Graphene material and preparation method thereof

A graphene and graphite technology, applied in the field of graphene materials and their preparation, can solve the problems of difficult peeling, limited graphene performance, low graphene monolayer rate, etc., achieve high monolayer rate, reduce peeling difficulty, improve The effect of preparation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

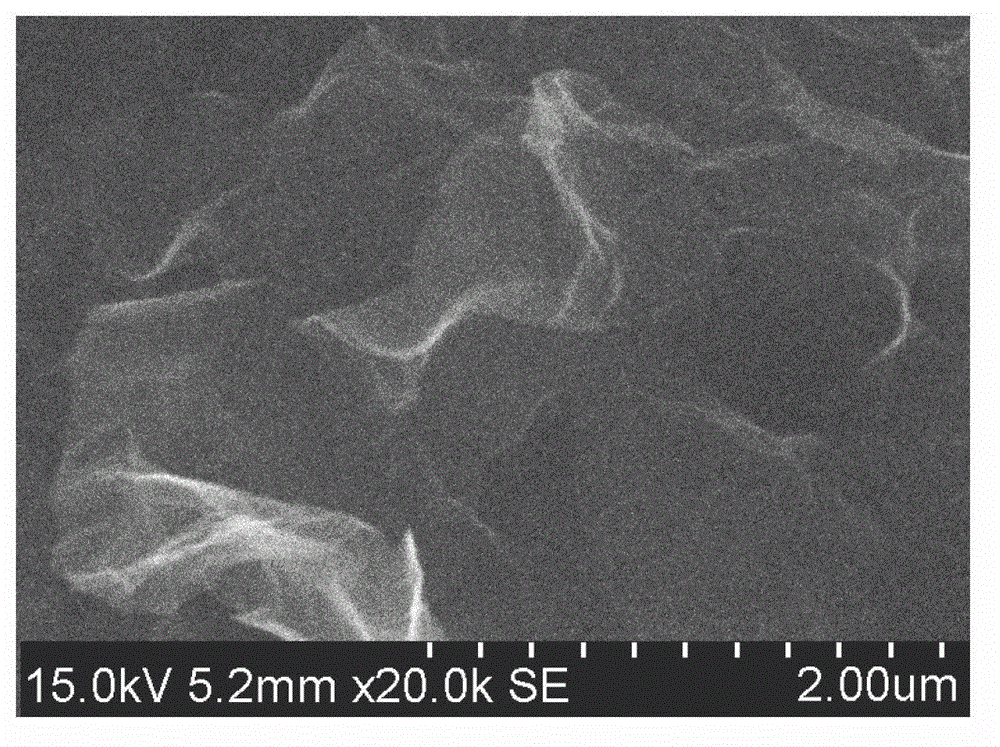

Image

Examples

preparation example Construction

[0027] A kind of preparation method of graphene material, comprises the steps:

[0028] (1) Under an inert gas atmosphere, mix graphite and alkali metal in a molar ratio of 1 to 5:1 and put it into a sealed container, vacuumize to 10-1000Pa, and then heat-treat at 200-1000°C for 12- 120 hours, obtain alkali metal intercalation graphite;

[0029] (2) Take alkali metal intercalated graphite, add it to the molten ionic liquid according to the ratio of solid-liquid ratio 1g: 10~100mL, stir evenly, put it into an ultrasonic pulverizer, and ultrasonically treat 0.5~100mL at a power of 2~10kW Minutes, obtain graphene suspension;

[0030] (3) Filtrating the graphene suspension, taking the filter residue, washing and filtering with an organic solvent, and then repeatedly washing and filtering with deionized water until the eluate is neutral, and drying the filtrate to obtain a graphene material.

[0031] The inert gas atmosphere is nitrogen, argon or helium.

[0032] The graphite is...

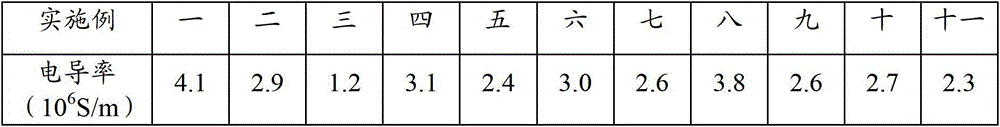

Embodiment 1

[0043] A kind of preparation method of graphene material, comprises the steps:

[0044] (1) In an environment filled with helium, mix natural phosphorus flake graphite and metal potassium at a molar ratio of 5:1, mix well and put it into a heat-resistant glass tube, then seal the heat-resistant glass tube and evacuate to 10Pa, heated to 200°C, and heat-preserved for 12 hours to obtain metallic potassium intercalated graphite;

[0045](2) Select 1-ethyl-3-methylimidazolium bromide (EtMeImBr) as the ionic liquid, melt it in a beaker to obtain 1L of EtMeImBr solvent, maintain the temperature of EtMeImBr solvent at 150°C, add 100g of step (1 ) of the obtained metal potassium intercalated graphite, after stirring evenly, put the beaker into an ultrasonic pulverizer, and ultrasonically treat it with a power of 10kW for 1 minute to obtain a graphene suspension;

[0046] (3) Filter the graphene suspension obtained in step (2), take the filter residue and immerse it in N,N-dimethylpyr...

Embodiment 2

[0049] A kind of preparation method of graphene material, comprises the steps:

[0050] (1) In an environment full of nitrogen, mix artificial graphite and metal lithium at a molar ratio of 2:1, mix well and put it into a heat-resistant glass tube, then seal the heat-resistant glass tube and evacuate to 100Pa, heat To 250°C, heat preservation and heat treatment for 20 hours to obtain metal lithium intercalated graphite;

[0051] (2) Use 1-ethyl-3-methylimidazolium chloride salt (EtMeImCl) as the ionic liquid, melt it in a beaker to obtain 1L of EtMeImCl solvent, maintain the temperature of the EtMeImCl solvent at 180°C, and add 10 g of the step (1 ) the obtained metal lithium intercalated graphite, after stirring evenly, put the beaker into an ultrasonic pulverizer, and ultrasonically treat it with a power of 10kW for 0.5 minutes to obtain a graphene suspension;

[0052] (3) Filter the graphene suspension obtained in step (2), take the filter residue and immerse it in N,N-dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com