Electronic device and its manufacturing method

A technology of electronic devices and components, which is applied in the field of electronic devices and their preparation, can solve problems such as poor vacuum in sealed chambers, and achieve the effect of reducing the difficulty of peeling and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

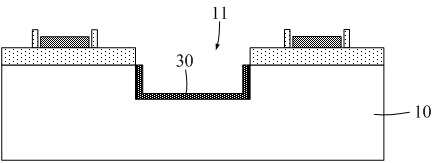

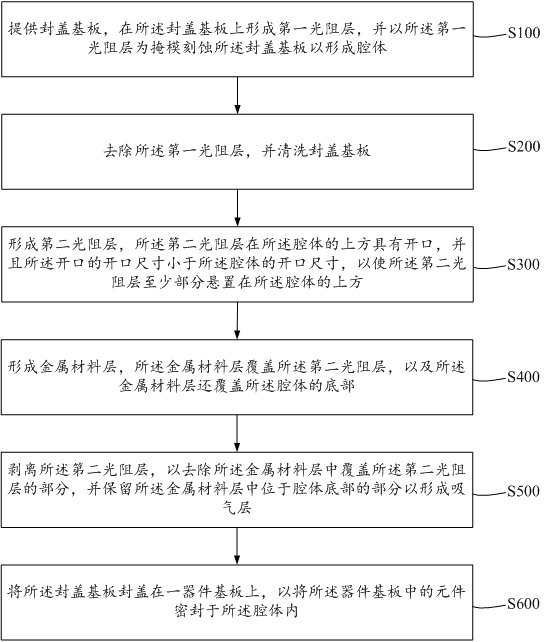

[0026] Therefore, the present invention provides a method for preparing an electronic device, so as to increase the vacuum degree of the formed sealed cavity and ensure the quality of the prepared gettering layer. Specifically, the preparation method of the electronic device provided by the present invention can refer to image 3 , which includes the following steps.

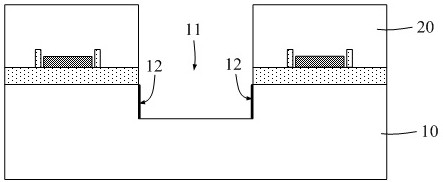

[0027] Step S100 , providing a first substrate, forming a first photoresist layer on the first substrate, and etching the first substrate using the first photoresist layer as a mask to form a cavity.

[0028] Step S200 , removing the first photoresist layer, and wet cleaning the first substrate.

[0029] Step S300, forming a second photoresist layer on the first substrate, the second photoresist layer has an opening above the cavity, and the opening size of the opening is smaller than the opening size of the cavity, The part of the second photoresist layer located in the cavity is suspended relative to the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com