Flexible substrate, production method thereof and display device

一种柔性基板、制作方法的技术,应用在非线性光学、仪器、光学等方向,能够解决无法生产大型化基板、柔性基板破损、黏附力不足等问题,达到减少不确定性因素的依赖、容易剥离、避免损伤的风险的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

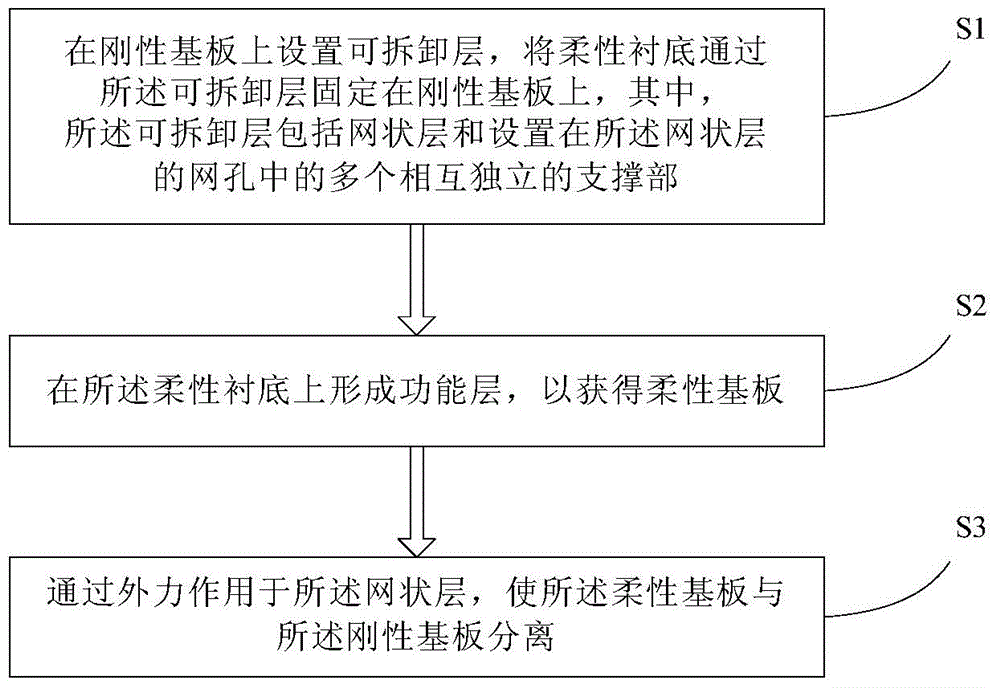

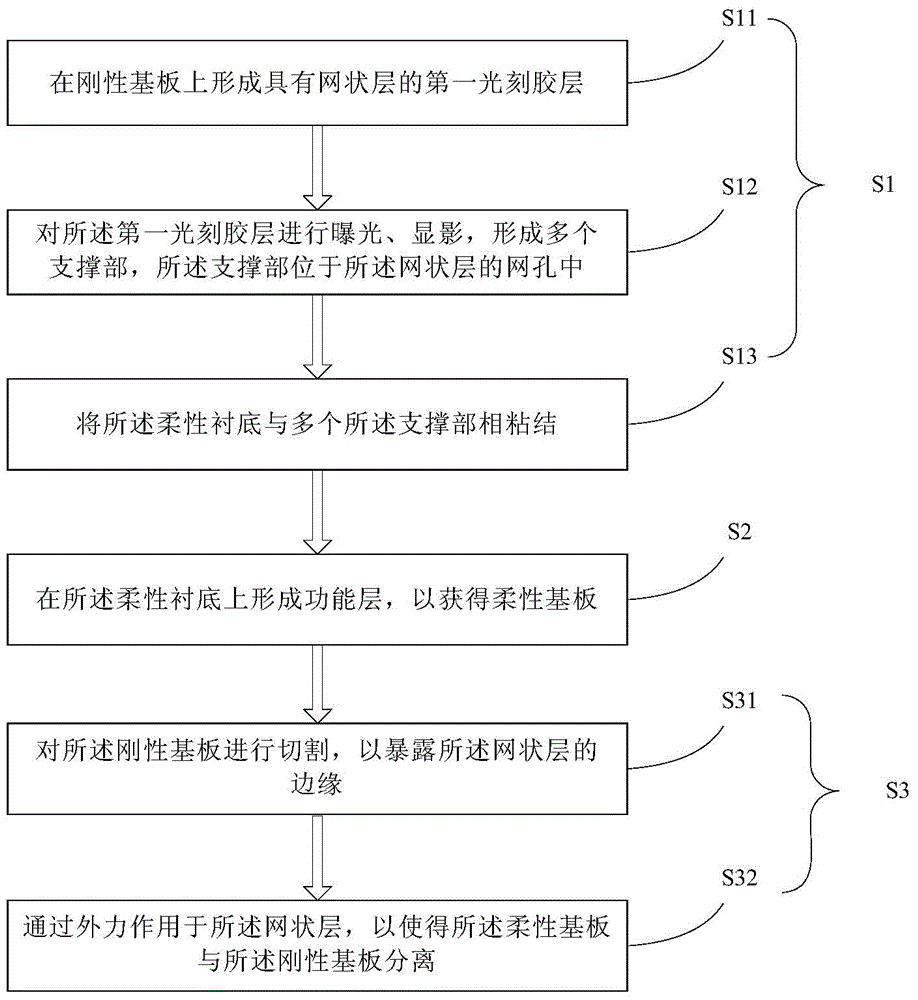

[0049] The invention provides a method for manufacturing a flexible substrate, such as figure 1 Shown, described preparation method comprises the following steps:

[0050] S1. A detachable layer is arranged on the rigid substrate, and the flexible substrate is fixed on the rigid substrate through the detachable layer, wherein the detachable layer includes a mesh layer and is arranged in the mesh of the mesh layer multiple mutually independent support parts;

[0051] S2. Forming a functional layer on the flexible substrate to obtain a flexible substrate;

[0052] S3. Using an external force to act on the mesh layer to separate the flexible substrate from the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com