LED epitaxial growth method taking graphene as buffer layer

A technology of epitaxial growth and buffer layer, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as difficult stripping, limited application, lattice mismatch, etc., to reduce the difficulty of stripping, reduce production costs, and reduce dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

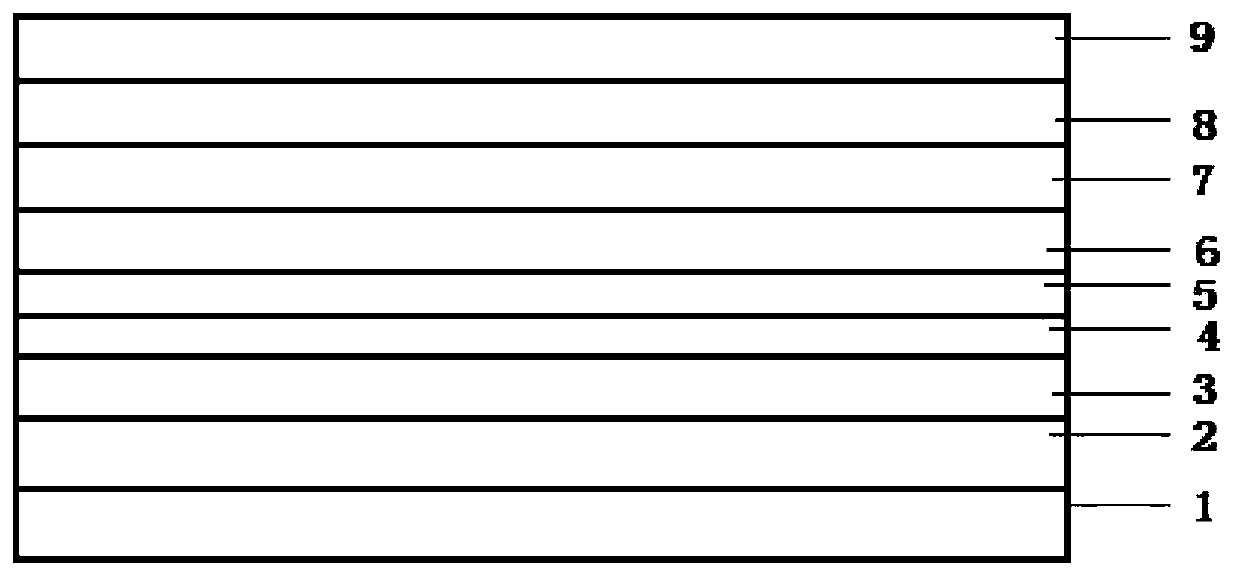

[0038] see figure 1 , a method for epitaxial growth of LEDs using graphene as a buffer layer, comprising the process of growing a graphene buffer layer 2 and an aluminum nitride layer 3 in sequence, specifically:

[0039] Step 1, growing a graphene buffer layer 2 on the substrate 1;

[0040] Step 2, growing an aluminum nitride layer 3 on the graphene buffer layer 2.

[0041] Described step 1 comprises the following steps:

[0042] Step 1.1, preparing the graphene buffer layer 2 separately, specifically: using chemical vapor deposition method, using methane as the carbon source, using copper foil as the substrate, placing the copper foil in a quartz tube, and the quartz tube is placed in a resistance furnace, sealed Quartz tube, heat up to 930-1100°C and keep it for 60-100 minutes, pass in argon gas with a flow rate of 150-200mL / min and keep it for 10-30 minutes, perform high-temperature preheating treatment on copper foil, and pass in a flow rate of 10-20mL / min Min of metha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com