Method for preparing graphene slurry

A technology of graphene and slurry, which is applied in the field of graphene, can solve the problems of small number of single-layer graphene, structural defects of graphene, and high difficulty, so as to achieve dense peeling contact surfaces, reduce the difficulty of peeling, and increase production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

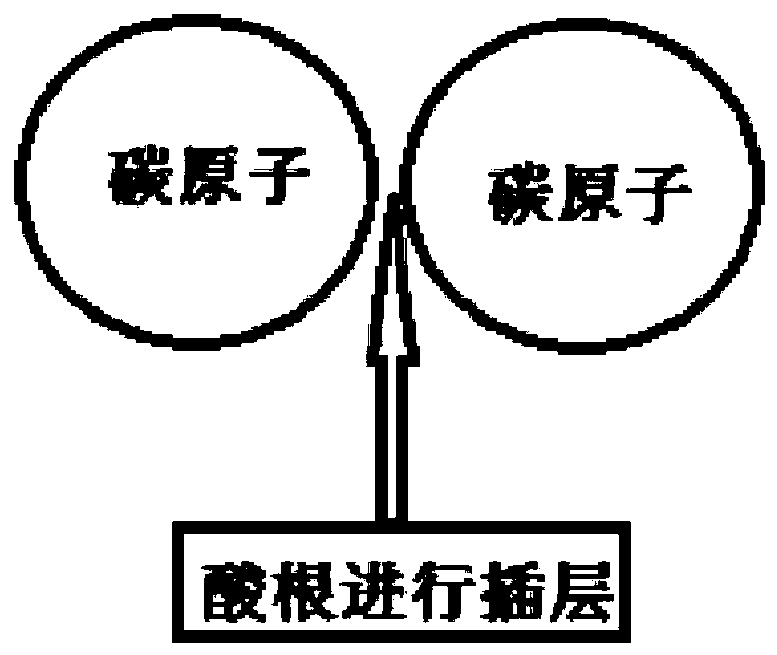

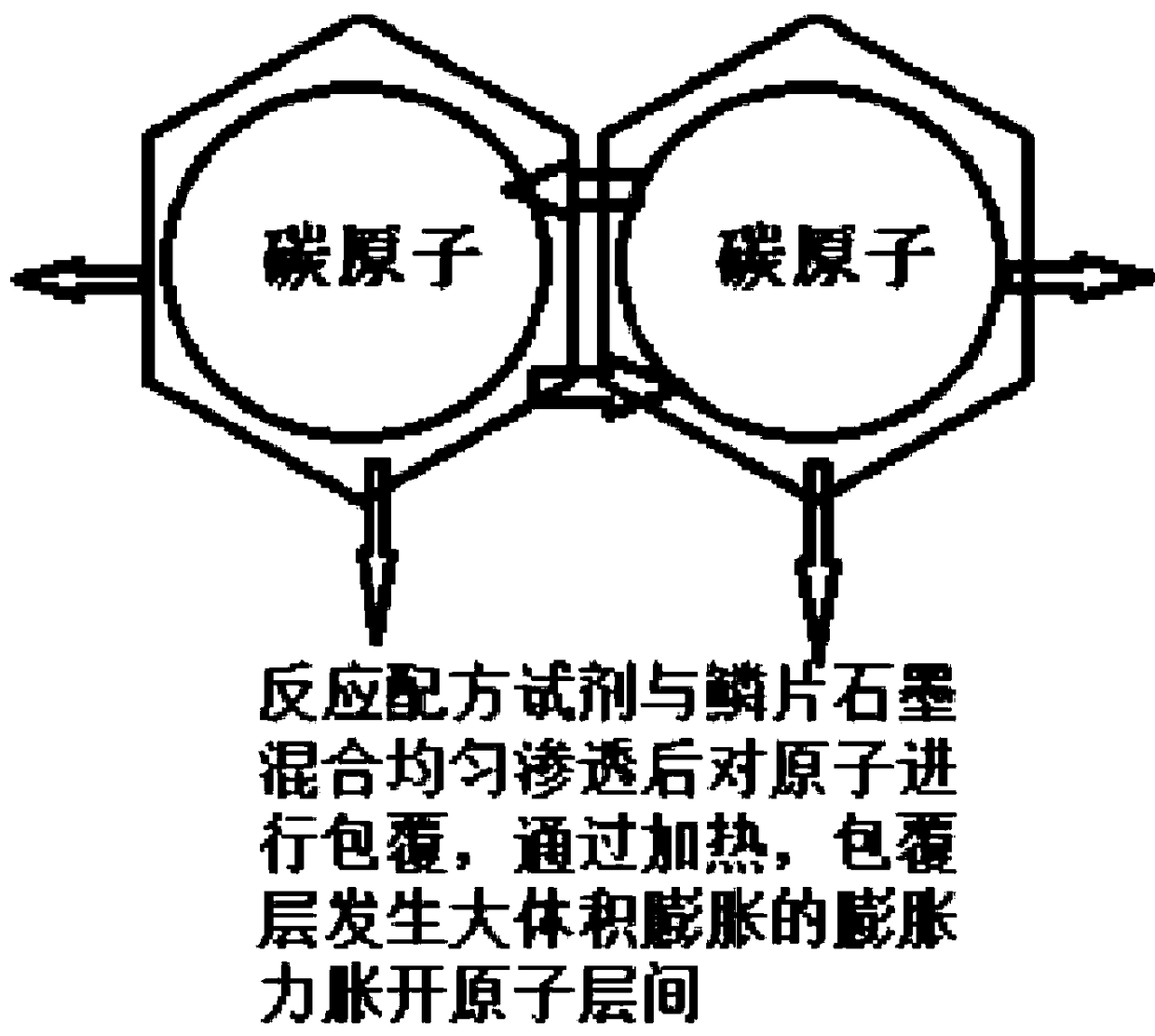

Problems solved by technology

Method used

Image

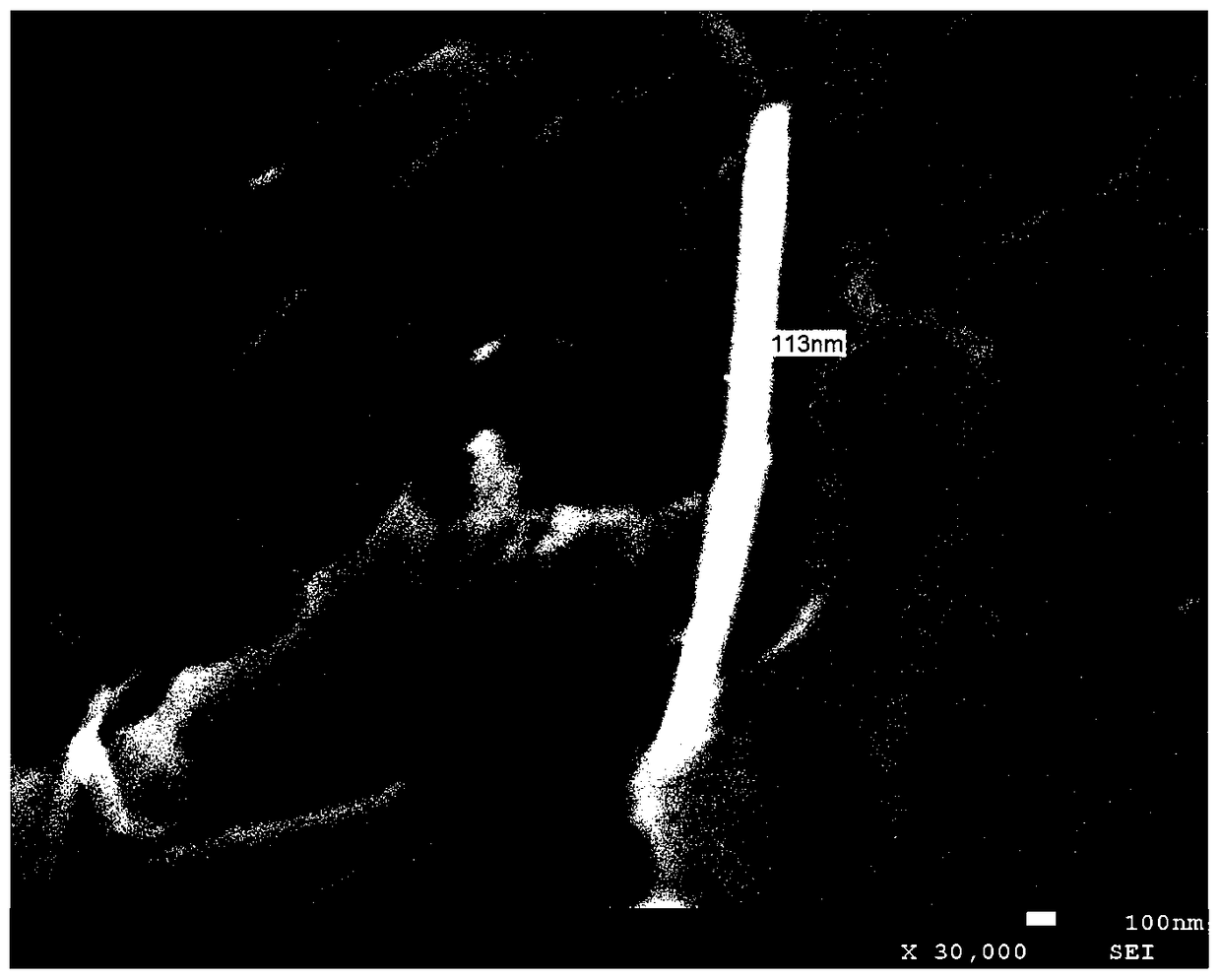

Examples

Embodiment 1

[0031] The graphene slurry applied to water-based coatings, its specific preparation steps are:

[0032] 1) Use high-magnification expandable graphite as raw material (the high-magnification expanded graphite is a product produced by Yichang Xincheng Graphite Co., Ltd., which is available for export, and the expansion multiple is 1500 times), expand at 1000 ° C, and then separate the material and gas Obtain graphite worms, pave them, and finally roll them into paper with a thickness of 0.1mm and a density of 1.25g / cm 3 ;

[0033] 2) The graphite paper obtained in step 1) is mechanically crushed to obtain graphite powder with a particle size of 100-300 μm;

[0034] 3) The graphite powder obtained in step 2) is crushed by a jet mill, and impurities and large-grained powder are removed by cyclone dust removal and three-stage bag dust removal, and the particle size is screened by a sieving machine to obtain more than 99% of the carbon content Graphite powder below 5um;

[0035]...

Embodiment 2

[0039] The specific preparation steps of the graphene slurry applied in the lithium battery field are as follows:

[0040] 1) Use high-magnification expandable graphite with an expansion factor of 1000 times as raw material (the high-magnification expanded graphite is a product produced by Yichang Xincheng Graphite Co., Ltd., which is available for export), expand at 900 ° C, and then separate the material and gas The graphite worms are obtained, then paved, and finally rolled into paper, with a thickness of 0.08mm and a density of 1.20g / cm 3 ;

[0041] 2) The graphite paper obtained in step 1) is mechanically crushed to obtain graphite powder with a particle size of 100-300 μm;

[0042] 3) The graphite powder obtained in step 2) is crushed by a jet mill, and impurities and large-grained powder are removed by cyclone dust removal and three-stage bag dust removal, and the particle size is screened by a sieving machine to obtain more than 99% of the carbon content Graphite pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com