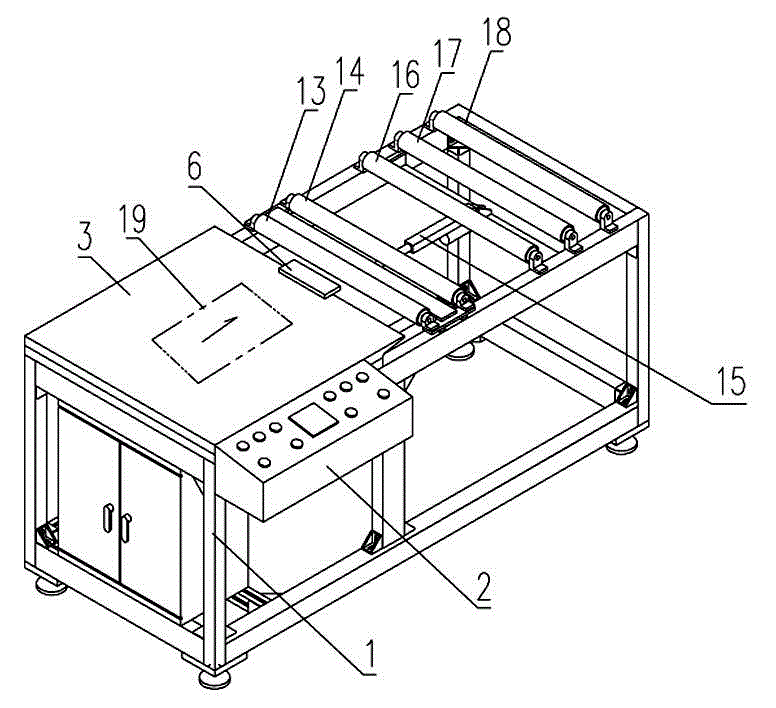

[0012] Such as Figure 1-3 As shown, the device for dismantling the polarizer of the liquid crystal display according to the present invention includes a frame 1 and a temperature controller 2 arranged on the frame 1; the left side of the frame 1 is provided with a liquid crystal display input platform 3, The right side of the frame 1 is provided with a glass substrate output idler group, and a polarizer separation mechanism is arranged below the gap between the liquid crystal display input platform 3 and the glass substrate output idler set on the frame 1; the liquid crystal display input platform 3 An electric heating aluminum plate 4 and a temperature sensor 5 for detecting the temperature of the electric heating aluminum plate 4 are embedded on the table. The electric heating aluminum plate 4 extends to the left edge position of the input platform 3 of the liquid crystal display screen. The signal input terminal of the temperature sensor 5 is connected to the temperature T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com